Positive electrode for zinc-air battery and its manufacturing method

An air battery and manufacturing method technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, can solve the problems of complex process, high price, high cost of raw materials, etc., and achieve simplified preparation process and change crystal phase structure And particle size, the effect of increasing the discharge current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

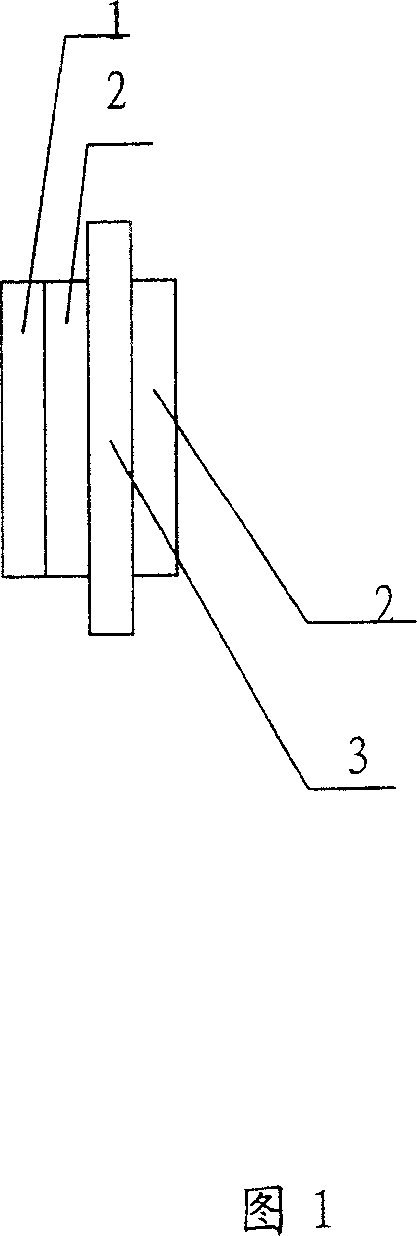

[0025] Referring to the accompanying drawing 1, the structure of the positive electrode for the zinc-air battery is waterproof layer 1; catalytic layer 2; current collector 3.

[0026] A method for manufacturing positive electrodes for zinc-air batteries. According to different types of batteries, use a shearing machine to cut iron nets into electrode sizes determined by battery specifications, and then put hydrochloric acid and distilled water with a volume ratio of 1:1 Remove oil and rust in the diluted hydrochloric acid, take out the iron grid and immerse it in the mixed solution of nickel sulfate and sodium hypophosphite with a volume ratio of 1:1, carry out electroless nickel plating on the iron grid, take it out and dry it Standby as current collector 3; put the electrolytic manganese dioxide into the oven, adjust the temperature of the oven to 340°C-400°C for 15 hours, take it out and grind it into 200-400-mesh manganese dioxide powder with a mortar as a catalyst; The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com