High-strength sulfur-oxygen nucleating agent

A sulfur-oxygen inoculant, high-strength technology, applied in the field of cast iron, can solve the problems of limited effect of added elements, small shrinkage tendency, unsatisfactory, etc., to inhibit the growth of dendrites, reduce deformed graphite, and prevent carbides produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

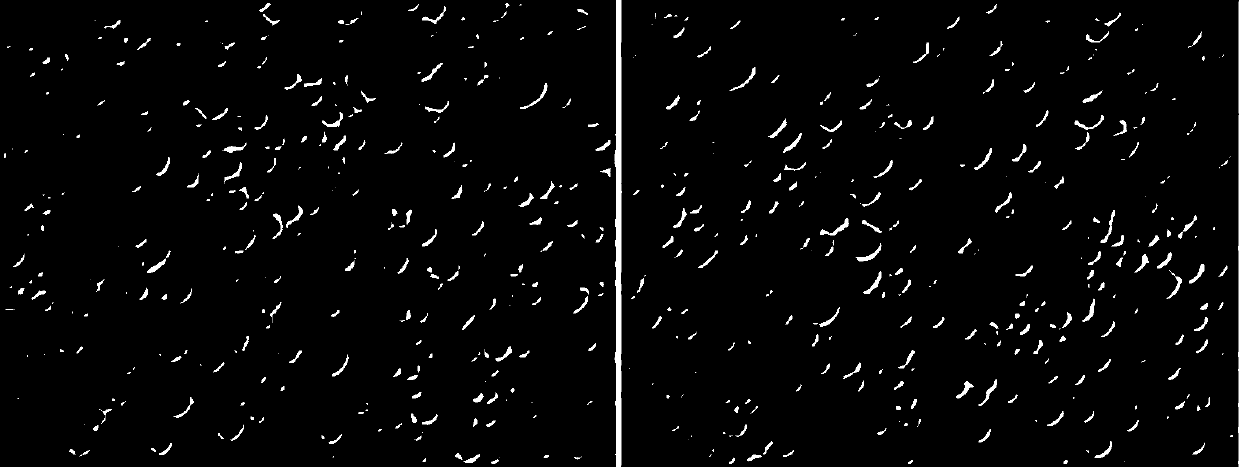

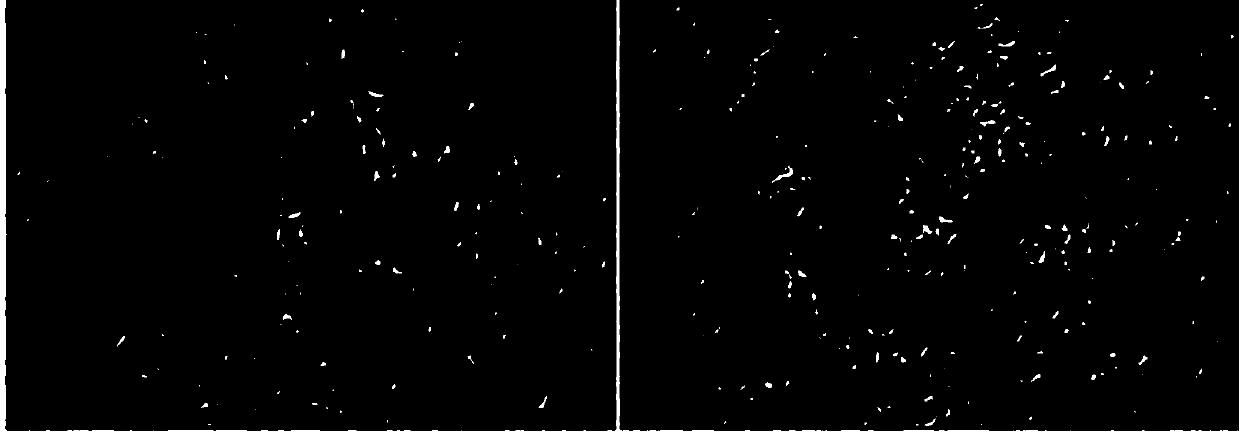

Image

Examples

Embodiment 1

[0036]A high-strength sulfur-oxygen inoculant, the mass percentage of elements contained in the sulfur-oxygen inoculant is: Si: 70-76%, Ca: 0.2-1.0%, Ba: 0.3-0.5%, La: 1.5-2.0 %, Al: 0.5-1.5%, S: 0.3-0.9%, O: 0.3-0.9%, Sb: 0.5-1.5%, and the balance is iron;

[0037] The sulfur-oxygen inoculant is prepared from the following raw materials in parts by weight:

[0038] 2-4 parts of steel scrap, 130-140 parts of ferrosilicon, 1-1.4 parts of silicon barium, 1-1.8 parts of silicon calcium, 2-4 parts of pure lanthanum, 1.5-2.5 parts of antimony, 1-2 parts of FeS, 1-1.4 parts of FeO .

[0039] The preparation process of the above-mentioned high-strength sulfur-oxygen inoculant comprises the following steps:

[0040] (1) Ingredients: Weigh the steel scrap, ferrosilicon, silicon barium, silicon calcium, pure lanthanum and antimony in the above parts by weight, and mix them;

[0041] (2) Melting: Add the above raw materials into an intermediate frequency induction furnace and melt for...

Embodiment 2

[0049] A high-strength sulfur-oxygen inoculant, the mass percentage of elements contained in the sulfur-oxygen inoculant is: Si: 73%, Ca: 0.6%, Ba: 0.4%, La: 1.75%, Al: 1.0%, S : 0.6%, O: 0.6%, Sb: 1.0%, the balance is iron;

[0050] The sulfur-oxygen inoculant is prepared from the following raw materials in parts by weight:

[0051] 3 parts of steel scrap, 135 parts of ferrosilicon, 1.2 parts of silicon barium, 1.4 parts of silicon calcium, 3 parts of pure lanthanum, 2 parts of antimony, 1.5 parts of FeS, 1.2 parts of FeO.

[0052] The preparation process of the above-mentioned high-strength sulfur-oxygen inoculant comprises the following steps:

[0053] (1) Ingredients: Weigh the steel scrap, ferrosilicon, silicon barium, silicon calcium, pure lanthanum and antimony in the above parts by weight, and mix them;

[0054] (2) Melting: put the above raw materials into an intermediate frequency induction furnace and melt at 1340°C for 35 minutes, and then perform water-cooled in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com