High-performance cold rolled phase transformation plasticity steel and preparation method thereof

A high-performance, plastic steel technology, applied in the field of alloy steel, can solve problems such as deterioration of the surface quality of the slab, and achieve the effects of avoiding surface defects, high strength, and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

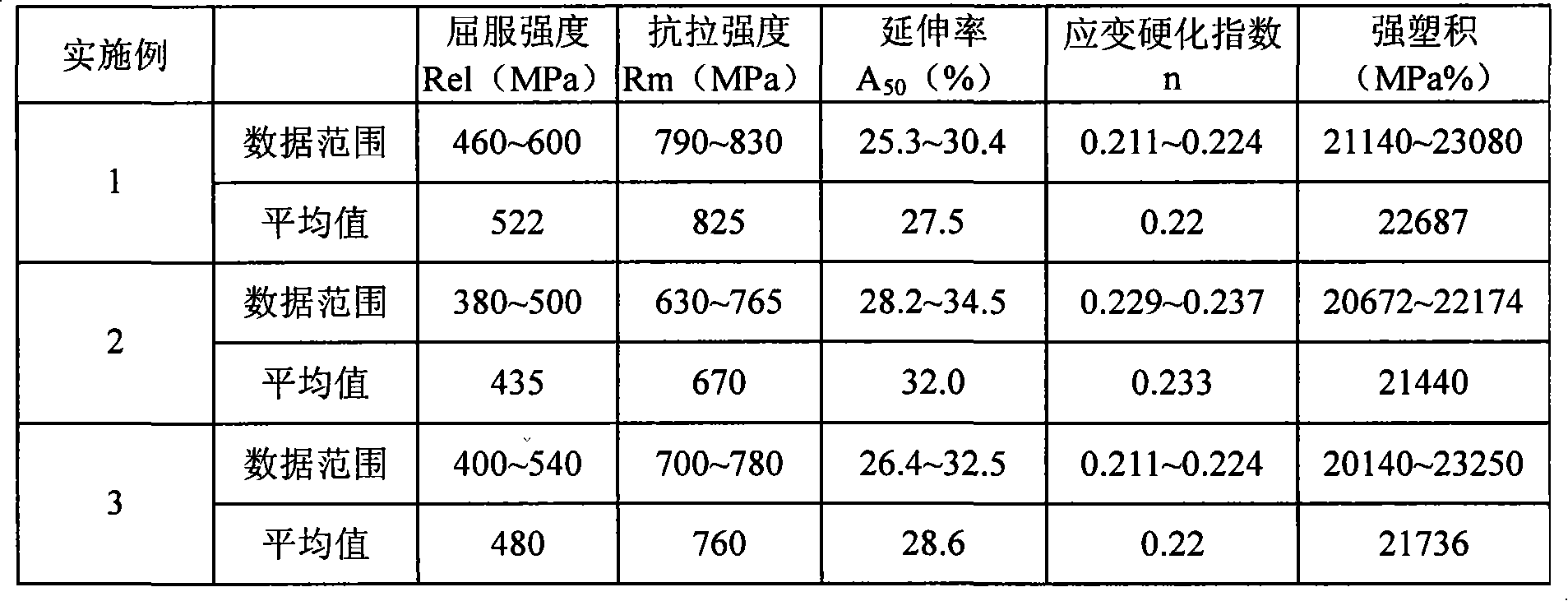

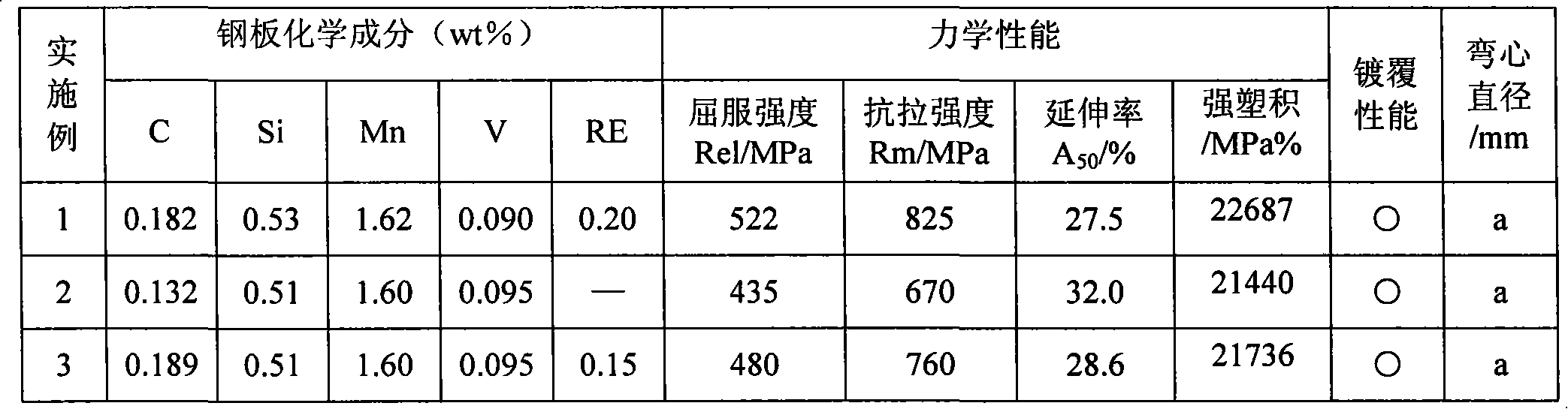

[0016] The chemical composition of the high-performance cold-rolled phase transformation plastic steel used in Example 1 of the present invention is shown in Table 1. The preparation process is as follows: the steel billet with the above composition is cold-rolled to make a steel plate with a thickness of 1.8mm; the steel plate is heated to 800°C for 180 seconds in a heat treatment furnace, and then rapidly cooled to 400°C at 30°C / s and isothermal for 550 seconds, and finally air-cooled to room temperature at 10°C / s to obtain a high-performance cold-rolled phase transformation plastic steel.

[0017] After testing, the relative amount (volume percentage) of the microstructure of the steel plate after heat treatment is: 62% ferrite, 8% retained austenite, and the balance is bainite. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It is not difficult to see from Table 2 that the high-performance cold-rolled phase-change plastic steel obt...

Embodiment 2

[0019] The chemical composition of the high-performance cold-rolled phase transformation plastic steel used in Example 2 of the present invention is shown in Table 1. The preparation process is as follows: the steel billet with the above composition is cold-rolled to make a steel plate with a thickness of 1.0mm; the steel plate is heated to 760°C for 90 seconds in a heat treatment furnace, and then rapidly cooled to 460°C at 40°C / s ℃ and isothermal for 50 seconds, and finally oil-cooled to room temperature at 20°C / s to obtain high-performance cold-rolled phase-change plasticity steel.

[0020] After testing, the relative amount (volume percentage) of the microstructure of the steel plate after heat treatment is: 73% ferrite, 13.2% retained austenite, and the balance is bainite. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It is not difficult to see from Table 2 that the high-performance cold-rolled phase-change plasticity steel obta...

Embodiment 3

[0022] The chemical composition of the high-performance cold-rolled phase transformation plastic steel used in Example 3 of the present invention is shown in Table 1. The preparation process is as follows: the steel billet with the above composition is cold-rolled to make a steel plate with a thickness of 1.5 mm; the steel plate is heated to 780 °C for 90 seconds in a heat treatment furnace, and then rapidly cooled to 430 °C at 30 °C / s ℃ and isothermal for 300 seconds, and finally air-cooled to room temperature at 10°C / s to obtain a high-performance cold-rolled phase transformation plastic steel.

[0023] After testing, the relative amount (volume percentage) of the microstructure of the steel plate after heat treatment is: 64% ferrite, 11.6% retained austenite, and the balance is bainite. The mechanical properties of the steel plates after heat treatment are shown in Table 2. It is not difficult to see from Table 2 that the method of the present invention has obtained a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com