Patents

Literature

132results about How to "Improve work hardening ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

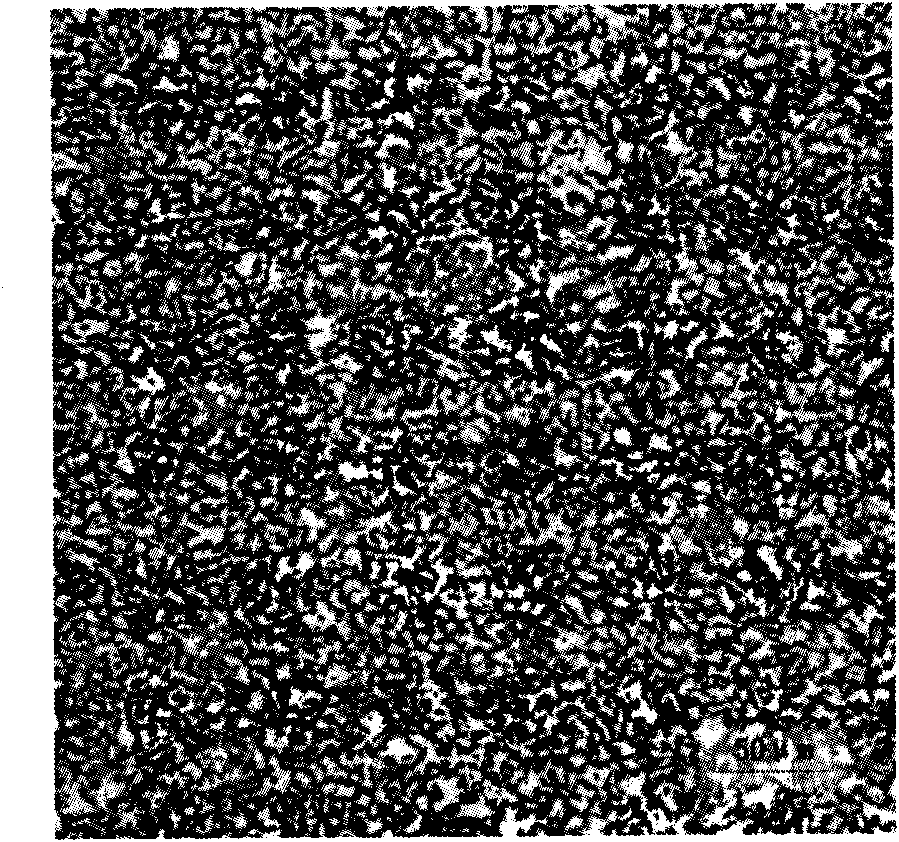

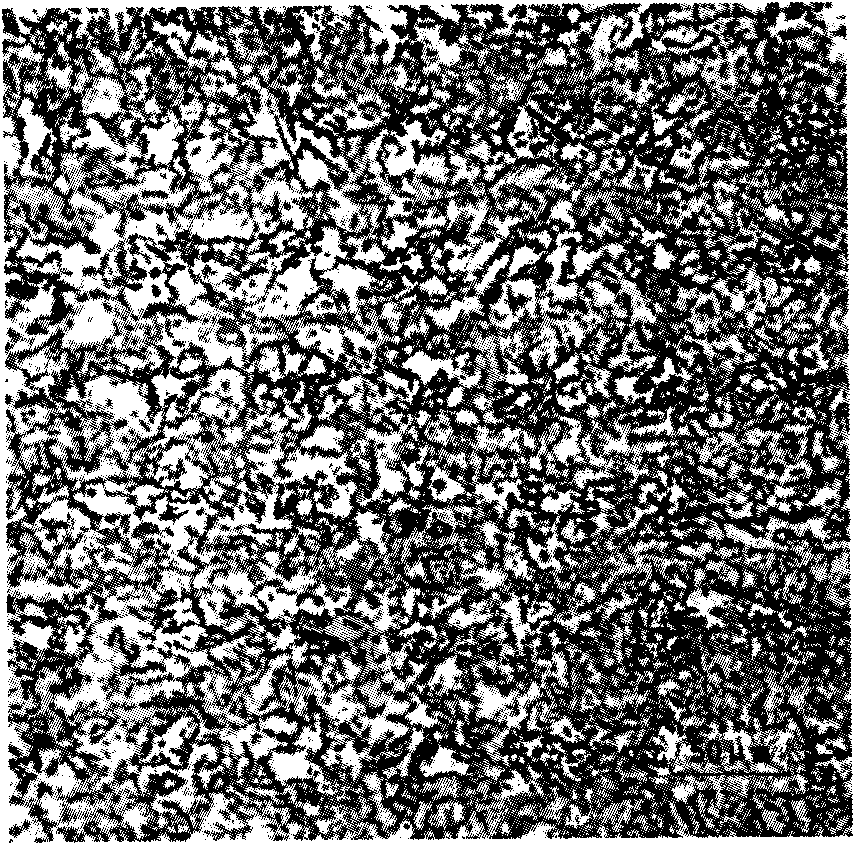

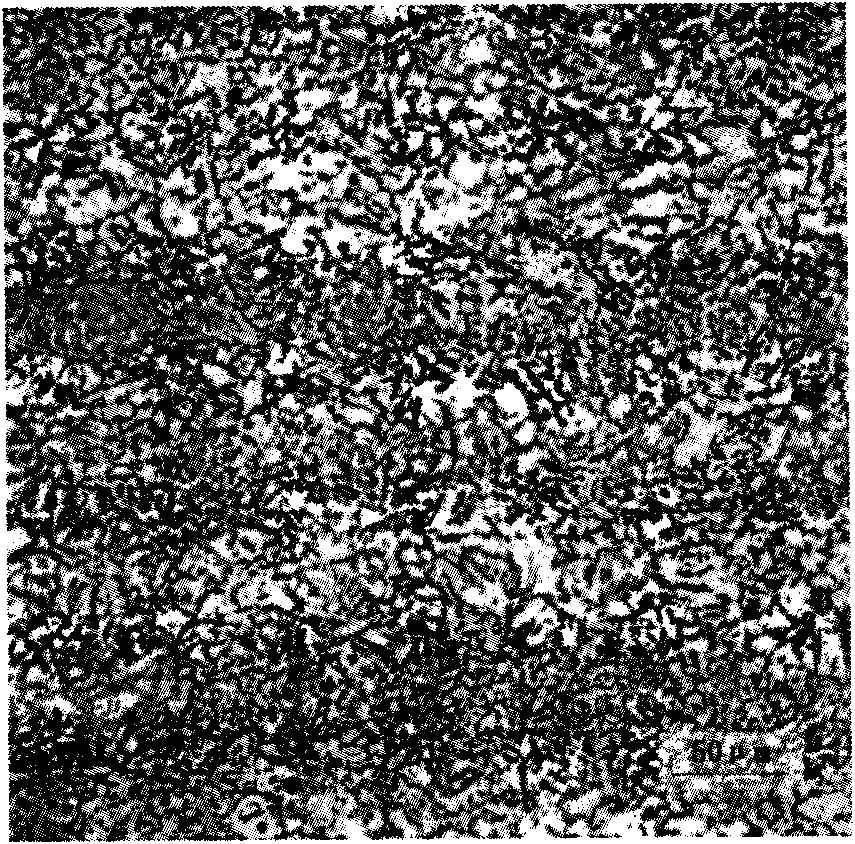

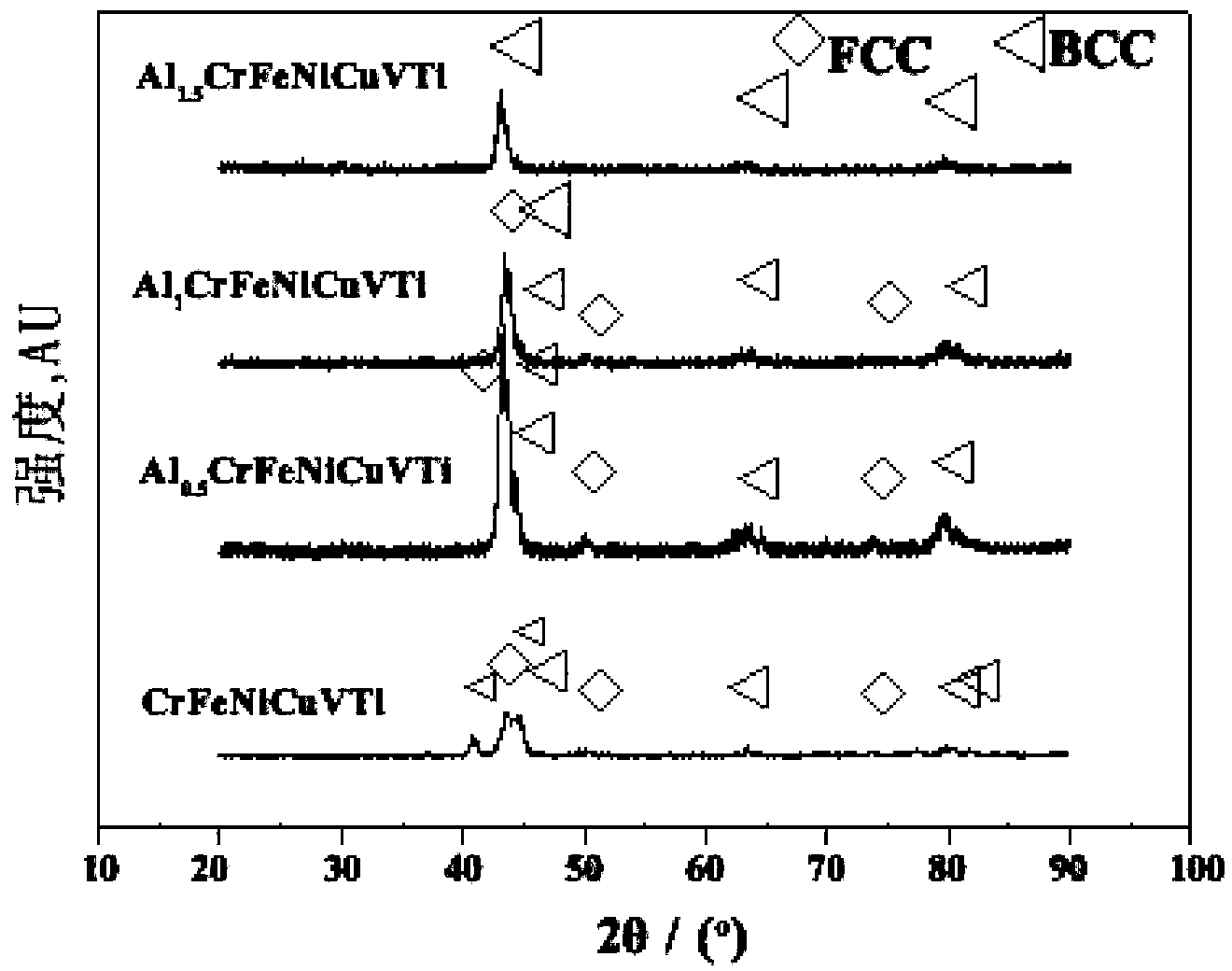

AlxCrFeNiCuVTi high-entropy alloy material and preparation method thereof

The invention relates to an AlxCrFeNiCuVTi high-entropy alloy material and a preparation method thereof. The high-entropy alloy comprises a component of AlxCrFeNiCuVTi, wherein x is a molar ratio, and the value range of x is 0.5-1.5. The preparation method of the alloy material comprises the following steps of: putting raw materials into a solution including acetone and ethanol, cleaning for 23-30 minutes by using an ultrasonic oscillator, and then drying in a 50DEG C drying oven for 6 hours; weighing alloys according to a molar ratio, and putting the alloys into a water-cooling copper crucible; when the air pressure in a furnace body reaches 3*10<-3>Pa, introducing high-purity argon to clean for 3-5 times; introducing high-purity argon to ensure that the air pressure in a furnace chamber is kept to be 0.8-0.9 atmospheric pressure, and then electrifying, wherein the smelting striking current is 30-40A, the current after stabilization is 90A, the time for smelting the alloys once is 10 seconds, and a sample needs to be smelted for 5 times repeatedly; and when the components of a smelted sample are uniformly cooled, taking the alloy out of the furnace. Compared with a conventional crystal alloy, the AlxCrFeNiCuVTi high-entropy alloy material has higher hardness, strength, high temperature stability, corrosion resistance and work hardening capacity.

Owner:梧州漓佳铜棒有限公司

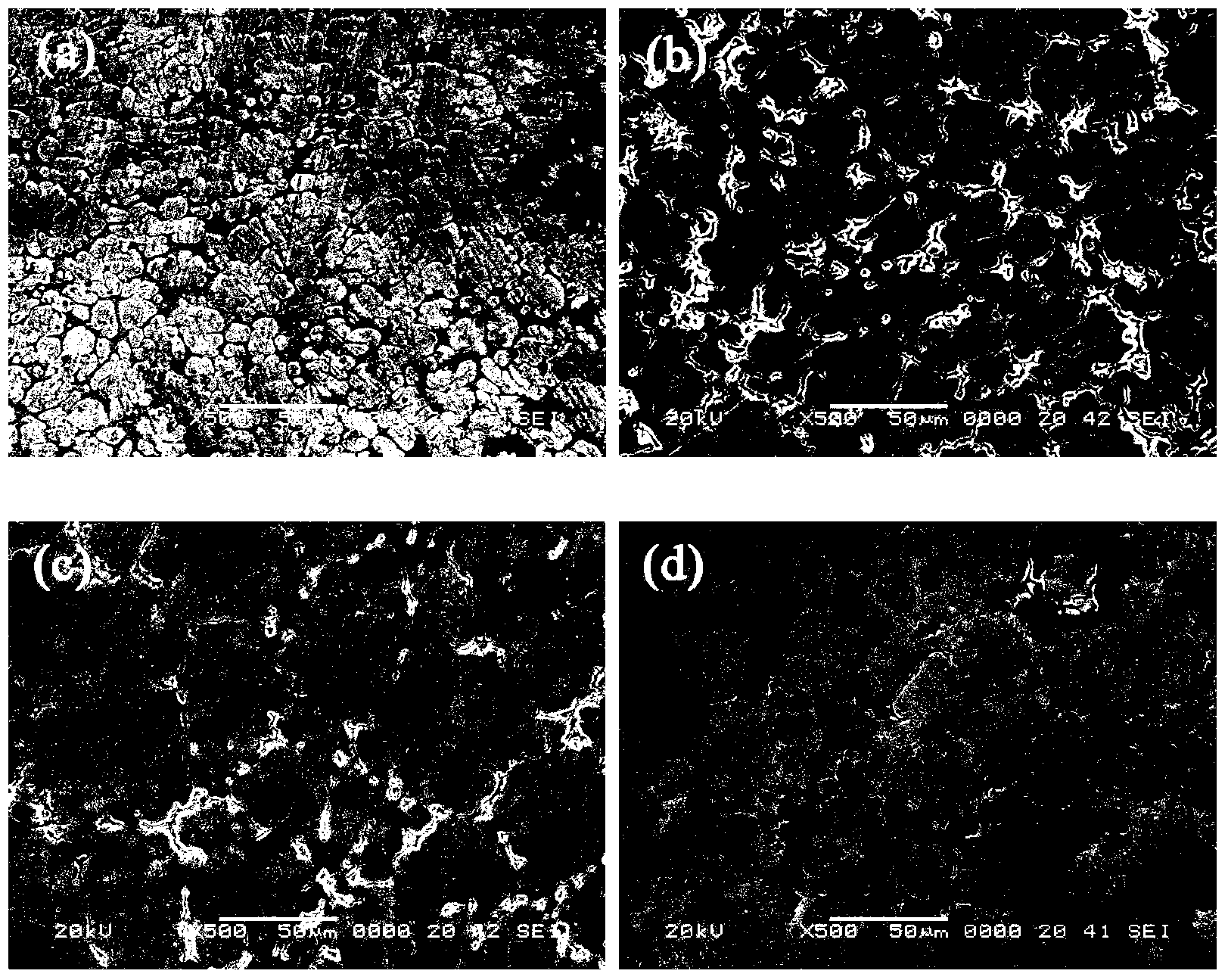

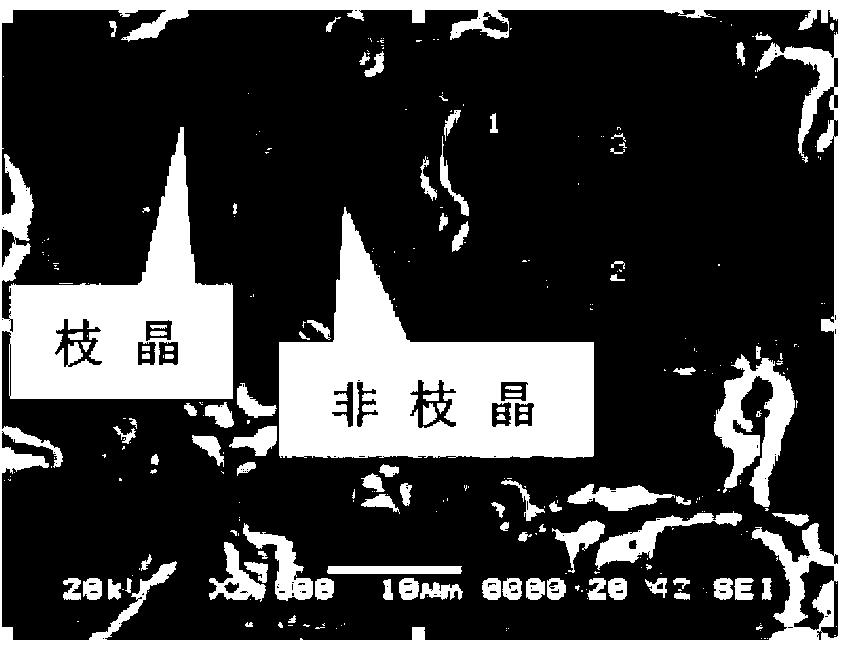

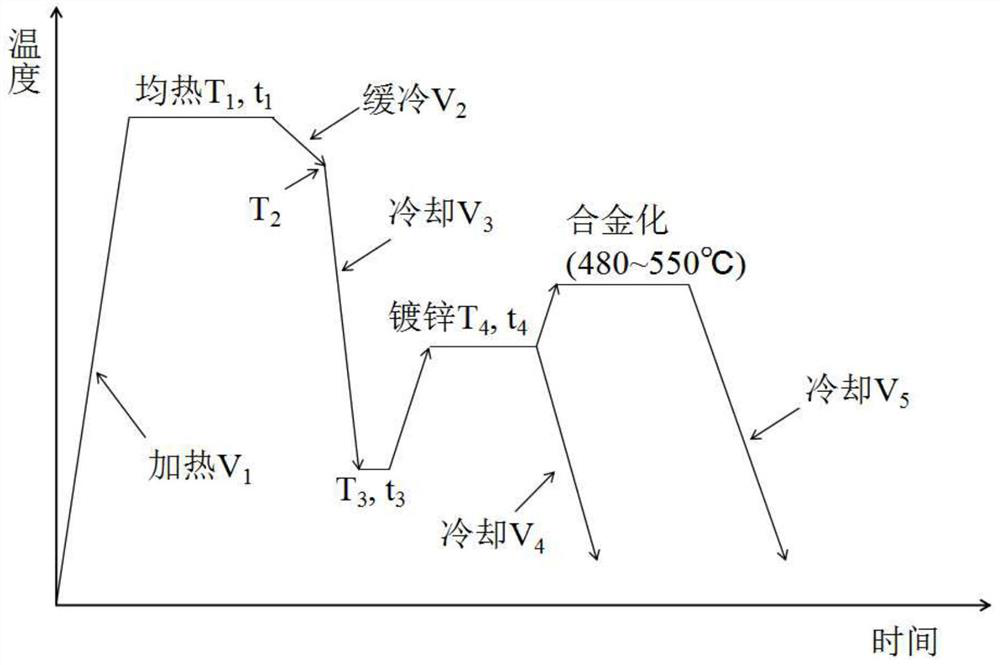

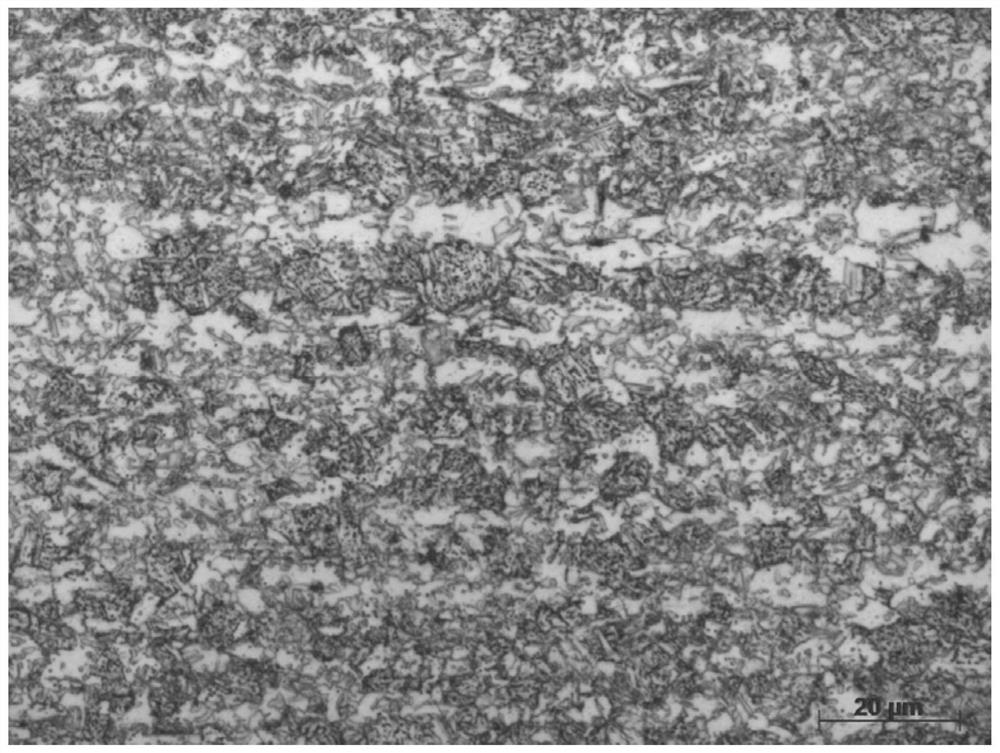

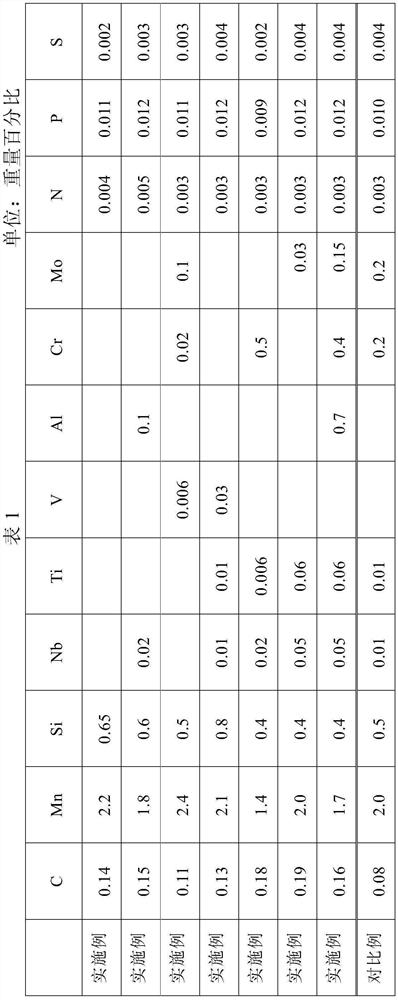

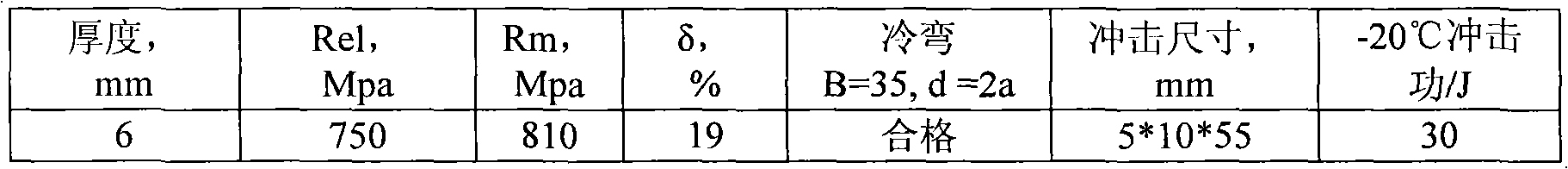

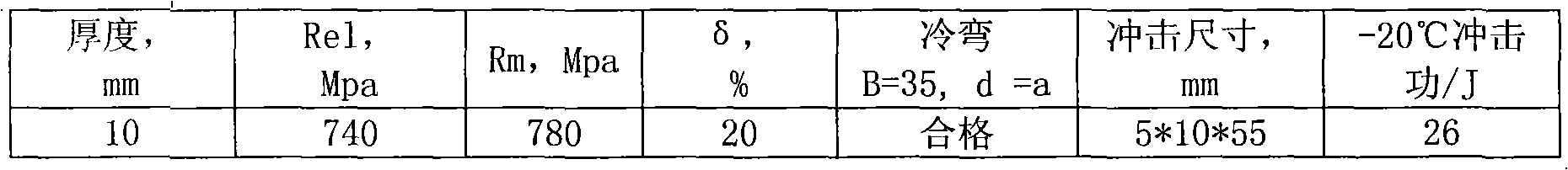

780MPa stage cold rolled hot galvanizing dual-phase steel with higher forming property and manufacturing method thereof

The invention discloses 780MPa stage cold rolled hot galvanizing dual-phase steel with a higher forming property and a manufacturing method thereof. The steel comprises chemical components including,by mass percent, 0.1 to 0.2% of C, 1.3 to 2.5% of Mn, 0.4 to 1.0% of Si, not larger than 0.02% of P, not larger than 0.01% of S, not larger than 0.008% of N and the balance Fe and inevitable impurities. After conventional smelting, hot rolling and cold acid continuous rolling, through a QP process, hot dip galvanizing recrystallization annealing is carried out, a final tissue of a galvanized sheetmainly comprises ferrite, tempered martensite and residual austenite, the tensile strength is larger than or equal to 780 MPa, the percentage elongation is larger than or equal to 18%, n10 to 20% islarger than or equal to 0.14, the hole expansion rate lambda is larger than or equal to 25%, through control over the cold rate, the galvanized sheet reduces use of alloy elements, and the needs of reducing the alloy cost and improving the hot galvanizing dual-phase steel forming property can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

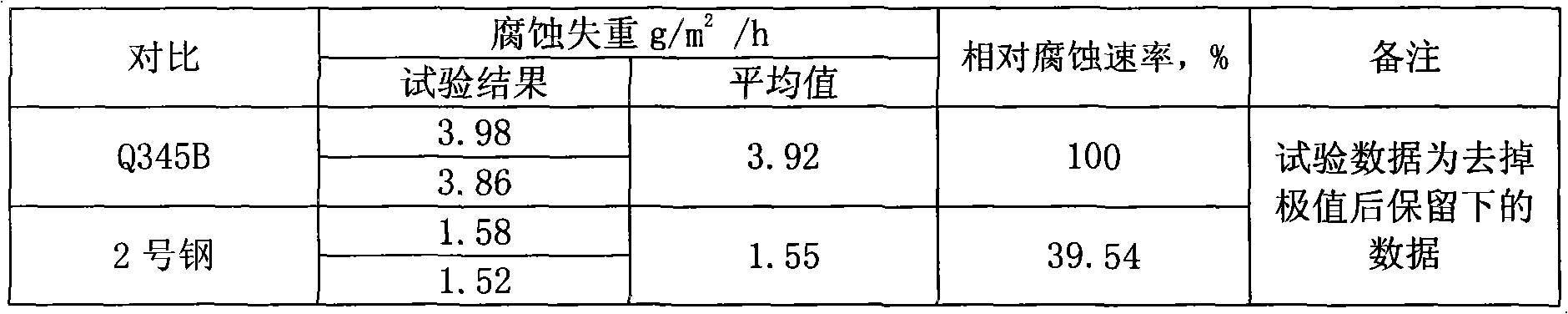

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

High-strength hot-dip galvanized steel sheet and high-strength alloyed hot-dip galvanized steel sheet excellent in mechanical cutting property, and manufacturing method thereof

ActiveUS20140287263A1High densityImprove work hardening abilityHot-dipping/immersion processesFurnace typesSheet steelSurface layer

There is provided a high-strength hot-dip galvanized steel sheet and the like excellent in mechanical cutting property, which are capable of obtaining high ductility while ensuring high strength with maximum tensile strength of 900 MPa or more. The high-strength hot-dip galvanized steel sheet has a sheet thickness of 0.6 to 5.0 mm and has a plating layer on a surface of a steel sheet with component compositions being set in appropriate ranges, in which the steel sheet structure contains a 40 to 90% ferrite phase and a 3% or more retained austenite phase by volume fraction. In the retained austenite phase, a solid solution carbon amount is 0.70 to 1.00%, an average grain diameter is 2.0 μm or less, an average distance between grains is 0.1 to 5.0 μm, a thickness of a decarburized layer in a steel sheet surface layer portion is 0.01 to 10.0 μm, an average grain diameter of oxides contained in the steel, sheet surface layer portion is 30 to 120 nm and an average density thereof is 1.0×1012 oxides / m2 or more, and moreover, a work hardening coefficient (n value) during a 3 to 7% plastic deformation is 0.080 or more on average.

Owner:NIPPON STEEL CORP

Aluminum alloy material with high bake hardening capability for 6-series automobile bodies

InactiveCN101985707AHigh bake hardening propertiesLower yield strengthSolution treatmentNatural aging

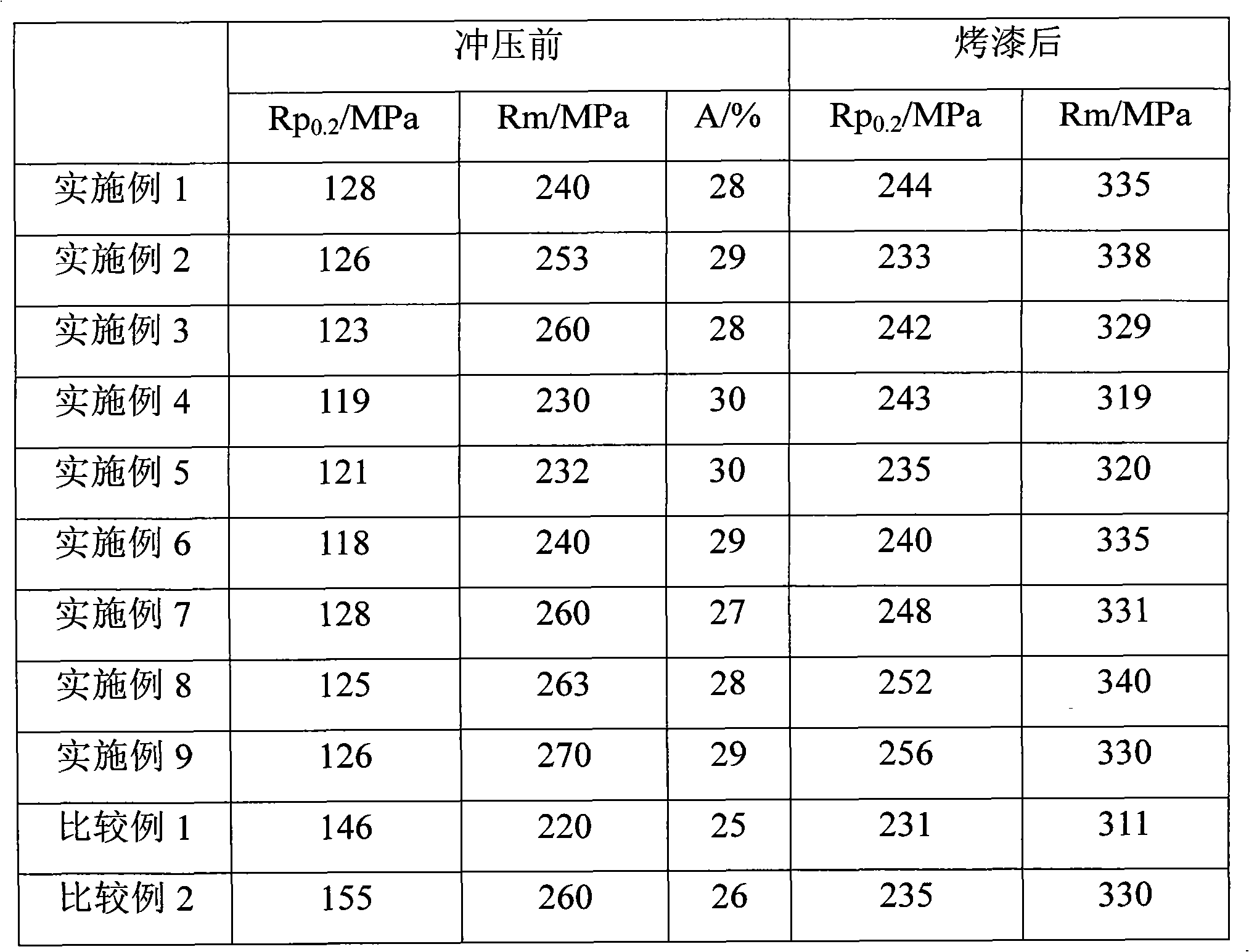

The invention provides an aluminum alloy material with high bake hardening capability for 6-series automobile bodies, which comprises the following components: 0.50-1.00wt% of Si, 0.60-1.30wt% of Mg, 0.01-0.30wt% of Cu, 0.05-0.20wt% of Mn, less than or equal to 0.10wt% of Cr, less than or equal to 0.15wt% of Ti, 0.05-0.25wt% of Fe and the balance of Al. After the material is formed by casting, the material is treated by homogenizing annealing, hot rolling, cold rolling, solution treatment and then natural aging. Before stamping, the yield strength of the material is lower than 130MPa; and after baking, the yield strength of the material is greater than 230MPa, and the tensile strength of the material is greater than 310MPa. The material has higher bake hardening ability, and simultaneously, the forming property of the material meets the using requirements, thus the material is an ideal material for manufacturing automobile bodies.

Owner:苏州有色金属研究院有限公司

Low-density ultrahigh-strength steel and preparation method thereof

ActiveCN106244927ALow costIn line with the development concept of energy saving and emission reductionChemical compositionCarbide

The invention relates to low-density ultrahigh-strength steel and a preparation method thereof, and belongs to the field of metal materials. The steel comprises the following chemical components in percentage by mass: 0.6 to 1.6 percent of C, 5 to 10 percent of Al, 15 to 30 percent of Mn, 0.01 to 0.2 percent of Nb, 0.1 to 3 percent of Mo, less than or equal to 5 percent of Cr, less than or equal to 0.5 percent of Ti, less than or equal to 2 percent of Si, less than or equal to 0.6 percent of B, and the balance of Fe and unavoidable impurity elements. According to the low-density ultrahigh-strength steel and the preparation method thereof, a NbMoC phase which is finely dispersed precipitates by compounding and adding the Nb and the Mo; precipitation is strengthened by cooperating with a kappa-carbide; the tensile strength reaches over 1,350 MPa, the elongation reaches over 10 percent and the density is 6.8 to 7.0 g / cm<3>; the low-density ultrahigh-strength steel is low in cost, is suitable for light weight of traffic transportation tools, such as vehicles and airplanes, and meets the development concept of energy conservation and emission reduction.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

High-nitrogen non-magnetic austenitic stainless steel and manufacturing method thereof

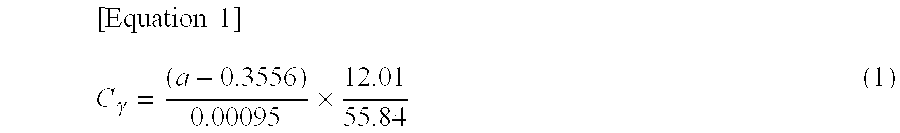

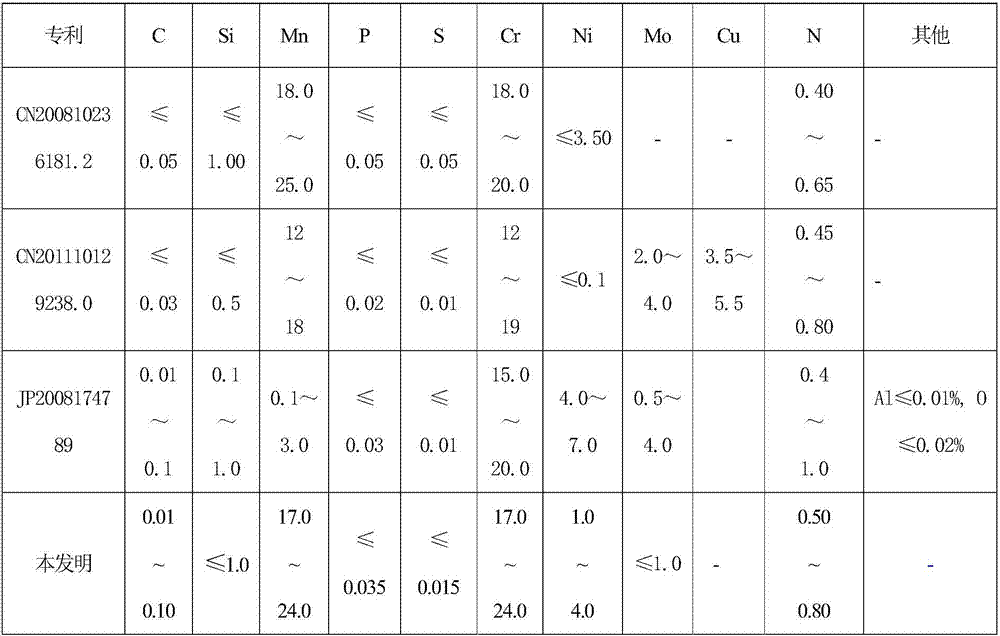

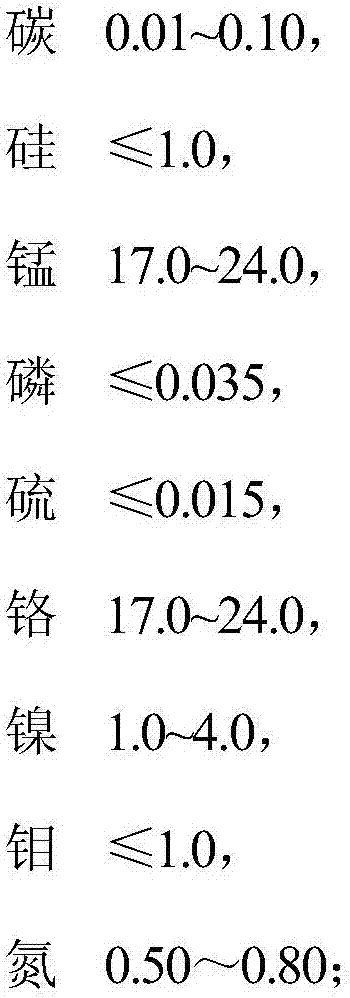

The invention relates to high-nitrogen non-magnetic austenitic stainless steel. The high-nitrogen non-magnetic austenitic stainless steel comprises following chemical components including, by weight percent, 0.01% to 0.10% of C, not larger than 1.0% of Si, 17.0% to 24.0% of Mn, not larger than 0.035% of P, not larger than 0.015% of S, 1.0% to 4.0% of Ni, 17.0% to 24.0% of Cr, not larger than 1.0%of Mo, 0.50% to 0.80% of N and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that the electric furnace+AOD+LF manner is adopted for smelting, continuous casting or die casting is adopted for making a slab ingot, and during continuous casting, the superheat degree is controlled to be smaller than 50 DEG C; a continuous casting blank or die casting slab ingotis put into a stepping type heating furnace to be heated, hot rolling on a rolling machine is carried out to form a board of the needed specification, the final rolling temperature ranges from 800 DEG to 950 DEG C, the hot-rolled board is subject to acid pickling, and the high-nitrogen non-magnetic austenitic stainless steel hot-rolled board finished product is obtained. The product has high yield strength, good ductility and toughness, corrosion resistance and wide application field and has no magnetism.

Owner:宝武特种冶金有限公司

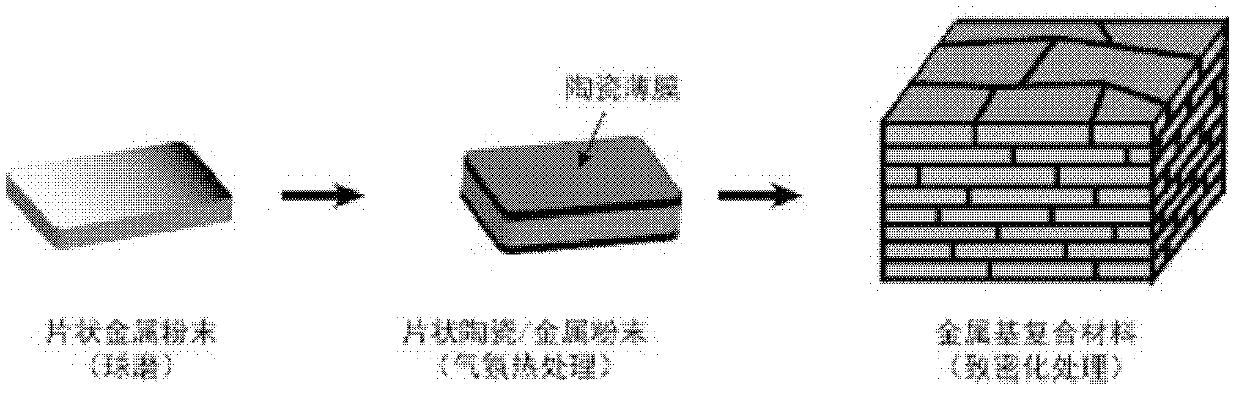

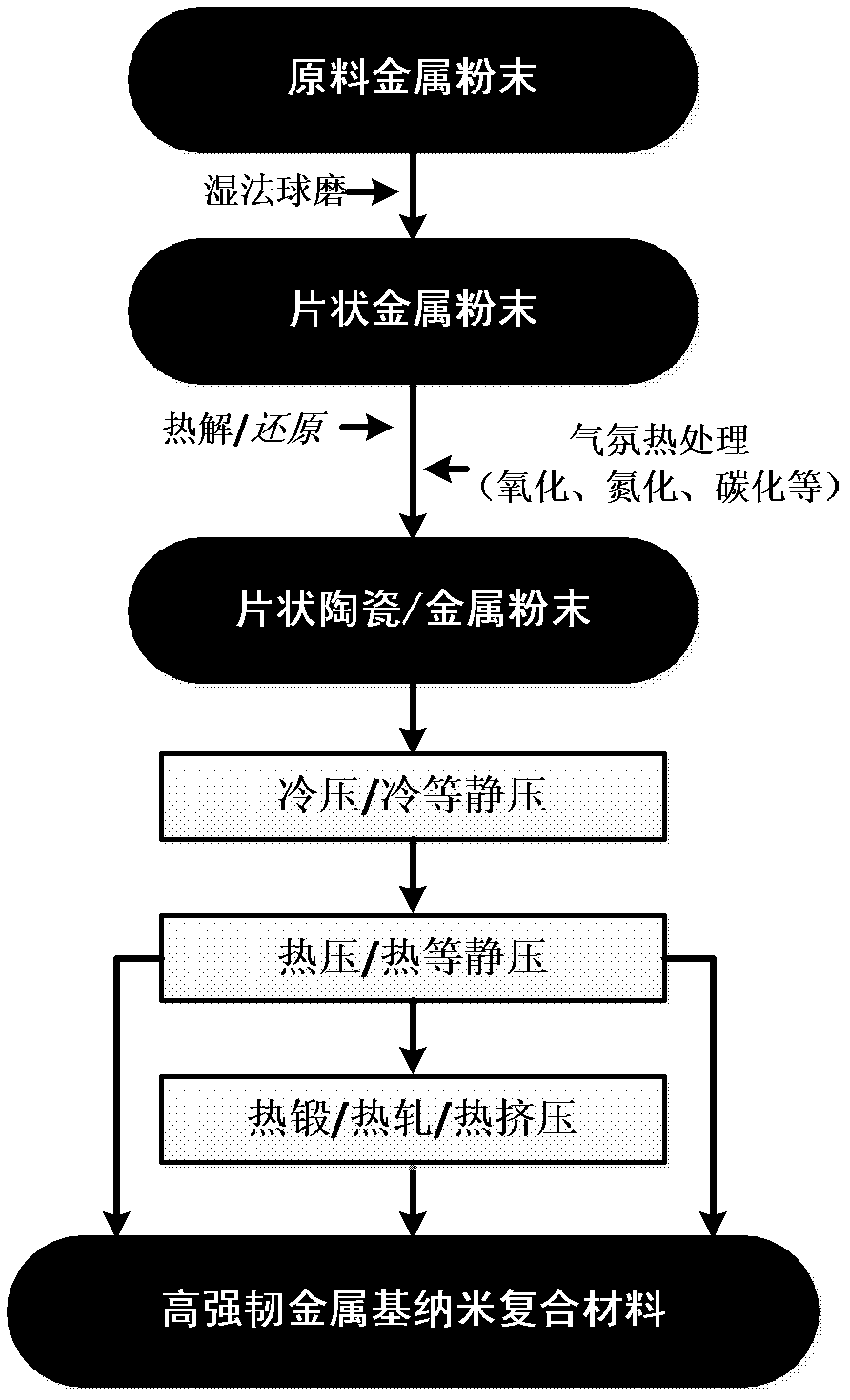

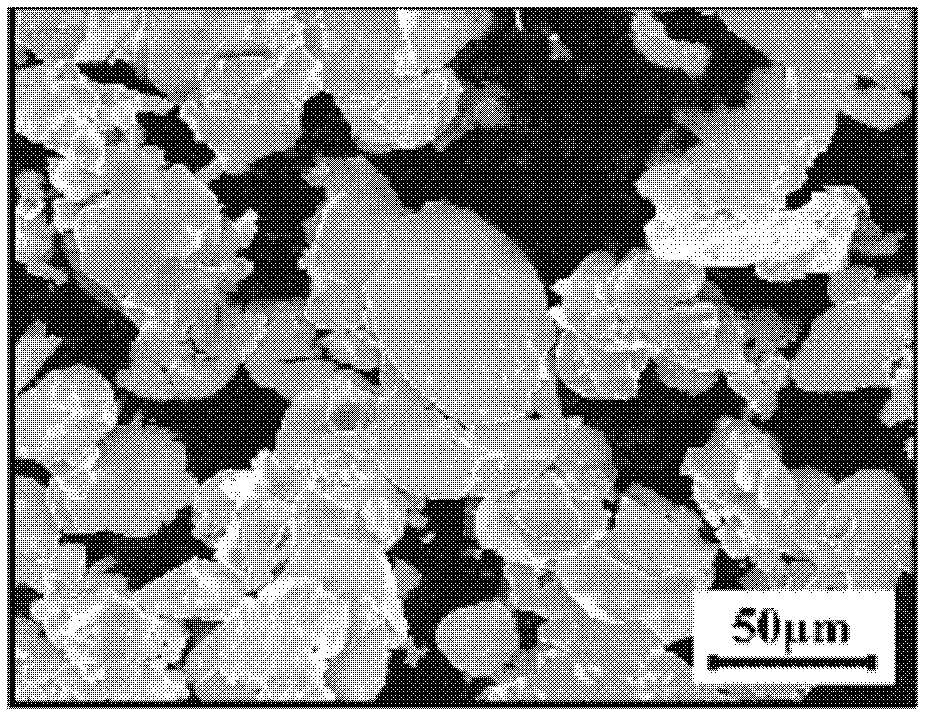

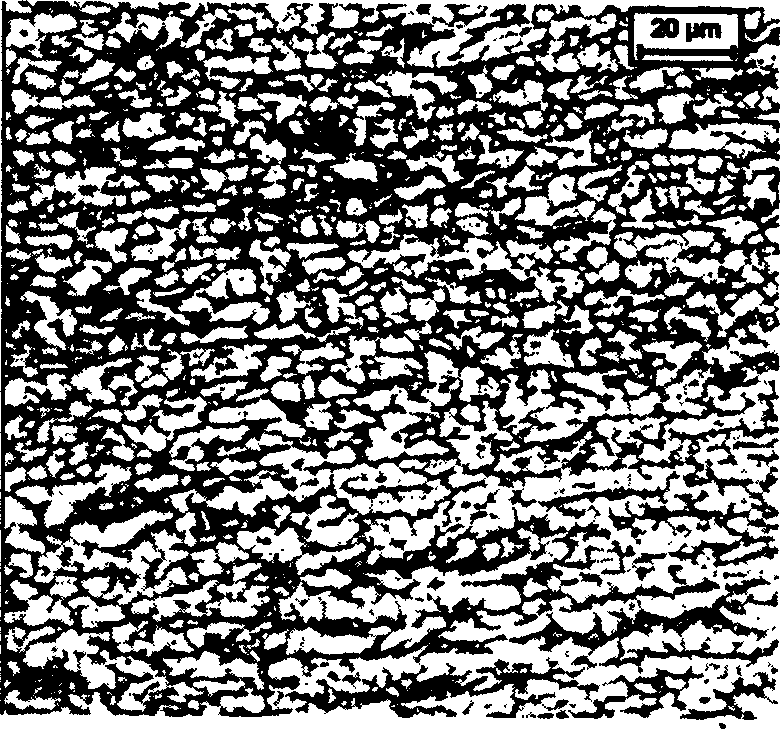

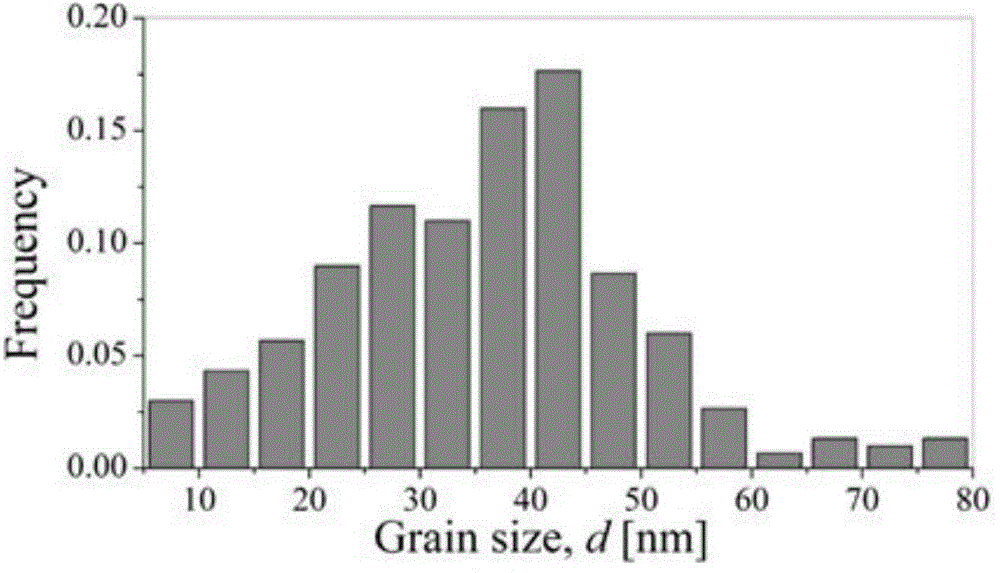

Preparation method of high-toughness metal-based nanometer composite material

The invention provides a preparation method of a high-toughness metal-based nanometer composite material and belongs to the technical field of composite materials. The preparation method provided by the invention comprises the following steps of: firstly, using an atmosphere heat treatment process, generating a layer of a nanometer ceramic thin film on the sheet-shaped metal powder through reaction in-situ; and then carrying out densifying treatment by using a powder metallurgical process, so as to obtain the large compact metal-based composite material. The metal-based composite material prepared by the invention has a metal / ceramic alternative laminated structure, wherein a ceramic layer can be used for effectively restraining the reply of a metal layer and the crystal grain growth, improving the high-position wrong storage capability, keeping a nanometer crystal matrix structure, and causing the rotation and inactivation of fissures, so as to realize mechanical properties matched with the high toughness. The preparation method provided by the invention is simple, convenient and practicable, can be used for realizing the macro-quantized preparation of the large-size composite material, and is good for prompting engineering applications of the metal-based nanometer composite material.

Owner:SHANGHAI JIAO TONG UNIV

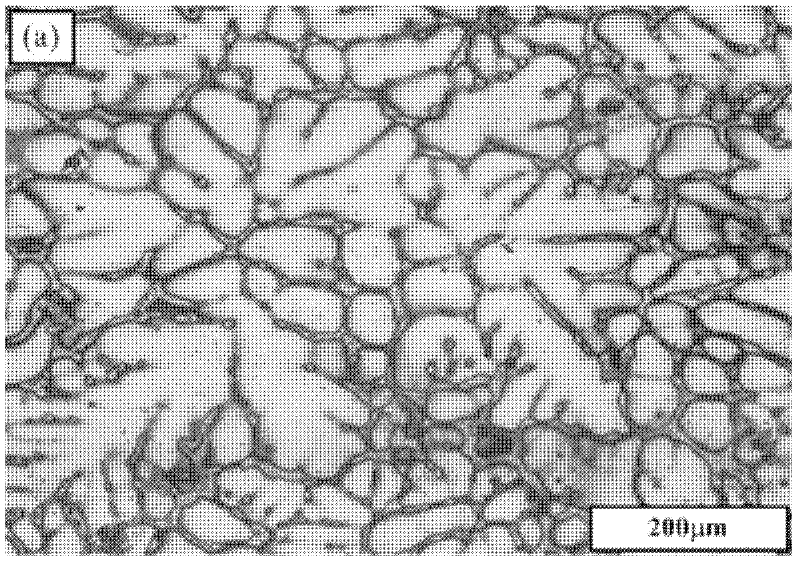

Tungsten-chromium-vanadium-containing high-manganese wear-resistant steel and preparation method thereof

The invention discloses a tungsten-chromium-vanadium-containing high-manganese wear-resistant steel and a preparation method thereof, and belongs to the technical field of wear-resistant materials. The preparation method comprises the following steps: firstly, with steel scrap, high manganese steel waste, a carburant, ferromanganese, nitrogen-containing ferromanganese, ferrotungsten, ferrochromium, ferrovanadium and metallic aluminum as raw materials, smelting tungsten-chromium-vanadium-containing high-manganese wear-resistant molten steel, when the temperature of the molten steel reaches 1520-1550 DEG C, tapping off and feeding in a steel ladle; inserting an alloy wire containing microalloy elements such as rare earth, titanium, niobium, boron, potassium, and magnesium into the molten steel in the steel ladle, the addition amount of the alloy wire accounts for 1.8-2.5wt% of that of the molten steel in the steel ladle, and the diameter phi of the alloy wire is 4.5-6.0 mm; pouring the treated molten steel in a mould; then cleaning a casting head and performing water toughening on a casting so that the tungsten-chromium-vanadium-containing high-manganese wear-resistant steel with excellent wear resisting property can be obtained.

Owner:BEIJING UNIV OF TECH

Preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy

The invention relates to a preparation method of ultrahigh-manganese steel based TiC steel bond hard alloy. The preparation method is characterized by comprising the following steps: preparing titanium powder and graphite powder into in-situ synthesized TiC powder with the required proportion according to the C / Ti atomic ratio of 0.8-1.0; preparing ferromolybdenum powder, ferrovanadium powder, ferrochromium powder, ferromanganese powder, ferrosilicon powder, iron powder, nickel powder, colloidal graphite and rare earth raw materials according to the required mass ratio of bonded-phase metal chemical components, performing ball-milling by a steel ball, adding absolute ethanol as a medium and PVA (polyvinyl alcohol), after the ball-milling process is finished, drying slurry, pressing for forming, and sintering to obtain the steel bond alloy. According to the preparation method, the ultrahigh-manganese steel based TiC steel bond hard alloy is prepared by combining an in-situ reaction synthesis technology with a liquid-phase sintering technology; as TiC is synthesized in situ in a substrate through reaction in the sintering process, the fineness of particles is improved, no sharp angle is formed on the surface, and a substrate interface is relatively good in adhesion and clean; the comprehensive mechanical property of the alloy can be improved, the price is low, and the process is simple and convenient.

Owner:JIANGSU HUICHENG MACHINERY MFG

Preparation method of low carbon 42MPa grade composite fortified ultrafine crystal grain band steel

A 420 MPa-class low-carbon band steel with superfine crystal grains contains C (0.1-0.14 wt.%), Si (0.18-0.40), Mn (0.85-1.10), P (0-0.01), S (0-0.01) and Fe (rest). Its preparing process includes such steps as smelting, conticasting, coarse rolling, fine rolling, cooling, and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (420-450 MPa), high tension strength (530-550 MKPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

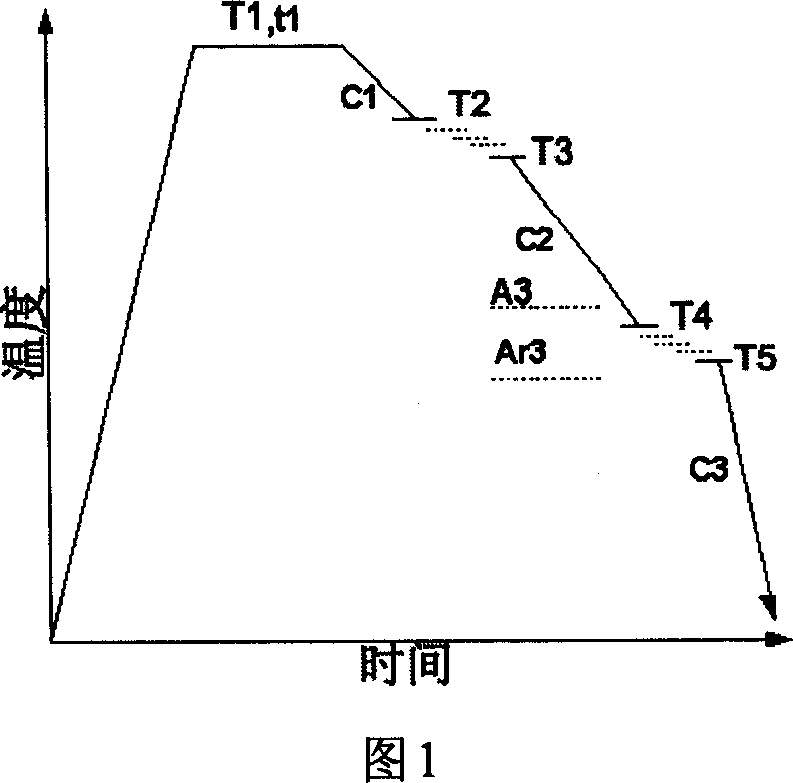

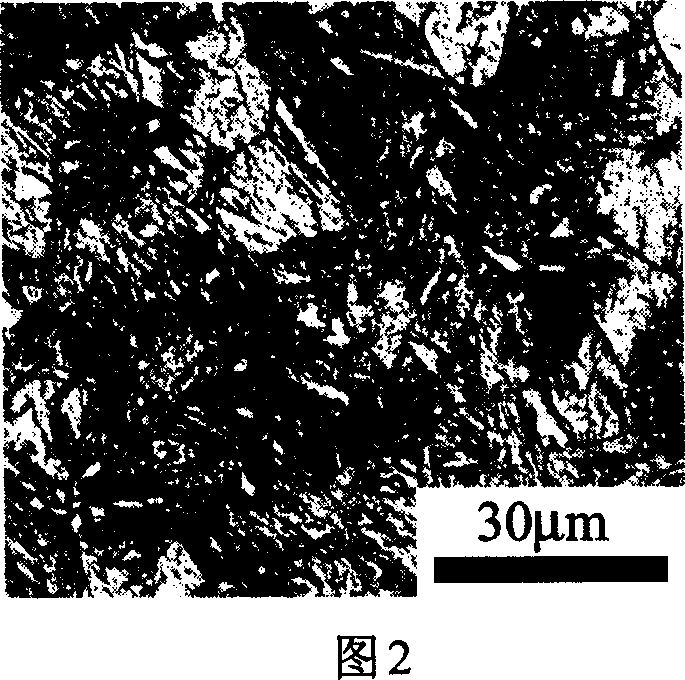

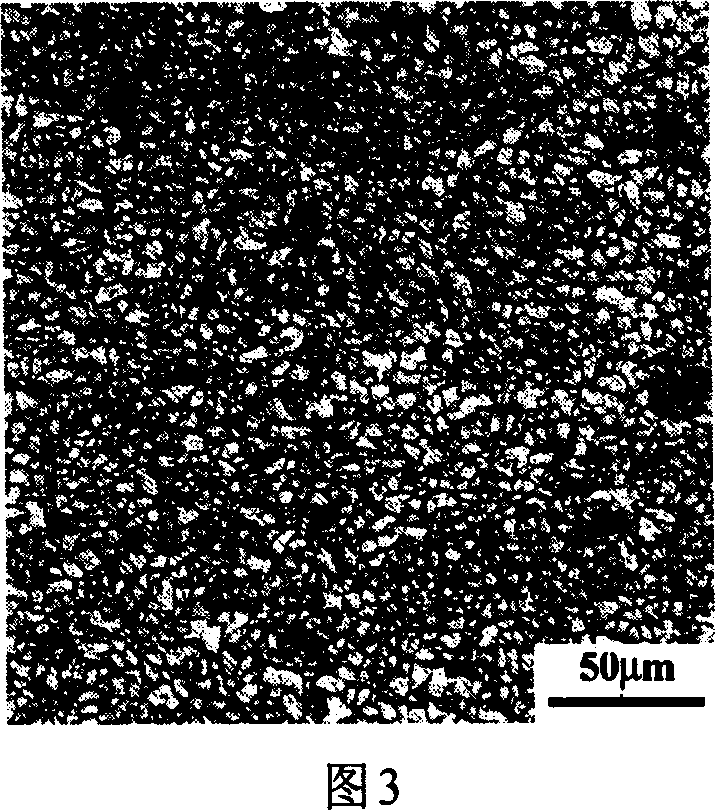

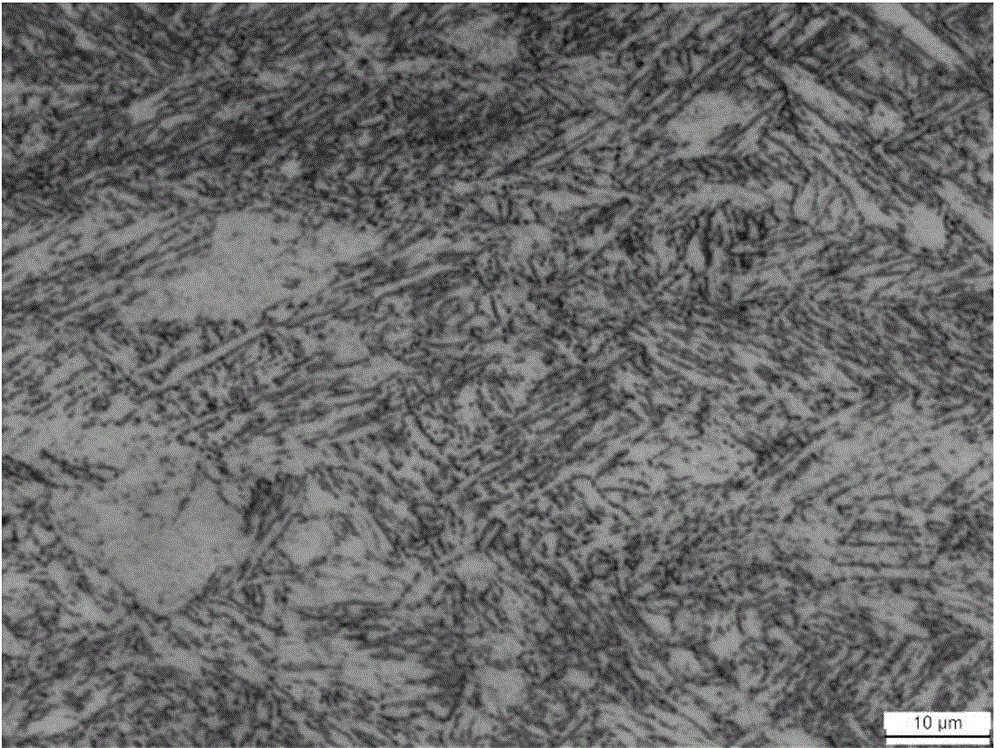

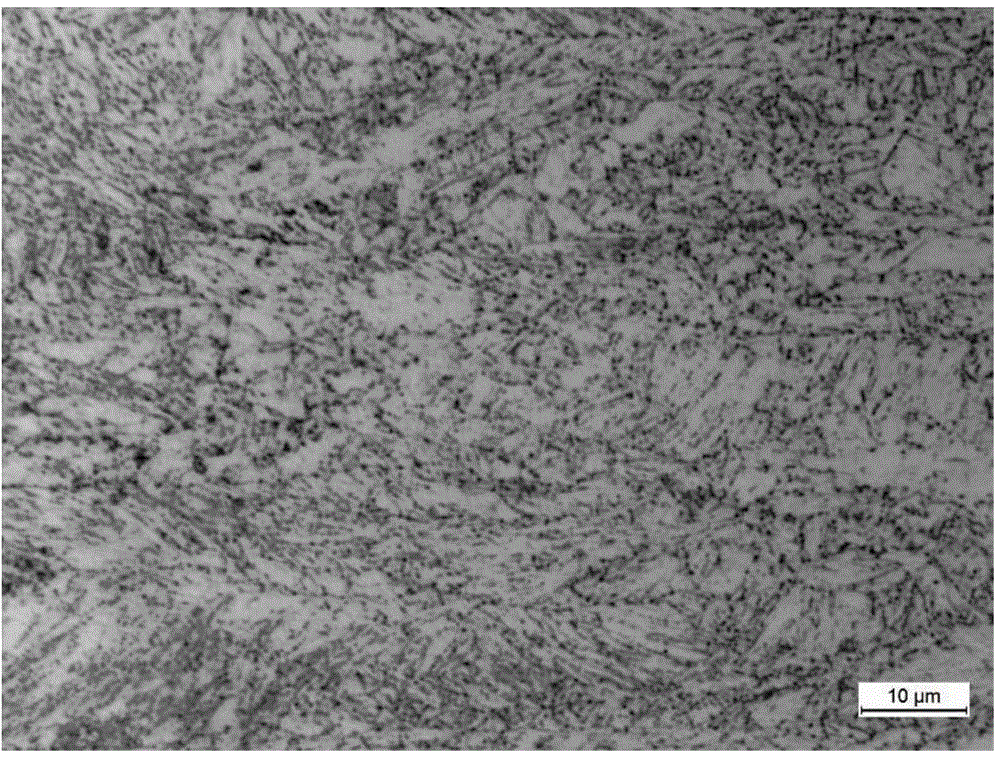

Method of preparing high-strength thin-crystal two-phase steel

InactiveCN101054621AHigh flex ratioImprove work hardening abilityHeat treatment process controlManganeseRoom temperature

The invention relates to a method for producing the fine grained dual phase steel, especially by low carbon(manganese) steel. The method comprises making the common low carbon(manganese) steel austenization, obtaining small austenitic organism after multi-pass deformation of recrystallized zone, over-cooling to a certain temperature in the temperature range of A3-Ar3 by proper cooling speed to apply multi-pass deformation with a strain rate between 0.1s-1 to 30s-1, getting 80-90% ferrite transforming mass by controlling each pass dependent variable, then quickly cooling or quenching to the room temperature. The average dimension of isometric ferrite grain in fine grained dual phase organism is less than 5 mum. The Martensite island integration number is 10-15% and the average dimension is less than 3 mum. The method is more controllable and is easy to apply on the conventional hot mill.

Owner:UNIV OF SCI & TECH BEIJING

High-wear-resistance carbide-containing austenitic ductile iron and preparation method thereof

The invention discloses high-wear-resistance carbide-containing austenitic ductile iron and a preparation method thereof and belongs to the technical field of wear-resistant materials. In order to provide the high-wear-resistance carbide-containing austenitic ductile iron which is good in hardness and toughness, the formula of the carbide-containing austenitic ductile iron is improved. The high-wear-resistance carbide-containing austenitic ductile iron comprises, by weight percentage, 3.50-3.90% of C, 2.90-3.50% of Si, 1.30-1.70% of Mn, less than 0.08% of P, less than 0.012% of S, 0.01-0.04% of RE, 0.025-0.04% of Mg, 0.08-0.18% of Cr, 0.17-0.32% of V, 0.08-0.18% of Ti, 0.30-0.40% of Cu, 0.001-0.006% of B and the balance Fe, wherein RE is rare-earth metal and is preferably Y. The high-wear-resistance carbide-containing austenitic ductile iron has the advantages that the surface hardness of the high-wear-resistance carbide-containing austenitic ductile iron can reach above HRC62, the impact toughness of the high-wear-resistance carbide-containing austenitic ductile iron is more than 2-3 times of that of chromium-based grinding balls, the high-wear-resistance carbide-containing austenitic ductile iron is excellent in comprehensive performance, breaking and distortion during use are avoided, abrasion is only about 200g per ton, and the high-wear-resistance carbide-containing austenitic ductile iron is promising in application prospect in wear-resistant component fields such as metallurgical mine machinery, coal mine machinery, cement industry, engineering machinery, power generating industry and agricultural machinery.

Owner:刘妍

Forged aluminum alloy having excellent strength and ductility and method for producing the same

InactiveUS20170247782A1Good effectHigh strengthMetal-working apparatusSolution treatmentChemical composition

Provided is a hot-forged 6xxx-series aluminum alloy having excellent corrosion resistance and still having both high strength and good ductility. A forged 6xxx-series aluminum alloy having a specific chemical composition after solution treatment is further subjected to warm working to introduce dislocations into the forged aluminum alloy microstructure. This allows the forged aluminum alloy after artificial aging to have a microstructure which has a high dislocation density, includes a large proportion of small angle grain boundaries, and has a high average number density of precipitates. Thus, the resulting forged aluminum alloy has a 0.2% yield strength of 400 MPa or more and an elongation of 10% or more and combines properties necessary for suspension parts.

Owner:KOBE STEEL LTD

Low-density Ti3Al strengthened super-strength steel and preparing method thereof

The invention relates to low-density Ti3Al strengthened super-strength steel and a preparing method thereof, and belongs to the field of metal materials. The chemical components of the steel comprise, by mass percent, 0.5% to 1.5% of C, 15% to 30% of Mn, 5% to 10% of Al, 5% to 20% of Ti, not larger than 5% of Cr, not larger than 0.2% of Nb, not larger than 2% of Si, not larger than 0.6% of B and the balance Fe and inevitable impurities. Through adding of Ti, Ti3Al is formed, the Ti3Al and k-carbide can jointly generate precipitation strengthening, the steel has the super-high strength and the good plasticity while the density is effectively reduced, the tensile strength reaches above 1350MPa, the ductility reaches above 10%, the density ranges from 6.5 g / cm<3> to 6.9 g / cm / <3>, and the manufacturing requirement of automobile structural parts is met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Hot-dip galvanized cold-rolled steel sheet and process for producing same

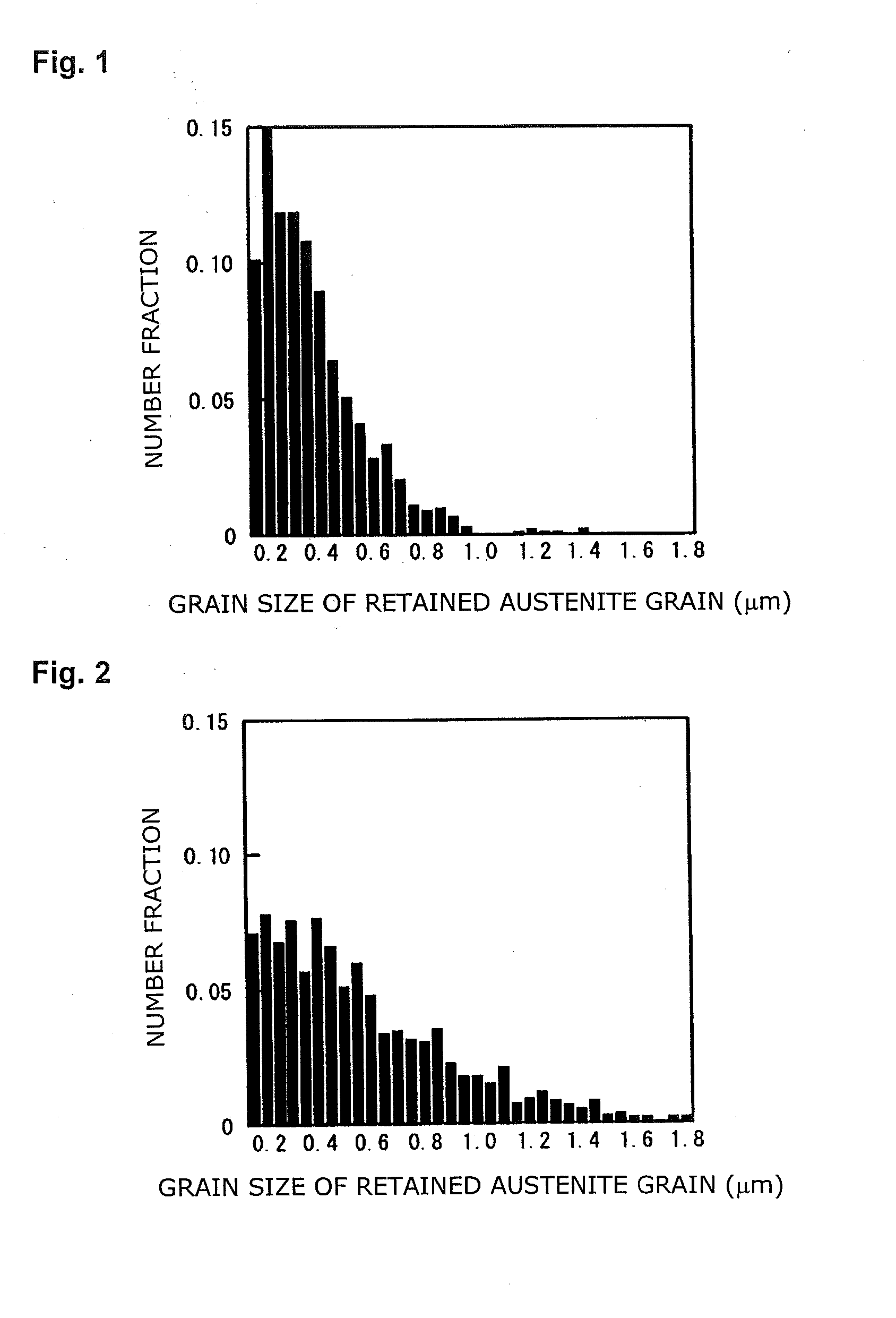

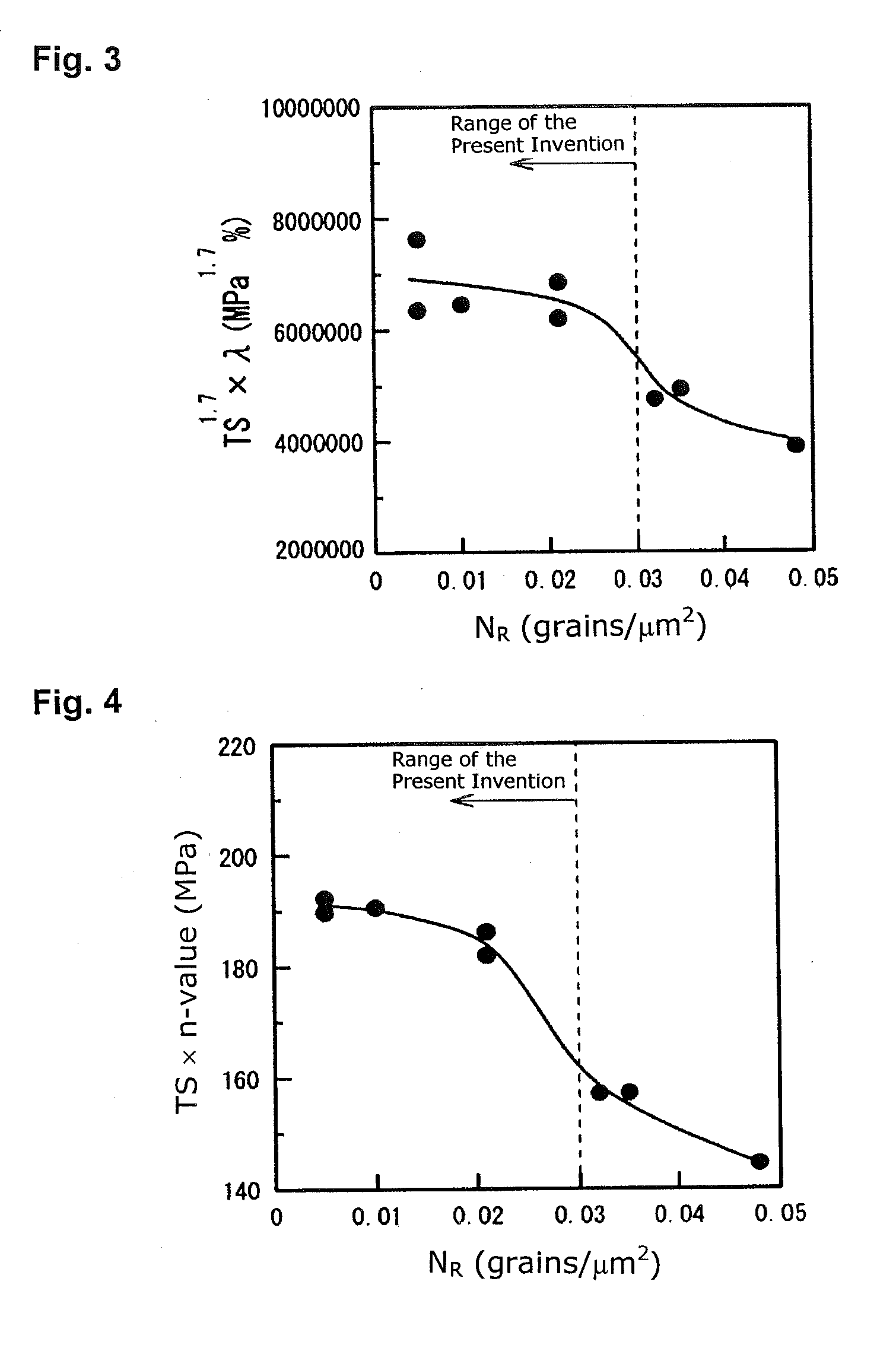

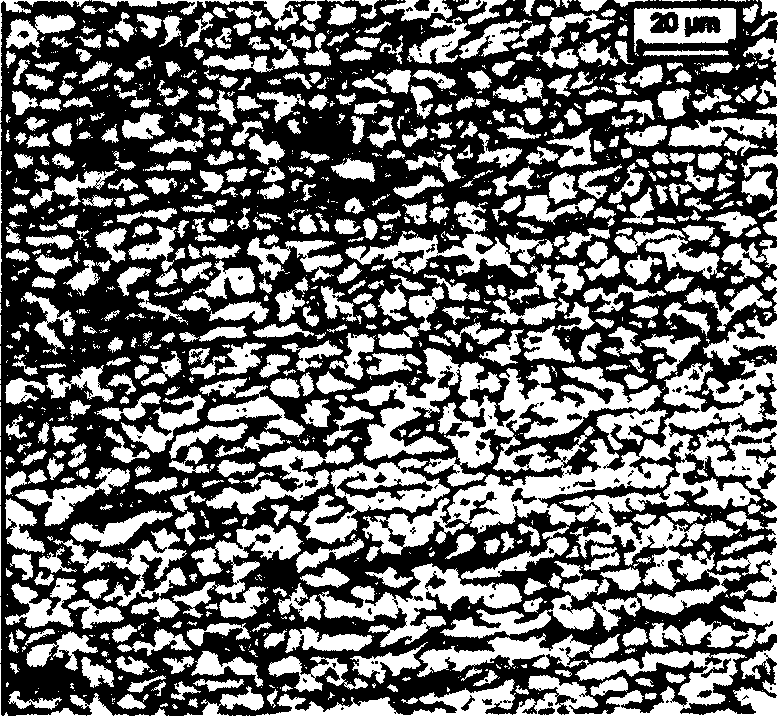

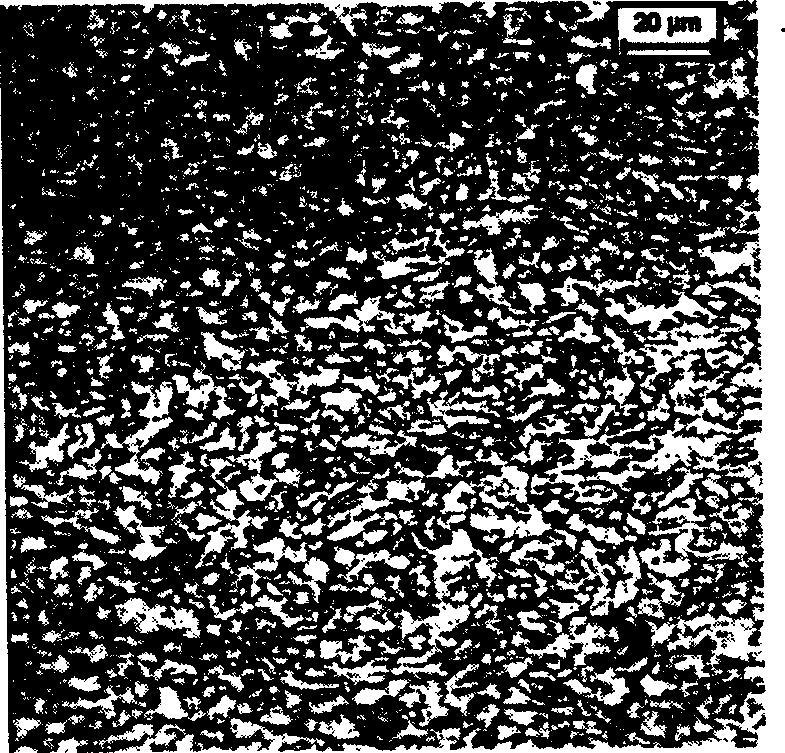

ActiveUS20140212686A1Improve stabilityImprove workabilityHot-dipping/immersion processesFurnace typesAustenite grainGalvanization

A hot-dip galvanized cold-rolled steel sheet has a tensile strength of 750 MPa or higher, a composition consisting, in mass percent, of C: more than 0.10% and less than 0.25%, Si: more than 0.50% and less than 2.0%, Mn: more than 1.50% and 3.0% or less, and optionally containing one or more types of Ti, Nb, V, Cr, Mo, B, Ca, Mg, REM, and Bi, P: less than 0.050%, S: 0.010% or less, sol. Al: 0.50% or less, and N: 0.010% or less, and a main phase as a low-temperature transformation product and a second phase as retained austenite. The retained austenite volume fraction is more than 4.0% and less than 25.0% of the whole structure, and has an average grain size of less than 0.80 □m. A number density of retained austenite grains having a grain size of 1.2 □m or more is 3.0□10−2 / □m2 or less.

Owner:NIPPON STEEL CORP

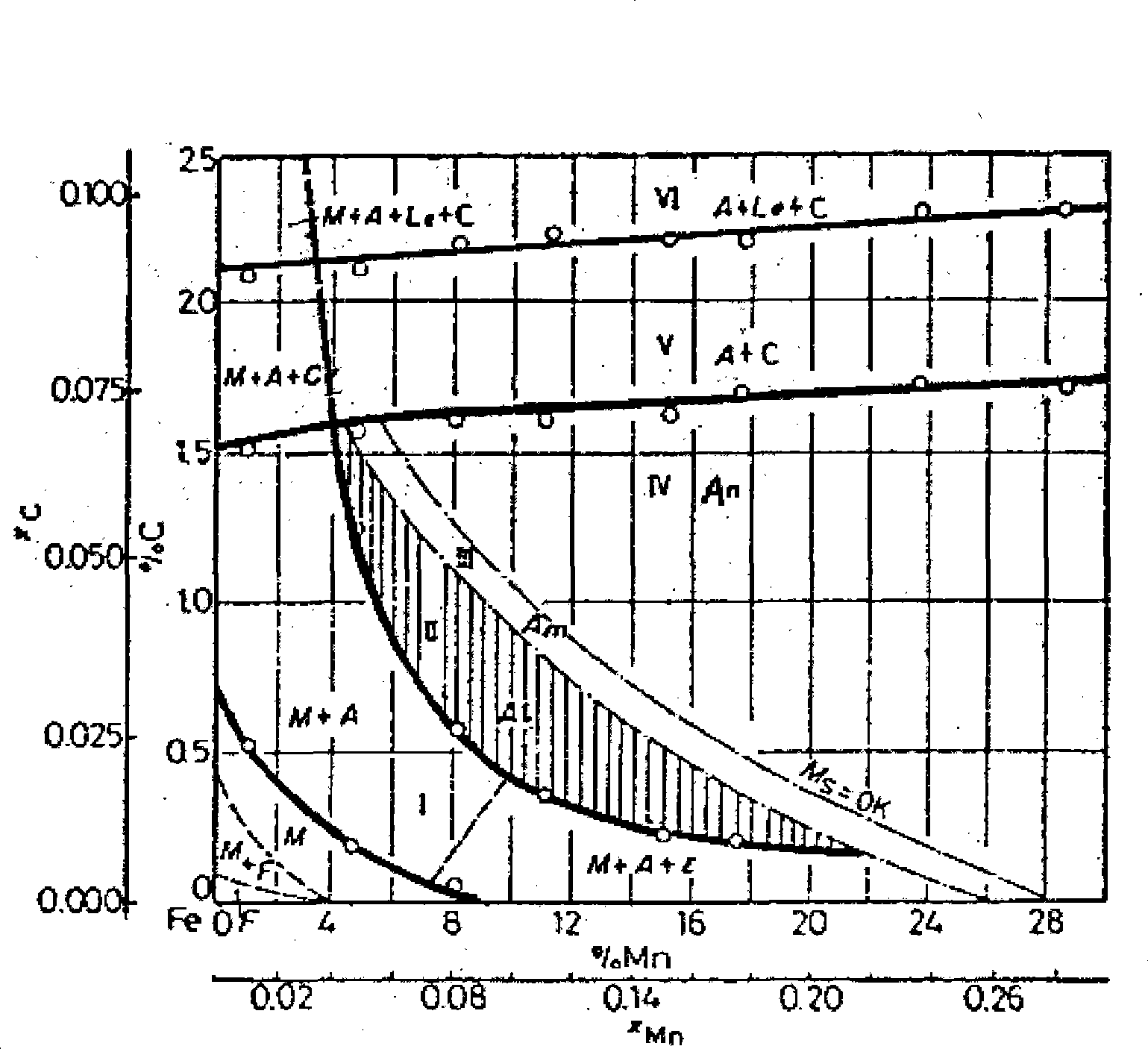

High manganese steel with ultra-low yield ratio and manufacturing method thereof

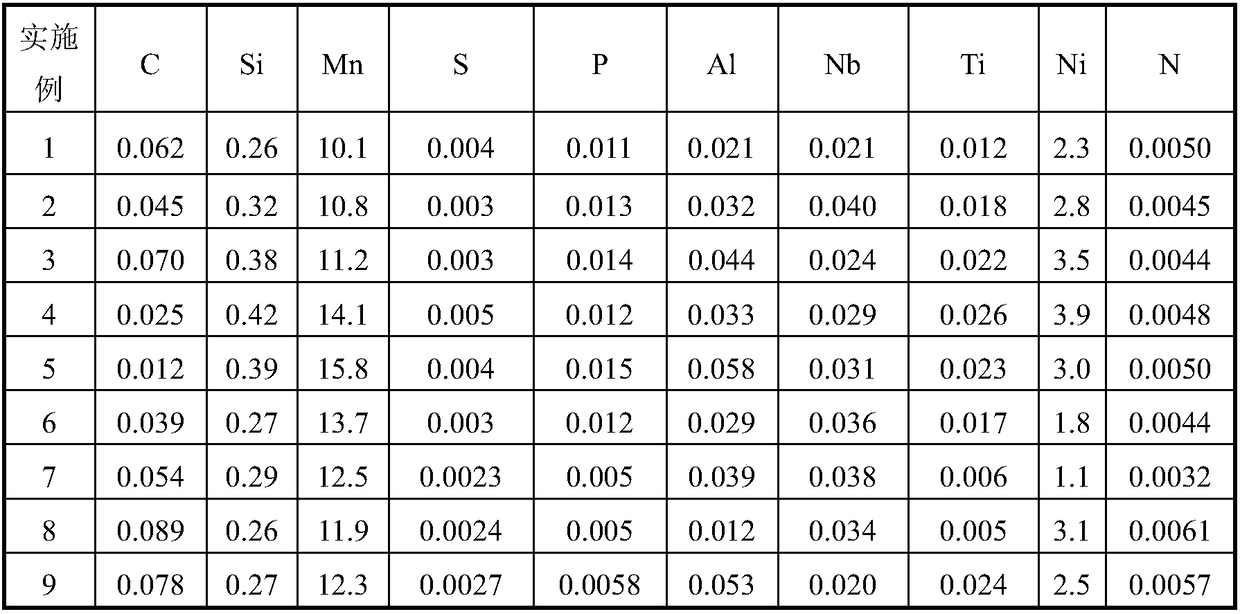

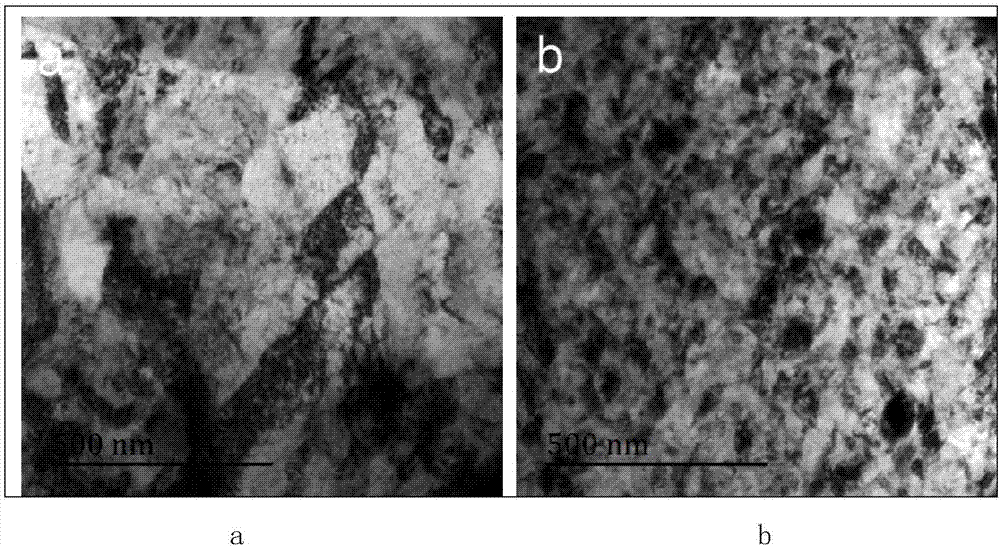

The invention discloses high manganese steel with an ultra-low yield ratio and a manufacturing method thereof. The high manganese steel comprises, by weight, 0.010-0.090% of C, 0.15-0.60% of Si, 10.0-16.0% of Mn, 0.020-0.040% of Nb, 0.005-0.03% of Ti, 1.0-4.0% of Ni, 0.020-0.060% of Al, no more than 0.020% of P, no more than 0.010% of S, no more than 0.0080% of N and the balance Fe and inevitableimpurities. Stacking for slow-cooling is conducted for more than 72 hours after continuous casting, and the temperature of a plate billet during cleaning is 100-200 DEG C; the heating temperature is 1150-1250 DEG C; at the first stage, the rolling starting temperature is 1150-1030 DEG C, and the finished rolling temperature is 1040-980 DEG C; at the second stage, the rolling starting temperature is 950-850 DEG C, the finished rolling temperature is 900-750 DEG C, and air cooling is conducted after rolling; and thermal treatment of one of normalizing, quenching, tempering or quenching + tempering is conducted after rolling. The yield ratio of the produced high manganese steel is 0.12-0.39, and the produced high manganese steel has excellent toughness and low-temperature toughness.

Owner:ANGANG STEEL CO LTD

Preparation method of laminar composite nanostructured nickel

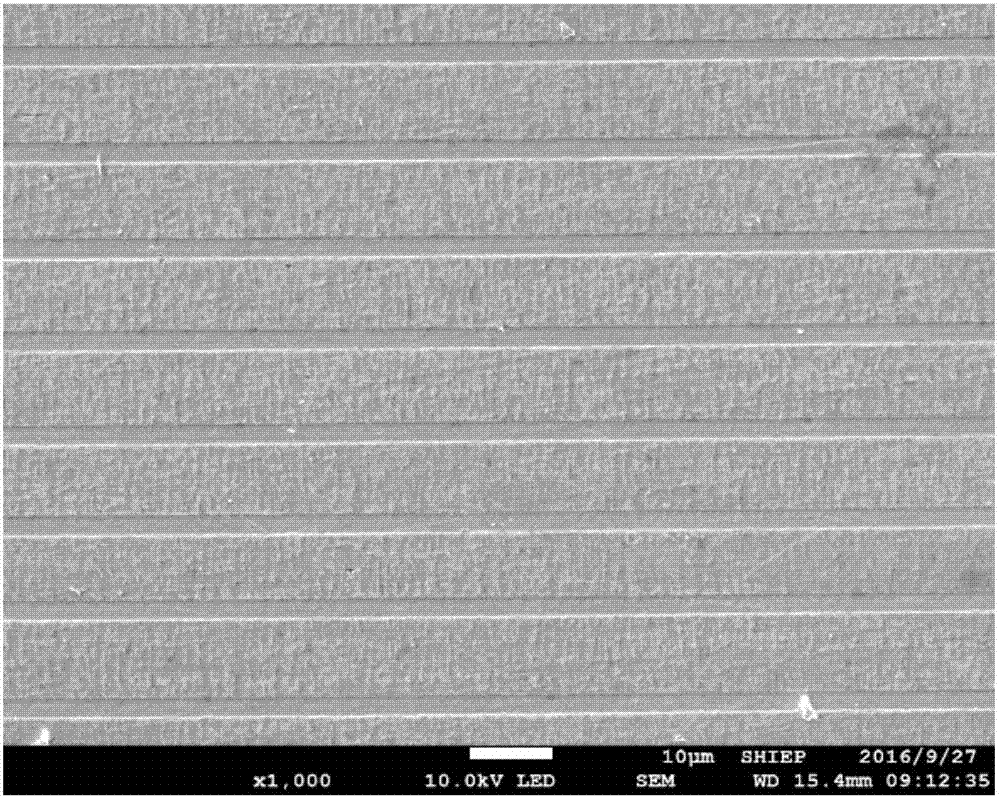

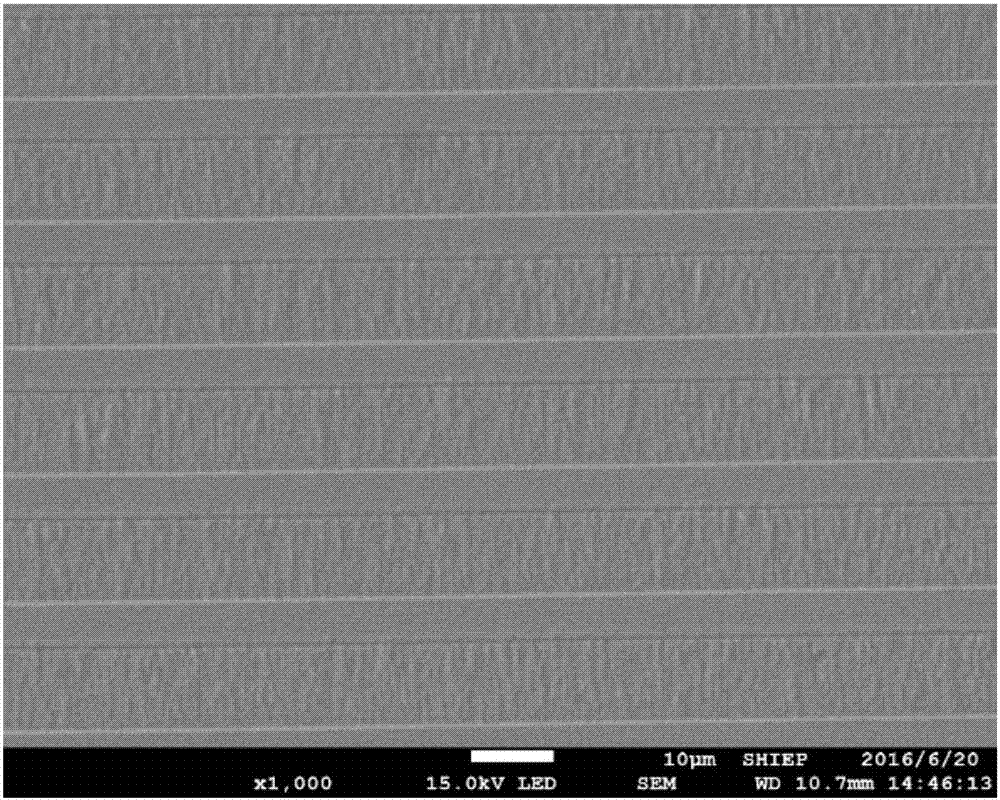

ActiveCN106929888AImprove mechanical propertiesMeeting high demands on mechanical propertiesMetallic materialsLayer thickness

The invention discloses a preparation method of laminar composite nanostructured nickel. A pretreated ordinary carton steel workpiece and a pure nickel plate are put in electrolyte consisting of 200-300 g of nickel sulfate, 30-40 g of nickel chloride, 30-40 g of boric acid, 2-8 g of sodium citrate, 2 g of composite additive and the balance of distilled water; the ordinary carbon steel workpiece, serving as a cathode, and the pure nickel plate, serving as an anode, are respectively connected with a negative pole and a positive pole of a direct-current voltage stabilization and current stabilization power supply; and circular alternating electrodeposition is performed by adopting two different current densities and the laminar composite nanostructured nickel alternately combined by two different grain layers is obtained. The preparation method realizes flexible control over the grain size and the layer thickness ratio of each single layer of the laminar composite nanostructured nickel plating layer through controlling two current densities and the deposition times under the two current densities. The prepared laminar composite nanostructured nickel is excellent in mechanical characteristic, can be used for a reinforced coating layer of a metal material, or serves as a high-performance structural material.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

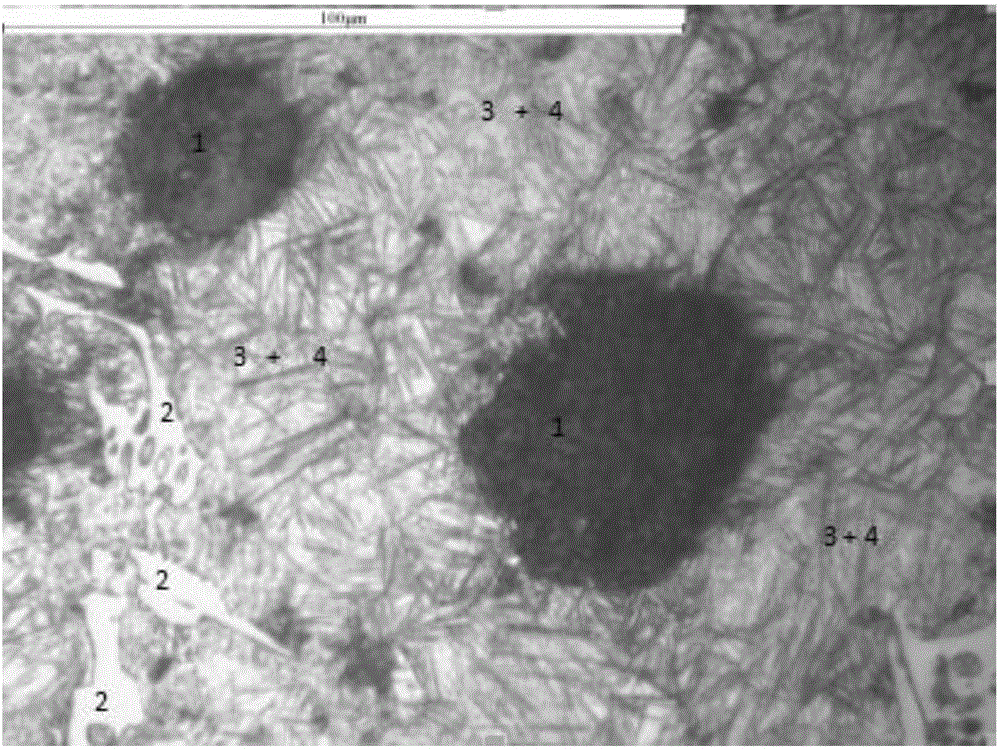

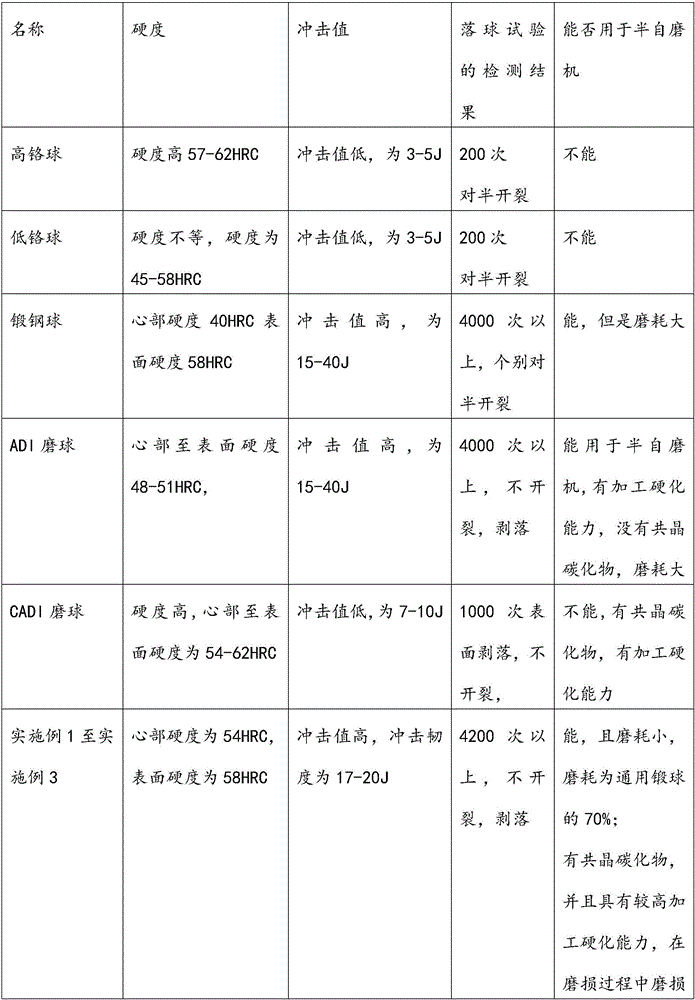

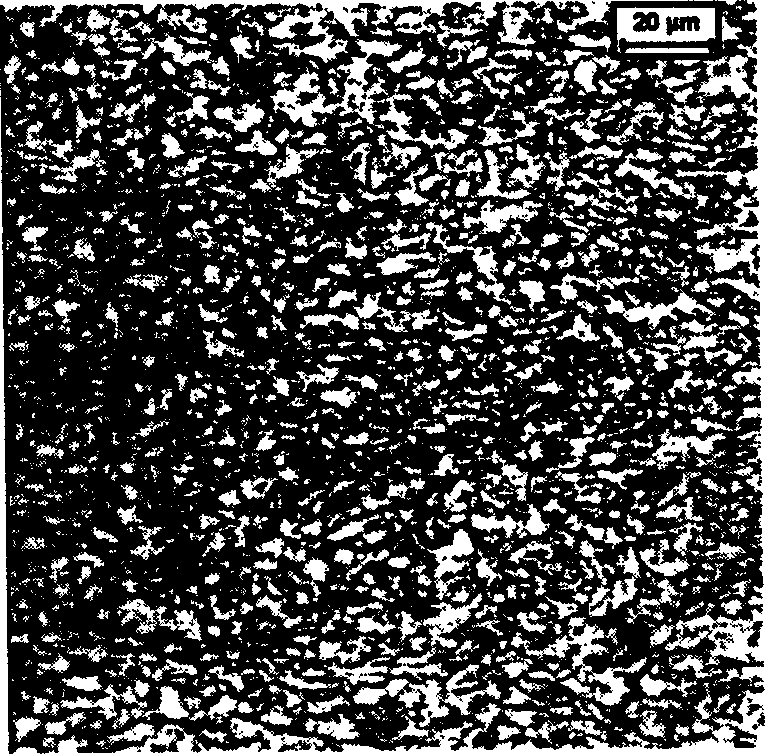

Spheroidal graphite ausferrite cast iron grinding ball suitable for being used in semi-automatic grinding machine and preparation process

The invention relates to a spheroidal graphite ausferrite cast iron grinding ball suitable for being used in a semi-automatic grinding machine and a preparation process. The spheroidal graphite ausferrite cast iron grinding ball is prepared from the following components in percentage by mass: 3.2 to 3.9 percent of carbon, 2.30 to 2.93 percent of silicon, 0.96 to 2.80 percent of manganese, 0.21 to 0.90 percent of chromium, 0.11 to 0.60 percent of copper, 0.10 to 0.80 percent of molybdenum, 0.10 to 0.68 percent of vanadium, 0.10 to 0.78 percent of titanium, 0.01 to 0.09 percent of niobium, greater than or equal to 0 and less than 0.05 percent of phosphorus, greater than or equal to 0 and less than 0.03 percent of sulfur, 0.03 to 0.05 percent of magnesium, 0.02 to 0.03 percent of rare earth elements and the balance of iron. The preparation process comprises the following steps: firstly, performing casting forming to prepare a cast grinding ball; secondly, performing thermal treatment on the cast grinding ball to prepare the spheroidal graphite ausferrite cast iron grinding ball. The hardness of the heart part of the spheroidal graphite ausferrite cast iron grinding ball disclosed by the invention is 54 HRC, and the surface hardness is 58 HRC; the impact toughness is 17 to 20 J / cm2; furthermore, the spheroidal graphite ausferrite cast iron grinding ball is higher in processing hardening capacity; in a wear process, a worn layer is processed to be hardened, so that the hardness can be up to 62 to 64 HRC, and the wear amount is 70 percent of that of a general forged ball.

Owner:CHENGDE RONGMAO CAST STEEL +1

Low carbon 520MPa grade composite fortified ultra fine crystal grain band steel

A 520 MPa-class low-carbon band steel with superfine crystal grains contains C (0.12-0.15 wt.%), Si (0.15-0.40), Mn (1.10-1.30), Nb (0.007-0.015), P (0-0.01), S (0-0.001 and Fe (rest), and is prepared through smelting, conticasting, heating, rolling twice, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (520-570 MPa), high tension strength (620-690 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Amorphous composite structure steel

ActiveCN106282849ALow yield ratioProne to plastic deformationMartensite transformationHigh intensity

The invention relates to an amorphous composite structure steel which comprises the following components in percentage by weight: 0.02-0.2% of C, 13-16% of Mn, 3-5% of Si, 10-12% of Cr, 0-2% of Re and the balance of Fe. The structure of the composite material is a gamma austenite phase+amorphous composite structure, and can generate gamma austenite-martensite phase transformation under the induction of stress to strengthen and toughen the metallic glass. The composite material has low yield-tensile ratio, can generate plastic deformation, and can reach high strength through the excellent work hardening capacity.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Cold-rolled steel sheet

ActiveUS20140241933A1Improve stabilityImprove workabilityFurnace typesHeat treatment furnacesAustenite grainChemical composition

A high-strength cold-rolled steel sheet excellent in ductility, work hardenability, and stretch flangeability, and having tensile strength of 780 MPa or more includes: a chemical composition containing, in mass percent, C: more than 0.020% to less than 0.30%, Si: more than 0.10% to 3.00% or less, Mn: more than 1.00% to 3.50% or less; and metallurgical structure whose main phase is a low-temperature transformation product, and whose secondary phase contains retained austenite. The retained austenite has a volume fraction relative to overall structure of more than 4.0% to less than 25.0% and an average grain size of less than 0.80 μm, and of the retained austenite, the number density of retained austenite grains whose grain size is 1.2 μm or more is 3.0×10−2 grains / μm2 or less.

Owner:NIPPON STEEL CORP

Low carbon 420 MPa grade composite fortified ultr-fine crystal grain band steel

A 420 MPa-class low-carbon band steel with superfine crystal grains contains C (0.10-0.14 wt.%), Si (0.18-0.40), Mn (0.85-1.10), P (0-0.01), S (0-0.01) and Fe (rest), and is prepared through smelting, conticasting, heating, rolling twice, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (420-450 MPa), high tension strength (530-550 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Preparaton method of low carbon 520 MPa grade composite fortified ultra fine crystal grain band steel

A 520 MPa-class low-carbon band steel with superfine crystal grains contains C (0.12-0.15 wt.%), Si (0.5-0.40), Mn (1.10-1.30), Nb (0.007-0.015), P (0-0.01), S (0-0.01) and Fe (rest), and is prepared through smelting, conticasting, coarse rolling, fine rolling, cooling and winding. Its advantages are multi-phase structure including ferrite, bainite and pearlite, high yield strength (520-270 MPa), high tension strength (630-690 MPa) and low cost. It can replace high-strength low-alloy steel.

Owner:NORTHEASTERN UNIV

Hot rolled strip steel with yield strength higher than 600MPa for mine rescue capsule and preparation method of hot rolled strip steel

InactiveCN102766820APlay the role of second phase strengtheningHigh strengthRoll mill control devicesMetal rolling arrangementsRoom temperatureStrip steel

A hot rolled strip steel with yield strength higher than 600MPa for a mine rescue capsule and a preparation method of the hot rolled strip steel belongs to the technical field of metallurgy materials. The hot rolled strip steel comprises, by weight percent, 0.04-0.08% of C, 0.1-0.3% of Si, 1.5-1.7% of Mn, 0.01-0.05% of Al, 0.4-0.5% of Mo, 0.4-0.6% of Cr, 0.04-0.06% of Nb, 0.02-0.05% of Ti, 0.2-0.35 of Cu, not more than 0.01% of P, not more than 0.01% of S, and the balance Fe. A metallographic structure of the hot rolled strip steel is granular bainite with the yield strength no less than 600MPa, tensile strength no less than 800MPa, and elongation percentage after fracture no less than 18% at room temperature. The yield strength is no less than 450MPa, tensile strength is no less than 650MPa, and elongation percentage after fracture is no less than 19% at a high temperature of 500 DEG C. Impact energy at 20 DEG C is larger than 47J. Cold bending property is qualified. Atmospheric corrosion resistance index I under industrial environments is no less than 4.5. Sensitivity coefficient Pcm of welding cold crack is not more than 0.26%. The preparation method includes: smelting molten steel according to the preset components, casting ingots, heating, rough rolling, finish rolling to obtain the strip steel with thickness of 4-14mm, and fast cooling to obtain the finished hot rolled strip steel. The hot rolled strip steel has fine room-temperature and high-temperature mechanical performance and fine erosion resistance.

Owner:NORTHEASTERN UNIV

High-strength high-toughness and high-plasticity low-carbon medium-manganese medium-thickness plate and manufacturing method thereof

The invention aims to provide a high-strength high-toughness and high-plasticity low-carbon medium-manganese medium-thickness plate and a manufacturing method thereof, and belongs to the technical field of steel materials. The medium-thickness plate is developed in a low-carbon Mn alloying mode and is high in strength, toughness and plasticity and uniform in thickness-direction structure. The medium-thickness plate comprises, by weight, 0.03-0.05% of C, 0.20-0.40% of Si, 3.00-6.00% of Mn, 0.005% of P or less, 0.003% of S or less, 0.5-1.50% of Ni and the balance of Fe and inevitable impurities, and the thickness of the medium-thickness plate ranges from 10 mm to 40 mm. The manufacturing method includes the steps that 1, a steel blank is heated to 1200 DEG C, heat is preserved for 2 h-3 h for sufficient austenitization, then one-stage or two-stage rolling is performed on the steel blank, and the plate is water-cooled to the indoor temperature after rolling; 2, the plate is placed in a heating furnace with the temperature of 610 DEG C-640 DEG C, heat is preserved for 2 h-3 h, and then the plate is quenched to the indoor temperature. The medium-thickness plate has the advantages of being uniform in thickness-direction structure, low in yield-strength ratio and high in strength, plasticity and toughness and has better structure performance than a traditional high-strength medium-thickness plate. The manufacturing method is simple and easy to implement.

Owner:NORTHEASTERN UNIV

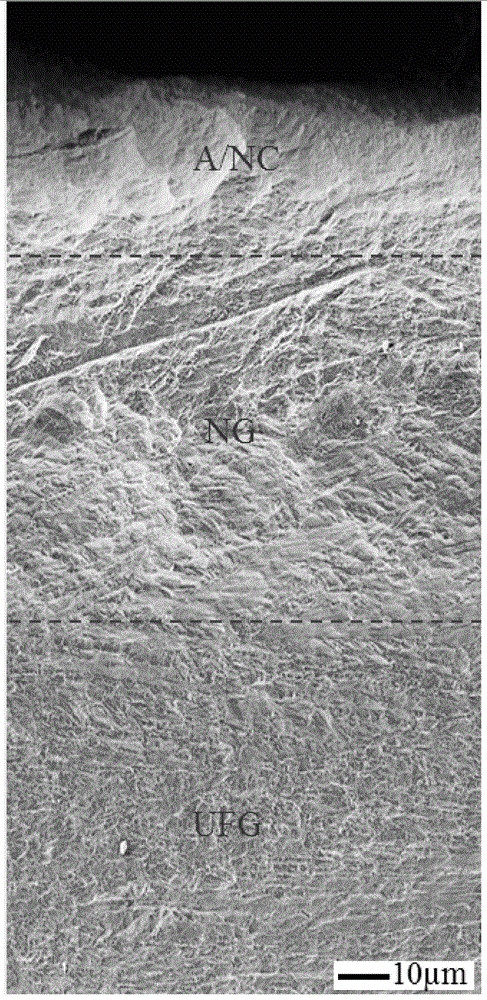

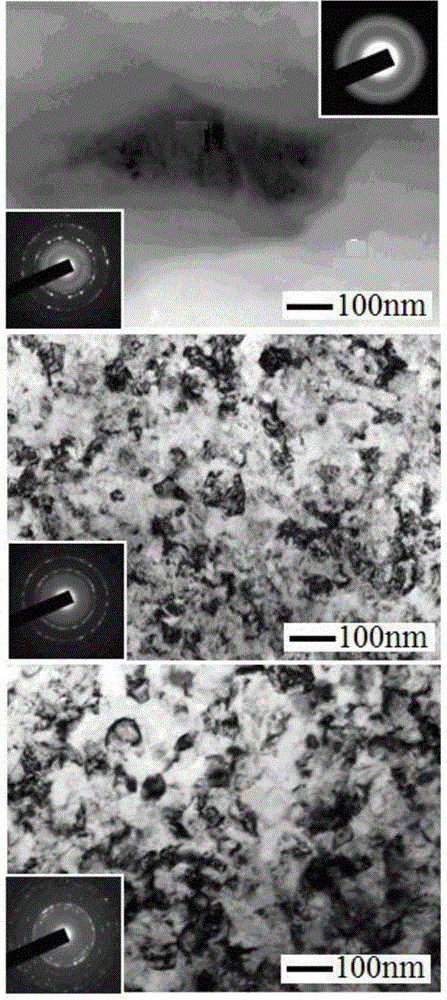

Method for fabricating gradient ultra-fine metal grains

The invention discloses a method for fabricating gradient ultra-fine metal grains. The ultra-fine metal grains in weak gradient distribution from the surface to the heart part are obtained in manners of liquid nitrogen cooling and gradually rolling, and then surface mechanical attrition treatment is carried out; the grains are further increased from the metal surface to the internal part in a gradient manner; and the ultra-fine metal grains in strong gradient distribution are finally obtained, so that the metal has high strength, high toughness and corrosion resistance, and excellent work hardening properties. The grains fabricated by the fabrication method are stable in quality, and simultaneously low in cost.

Owner:SUZHOU VOCATIONAL UNIV

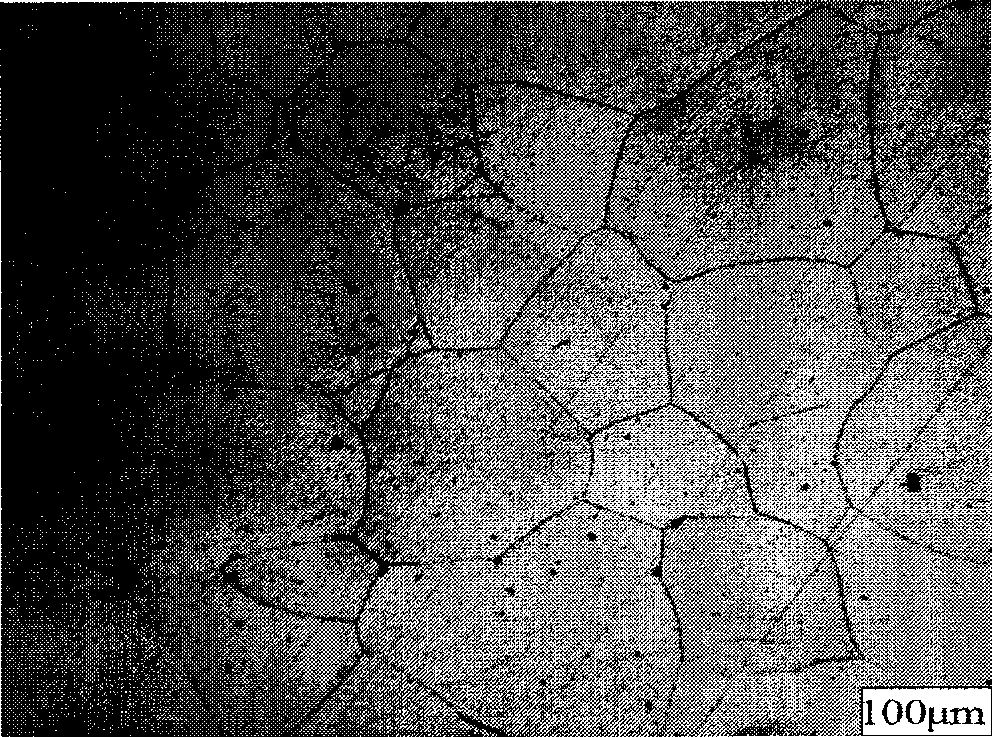

Variable temperature martensite local strengthening austenite low manganese steel hammer head material and preparation process thereof

The invention relates to a variable temperature martensite locally strengthened austenite manganese steel hammer head material and a preparation technology thereof, wherein a substrate of the material is a metastable austenite with a thinned structure, good toughness and improved work hardening capacity; a strengthened region is provided with a deep cooling martensite with high initial hardness and a small number of metastable martensites; and an intermediate transition region is provided with a mixed structure of the deep cooling martensites and the austenites with gradually changed gradient. The preparation technology comprises the following technological steps: a) design of the compositions of the substrate of manganese steel of metastable austenites; b) modification in a ladle before a furnace; c) direct water toughening after solidification; and d) acquisition of a surface layer or a local martensite transformation gradient strengthened layer. The material is characterized in that the structure of the strengthened layer is the variable temperature martensites (M) with high hardness and a small number of the metastable austenites (A); other parts are provided with the austenites with high toughness; and an intermediate transition layer is provided with a mixed structure of the Ms and the As with gradually changed gradient. Moreover, the preparation technology integrates design of the compositions of the manganese steel of the metastable austenites, the energy-saving heat treatment technology and the short-time local temperature variation treatment technology.

Owner:JILIN UNIV

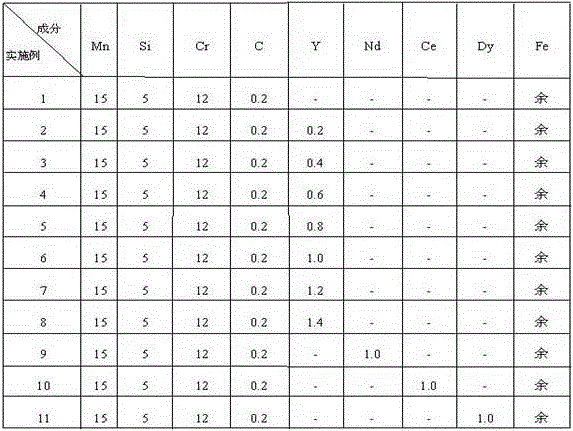

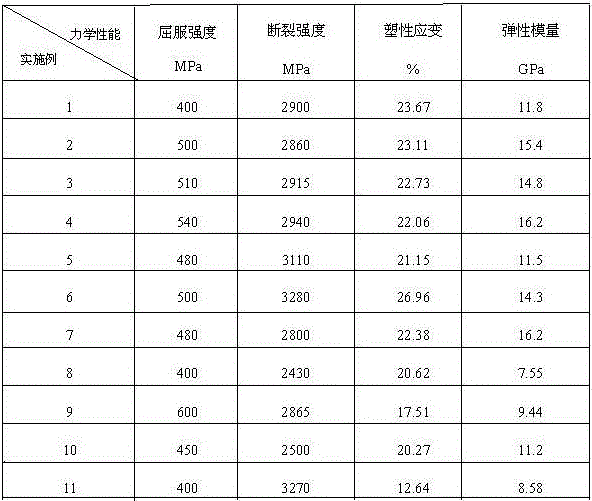

High-work-hardening magnesium alloy and preparation method thereof

The invention relates to a high-work-hardening magnesium alloy and a preparation method thereof, which belong to the field of metal materials. The alloy comprises the following chemical components in percentage by mass: 2.3-4.5 percent of tin, 0.1-3.85 percent of zinc and the balance of magnesium and unavoidable impurities; the magnesium alloy can further comprise one or more of 0.01-2.0 percent by mass of silicon, 0.01-3.0 percent of antimony, 0.01-3.0 percent by mass of tellurium, 0.01-1.5 percent by mass of strontium, 0.01-2.0 percent by mass of manganese and 0.01-3.0 percent by mass of rare earth elements; and the rare-earth elements include neodymium, lanthanum, yttrium and cerium. The preparation method comprises the following steps of: melting magnesium, adding tin and zinc, and adding additive elements and rare earth elements; and blowing, stirring, refining, removing slag, standing, directly pouring a melt into an ingot, and thermally extruding into a tubular product, a section or a plate. The alloy has the advantages of high-work-hardening capability, high plastic molding, simple and reliable preparation process, easiness for popularizing and application, and the like.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com