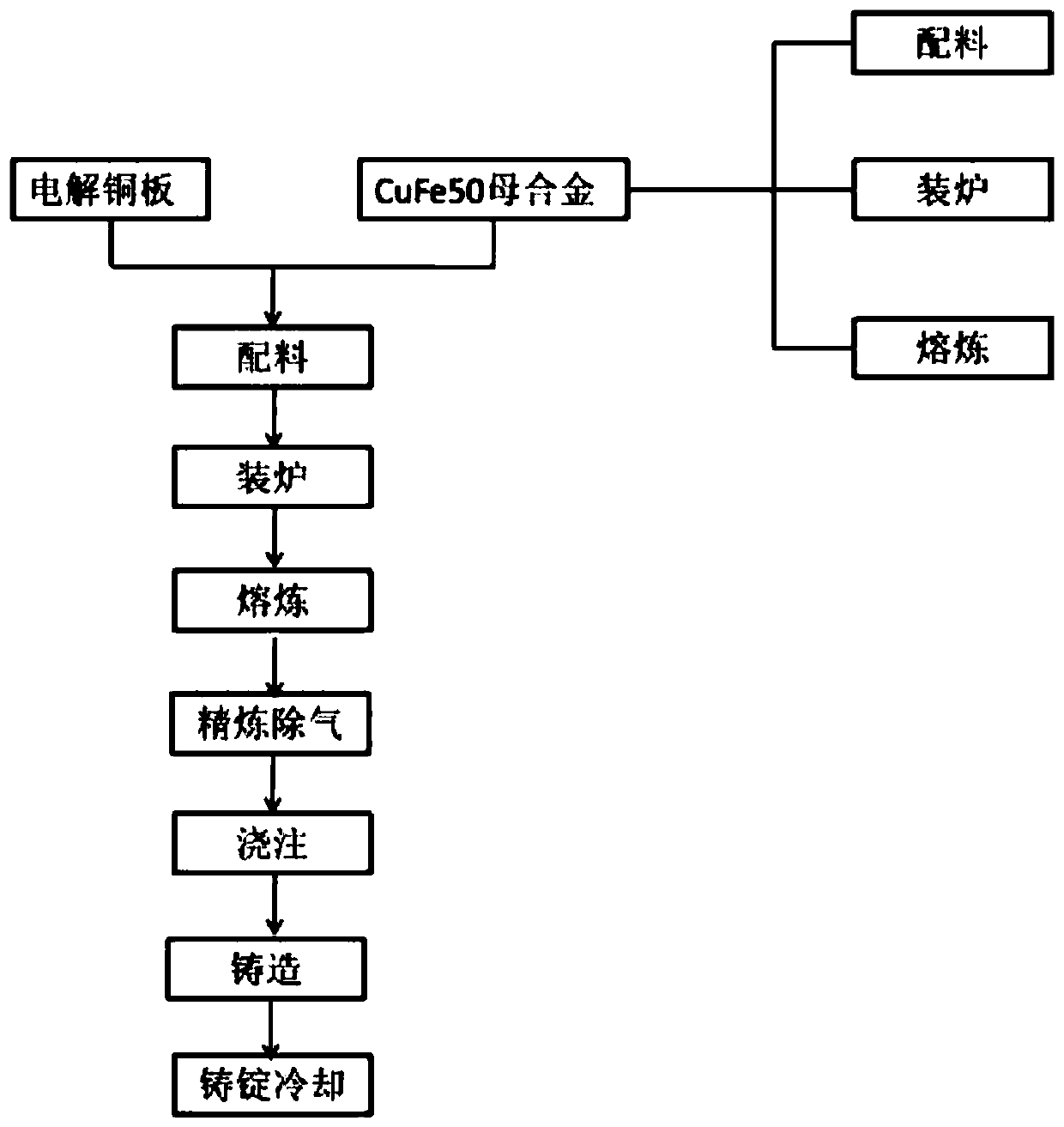

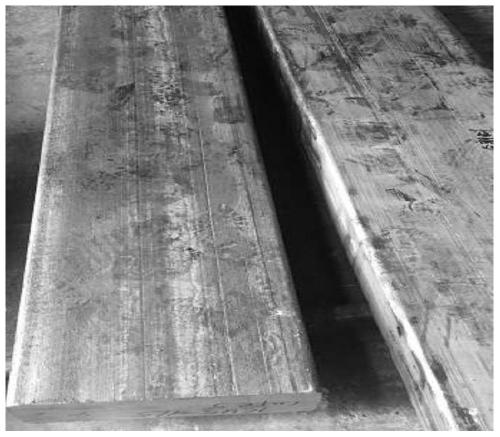

Production process of non-vacuum downwards-drawing continuous casting copper-iron alloy slab ingot

A production process and technology of copper-iron alloy, which is applied in the field of production process of non-vacuum lead-casting copper-iron alloy slab, can solve the problems of easy substitution of impurity elements and high cost, achieve control of alloy composition and oxygen content, low equipment requirements, The effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0039] (1) Melting steps of CuFe50 master alloy:

[0040] The first step: batching and loading into the furnace, weighing Cu and Fe raw materials according to the ratio of content percentage of 1:1, mixing them evenly, putting them into a crucible and putting them in a vacuum melting furnace;

[0041] Step 2: Vacuum induction smelting, turn on the mechanical pump and the low vacuum baffle valve to evacuate, and when the P in the vacuum melting furnace is ≤0.08MPa, turn on the Roots pump; when the vacuum is evacuated to P≤4Pa, the power of the heating device will increase To 20KWKW, keep warm for 5min; the heating power of the heating device is raised to 40KW, and keep warm for 5min; ;When the pressure in the furnace rises to 0.08Mpa, stop charging with argon, increase the power to 65KW, and refine for 1min;

[0042] Step 3: Casting out of the furnace, reduce the power of the vacuum melting furnace to 35KW, keep it for 0.5 minutes and start pouring into the casting mold, turn ...

Embodiment 4-6

[0056] (1) Melting steps of CuFe50 master alloy:

[0057] The first step: batching and loading into the furnace, weighing Cu and Fe raw materials according to the ratio of content percentage of 1:1, mixing them evenly, putting them into a crucible and putting them in a vacuum melting furnace;

[0058] Step 2: Vacuum induction smelting, turn on the mechanical pump and the low vacuum baffle valve to evacuate, and when the P in the vacuum melting furnace is ≤0.08MPa, turn on the Roots pump; when the vacuum is evacuated to P≤4Pa, the power of the heating device will increase to 30KW, keep warm for 10min; the heating power of the heating device is raised to 50KW, and keep warm for 10min; Gas; when the pressure in the furnace rises to 0.08Mpa, stop charging with argon, raise the power to 75KW, and refine for 2 minutes;

[0059] Step 3: Casting out of the furnace, reduce the power of the vacuum melting furnace to 45KW, keep it for 0.5 minutes and start pouring into the casting mold,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com