Simulation method for macrosegregation of continuous casting slab

A simulation method and macrosegregation technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high cost, unrealizable production cost, and inability to correctly reflect the actual situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

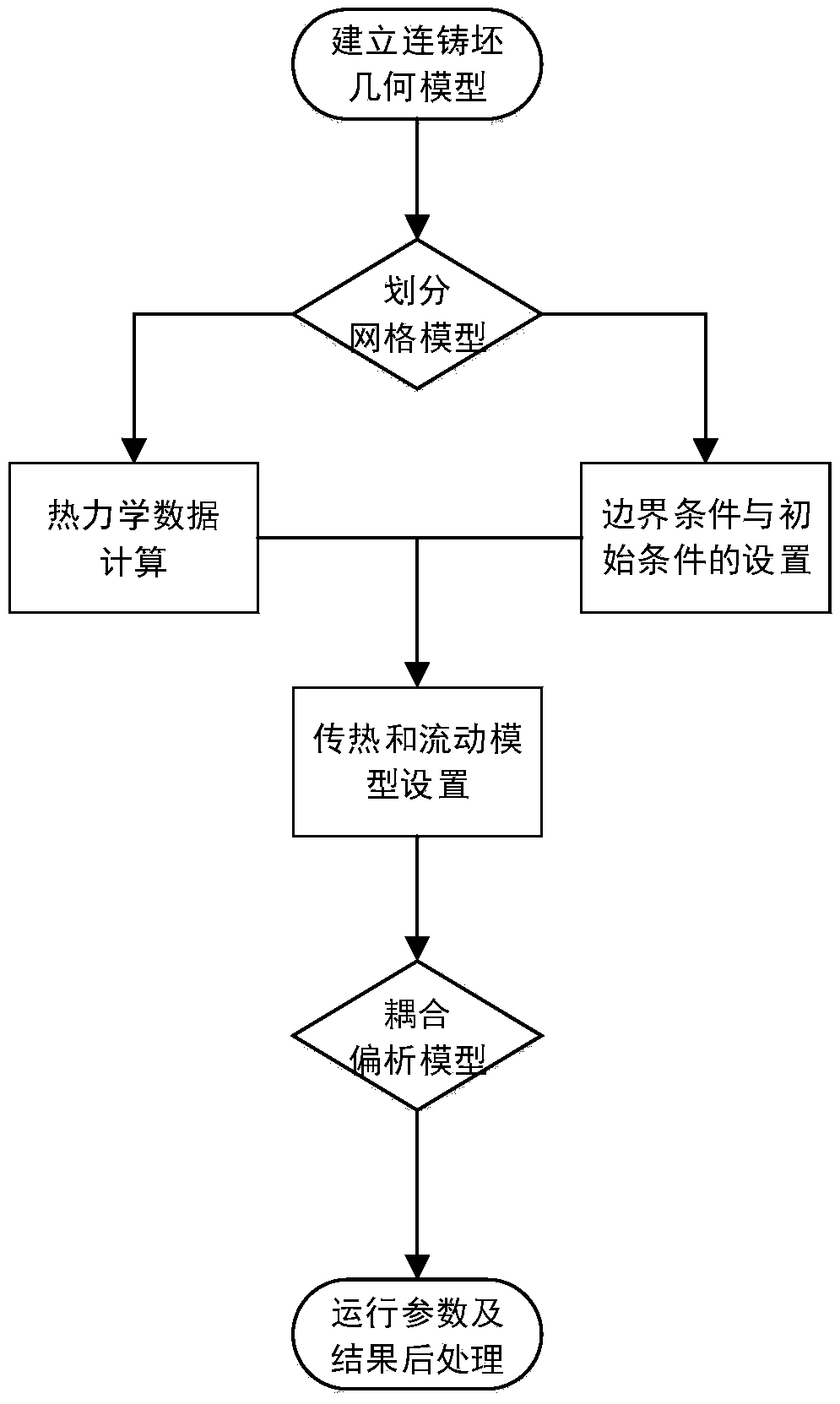

[0081] Simulation methods for macro-segregation of continuous casting slabs, such as figure 1 shown, including the following steps:

[0082] Step 1: Establish the geometric model of the continuous casting slab: Based on the size of the continuous casting slab under actual working conditions, taking into account the structural symmetry of the continuous casting slab, take a quarter of its section for research, and establish a three-dimensional slice model of the continuous casting slab. The size is length×width×thickness, and the specification of the continuous casting slab is generally expressed as length×width, and the present invention is applicable to all continuous casting slabs. But the value of its thickness should be within 5-10mm.

[0083] Step 2: Divide the mesh model: Divide the 3D slice model established in step 1 into a mesh to obtain a 3D mesh model.

[0084] It should be noted that the present invention is designed for the flow of molten steel, so hexahedral gr...

Embodiment 2

[0135] This embodiment is a specific application based on Embodiment 1:

[0136] (1) Grid model establishment

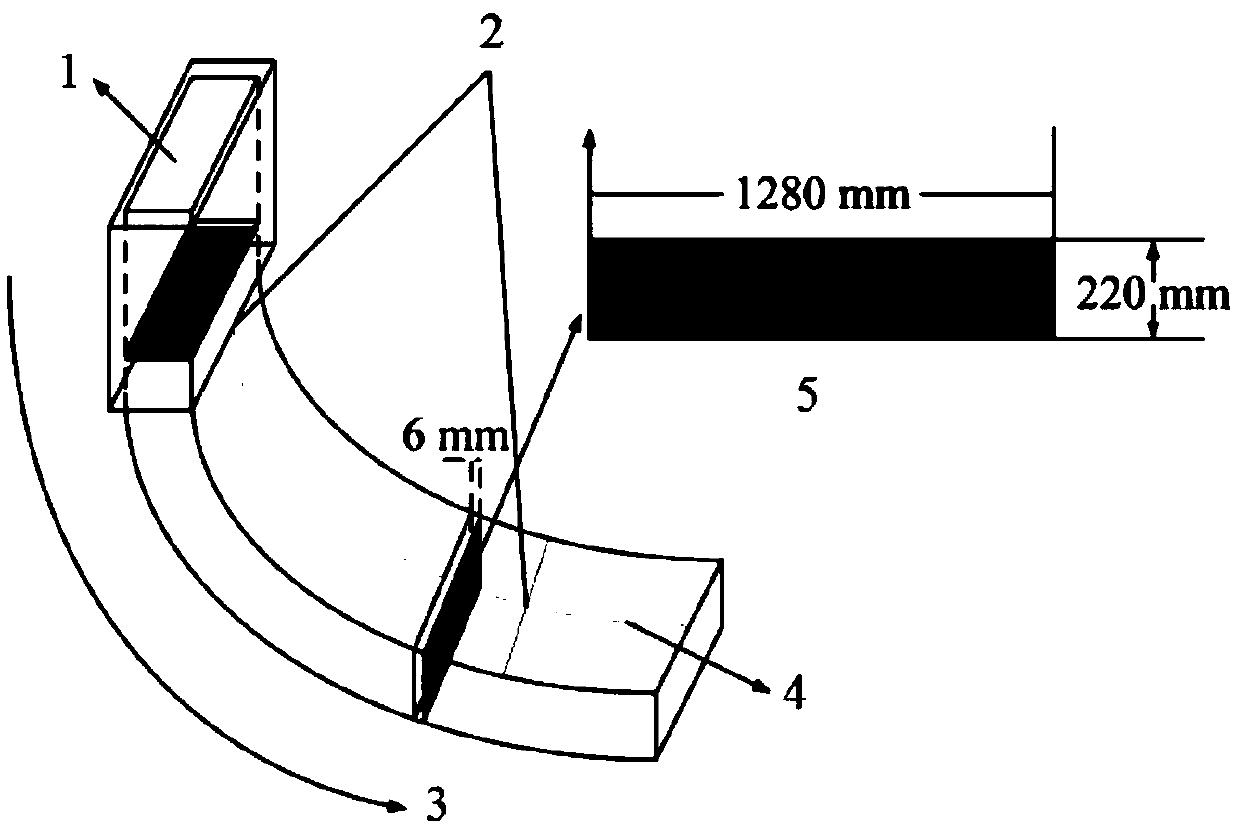

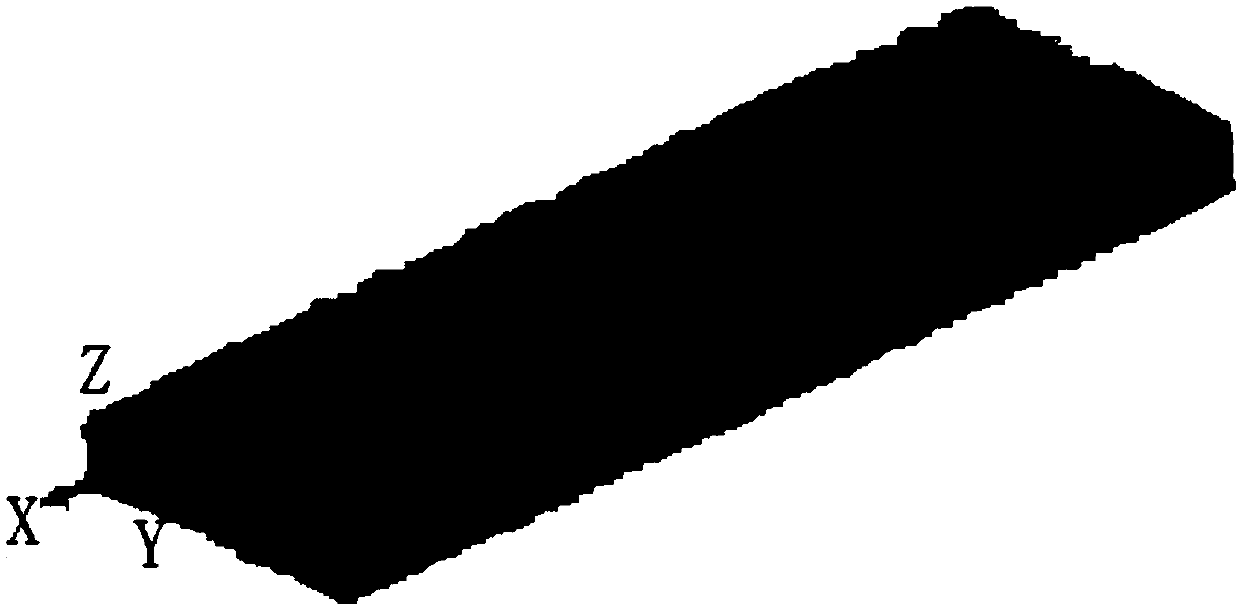

[0137] Geometric models can be established in SOLIDWORKS software, such as figure 2 The three-dimensional slice model of the continuous casting slab is established as shown, in which, 1 is the crystallizer, 2 is the secondary cooling zone, 3 is the casting direction, 4 is the center line of the wide face, and 5 is the cross-sectional size of the slice, considering the structure of the continuous casting slab Symmetry, take its 1 / 4 section for research, its size is 640mm×110mm×6mm, save the model in igs format; import the model in igs format into the Meshing module in ProCAST, divide the surface mesh and volume mesh in turn to get A schematic diagram of the mesh of the model, such as image 3 As shown, the grid type is a hexahedral grid. Finally, check the grid quality. It is required that the grid quality of all grids should be greater than 0.4. Repair low-quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com