Patents

Literature

180results about How to "Reduce the degree of segregation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

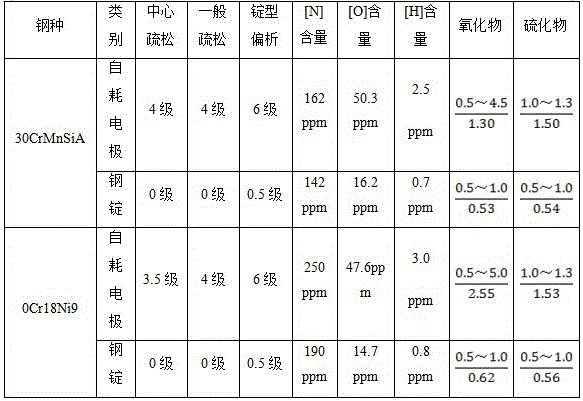

Method for melting nickel-base high temperature alloy with electro-slag furnace

The invention relates to a method for melting a nickel-base high temperature alloy with an electro-slag furnace. The method includes the following methods: loading materials, welding a high temperature alloy electrode and a false electrode to be smelted together, and placing slag materials at the bottom of a crystallizer; blowing the welded electrodes with inert gases, and closing a protection cover; protecting a smelting closing smoke exhaust valve, and feeding an Ar gas into the crystallizer and the protection cover; striking an arc and melting slag; cleaning smelting slag materials, starting a smelting period, and swinging a slag resistor for less than 0.5 m omega during the smelting process; adding oxidizing agents, and adding metal aluminum powder continuously or at intervals to serve as deoxidizing agents during an electro-slag re-melting process; adopting feeding thorough three stages, power feeding is decreased rapidly, power feeding is decreased slowly, and finally heat is preserved at constant power; and casting a die, cooling and demolding the die. According to the method for melting the nickel-base high temperature alloy with the electro-slag furnace, the surface of a nickel-base high temperature steel ingot has no slag groove defect, and the burning losses of Al and Ti are less than or equal to 5%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

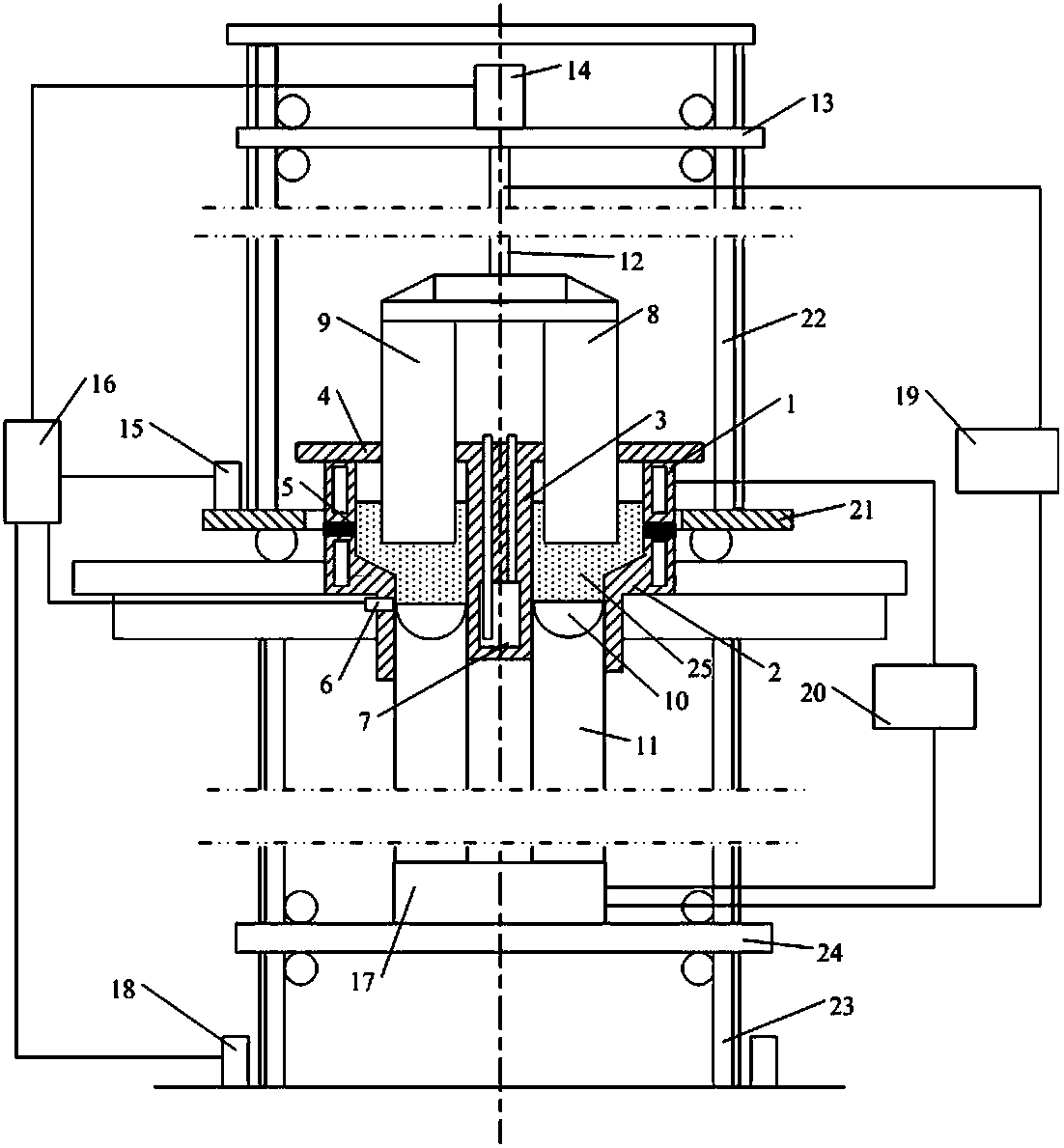

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

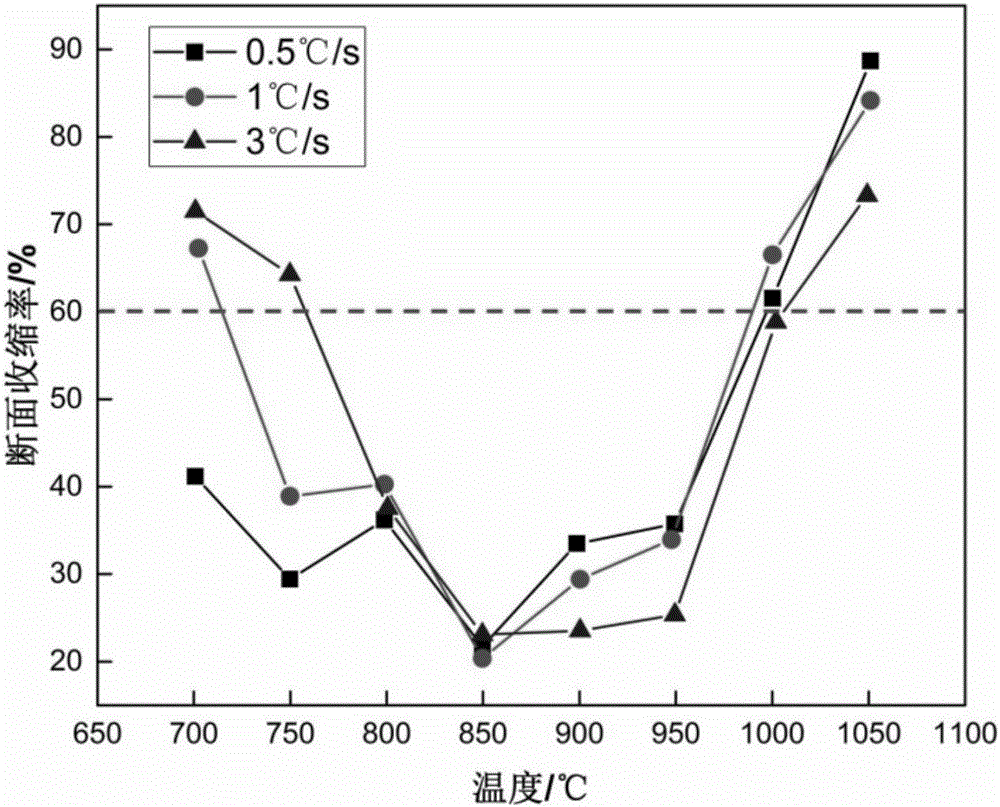

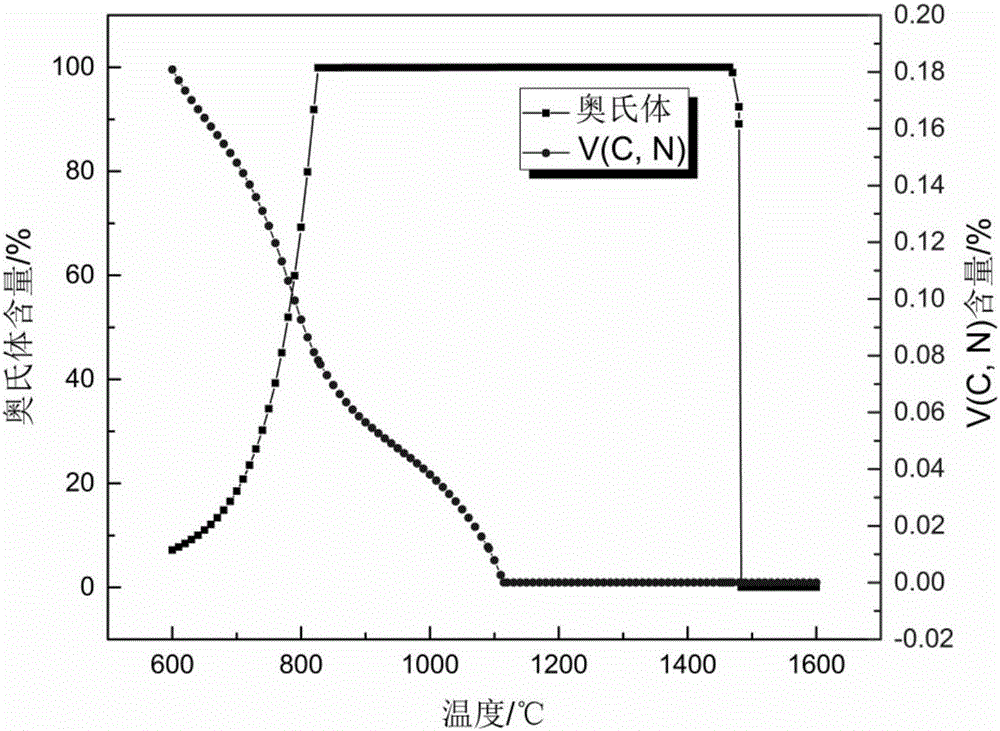

Microalloyed steel continuous casting cooling control method based on steel grade solidification characteristic and evolution of microstructures

The invention relates to a microalloyed steel continuous casting cooling control method based on the steel grade solidification characteristic and evolution of microstructures. The critical technical contents of the microalloyed steel continuous casting cooling control method comprise steel grade solidification characteristic experimental analysis, continuous cast blank solidification structure numerical simulation, continuous casting cooling process water amount regulation and control and the like. Change rules of the thermoplasticity and a third brittle temperature range of a target steel grade at different cooling rates are determined through experiments at first, then the influences of the cooling rates on austenite / ferrite transformation and the microalloy element second-phase particle precipitation law are comprehensively analyzed with te combination with the experiments, and finally, the microalloyed steel square blank continuous casting cooling precise control strategy of "low superheat pouring, low cooling of a third secondary cooling zone and high cooling of a fourth secondary cooling zone" is provided, relevant regulation and control schemes, that is, the superheating temperature is 23 DEG C (the original value is 37 DEG C), the water amount of the third secondary cooling zone is 2.6 L / min (the original value is 51.5 L / min), and the water amount of the fourth secondary cooling zone is 165.6 L / min (the original value is 18.4 L / min) are made a new continuous casting secondary cooling regulation and control mechanism based on the microalloyed steel characteristic is built, a cast blank solidification structure is optimized, and the strength of a surface microstructure of the solidification structure is improved.

Owner:UNIV OF SCI & TECH BEIJING

Clean steel and manufacturing method

InactiveCN101096736AReduce heat lossQuality assuranceTemperature control deviceMetal rolling arrangementsMetallurgyImpurity

The invention discloses clean steel and its manufacturing method, which comprises the following parts: C<=0.0030%, Si<=0.0030%, 0.10%-0.30%Mn, P<=0.0030%, S<=0.0030, 0.01%-0.06%Al, Ti<=0.09%, Nb<=0.05%, N<=0.0030%, O<=0.0030%, H<=0.0002%, Fe and unavoidable impurity. The method comprises the following steps: desulfurizing hot iron; bessemerizing; refining outside the furnace; casting the middle sheet plate blank continuously; loading hotly and directly; heating the furnace; roughing down; planishing; cooling lamellar flow; batching; cleaning with acid ; rolling coldly; annealing ( flattening; shearing ). The invention reduces the inclusion content in the steel by controlling the proper content of C, Mn, P, S, N, O, and H, which makes the inclusion shape fine and dispersing, the composition homogeneous and the structure homogeneous, and guarantees the integrated property.

Owner:ANGANG STEEL CO LTD

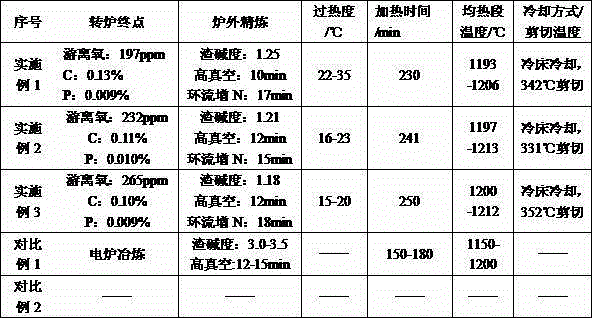

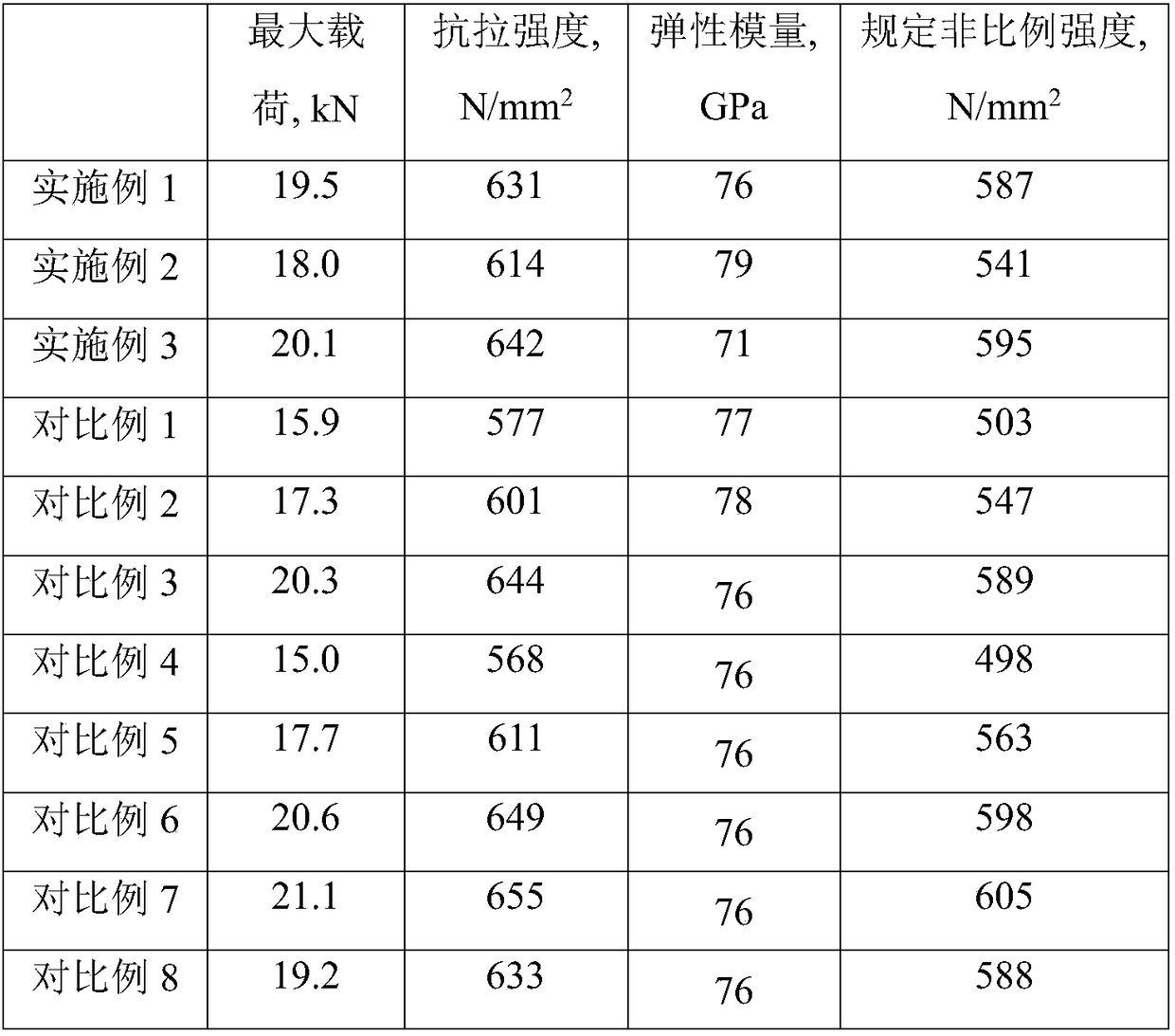

Steel for deep sea oil extraction equipment and manufacturing method of steel forge piece for deep sea oil extraction equipment

ActiveCN105483542AAvoid crackingImprove mechanical propertiesMetal-working apparatusMechanical propertyToughness

The invention discloses steel for deep sea oil extraction equipment and a manufacturing method of a steel forge piece for the deep sea oil extraction equipment. The manufacturing method comprises the steps that a special steel material is used as a blank, the surface of the blank is coated with a glass-like coating, the free forging and bound forging composite forging way is adopted for forging the blank, and a secondary forged blank is obtained; the secondary forged blank is normalized, the temperature is increased to 1150-1200 DEG C in a slow-fast-slow gradient heating mode, then quenching heat treatment is carried out in a water cooling-air cooling ternary cycle alternate mode, secondary tempering treatment in the tempering-water cooling-tempering-water cooing mode is carried out on the quenched secondary forged blank, and therefore the steel forge piece for the deep sea oil extraction equipment is obtained. Quenching cracking of large forge pieces in complex shapes is effectively prevented by combining the forging technology with the heat treatment technology, the comprehensive mechanical property, particularly the low-temperature toughness of the manufactured steel forge piece for the deep sea oil extraction equipment is greatly improved, and the manufactured steel forge piece can be well applicable to deep sea low-temperature working condition environment.

Owner:NANJING INST OF TECH +1

Slag system used for preparing nickel base alloy through electroslag remelting and use method of slag system

InactiveCN105132701ASolving Remelted Surface Quality IssuesEliminate harmful phaseChemical compositionSlag

The invention provides a slag system used for preparing a nickel base alloy through electroslag remelting and a use method of the slag system. The slag system comprises, by mass, 65%-70% of CaF2, 10%-16% of Al2O3, 10%-16% of CaO, 2%-5% of MgO, 2%-5% of TiO2 and not more than 0.8% of impurities. When the slag system is used, prepared slag is baked and then added to an argon-shielded electric slag furnace crystallizer to be melted, then 700 DEG C advanced ultra-supercritical coal fired boiler nickel base alloy is remelted, and slow cooling and mold stripping are conducted after remelting. According to the slag system used for preparing the nickel base alloy through electroslag remelting and the use method of the slag system, burning losses of easily-oxidized elements in the alloy can be effectively reduced, the head and tail distribution of the alloy can be uniform, the segregation degree of elements is reduced, and the surface quality problem of electroslag remelting can be effectively solved.

Owner:NORTHEASTERN UNIV +1

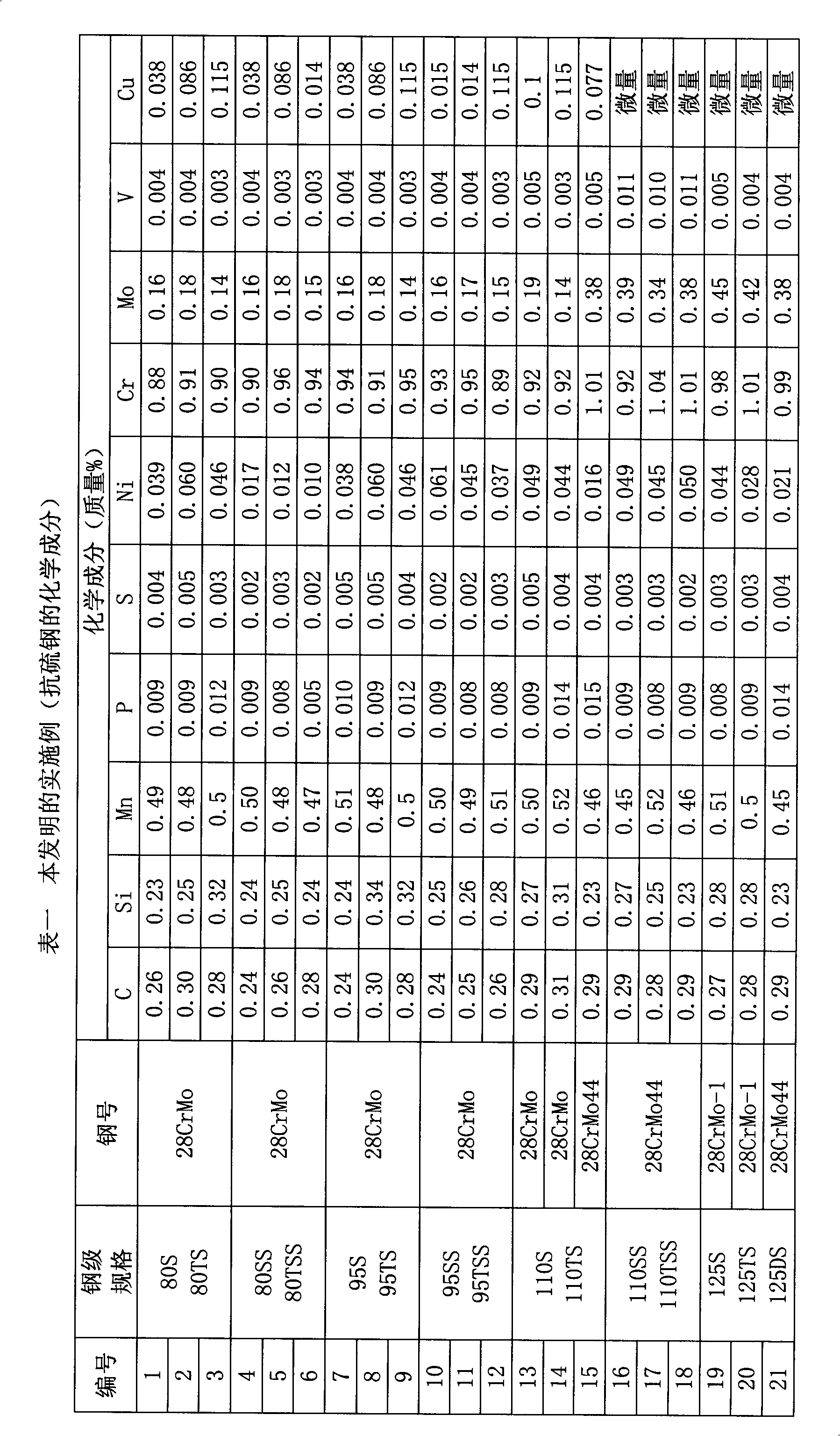

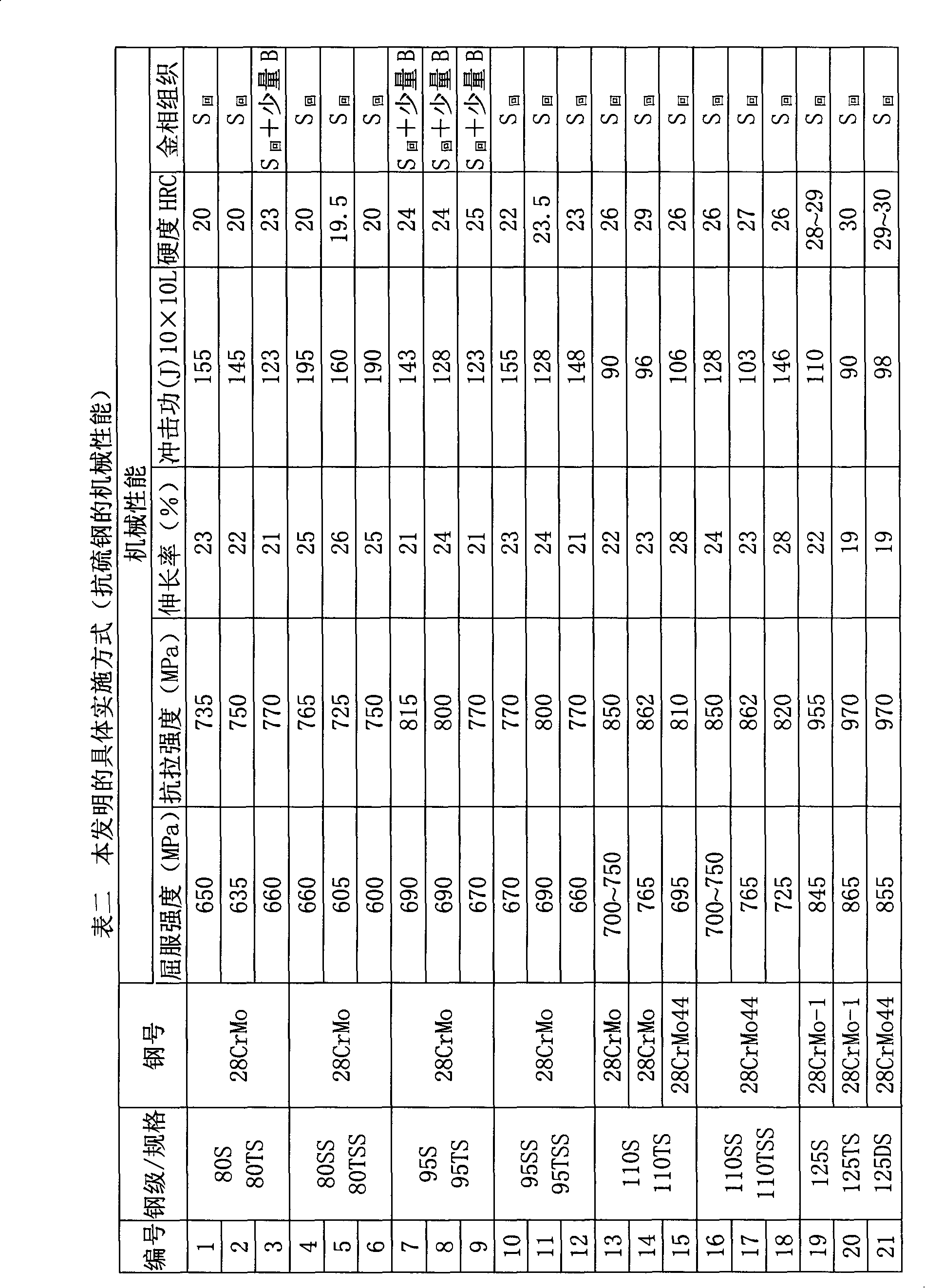

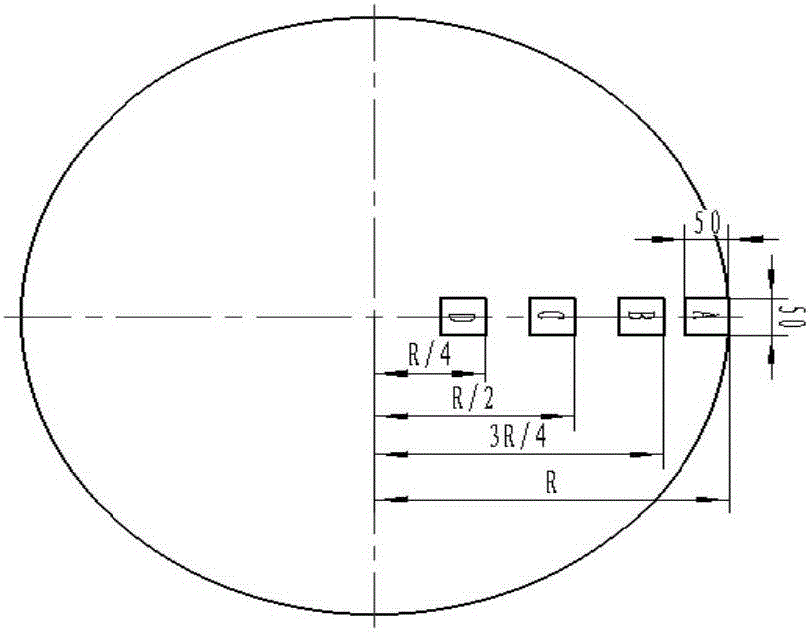

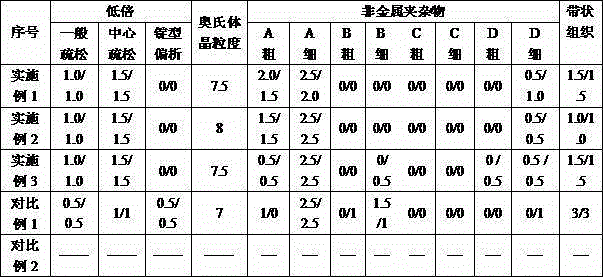

Clean steel smelting method of anti-S steel oil well pipe

InactiveCN101643882AQuality assuranceGuaranteed performanceElectric furnaceProcess efficiency improvementElectric arc furnaceChemical composition

The invention provides a clean steel smelting method of an anti-S steel oil well pipe, which relates to a smelting and preparing technology of an oil well pipe blank used in a corrosive oil-gas fieldenvironment. Clean steel comprises suitable chemical compositions by weight percent: 0.20-0.35 percent of C, not more than 1.00 percent of Si, not more than 0.60 percent of Mn, not more than 0.015 percent of P, not more than 0.010 percent of S, not more than 1.50 percent of Cr, 0.15-1.0 percent of Mo, 0.01-0.06 percent of Als, not more than 0.09 percent of Ti, not more than 0.05 percent of Nb, notmore than 0.0030 percent of N, not more than 0.0030 percent of O, not more than 0.0002 percent of H and Fe and the balance of unavoidable impurities. The clean steel smelting method adopts the following production technical lines by aiming at the clean steel with the compositions: choosing matching materials; smelting in an arc furnace; refining in an LF furnace; refining in a VD furnace; continuously casting in an arc shape; controlling hydraulic pressure and casting in full protection. The clean steel smelting method reduces the impurity content in the steel by controlling the proper content of C, Mn, P, S, Cr, Mo, N, O, H, and the like, the impurities are smaller and dispersive by the control of a subsequent technology, the component distribution is more uniform, tissues are evenly thinned, and the combination property of the anti-sulfur oil well pipe is ensured.

Owner:朝阳西姆莱斯石油铸钢管件有限公司 +1

High-strength cold-roll-forming structural steel and method for producing same

InactiveCN1970811AInhibition of segregationFast solidificationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses a high-strength cool-bent moulding structural steel and manufacturing method, which comprises the following parts: 0.03-0.12% C,0.08-0.50% Si,1.20-1.95% Mn,not more than 0.02% P,not more than 0.006% S, 0.05%-0.15% Mo,0.005-0.055% Als,0.03-0.07% Nb,0.08-0.15% Ti,0.01-0.05% V ,0.0008-0.004% Ca and Fe and inevitable impurity with Ceq not more than 0.42%. The making method is characterized by the following: controlling the fusing point of smolten steel over 15-30 deg.c; casting continuously; setting drawing speed of casting bland at 1.5-4.0m / min and blank thickness between 100 and 200mm; heating in the furnace directly; setting the even heating temperature at 1100-1250 deg.c, fine-rolling temperature at 940-1070 deg.c and outlet temperature at 840-920 deg.c; freezing rapidly after 0-7s; setting the coiling temperature at 500-610 deg.c with yielding strength of steel board over 700Mpa and drawing-proof strength between 750 and 950Mpa and extending rate over 17%.

Owner:ANGANG STEEL CO LTD

Continuous casting technology for reducing carbon segregation of wind electricity medium carbon steel continuous casting round billet

ActiveCN106552910AReduce the degree of segregationMeet the stringent requirements of segregationElectricitySteelmaking

The invention discloses a continuous casting technology for reducing carbon segregation of a wind electricity medium carbon steel continuous casting round billet. The technological processes of converter steelmaking, LF refining, RH vacuum degassing, large-section round billet continuous casting and slow cooling are adopted. The stirring mode with crystallizer electromagnetic stirring and tail-end electromagnetic stirring being combined is adopted in the continuous casting round billet, the crystallizer electromagnetic stirring parameter is 380A / 3.0Hz, and alternate or continuous electromagnetic stirring serves as the stirring mode. The tail-end electromagnetic stirring parameter is 200 / 3.0Hz, and alternate electromagnetic stirring serves as the stirring mode. The crystallizer cooling water flow is 4700L / min(+ / -35L), the secondary-cooling spraying water volume is 0.18L / min, water allocation of all zones is 50%, 35% and 15% separately, and the pulling rate is 0.33m / min when the degree of superheat of molten steel is in the working condition of 25-40 DEG C. By means of the continuous casting technology, the carbon segregation degree is effectively lowered, and the strict requirement for the carbon segregation of wind electricity medium carbon steel is met.

Owner:建龙北满特殊钢有限责任公司

Nitrogen-added 20MnCr5 gear steel and production method thereof

The invention relates to nitrogen-added 20MnCr5 gear steel. The gear steel comprises, by weight, 0.18-0.21% of C, Si with the amount smaller than or equal to 0.12%, 1.25-1.35% of Mn, 1.16-1.24% of Cr, P with the amount smaller than or equal to 0.020%, 0.020-0.030% of S, 0.025-0.045% of Al and 0.0060-0.0100% of N. The gear steel further comprises, by weight, Ni with the amount smaller than or equal to 0.10%, Cu with the amount smaller than or equal to 0.10%, B with the amount smaller than or equal to 0.0003%, O with the amount smaller than or equal to 15*10-6, and the balance Fe and other trace residual elements. The gear steel has the advantages of being stable in performance, small in heat treatment deformation and good in surface quality, and achieving hardenability band narrowing.

Owner:SGIS SONGSHAN CO LTD

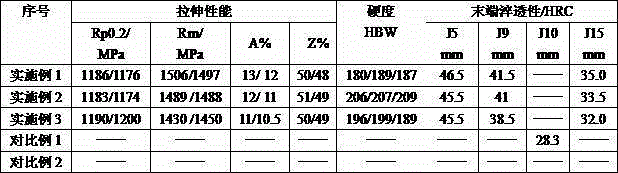

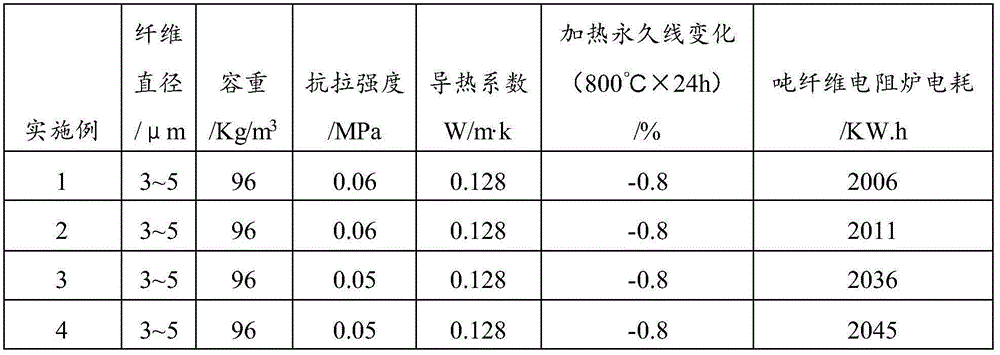

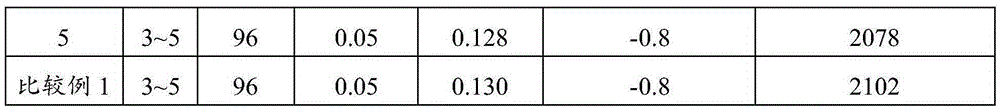

Method for preparing alumina silicate fibers

ActiveCN105417949AImprove processing and mixing uniformityReduce the degree of segregationGlass making apparatusFiberGranularity

The invention provides a method for preparing alumina silicate fibers. The method comprises the following steps that raw material clinker of the alumina silicate fibers is sequentially subjected to smashing, fusion and centrifugal thread throwing, and the alumina silicate fibers are obtained; according to the grain size distribution of smashing, the mass percentage of particles with the grain size of 2 mm to 5 mm ranges from 50% to 99%, and the mass percentage of particles with the grain size of 0 to 2 mm ranges from 1% to 50%. The smashing grain size is limited below 5 mm, and through the reasonable grain size ratio, the fusion speed of raw materials can be increased, energy consumption can be reduced, and the defect that the raw material granularity is too small can be overcome. Under the condition of adopting the same raw materials and production conditions, and about 100 kW.h of energy can be saved when per ton of alumina silicate fibers are produced according to the method.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Forging and heat treating technology of 7085 aluminum alloy

The invention relates to a forging and heat treating technology of 7085 aluminum alloy. The forging and heat treating technology comprises the following operation steps of blank material purchasing, blank material cutting and discharging, forging and heating, blank making, inner bore machining, heating, mandrel supporter bore broadening, remelting and heating, ring rolling, cooling, solid solution, cold deformation, aging and machining to the required size. According to the forging and heat treating technology, operation is convenient, transgranular precipitates and grain boundary precipitates are regulated and controlled through a multi-step aging technique under the condition of ensuring the strength, and the stress resistance and the corrosion resistance are promoted.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

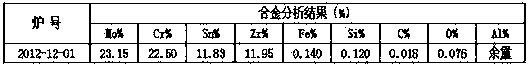

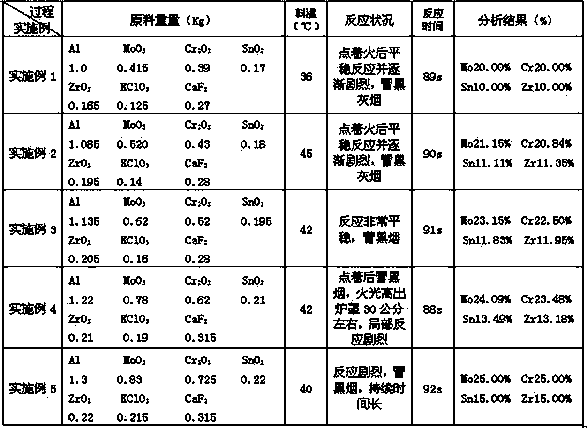

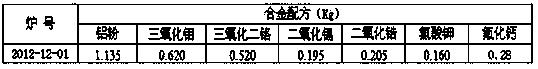

Intermediate alloy for preparation of titanium alloy and preparation method thereof

The invention discloses an intermediate alloy for preparation of titanium alloy and a preparation method thereof, relating to aluminum-molybdenum-tin (aluminum-molybdenum-tin-based) intermediate alloys for preparation of the titanium alloy and preparation methods thereof. The alloy is characterized by containing the following alloy compositions in percentage by weight: 20.0-25.0% of Mo, 20.0-25.0% of Cr, 10-15% of Sn, 10-15% of Zr and the balance of Al. According to the aluminum-molybdenum-tin-chromium-zirconium alloy disclosed by the invention, metallic compounds, which take molybdenum, tin, chromium, zirconium and the like as main ingredients, have the characteristics of good brittleness and easiness in fracture, and a titanium alloy production process is shortened and is easier in operation. According to the preparation method, oxides are taken as raw materials, so that the cost is low, the smelting process is stable, and the state of alloy forming is good; the alloying is uniform, and elemental metals are added to titanium sponge and aluminum beans in the form of intermediate alloy, so that the degree of segregation of the titanium alloy is lowered.

Owner:CHENGDE TIANDA VANADIUM IND

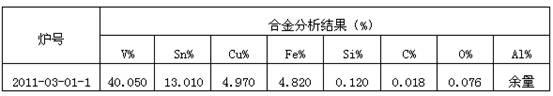

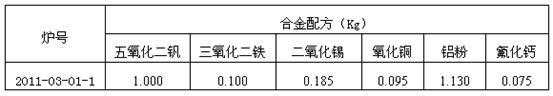

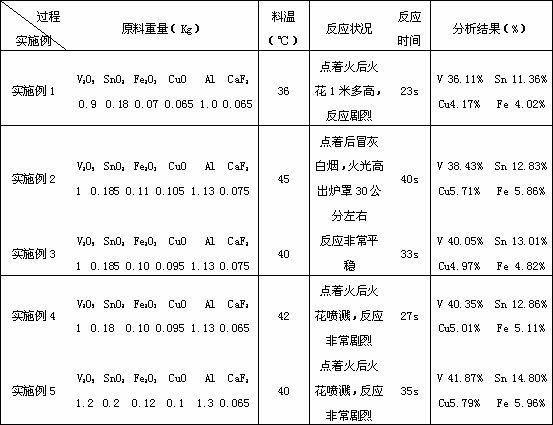

Aluminium-vanadium-tin-copper-iron intermediate alloy and preparation method thereof

The invention relates to an aluminium-vanadium-tin-copper-iron intermediate alloy and a preparation method thereof, and relates to an aluminium-vanadium-tin (aluminium-vanadium-tin-based) intermediate alloy for the preparation of the titanium alloy and a preparation method thereof. The intermediate alloy is characterized in that the alloy comprises the following components by weight percent: 36.0%-42.0% of V, 11.0%-15.0% of Sn, 4.0%-6.0% of Fe, 4.0%-6.0% of Cu and the balance Al. The preparation process adopts the metallothermics. The aluminium-vanadium-tin-copper-iron alloy is a metal compound using vanadium, tin, copper, iron and the like as main components and has the characteristics of high brittleness and easiness in breakage, thus the production process of the titanium alloy can be shortened and the operations of the production process of the titanium alloy are easier. The aluminium-vanadium-tin-copper-iron alloy uses oxides as raw materials and has low cost, the smelting process is stable, the formed state of the alloy is good; and alloying is uniform, the alloy is added in spongy titanium and aluminium shot in an intermediate alloy manner, and the degree of the segregationof the titanium alloy is reduced.

Owner:CHENGDE TIANDA VANADIUM IND

Method for preparing high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining

The invention provides a method for preparing a high-purity nickel-based superalloy through integration of vacuum induction melting and electron beam refining. The method comprises the following stepsof S1, pretreatment of raw materials; S2, charging into a furnace; S3, vacuum induction melting; and S4, electron beam refining, so that the refined alloy is obtained. By coupling vacuum induction melting and electron beam refining, a superalloy mother alloy is melted through a vacuum induction method, then the superalloy is further purified through electron beam refining, the segregation degreeis reduced, the metallurgical quality of a superalloy cast ingot is improved by fully utilizing the advantages of induction melting and electron beam refining, and finally, high-purity preparation ofthe alloy is realized.

Owner:DALIAN UNIV OF TECH

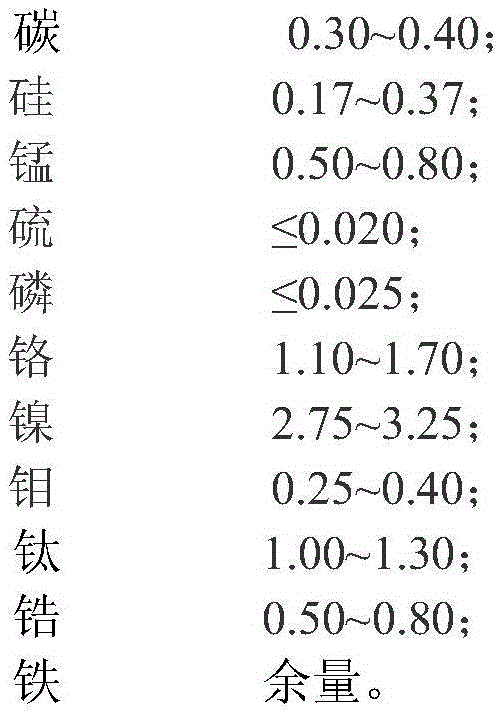

Manufacturing method of steel and forge piece thereof for valve seat of deep sea oil extraction equipment

ActiveCN105671431AAvoid crackingImprove mechanical propertiesValve arrangementsMetal-working apparatusIce waterRoom temperature

The invention discloses a manufacturing method of steel and a forge piece thereof for a valve seat of deep sea oil extraction equipment. The manufacturing method comprises the following steps: taking special steel as a blank, coating the surface of the blank by using a glassy coating, and forging the blank in a mode of composite forging including free forging and die forging to obtain a secondary forging stock of the valve seat; normalizing the forging stock of the valve seat, and carrying out quenching thermal treatment on the forging stock of the valve seat by using a four-stage intermittent quenching process including ice water cooling, air cooling, boiling water cooling and common water cooling; heating a valve seat forge piece subjected to quenching thermal treatment to the temperature of 675-690 DEG C and insulating for 10 hours at least, discharging from a furnace, and cooling in air until the temperature is equal to room temperature so as to obtain a steel forge piece for the valve seat of the deep sea oil extraction equipment. By combination of a forging process and a thermal treatment process, quenching cracking of a large force piece which is complicated in shape is prevented effectively, and comprehensive mechanical property, particularly low-temperature toughness, of the manufactured steel forge piece for the valve seat of the deep sea oil extraction equipment is improved greatly, so that the steel forge piece can be well suitable for a deep sea environment under the working condition of low temperature.

Owner:NANJING INST OF TECH

Method for reducing macro segregation at 1/2R position of bearing steel wire rod

ActiveCN104308111AReduce segregationInhibition of long-distance diffusionTemperature control deviceWire rodHeating time

The invention discloses a method for reducing macro segregation at the 1 / 2R position of a bearing steel wire rod, and relates to the metallurgy field. The bearing steel wire rod with the macro segregation at the 1 / 2R position relieved or eliminated is obtained by controlling the electromagnetic stirring intensity, frequency, the total water of a secondary cooling zone, the specific water flow, the casting temperature and pulling rate in the bearing steel continuous casting process, carrying out heat preservation and retarded cooling on a continuous casting billet after continuous casting is carried out, controlling heating time and temperature in the blooming process, carrying out cooling in heap in a heat preservation pit after blooming is carried out, and controlling rough rolling temperature, fine rolling temperature and spinning temperature in the rolling process and the cooling rate and cooling temperature after spinning is carried out. The segregation at the 1 / 2R position of the bearing steel wire rod obtained according to the method is smaller than or equal to 1.5, and quality of a bearing steel product is improved greatly.

Owner:武安市裕华钢铁有限公司

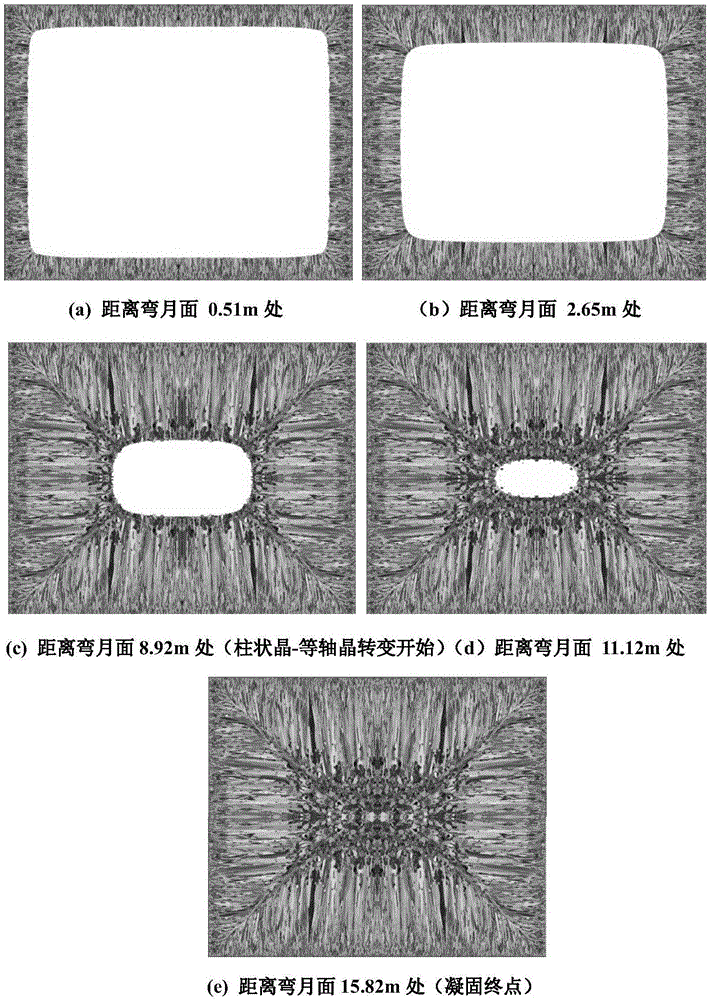

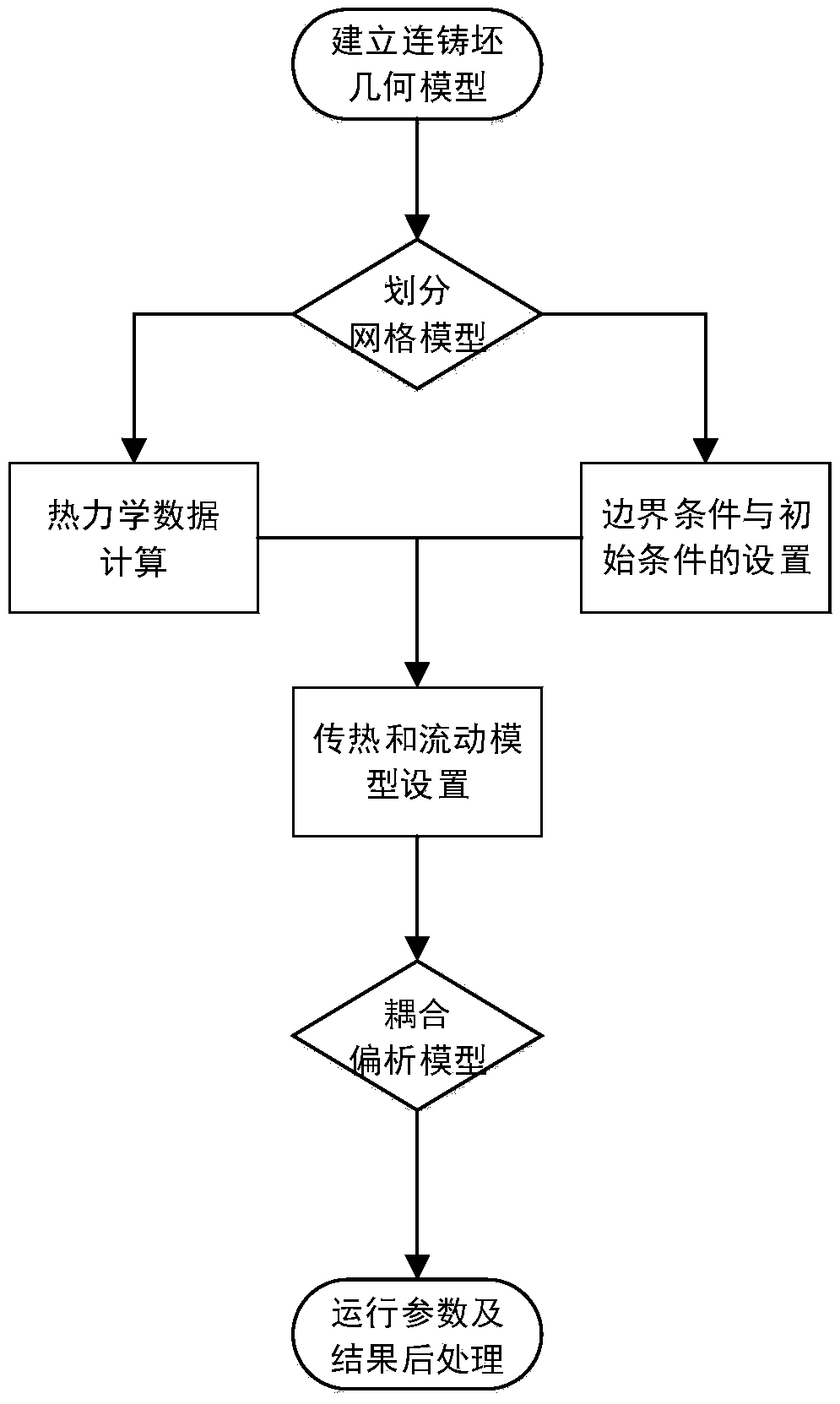

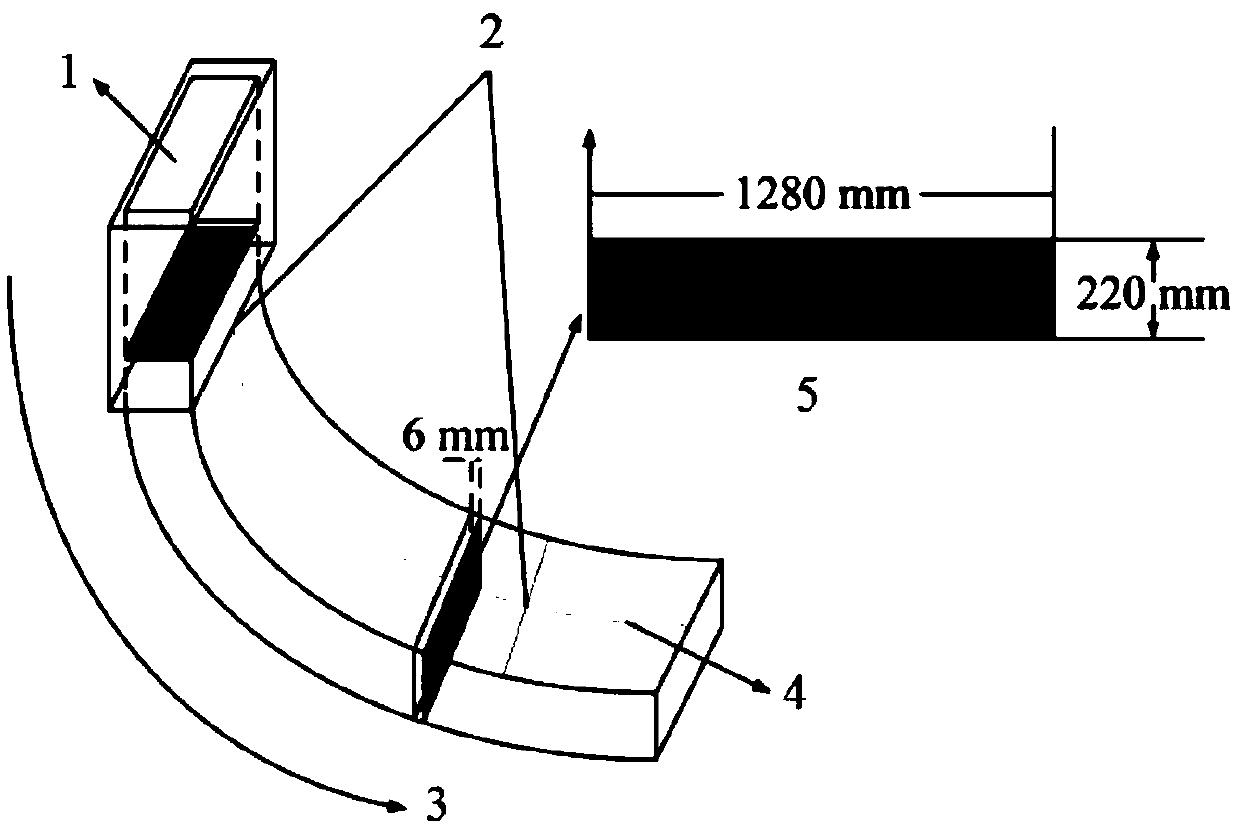

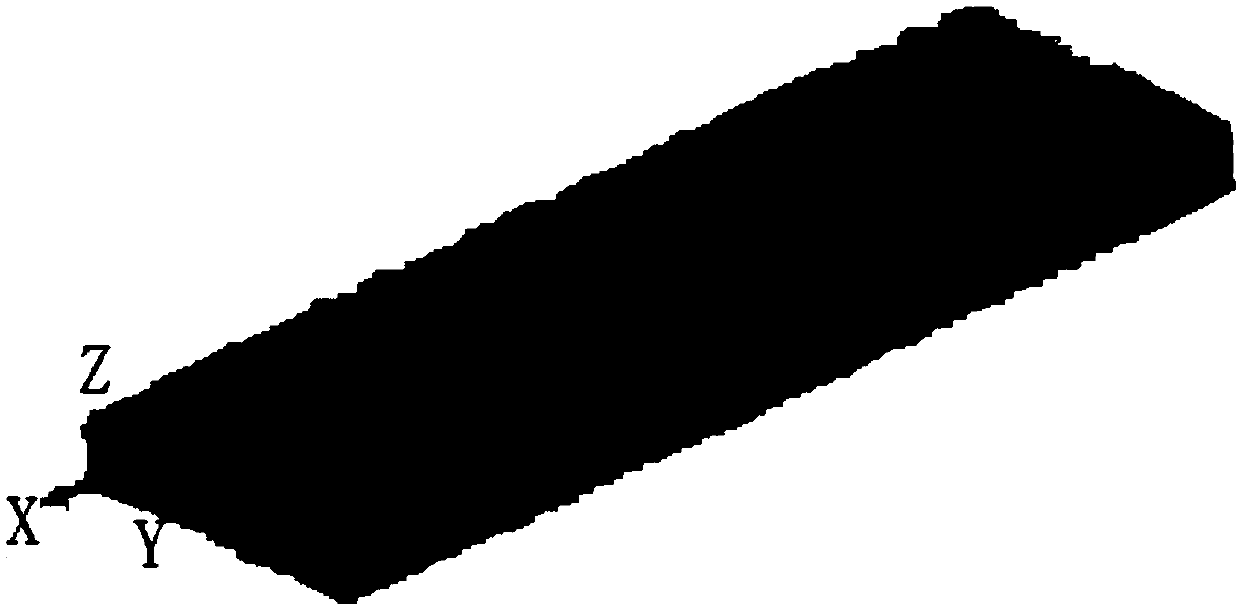

Simulation method for macrosegregation of continuous casting slab

InactiveCN108647376AImprove segregationLow costDesign optimisation/simulationSpecial data processing applicationsDistribution ruleMesh grid

The invention relates to a simulation method for macrosegregation of a continuous casting slab. The method comprises the following steps: building a continuous casting slab three-dimensional slice model according to the length x width x thickness of the continuous casting slab, dividing the three-dimensional slice model into grids to obtain a three-dimensional grid model; obtaining thermodynamic data according to solute compositions of the continuous casting slab steel grade and the mass percentage; obtaining a heat transfer boundary condition, a molten steel initial condition and a flow boundary condition of a continuous casting slab model; and constructing a solidification and heat transfer model and a molten steel flow model of the continuous casting slab according to the thermodynamicdata, the heat transfer boundary condition, the molten steel initial condition and the flow boundary condition, so as to calculate and obtain solute element concentrations, as the following formulas,at each point of a section of the continuous casting slab. The simulation method for the macrosegregation of the continuous casting slab provided by the invention can obtain the macrosegregation conditions of different elements in the steel, the solute distribution rule of the whole section of the casting slab and the like, provide reliable data support for the actual production process, and optimize process parameters of a continuous casting operation, thereby improving the quality of the continuous casting slab.

Owner:NORTHEASTERN UNIV

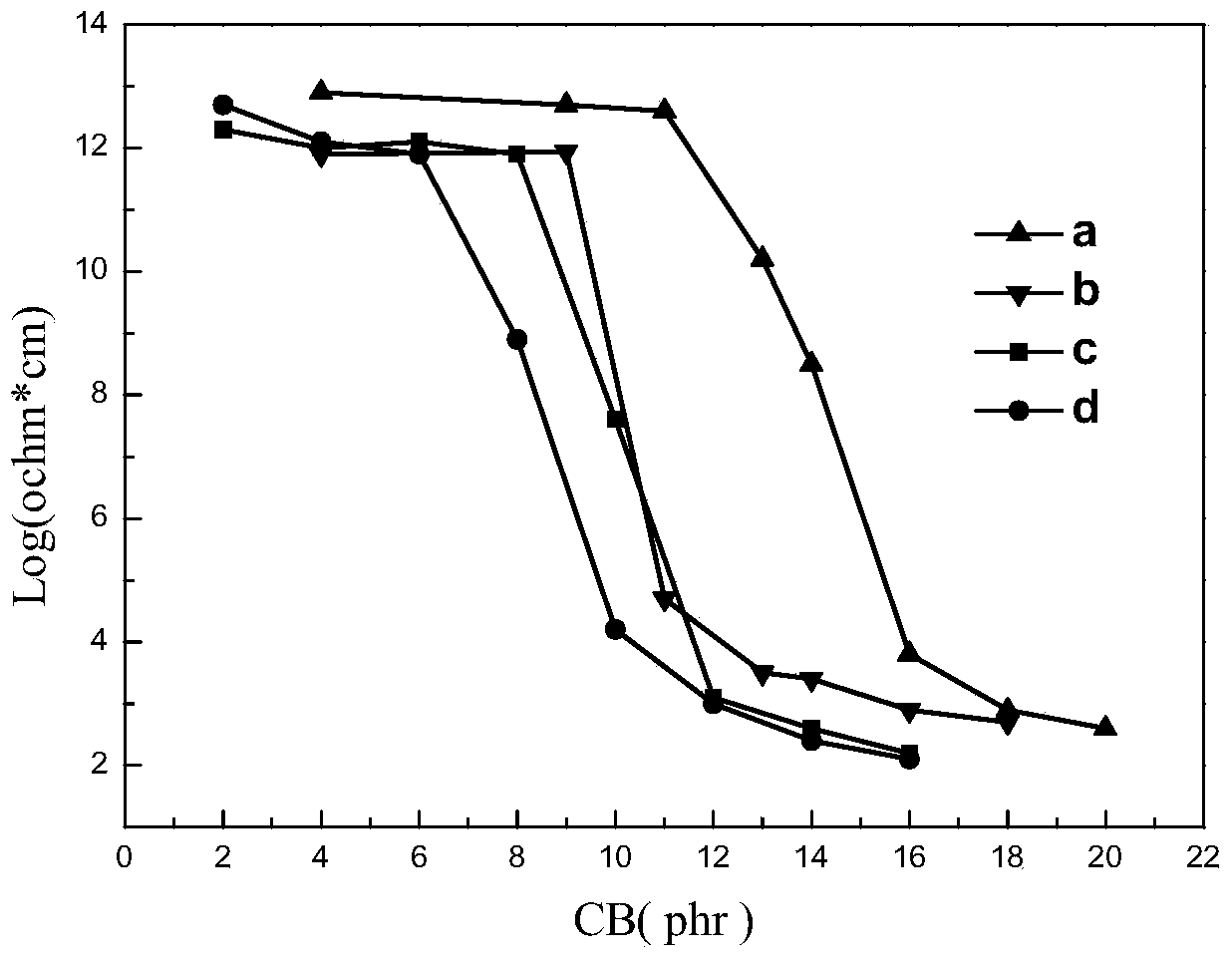

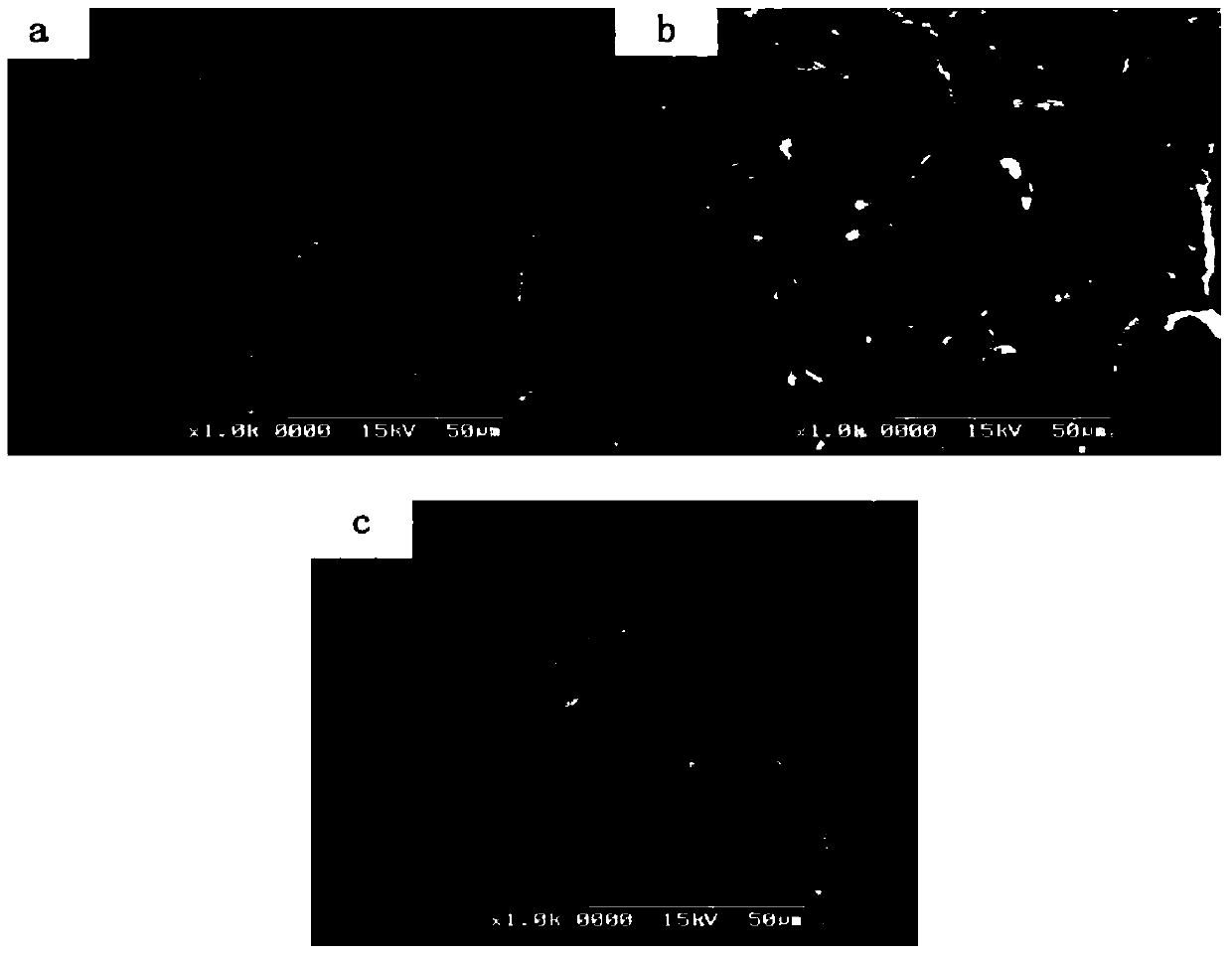

High-density polyethylene/graphene/polyaniline composite material and synthetic method thereof

The invention discloses a high-density polyethylene / graphene / polyaniline composite material and a synthetic method thereof. According to the high-density polyethylene / graphene / polyaniline composite material, the surface of graphene is coated with polyaniline to form a polyaniline / graphene blend, and the polyaniline / graphene blend is dispersed in a high-density polyethylene substrate. As the polyaniline (PANI) coats the graphene (CB) to be blended with the high-density polyethylene (HDPE) substrate, the dispersity of the graphene is improved, the degree of crystallinity of the high-density polyethylene is reduced, therefore, the PTC intensity and the stability of the polyethylene / graphene / polyaniline composite material are improved.

Owner:TAICANG JINKAI SPECIAL TYPE CABLE

Manufacturing method of aluminum alloy cartridge shell and cartridge shell

InactiveCN109158604AFast coolingFine and uniform grainAnodisationCartridge ammunitionAnodic oxidationCopper

The invention provides an aluminum alloy cartridge shell and a manufacturing method of the aluminum alloy cartridge shell. The manufacturing method of the aluminum alloy cartridge shell includes the following steps that S1, an aluminum alloy raw material is prepared, and an aluminum alloy solution is smelted; S2, an aluminum alloy cartridge shell blank is prepared; S3, forming treatment is conducted; and S4, surface treatment is conducted. According to the structural features and the use environments of the cartridge shell, alloy components are designed scientifically and reasonably, the aluminum alloy cartridge shell is manufactured after a 3D jet molding fast solidifying technology, multi-pass die stamping forming treatment and hard anodizing surface treatment, the whole set of technological process is complete, operability is high, and the purpose of replacing traditional copper and steel cartridge shells can be achieved.

Owner:HUNAN UNIV OF TECH

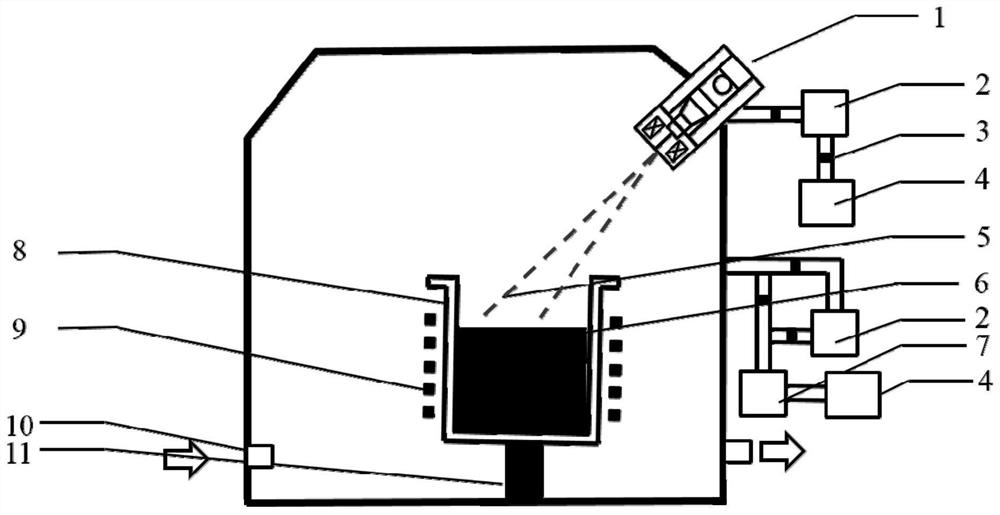

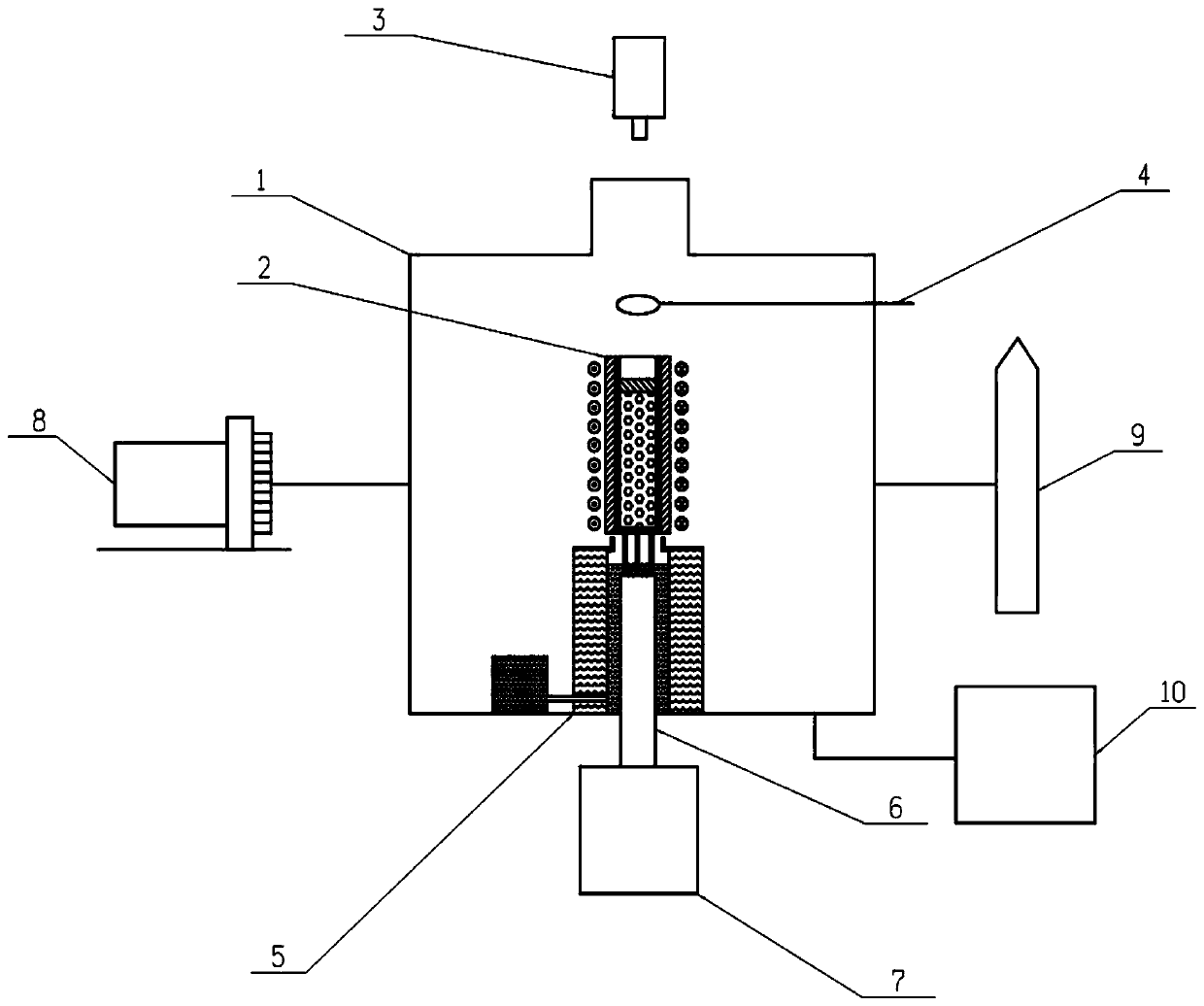

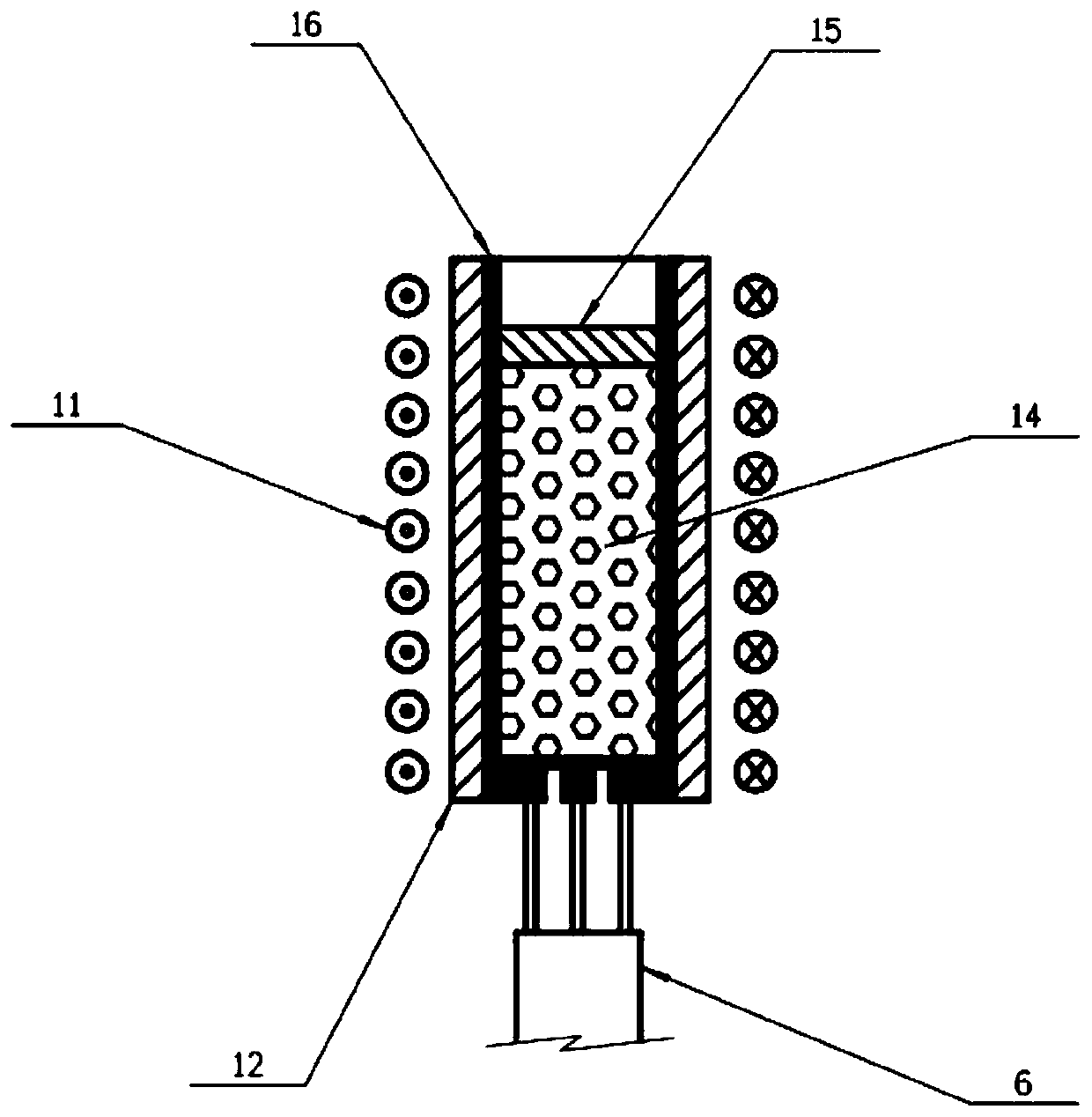

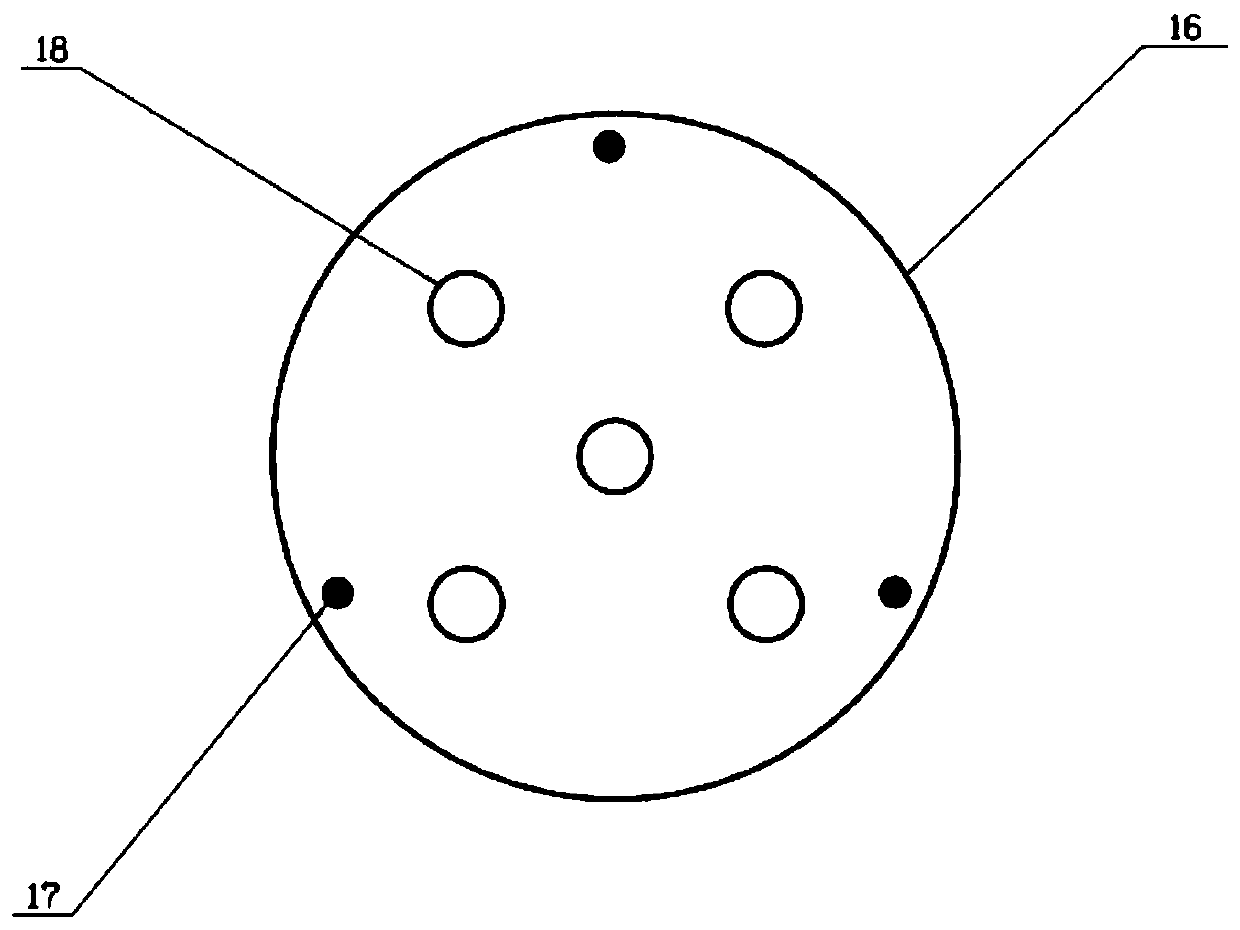

Multi-mode excitation deep supercooling directional solidification device and method

ActiveCN111299553APrecise speed controlPrecisely control the areaProcess efficiency improvementCrucibleLiquid state

The invention relates to the technical field of directional solidification, in particular to a multi-mode excitation deep supercooling directional solidification device and method. The multi-mode excitation deep supercooling directional solidification device comprises a reaction furnace, a smelting device, a feeding device, an excitation device, a drawing rod and a drawing device, wherein the feeding device is used for adding a purifying agent into a crucible in a hot melting process, the excitation device comprises an excitation chamber capable of being filled with liquid metal, a water cooling ring layer and a liquid level controller communicating with the excitation chamber, the liquid level controller is used for controlling the liquid level of the liquid metal in the excitation chamber, and the drawing device is capable of pulling at least a portion of the crucible into the excitation chamber at a predetermined speed range by means of the drawing rod. According to the directionalsolidification device, deep supercooling of melt is achieved through a method of combining glass purification and circulating superheating, moreover, smelting, liquid metal / water dual cooling and thedrawing device are ingeniously combined, different modes can be selected to stimulate directional solidification of the deep supercooled melt, and therefore deep supercooled directional solidificationcastings with different structures and performance characteristics can be obtained, and more research and application requirements are met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Manufacturing method for steel forging used for critical component of deep sea Christmas tree

ActiveCN105671280AImprove mechanical propertiesGuaranteed mechanical propertiesMetal-working apparatusMedium frequencyWater cooling

The invention discloses a manufacturing method for a steel forging used for a critical component of a deep sea Christmas tree. The manufacturing method comprises the following steps that 1, F22 alloy steel and Fe-Ga intermediate alloy serve as the raw materials and are smelted to be high-quality molten steel in a medium frequency electric furnace; 2, liquid die forging is conducted on a hydraulic press, demolding is conducted at the temperature of about 1200 DEG C, a blank is forged through the forging mode that free forging and restrained forging are composited, and thus a secondary forging blank is obtained; 3, quenching heat treatment is conducted on the secondary forging blank through the mode that water cooling and air cooling are cycled and alternated for two times; and 4, secondary tempering treatment is conducted on the quenched secondary forging blank through the steps of tempering, water cooling, re-tempering and re-water-cooling, so that the steel forging used for the critical component of the deep sea Christmas tree is obtained. According to the manufacturing method for the steel forging used for the critical component of the deep sea Christmas tree, quenching cracks of the complex-shaped large forging is effectively prevented by combining the forging process with the heat treatment process; in addition, the comprehensive mechanical property, especially the low-temperature toughness of the manufactured steel forging used for the critical component of the deep sea Christmas tree is substantially improved, and the steel forging can be well applied to a deep sea low-temperature working condition environment.

Owner:NANJING INST OF TECH

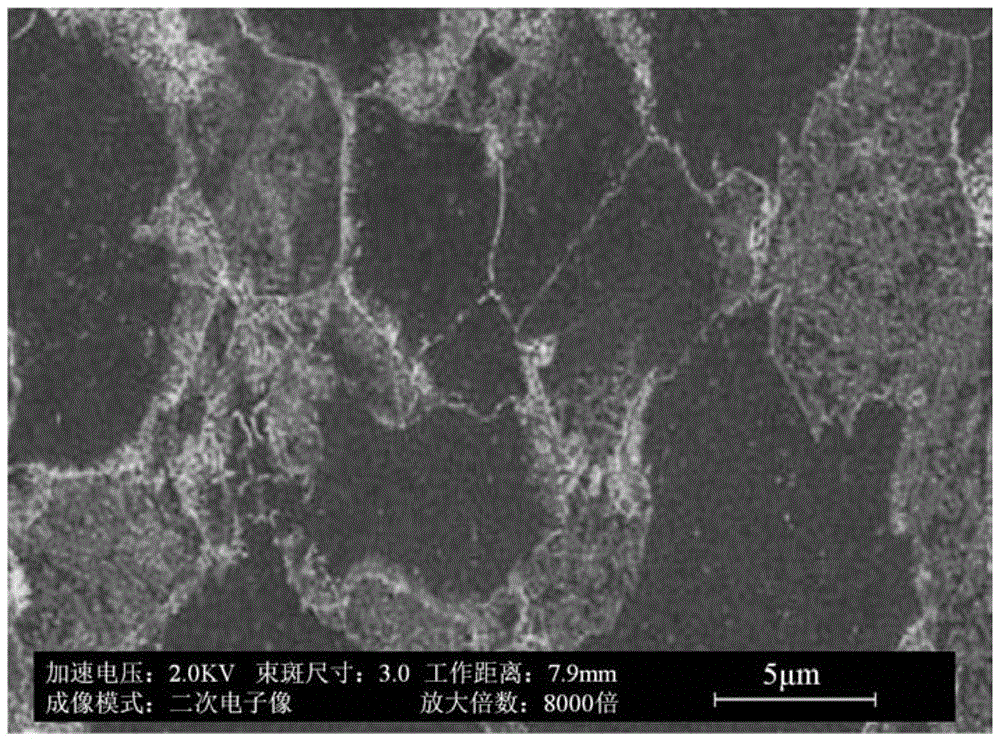

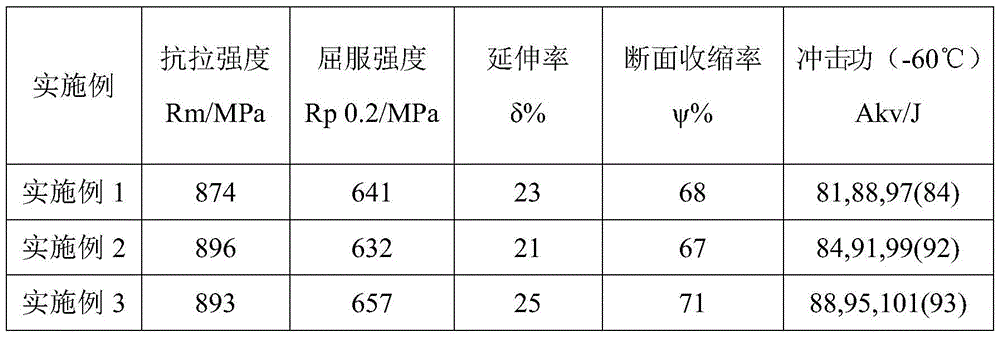

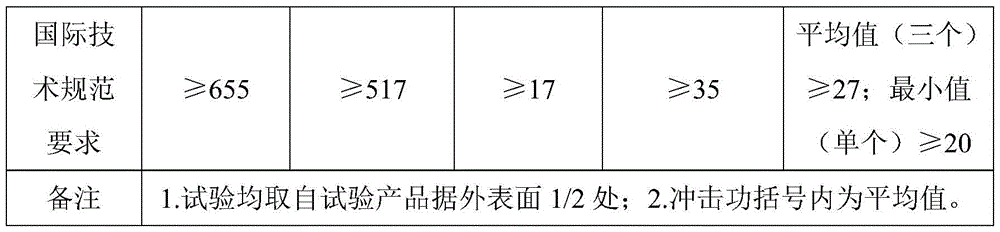

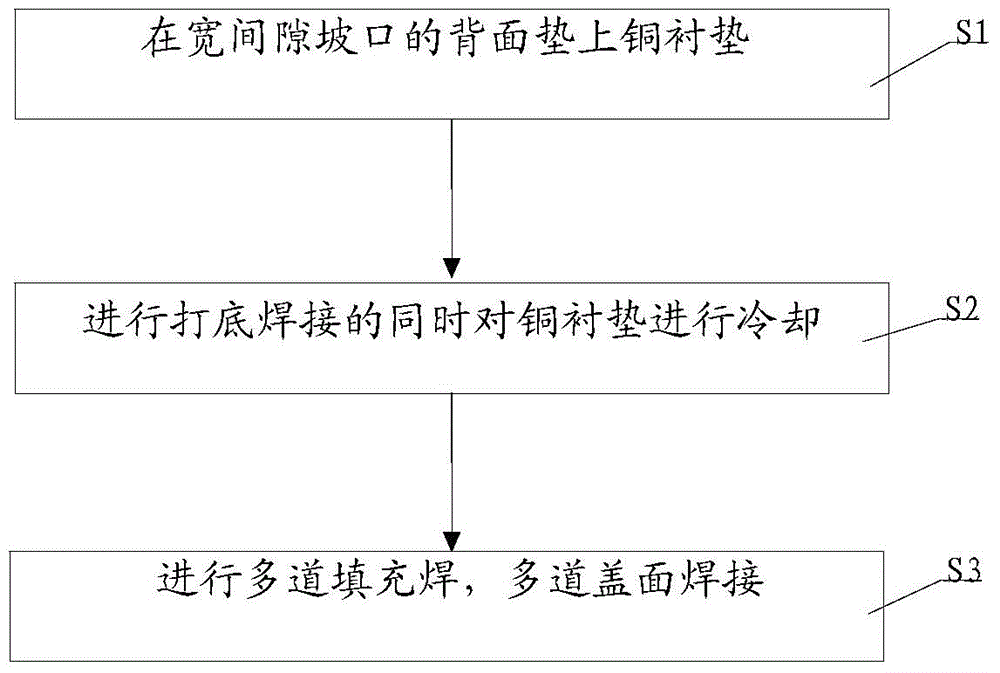

Wide-gap square butt joint welding technology and welding structure

ActiveCN104526112AFine and uniform grainReduce the degree of segregationWelding/cutting auxillary devicesArc welding apparatusTest sampleButt joint

The invention relates to a wide-gap square butt joint welding technology and welding structure. A copper liner is adopted to replace a ceramic liner, and the problem that ceramic is molten and stirred to generate slag inclusion is avoided. In the backing weld process, the copper liner is cooled, a weld joint is fast cooled and formed, meanwhile, a weld connector is prevented from generating an overheated structure, the segregation degree is effectively reduced, and the mechanical performance of the weld connector is improved. A solid welding wire is used for backing weld, and weld cracks are not prone to being generated. A contrast test shows that when a gap is 12 mm, the ceramic liner is adopted for single-face CO2 welding, the formed surface of the weld joint on the back face is wide, backing thickness is increased, the weld joint is overheated, reinforcement height is large, forming deteriorates, the liner is prone to falling off, and impact toughness is reduced severely; through the wide-gap square butt joint welding technology, the weld joint is formed attractively and is golden, a backing weld channel on a macro-test sample is small and even in grain, and a welding technology test displays that all indexes of the mechanical performance of the whole weld connector meet the requirement of EH36 steel plates.

Owner:FUJIAN MAWEI SHIPBUILDING

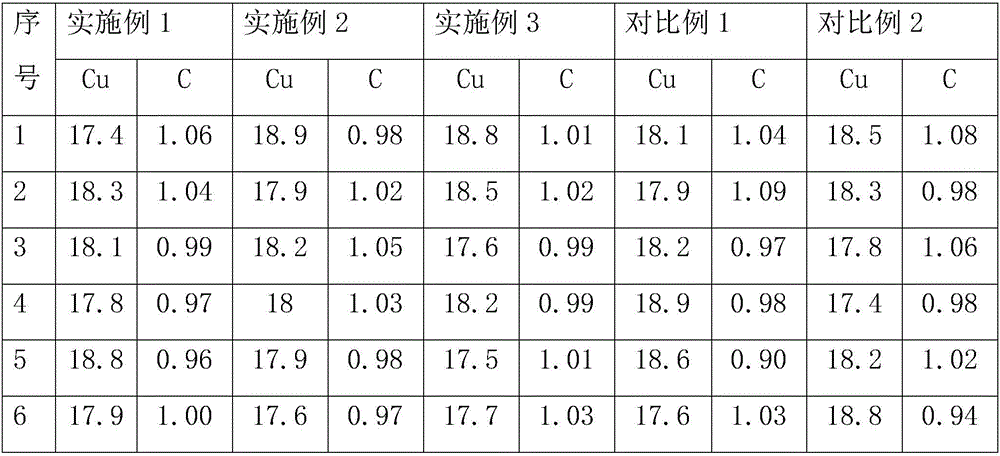

Electroslag remelting fluoride-free slag and electroslag remelting method thereof

The invention provides electroslag remelting fluoride-free slag and an electroslag remelting method thereof. The fluoride-free slag is prepared from, by weight, 45-55 parts of CaO, 35-45 parts of Al2O3, 5-10 parts of MgO and 2-5 parts of SiO2. The method comprises the steps that the fluoride-free slag is baked, an electroslag remelting furnace is assembled, the baked fluoride-free slag and a deoxidizing agent are added into a crystallizer of the electroslag remelting furnace for arcing, a graphite electrode is used for arcing and slagging, then the graphite electrode is replaced with a consumable electrode for melting, the voltage is set from 51 V to 54 V, the current is set from 7700 A to 8100 A, electricity is supplied for remelting melt, and aluminum powder is added in the remelting process for deoxygenation. The fluoride-free slag can reduce pollution produced to the environment in the electroslag remelting process, and meanwhile it can be ensured that an electroslag remelting ingot is good in molding, smooth and clean in surface, small in segregation degree, tight and uniform in structure and low in gas content.

Owner:宝武特冶航研科技有限公司

Slag system for electroslag remelting of high-temperature alloy and use method of slag system

The invention provides a slag system for electroslag remelting of a high-temperature alloy. The slag system comprises the following chemical components, by weight percent, 47-53% of CaF2, 20-25% of Al2O3, 17-22% of CaO, 4-6% of MgO, 1-3% of TiO2, 1-4% of HfO2, and the balance FeO, C and impurities. With the adoption of the mode, by adding 1-4% of HfO2, the burning loss of a hafnium element is inhibited, and the component deviation of the hafnium element at the head and tail of an electroslag steel ingot is prevented; by using the slag system for remelting the high-temperature alloy, recovery rates of Al, Ti, Hf and the like are high, and reach 92-98%; a high-temperature alloy steel ingot molten by using the slag system is good in quality, and has no slag runner defect; and the melting velocity of a remelting process is stable, the degree of segregation of the hafnium element is reduced, and the yield of hafnium is raised.

Owner:深圳市万泽中南研究院有限公司

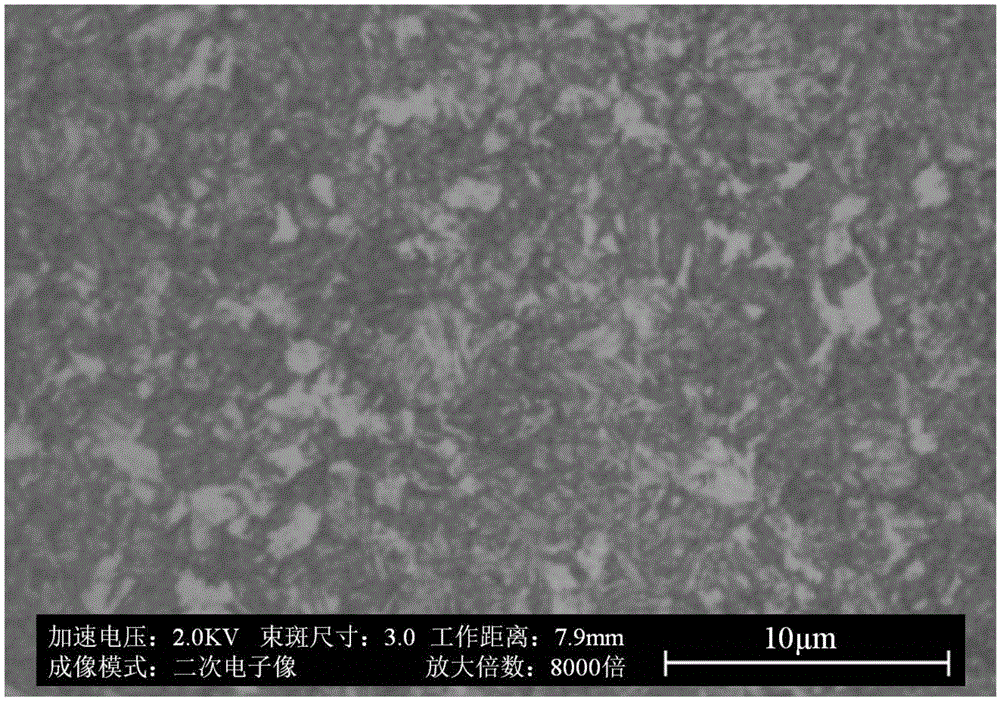

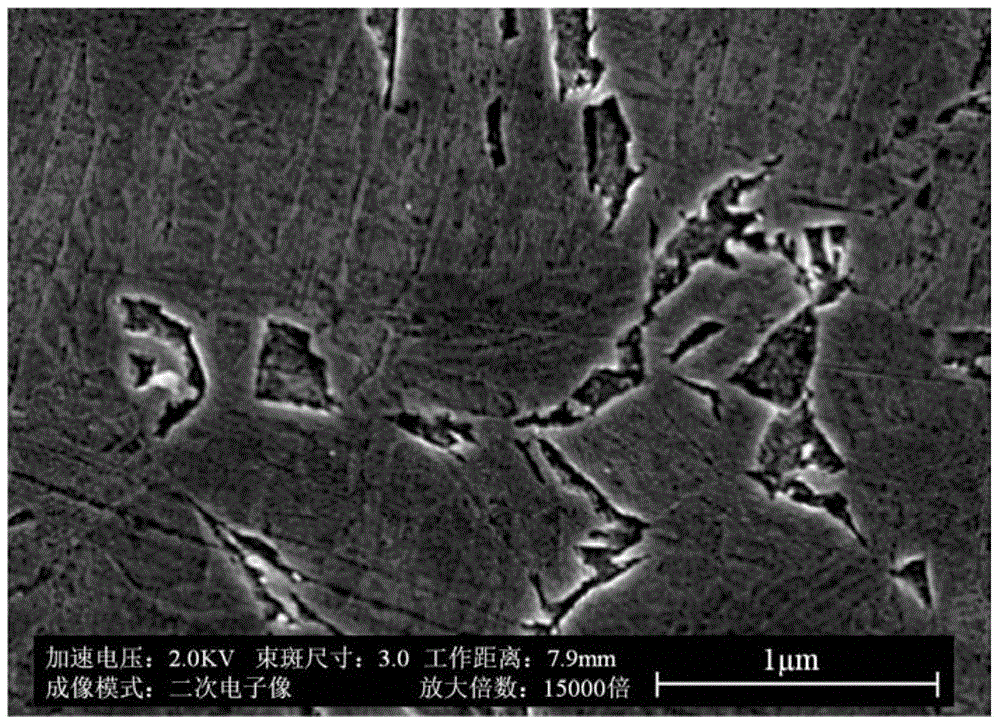

Grain boundary toughening high-hardness iron-based wear-resistant material and preparation method thereof

InactiveCN110172693AReduce the degree of segregationUnderstand the purposeMolten spray coatingMolten casting coatingWear resistantHardness

The invention discloses a grain boundary toughening high-hardness iron-based wear-resistant material and relates to the technical field of metal materials. The grain boundary toughening high-hardnessiron-based wear-resistant material belongs to an Fe-C-M-j alloy material and comprises Fe, C, a carbide forming element M and a carbon activity regulation and control element j, wherein the carbide forming element M comprises Cr, Mo, W, V, Ti and Nb; the carbon activity regulation and control element j comprises Ni, Co, Si, Cu, Al and B. The invention further discloses a preparation method of thegrain boundary toughening high-hardness iron-based wear-resistant material. The preparation method belongs to one of the laser cladding method, the plasma surfacing method, the arc surfacing method and the rapid solidification casting method. The segregation degree of as-cast structure intergranular carbide is greatly reduced by sufficiently adding the carbon activity regulation and control element. Accordingly, the high-hardness iron-based wear-resistant material mainly of which austenite toughening phases are mainly formed between dendrite crystals or at grain boundaries is obtained.

Owner:SHANGHAI JIAO TONG UNIV

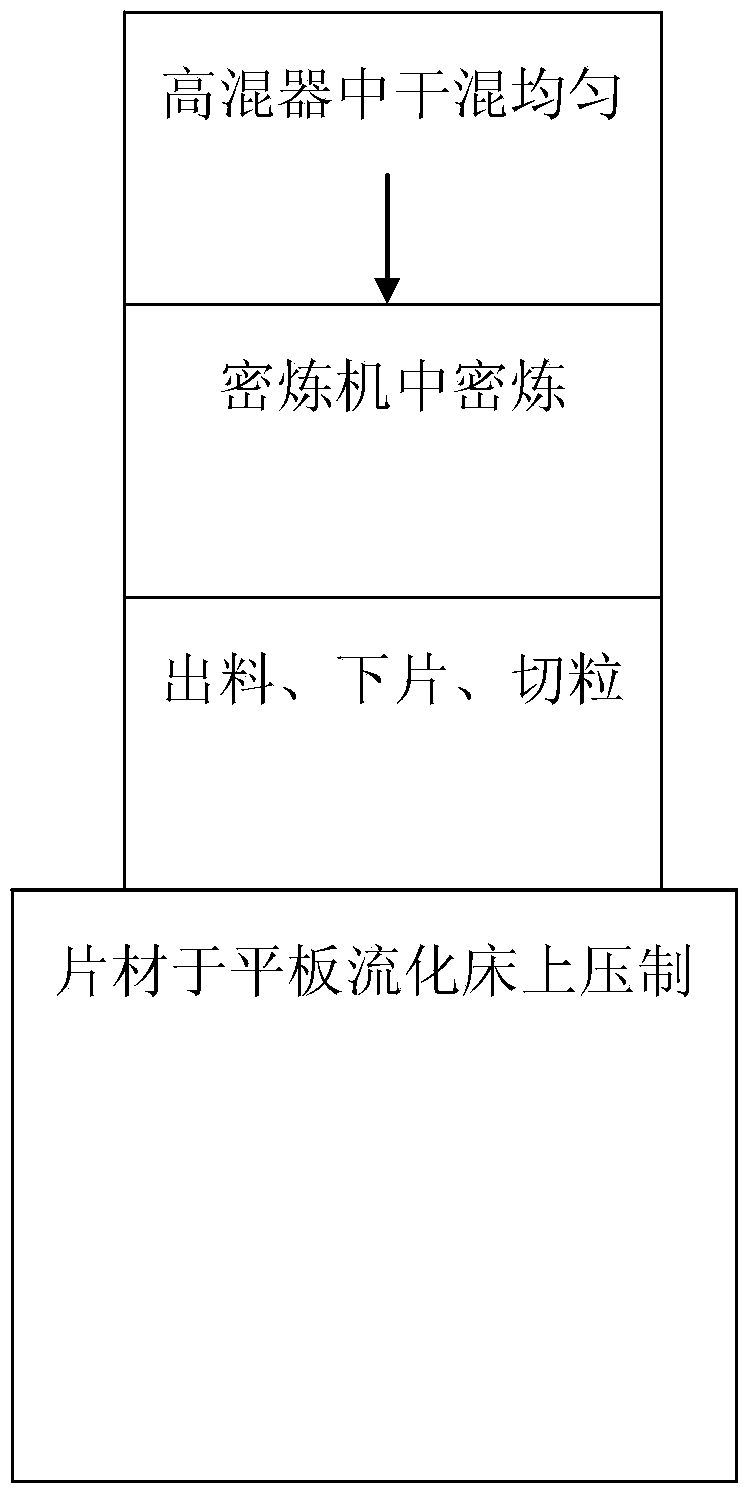

Preparing method of iron-based molding mixture

ActiveCN106270483AReduce the degree of segregationImprove bindingTransportation and packagingMetal-working apparatusIron powderGraphite

The invention discloses a preparing method of an iron-based molding mixture. The method comprises following steps: raw materials are weighed; iron powder, copper powder, graphite, a liquid bonding agent and a lubricating agent are weighed according to the formula requirement; the iron powder is wetted; the liquid bonding agent is added into the iron powder for standing for 20 min to 200 min, and wetted iron powder is formed; in the mixing process, the wetted iron powder, the graphite and the lubricating agent are put into a mixing machine, and sufficient mixing is carried out; the copper powder is added into the mixing machine, after sufficient mixing, the copper powder is taken out, and the mixture is obtained. According to the method, the bonding agent is sufficiently wetted with the iron powder to form the wetted iron powder, the graphite is easily bonded with the wetted iron powder, the segregation degree of the graphite can be reduced, particularly for the condition that the wetted iron powder is added into the mixing machine to be sufficiently mixed, and then graphite is added, the graphite surface is dried, a bonding agent film is arranged on the surface of the iron powder, and the iron powder and the bonding agent film are combined more easily.

Owner:合肥波林新材料股份有限公司

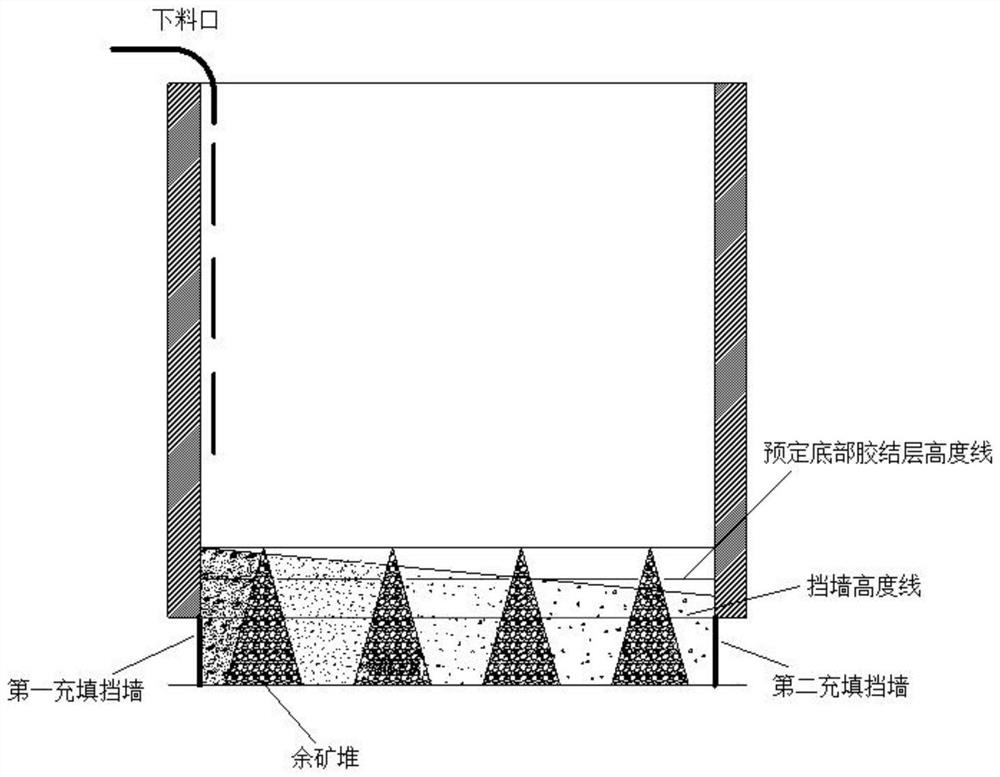

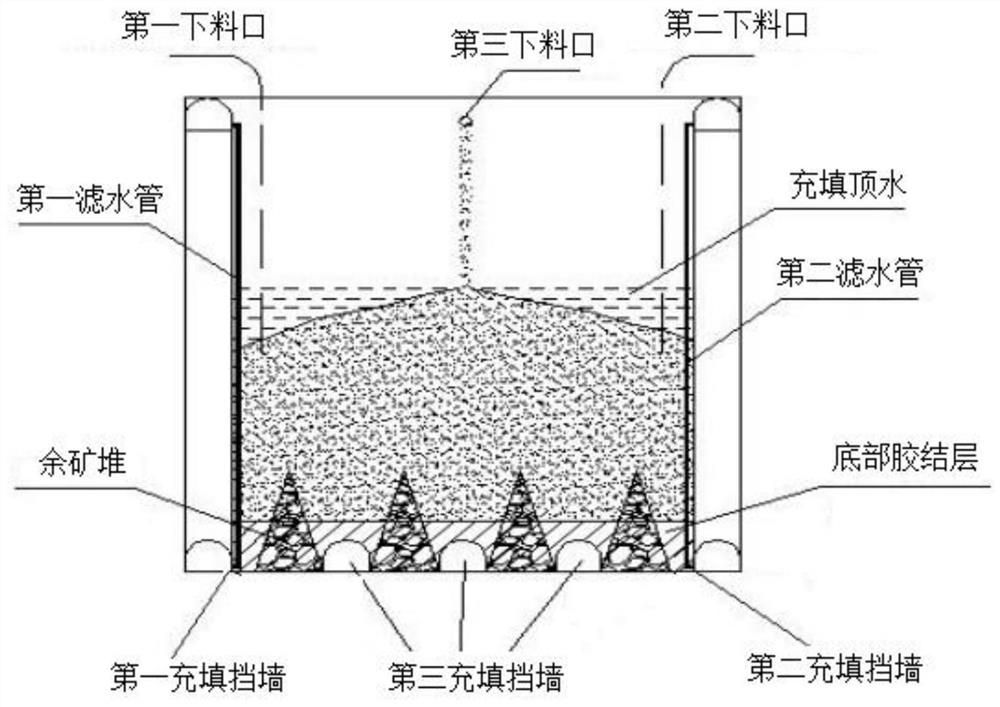

Multipoint filling method of mine goaf full tailings

ActiveCN111963237AReduce the degree of segregationReduce flow distanceUsing optical meansMaterial fill-upWater filterMining engineering

The invention provides a multipoint filling method of mine goaf full tailings, and belongs to the technical field of goaf filling. According to the multipoint filling method, the goaf internal structure can be accurately obtained by adopting a three-dimensional scanning technique, the bottom cemented filling amount can be accurately calculated, the filling height is detected, the filling effect isincreased, and high-precision filling is realized. According to the multipoint filling method, both ends of the top of a room are fed at the same time so as to fill full tailings at the bottom, the cemented slurry flow distance can be reduced, the degree of tailing segregation is reduced, the bottom cemented filling effect is good, and a first filling retaining wall and a second filling retainingwall which are arranged on both ends of the bottom of the room can be effectively protected. According to the multipoint filling method, the middle of the top of the room is fed so as to fill full tailings on the top, and water filter pipes are respectively arranged on both ends of the room for dehydration, so that the dehydration effect can be effectively increased.

Owner:临沂会宝岭铁矿有限公司

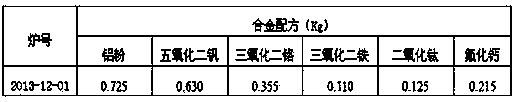

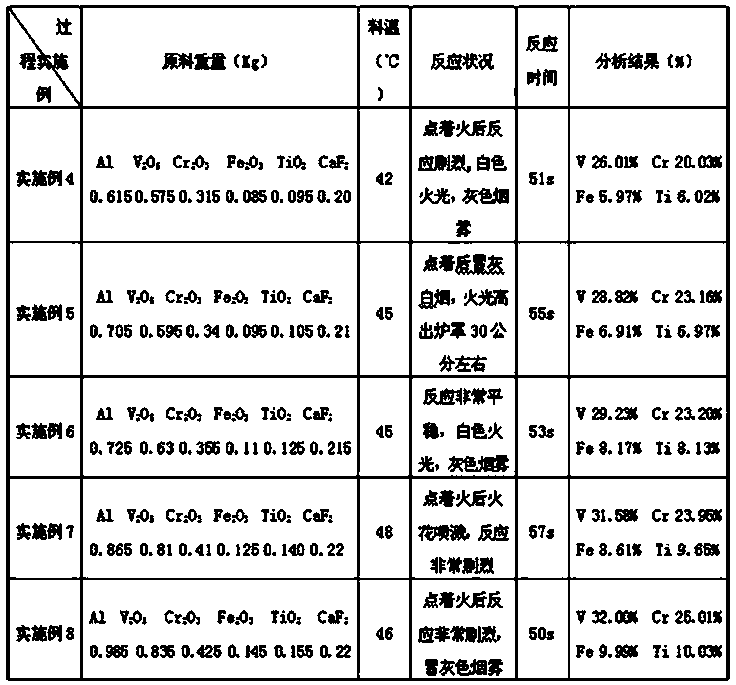

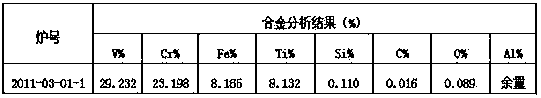

Al-V-Cr-Fe-Ti intermediate alloy and preparation method thereof

The invention provides an Al-V-Cr-Fe-Ti intermediate alloy and a preparation method thereof, relating to an Al-V (Al-V-based) intermediate alloy for preparing titanium alloy and a preparation method of the Al-V (Al-V-based) intermediate alloy. The Al-V-Cr-Fe-Ti intermediate alloy is characterized by being prepared from the following components in percentage by weight: 26.0-32.0% of V, 20.0-25.0% of Cr, 6-10% of Fe, 6-10% of Ti and the balance of Al. A metallothermic reduction method is adopted in the preparation process. The Al-V-Cr-Fe-Ti intermediate alloy as a metallic compound with vanadium, chromium, titanium, ferrum and the like as main components has the characteristics of good brittleness and breakability and can be used for shortening the production process of titanium alloy and ensuring that the production process of the titanium alloy is easier to operate. Oxides are used as raw materials, so that the Al-V-Cr-Fe-Ti intermediate alloy is low in cost, stable in smelting process and good in alloy formation state; in addition, the Al-V-Cr-Fe-Ti intermediate alloy is uniform in alloying and is added into titanium sponge and aluminum shots in an intermediate alloy form, so that the segregation degree of the titanium alloy is reduced.

Owner:CHENGDE TIANDA VANADIUM IND

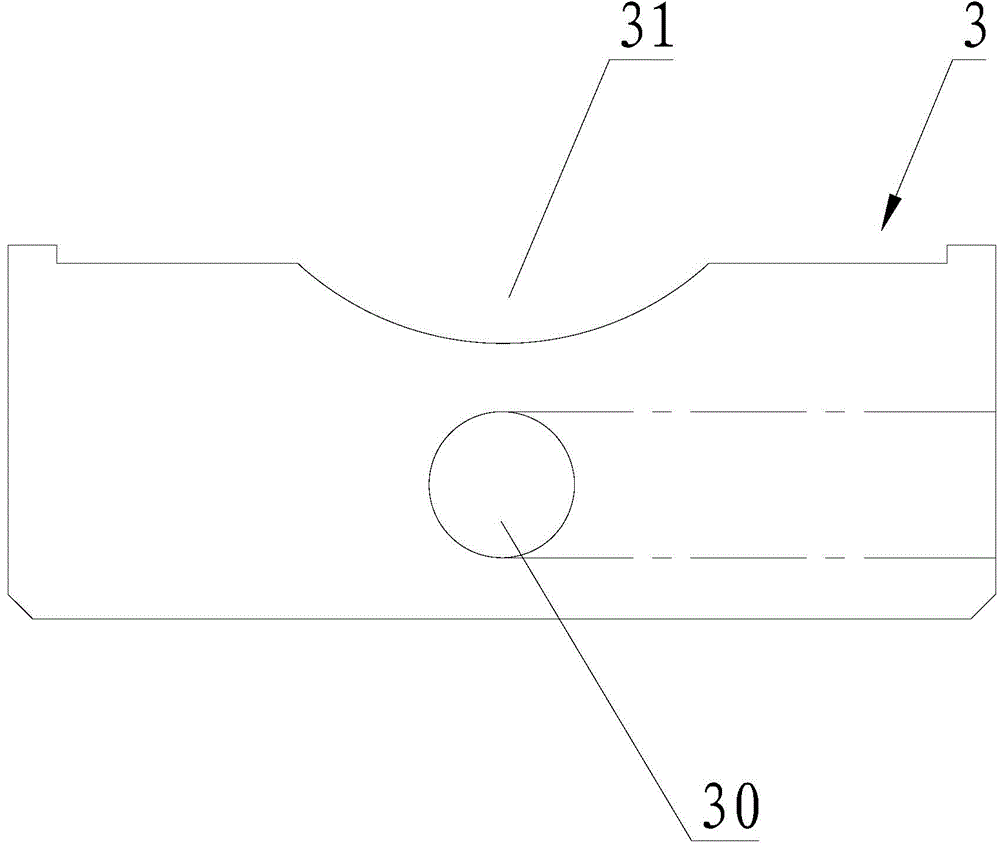

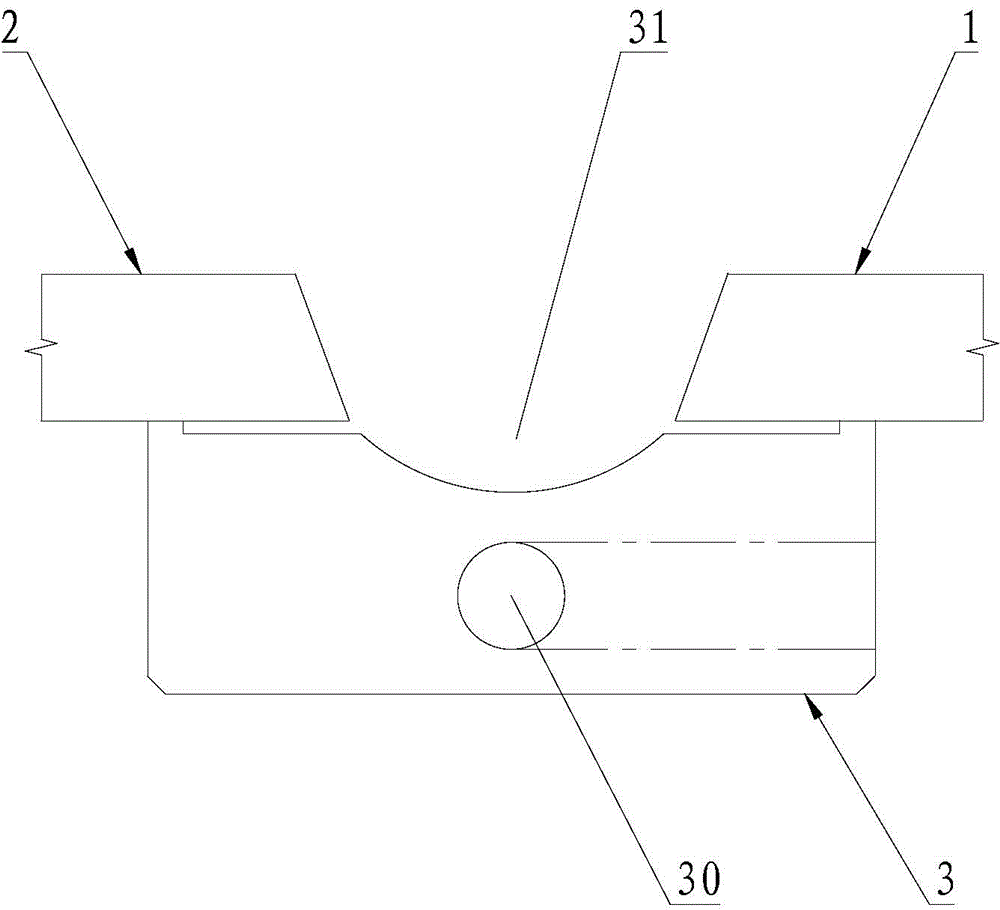

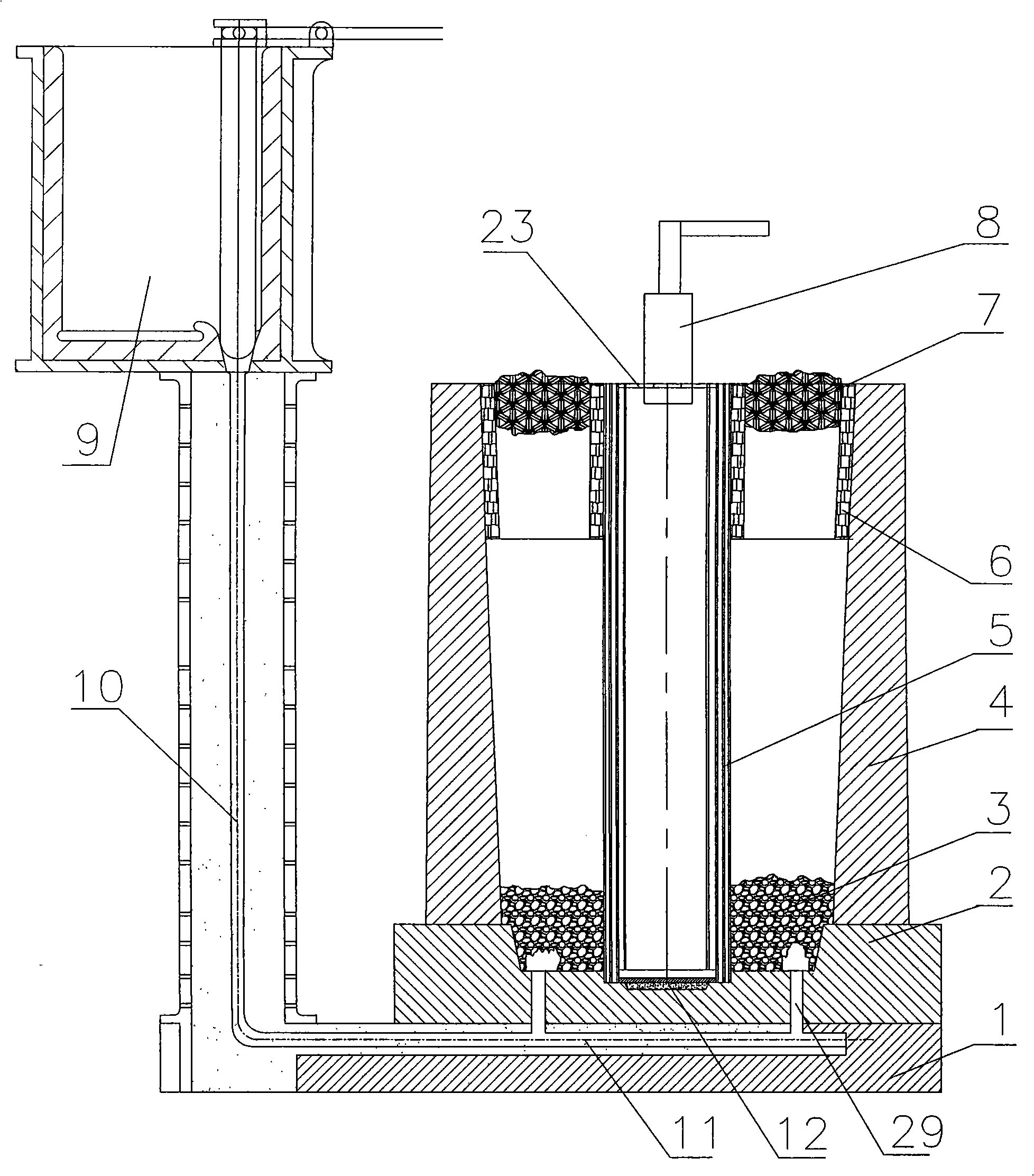

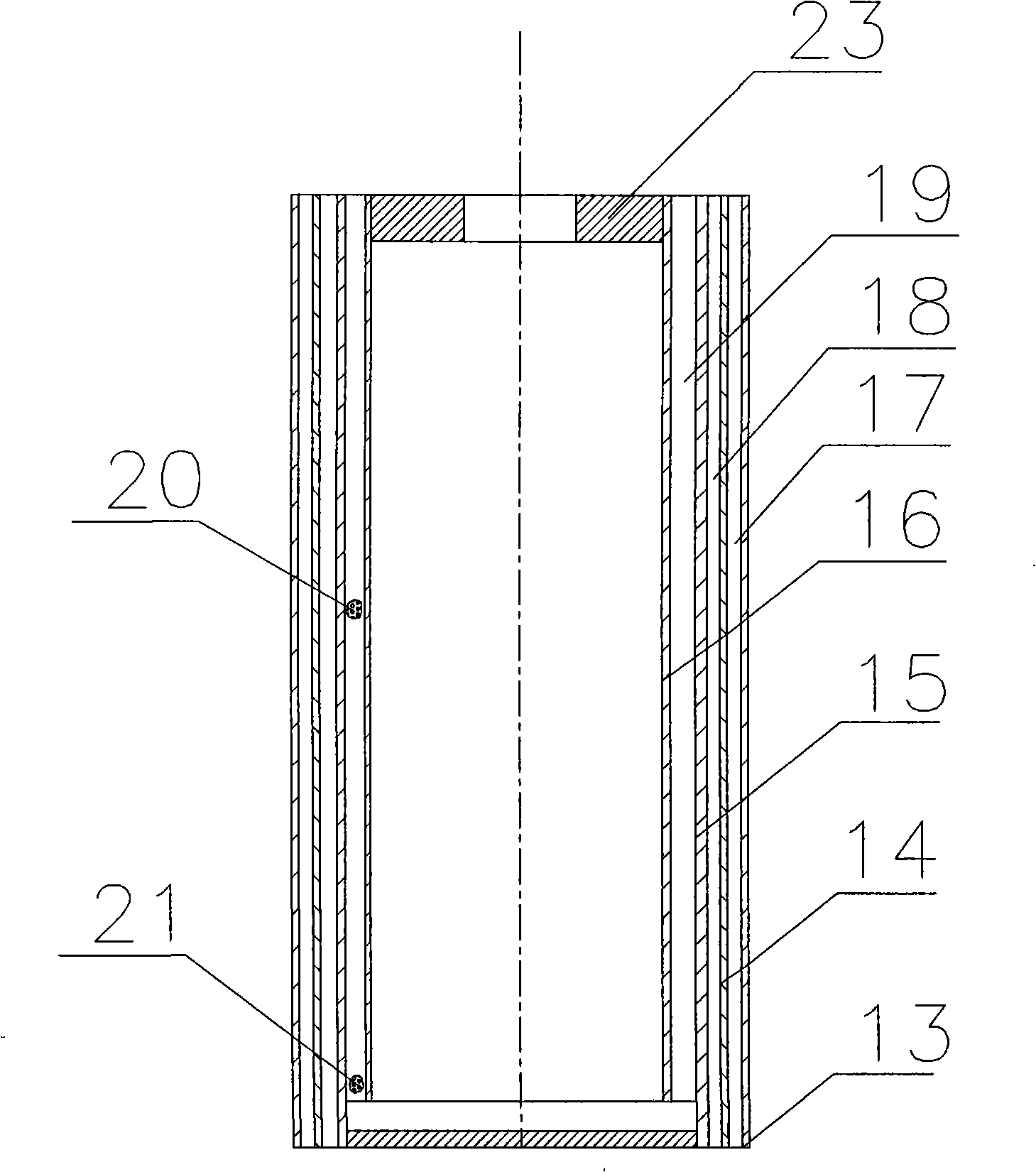

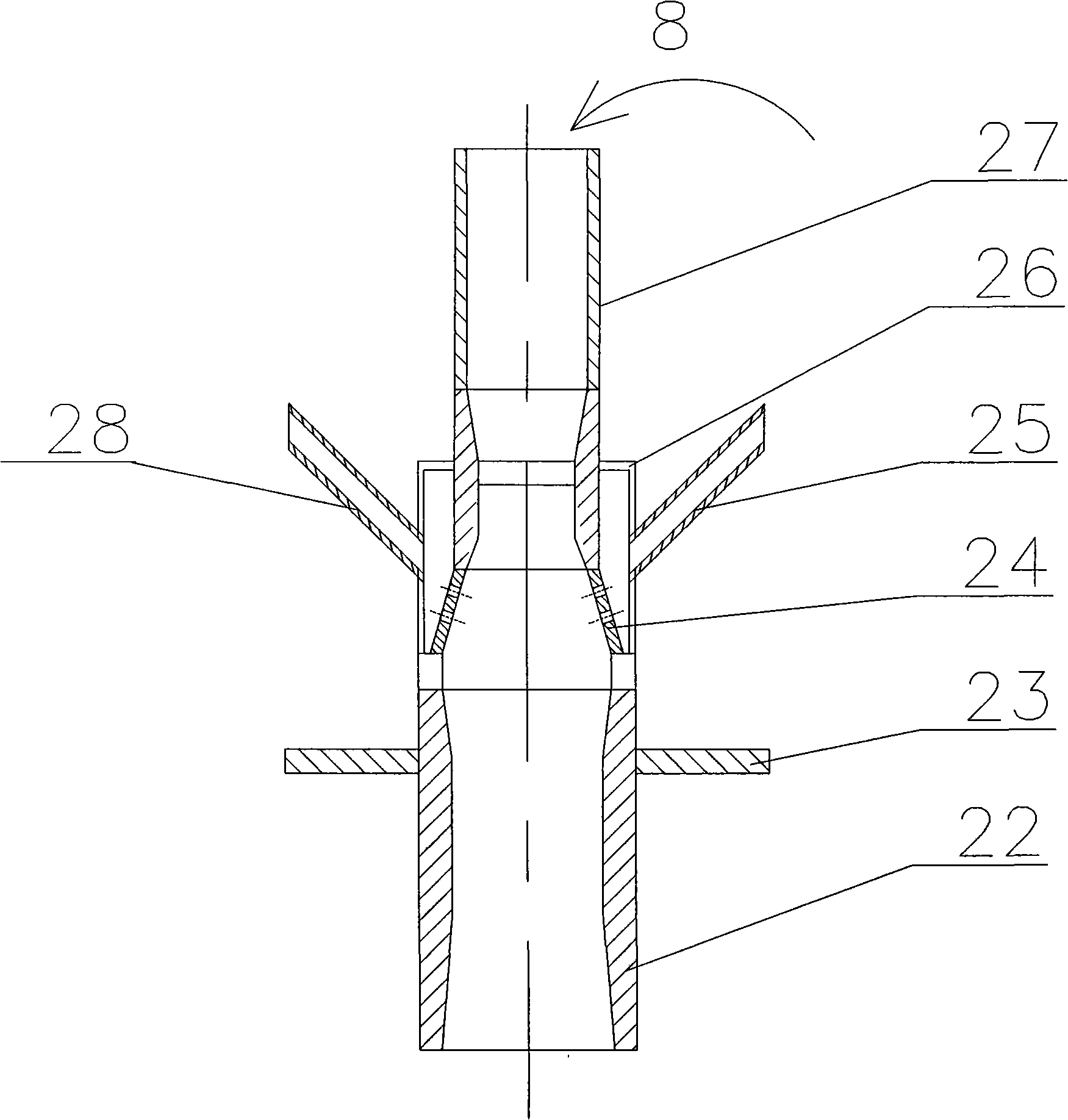

Method for producing movable core low segregation large-sized hollow steel ingot

The invention relates to a preparation technique for heavy hollow ingots of all levels between 50 tons to 300 tons, in particular to a manufacturing method for heavy hollow ingots with a movable core and low segregation. The manufacturing method is applicable to the preparation process of all heavy hollow ingots cast by adopting movable cores, including the casting of the hollow ingots of various shapes, specifications and materials; besides utilizing simulation means of computers to reasonably design a mould and a casting system for ingots, the manufacturing method mainly adopts a pore-forming technology with a movable core, an intensive cooling technology for various media at different stages, a movable core protection technology, a technology for controlling the flow of a cooling medium and the temperature of the movable core, an atomizing device for the cooling medium, an early electro slag protection and argon protection technology for molten metal and a technology for protecting the chassis from big temperature variation, thereby guaranteeing the purity of the molten metal and the operability and the stability of the casting technique, mitigating the segregation, controlling the segregation position, locating the segregation band of the hollow ingots in the middle position and increasing the utilization rate and the application range of the hollow ingots.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com