A kind of nb, v composite 700mpa grade high-strength anti-seismic reinforcement steel and its production method

A technology of seismic reinforcement and production method, which is applied in the field of Nb, V composite 700MPa grade high-strength seismic reinforcement steel, can solve the problems of low strength of seismic reinforcement steel, and achieves the effect of facilitating pouring, avoiding overoxidation and preventing secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

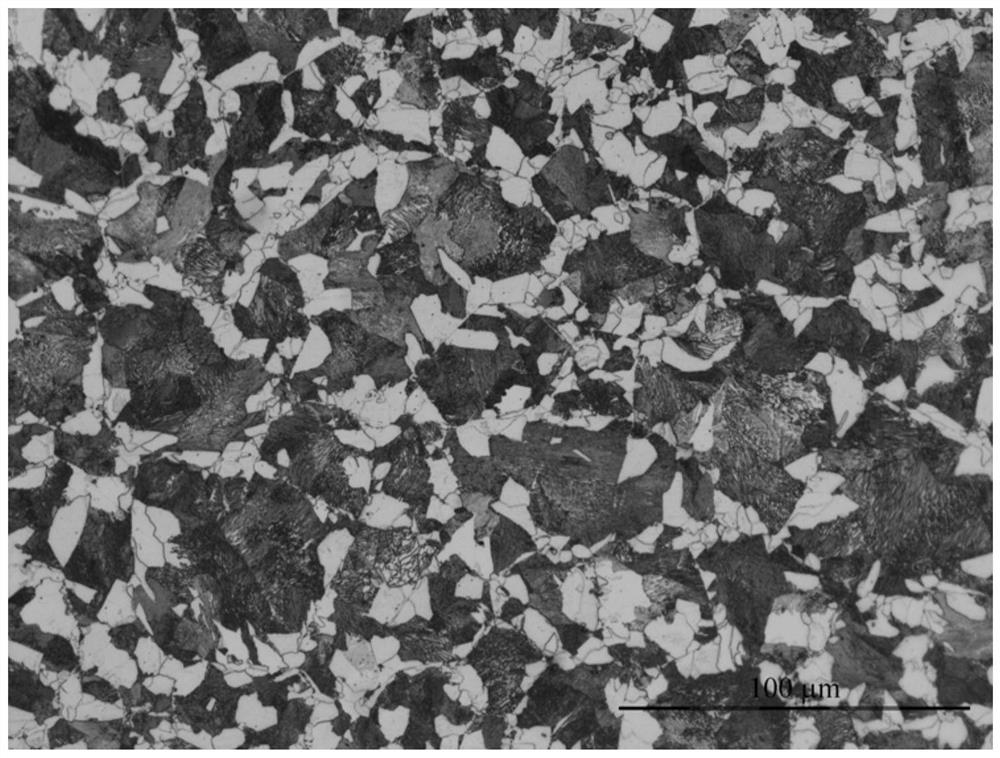

Image

Examples

Embodiment 1

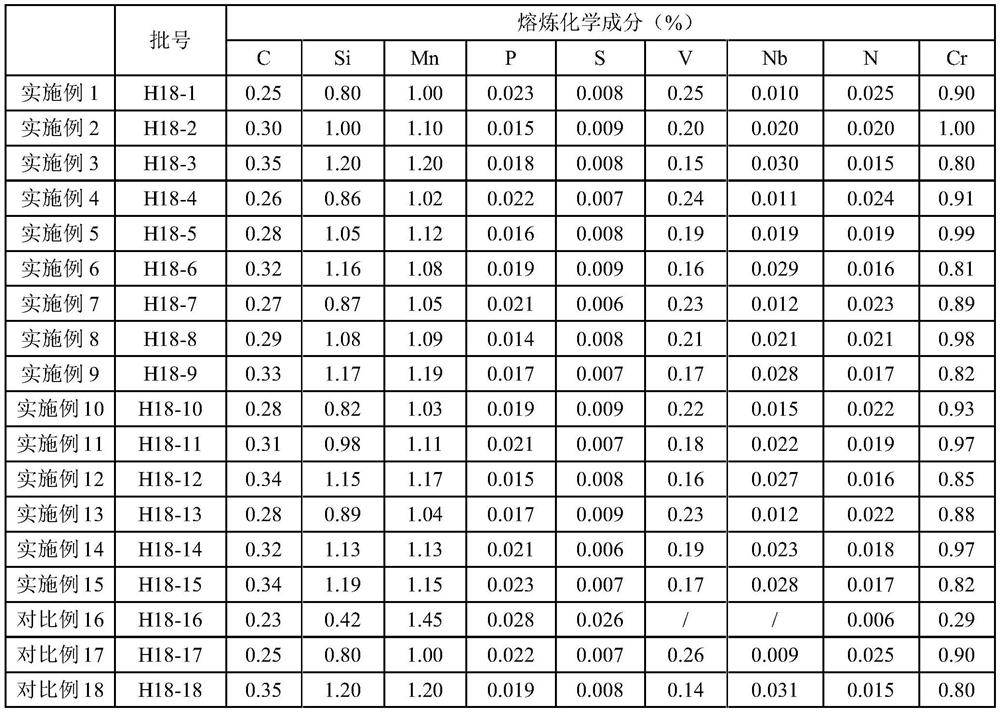

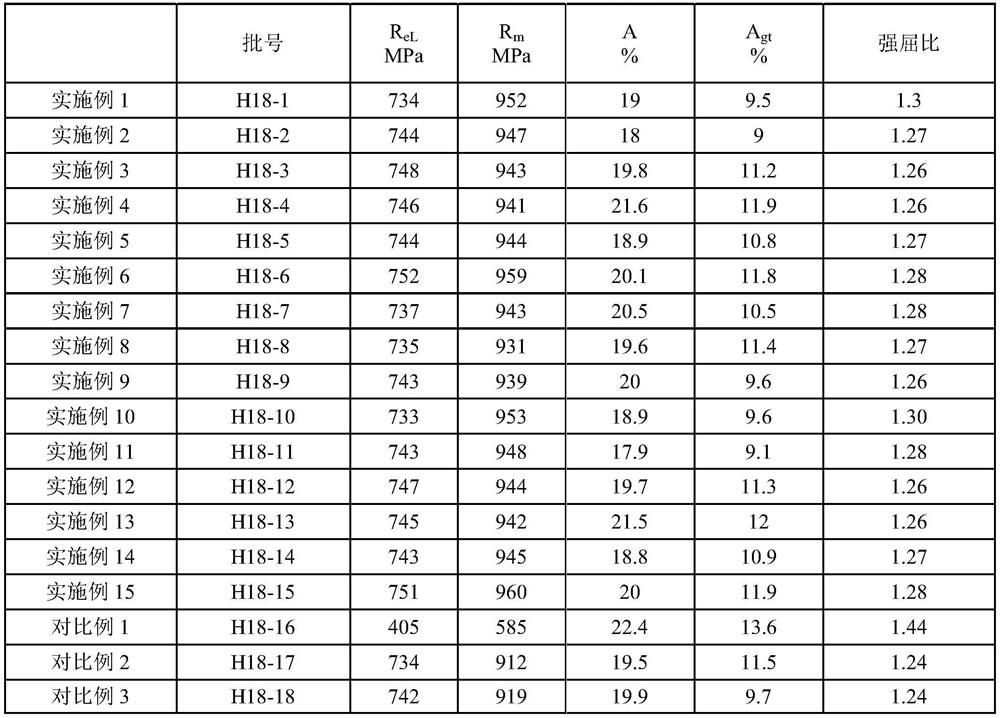

[0068] The main chemical composition and mass percentage of a 700MPa grade hot-rolled ribbed high-strength steel in this embodiment are shown in Example 1 in Table 1.

[0069] A kind of processing method of 700MPa level hot-rolled ribbed high-strength steel bar of the present embodiment comprises the following steps:

[0070] S1. Converter or electric arc furnace steelmaking, converter or electric arc furnace end point C ≥ 0.05%, P, S ≤ 0.015%, and slag blocking tapping; when tapping 1 / 4 of the steel, first add deoxidizer for deoxidation, after deoxidation is completed Add Nb iron and VN alloy, and finish adding when 3 / 4 of the steel is tapped, and the tapping temperature is 1710°C.

[0071] S2. The ladle is blown with argon for 5 minutes; the composition and temperature of the molten steel in the upper and lower parts of the ladle are uniform to ensure the uniformity and stability of the performance of the steel bar.

[0072] S3, LF furnace refining, blowing argon into the L...

Embodiment 2

[0080] The main chemical components and mass percentages of a 700MPa-grade hot-rolled ribbed high-strength steel in this embodiment are shown in Example 2 in Table 1.

[0081] A kind of processing method of 700MPa level hot-rolled ribbed high-strength steel bar of the present embodiment comprises the following steps:

[0082] S1. Converter or electric arc furnace steelmaking, converter or electric arc furnace end point C ≥ 0.05%, P, S ≤ 0.015%, and slag blocking tapping; when tapping 1 / 4 of the steel, first add deoxidizer for deoxidation, after deoxidation is completed Add Nb iron and VN alloy, and finish adding when 3 / 4 of the steel is tapped, and the tapping temperature is 1705°C.

[0083] S2. The ladle is blown with argon, and the argon blowing time is 6 minutes; the composition and temperature of the molten steel in the upper and lower parts of the ladle are uniform, so as to ensure the uniformity and stability of the performance of the steel bar.

[0084] S3, LF furnace ...

Embodiment 3

[0092] The main chemical components and mass percentages of the 700MPa grade hot-rolled ribbed high-strength steel of this embodiment are shown in Example 3 in Table 1.

[0093] A kind of processing method of 700MPa level hot-rolled ribbed high-strength steel bar of the present embodiment comprises the following steps:

[0094] S1. Converter or electric arc furnace steelmaking, converter or electric arc furnace end point C ≥ 0.05%, P, S ≤ 0.015%, and slag blocking tapping; when tapping 1 / 4 of the steel, first add deoxidizer for deoxidation, after deoxidation is completed Add Nb iron and VN alloy, and finish adding when 3 / 4 of the steel is tapped, and the tapping temperature is 1700°C.

[0095] S2. The ladle is blown with argon for 5 minutes; the composition and temperature of the molten steel in the upper and lower parts of the ladle are uniform to ensure the uniformity and stability of the performance of the steel bar.

[0096] S3, LF furnace refining, blowing argon into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com