Low-temperature lead-free solder alloy and vacuum casting method thereof

A lead-free solder alloy, vacuum casting technology, used in welding/cutting media/materials, welding media, manufacturing tools, etc., can solve the problems of lead and its compounds being toxic, health damage, etc., and achieve good wettability and anti-oxidation. properties, improved oxidation resistance, and high yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

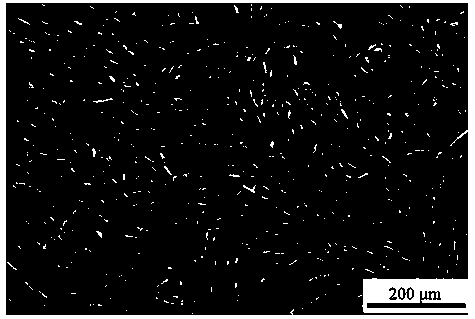

Image

Examples

Embodiment 1

[0021] Example 1: The composition and mass percentage of this high-reliability low-temperature lead-free solder alloy are: Zn 11%, Bi8.5%, In 7%, Ag 0.8%, Mg 0.5%, V 0.3%, Zr 0.3%, Ga 0.3%, Ge 0.3%, the balance is Sn and inevitable impurities.

[0022] The preparation method is (1) industrial pure tin (Sn: 99.95wt%), industrial pure bismuth (Bi: 99.95wt%), industrial pure zinc (Zn: 99.9wt%) and indium, silver, magnesium, vanadium, zirconium , Gallium and germanium metals were polished with 320 grit sandpaper to remove the oxide layer, and put them in a blast drying oven (40℃) for drying and preheating; (2) using graphite crucible for alloy casting, before using crucible and slagging tools The surface of the bell jar, etc. is cleaned to remove impurities, and then placed in an oven at 40℃ to remove moisture before use. The temperature of the vacuum melting furnace is increased to 250℃, and the pure tin, which accounts for 30% of the total mass of pure tin, is placed at 245℃. Afte...

Embodiment 2

[0025] Example 2: The composition and mass percentage of the high-reliability lead-free solder alloy are: Zn 8%, Bi 5%, In4%, Ag 0.1%, Mg 0.05%, V 0.01%, and the balance is Sn and unavoidable 的impurities.

[0026] The preparation method is (1) industrial pure tin (Sn: 99.95wt%), industrial pure bismuth (Bi: 99.95wt%) and industrial pure zinc (Zn: 99.9wt%), and indium, silver, magnesium, vanadium metal Grind and remove the oxide layer with 320 grit sandpaper, respectively, and put them in a blast drying box (40℃) for drying and preheating; (2) Use graphite crucible for alloy casting, use the front crucible, slagging tool, bell jar and other surfaces Clean and remove impurities, and then put it in a 40℃ oven to bake to remove moisture before use. The vacuum melting furnace temperature gradient is raised to 250℃, and 20% of the total mass of pure tin is melted into a molten pool at 240℃ , Add the remaining pure tin; after the pure tin is completely melted, heat up to 270°C; (3) Add ...

Embodiment 3

[0029] Embodiment 3: The composition and mass percentage of the high-reliability lead-free solder alloy are: Zn 15%, Bi 12%, In10%, Ag 1.5%, Mg 1%, V 0.5%, Zr 0.5%, Ga 0.5% , Ge 0.5%, the balance is Sn and unavoidable impurities.

[0030] The preparation method is (1) industrial pure tin (Sn: 99.95wt%), industrial pure bismuth (Bi: 99.95wt%) and industrial pure zinc (Zn: 99.9wt%), as well as indium, silver, magnesium, vanadium, The zirconium, gallium, and germanium metals were polished with 320 grit sandpaper to remove the oxide layer, and placed in a blast drying oven (40°C) for drying and preheating; (2) Using graphite crucible for alloy casting, crucible and slag removal before use The surface of tools, bell jars, etc. are cleaned to remove impurities, and then placed in an oven at 40℃ to remove moisture before use. The temperature gradient of the vacuum melting furnace is raised to 250℃, and 40% of the total mass of pure tin is put at 250℃. After melting into a molten pool, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com