Patents

Literature

162 results about "Vacuum casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum casting is a casting process for elastomers using a vacuum to draw the liquid material into the mold. This process is used when air entrapment is a problem, there are intricate details or undercuts, or if the material is fiber or wire reinforced.

Method for preparing TiAl-based alloy formwork by precision-investment casting

InactiveCN101462151AFast moisture absorptionGood hygroscopicityFoundry mouldsFoundry coresWaxOxide ceramic

The invention discloses a method for preparing a shuttering for a precision investment casting TiAl-based alloy, and relates to a method for preparing an oxide ceramic shuttering. The method solves the problems of slow drying for making the shuttering, longer production period for cast and high cost during production of a TiAl-based alloy precise cast. The preparation method comprises: firstly, adopting SLS technology to prepare a fusible pattern; secondly, coating polyvinyl alcohol on the surface of bauxite and grinding the bauxite into granules; thirdly, smearing a shuttering surface layer; fourthly, smearing a shuttering back layer; fifthly, removing wax from the shuttering, and roasting the shuttering; and sixthly, casting the TiAl-based alloy in vacuum to obtain the TiAl-based alloy cast. The method only needs 13 to 15 days to obtain the TiAl-based alloy precise cast from CAD design, but the prior method at least needs 45 to 60 days, so the method saves nearly two thirds of production period, and the manufacturing cost is correspondingly lowered.

Owner:HARBIN INST OF TECH

Method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through V method

ActiveCN102941333ASpeed up the flowReduce scour forceFoundry mouldsFoundry coresVacuum castingUltra high pressure

The invention discloses a method for producing ultrahigh pressure switch pressure-bearing aluminum alloy tanks under low pressure through a V method in the technical field of vacuum casting, which comprises the following processing steps: jig manufacture, low-temperature gating system manufacture, upper tank molding, lower tank molding, lower core mould assembling, casting and pressure removing and picking. The method solves the defects of slag inclusion, pores, pinholes and the like of cast caused by intensive scouring of molten metal to cast, and simultaneously can solve the problems that the cavity casting system occupies excessive molten metal, and particularly the product yield of cast with low wall thickness and large size is low.

Owner:NANYANG HUISEN PRECISION INSTR CASTING

Casting method of using 3D printing to make shell mold and vacuum casting device for use in the casting method

InactiveUS20170312813A1Improve efficiencyReduce labor intensity and pollutionAdditive manufacturing apparatusFoundry mouldsComputer-aidedGraphic design

A casting method of using 3D printing to make shell mold, comprising the following steps of: conducting computer-aided graphic design based on the product to be manufactured; importing the graphic design into the 3D printer to print a 3D shell mold; conducting a sintering process of the printed shell mold for solidifying thereof; using the sintered shell mold as a casting cavity, injecting a molten raw material into the shell mold for formation; in the end, taking out the whole shell mold and breaking the shell mold to obtain a cast product; reprocessing the cast product to obtain a finished product; wherein printing materials of the 3D printing are made of a liquid mixture of photosensitive resin and ceramic powder, thereby improving production efficiency and reducing labor intensity as well as pollution.

Owner:WU CHENG KUAN

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

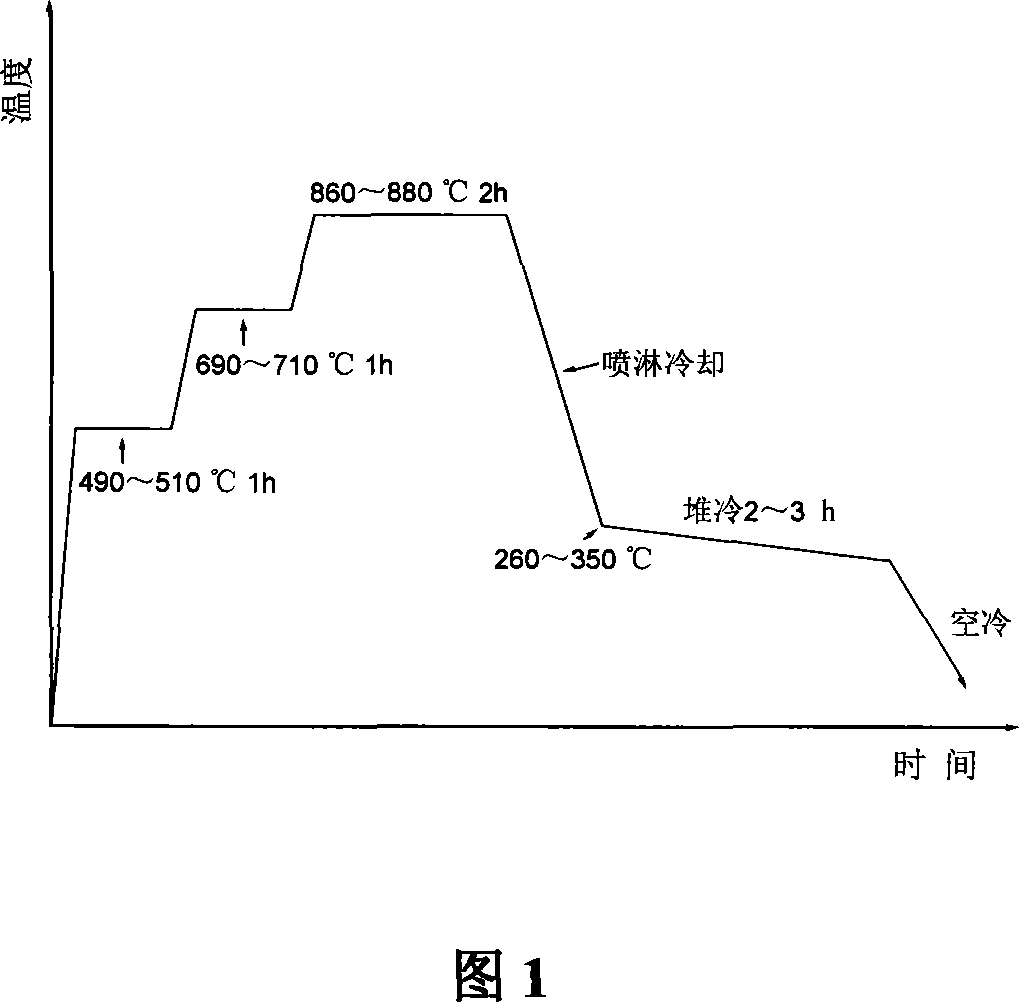

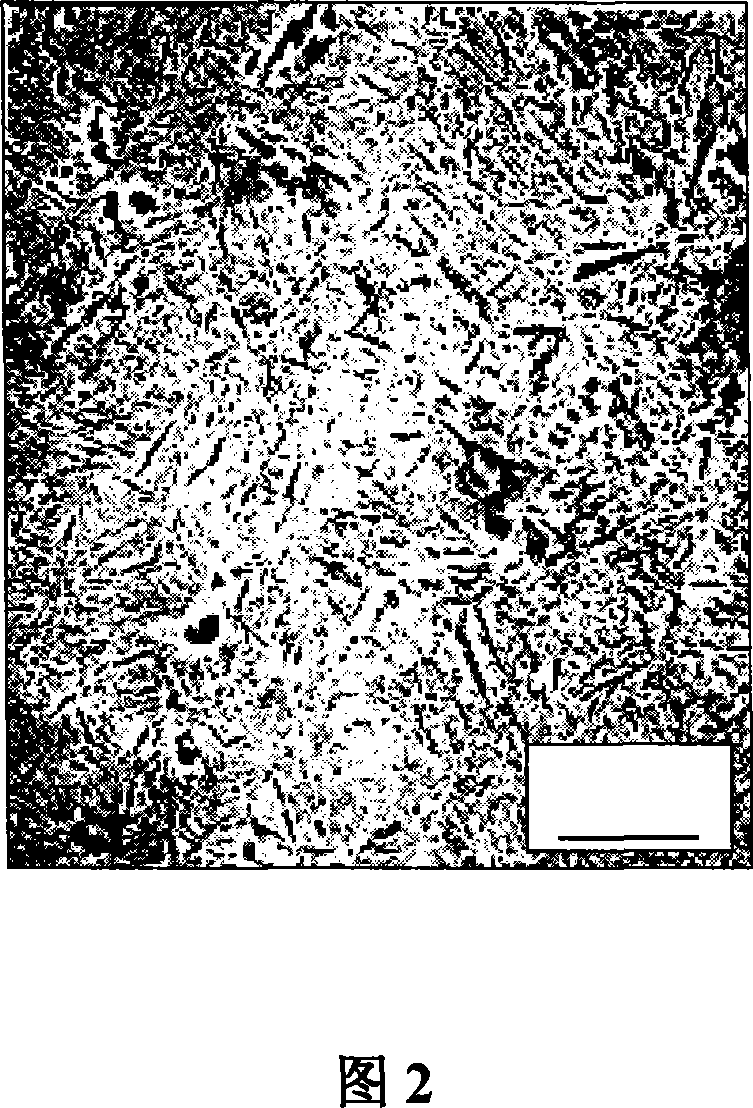

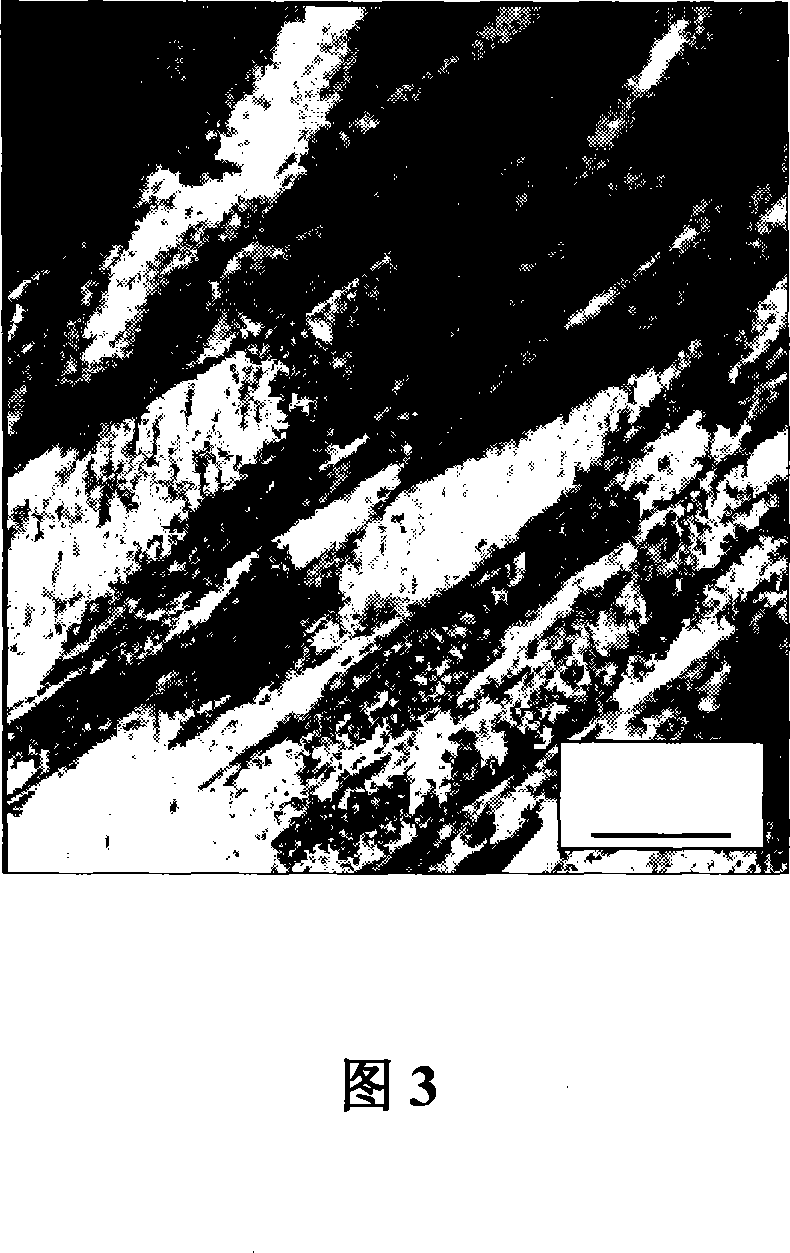

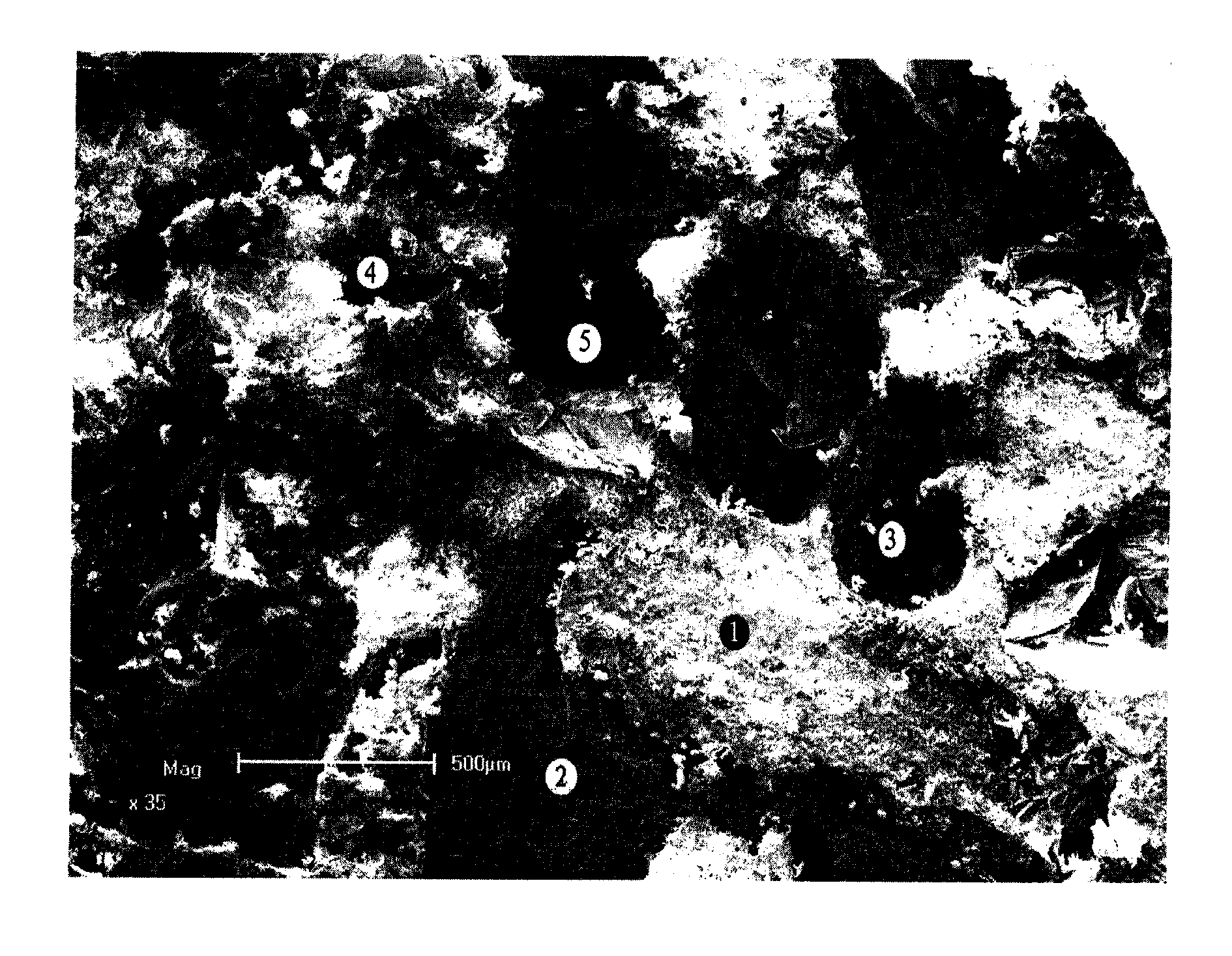

Wear-resistant bainite cast steel liner plate and its manufacture process

InactiveCN101045972AImprove hardenabilityImprove performanceFurnace typesMoulding machinesWear resistantHardness

The present invention relates to one kind of wear resistant bainite cast steel liner plate and its manufacture process. The cast steel liner plate material consists of C 0.45-0.55 wt%, Si 1.6-2.0 wt%, Mn 2.8-3.3 wt%, P not more than 0.06 wt%, S not more than 0.04 wt% and Fe for the rest. Its manufacture process includes smelting in a medium frequency induction furnace, vacuum casting, cooling controlling heat treatment to obtain complex phase bainite structure, and final low temperature tempering. The liner plate material consists of needle like bainite as main component, small amount of martensite and residual austenite, and has hardness of HRC53-55, impact toughness of 22-27 J / sq cm, and excellent comprehensive performance.

Owner:YUNNAN KUNGANG WEAR RESISTANT MATERIAL SCI

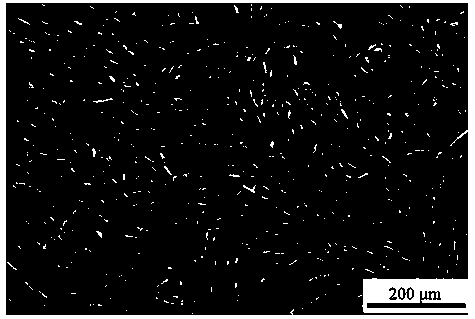

Cast silicon carbide composite material and preparation method thereof

The invention relates to the technical field of a composite material, and particularly relates to a cast silicon carbide composite material and a preparation method thereof. Aluminum oxide ceramics, high-density polyethylene and a rubber lining material cannot simultaneously meet the requirements of equipments on the abrasive resistance, the corrosion resistance and the mechanical strength at present. Import special ceramics equipment is high in price although long in service life so as to result in the problems of high operation and production costs. The cast silicon carbide composite material provided by the invention mainly contains silicon carbide, a short glass fiber, alumina powder, a carbon fiber, an adhesive component and an additive. Kinds of products with complicated shapes can be manufactured by adopting a vacuum casting production technology. The material is good in abrasive resistance, strong in chemical resistance, high in mechanical strength, and applicable to solid-liquid and solid-gas dual-phase medium conveying equipments.

Owner:北京中电联众电力技术集团有限公司

High-strength high-plasticity high-yield-ratio magnesium-lithium alloy and preparation method and application thereof

ActiveCN112593131AGood solid solution strengthening effectMorph coordinationDigital processing power distributionVacuum castingSolution treatment

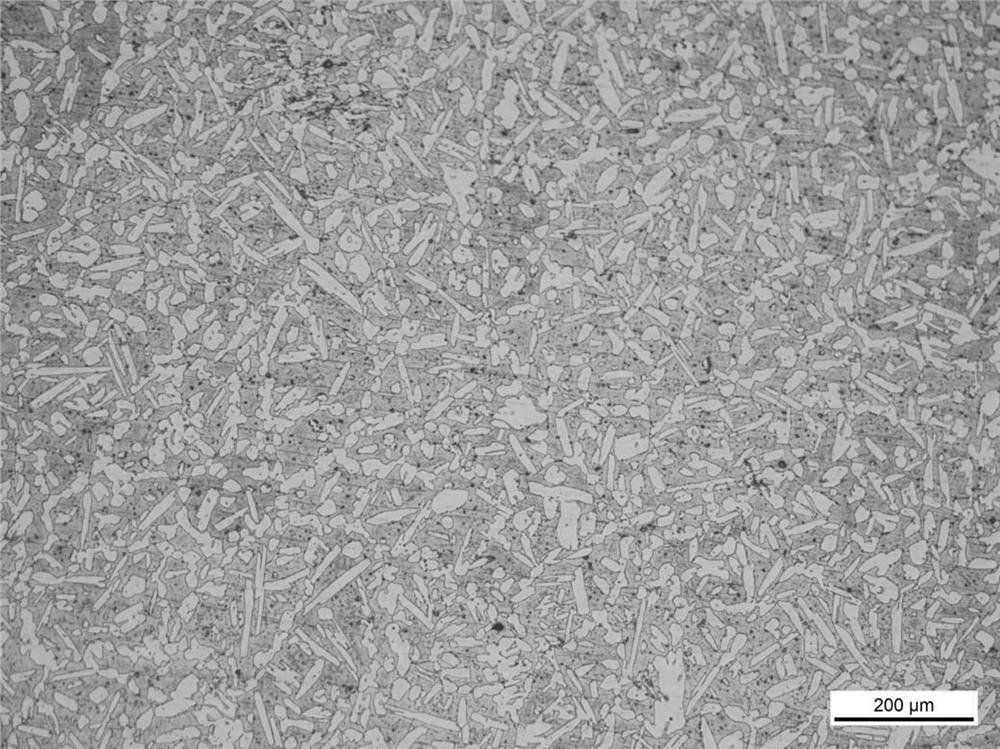

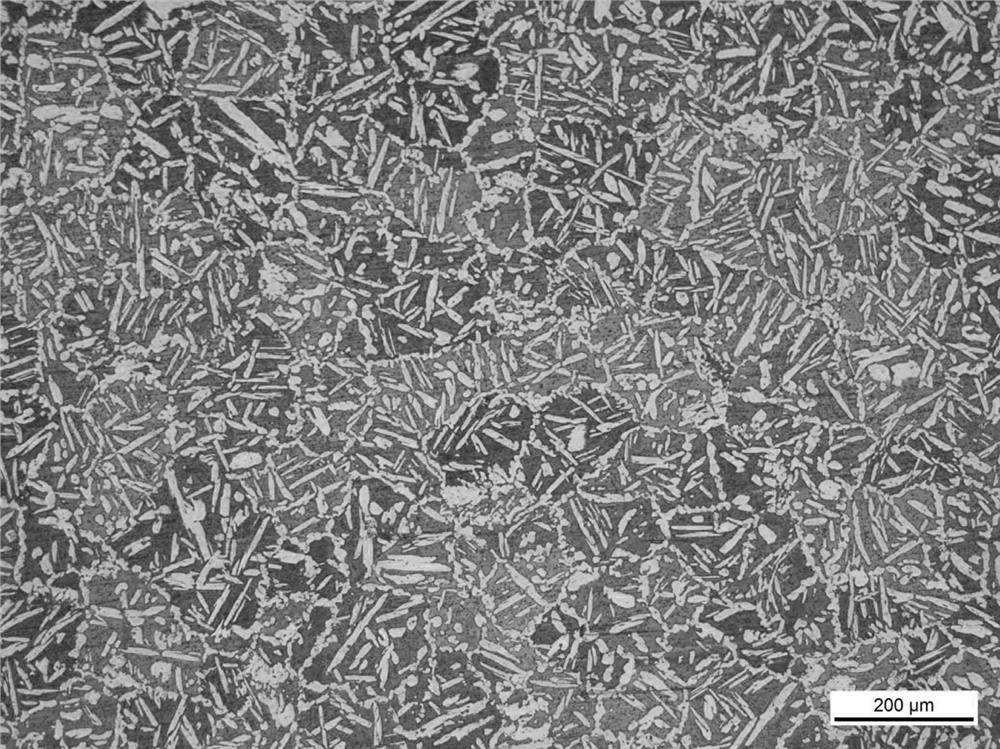

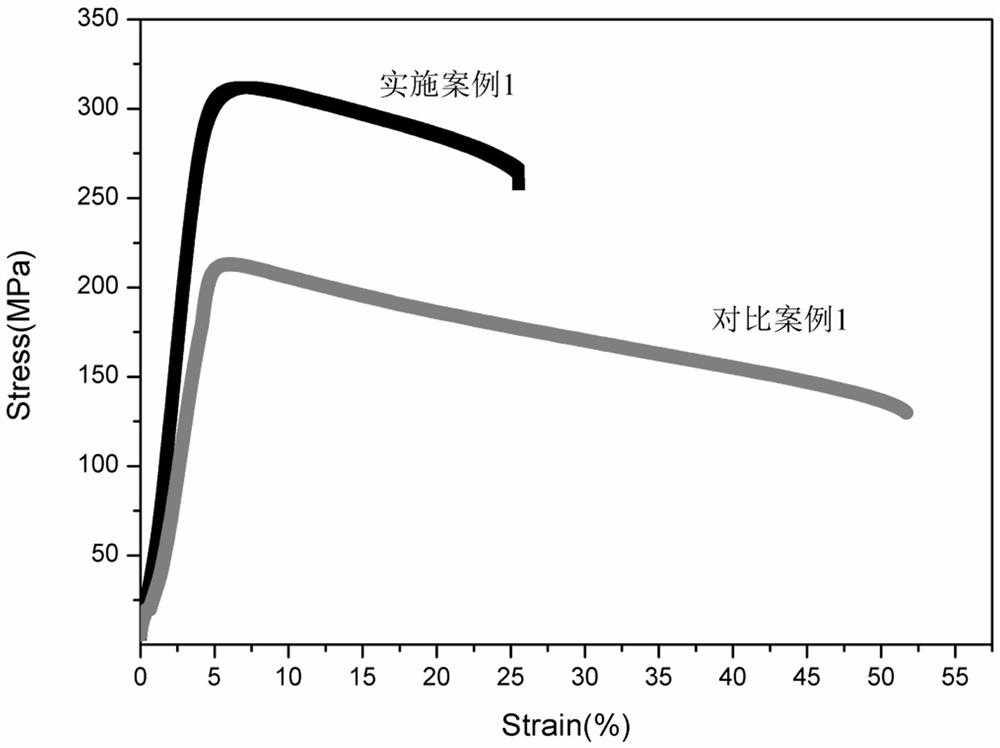

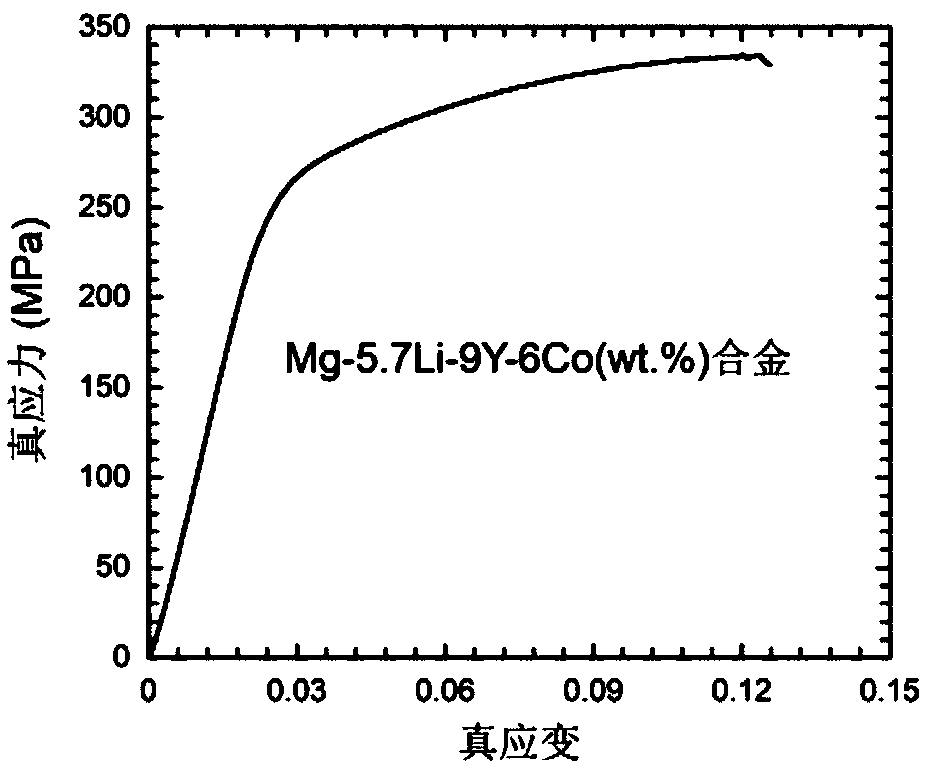

The invention belongs to the technical field of magnesium-lithium alloy material preparation, and particularly relates to a high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and apreparation method and application thereof. The high-strength high-plasticity high-yield-ratio magnesium-lithium alloy and the preparation method and application thereof are used for solving the problems of low absolute strength, difficult matching of strong plasticity and yield ratio of the magnesium-lithium alloy, the high-strength high-plasticity high-yield-ratio magnesium-lithium alloy material with high yield ratio, good plasticity, stable quality and high purity is obtained by designing the components of the magnesium-lithium alloy, optimizing a vacuum casting process and adopting a novel deformation heat treatment process, and the magnesium-lithium alloy has an industrialized practical application prospect. According to the preparation method of the high-strength, high-plasticity and high-yield-ratio magnesium-lithium alloy, the plastic processing procedure is simple, the maneuverability is high, only medium-high temperature solution treatment and medium-low temperature deformation are needed, intermediate process annealing is not needed, the yield is high, the economical efficiency is high, and the magnesium-lithium alloy product with the tensile strength of 330 MPa, the yield strength of 314 MPa, the elongation of 16% and the yield ratio of up to 95% or above can be obtained through the method.

Owner:郑州轻研合金科技有限公司

Nickel-copper alloy with high strength and high corrosion resistance and manufacturing method thereof

The invention discloses a nickel-copper alloy with high strength and high corrosion resistance and a manufacturing method thereof. The method takes electrolytic copper and electrolytic nickel as major components, a small amount of manganese, iron, silicon, metal magnesium and metal titanium is added, and the impurity accounts for less than or equal to 0.5%. According to the invention, the components are sequentially put into a smelting furnace and subjected to the steps of smelting, stirring and slag extraction, refining, casting formation and the like to obtain a finished product of the nickel-copper alloy. Through the invention, the tensile strength is 670-720Rm / MPa, the elongation is 6-7.5, the strength is improved by 15% over the existing domestic nickel-copper alloy, and the corrosion resistance is improved by about twice. The nickel-copper alloy disclosed by the invention is widely applicable, has long service life and the like, can be used for producing plates, belts, pipes, rods, lines and forgings, and is applied to the industries such as shipbuilding, chemical industry, machinery manufacturing, aerospace, electronics and the like. The manufacturing method disclosed by the invention changes the original vacuum casting process, adopts a semi-continuous smelting method and reduces the production cost.

Owner:沈阳有色金属研究所有限公司

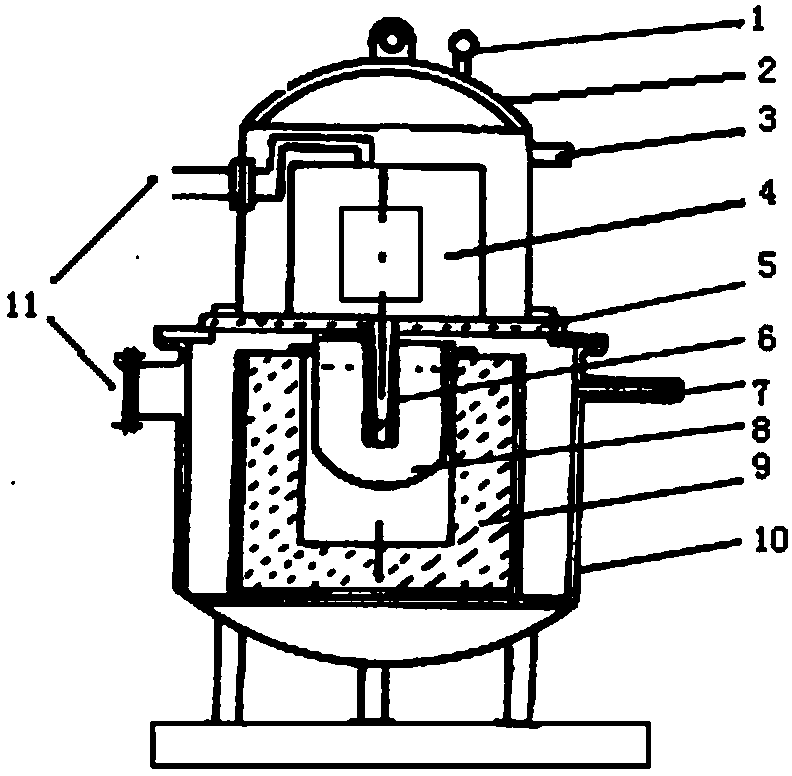

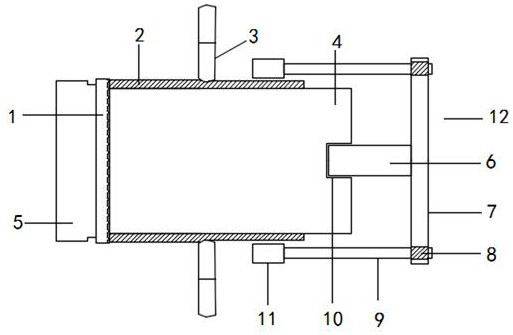

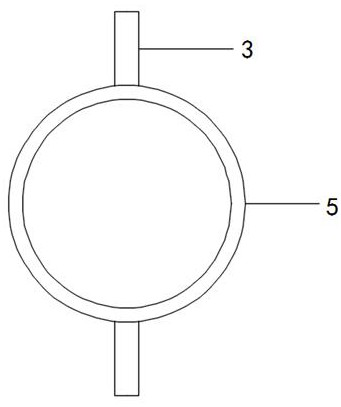

Multiple ingot vacuum running castings device and method for vacuum running castings using same

ActiveCN101249559AImprove qualityGuarantee the pouring qualityCasting plantsMolten metal conveying equipmentsIngotVacuum pump

The invention relates to a multi-ingot vacuum casting device and a method for implementing vacuum casting by using the device. The multi-ingot vacuum casting device comprises a pedestal, steel ingot molds, a vacuum tank, a vacuum cover, a vacuum cover vehicle, a tundish, a slide gate nozzle mechanism, a guide sleeve, a separation pipe, a lifting mechanism, a viewing window, a pump-out pipe, a vacuum pump system, a main vacuum valve, and a vacuum break valve, wherein the pedestal is arranged in the vacuum tank; the steel ingot molds are arranged on the pedestal; a vacuum cover is connected with a lifting mechanism arranged on the vacuum cover vehicle; the slide gate nozzle mechanism is arranged on the tundish; the guide sleeve and the viewing window are arranged on the vacuum cover; the slide gate nozzle mechanism, the guide sleeve and the steel ingot molds are communicated with each other; the main vacuum valve and the vacuum valve are arranged on the pump-out pipe; and the pump-out pipe is connected with the vacuum tank and the vacuum pump. The inventive technical proposal also includes the method for implementing vacuum casting by using the device. The multi-ingot vacuum casting device has the advantages that (1) the device has simple structure; (2) the molten steel casting process is carried out under high-vacuum condition to improve the quality of molten steel and eliminate the problem of unstable quality of small ingots formed by air casting; and (3) a plurality of ingots can be formed by one step, thus improving the production efficiency.

Owner:ZHEJIANG HANGZHEN ENERGY TECH CO LTD

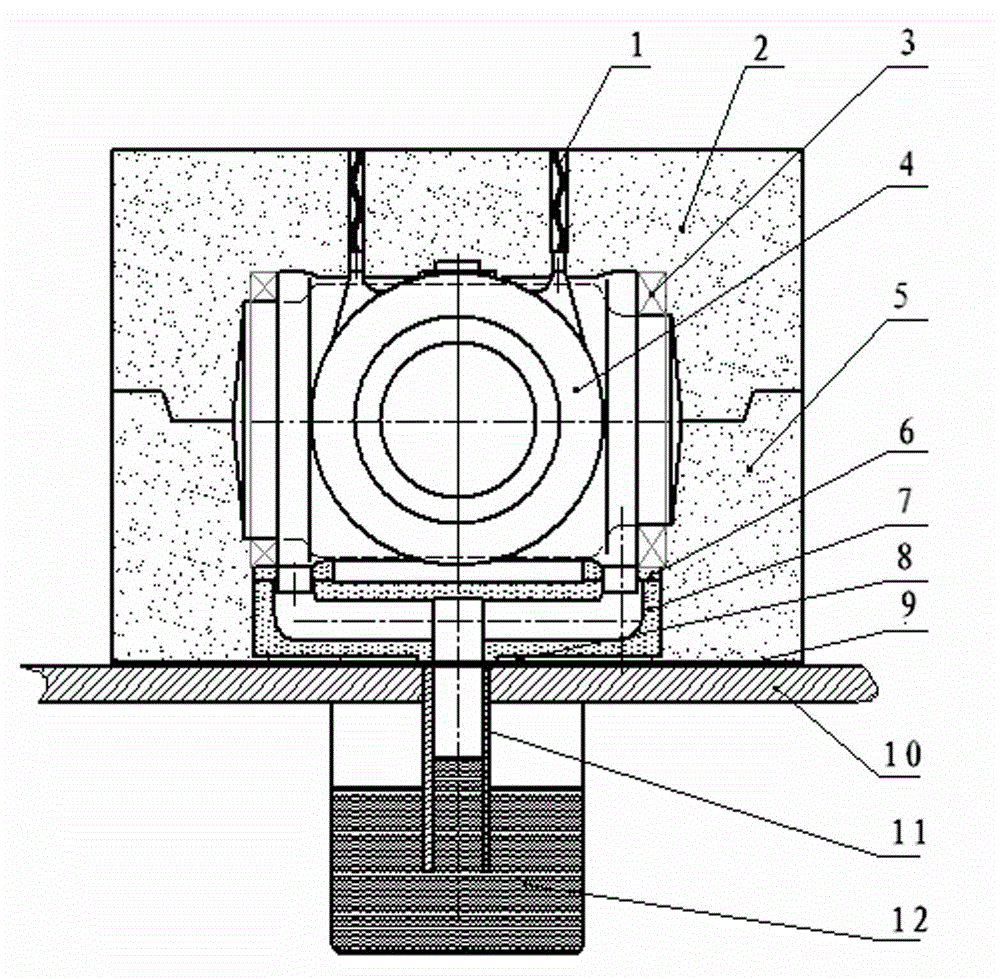

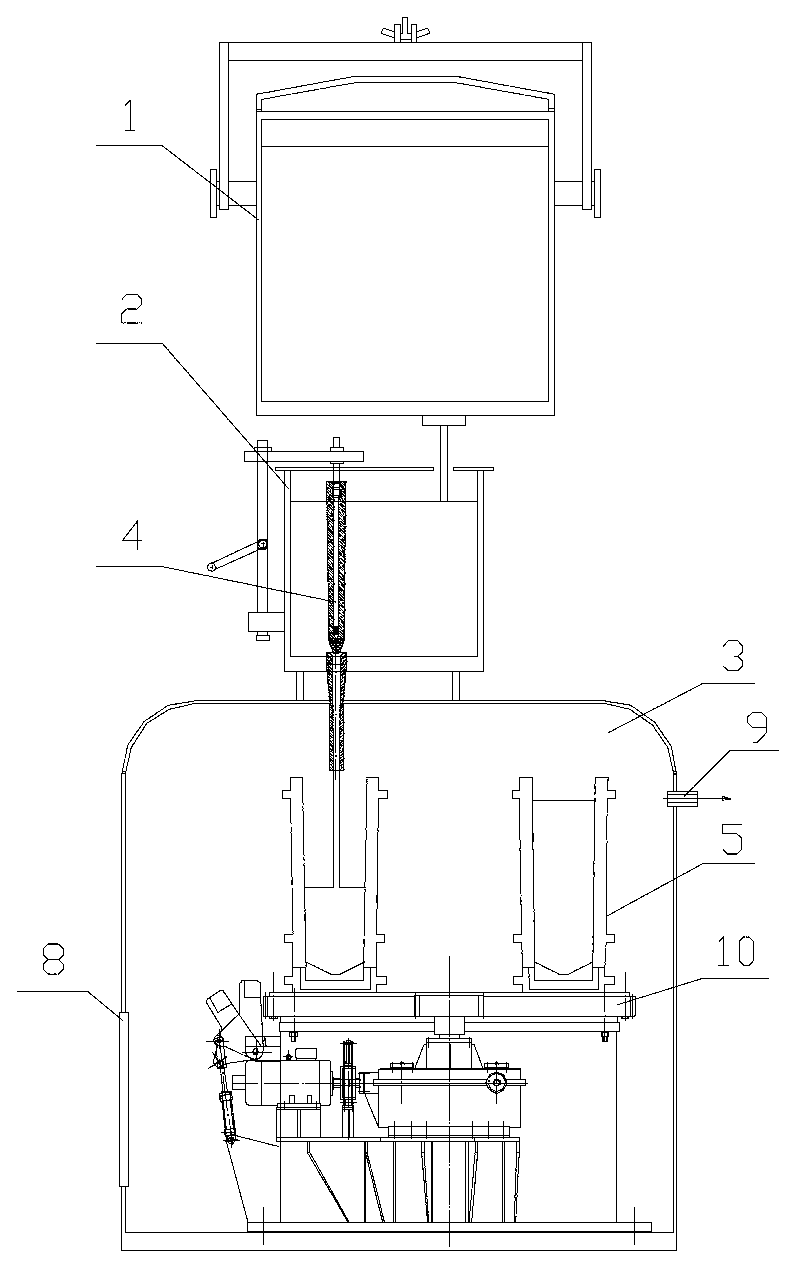

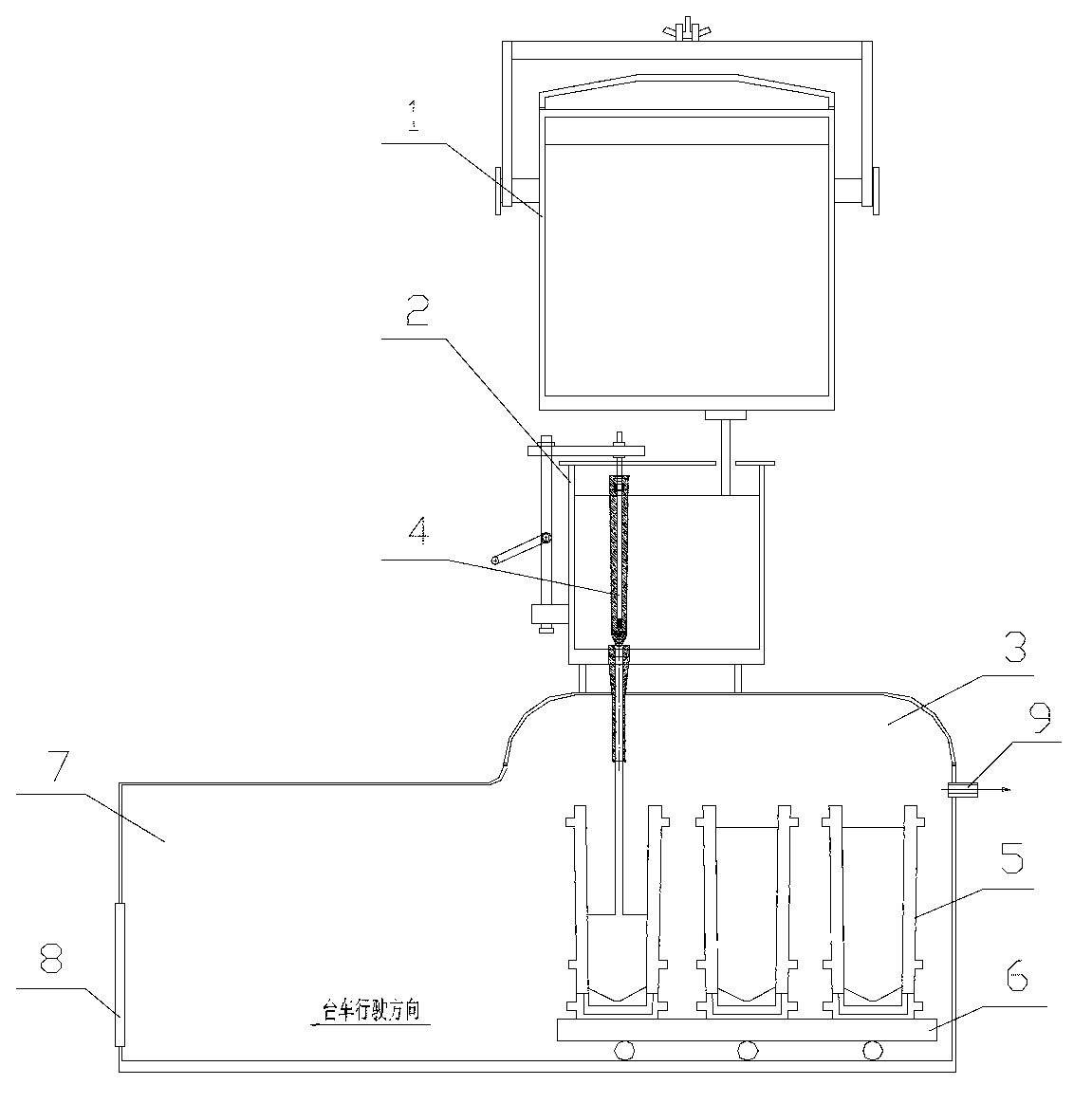

Steel ingot vacuum casting device

The invention relates to a casting device, in particular to a steel ingot vacuum casting device. The steel ingot vacuum casting device comprises a refining ladle, a middle ladle and a vacuum tank, wherein the middle ladle is arranged below the refining ladle; the vacuum tank is arranged below the middle ladle; the middle ladle is connected with the vacuum tank through a plug rod; at least two steel ingot dies are arranged in the vacuum tank, are arranged on a moveable trolley in one line or are peripherally arranged on a rotary platform; and when one steel ingot die is positioned at a casting station, the steel ingot die is positioned right below the plug rod. The steel ingot vacuum casting device is simple in structure, flexible and variable. The requirement of casting a plurality of steel ingots by one vacuum chamber and one middle ladle can be completely met, the yield of molten steel is improved, the consumption of the middle ladle is reduced, the stable running of a production organization is facilitated, and the production and running cost is low.

Owner:JIANGSU YONGGANG GROUP CO LTD

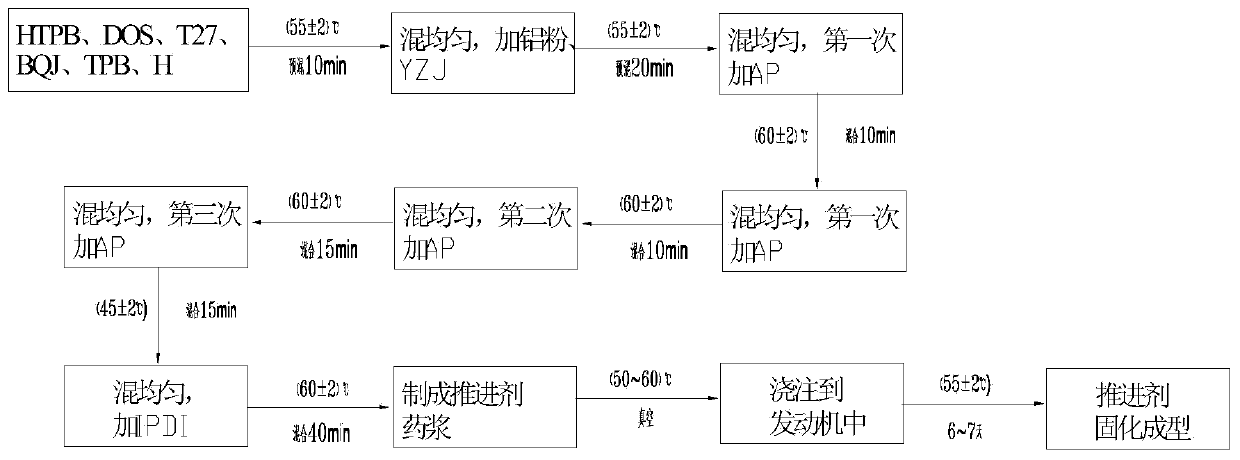

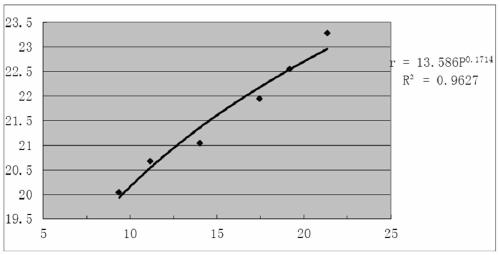

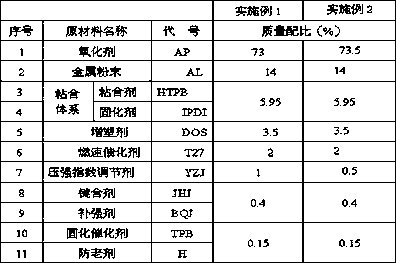

Hydroxyl-terminated polybutadiene composite solid propellant with high strength and low pressure index, and preparation method thereof

The invention belongs to the field of production of composite solid propellants, and discloses a hydroxyl-terminated polybutadiene composite solid propellant with a high strength and a low pressure index. The composite solid propellant comprises, by mass, 73-73.5% of an oxidant, 14% of metal powder, 5.95% of a bonding system, 3.5% of a plasticizer, 2% of a combustion catalyst, 0.5-1% of a pressureindex regulator, 0.4% of a bonding agent and a reinforcing agent, and 0.15% of a curing catalyst and an antioxidant. The invention also discloses a preparation method of the composite solid propellant. The preparation method comprises the following steps: 1, pre-baking solid raw materials: sieving ammonium perchlorate and aluminum powder; 2, weighing and premixing: premixing the raw materials according to the above mass proportions, adding the aluminum powder, and performing premixing; 3, mixing : adding the oxidant to the obtained premixed slurry in batches, performing uniform mixing, addingthe curing agent, and performing mixing; 4, casting: casting a propellant slurry by a vacuum casting process; and 5, curing: heating and curing a mold and an engine shell which are filled with the propellant slurry. The composite solid propellant can meet the requirements of charges of rockets and missile solid engines in a high-overload and high-pressure working state.

Owner:江西航天经纬化工有限公司

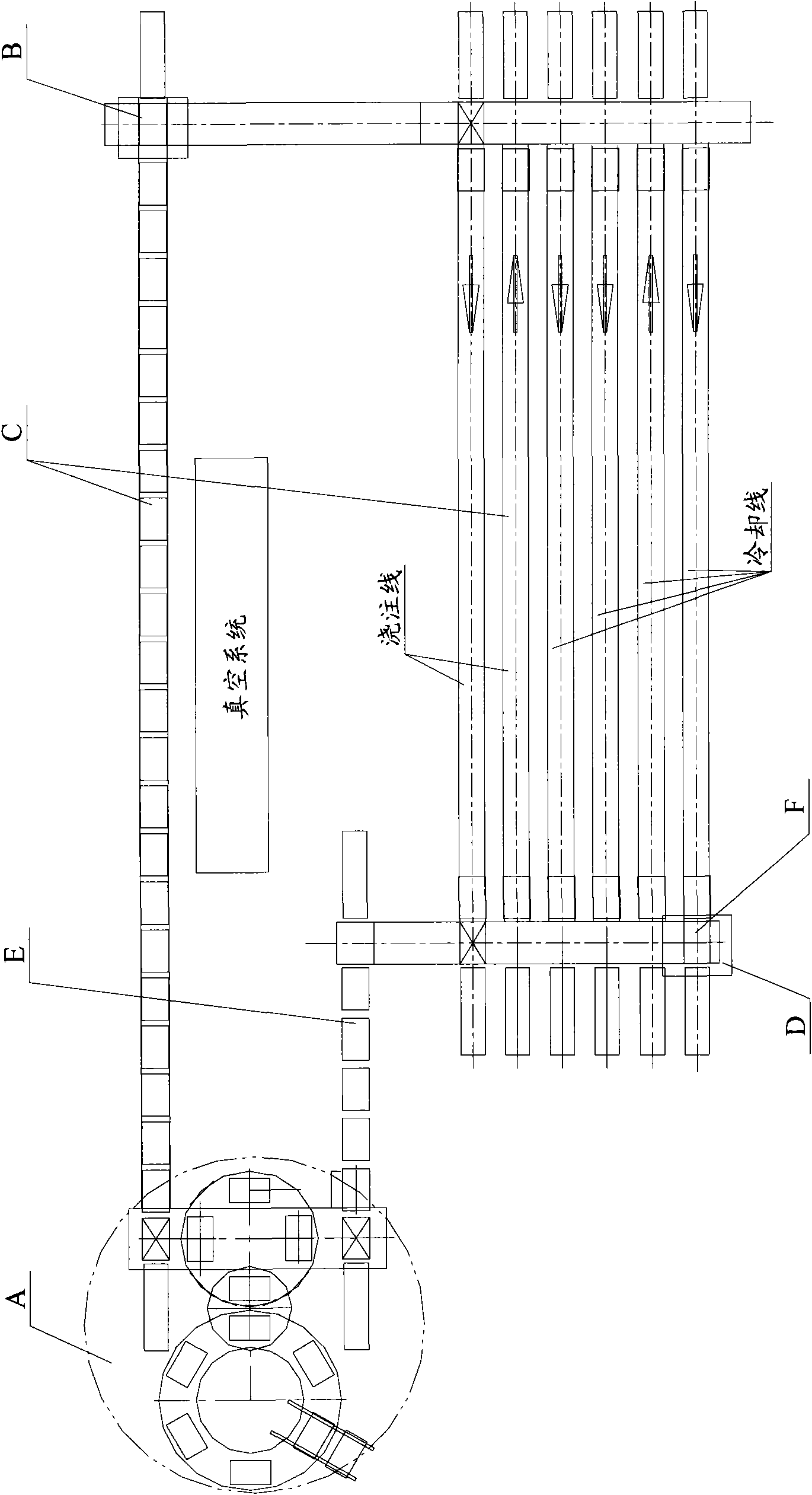

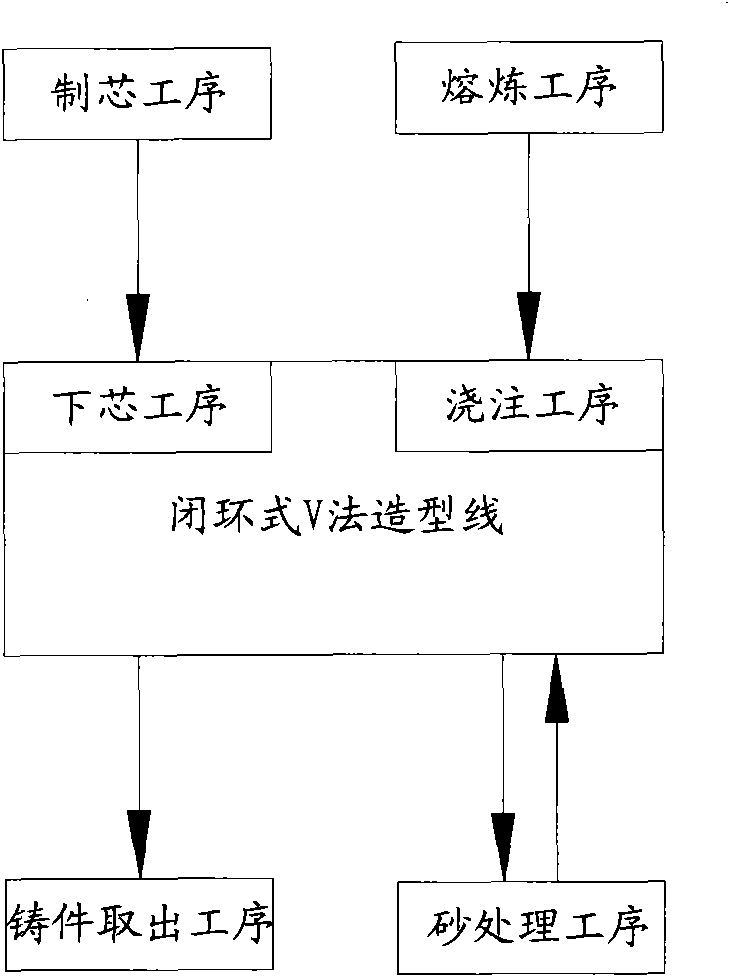

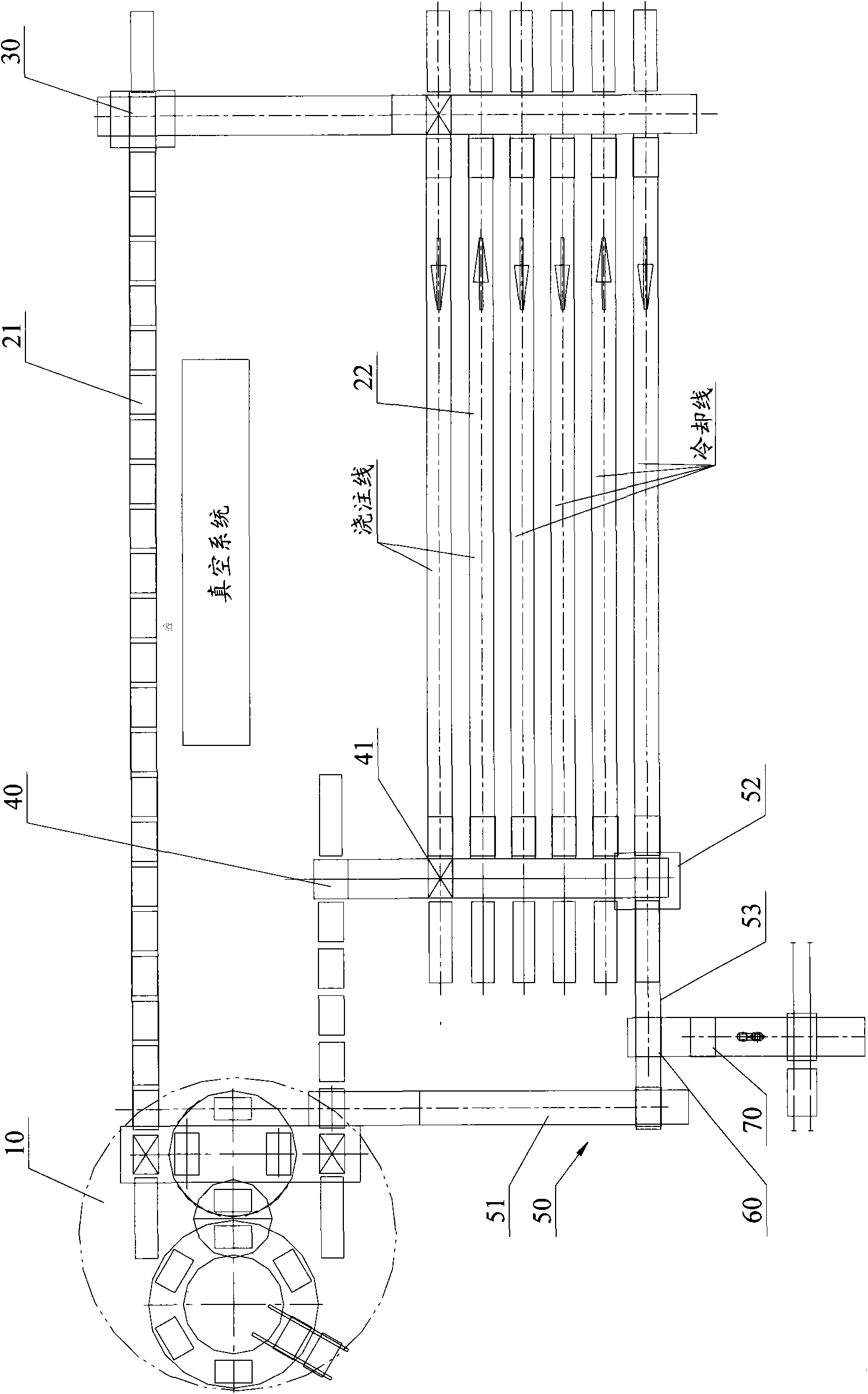

Sand box returning mechanism, returning method using same and vacuum casting line

InactiveCN101637804AReduce labor intensityAvoid unsafe hazardsMoulding flasksMechanical engineeringSilicon

The invention discloses a sand box returning mechanism used for a vacuum casting line system and comprising a sand box returning line, a sand box hoisting bracket and a roller way, wherein the rear end of the sand box returning line is connected with a casting mechanism of the casting line system so that a sand box can be conveniently returned to the casting mechanism; the sand box hoisting bracket is provided with a vertically arranged guide rod and a clamping component moving upwards and downwards along the guide rod. At least one pair of clamping paws of the clamping component are respectively hinged with a clamping component body so as to facilitate the opening and closing operation. The front end of the roller way is positioned above a supporting plate returning shuttle car, and the rear end thereof is positioned above the front end of the sand box returning line. The roller way passes through the upper side of a sand dropping mechanism so as to facilitate the directional walk ofthe sand box hoisting bracket among the supporting plate returning shuttle car, the sand dropping mechanism and the sand box returning line, thereby reliably guaranteeing an operator to keep away froman area with high temperature, high silicon dust content and high danger. Based on the sand box returning mechanism, the invention also provides a returning method using the sand box returning mechanism and a vacuum casting line with the sand box returning mechanism.

Owner:CRRC QIQIHAR ROLLING CO LTD

Anticorrosion high-strength alloy and smelting method thereof, as well as product of alloy and processing method of same

ActiveCN101525715AHigh strengthAccelerated corrosionMolten metal pouring equipmentsTemperature control deviceSmelting processChemical element

The invention discloses an anticorrosion high-strength alloy, consisting of the following elements in percentage by weight: 30 to 40 percent of Ni, 18 to 22 percent of Cr, 7 to 12 percent of Mo, and the balance of Co and unavoidable impurities. The content of the impurities has the following elements in percentage by weight: less than 0.05 percent of C, less than 0.20 percent of Si, less than 0.25 percent of Mn, less than 0.010 percent of S, less than 0.015 percent of P, less than 1.0 percent of Tim, and less than 2.0 percent of Fe. The smelting method comprises the following steps: 1) selecting the required chemical elements, smelting the elements in a vacuum inductance furnace, regulating the content of each element in the smelting process to ensure the weight of each element accords with the designing requirement, controlling the content of impurity elements as low as possible, and casting the alloy into a consumable electrode by a vacuum casting method; and 2) carrying out electroslag remelting on the consumable electrode to further reduce the content of impurity elements to ensure that the electrode accords with the designing requirement to obtain an electroslag remelt ingot with excellent quality. The alloy and the metal product manufactured by the corresponding process method have higher strength and excellent anticorrosion performance.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

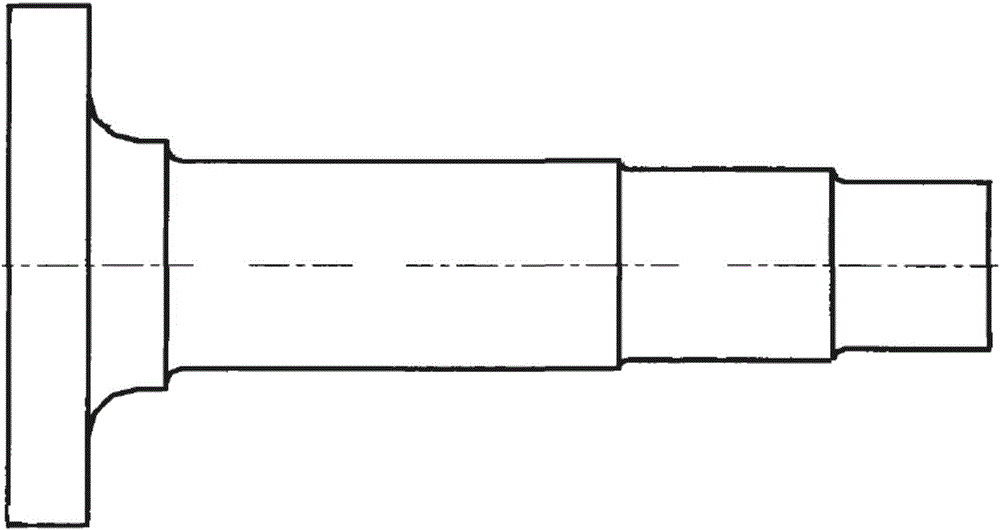

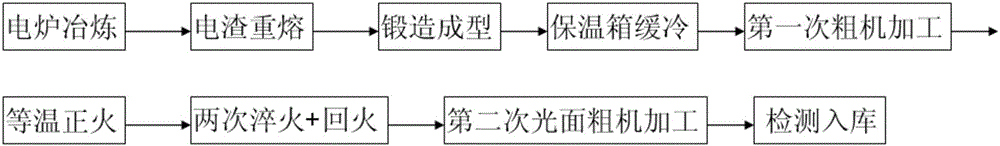

34CrNiMo6 wind power main shaft forging forming method for low wind speed wind turbine set

InactiveCN106425285AReduce the generation of unbalanced tissueImprove mechanical propertiesEngine manufactureMachines/enginesWind powerSmelting

The invention discloses a 34CrNiMo6 wind power main shaft forging forming method for a low wind speed wind turbine set. The method includes the step a of adopting of electric furnace smelting, secondary refining, vacuum gas removing and vacuum steel ingot raw material casting and smelting; the step b of electro-slag remelting of a steel ingot raw material in the step a; the step c of pre-forging for blank manufacturing; the step d of final forging forming; the step e of slow cooling of a heat-preserving box; the step f of first-time rough machining, and ultrasonic non-destructive detection; the step g of isothermal normalizing for preparing heat treatment; the step h of two times of quenching and tempering final heat treatment; and the step i of detection for qualification and packaging and warehousing. By means of the 34CrNiMo6 wind power main shaft forging forming method for the low wind speed wind turbine set, the structure property of the flange portion of a wind power main shaft and the variable cross-section shaft portion is made to be uniform, and the mechanical performance of the 34CrNiMo6 wind power main shaft of the low wind speed wind turbine set is greatly improved.

Owner:JIANGSU JINYUAN FORGE

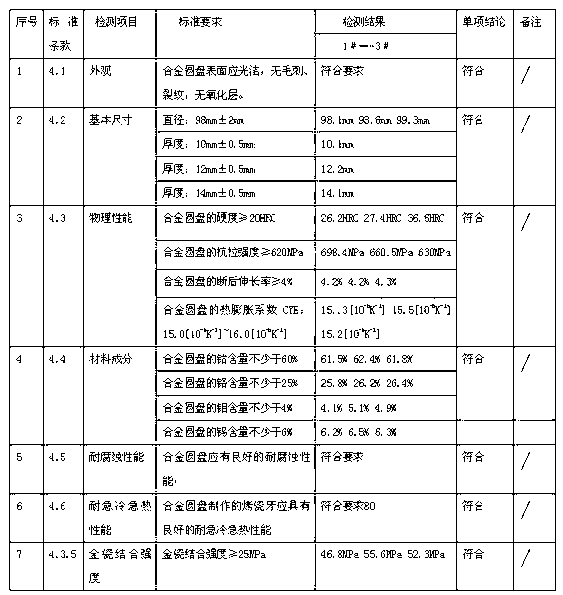

Method for manufacturing dental cobalt-chromium ceramic alloy disc material

InactiveCN103340689ANo crackHigh bonding strengthTooth crownsTeeth cappingThermal dilatationWire cutting

The invention relates to a method for manufacturing a dental cobalt-chromium ceramic alloy disc material suitable for a CAD / CAM (Computer Aided Design / Computer Aided Manufacturing) tooth carving machine, belonging to the technical field of a dental material. The method comprises the following steps of: preparing furnace charge, then putting the furnace charge into a furnace for vacuum melting and vacuum casting, and rolling with a rolling mill, wherein the rolling temperature is 1200-1300 DEG C, the rolling deformation is 2.6-4.8 percent, and the rolling pass is 2-6 passes; forming a semi-finished product material; and finally according to the needed thickness, causing the semi-finished product material to be subjected to wire cutting and turning of a turning lathe to obtain the dental cobalt-chromium ceramic alloy disc materials with different thicknesses suitable for the CAD / CAM tooth carving machines. The dental cobalt-chromium ceramic alloy disc material provided by the technical scheme has the advantages of smooth and clean surface, good compactness, no crack, good biocompatibility with a human body, good corrosion resistance, appropriate strength, hardness, extensibility and thermal expansion properties and good metal and ceramic powder bonding strength.

Owner:南通今日高科技新材料股份有限公司

High-strength single-phase (alpha phase) Mg-Li alloy material and preparation method thereof

The invention provides a high-strength single-phase (alpha phase) Mg-Li alloy material and a preparation method thereof, and belongs to the field of metal structural materials. The Mg-Li alloy material is prepared from components in percentage by weight as follows: 0-5.7% of Li, 6.0%-9.0% of rare earth elements, 3.0%-6.0% of Co and the balance of Mg and inevitable impurities. The preparation method of the Mg-Li alloy material comprises the following steps: preheated raw metal is melted in vacuum, an alloy solution is obtained, poured to a mold and cooled, and a cast-state Mg-Li alloy is obtained; the obtained cast-state Mg-Li alloy is subjected to homogenization treatment; the homogenized Mg-Li alloy is rolled at low temperature, wherein low-temperature rolling adopts cross accumulative roll bonding. The Mg-Li alloy material is prepared through steps of vacuum casting, homogenization treatment and low-temperature rolling by reasonably selecting alloy elements and controlling content and proportion of the alloy elements, and has the advantages of high cleanness, high strength and high plasticity.

Owner:ZHEJIANG OCEAN UNIV

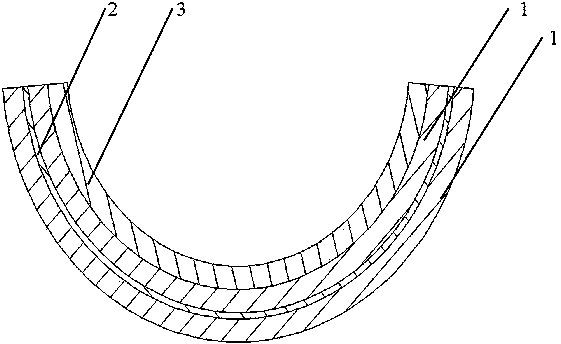

Arched composite alloy protection plate module and production technology thereof

InactiveCN103471467AImprove the protective effectResist damageArmoured vehiclesVacuum castingTempering

The invention belongs to the technical field of vehicle protection, and relates to an arched composite alloy protection plate module and a production technology thereof. The arched composite alloy protection plate module is arched and mainly composed of metal matrixes and a metal mesh, and the metal mesh is composited in the metal matrixes. The arched composite alloy protection plate module is produced with an FV casting technology. The production technology includes the steps: (1) producing a full mold, and using polystyrene foam beads for forming a protection plate template by foaming; (2) coating the template of the protection plate module with fireproof paint, and after drying, placing the dried template into a vacuum casting box for vacuumizing prior to molding by casting; (3) subjecting the arched composite alloy protection plate module molded by casting to heat treatment, and sequentially performing annealing, normalizing and tempering. Vehicle bodies are sufficiently protected against damage caused by shock waves of explosive, personal safety of passengers is protected sufficiently and effectively, and particularly effect in protecting against the explosive less than 10 kilos is better.

Owner:LIAONING BAOLI SPECIAL VEHICLES

High-purity bismuth-lead alloy and preparation method thereof

The invention discloses a high-purity bismuth-lead alloy and a preparation method thereof. The preparation method comprises the steps that a compounding step is carried out, specifically, according tothe composition design of the bismuth-lead alloy, massive lead materials and bismuth materials are used as raw materials for compounding and mixing; a smelting step is carried out, specifically, themixed raw materials are smelted under vacuum; a cooling step is carried out, specifically, alloy melt obtained after smelting is subjected to cooling; a filtering step is carried out, specifically, the alloy melt after cooling is subjected to filtration treatment; and a casting step is carried out, specifically, the filtered alloy molt is casted into a mold under vacuum and cooled to obtain an alloy ingot. According to the high-purity bismuth-lead alloy and the preparation method thereof, through the combination of high-temperature vacuum melting and low-temperature vacuum casting, oxides andother metal impurities in the lead and bismuth raw materials can be efficiently and advantageously removed, so that the purity of the alloy reaches above 99.998%. And through timing electromagnetic stirring and controlling of the weight of a single alloy ingot, the overall composition of the alloy is uniform and controllable, and the problem of excessive composition segregation is avoided.

Owner:安泰天龙钨钼科技有限公司 +1

Megavolt paper film composite capacitor arm, modular high voltage pulse capacitor and designing and manufacturing method thereof

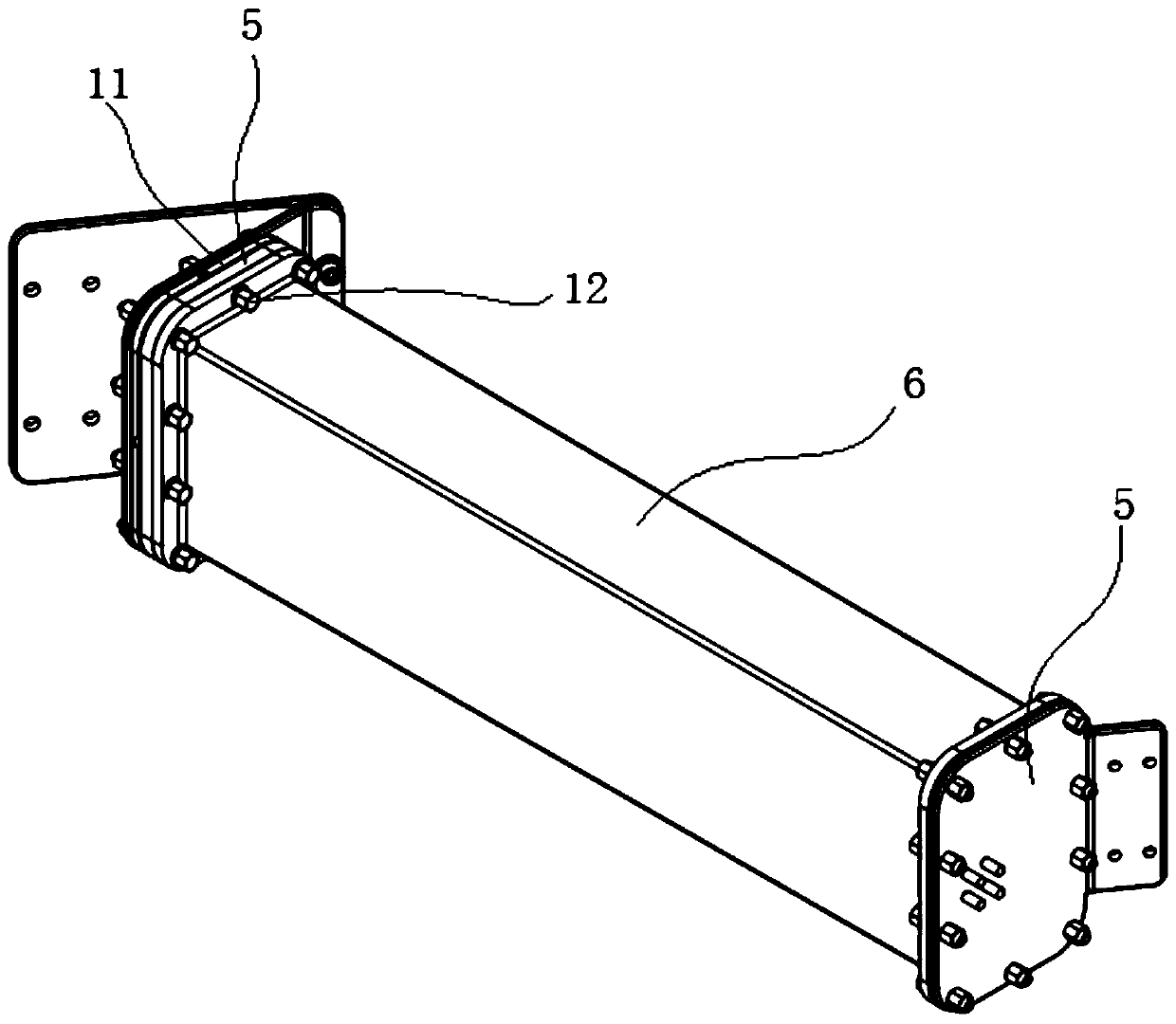

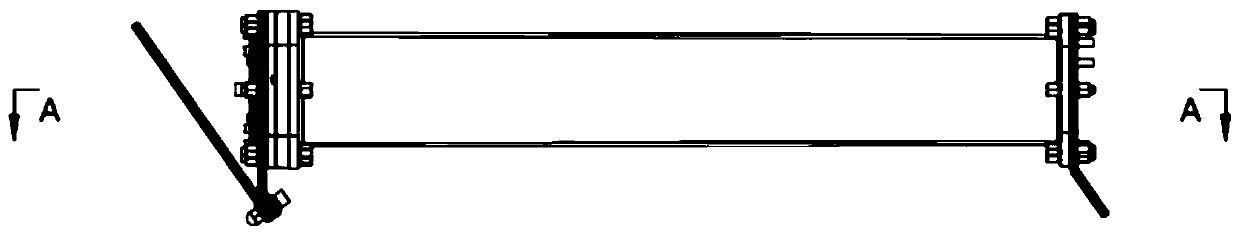

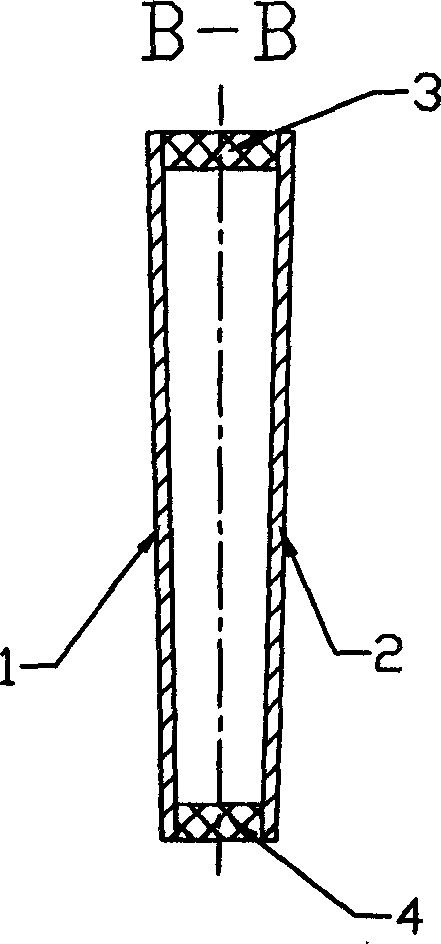

ActiveCN110189916AMeet the compressive strengthMeet structural strengthTesting dielectric strengthMultiple fixed capacitorsCapacitanceElectromagnetic pulse

The invention provides a megavolt paper film composite capacitor arm, a modular high voltage pulse capacitor and a designing and manufacturing method thereof and is applied to an electromagnetic pulsesimulation device utilizing transformer oil insulation. The megavolt paper film composite capacitor arm includes a casing, end caps, a capacitor element, an expander and a metal cavity, wherein the casing is made of an FRP material in a vacuum casting process and is in the square tube shape, the end caps are two and are respectively fastened and sealed at flanges at both ends of the casing, a screw hole is formed in one end cap, the other end cap is provided with an oil hole, the capacitor element and the metal cavity are disposed in the casing, the metal cavity is close to the end cap with the screw hole, the expander is disposed in the metal cavity, a gas nozzle extends out of the casing and the end caps in sequence, the capacitor element is formed by sequentially laminating a polypropylene film, a capacitor paper and a metal aluminum foil, the metal cavity is a cylindrical structure opening at one end, an enclosed end of the metal cavity closely compresses the capacitor element, and the metal cavity is filled with an insulating medium.

Owner:NORTHWEST INST OF NUCLEAR TECH

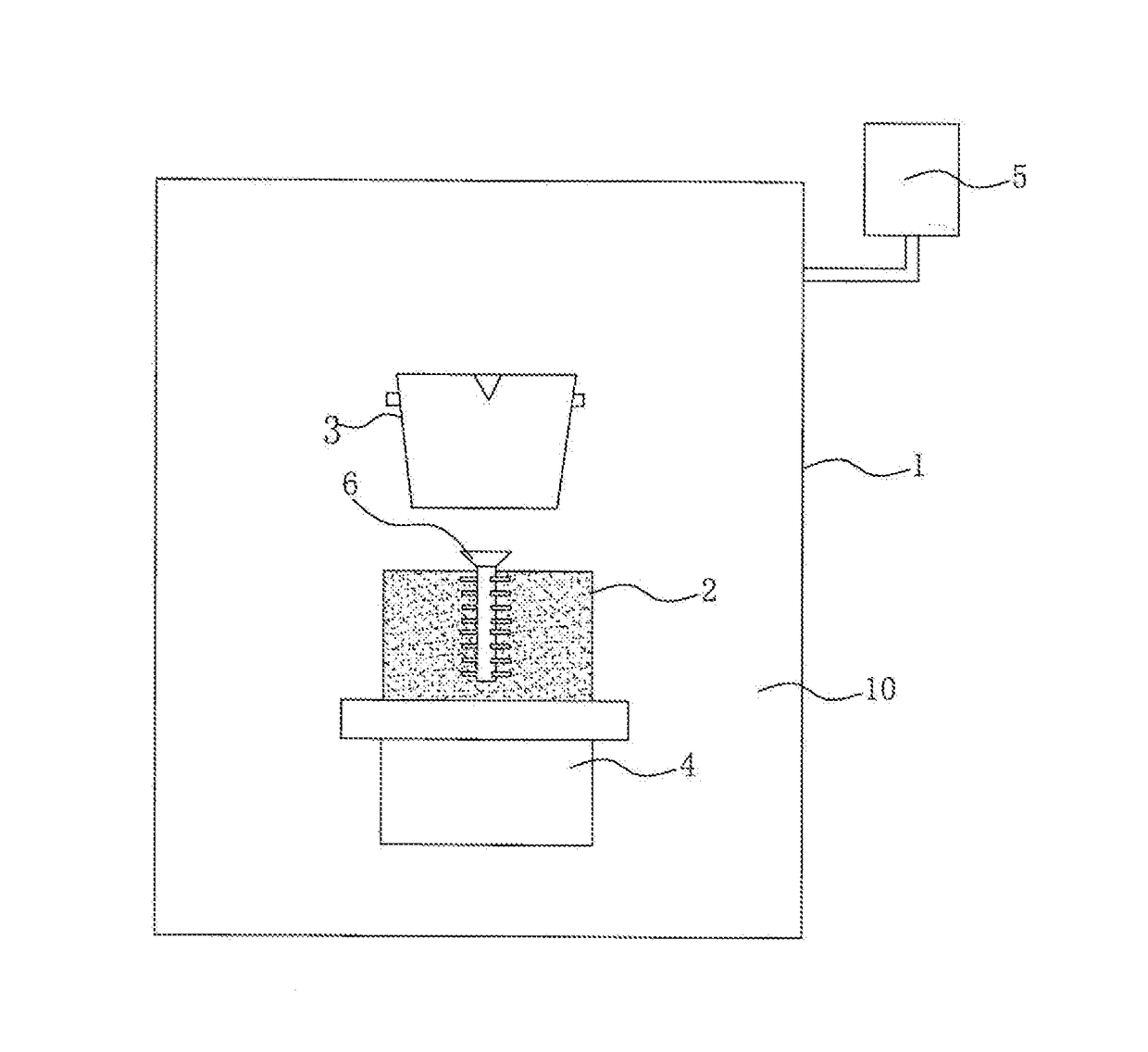

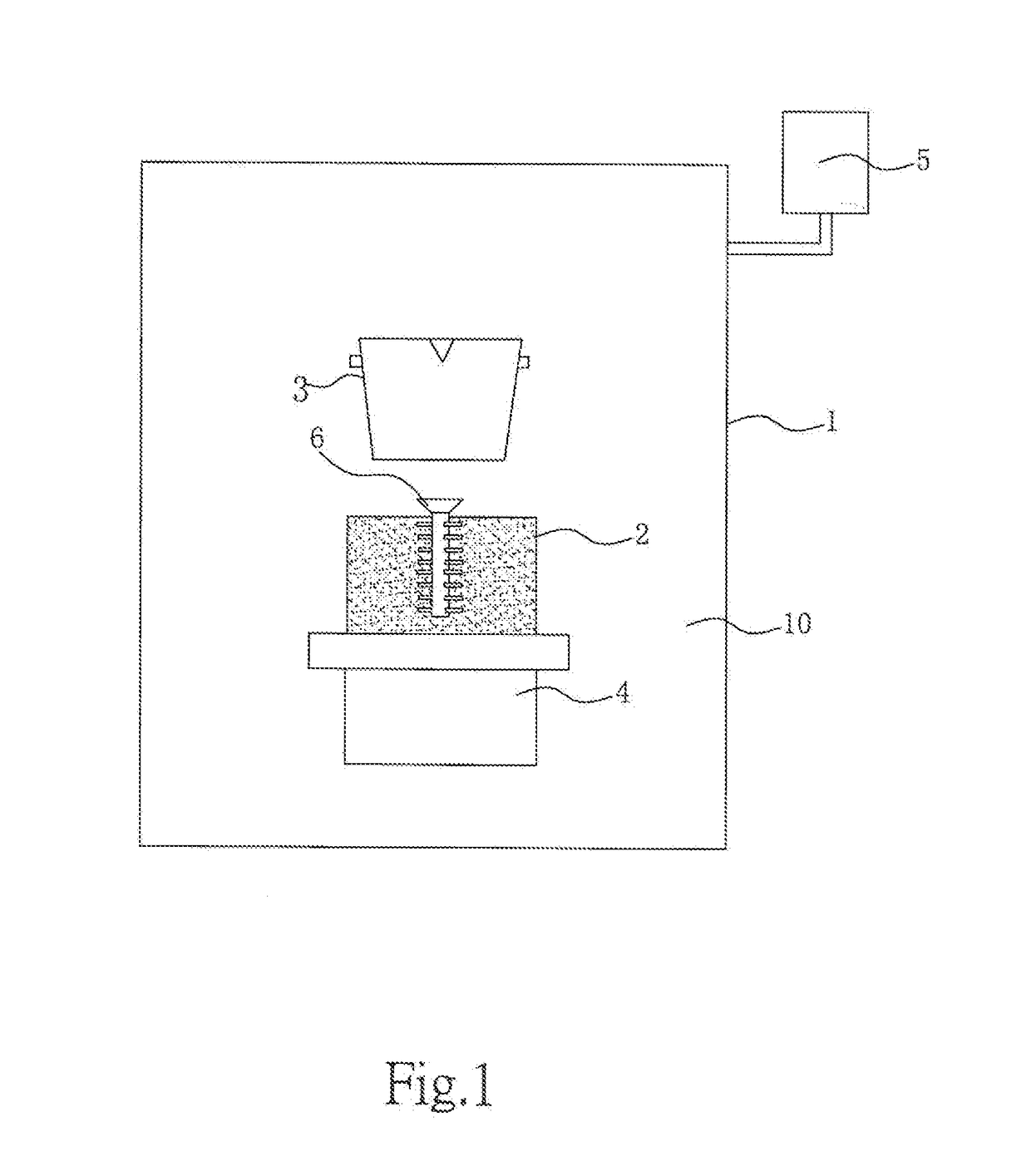

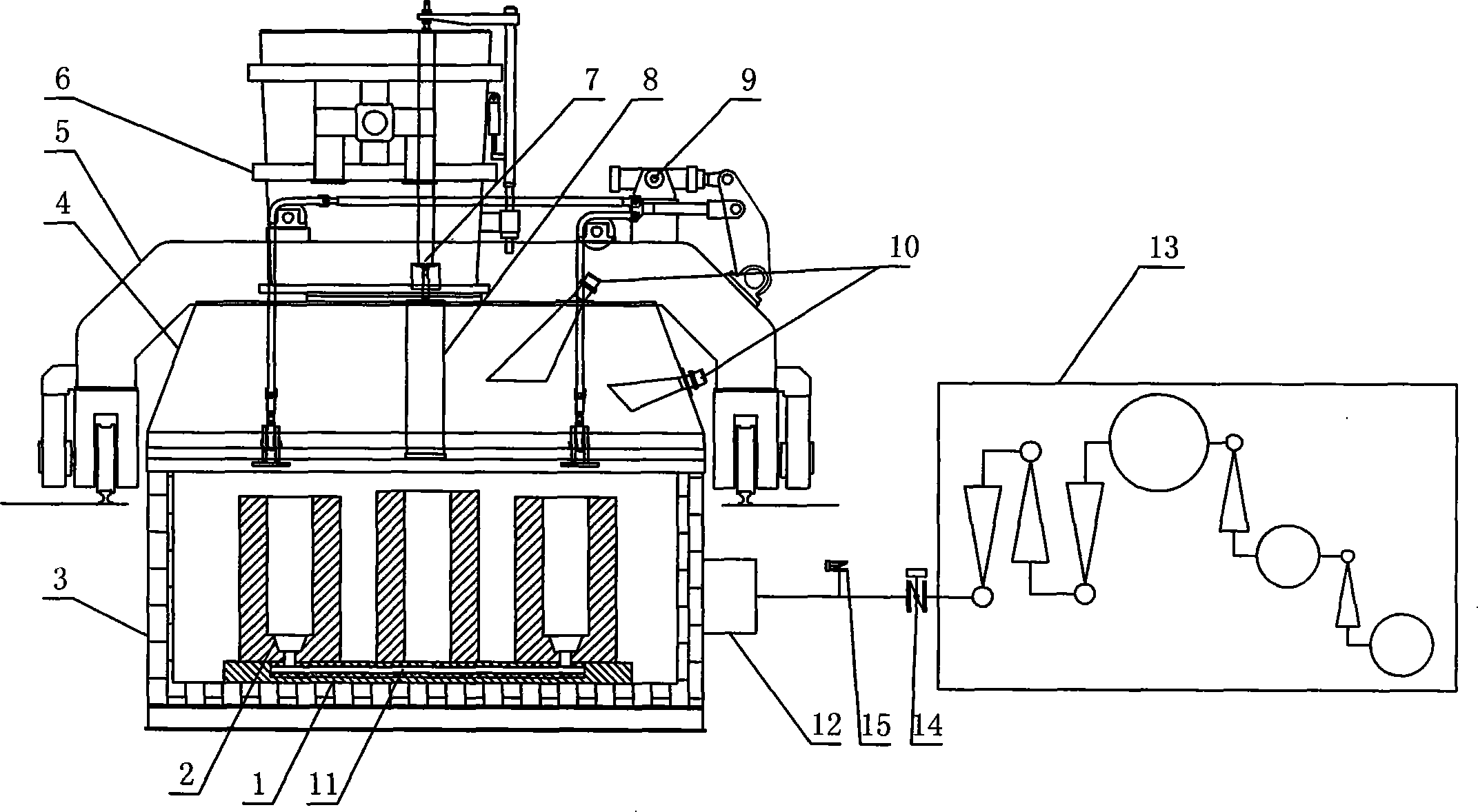

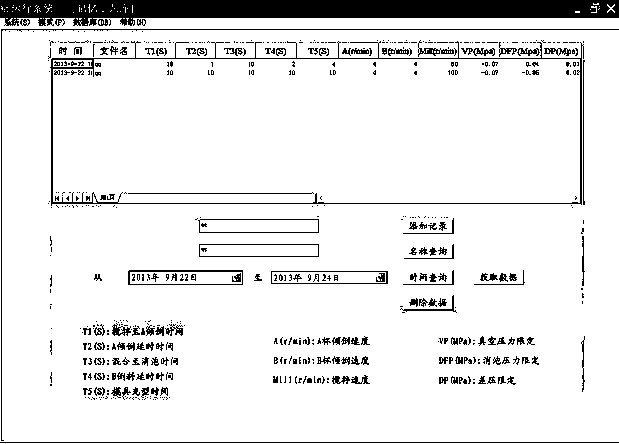

Fully-automatic vacuum casting control system and method thereof

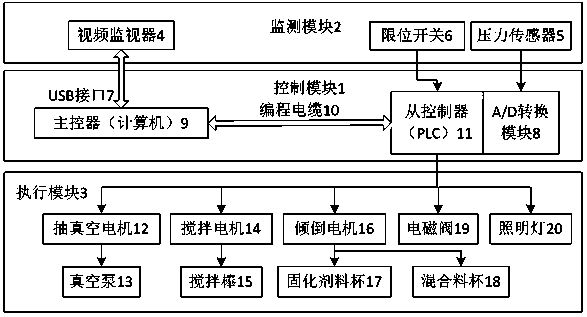

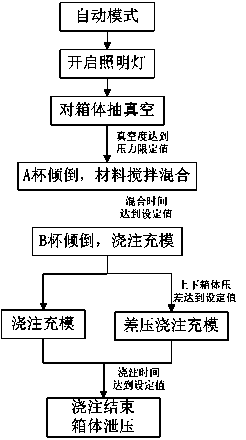

The invention relates to a fully-automatic vacuum casting control system and a method thereof. The system comprises a monitoring module, a controlling module and an executing module, the controlling module is composed of a master controller computer and a slave programmable logic controller, the monitoring module is formed by a video monitor, a pressure sensor and a limit switch, and the executing module is formed by connecting an evacuation motor with a vacuum pump, connecting a stirring motor with a stirring bar, connecting an overturning motor with a curing agent cup and a mixture cup, and adopting a solenoid valve and an illuminating lamp. The control method realizes the visual, automatic and intelligent control of a vacuum casting process. The system and the method substantially save the human resource cost, and improve the casting work efficiency and the product quality.

Owner:SHANGHAI UNIV

Preparation method for zirconium-copper thick-wall straight cylindrical part through cold power spinning

PendingCN112676426AUniform tissueEasy to spin deformationMetal-working apparatusVacuum castingManufacturing cost reduction

The invention discloses a preparation method for a zirconium-copper thick-wall straight cylindrical part through cold power spinning, and particularly relates to the technical field of material forming. According to the technical scheme, a stop device, a zirconium-copper material, a spinning roller, a core mold and a main shaft are included, and the preparation method specifically comprises the following working procedures of S1, firstly, calculating a feeding volume according to the thickness T, the length L and the process allowance of a target product, and performing vacuum casting on raw materials to obtain a casting blank; and S2, freely forging the casting blank. The preparation method for the zirconium-copper thick-wall straight cylindrical part through cold power spinning has the beneficial effects that the forging process limitation is avoided, and the characteristics of the spinning process are fully utilized; the machining quality and precision of the part are improved, and the preparation method has the effects of improving the utilization rate of the zirconium-copper material and the production efficiency and reducing the manufacturing cost.

Owner:西安博赛旋压科技有限公司

Short-flow preparation method of aluminum-containing titanium alloy

The invention discloses a short-flow preparation method of an aluminum-containing titanium alloy. Common titanium sponge or titanium-based sponge alloy (which is prepared by metallurgy of titanium, aluminum, tin, molybdenum and the like, alloying of titanium, aluminum, tin, zirconium, molybdenum and the like and merging in one technological process) is used as a raw material, and a low-cost and high-quality titanium alloy cast ingot is obtained through one-time smelting and casting by adopting an electron beam or plasma or induction or vacuum self-consuming electric arc smelting technology. The raw material cost is low, a multi-component alloy element preparation process required by a traditional process is omitted, a repeated remelting casting (casting for 2-4 times) process of a titanium alloy ingot is omitted, the process is simplified, the flow is shortened, the casting cost is reduced, and the casting efficiency is improved. As the high-temperature and high-vacuum casting times are reduced by about 70%, the oxidation and volatilization loss of aluminum, tin, manganese and the like is greatly reduced, alloy components are easier to control, and the quality of the cast ingot is greatly improved.

Owner:XINJIANG UNIVERSITY

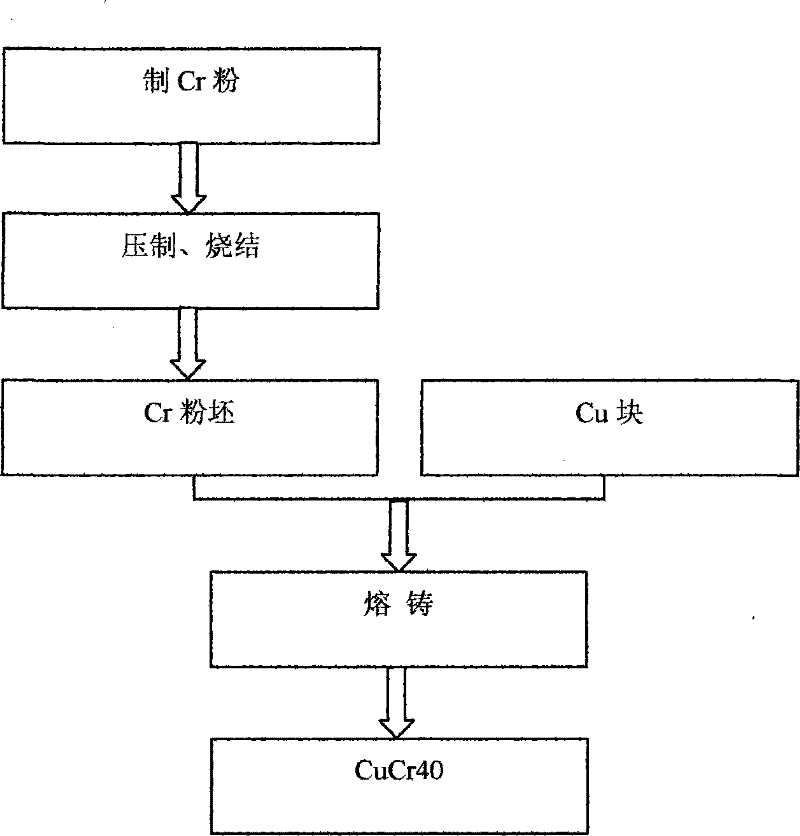

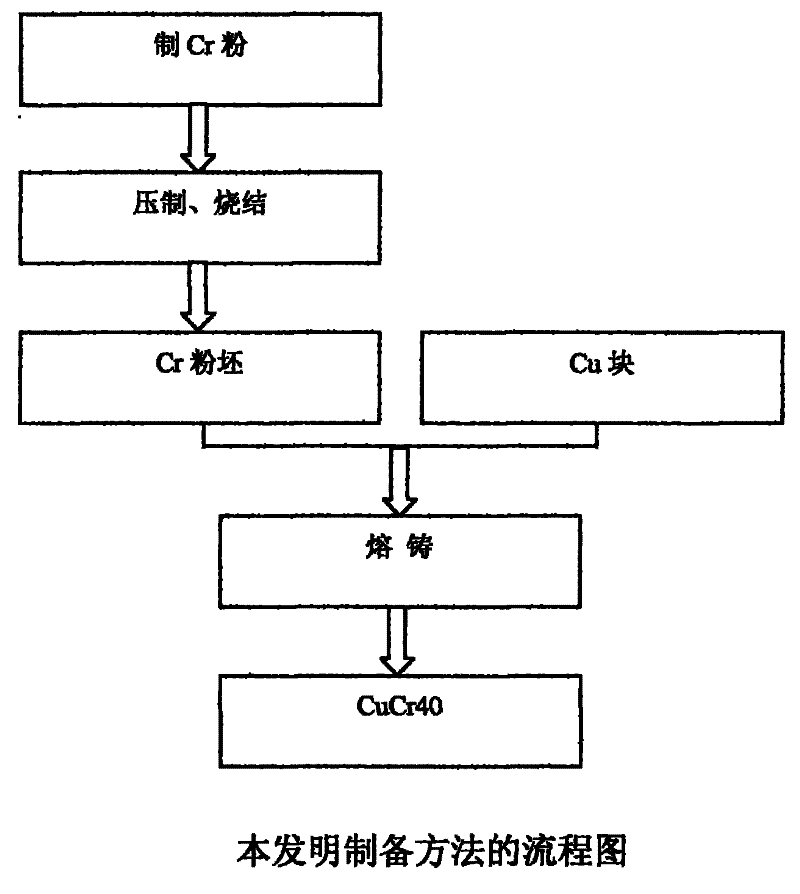

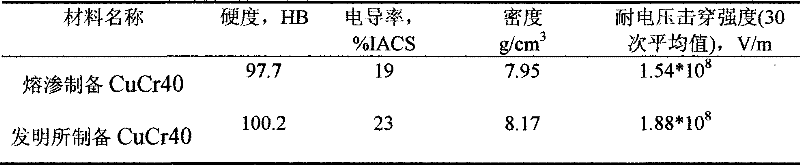

Method for preparing cucr 40 contact material by vacuum casting method

The invention discloses a CuCr40 electric contact prepared by adopting a vacuum melting casting method, which belongs to the technical field of metal material preparation. Its composition by weight percentage is: 40% Cr, and the rest is Cu. It is prepared by the following method: under the protection of low-temperature liquid, the Cr block is processed into Cr powder by grinding and crushing machine, the Cr powder is pressed and sintered into Cr powder, and then the Cu block and Cr powder are put into a vacuum furnace Heating, casting after melting, and then producing CuCr40 electrical contact material after cooling. The invention has the advantages of crushing Cr lumps into Cr powder, and then pressing and sintering to make Cr powder billets, which lowers the melting temperature and shortens the melting time. The preparation method of the invention has simple process and low cost, and the prepared CuCr40 composite material has superior performance compared with the infiltrated CuCr40 composite material.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

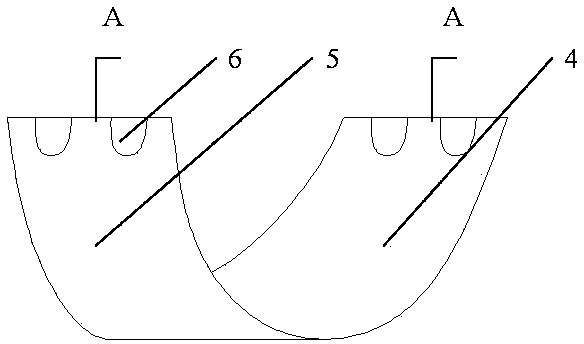

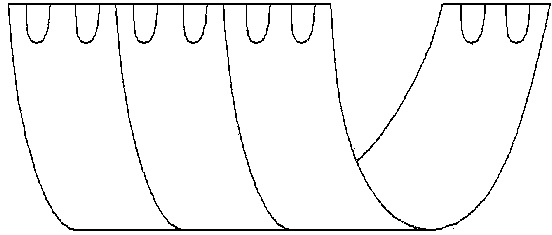

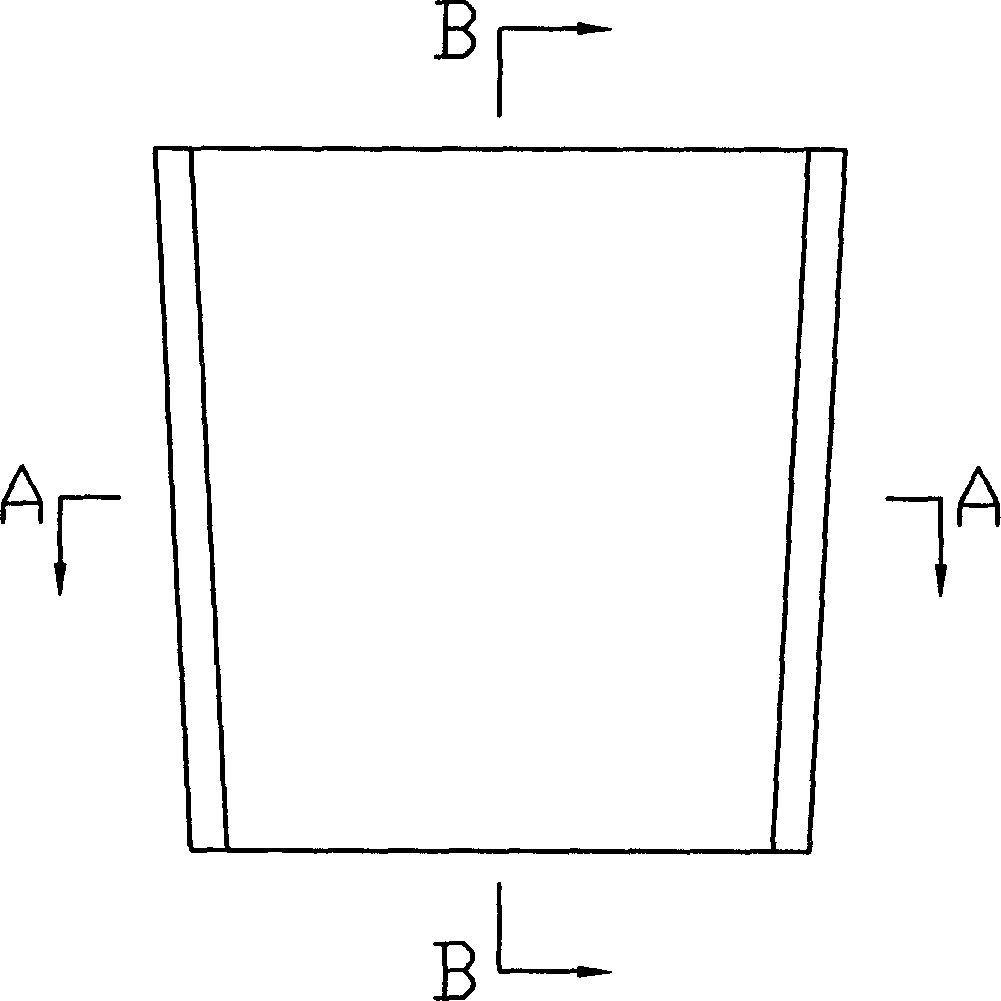

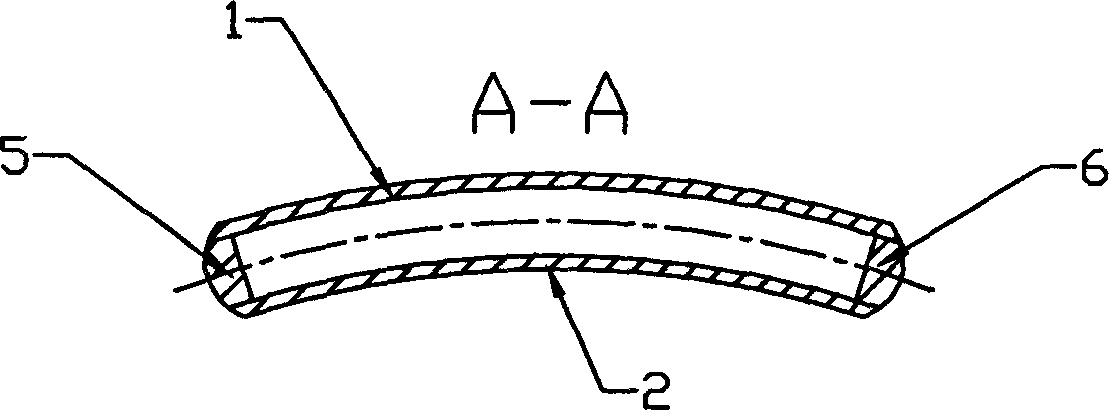

Isolation gas channel formation mould for vacuum casting transformer coil and its prepn. method

A mould for forming the isolating air channel of the windings in transformer by vacuum casting is made up of the arc section with sealed cavity through using conic internal arc wall plate, reverse-conic external arc wall plate and upper and lower ring plates to construct a hollow cylinder, temporarily installing the oblique side plates between said internal and external wall plates to form several hollow formworks, cutting and taking the internal and external arc wall plates and upper and lower ring plates of each hollow formwork, and riveting said ring plates and left and right oblique side plates onto said arc wall plate to form conic hollow formwork.

Owner:FUZHOU TIANYU ELECTRIC +1

Low-zirconium mullite draft tube brick and preparation method thereof

The invention relates to a low-zirconium mullite draft tube brick and a preparation method thereof, belonging to the field of refractory materials. The low-zirconium mullite draft tube brick comprises the following raw materials by weight: 45 to 55 parts of fused mullite, 15 to 25 parts of zirconia, 3 to 8 parts of Guangxi white mud, 15 to 25 parts of andalusite, 2 to 5 parts of kyanite and 1 to 5 parts of lignin. According to the invention, through selection of types and particle sizes of the raw materials and cooperative usage of sintering temperature and time provided by the invention, the prepared draft tube brick has the characteristics of excellent anti-scouring performance and high temperature resistance, small creep deformation, good thermal stability, etc. and is applicable to vacuum casting of large steel ingots in a nuclear power product.

Owner:四川锦圆耐材有限公司

Ultralight aluminum-lithium alloy and preparation method and application thereof

The invention belongs to the technical field of aluminum-lithium alloys, and particularly relates to an ultra-light aluminum-lithium alloy and a preparation method and application thereof. According to the preparation method, through composite microalloying and the processes of vacuum casting, deformation processing, heat treatment and the like, the problems of oxidation burning loss and layering segregation caused by high Li and Mg contents are solved, and the ultra-light aluminum-lithium alloy with high plasticity and good matching is obtained. The ultra-light aluminum lithium alloy is prepared from the following components in percentage by mass: 3.0 to 8.0 percent of lithium, 3.0 to 9.0 percent of magnesium, 0.01 to 0.03 percent of beryllium, 0.01 to 0.30 percent of antimony, 0.10 to 0.80 percent of manganese, 0.02 to 0.20 percent of titanium, 0.10 to 0.30 percent of scandium, 0.05 to 0.30 percent of zirconium and the balance of aluminum. The obtained ultra-light aluminum-lithium alloy has excellent comprehensive performance, and the performance that the density is 2.18 g / cm < 3 >, the tensile strength is 340 MPa, the yield strength is 308 MPa, and the percentage elongation after fracture is 10.4% can be achieved. The ultra-light aluminum-lithium alloy is good in strength and plasticity, and can be used as an advanced light-weight structural material to replace a conventional aluminum alloy component on an aircraft.

Owner:郑州轻研合金科技有限公司

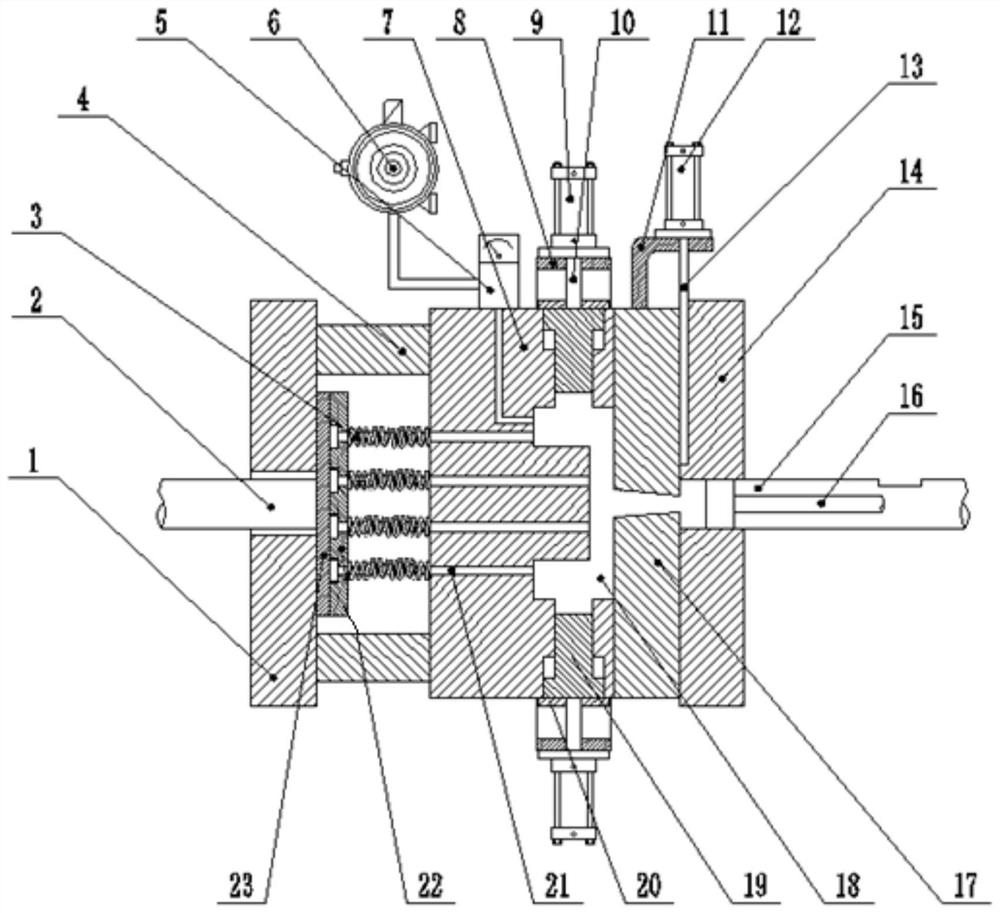

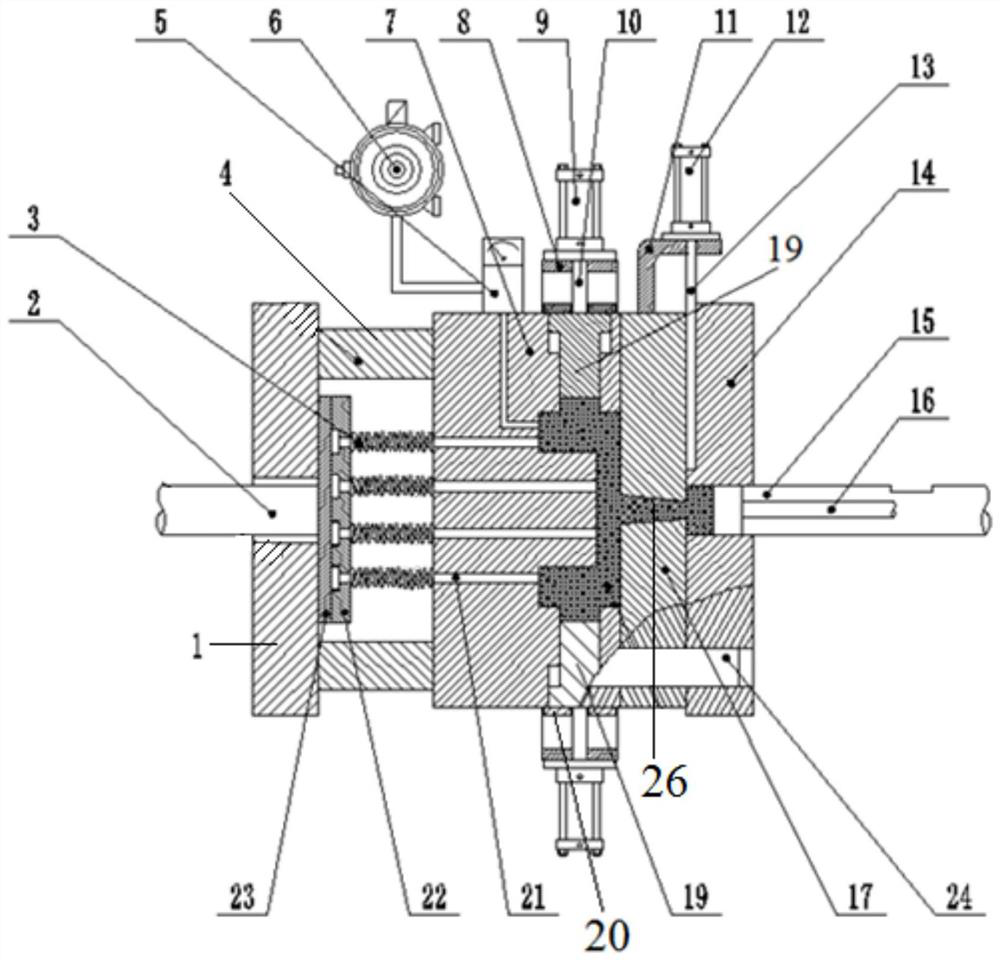

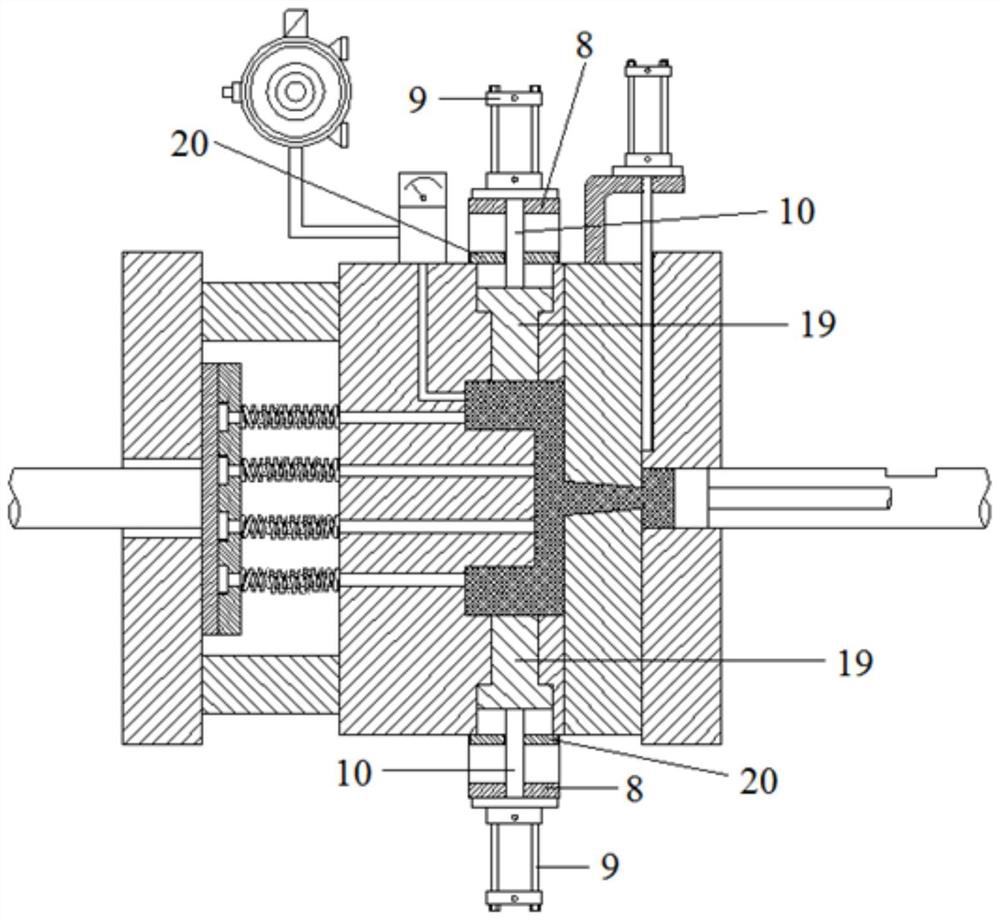

Light alloy vacuum high-pressure casting flexible loading casting-forging composite forming device and application method thereof

The invention discloses a light alloy vacuum high-pressure casting flexible loading casting-forging composite forming device and an application method thereof, and relates to a light alloy vacuum casting-forging composite forming device and an application method thereof. The invention aims to solve the technical problem that casting defects at a thick wall are difficult to regulate and control in the current alloy vacuum die-casting technology. According to the device, a vacuum pump is used for pumping out gas in a cavity before aluminum alloy or magnesium alloy melt enters the cavity of a die, so that gas residues in the cavity are greatly reduced, the gas entrapment degree of a die casting is obviously lowered, and the effect of improving the mechanical properties and compactness of the die casting is obvious; and a flexible loading system which is composed of a flexible loading hydraulic cylinder, a flexible loading dowel bar, a flexible loading limiting plate and a flexible loading block and mounted on a movable die is adopted to conduct local loading and forced feeding on the liquid-solid aluminum alloy or magnesium alloy melt, so that the casting defects at the thick wall are obviously reduced, which is beneficial for improving the compactness and macroscopic mechanical properties of the casting.

Owner:HARBIN INST OF TECH

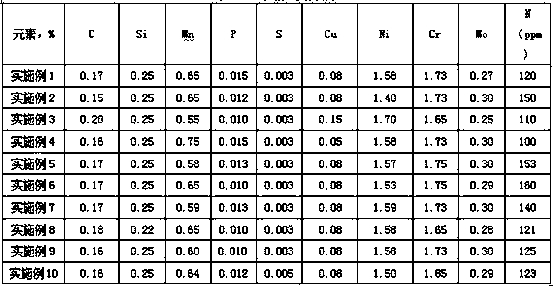

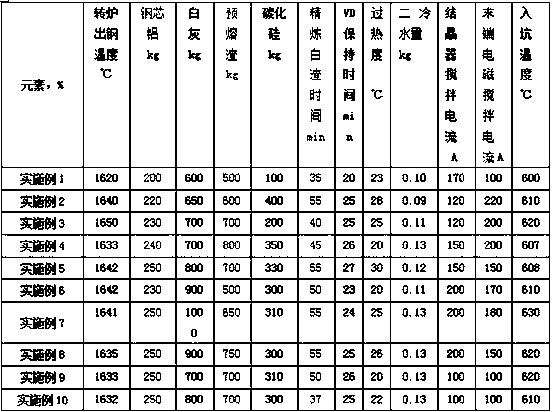

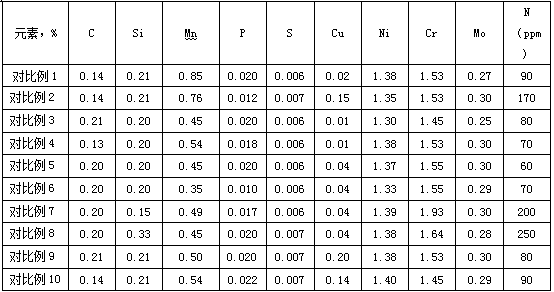

Narrow-hardenability industrial gear steel and production method thereof

The invention relates to narrow-hardenability industrial gear steel. A steel plate comprises the following chemical components of, by weight percentage, 0.15% to 0.19% of C, 0.22%-0.30% of Si, 0.55%-0.75% of Mn, 1.65%-1.85% of Cr, 0.25%-0.35% of Mo, 1.40%-1.70% of Ni, S<=0.005%, P<=0.015%, 0.05%-0.15% of Cu, 100-160 ppm of N, the balance being Fe and unavoidable impurities. The invention further relates to a production method of the high-end narrow-hardenability industrial gear steel. The production method comprises the steps of converter tapping, refining, VD high vacuum, casting and continuous casting. The narrow-hardenability industrial gear steel and the production method meet city rail and high-speed rail speed reducer gear steel end quenching performance requirements.

Owner:石钢京诚装备技术有限公司

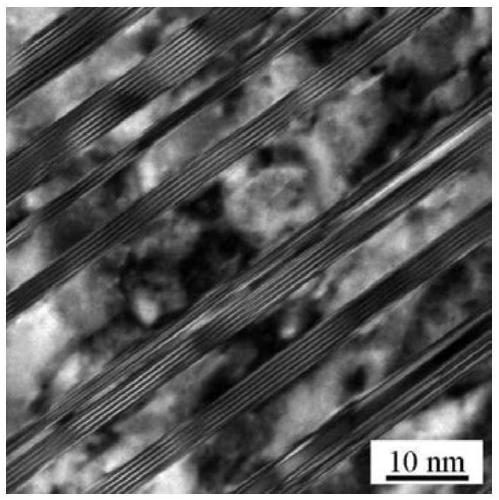

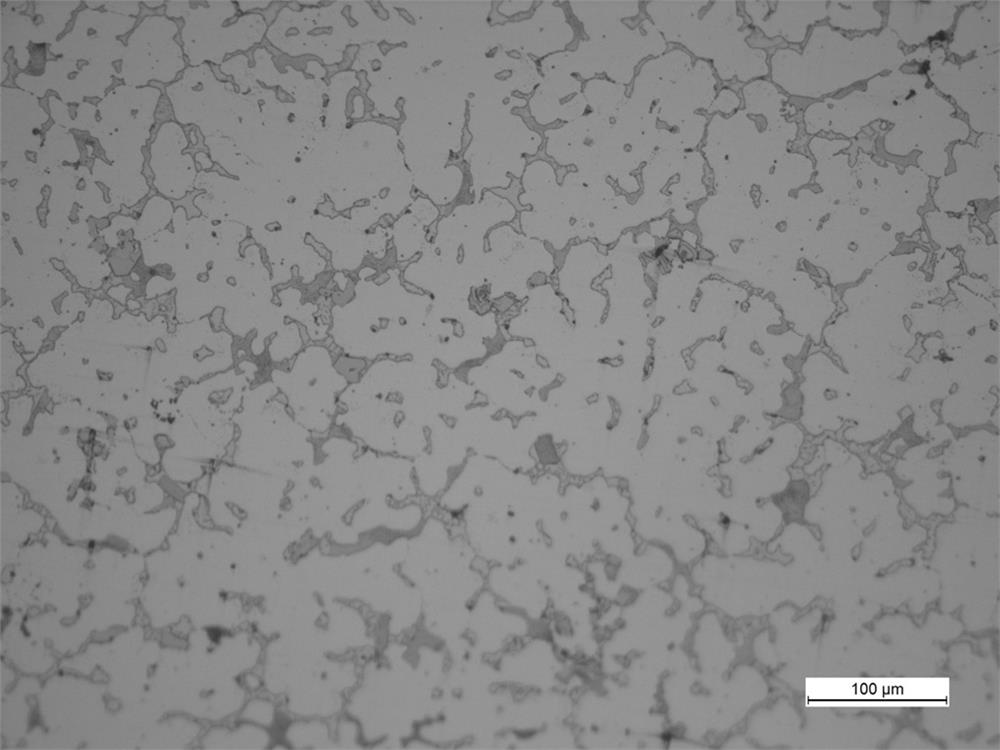

Co-Cr-Mo-N alloy and preparation method thereof

The invention relates to the field of material processing and discloses a preparation method of Co-Cr-Mo-N alloy. The preparation method comprises the steps of vacuum melting - vacuum casting - heat treatment - rolling - cutting. The Co-Cr-Mo-N alloy is vacuum melted and cast, heated to the temperature of 1,150-1,350 DEG C and rolled into a star shape, wherein the single rolling amount is 10%-18%,and the finish-rolling diameter is 8-10mm. According to the preparation method, a rolling method is used for processing the Co-Cr-Mo-N alloy to form a slender rod, the processing technology is simple, processing efficiency is effectively improved, a product is fine in structure, a bulky phase is crushed, density is improved, and the mechanical properties of the material are improved.

Owner:江苏应用元素科技有限公司

Low-temperature lead-free solder alloy and vacuum casting method thereof

ActiveCN109926750APrevent infiltrationNo penetrationWelding/cutting media/materialsSoldering mediaSmelting processMechanical property

The invention discloses a low-temperature lead-free solder alloy which is characterized by being prepared from the following components in percent by mass: 8-15% of Zn, 5-12% of Bi, 4-10% of In, 0.1-1.5% of Ag, 0.05-1% of Mg, 0.01-2% of M and the balance Sn and inevitable impurities, wherein the mass percent of Sn is not smaller than 58.5%, and M is RE or at least one of V, Zr, Ga and Ge. The Sn-based low-temperature alloy solder provided by the invention has excellent wettability and good mechanical properties, and the reliability of welding spots is enhanced. Meanwhile, by smelting the components in a vacuum condition, influence of oxidative burning loss and oxidizing slag in the smelting process of metals to reliability of the welding spots can be avoided. The low-temperature lead-freesolder alloy can be applied to welding electronic parts and components with the not high heating temperature, so that the demand on light and thin development of electronic products is met.

Owner:云南锡业集团(控股)有限责任公司研发中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com