Patents

Literature

221results about How to "Improve strong plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

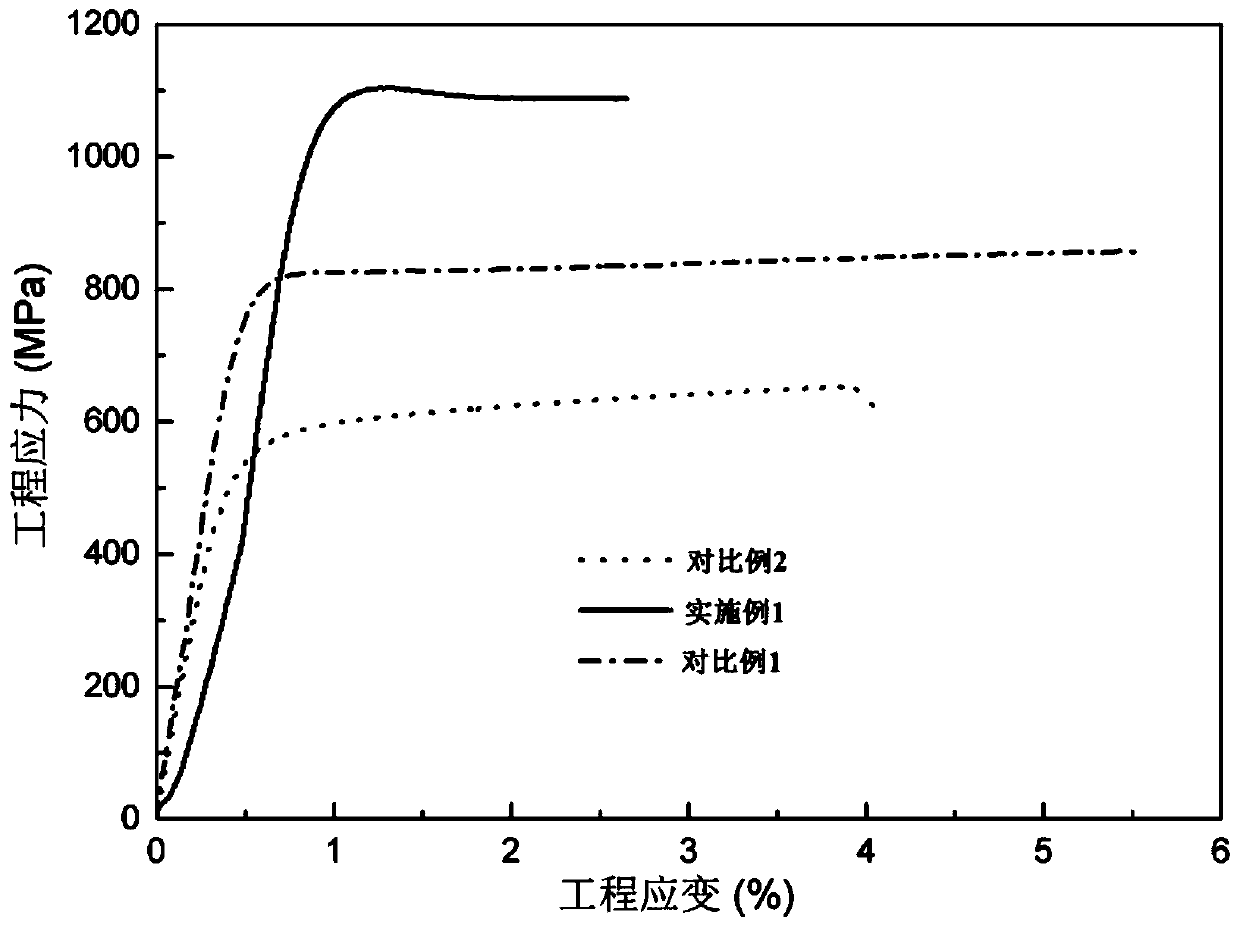

Steel plate for hot stamping, hot stamping process and hot-stamped member

ActiveCN104846274ALow austenitizing temperatureQuenching temperature is lowShaping toolsFurnace typesHot stampingMartensite transformation

The invention relates to a steel plate for hot stamping, a hot stamping process and a hot-stamped member. The steel plate for hot stamping is characterized by comprising, by weight, 0.18 to 0.42% of C, 4 to 8.5% of Mn and 0.8 to 3.0% of Si and Al, with the balance being Fe and avoidable impurities, wherein the alloy component of the steel plate satisfy the condition that the actual measured value of martensite phase transformation beginning temperature is no more than 280 DEG C. A manufacturing method for the hot-stamped member comprises the following steps: heating a material to 700 to 850 DEG C and carrying out stamping; then carrying out cooling in a die or air cooling or cooling in other manners to 150 to 260 DEG C below the martensite phase transformation beginning temperature; and heating the stamped member to 160 to 450 DEG C, maintaining the temperature for 1 to 100,000 s, carrying out tempering heat treatment and cooling the stamped member to room temperature. The hot-stamped member prepared in the invention has yield strength of no less than 1200 MPa, tensile strength of no less than 1600 MPa and total elongation percentage of no less than 10%.

Owner:EASYFORMING STEEL TECH CO LTD

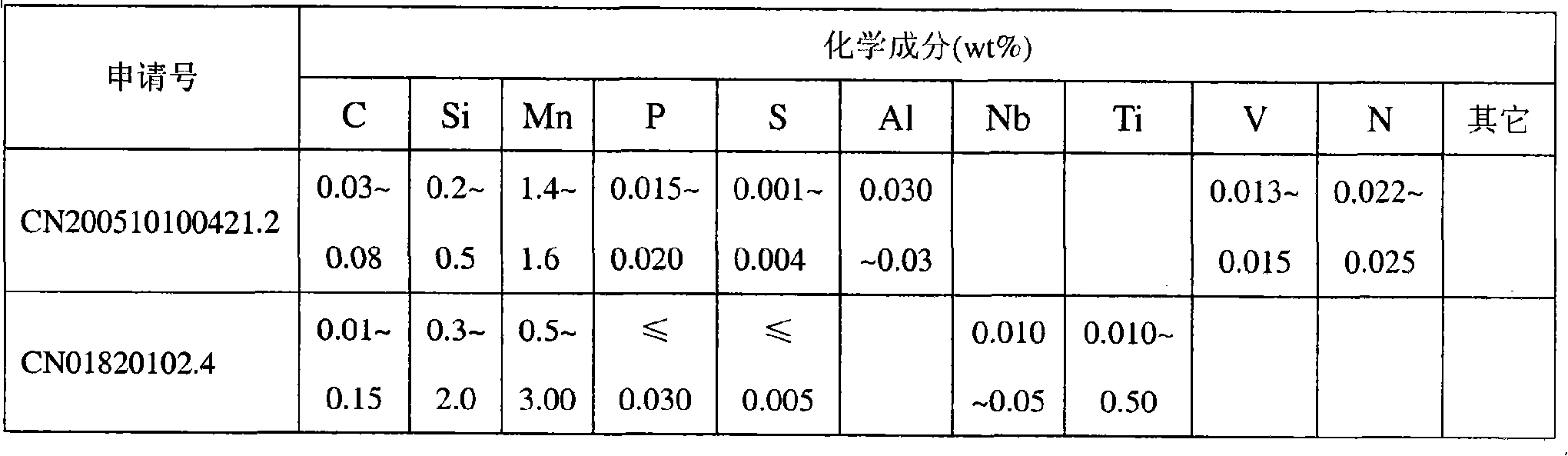

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

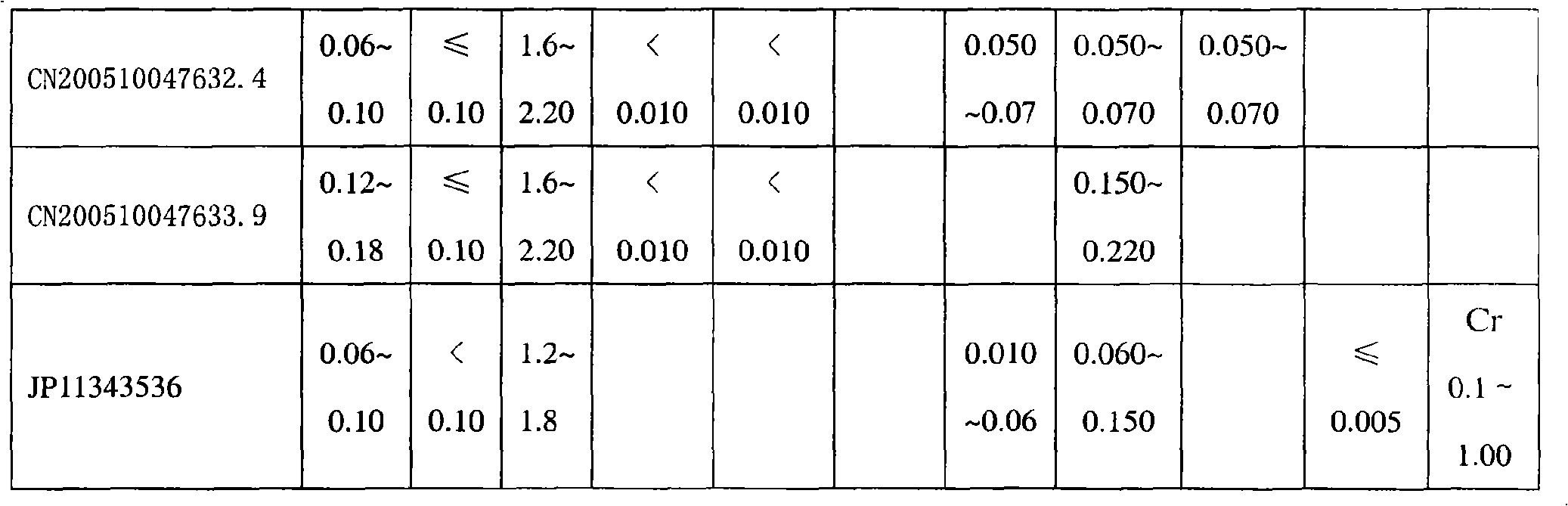

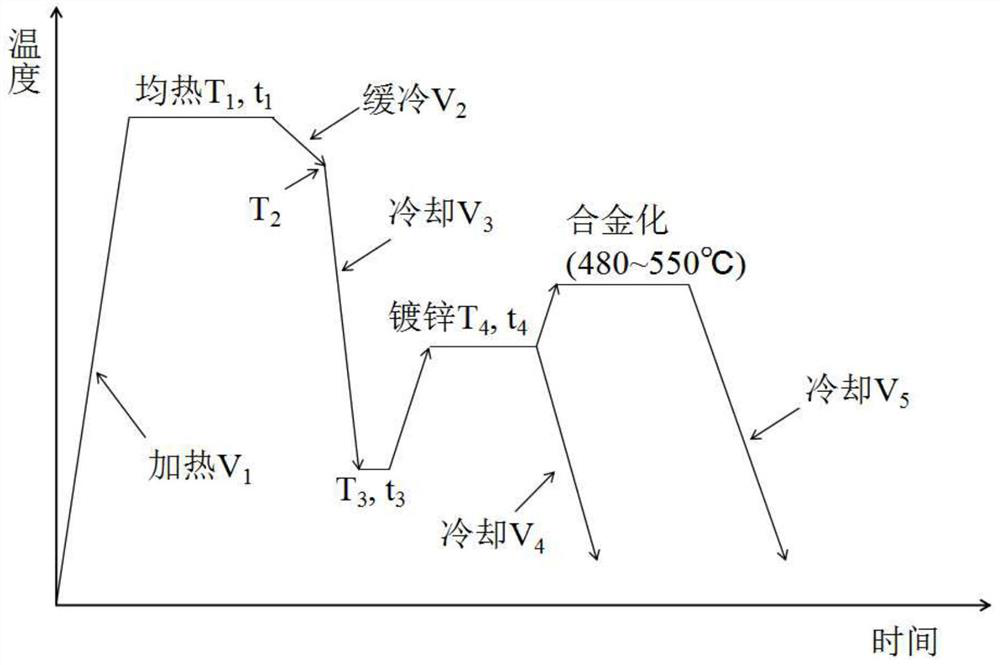

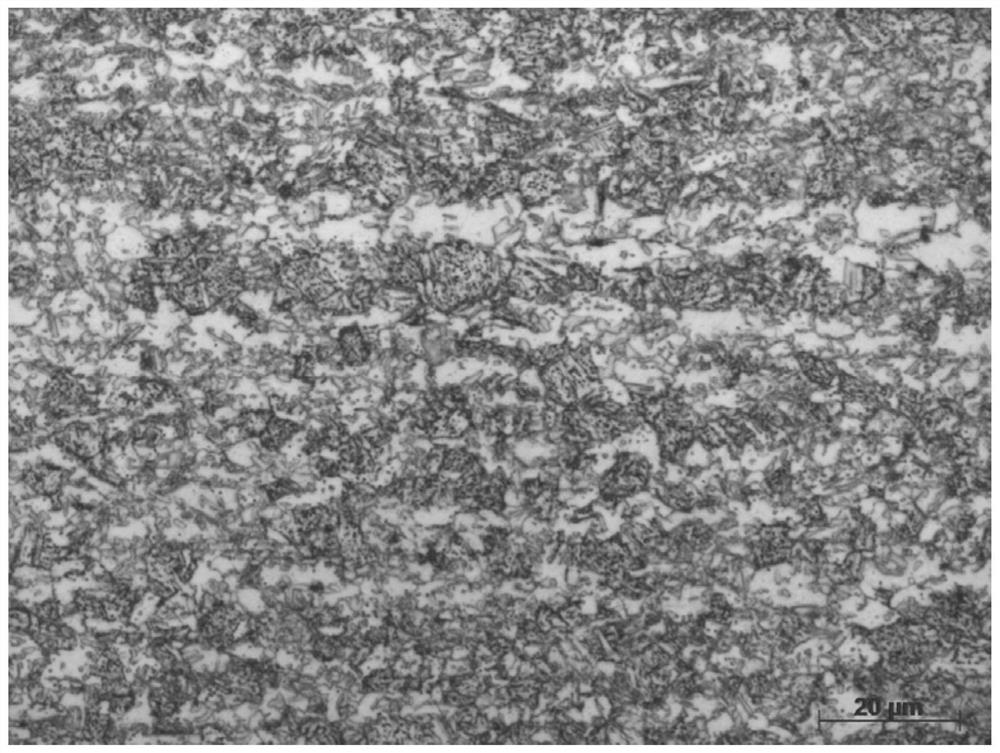

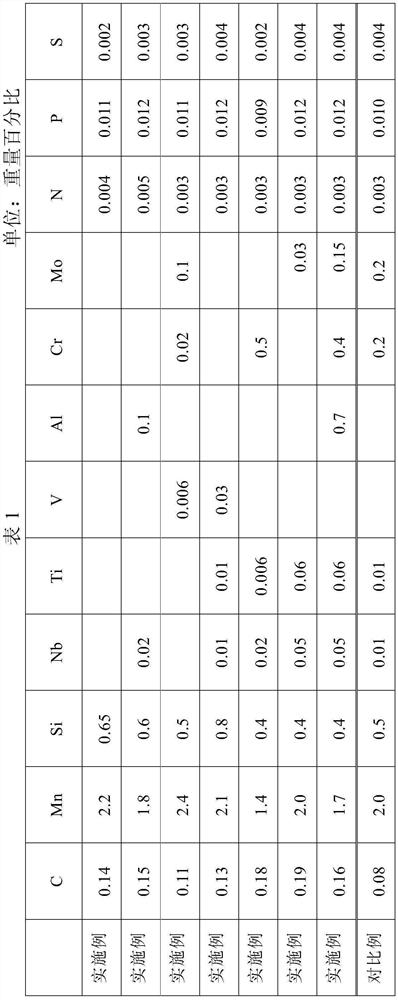

780MPa stage cold rolled hot galvanizing dual-phase steel with higher forming property and manufacturing method thereof

The invention discloses 780MPa stage cold rolled hot galvanizing dual-phase steel with a higher forming property and a manufacturing method thereof. The steel comprises chemical components including,by mass percent, 0.1 to 0.2% of C, 1.3 to 2.5% of Mn, 0.4 to 1.0% of Si, not larger than 0.02% of P, not larger than 0.01% of S, not larger than 0.008% of N and the balance Fe and inevitable impurities. After conventional smelting, hot rolling and cold acid continuous rolling, through a QP process, hot dip galvanizing recrystallization annealing is carried out, a final tissue of a galvanized sheetmainly comprises ferrite, tempered martensite and residual austenite, the tensile strength is larger than or equal to 780 MPa, the percentage elongation is larger than or equal to 18%, n10 to 20% islarger than or equal to 0.14, the hole expansion rate lambda is larger than or equal to 25%, through control over the cold rate, the galvanized sheet reduces use of alloy elements, and the needs of reducing the alloy cost and improving the hot galvanizing dual-phase steel forming property can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength high-toughness low temperature steel for ship and manufacture method thereof

ActiveCN102851591AAchieve sex changeImprove purityRoll mill control devicesProcess efficiency improvementCrack resistanceHeat-affected zone

The invention discloses high-strength high-toughness low temperature steel for ship and manufacture method thereof. The steel is composed of (by wt%) C 0.04-0.12, Si 0.20-0.55, Mn 0.8-1.4, P 0.005-0.015, S less than or equal to 0.005, Als 0.02-0.07, N less than or equal to 0.005, Cu 0.05-0.40, Ni 0.05-0.50, and Fe and unavoidable impurity in balance, with Ni / Cu of 1.2-1.5; and one or more than two of Nb 0.005-0.03, Ti 0.005-0.02, Ca 0.001-0.006, and Mg 0.0005-0.002. The steel has advantages of low compression ratio, high strength, good low temperature impact energy, good texture uniformity, and good elongation, to ensure low hardenability and cold crack resistance of repair welding heat-affected zone even if under polar climate condition.

Owner:ANGANG STEEL CO LTD

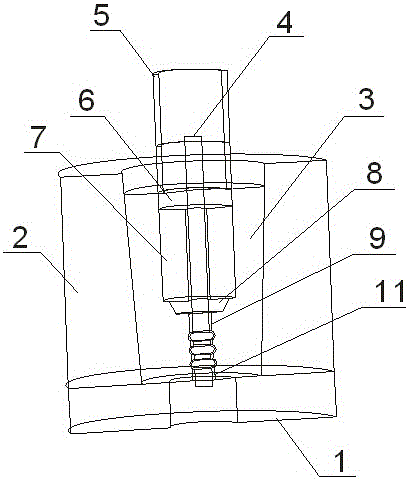

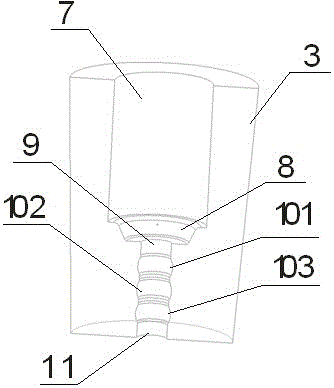

Expanding metal material and bulged tube device for petroleum oil well

ActiveCN1594631AImprove strong plasticitySmooth expansion deformationFluid removalPipe elementsInternal pressureWell drilling

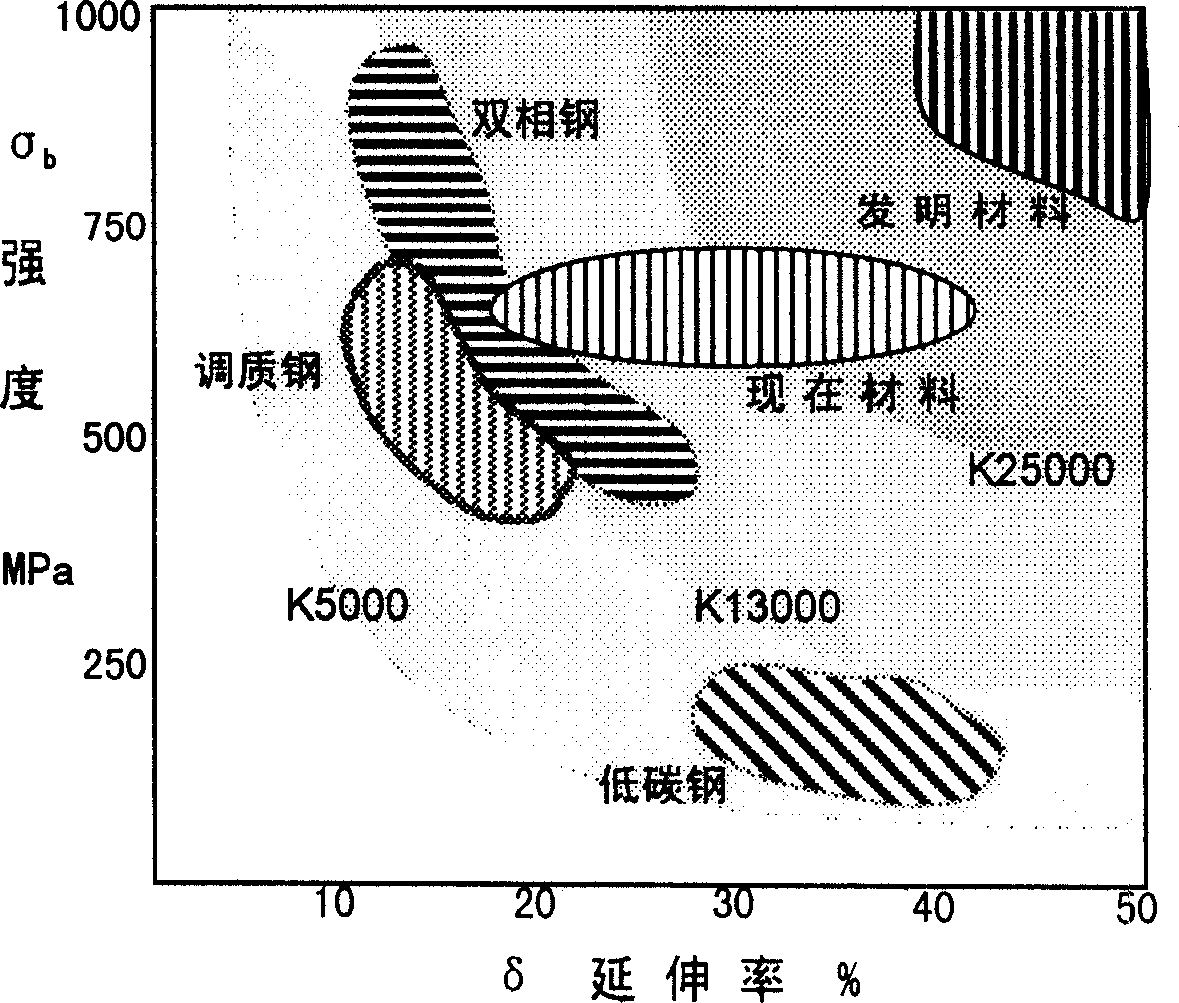

The invention relates to an expanding metal material and expansion tube device for oil well. Expanding metal material consists of :C:0.03-0.5; Si:0-6.0; Mn:0-15; Cr:0-20; Ni:0-20; N:0.02-0.08; P<=0.03; S<=0.03; mixed rare earth:0.1; Ti:0-0.8; Zr:0-1.47; surplus Fe in which carbide gross of TiC and ZrC is 0.1-1.5%. Plasticity K=sigma*delta, amount to 3800MPa%,expansion tube shape memory connector can keep good sealing state after enlarging the diameter, and internal pressure resistance of expansion tube is close to 50Mpa. Warhead piston , centralizer and hydraulic anchor fixing machine all have a simple structure, operate stably, be used easily. The invention has significance in well drilling, well completion and mending well segment, so does other duct mending.

Owner:SHANGHAI GLOBE PETRO EQUIP

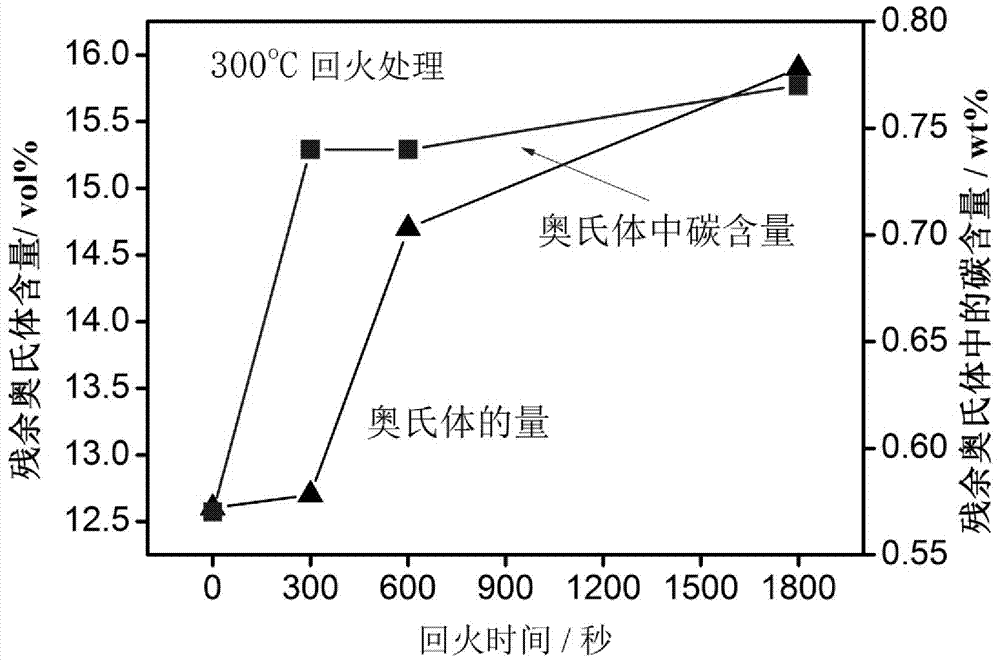

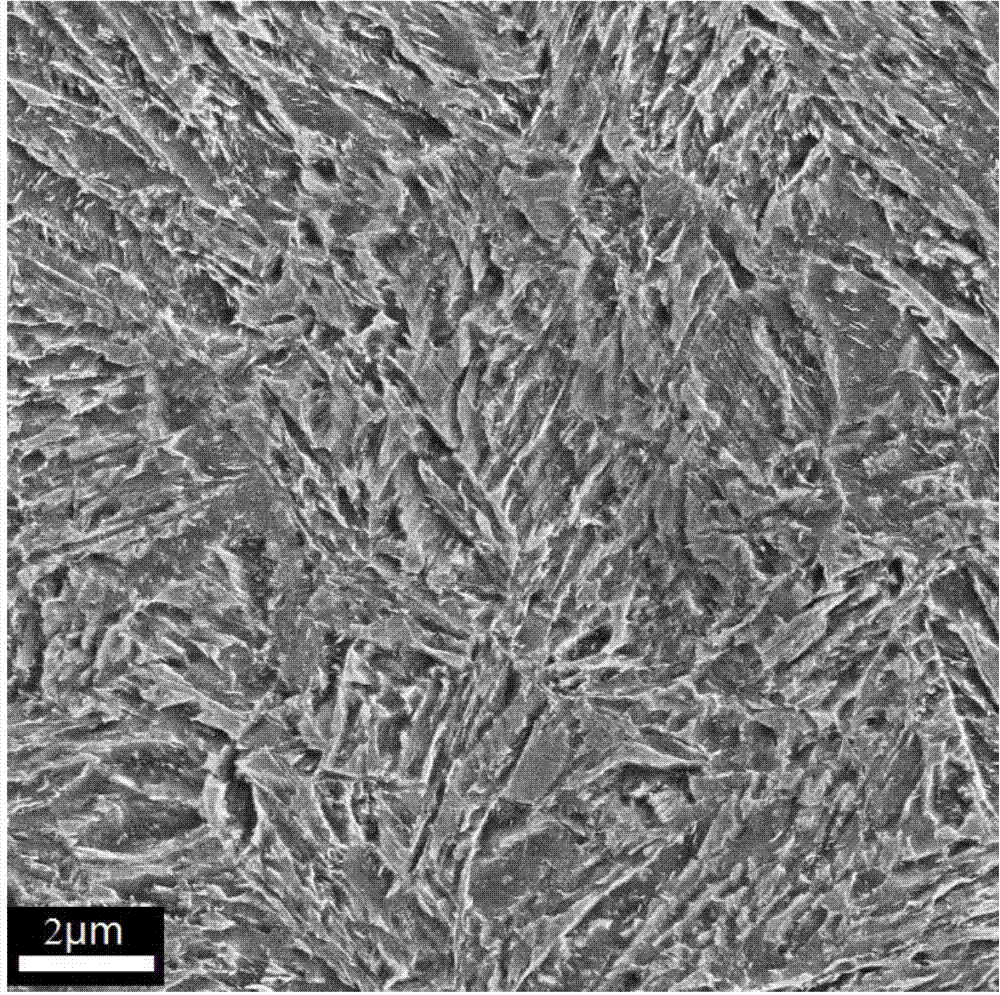

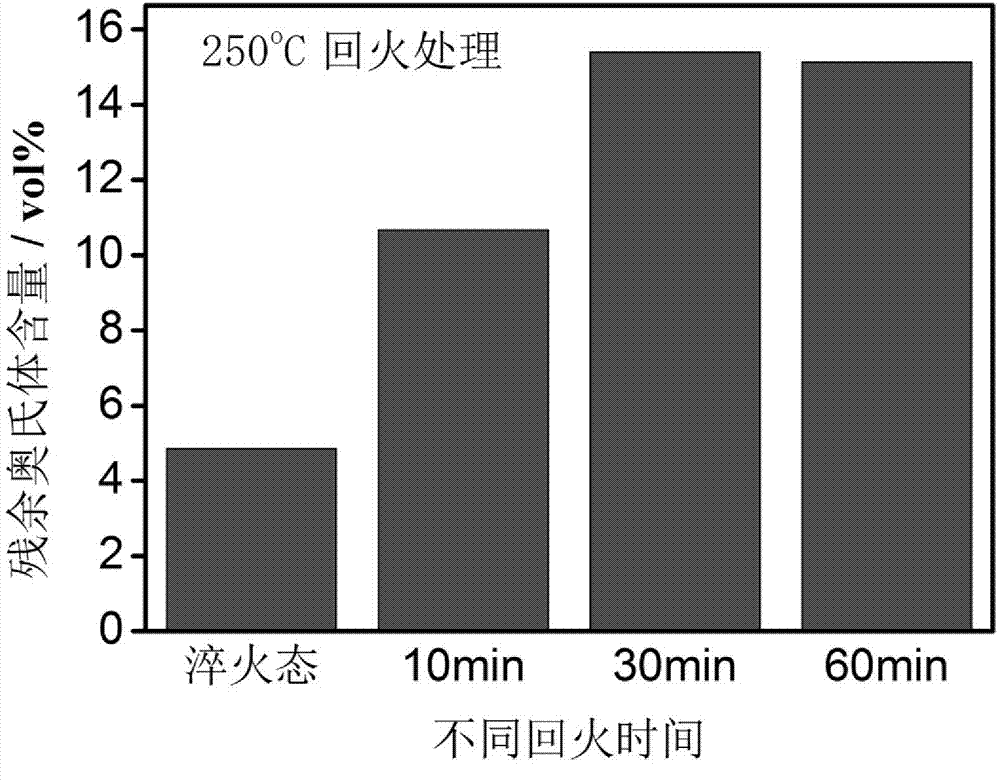

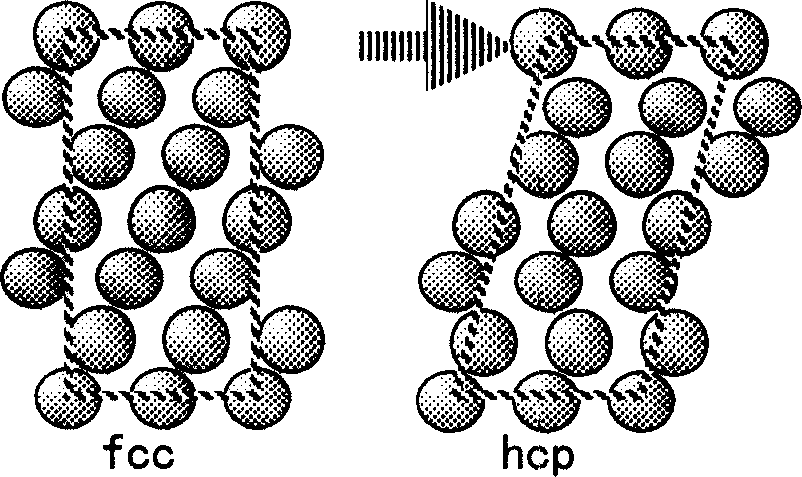

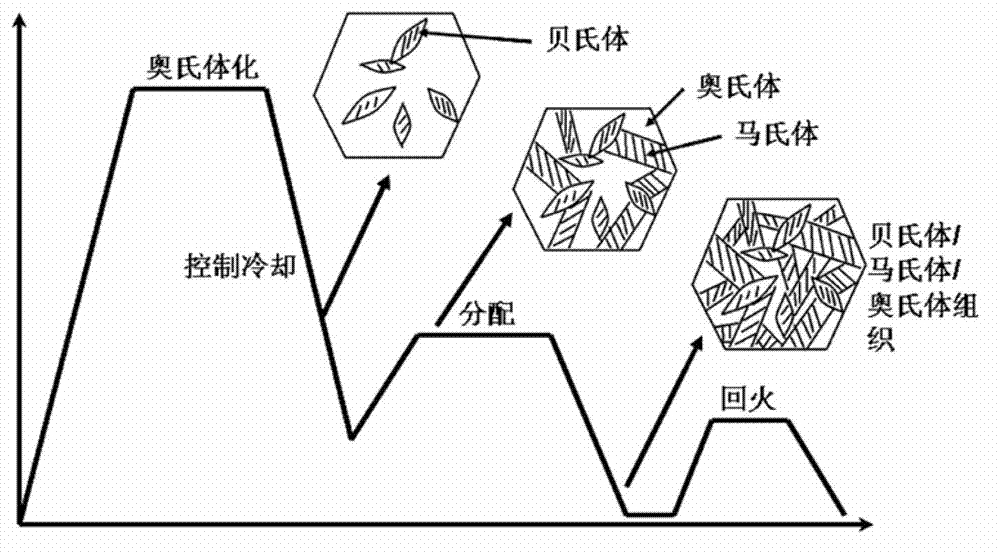

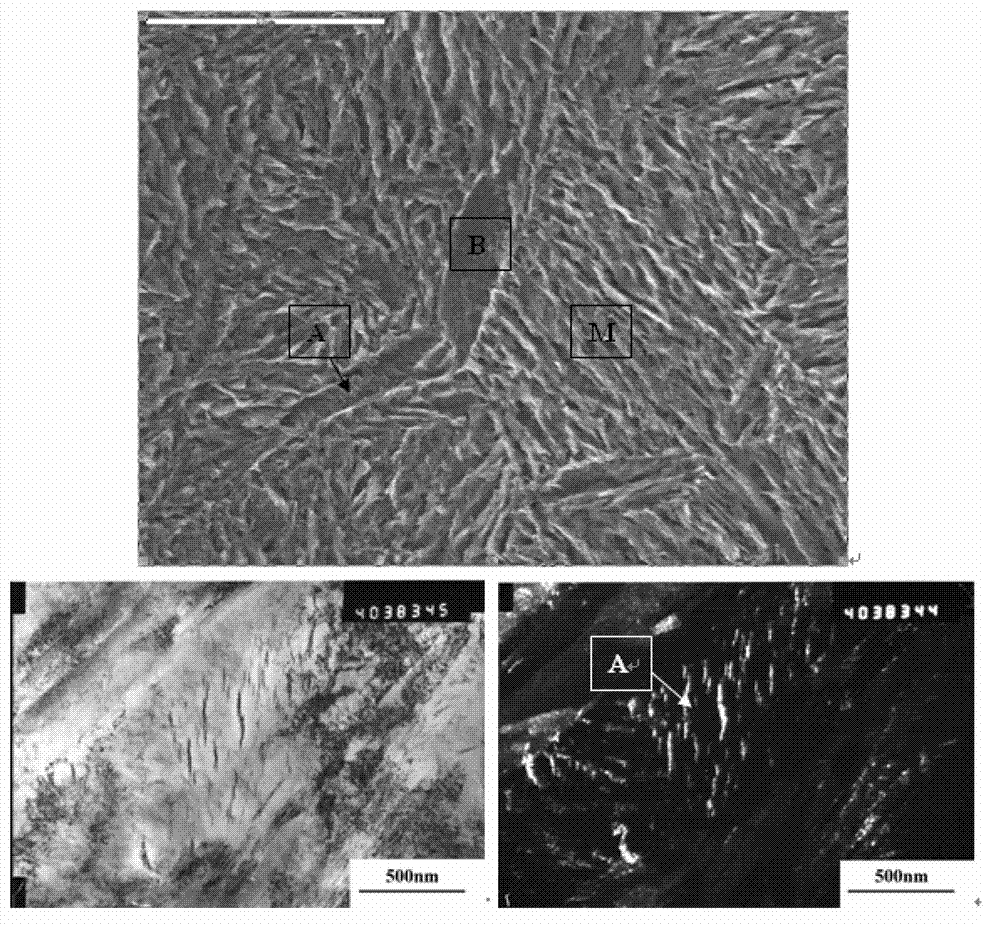

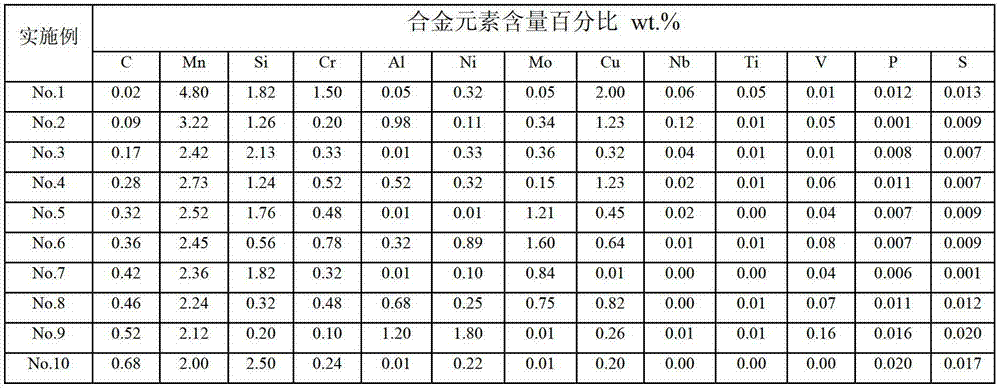

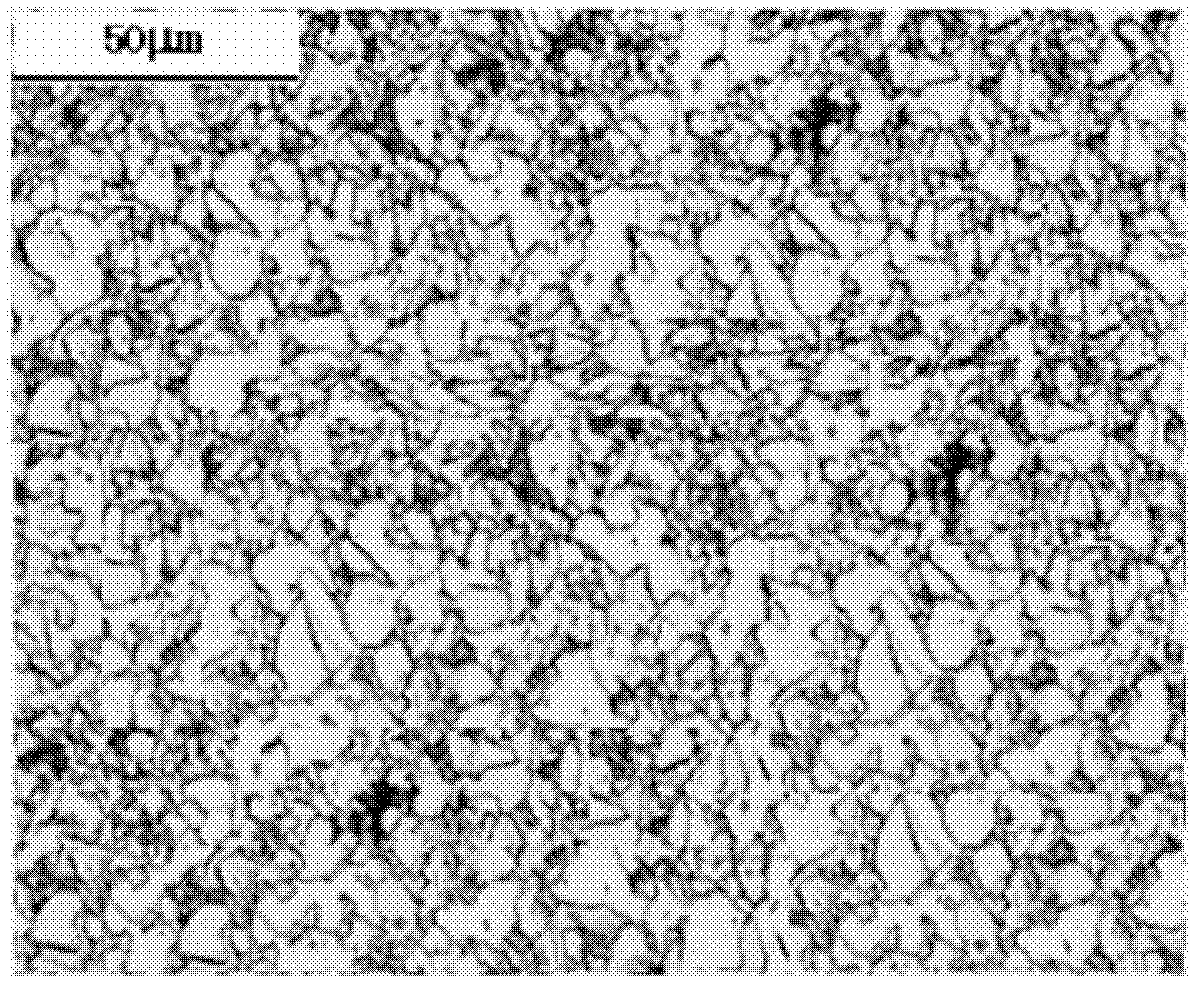

Preparation method of bainite/martensite/austenite composite high-strength steel

InactiveCN103243275AImprove stabilityOvercome the disadvantage of high costHeat treatment process controlSmelting processThick wall

The invention discloses a preparation method of bainite / martensite / austenite composite high-strength steel, belonging to the field of low-alloy high-strength steel. According to the composite high-strength steel, C, Mn, Si and Cr are used as main alloy elements, Al, Ni, Mo, Cu, Nb, Ti, V and the like are added, and the balance is Fe. The preparation method comprises the following steps: smelting, casting, forging or rolling to prepare rails, thick-wall pipes, large-section bars or thick pipes and the like by adopting a conventional steel-smelting process; carrying out austenitizing; controlling cooling by adopting different cooling media to obtain a part of bainite tissue in the cooling process; instantly carrying out distribution treatment and low-temperature tempering treatment so as to finally obtain a bainite / martensite / austenite composite tissue which is good in strong plasticity and toughness coordination, wherein the distribution time is 30-360 minutes. For a component which is large in size and easy to crack in quenching, the bainite / martensite / austenite composite high-strength steel has wide application prospect.

Owner:BEIJING JIAOTONG UNIV

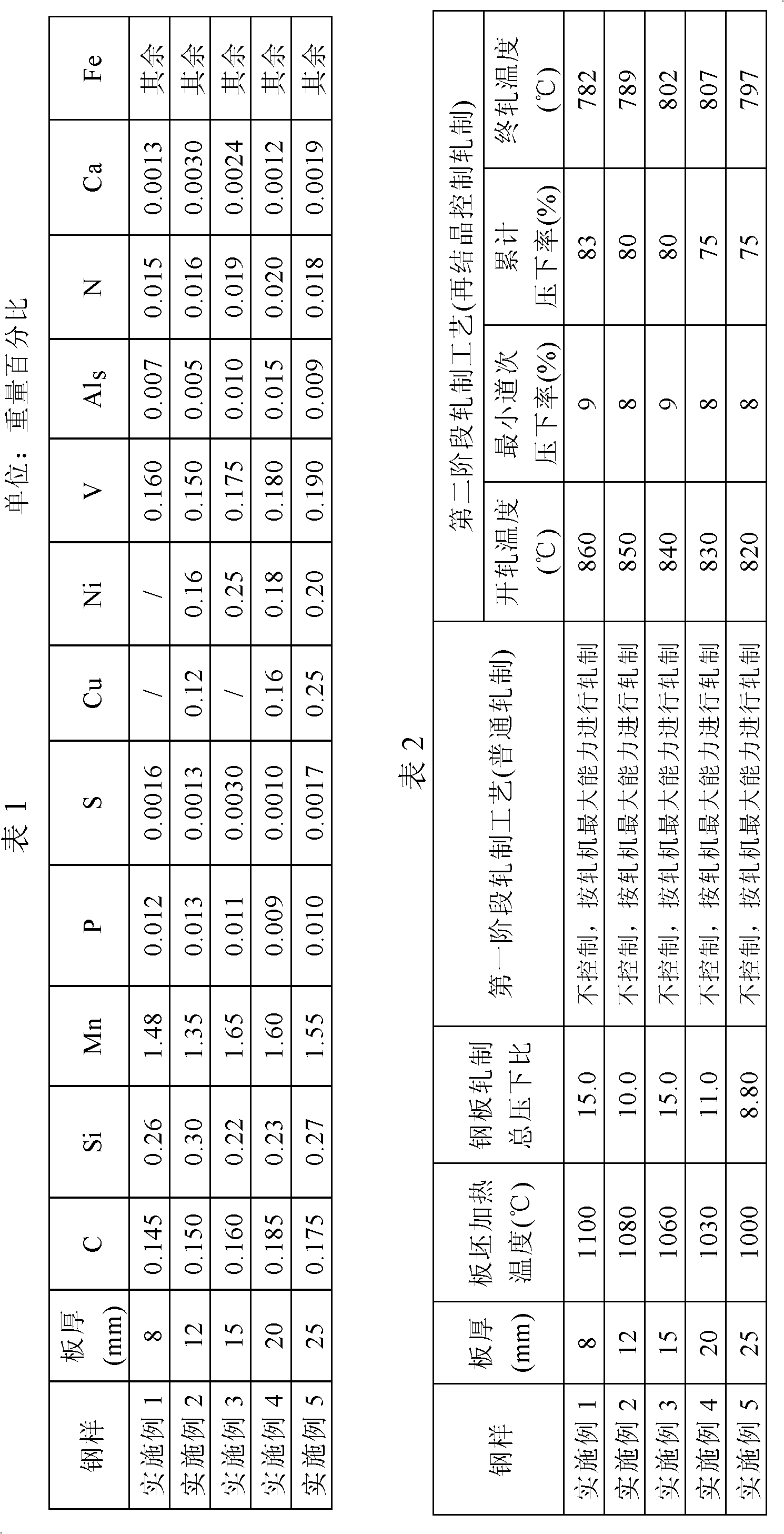

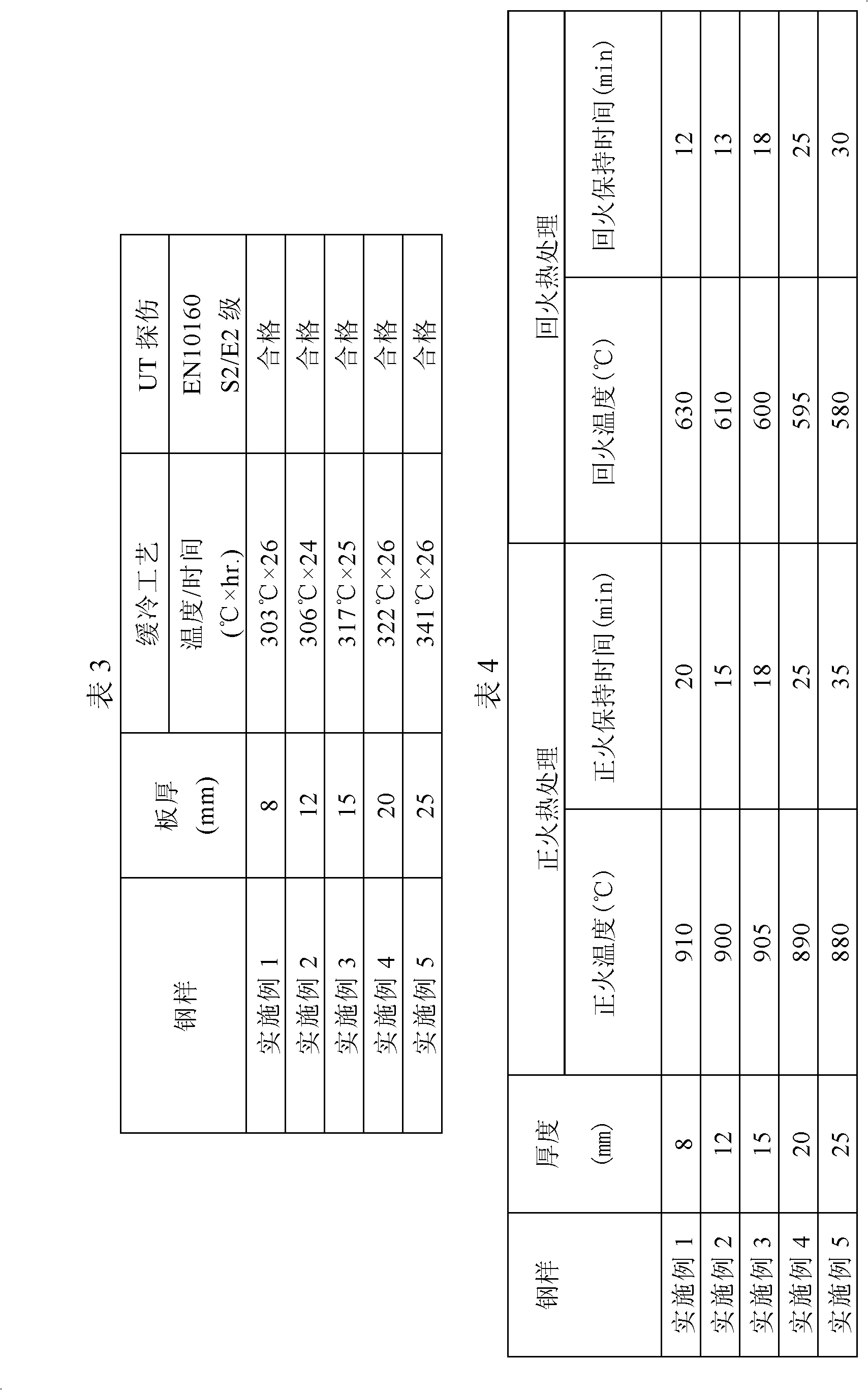

60kg-level low-cost and high-toughness steel plate and production method thereof

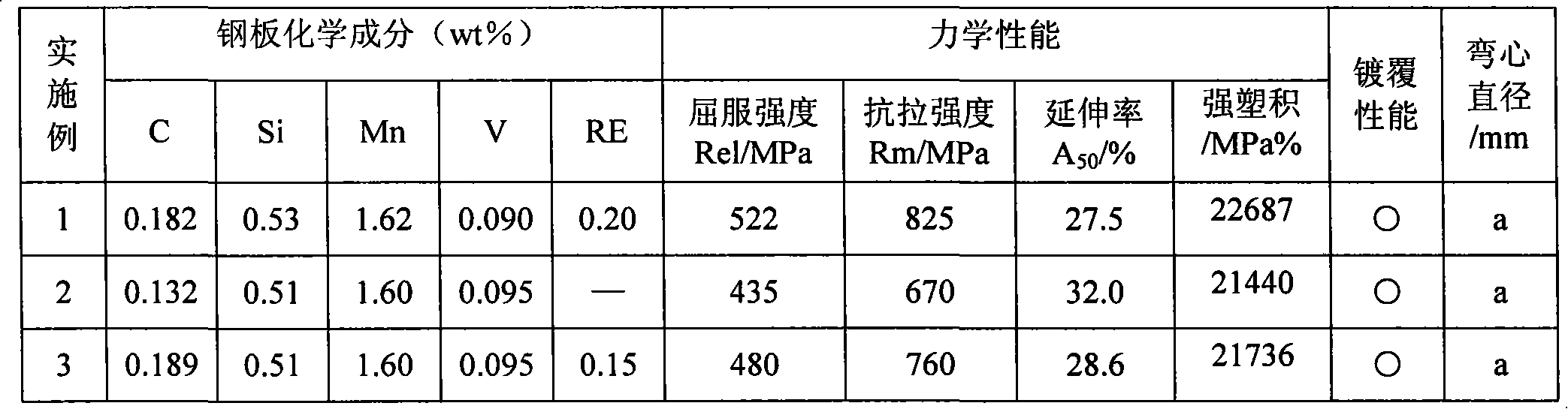

Disclosed are a 60kg-level low-cost and high-toughness steel plate and a production method thereof. The 60kg-level low-cost and high-toughness steel plate comprises, in weight percentage, 0.145%-0.185% of C, not less than 0.30% of Si, 1.35%-1.65% of Mn, not less than 0.013% of P, not less than 0.003% of S, not less than 0.25% of Cu, not less than 0.25% of Ni, 0.005%-0.015% of AlS, 0.150%-0.190% of V, 0.015%-0.020% of N, 0.001%-0.003% of Ca, and the balance of Fe and unavoidable impurities. Based on an alloyed component system of medium C, low Si, high Mn, ultralow AlA and high V with metallurgical technical control, RCR-NT (recrystallization controlled rolling-normalized tempering) processes are optimized, the microstructure of the finished steel plate includes even and small ferrite, pearlite and trace granular bainite, average grain size of the ferrite is smaller than 15 micrometers, even and fine match of high toughness and high plasticity is obtained, and the steel plate has extremely fine low-temperature toughness. The steel plate is especially applicable to large-sized steel structured containers, such as bearing components, petroleum storage tanks, mobile tankers and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

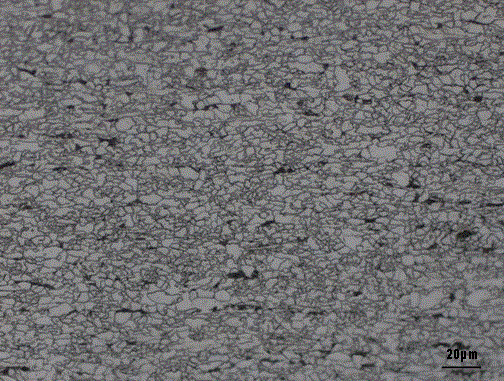

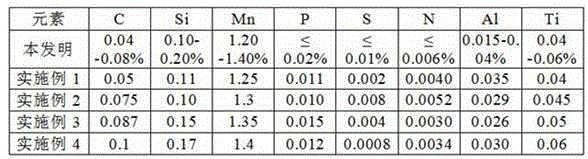

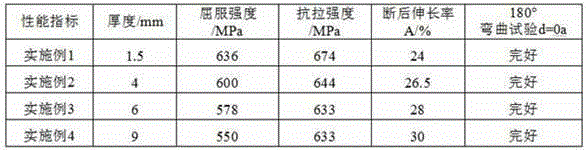

Hot rolled steel plate with yield strength of 450 MPa, and making method of hot rolled steel plate

The invention relates to a hot rolled steel plate with the yield strength of 450 MPa, and a making method of the hot rolled steel plate to solve the technical field of high production cost of present hot rolled steel plates with the yield strength of 450 MPa. The hot rolled steel plate with the yield strength of 450 MPa comprises, by mass, 0.04-0.08% of C, 0.10-0.40% of Si, 1.20-1.50% of Mn, 0.02% or less of P, 0.01% or less of S, 0.0060% or less of N, 0.015-0.040% of Al, 0.04-0.06% of Ti, and the balance of iron and inevitable inclusions, the structure of the steel plate is ferrite and an extremely small amount of pearlite, the yield strength of the hot rolled steel plate is not less than 450 MPa, the tensile strength is not less than 590 MPa, and the elongation after fracture is not less than 20%. The hot rolled steel plate can be used in the fields of engineering machines, automobiles, railways and containers.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

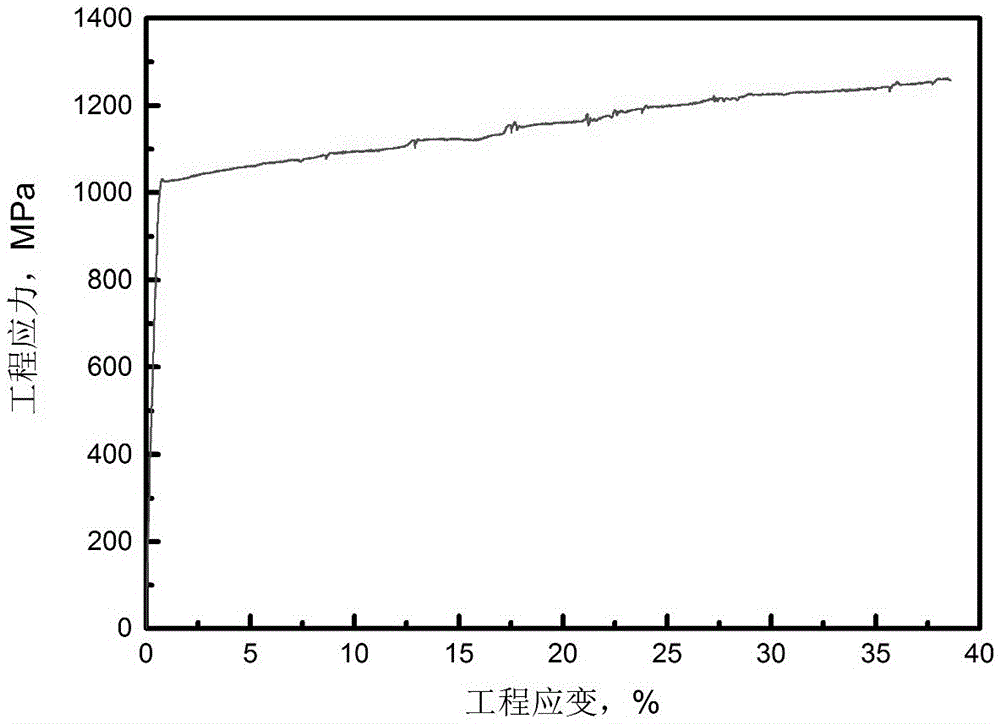

Steel for stamping formation and forming component and heat treatment method thereof

The invention relates to steel for stamping formation. The steel is characterized by comprising the following components in percentage by weight: 0.22-0.48% of C, 5-9.5% of Mn, 0.5-3.0% of Si+Al and the balance of Fe and inevitable impurities, wherein the steel is a hot-rolled, or hot-rolled and acid-washed, or hot-rolled, acid-washed and plated steel coil or steel plate, or is a cold-rolled and annealed or cold-rolled and plated steel coil or steel plate. The invention further relates to a stamping formation process and a stamping formation component based on the steel, which are mainly applied to but not limited in a vehicle structural part. The steel coil or steel plate or the formation component is obtained by heating up to a temperature of 650-780 DEG C and keeping the temperature by 0.5-60 minutes, and contains residual austenite above 30% (calculated by volume fraction). The mechanical performances reach the following conditions: 0.5-1.2 GPa of yield strength, 1.0-1.5 GPa of tensile strength, and strength and ductility production (tensile strength multiplied by ductility) above 25 GPa%. The invention further relates to a forming component and a heat treatment method of the steel.

Owner:EASYFORMING STEEL TECH CO LTD

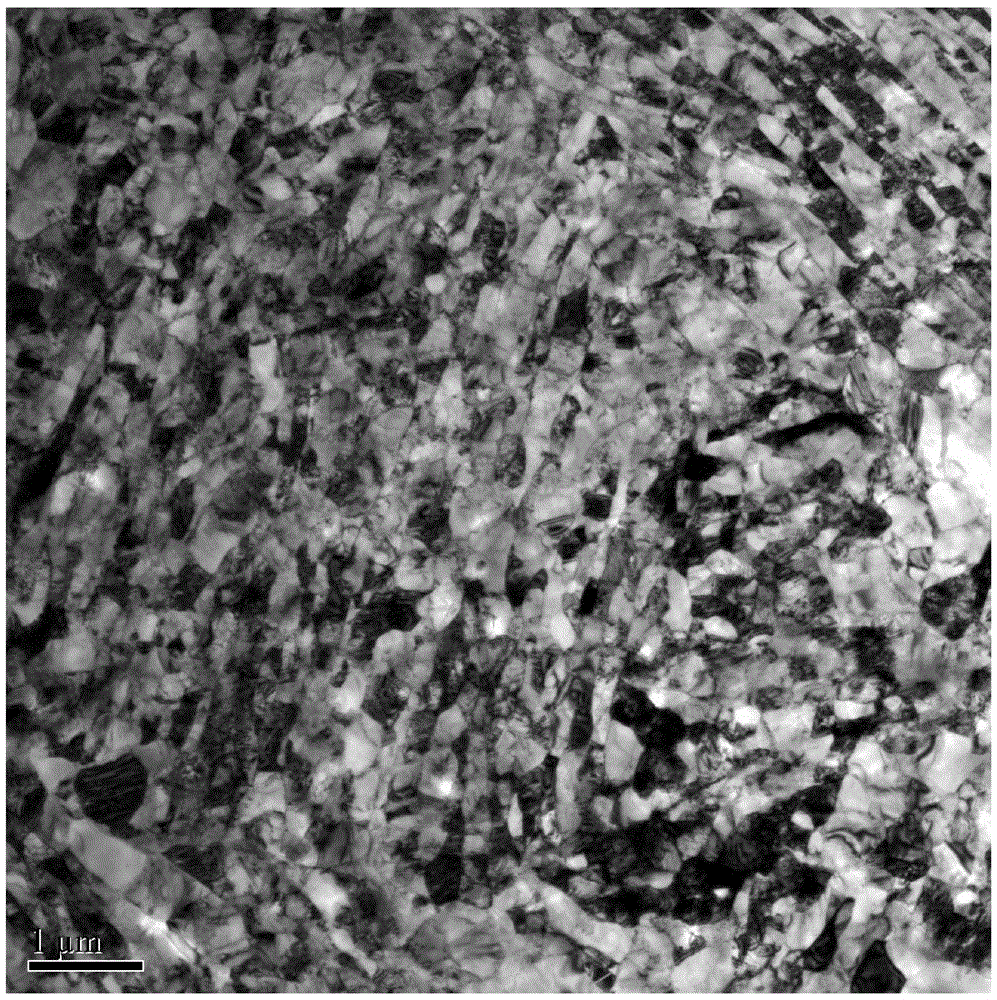

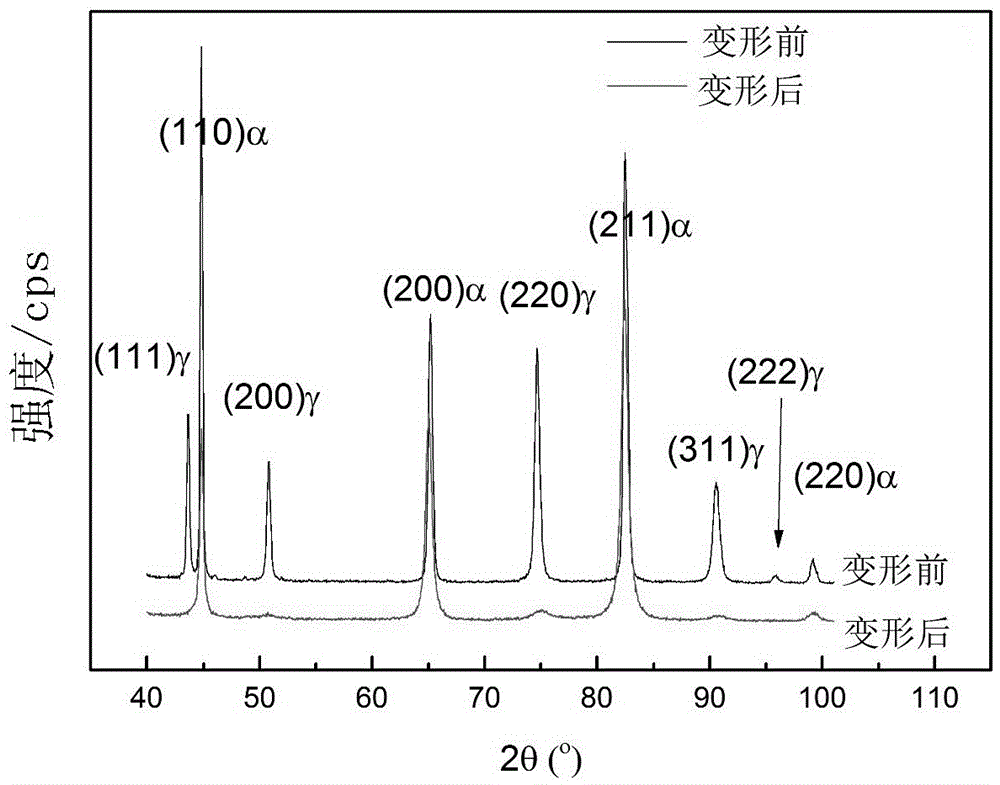

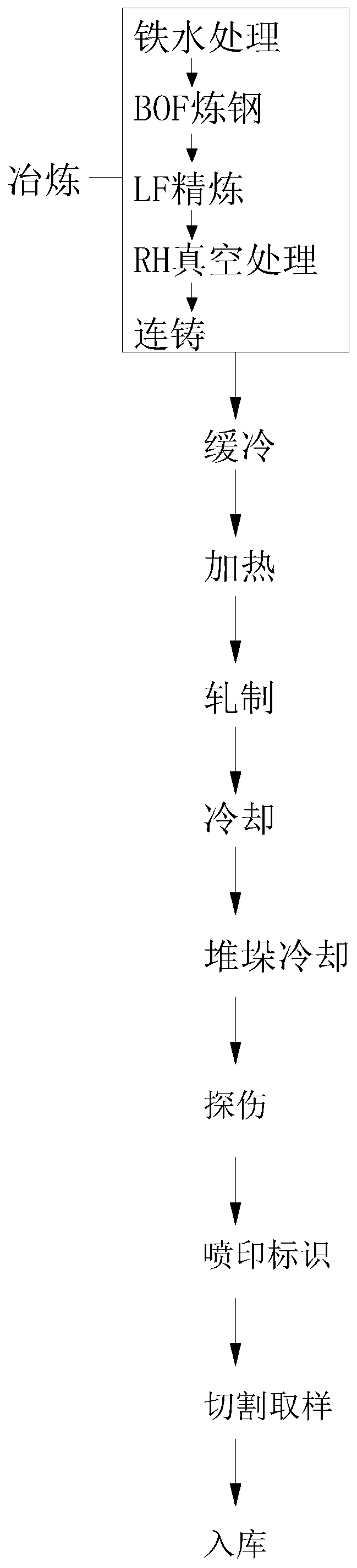

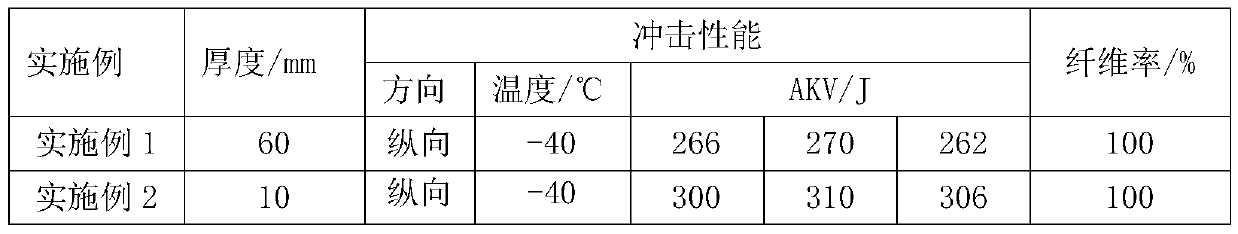

Weather-resistant bridge steel with yield strength not less than 345 MPa and preparation method thereof

The invention relates to weather-resistant bridge steel with yield strength not less than 345 MPa and a preparation method thereof. The weather-resistant bridge steel with the yield strength not lessthan 345 MPa comprises the following components of, in percentage by weight, 0.07%-0.11% of C, 0.15%-0.30% of Si, 0.80-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.01-0.04% of Al, 0.20-0.40% of Cr, 0.20-0.40% of Cu, 0.20-0.50% of Ni, 0.020-0.050% of Nb, 0.010-0.040% of Ti and the balance Fe and inevitable impurities; and the preparation method comprises thefollowing steps of smelting, slow cooling, heating, rolling, cooling and stacking and cooling. According to the weather-resistant bridge steel with the yield strength not less than 345 MPa and the preparation method thereof, the low-cost micro-alloying design is adopted, the production period is short, the cost is low, popularization and application are facilitated, the weather-resistant bridge steel has excellent welding performance, strong toughness and strong plasticity matching performance, low yield ratio, corrosion resistance, weather resistance, welding performance and anti-fatigue performance, compared with traditional weather-resistant steel, the weather resistance is improved by one time or above, the weather-resistant bridge steel can replace the traditional high-strength weathering steel, and can be applied to the fields of bridges, outdoor tower frames and the like without coating, so that the use cost and the maintenance cost are reduced.

Owner:SD STEEL RIZHAO CO LTD

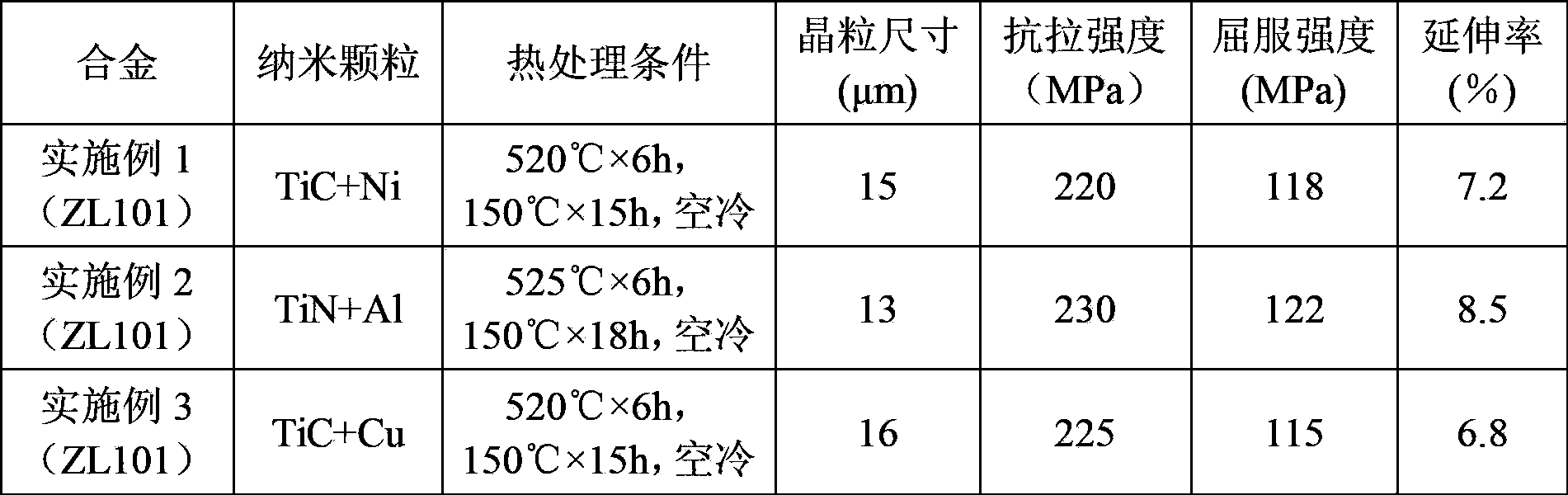

Nanometer refining method of Al-Si system aluminum alloy structure

The invention relates to a nanometer refining method of an Al-Si system aluminum alloy structure. The method is characterized by comprising the steps that TiC or TiN or AlN nano-particles are selected for metal wrapping processing, and after the preprocessed nano-particles are dried, the nano-particles are wrapped by aluminum foil to be used; aluminum alloy is subjected to fusion, temperature is raised to 730 DEG C-740 DEG C, and standing is carried out for 10 min-15 min in a heat-preservation mode; the preprocessed nano-particles are added into an aluminum alloy fusion body, mechanical stirring is carried out for 3 min-10 min, temperature is raised to 730 DEG C-750 DEG C, and standing is carried out for 10 min-20 min in a heat-preservation mode; metal type casting is used, and an aluminum alloy ingot is obtained; and the obtained aluminum alloy ingot is placed in a heat treatment furnace for heat treatment, and finally cooling is carried out to room temperature. The nano-particles are introduced, nucleation rate is improved, crystalline grains and a silicon phase structure are refined, then the obtained alloy is subjected to heat processing, and aluminum alloy materials with small and even structures and good strength and plasticity are obtained. The obdurability of the Al-Si alloy can be obviously improved, and compared with traditional Al-Si alloy, alloy tensile strength and elongation rate can be improved by at least 15% and at least 40% respectively.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

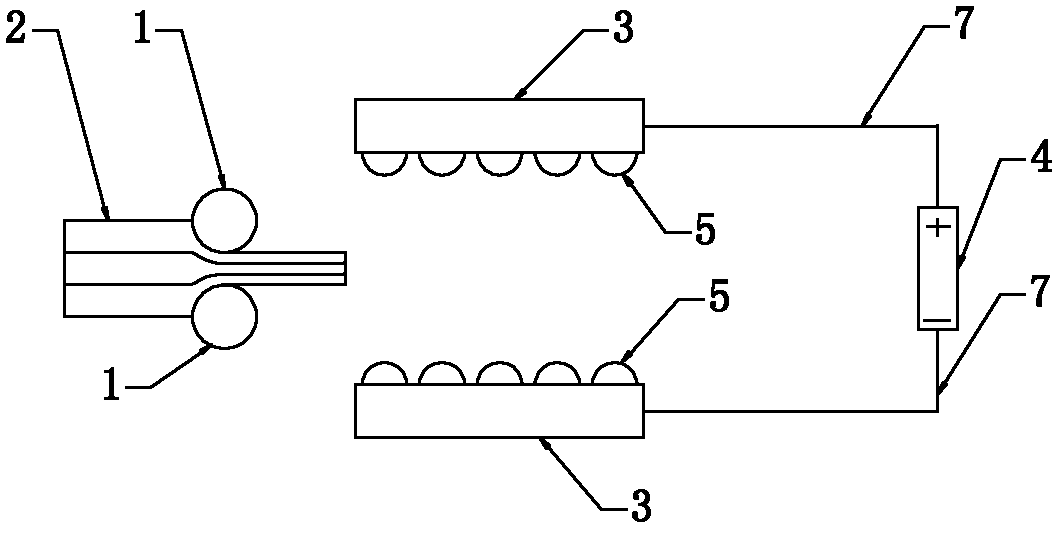

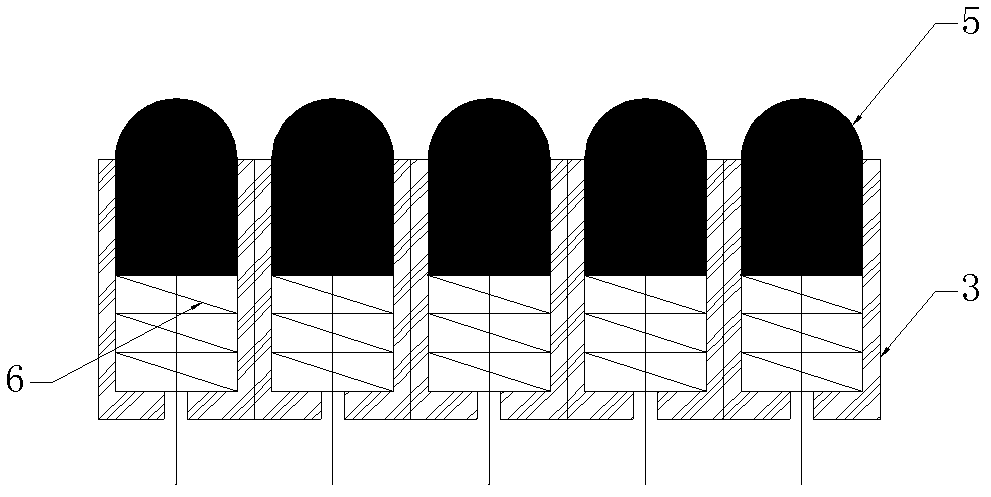

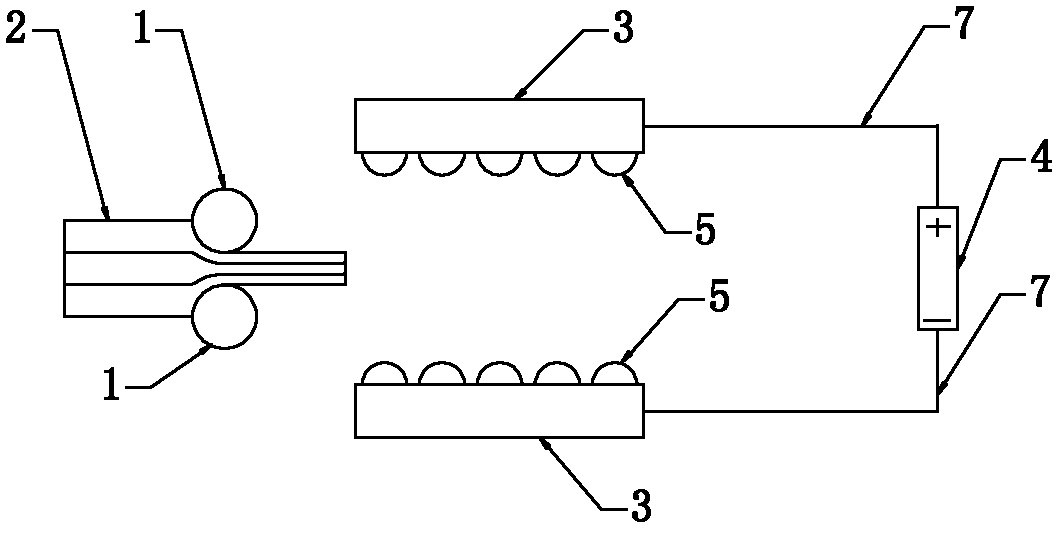

Preparation method and device for three-dimensional (3D) gradient plates produced through multi-layer rolling and multi-point electric pulse treatment

InactiveCN102489530AImprove strong plasticityImprove bindingAuxillary arrangementsMetal rolling arrangementsElectricityElectrical impulse

The invention discloses a preparation method and a device for three-dimensional (3D) gradient plates produced through multi-layer rolling and multi-point electric pulse treatment, which belong to the rolling field of metal materials. The device is composed of electrifying devices, a pulse power and a roller. The plates to be processed are of multi-layer composite structure, grains between different layers are in graded distribution in terms of size, and the plates are first rolled through the roller and then processed through electric pulse. Electricity is led to the rolled plates through the pair of symmetrical electrifying devices, and conductive parts of each electrifying device are distributed in array mode. In the three-dimensional directions, sizes of grains of the processed plates have the change of gradient. By designing a series of different lamination combination sequences and multi-point electric pulse distribution, plates of different microstructures can be obtained by means of control, then materials of high strength and high plasticity can be screened out, and meanwhile combination of layers can be enhanced through electric pulse annealing treatment.

Owner:SHANGHAI JIAO TONG UNIV

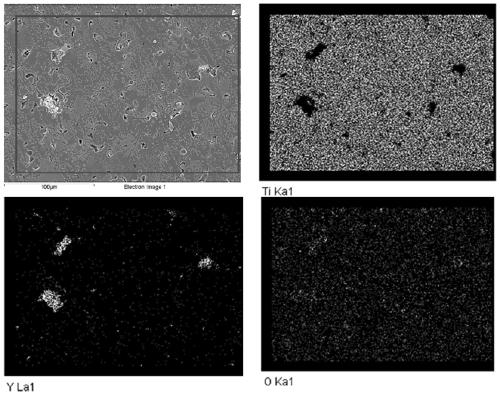

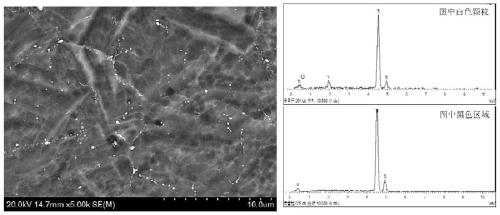

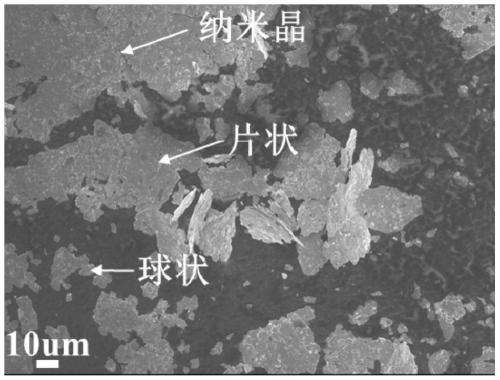

Rare earth modified high oxygen titanium powder for 3D printing and preparation method

InactiveCN109988940AImprove strong plasticityBreak through the limitations of poor plasticityAdditive manufacturing apparatusIncreasing energy efficiencyRare-earth elementDehydrogenation

The invention relates to a rare earth modified high oxygen titanium powder for 3D printing and a preparation method. The rare earth modified high oxygen titanium powder for 3D printing is a powder product prepared by adding a rare earth additive to a pure titanium matrix, wherein the addition amount of the rare earth additive is 0.05%-1.5% of the total mass of an alloy. Compared with the prior art, a certain amount of rare earth elements are added to hydrogenation dehydrogenation titanium powder or TiH2 powder, an electrode rod is made by a powder metallurgy method (cold isostatic pressure, molding pressure or hot isostatic pressure) after mixing, and then the high oxygen titanium powder is prepared by aerosol atomization. The tensile strength of the rare earth modified titanium powder is500-900 MPa after 3D printing, and the elongation is 15%-30%. The rare earth modified high oxygen titanium powder for 3D printing and the preparation method can effectively use the low cost and high oxygen hydrogenation dehydrogenation titanium powder or the TiH2 powder to obtain 3D printing materials with excellent high-plasticity, and havea good application prospect.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Microalloying steel for ultra-high-strength sucker rod

InactiveCN101307413AImprove strong plasticityImprove organizationChemical compositionMicroalloyed steel

The invention relates to a Nb microalloyed steel for an ultrahigh strength sucker rod. The sucker rod made of steel is suitable for a heavy oil well, a deep well, a large pump strong exploitation well, etc, and is a special type oil rod urgently needed for oil fields in China. The steel comprises the following chemical compositions in percentage by weight: 0.12 to 0.20 percent of C, 0.50 to 1.60 percent of Si, 0.90 to 1.60 percent of Mn, 0.90 to 2.00 percent of Cr, less than or equal to 0.20 percent of Mo, less than or equal to 0.20 percent of Ni, 0.035 to 0.055 percent of Nb, 0.010 to 0.030 percent of Ti, less than or equal to 0.050 percent of V, 0.0010 to 0.0020 percent of B, less than or equal to 0.025 percent of P, less than or equal to 0.020 percent of S and the balance being Fe. The tensile strength of rolled steel is high than 965 MPa; the minification of a plastic surface is higher than 50 percent; and the specific elongation delta200 of the plastic surface is more than 10 percent. The Nb microalloyed steel is suitable for manufacturing the sucker rod for an overweight loaded oil pumping field and has good fatigue resistance, corrosion resistance and economy.

Owner:SHOUGANG CORPORATION

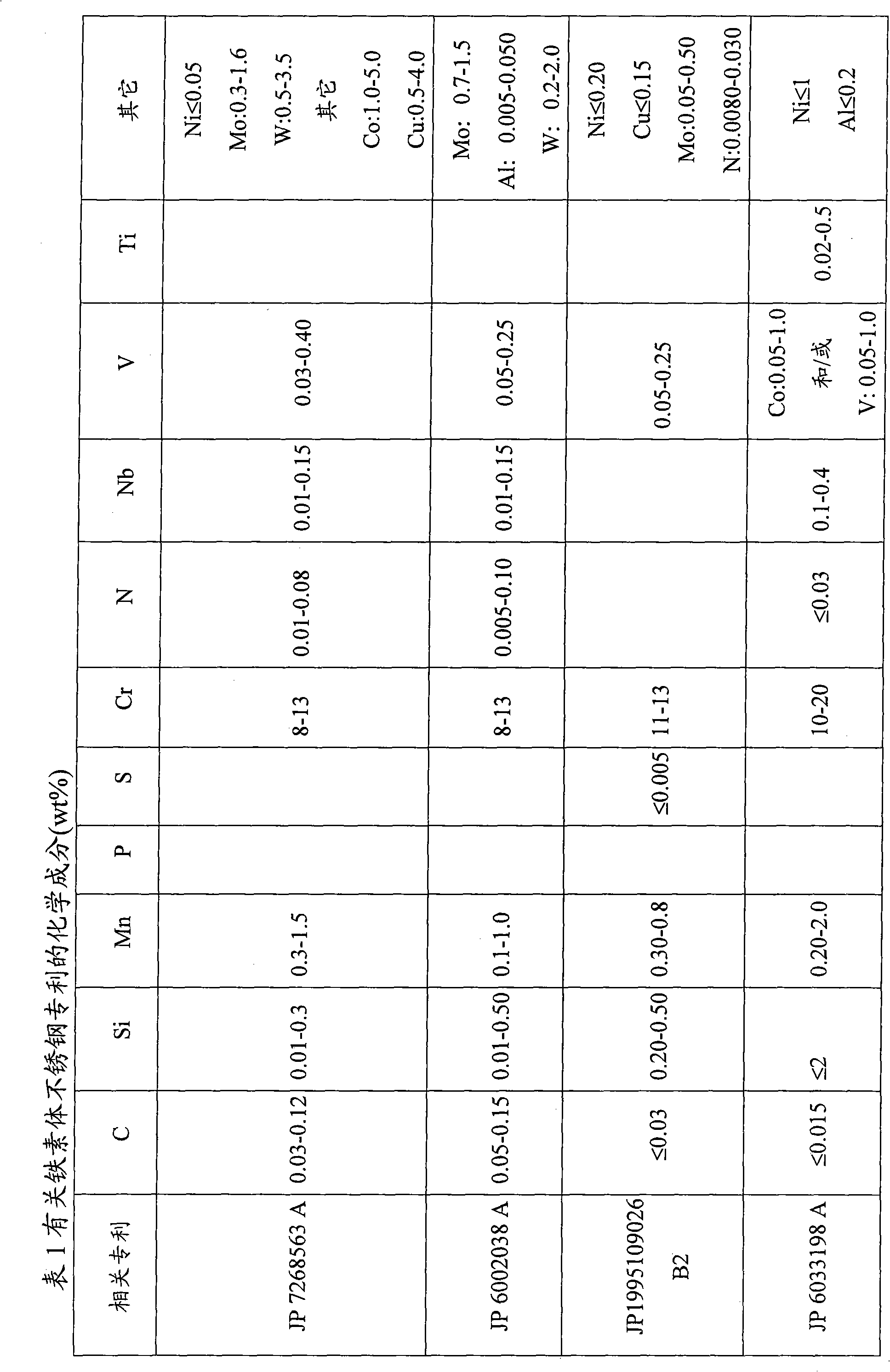

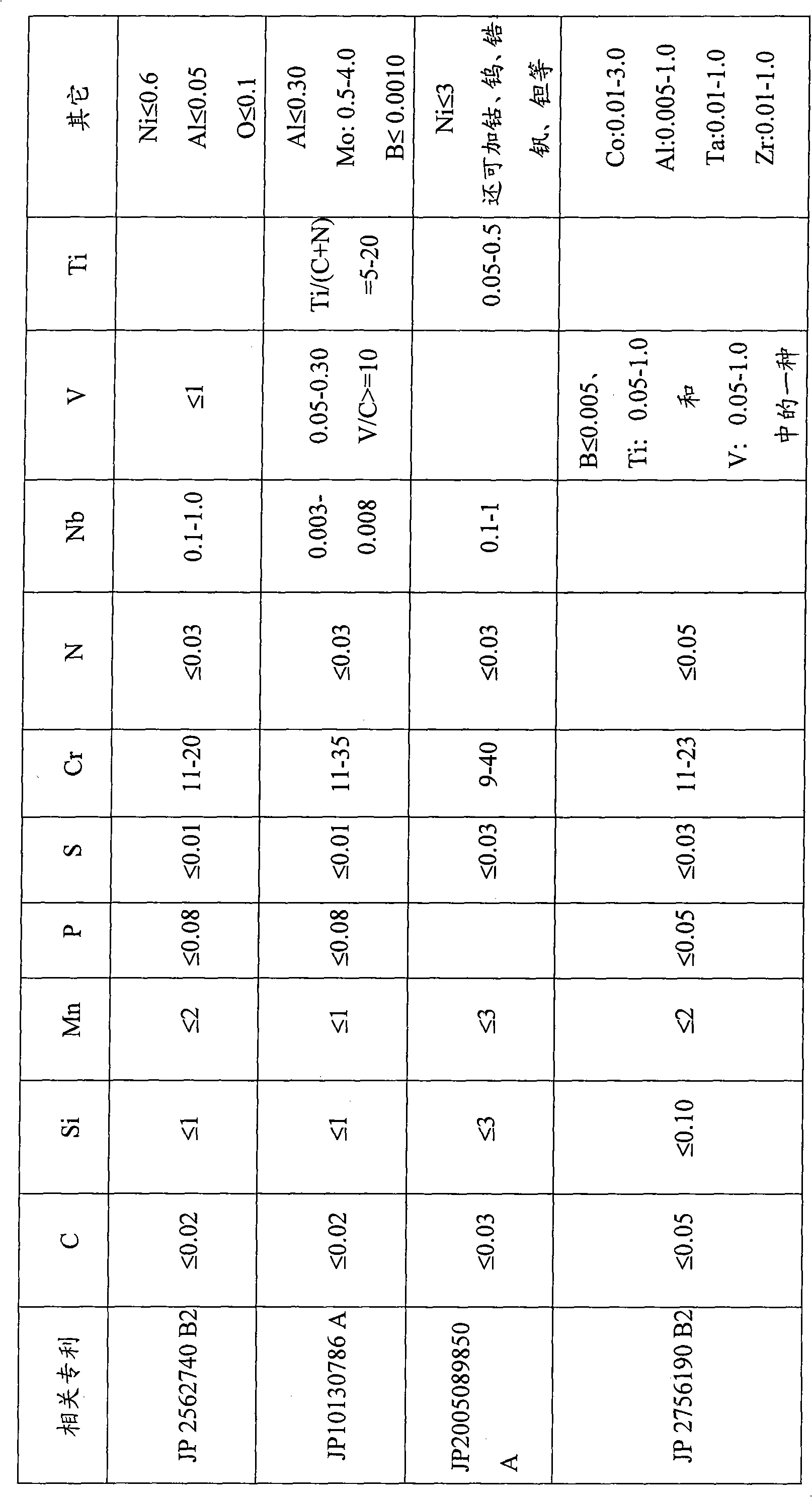

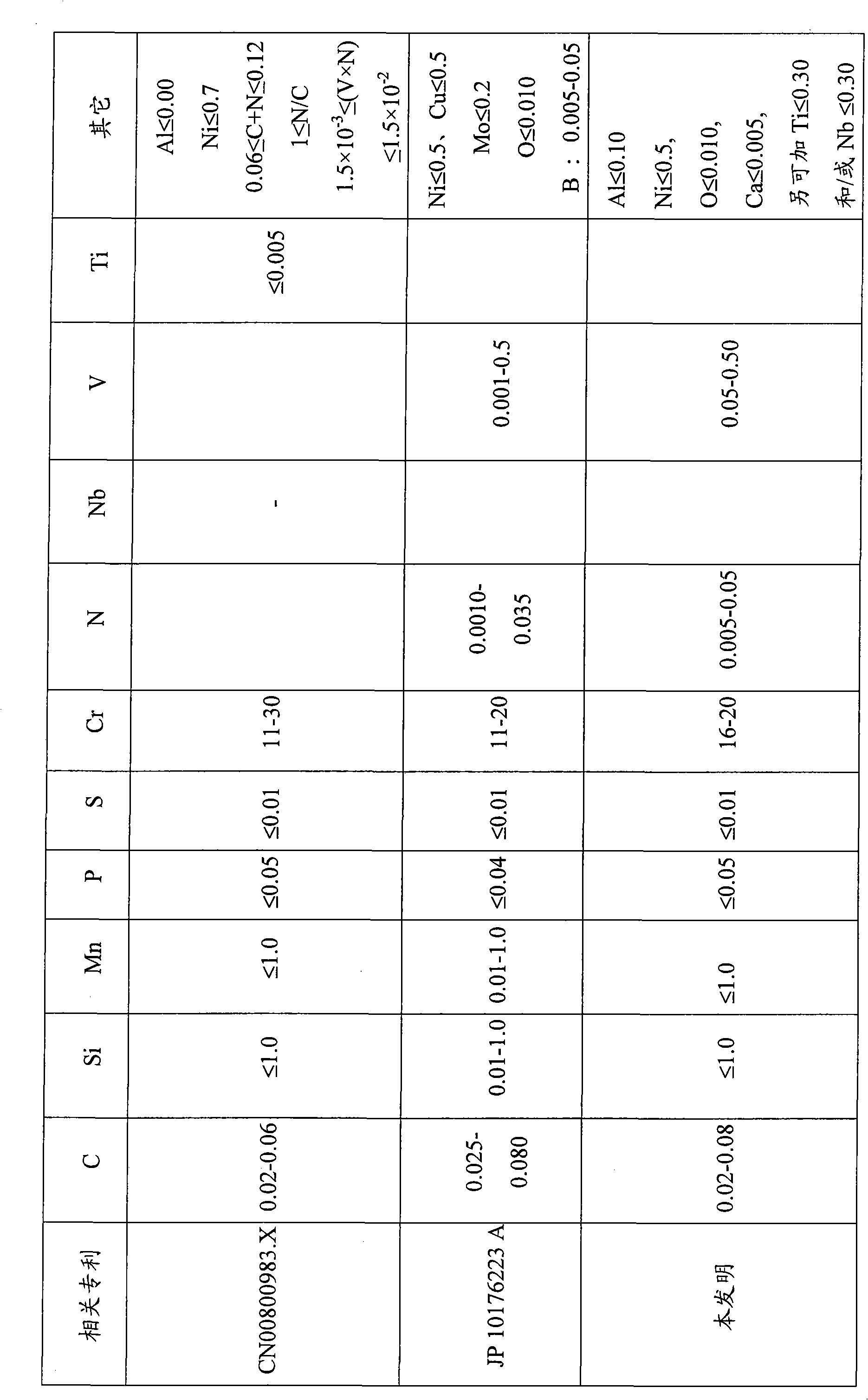

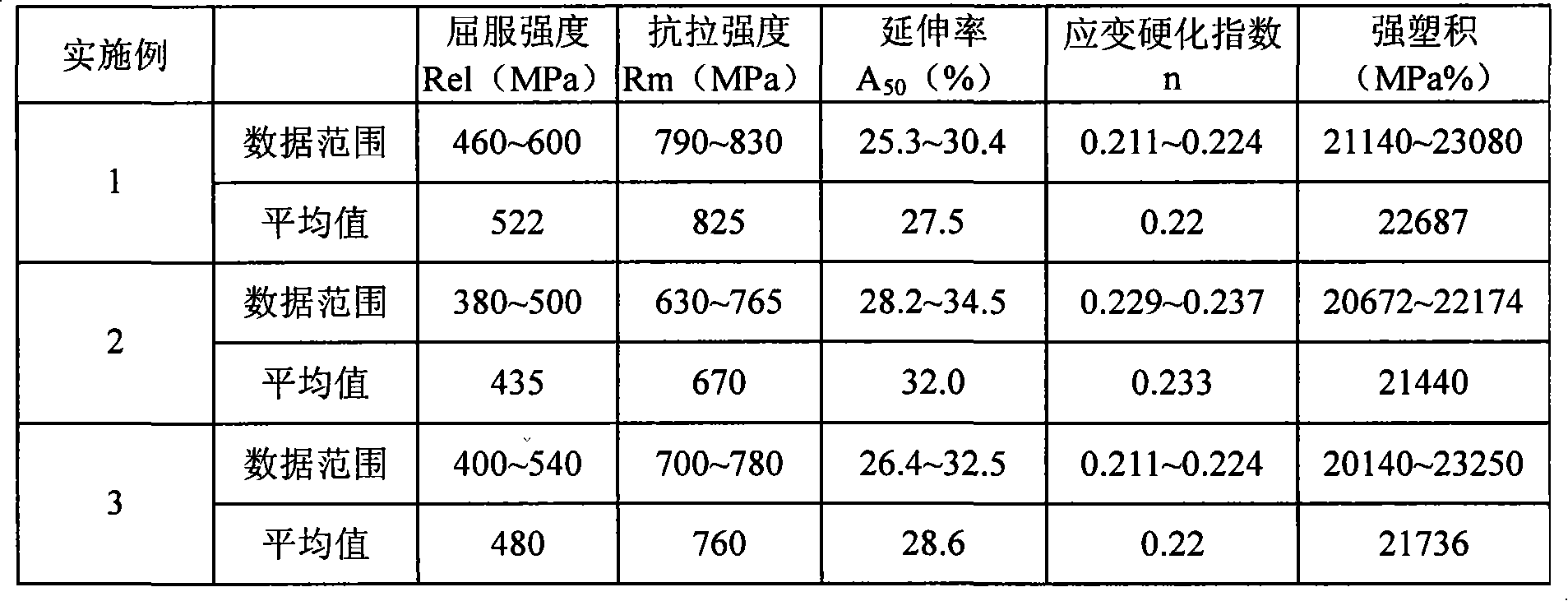

Medium chromium ferrite stainless steel and making method thereof

InactiveCN102041452AImprove strong plasticityImprove corrosion resistanceRoll force/gap control deviceTemperature control deviceChemical compositionImpurity

The invention provides medium chromium ferrite stainless steel which comprises the following chemical compositions in percentage by weight: 0.02-0.08 percent of C, not more than 1.0 percent of Si, not more than 1.0 percent of Mn, not more than 0.05 percent of P, not more than 0.01 percent of S, 16-20 percent of Cr, 0.05-0.50 percent of V, 0.005-0.05 percent of N, not more than 0.10 percent of Al, not more than 0.5 percent of Ni, not more than 0.010 percent of O, not more than 0.005 percent of Ca, additional not more than 0.30 percent of Ti and / or not more than 0.30 percent of Nb, and the balance of iron or other inevitable impurities. The invention also provides a making method of the medium chromium ferrite stainless steel, comprising the following steps of, firstly, heating a billet or a cast blank with the heating temperature of 1000-1250 DEG C; secondly, carrying out hot rolling; thirdly, annealing and pickling; fourthly, carrying out cold rolling; and fifthly, annealing and pickling. By adopting the composition design and the making method, a steel plate with good strength and plasticity, corrosion resistance and transverse performance is produced, thereby the machining needs of household appliances and products are met.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance cold rolled phase transformation plasticity steel and preparation method thereof

InactiveCN101613827AHigh strengthImprove plasticityTemperature control deviceFurnace typesChemical compositionRoom temperature

The invention provides a high-performance cold rolled phase transformation plasticity steel, which comprises the following chemical compositions: 0.05 to 0.3 percent of C, 0.1 to 0.6 percent of Si, 0.5 to 2.0 percent of Mn, 0.01 to 0.1 percent of P, 0.01 to 0.5 percent of V, 0.01 to 0.03 percent of N and the balance of Fe and inevitable impurities. The preparation method comprises that: (1) after converter smelting, precision rolling and slab continuous casting, the steel is subjected to hot rolling, the finishing temperature is between 750 and 900DEG C, the coiling temperature is between 550 and 700DEG C, and then the steel is subjected to cold rolling in rolling reduction between 40 and 80 percent to be made into a steel plate with the thickness between 0.5 and 2.0mm; and (2) the steel plate is subjected to heat treatment, namely the steel plate is kept isothermally at a temperature of between 700 and 850DEG C for 0.5 to 6 minutes, cooled to between 300 and 500DEG C in a rate of between 10 and 50DEG C / s, kept isothermally for 0.5 to 10 minutes, and finally cooled by air or oil to room temperature in a rate of between 5 to 20DEG C / s. The high-performance cold rolled phase transformation plasticity steel adopts special composition design and heat treatment process, so that low-silicon and low-carbon steel not containing Al has excellent strength-plasticity, good weldability, hot dip property and surface quality of casting blanks.

Owner:ANGANG STEEL CO LTD +1

High-strength anti-seismic steel bar and rolling process thereof

The invention discloses a high-strength anti-seismic steel bar. The steel bar comprises, by weight, 0.24-0.28% of C, 0.50-0.80% of Si, 1.40-1.60% of Mn, less than or equal to 0.040% of S, less than orequal to 0.040% of P, 0.120-0.160% of V, 0.010-0.030% of Nb, 0.0140-0.0220% of N, and the balance being Fe and inevitable impurities. The rolling process comprises the following steps: (1) preparingmaterials according to the components by weight; (2) preparing a steel billet of suitable size; (3) rolling, wherein heating temperature of the steel billet is 1000-1200 DEG C, soaking temperature is1150-1230 DEG C, and rolling temperature is 1100-1200 DEG C; and (4) treating on a cold bed for natural cooling after heating and rolling, and then carrying bundling and stacking. A steel bar alloy system is simple and is easy for blank smelting and continuous casting efficient production; precious alloys such as nickel and molybdenum are not adopted, the content of niobium and vanadium is low, and the product alloy cost is low; and the developed high-strength steel bar has excellent comprehensive performance and safety performance, the durability and the safety of key engineering buildings can be ensured, and the application and popularization prospects are good.

Owner:NANJING IRON & STEEL CO LTD

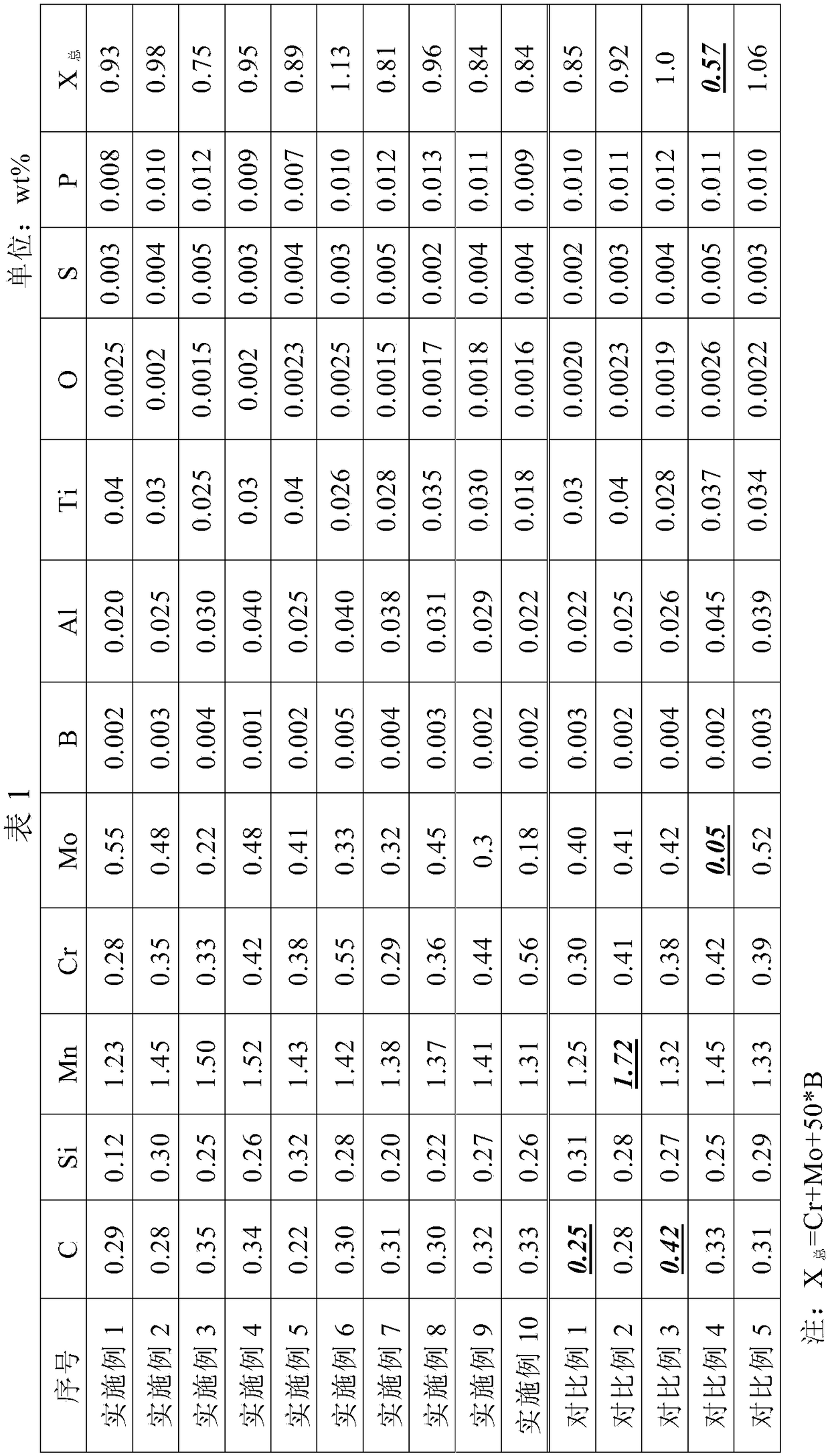

Steel tube used for hollow stabilizer bar of automobile and manufacturing method of steel tube

The invention discloses a steel tube used for a hollow stabilizer bar of an automobile and a manufacturing method of the steel tube. The steel tube is prepared from the following chemical components in mass percent: 0.28 to 0.40 percent of C, 0.05 to 0.35 percent of Si, 1.05 to 1.60 percent of Mn, 0.1 to 0.6 percent of Mo, 0.001 to 0.006 percent of B, 0.015 to 0.060 percent of Al, 0.1 to 0.8 percent of Cr, 0.003 to 0.06 percent of Ti, not greater than 0.006 percent of S, not greater than 0.015 percent of P, not greater than 0.003 percent of O and the balance Fe and other inevitable impurities,wherein Mo+50B+Cr is not less than 0.7 percent but is not greater than 1.3 percent. The steel tube disclosed by the invention is high in strength and plasticity, has high torsion fatigue resistance under a relatively high stress level, and can meet the using requirement of the stabilizer bar under a high-stress condition; and the specific performance indexes are shown as follows: as-quenched tensile strength is not less than 1700 MPa, as-quenched yield strength is not less than 1300 MPa, as-quenched ductility is not less than 12 percent, inner surface decarburization depth and outer surface decarburization depth are both 0, and under the condition of 550 MPa, the number of times of torsion fatigue is greater than 1200000.

Owner:BAOSHAN IRON & STEEL CO LTD

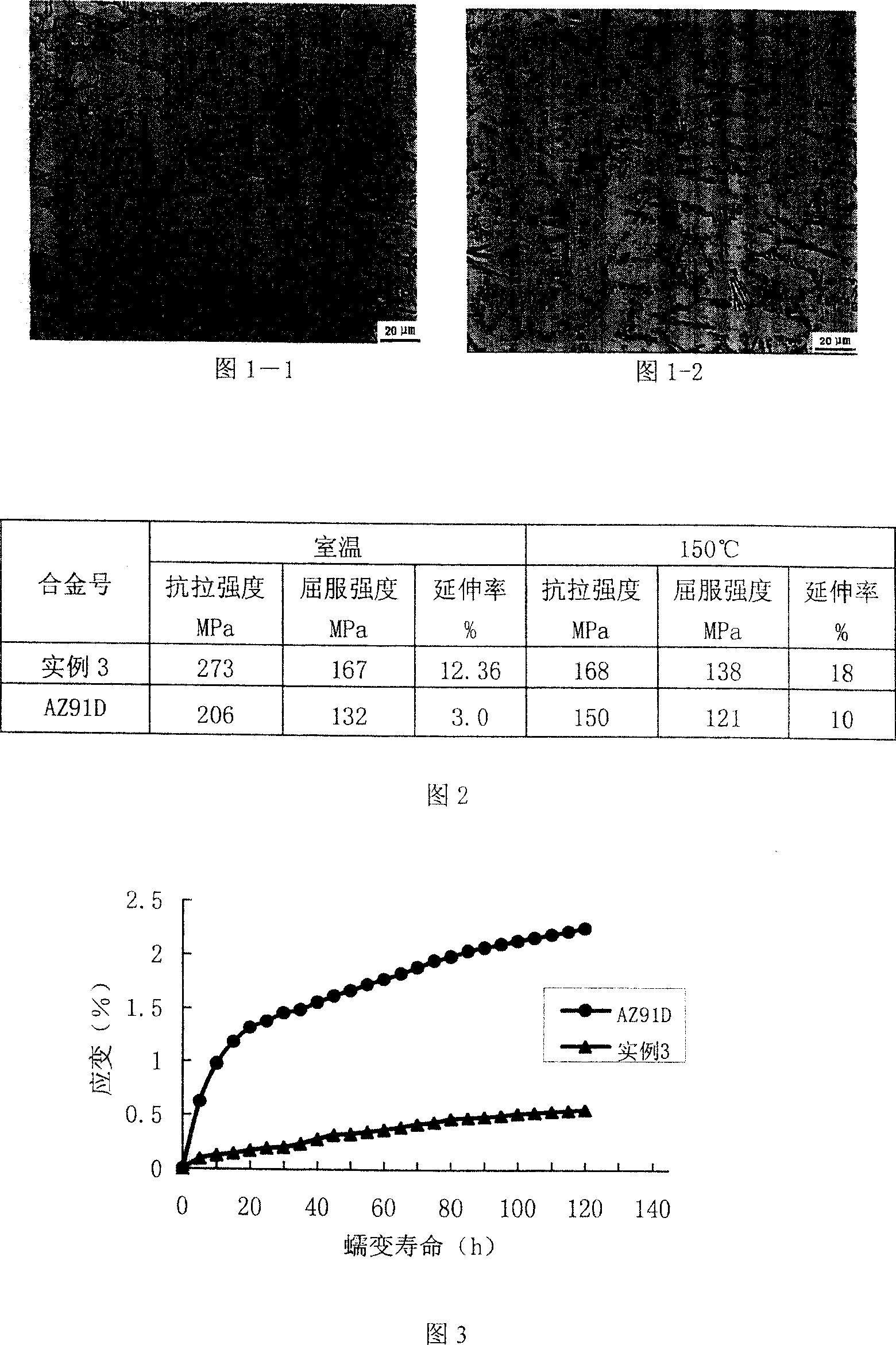

Magnesium alloy

The present invention is one kind of magnesium alloy with high strength, high toughness and high heat resistance and for casting structural part of automobile and motorcycle. The magnesium alloy includes Al 6.50-8.70 wt%, Zn 0.41-1.20 wt%, Mn 0.10-1.0 wt%, mixed Ce-rice RE 0.50-4.00 wt%, impurity element Be not more than 0.10 wt%, Cu not more than 0.030 wt%, Ni not more than 0.002 wt%, Fe not more than 0.005 wt%, Si not more than 0.005 wt%, and Mg for the rest. Compared with traditional cast magnesium alloy, the present invention has compact structure, high strength, high toughness, high heat resistance and capacity of meeting the requirement of structural part in safety performance.

Owner:CHONGQING UNIV

Near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy and preparation method

The invention provides a near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy and a preparation method. The near-eutectic type high-strength heat-resistant Al-Ce-series aluminumalloy is prepared from the following elements in percentage by weight: 5.00 percent to 15.00 percent of Ce, 0.01 percent to 5.00 percent of Fe, 0.10 percent to 1.20 percent of Mg, 0.05 percent to 1.00 percent of Si, 0.001 percent to 5.00 percent of Cu, 0.001 percent to 0.40 percent of Co, 0.001 percent to 0.85 percent of B, 0.001 percent to 0.20 percent of Ti, 0.001 percent to 0.15 percent of V,0.001 percent to 0.12 percent of Cr, 0.001 percent to 0.12 percent of Mn, 0.001 percent to 0.15 percent of Ni, and the balance aluminum. The near-eutectic type high-strength heat-resistant Al-Ce-series aluminum alloy provided by the invention has high strength and high heat resistance, the tensile strength at the room temperature reaches to more than 440MPa, and the tensile strength at 300 DEG C reaches to more than 250MPa; and the cost of raw materials for preparing the aluminum alloy is low, and a preparation process is simple.

Owner:SHANGHAI JIAO TONG UNIV

Wire rod for high-carbon steel wire and preparation method of wire rod

The invention discloses a wire rod for a high-carbon steel wire and a preparation method of the wire rod. The wire rod comprises the following chemical components by weight percent: 0.68-0.88% of C, 0.15-0.30% of Si, 0.45-0.55% of Mn, less than or equal to 0.015% of P, less than or equal to 0.02% of S, less than or equal to 0.05% of Ni, less than or equal to 0.01% of Ti, less than or equal to 0.05% of Al, less than or equal to 0.006% of N, 0.05-0.50% of Cr or / and 0.05-0.25% of V and the balance of Fe. The preparation method comprises the procedures of hot metal pretreatment, converter smelting, LF refining, continuous casting, heating, wire rolling and cooling and the like. Compared with original 70 steel, the wire rod prepared by micro-alloying treatment of a 70 steel wire rod has the advantages that the tensile strength is improved by 90-120 MPa while the percentage elongation is only reduced by 5-20%, and the wire breakage ratio during follow-up drawing into a steel wire is 1.8-2.3 times / ton.

Owner:HENAN BEST STEEL WIRE PRODS

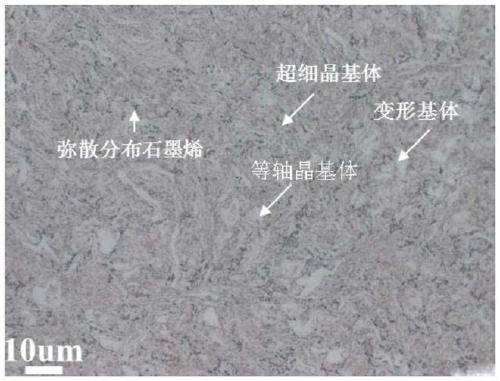

Preparation method of graphene enhanced FCC-type high-entropy alloy

ActiveCN111534712AImprove strong plasticityGood strength and plasticity matchingHigh entropy alloysGraphite

The invention discloses a preparation method of a graphene enhanced FCC-type high-entropy alloy. The method comprises the steps that 1, FCC-type high-entropy alloy powder is prepared by a gas atomization method; 2, the FCC-type high-entropy alloy powder is subjected to ball milling and then dried; 3, the dried FCC-type high-entropy alloy powder is mixed with graphene nanoflakes, then composite powder is obtained by ball milling; and 4, the composite powder is subjected to spark plasma sintering, and the graphene enhanced FCC-type high-entropy alloy is obtained after cooled in a furnace. According to the preparation method, short-time high-energy ball milling is adopted, so that the FCC-type high-entropy alloy powder forms multi-scale lamellar structures and produces fine nanocrystals, combined with low-energy ball milling, the graphene nanoflakes are completely and evenly dispersed between the lamellar structures, the graphene enhanced FCC-type high-entropy alloy with multi-scale crystals is prepared, the strengthening effect is effectively enhanced, and the good matching of strength and plasticity is achieved.

Owner:西安稀有金属材料研究院有限公司 +1

Economical duplex stainless steel sheet and preparation method thereof

The invention discloses an economical duplex stainless steel sheet and a preparation method thereof. The stainless steel sheet comprises the following components in percentage by mass: 0.08 to 0.13 percent of C, 20 to 23 percent of Cr, 4 to 6 percent of Mn, 0.5 to 1.5 percent of Ni, 0.2 to 0.5 percent of Mo, 0.1 to 0.25 percent of N and the balance of iron and other inevitable impurities. The preparation method comprises the following steps: selecting and melting a raw material into molten steel according to the components; casting the molten steel into an ingot; performing hot rolling cogging and surface figuring on the ingot after a riser part is cut; performing hot rolling to obtain a hot-rolled plate with a thickness of 3 to 6mm; performing annealing, acid washing and cold rolling on the hot-rolled plate to obtain a sheet with a thickness of 1 to 1.5mm; performing solution annealing to obtain the economical duplex stainless steel sheet. According to the economical duplex stainless steel sheet and the preparation method thereof, by reasonable alloying design, the strength and the plasticity of the stainless steel sheet can be improved, hot rolling edge cracking can be eliminated, and the quality and the yield of the hot-rolled plate are greatly improved.

Owner:NORTHEASTERN UNIV

Heat processing technology of high-carbon carbon steel coil rod for steel wire rope

InactiveCN102719643AImprove plasticityImprove toughnessFurnace typesHeat treatment bathsCarbon steelHeat processing

The invention discloses a heat processing technology of a high-carbon carbon steel coil rod for a steel wire rope. The heat processing technology is characterized by comprising the following steps of: carrying out hot rolling, water passing and cooling and coiling on the high-carbon carbon steel coil rod with the diameter of 6mm-16.5mm so as to obtain coil rod; when the prepared coil rod reaches the temperature range of 820 DEG C-900 DEG C, rapidly throwing the coil rod in a salt groove to keep for 2 seconds-40 seconds in salt bath lower than sorbite temperature at constant temperature; and then putting the coil rod into salt bath or lead bath with the sorbite temperature range to keep at constant temperature for 5 minutes-15 minutes, taking out and cooling naturally, thereby completing the heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope can effectively refine the sorbite clique size and interlayer spacing and can improve the uniformity of interlayer spacing; and the product has the advantages of high intensity plasticity, excellent fatigue resistance, long service and the like. The heat processing technology of the high-carbon carbon steel coil rod for the steel wire rope has an obvious effect of improving the high plasticity of a coil rod wire material.

Owner:GUIZHOU UNIV

980MPa-grade cold-rolled dual-phase steel with yield strength exceeding 700MPa and production method thereof

InactiveCN112593154AImprove hardenabilityInhibit growthContinuous annealingUltimate tensile strength

The invention discloses 980MPa-grade cold-rolled dual-phase steel with the yield strength exceeding 700MPa and a production method thereof, and belongs to the technical field of steel smelting. The 980MPa-grade cold-rolled dual-phase steel with the yield strength exceeding 700MPa comprises the following chemical components in percentage by mass: 0.07-0.12% of C, 0.20-0.60% of Si, 1.50-2.20% of Mn,less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015-0.070% of Als, less than or equal to 0.0045% of N, 0.02-0.50% of Mo, 0.010-0.040% of Nb, 0.010-0.040% of Ti, 0.40-0.70% ofCr and the balance of Fe and unavoidable impurities. The production method comprises the processes of smelting, hot rolling, acid rolling, continuous annealing and the like. According to the 980MPa-grade cold-rolled dual-phase steel with the yield strength exceeding 700MPa provided by the invention, the steel has excellent mechanical properties, the yield strength is 710-770MPa, the tensile strength is 995-1080MPa, the elongation A80 is 9.0-13.0%, and the problem of low yield strength in the existing 980MPa-grade cold-rolled dual-phase steel can be effectively solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

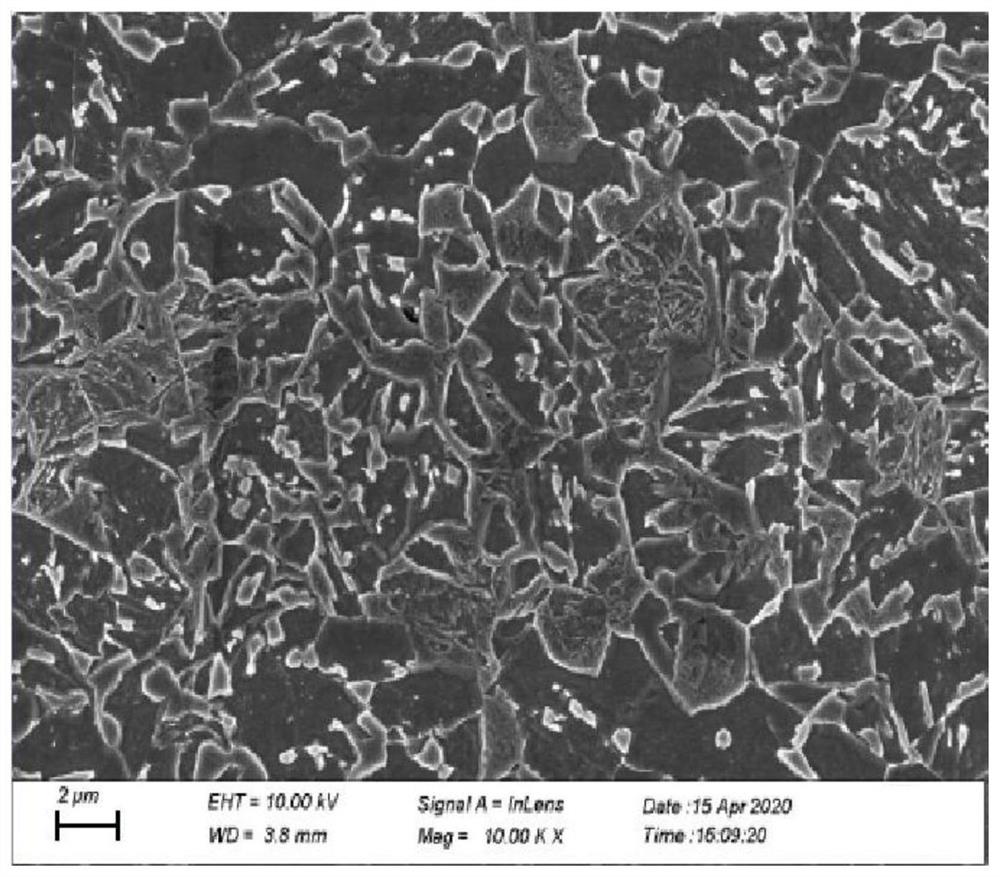

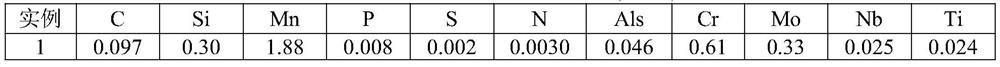

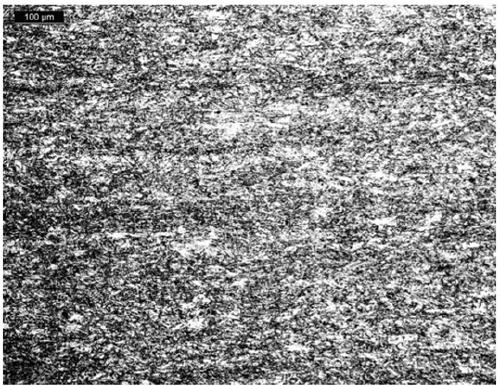

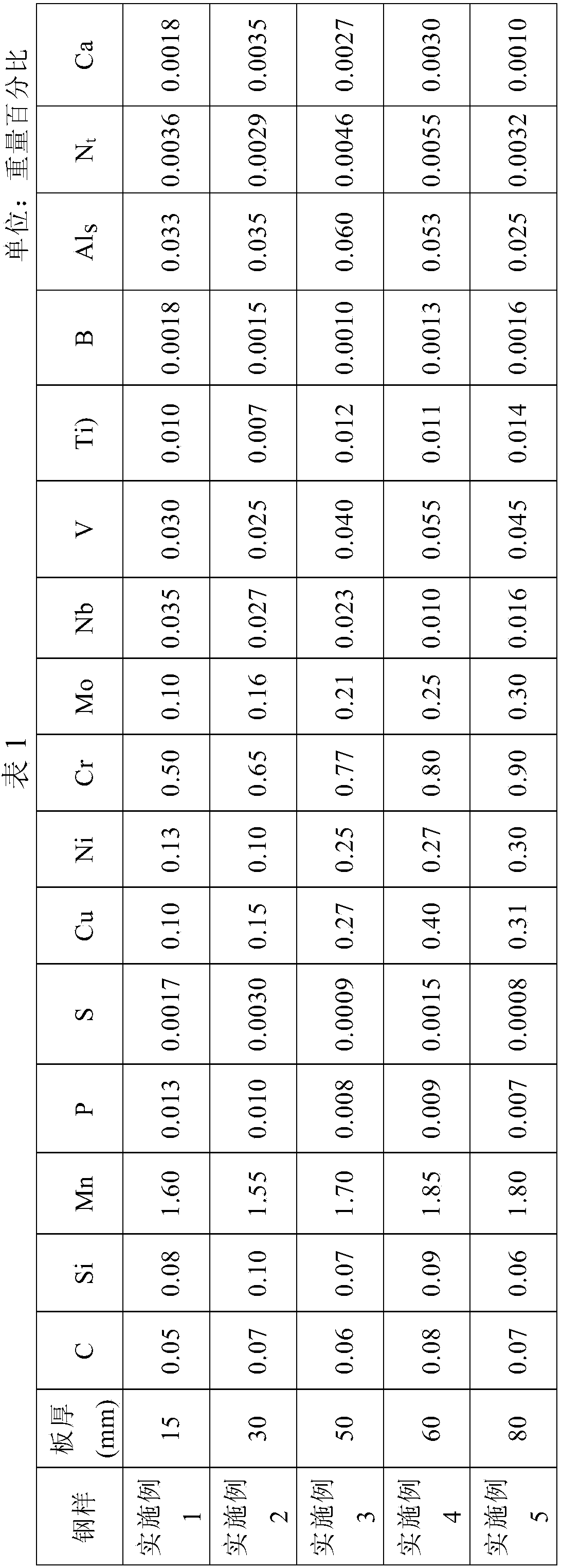

Low-cost, high-toughness and excellent-weldability 800 MPa-grade quenched and tempered steel plate and manufacturing method thereof

The invention discloses a low-cost, high-toughness and excellent-weldability 800 MPa-grade quenched and tempered steel plate and a manufacturing method thereof. An ultra-low C- ultra-low Si-high Mn (Cu + Ni + Mo + high Cr) alloying-(Ti + V + B) micro-alloyed component system is taken as a foundation, the content of acid-soluble Als in steel is properly improved, and (% Als) is larger than or equalto 10 * [(% Nt)-0.292 (% Ti)], metallurgy technology control measures are adopted, specifically, a large-angle bainite lath / a martensite lath grain boundary forming index chi is controlled to be larger than or equal to 2.1, (% C) * [(% Si) +0.83 (% Mo) +1.12 (% Nb) +0.89 (% Als) +0.45 (% V)] is controlled to be less than or equal to 0. 031, a Di index * zeta * T cooling acceleration start temperature * [(T cooling acceleration start temperature-T cooling acceleration stop temperature) / (T cooling acceleration start temperature +T cooling acceleration stop temperature)] / t is controlled to be larger than or equal to 1535, Ca is treated and the Ca / S ratio is within 1.00-3.00, and CR + DQ + an off-line tempering process T is optimized, so that the microscopic structure of a finished steel plate is composed of uniform and fine lower bainite and lath martensite, the average size of eutectic cells is 20 micrometers or below, and excellent strong plasticity and high toughness are obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

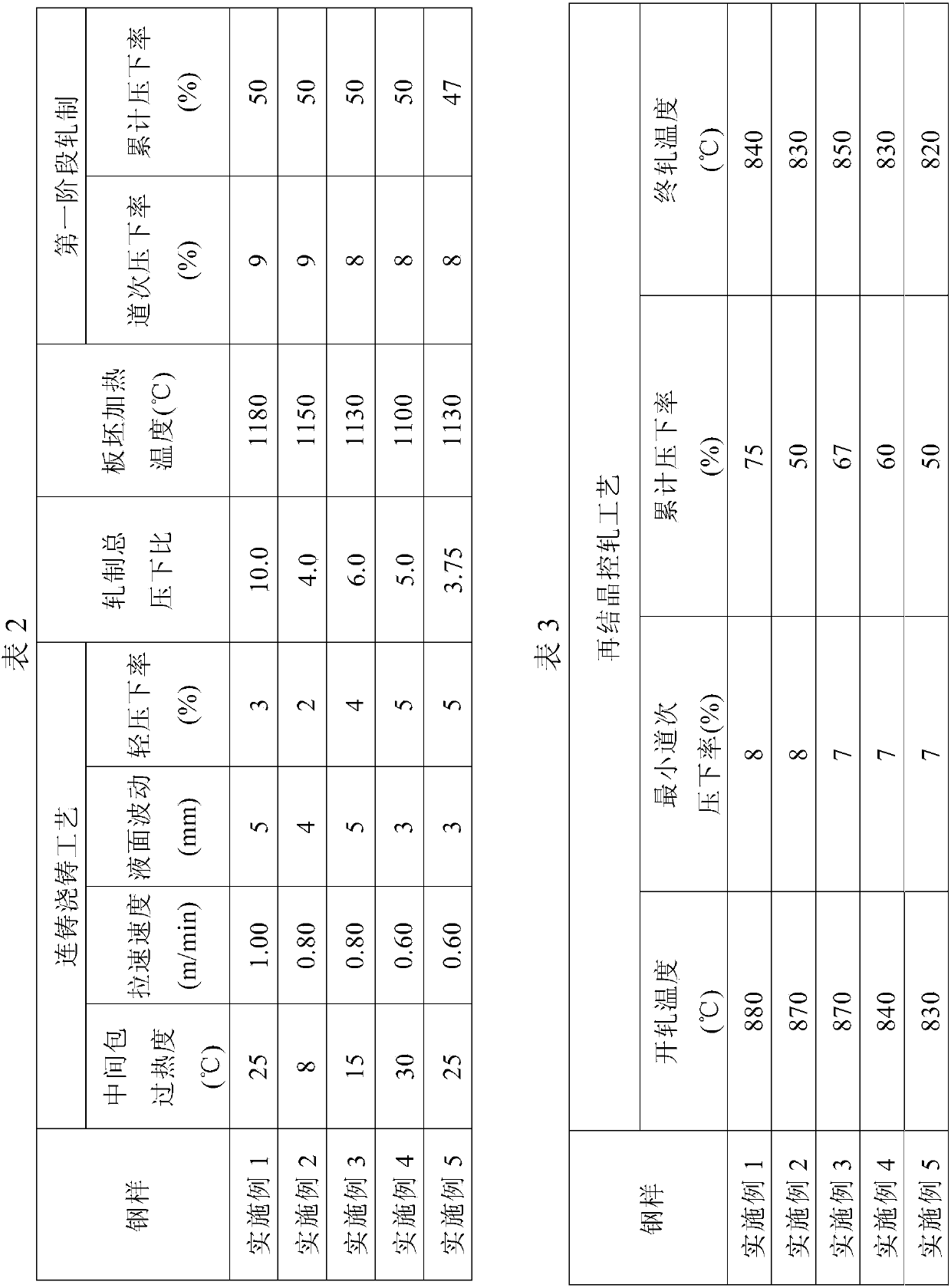

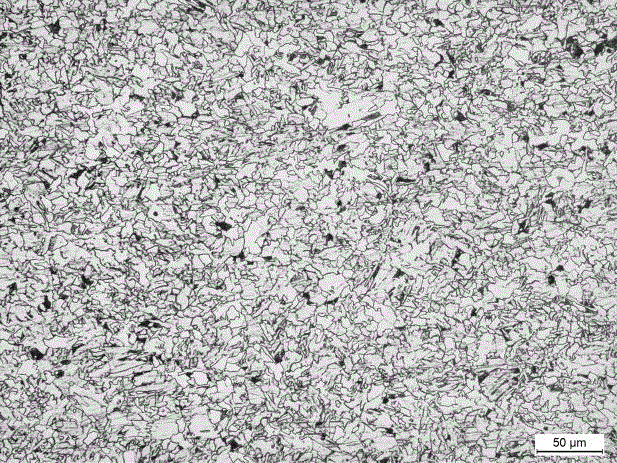

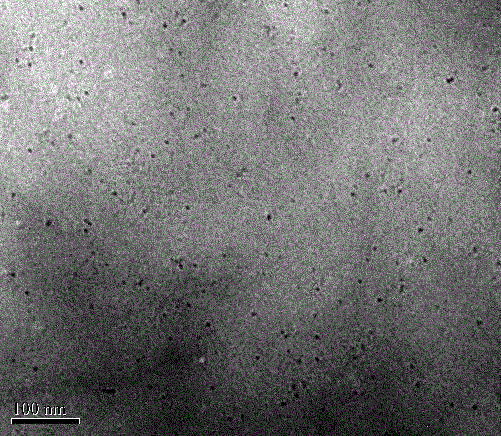

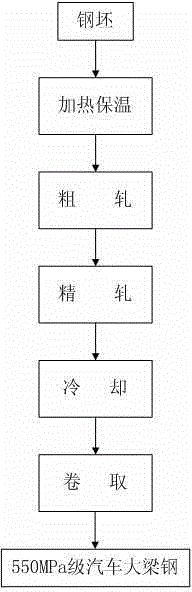

Automobile beam steel with tensile strength of 550MPa and preparation method for automobile beam steel

The invention provides automobile beam steel with tensile strength of 550MPa and a preparation method for the automobile beam steel. The automobile beam steel comprises the following chemical components in percentage by mass: 0.04-0.12% of C, 0.05-0.35% of Si, 0.5-1.2% of Mn, less than and equal to 0.015% of S, less than and equal to 0.02% of P, 0.02-0.05% of Als, 0.02-0.06% of Ti, and the balance of Fe and inevitable impurities. The tissue of the automobile beam steel is quasi-polygonal ferrite and pearlite, wherein the volume fraction of the quasi-polygonal ferrite is 82-96%, the volume fraction of the pearlite is 4-18%, and the mean grain size is 5-9 microns. The invention further provides a preparation method for the automobile beam steel. A steel billet adopting the chemical component proportion is subjected to a reasonable process design, cheap micro alloy titanium is used to replace noble micro alloy niobium and vanadium, the production cost is reduced while load of a rolling mill and a rolling machine is reduced, the production efficiency is improved, and the automobile beam steel with tensile strength of 560 MPa to 590 MPa is obtained.

Owner:NORTHEASTERN UNIV +1

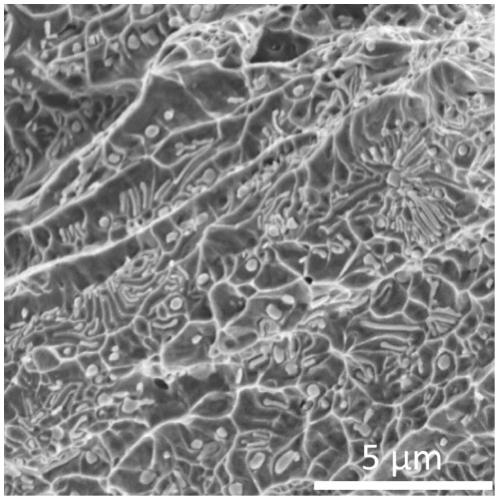

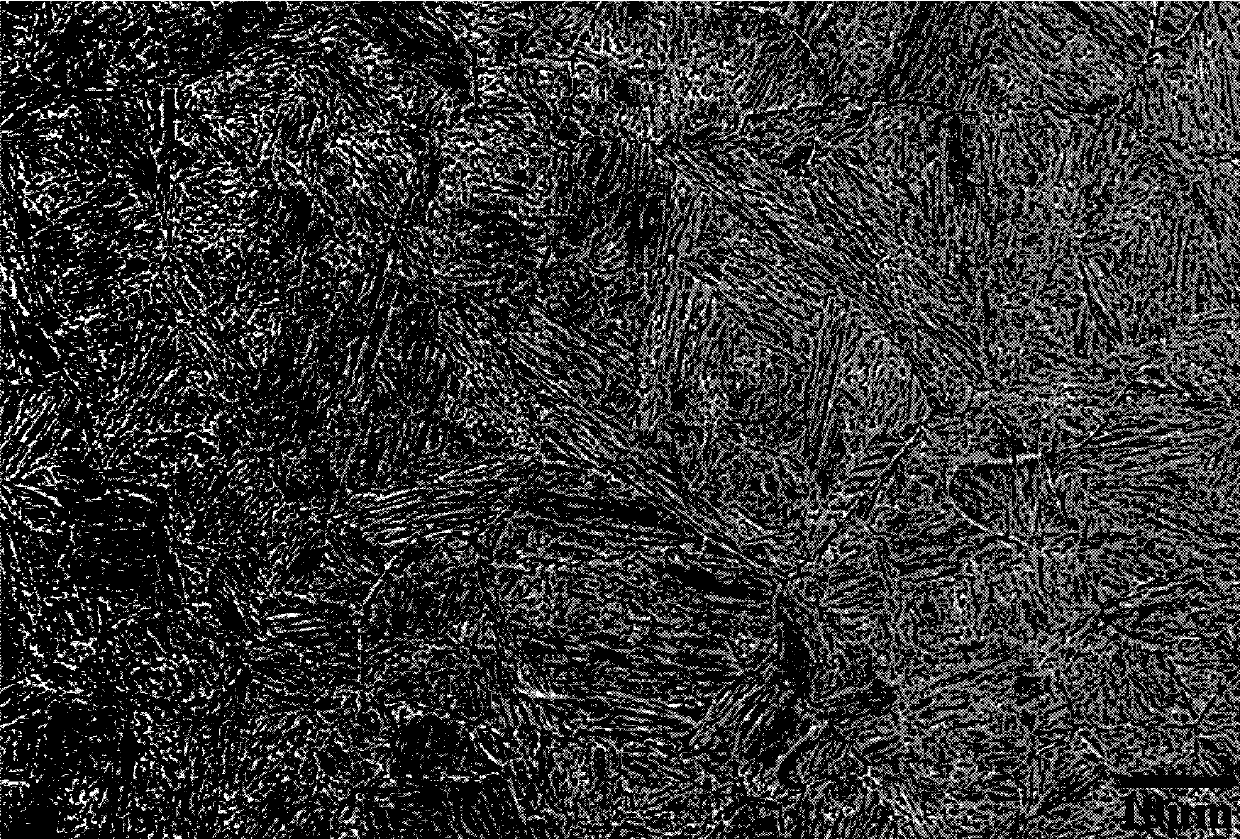

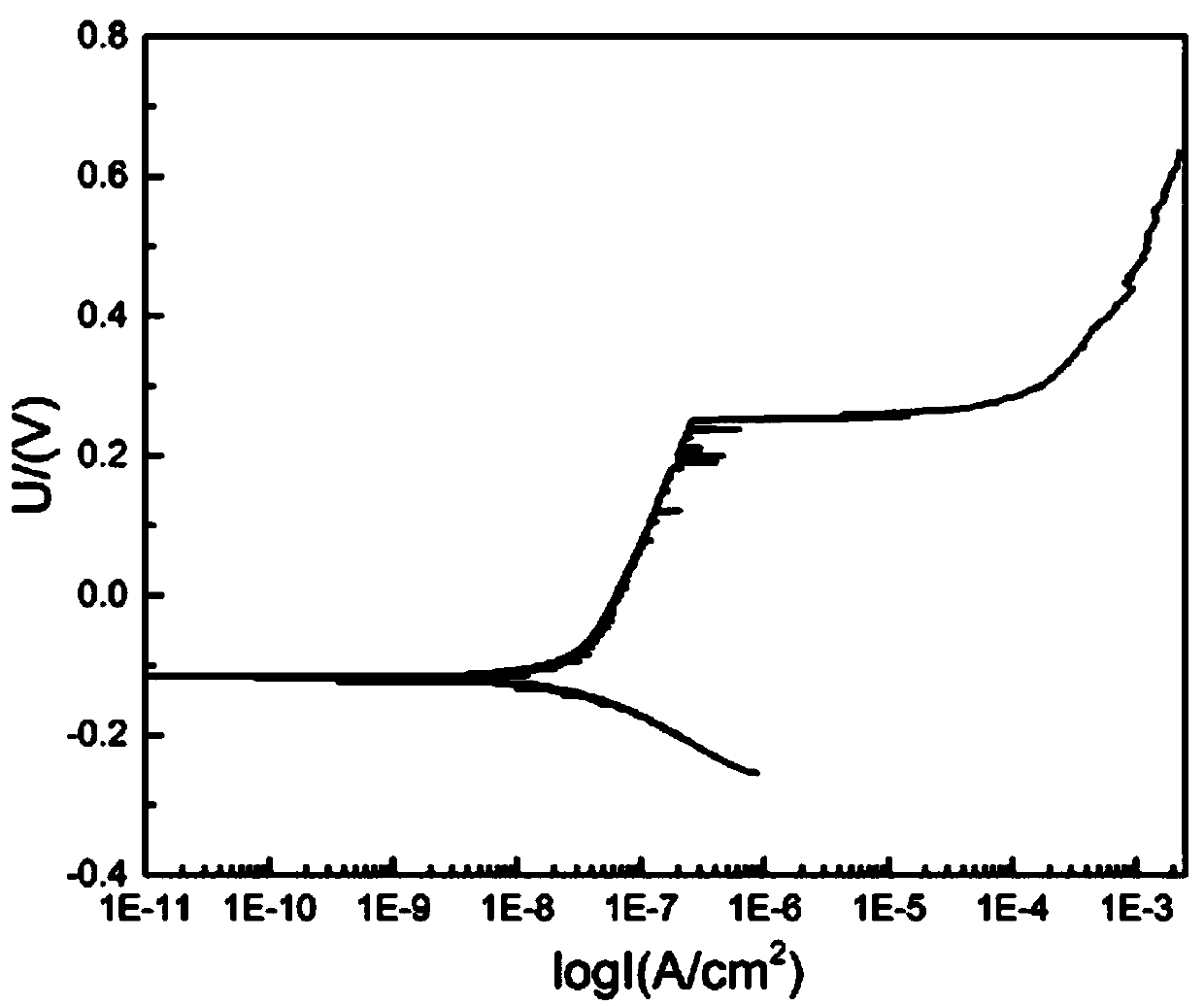

Nearly beta-type high-toughness titanium alloy and preparation method thereof

The invention discloses a nearly beta-type high-toughness titanium alloy. The nearly beta-type high-toughness titanium alloy comprises the following components in percentage by mass: 4.0%-5.5% of Al,0.8%-1.8% of Zr, 3.0%-4.5% of Mo, 1.0%-2.0% of V, 1.5%-2.5% of Fe, 2.5%-3.5% of Cr, no more than 0.12% of B, and the balance Ti and inevitable impurities. The invention also discloses a preparation method of the nearly beta-type high-toughness titanium alloy. According to the preparation method, a large amount of TA15 recycled material is adopted as a raw material; an Al-Zr system is adopted to reinforce an alpha phase in the titanium alloy, and a Mo-V-Cr-Fe system is adopted to reinforce a beta phase in the titanium alloy, so that the coupling reinforcement effect is enhanced; the titanium alloy has good strength and toughness matching; the aluminum equivalent and the molybdenum equivalent of the titanium alloy are controlled, so that the great strength and toughness of the titanium alloyis ensured; and the TA15 titanium alloy recycled material is used as a raw material, so that the preparation cost is greatly reduced.

Owner:WESTERN TITANIUM TECH

High-strength stainless steel, heat treatment process and forming member

InactiveCN109594022AImprove pitting resistanceImprove plastic toughnessProcess efficiency improvementRoom temperatureCarbide

The invention relates to high-strength stainless steel, a heat treatment process and a forming member. The high-strength stainless steel is prepared from the following components according to weight percent: 0.2 to 0.35% of C, 0.7 to 3.50% of Mn, 0.6 to 2.0% of Si, 11 to 17% of Cr, less than or equal to 0.20% of Nb, less than or equal to 0.20% of Ti and the balance of Fe and impurities. The heat treatment process comprises the following steps of (a) heating the high-strength stainless steel to 1000 to 1200 DEG C, and then insulating for 1 to 3600 s; (b) cooling the high-strength stainless steel treated in the step (a) below 100 DEG C; and (c) heating the high-strength stainless steel treated in the step (b) to 150 to 400 DEG C, then insulating for 10 to 10000 s, and then cooling to room temperature in any cooling mode. The forming member is made of the high-strength stainless steel, and the microstructure of the forming member is composed of 5% to 30% of retained austenite, 70% to 95%of martensite, less than 1% of Nb and Ti carbide and less than 2% of Cr carbide in an area.

Owner:IRONOVATION MATERIALS TECH CO LTD

Forming mold and method for ultra-fine grain hollow magnesium alloy profile

The invention discloses a forming mold and method for an ultra-fine grain hollow magnesium alloy profile. The forming mold comprises a base, a concave die outer sleeve, a concave die inner sleeve, an extruding needle, an extruding shaft and an extruding pad, wherein the concave die inner sleeve is provided with a forming concave die. The forming method the following steps: (1) fixedly connecting the extruding pin and the extruding shaft with an inner sliding block and an outer sliding block of a double-acting extruding machine; (2) heating an ultra-fine grain hollow cylinder blank above a re-crystallization temperature; (3) putting the heated blank into a feeding section of the forming concave die; (4) starting the double-acting extruding machine to position the extruding needle, and pushing the extruding shaft and the extruding pad through the outer sliding block to extrude the blank; and (5) finally forming a tubular product by virtue of the extrusion of the outer sliding block of the extruding machine. According to the forming mold and method, the continuous plasticity of the magnesium alloy tubular product in the machining process can be effectively improved, the mechanical property can be enhanced, and the large-batch production machining can be realized.

Owner:重庆昱华新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com