Method of preparing high-strength thin-crystal two-phase steel

A dual-phase steel, fine-grained technology, applied in the direction of manufacturing tools, heat treatment equipment, heat treatment process control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

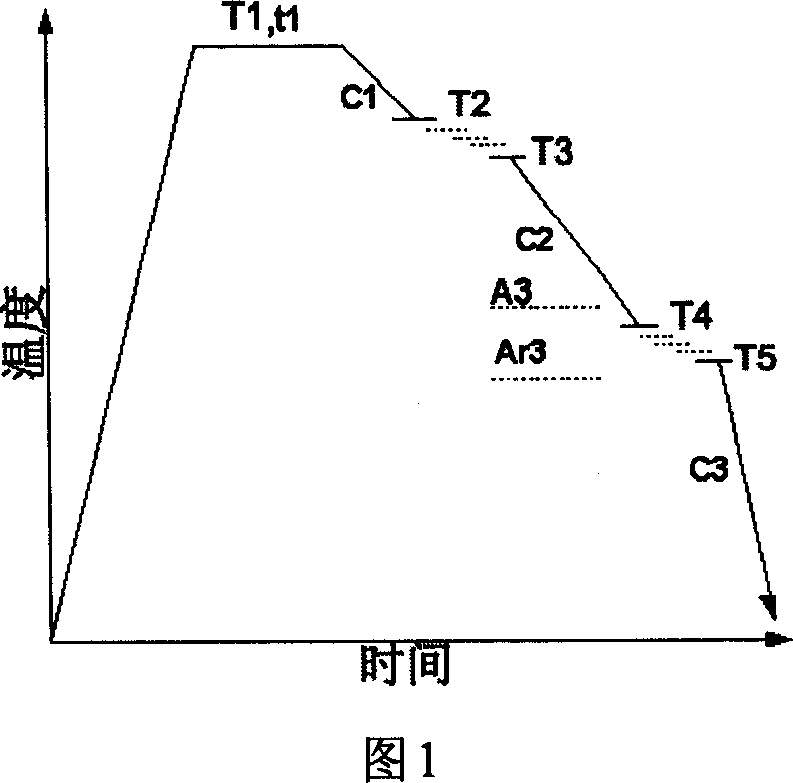

Method used

Image

Examples

Embodiment 1

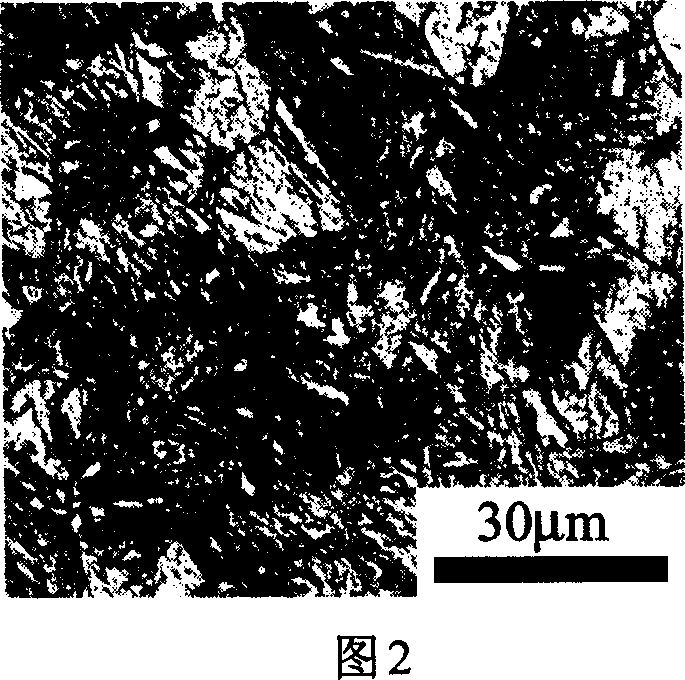

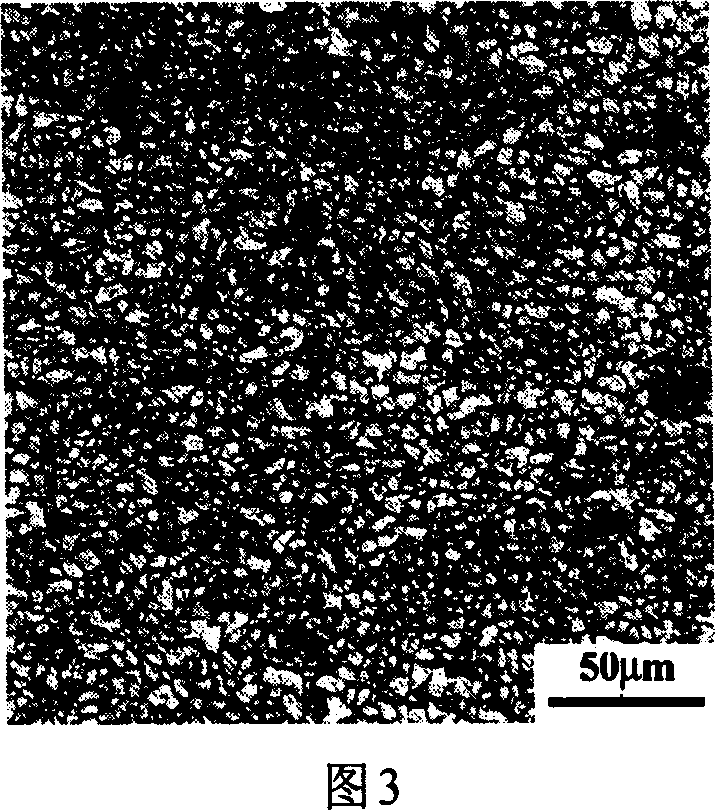

[0013] Select the low-carbon steel whose chemical composition is: 0.087%C, 1.24%Mn, 0.35%Si, and the balance is Fe. Its A was measured by thermal dilatation method 3 is 860°C, cooling rate C2 is 30°C / s, Ar 3 It is 760°C. After heating the low-carbon steel to 1200°C for 5 minutes, at 1100°C and 1000°C in the temperature range of T2~T3 respectively for 1s -1 The strain rate is deformed, and the deformation amount of each pass is 30%, and the recrystallized austenite structure of about 25 microns is obtained as shown in Fig. 2 . Afterwards, cool at a cooling rate of 30°C / s to 820°C in the temperature range of T4~T5, and -1 The deformation rate is 30% in two passes, the interval between the two passes is 1s, and the cooling rate is 60°C / s to room temperature, and the fine-grained dual-phase structure shown in Figure 3 is obtained. The average grain size of ferrite is about 3.94 microns, the average size of martensitic islands is about 2.56 microns, and the volume fraction is a...

Embodiment 2

[0015] The chemical composition of the selected steel grade is the same as in Example 1. Heat the low-carbon steel to 1200°C for 5 minutes and then heat it at 1100°C and 1000°C in the temperature range of T2~T3 for 1s -1 The strain rate is deformed, and the deformation amount of each pass is 30%, and the recrystallized austenite structure of about 25 microns is obtained as shown in Fig. 2 . After that, cool down to 800°C at a cooling rate of 15°C / s and take 10s -1 The deformation rate is 30% in two passes, the interval between the two passes is 10s, and the cooling rate is 60°C / s to room temperature, and the fine-grained dual-phase structure shown in Figure 4 is obtained. The average grain size of ferrite is about 4.09 microns, the average size of martensitic islands is about 3.33 microns, and the volume fraction is about 10%.

Embodiment 3

[0017] The hot-rolled slab of ordinary low-carbon manganese steel is used, and its chemical composition is: 0.09%C, 1.4%Mn, 0.35%Si, and the balance is Fe. The original thickness of the blank is 15mm. The multi-pass reversible rolling test was carried out on the 350 four / two-high reversible hot strip experimental rolling mill, and the rolling speed used was 500mm.s -1 . The hot rolling process is: 1200°C for 30 minutes, then air-cooled to 1100°C to start rolling, two passes of rolling with a reduction of 30%, the interval between passes is 5s, and the temperature after the second pass is 1000°C about. After that, air cooling (cooling rate is about 12°C / s) to 840°C for two consecutive rolling passes with a reduction of 30%, the interval between passes is 3s, the final rolling temperature is 790°C, and water cooling after rolling. Figure 5 is the SEM morphology of the fine-grained dual-phase structure obtained under this process. The average grain size of ferrite is about 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com