780MPa stage cold rolled hot galvanizing dual-phase steel with higher forming property and manufacturing method thereof

A manufacturing method, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as poor manufacturability and increased alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

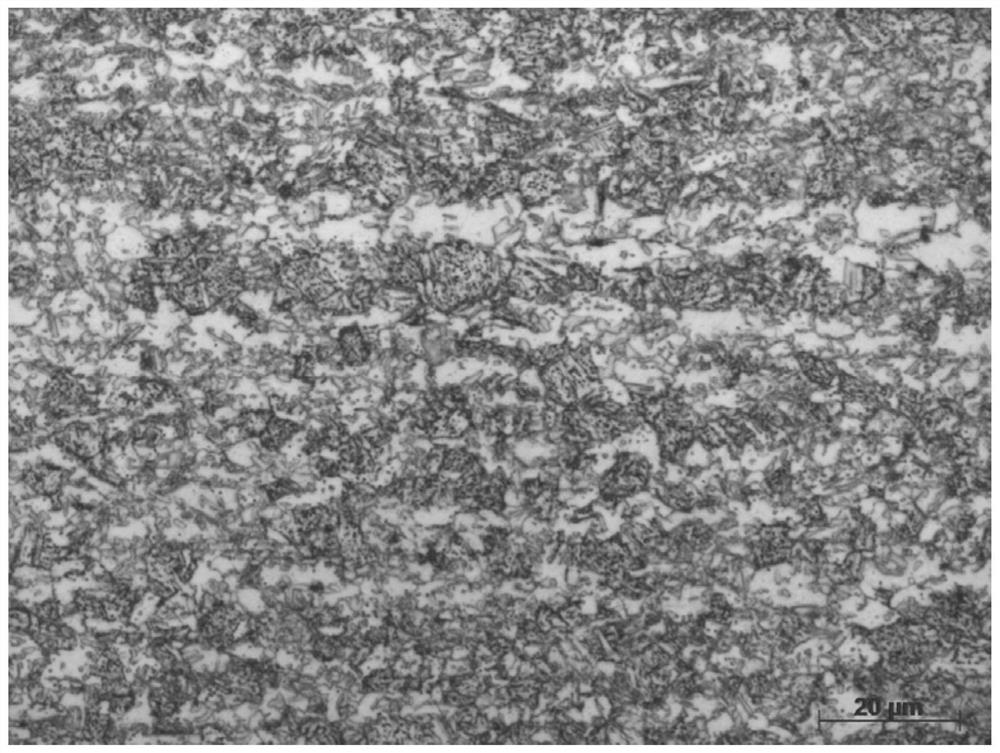

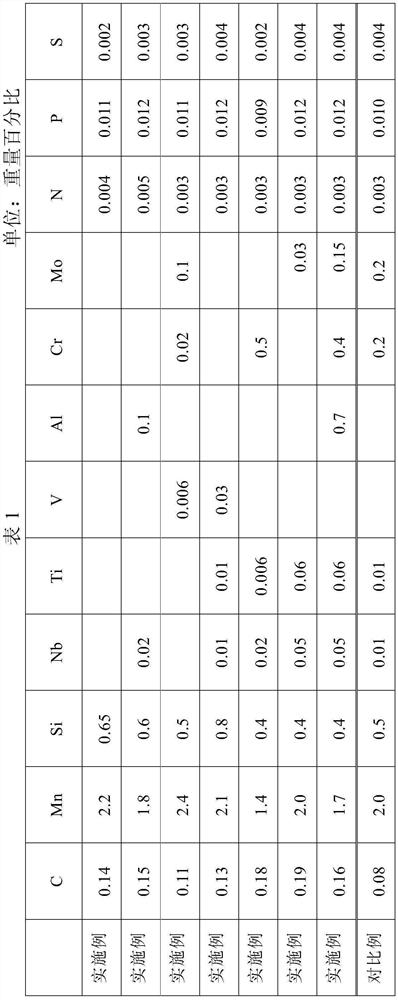

[0052] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described, and the embodiment of the present invention is implemented on the premise of the technical solution of the present invention, has provided detailed implementation mode and specific operation process, but protection scope of the present invention is not limited to following Example.

[0053] Table 1 is the composition of the examples of the present invention, Table 2 is the manufacturing process parameters of the examples of the present invention, and Table 3 is the mechanical properties of the examples of the present invention.

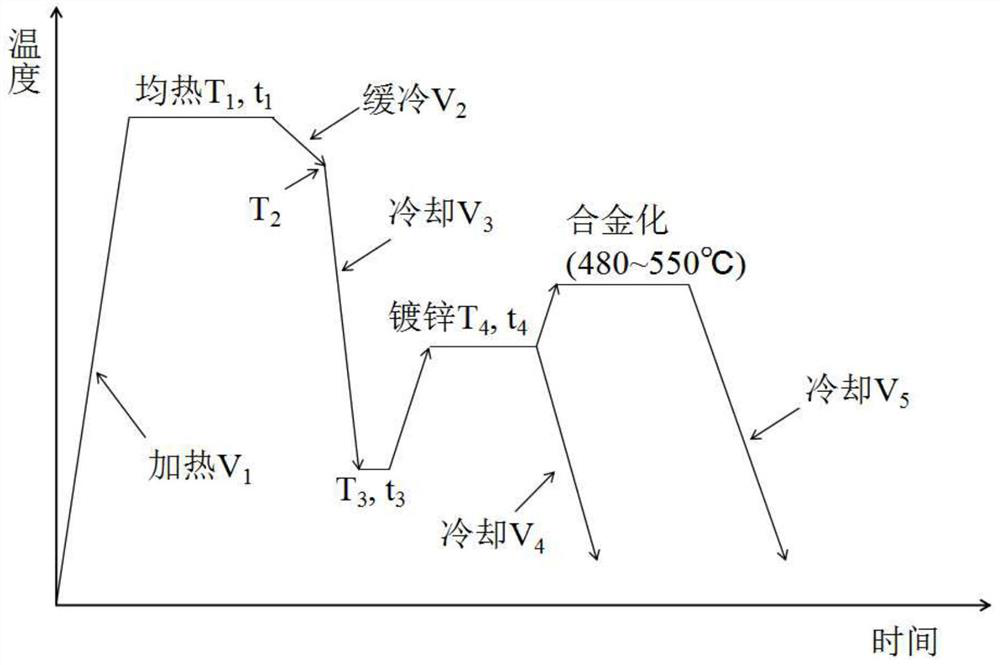

[0054] The steel materials with the composition shown in Table 1 are smelted and cast to make cast slabs; after holding at a reheating temperature of 1200-1260°C for not less than 1 hour, hot rolling and finish rolling are completed at a final rolling temperature above 850°C. The thickness of the rolled plate is about 3.6 mm; the hot-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com