Patents

Literature

514results about How to "Inhibit peroxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

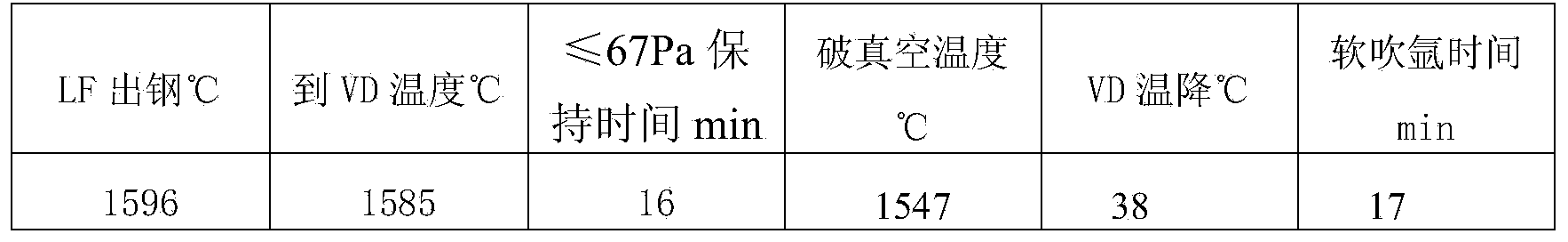

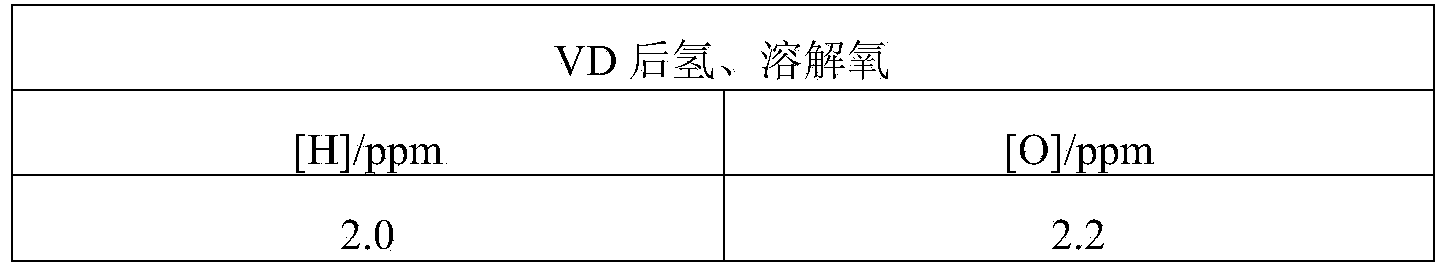

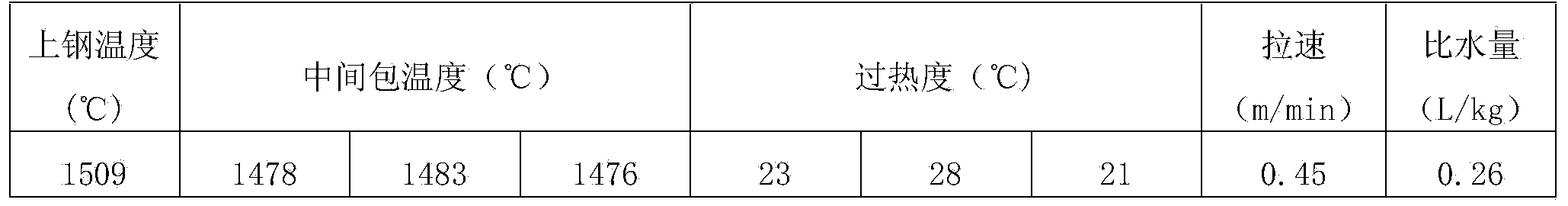

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Process method for preparing cold brewing tea by ice crystallization cell wall breaking

InactiveCN101669553AInhibit peroxidationImprove solubilityPre-extraction tea treatmentData controlDrinking habits

The invention discloses a method for preparing cold brewing tea by ice crystallization treatment. The method comprises the following steps: putting fresh tea leaves in a low-temperature environment below 40 DEG C below zero for ice crystallization; putting the tea leaves subjected to the ice crystallization treatment into a vacuum container; slubbing the tea leaves in the vacuum container; heatingthe vacuum container at a heating temperature of between 70 and 100 DEG C; and stirring the tea leaves in the heated vacuum container until the tea leaves are dried. The ice crystallization process,which is adopted for replacing the conventional withering process, can change the conventional process depending on human experience control into data control and significantly improve the product consistency; the ice crystallization cooperated with the enzymatic oxidation of vacuum negative pressure isolated environment oxygen can avoid the problem of peroxided sensitive substances in the tea leaves; the adoption of an ice crystallization wall breaking process combined with vacuum evaporation dewatering drying can avoid the problem of reoxidation in the drying process; the tea prepared by theice crystallization wall breaking process has better solubility in cold water; the cold water brewing tea prepared by the ice crystallization wall breaking process can improve tea drinking habits ofhuman beings; and the adoption of the cold water brewing tea can save a large amount of energy for boiling water. The method can also be used for preparing cold water brewing beverages by using otherplants to conventionally be soaked in water for drinking, such as ginseng leaves, ginkgo leaves, chrysanthemums, green plums, olives and the like, thereby providing a new idea for enriching markets.

Owner:苏少宁

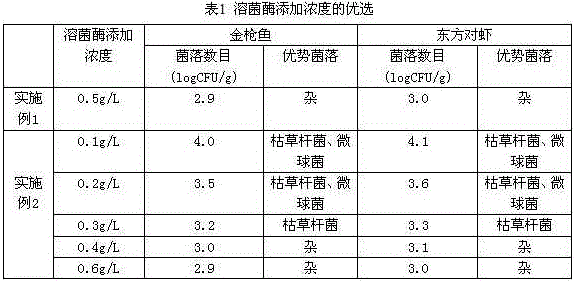

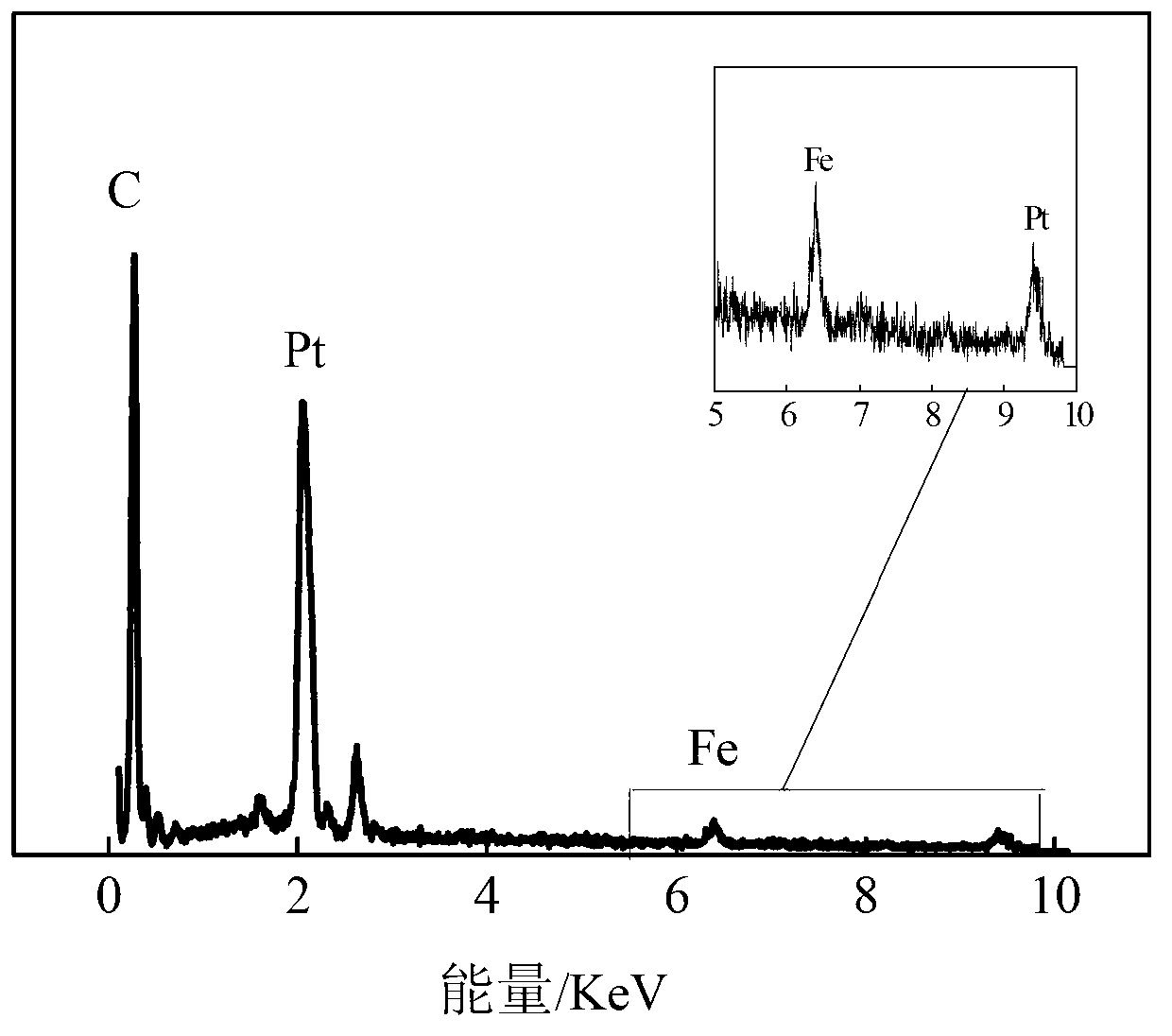

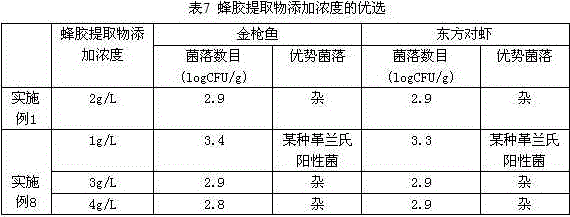

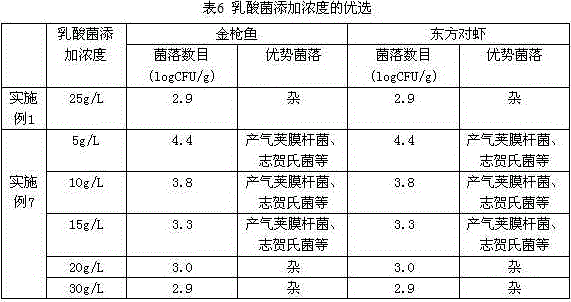

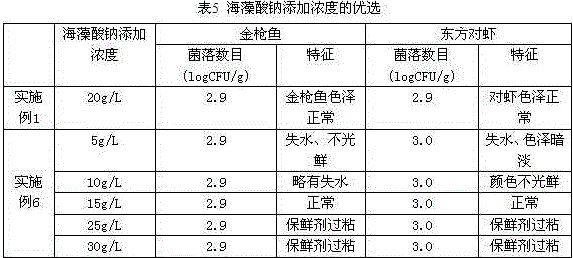

Formula of aquatic product composite preservative

InactiveCN106259830AStrong Broad Spectrum ResistanceEnhanced inhibitory effectNatural extract food ingredientsMeat/fish preservation using chemicalsPropolisAllium sativum

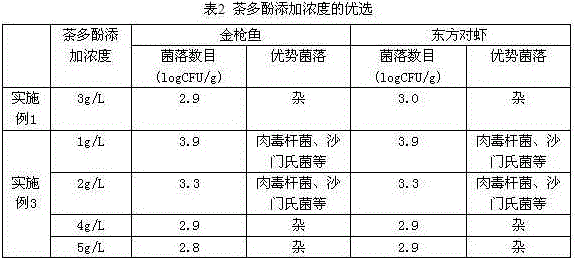

The invention relates to a formula of an aquatic product composite preservative. The formula of the aquatic product composite preservative is characterized in that the aquatic product composite preservative in each liter of distilled water comprises the following components: 0.4 to 0.6 g of muramidase, 2.5 to 3.5 g of tea polyphenol, 16 to 20 g of carboxymethyl chitosan, 10 to 14 g of nisin, 25 to 35 g of potassium sorbate, 17 to 23 g of sodium alginate, 20 to 30 g of lactobacillus, 1.5 to 2.5 g of propolis extracts and 10 to 14 g of spice extracts; and the spice extracting liquid comprises the raw materials: galangal, garlic, onion, cinnamon, clove and rosemary. The aquatic product composite preservative provided by the invention is prepared by compounding biological preservatives, is safe and non-toxic, has simple preparation and application methods, prominent microbial inhibition effect and good preservation effect, can greatly prolong the shelf life of frozen aquatic products, and has important industrial value.

Owner:黎建波

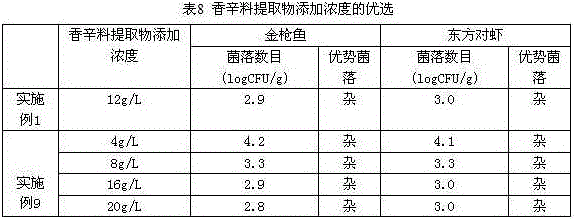

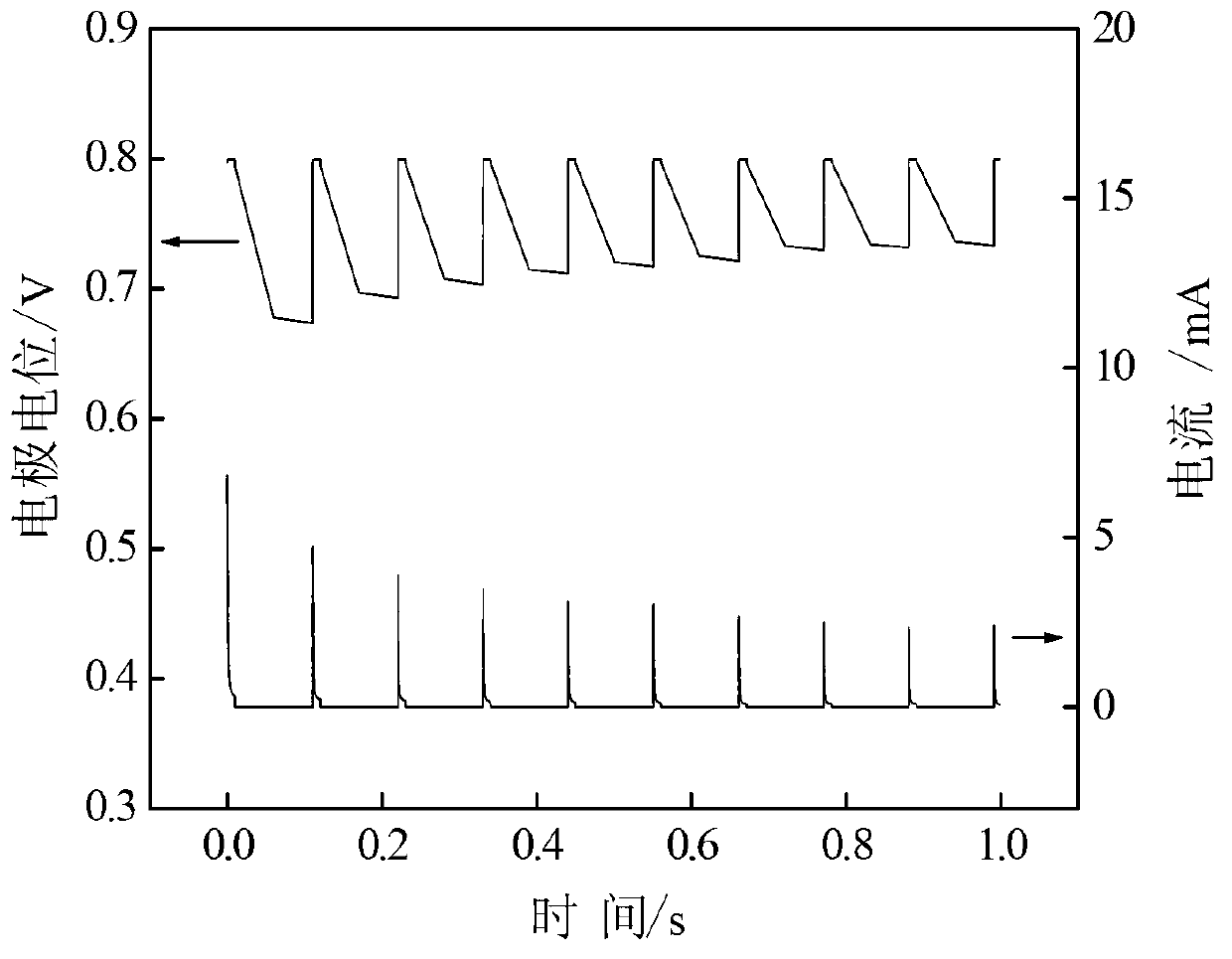

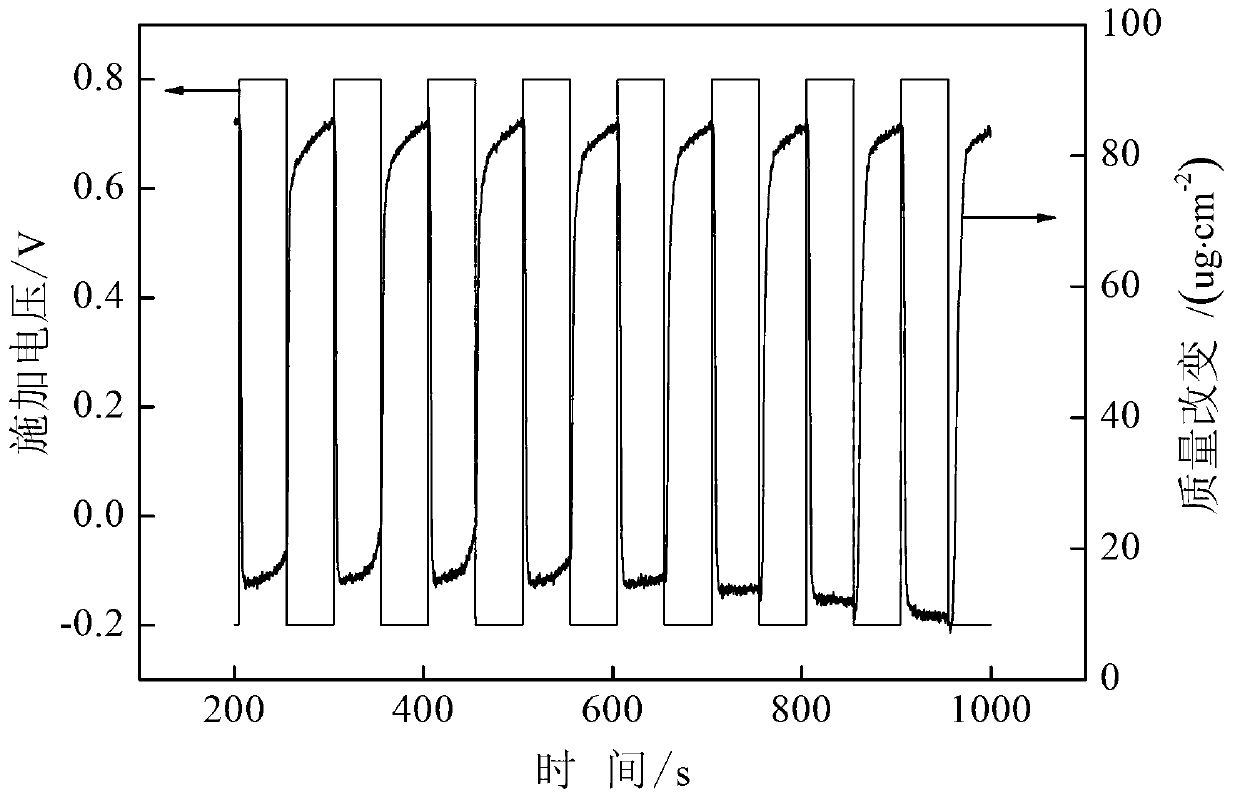

Preparation method of ion imprinted polymer film

ActiveCN103214689AEasy to operateMild preparation conditionsSemi-permeable membranesDispersed particle separationIn situ polymerizationRare earth ions

Belonging to the fields of electroactive functional polymer film material preparation and selective separation of ions, the invention relates to a preparation method of an ion imprinted polymer film. The invention is characterized by relating to a preparation method of an ion imprinted polymer film with an electronic control cation exchange function. The method includes: preparing a water solution of the monomer for polymer preparation, an electrolyte solution, a protonic acid solution, an imprinted ion solution and a doping ion solution, then mixing the five solutions, conducting in situ polymerization on a conductive substrate by a monopolar pulse electrodeposition method so as to synthesize imprinted ion removed ferricyanic group doped polymer film by one step. Being simple and fast to operate, the method provided in the invention needs no additional pickling step and can realize imprinted ion removal in situ. Also, the preparation conditions are mild and are easy to control. The ion imprinted polymer film prepared by the method has an electronic control cation exchange function, and can be used for selective removal of heavy metal ions in water or separation recycling of rare earth ions.

Owner:TAIYUAN UNIV OF TECH

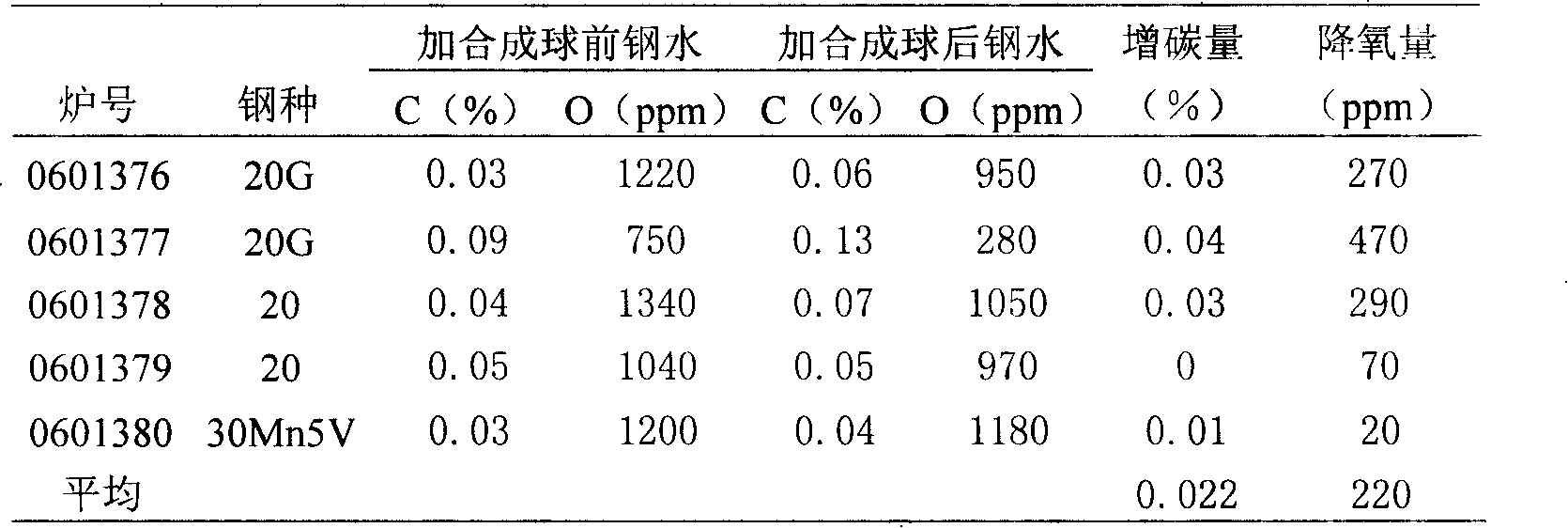

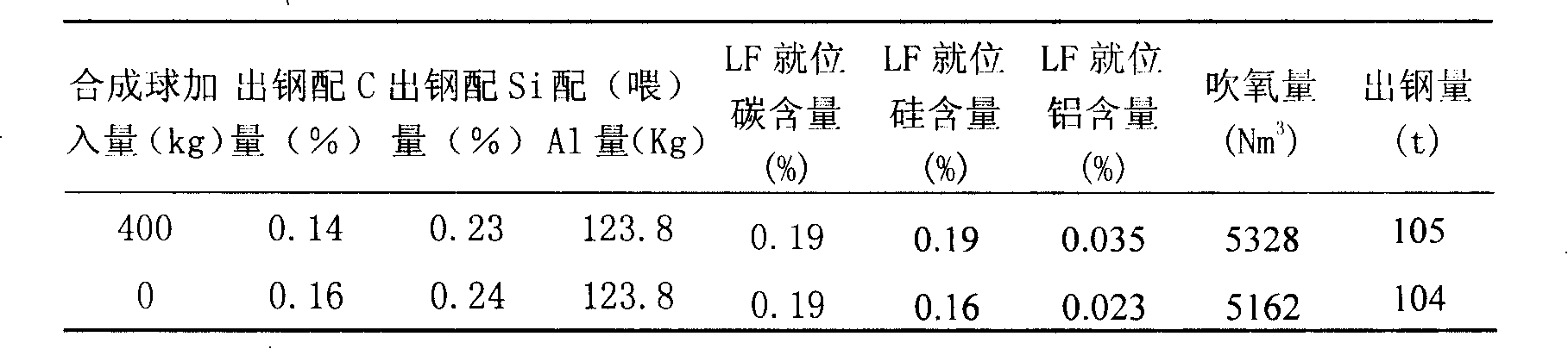

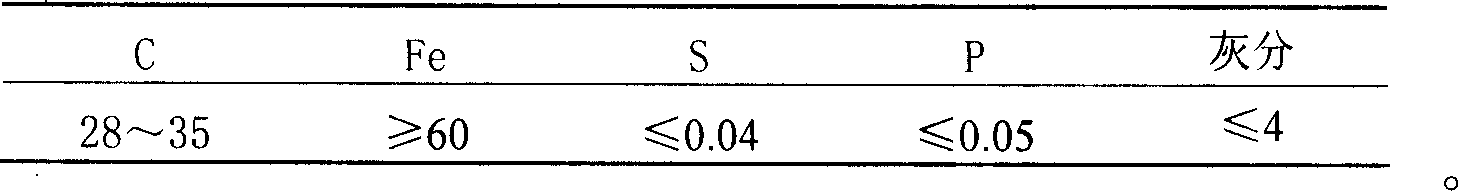

Pre-deoxidation recarburization process for arc furnace steel-smelting molten steel with slag

The invention relates to a pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace, comprising the following steps: (1) charging; (2) electrifying melting; (3) oxygen blowing to boost melting; (4) oxidation refining; (5) temperature measuring and sampling; (6) addition of deoxidizer (7) tapping. The pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace solves the problems in the prior art of high oxidation of molten steel in the electric-arc steelmaking furnace and low carbon content. The pre-deoxidation and carburization craft of molten steel with slag in the electric-arc steelmaking furnace has the advantages that: 1. the craft has easy operation and obvious effect. The carbon content of the steel in the electric furnace is increased, the oxygen content in molten steel is decreased and over-oxidation of the molten steel is avoided. 2. the addition of deoxidizer used for the molten steel outside the furnace is reduced, impurities content in steel is reduced and yielding rate the of the alloy is enhanced.

Owner:TIANJIN PIPE GROUP CORP

Skin care oil containing peony oil and preparation method thereof

ActiveCN103271860AImprove circulationAnti agingCosmetic preparationsToilet preparationsBiotechnologyMeadowfoam seed oil

The invention belongs to the technical field of skin care oil medicine, in particular to skin care oil medicine containing peony oil and a preparation method thereof. The skin care oil medicine provided by the invention comprises the following components in parts by weight: main ingredients: peony seed oil, caprylic / capric triglyceride, cyclopentasiloxane and 1, 2 - butyl glycol 1-12, wherein the peony oil is peony seed oil or peony essence oil or the mixture of peony seed oil and peony essence oil; auxiliary ingredients: isostearic acid, butylated hydroxytoluene, avocado oil, simmondsia chinensis seed oil, meadowfoam seed oil and macadamia ternifolia seed oil; the skin care oil medicine containing peony oil prepared by the method provided by the invention can remarkably improve of the skin epidermis cell cycle function, promote the microcirculation of the blood capillary of the dermal skin effect, inhibit lipid peroxidation, improve metabolism, delay skin aging process, is provided with anti-wrinkle, moisturizing and whiting effect, people feels smooth and comfortable after the skin care oil medicine is used on the skin, and the skin care oil medicine containing peony oil is provided with better effect to chloasma, aging skin wrinkles, skin cutin hardening peeling and skin chap.

Owner:HEZE YAO & SHUN PEONY BIOTECH

Anti-aging skincare mask containing crithmum maritimum

InactiveCN107334725ALow freezing pointEasy to synthesizeCosmetic preparationsToilet preparationsFennel extractCentella asiatica extract

The invention discloses an anti-aging skincare mask containing crithmum maritimum. The anti-aging skincare mask is prepared from a skin conditioner component, an auxiliary component and water, wherein the skin conditioner component is prepared from 2%-6% by mass of butanediol, 2%-5% by mass of glycerin, 0.1%-0.5% by mass of a crithmum maritimum extract, 1%-5% by mass of a pseudoalteromonas fermentation product extract, 1%-5% by mass of acetyl hexapeptide-8, 0.5%-3% by mass of a Centella asiatica extract, 0.5%-2% by mass of D-panthenol, 0.03%-0.1% by mass of sodium hyaluronate, 1%-5% by mass of Chamomile German water, 0.5%-3% by mass of corn protein amino acids, 1%-3% by mass of a lotus extract, 0.5%-2% by mass of bio-saccharide gum-1 and 0.1%-0.3% by mass of allantoin. The anti-aging skincare mask containing crithmum maritimum can inhibit lipid peroxidation and inflammatory reaction, rebuild water balance and brighten complexion and has effects of preserving moisture, resisting aging, brightening the complexion and realizing anti-allergic repair.

Owner:广州蜜妆生物科技有限公司

Aluminum-containing and sulfur-containing series gear steel smelting process

ActiveCN104611502AControl Si contentInhibit peroxidationProcess efficiency improvementElectric furnaceGranularitySmelting process

The invention discloses an aluminum-containing and sulfur-containing series gear steel smelting process. Liquid iron is required to contain 0.20-0.50% of Si, less than or equal to 0.035% of S, and less than or equal to 0.110% of P, and at a temperature T greater than or equal to 1250 DEG C; lime for an electric furnace and refining is required to contain greater than or equal to 90% of CaO and less than or equal to 1.2% of SiO2, and has the activity degree of greater than or equal to 300 and the granularity of 10-40mm; a low-silicon refining agent is required to contain greater than or equal to 45% and less than or equal to 55% of CaO, less than or equal to 2.0% of SiO2, and greater than or equal to 35% and less than or equal to 40% of Al2O3. The liquid iron hot charge ratio of the electric furnace reaches up to 90%; for LF refining, a first strong and later weak deoxidization manner is adopted; at the middle-late stages, a weak deoxidizer is adopted for furnace slag maintenance to realize further deoxidization. Meanwhile, deoxidization and S removal are performed, and then an S wire is fed to obtain a certain S content; in addition, the S wire is allowed to be fed only in more than 5 minutes after the denaturalization treatment of feeding a calcium-iron wire into VD liquid steel, and therefore, the formation of CaS inclusion in a clogging material at other water gap is prevented; and at last, the castability of the liquid steel is guaranteed while excellent structural properties of the steel product are obtained, and the purity of the liquid steel is improved.

Owner:ZENITH STEEL GROUP CORP +1

Puffed snakehead compound particle feed and Chinese herbal medicine premix added therein

ActiveCN101785531AGuaranteed palatabilitySolve the non-bottleneck of developmentAnimal feeding stuffForsythia suspensaRadix bupleuri

The invention discloses a Chinese herbal medicine premix added in a puffed snakehead compound particle feed, which comprises the following components by weight proportioning: Artemisia annua to Forsythia Suspensa to radix sophorae flavescentis to radix bupleuri to folium eucalypti to radix gentianaeto common andrographis herb to folium artemisiae argyi to apocynum venetum is 3-5:1-3:1-3:2-5:3-5:2-5:2-4:1-3:1-3. The invention also discloses a puffed snakehead compound particle feed comprising the basic formula of fish meal and bean pulp, and 1-5 weight percent of the Chinese herbal medicine premix is added in the basic formula. The puffed snakehead compound particle feed of the invention can strengthen snakehead immunological capability, prevent and treat diseases and improve snakehead meat quality and flavour.

Owner:HANGZHOU FEIXUN BIO TECH

Beautifying and nursing essence and preparation method thereof

InactiveCN103908424AAvoid allergic reactionsNo side effectsCosmetic preparationsToilet preparationsCuticleUmbilical cord tissue

The invention discloses a beautifying and nursing essence and a preparation method thereof. The essence is prepared from an epidermis cell nutrient solution and contains a plurality of cell growth factors, amino acids and vitamins. The essence mainly comprises an epidermal growth factor, a fibroblast growth factor, collagen type I, a stem cell growth factor, a horn cell growth factor and amino acids and vitamins including gamma-aminobutyric acid, coenzyme Q, medical vitamin C, medical vitamin B5 and medical vitamin E. The preparation method for the essence comprises the following steps: acquisition of epidermis of umbilical cord tissue of a newborn; cell culture; collection of a cell nutrient solution; filtration sterilization; condensation of a volume; addition of active components; addition of glycerin and hyaluronic acid; etc. The beautifying and nursing essence provides a plurality of endogenous nutritional ingredients with physiological activity for the skin, can promote metabolism of epidermis cells and repair damaged cells, has a moisture retention effect and is applicable to skin beautifying and nursing.

Owner:奥思达干细胞有限公司

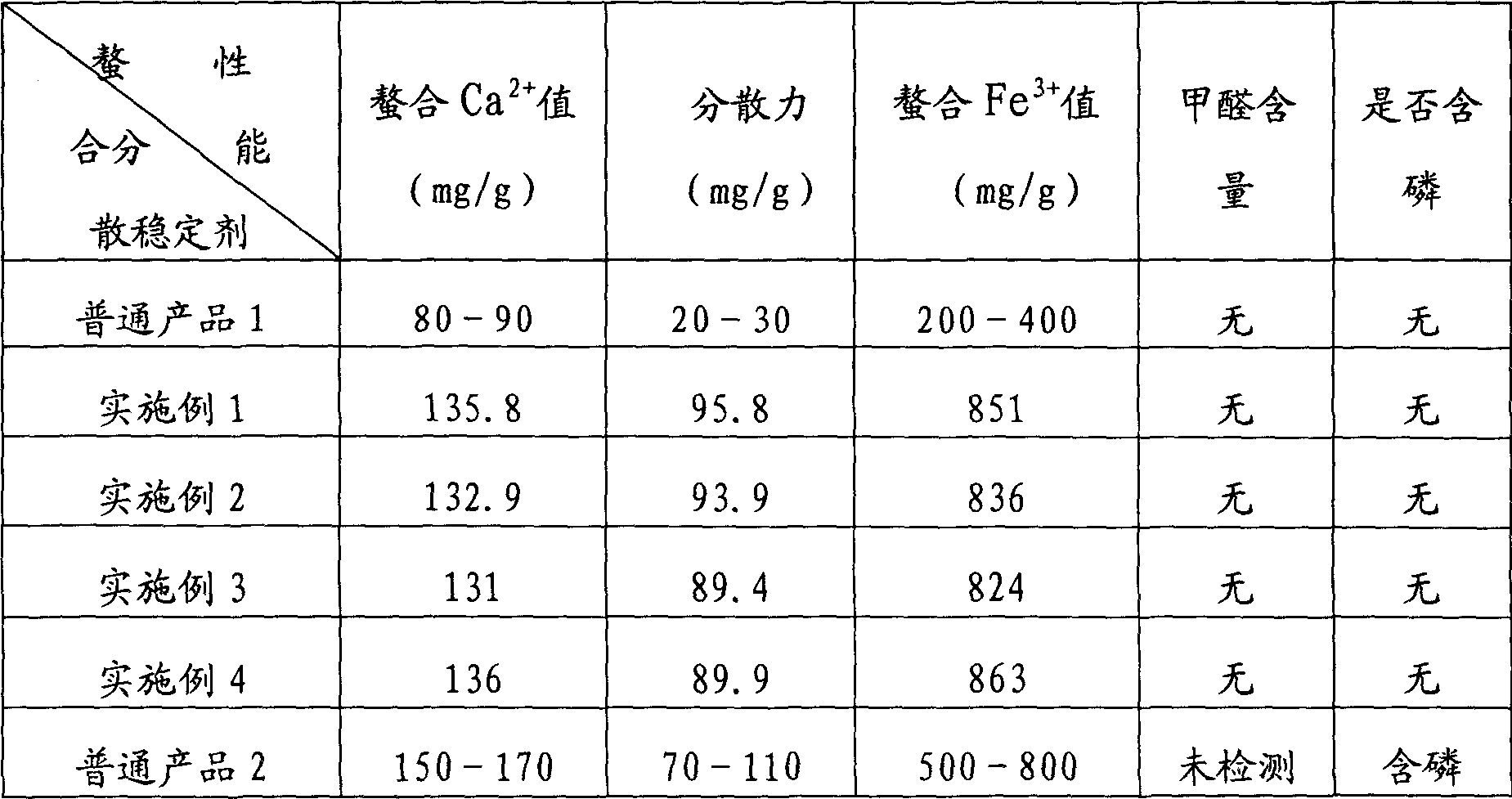

Non-phosphate alkaliproof highly effective chelating dispersion stabilizer, preparation process and use thereof

InactiveCN1923350AReduce adverse effectsQuality improvementTransportation and packagingScale removal and water softeningHydrolysatePhosphate

The invention relates to a polyamide polyamide high-efficiency chelate disperse stabilizer and relative production. Wherein, said stabilizer is formed by macromolecule polymer, alkyl poly-glycoside hydrolysate, and water, while their components are 60-95, 5-10, and 0-30; the chelate Ca=800mg / g. The molecule weight of said invention is 500-2000. And its production can avoid dangerous chemicals, with better degradation, strong chelate ability.

Owner:SICHUAN TEXTILE SCI RES INST +1

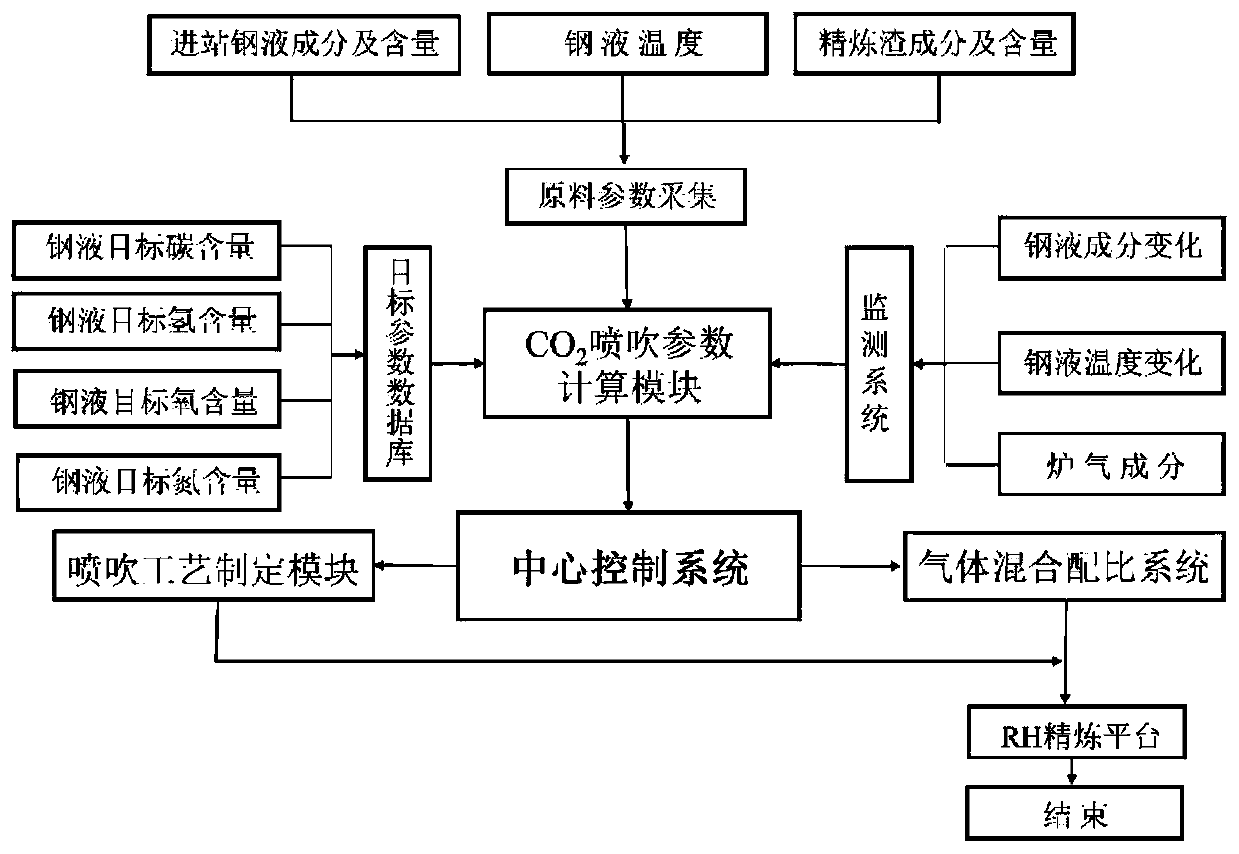

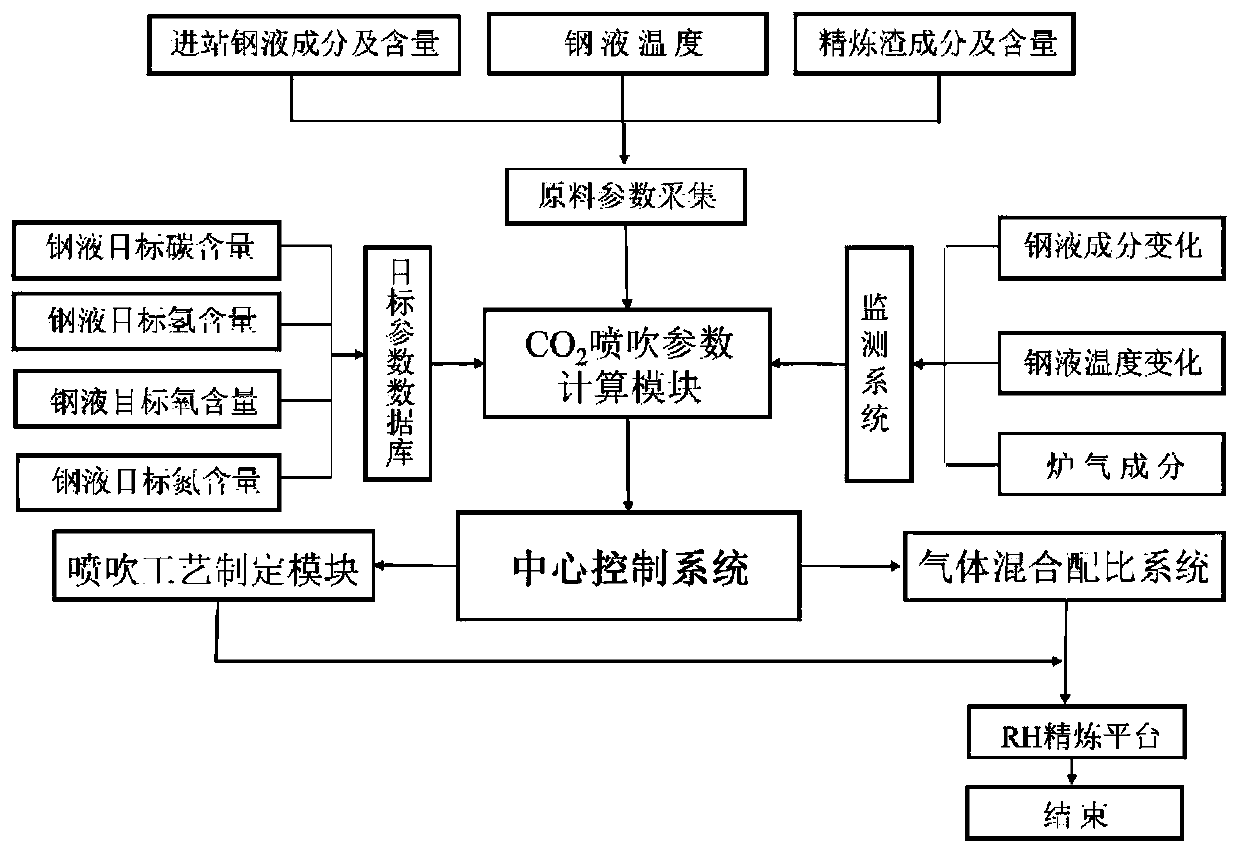

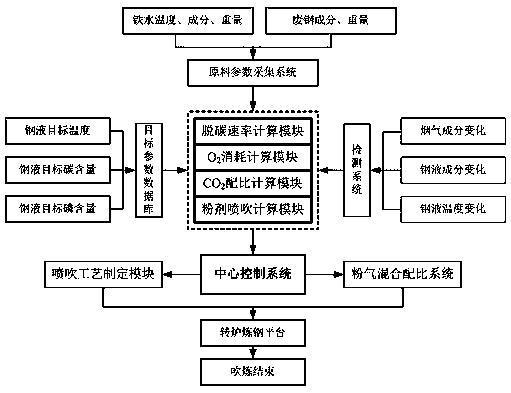

Dynamic control method for refining ultra-low carbon steel through RH CO2 spraying

The invention belongs to the technical field of steelmaking, and particularly relates to a dynamic control method for refining ultra-low carbon steel through RH CO2 spraying. The dynamic control method is suitable for a 30-300 t RH ladle refining process. In the RH refining process, O2 and CO2 are adopted as top-blowing gases, Ar and CO2 are used as lifting gases; molten steel components in the refining process are predicted based on material conservation according to RH refining in-station molten steel component data, refining process furnace gas component data and vacuum equipment working conditions; the top blowing and lifting gas flow is dynamically adjusted according to requirements of target components of refined molten steel stage by stage; on the basis of strengthening the stirringeffect of the RH refining process, the nitrogen content in the molten steel is further reduced, and the quality of molten steel is improved; and meanwhile, excessive oxidation of the molten steel inthe RH decarbonization process is avoided, the consumption of a deoxidized alloy is reduced, and on the basis of reducing the consumption of Ar, the production cost is further reduced, and the refining period is shortened. As a result, the alloy consumption is reduced by 3%-8%, the RH refining period is shortened by 1-2 minutes, the denitrification amount is increased by (3-10)*10<-6>, and the quality of the molten steel is improved.

Owner:UNIV OF SCI & TECH BEIJING

Face film

A face mask for nourishing face skin, taking care of face skin health, whitening and beautifying skin, and removing spots is prepared from solution of propolis in alcohol, royal jelly, honey, beeswax, ginseng, safflower, motherwort, Chinese angelica root, ratoginseng, cellulose and water.

Owner:刘富堂

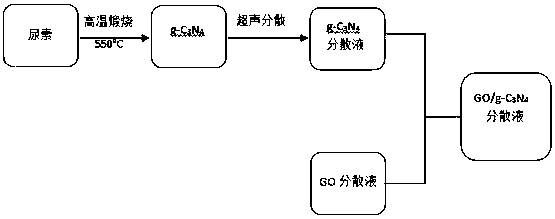

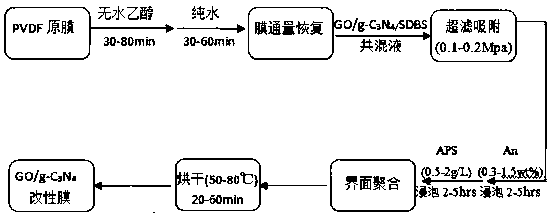

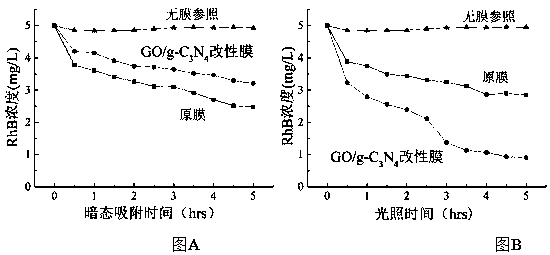

Graphene oxide and graphite-phase carbon nitride composite modified membrane material and preparation method thereof

ActiveCN109433013AImprove hydrophilicityImprove pollutionMembranesPhysical/chemical process catalystsAnilineMembrane function

The invention discloses a GO (graphene oxide) and g-C3N4 composite modified membrane material. A preparation method includes steps: activating an original membrane to recover original membrane flux; adding a surfactant into GO and g-C3N4 mixed dispersion liquid to obtain mixed liquid; soaking the activated original membrane into the mixed liquid to realize ultrafiltration adsorption, and soaking the membrane into aniline hydrochloric acid solution; taking out after soaking is finished, and soaking in hydrochloric acid solution of ammonium persulfate immediately to enable interface polymerization reaction; finally, drying the membrane to obtain the composite modified membrane material. By an ultrafiltration adsorption and interface polymerization combined modification method, GO and g-C3N4are combined for surface composite modification of the membrane material, and a visible light responsive catalytic modified membrane is developed. The novel modified membrane is low in preparation cost and recyclable, pollution resistance is remarkably improved, firmness in modifying agent and photocatalyst loading is achieved, the visible catalytic performance and hydrophilic performance are remarkably enhanced, the forbidden bandwidth of a membrane function layer is decreased, the problem of secondary pollution is avoided, and a promising application prospect is achieved.

Owner:GUANGDONG UNIV OF TECH

Fruit jelly capable of relieving asthenopia

Owner:SHENGQUAN HEALTANG

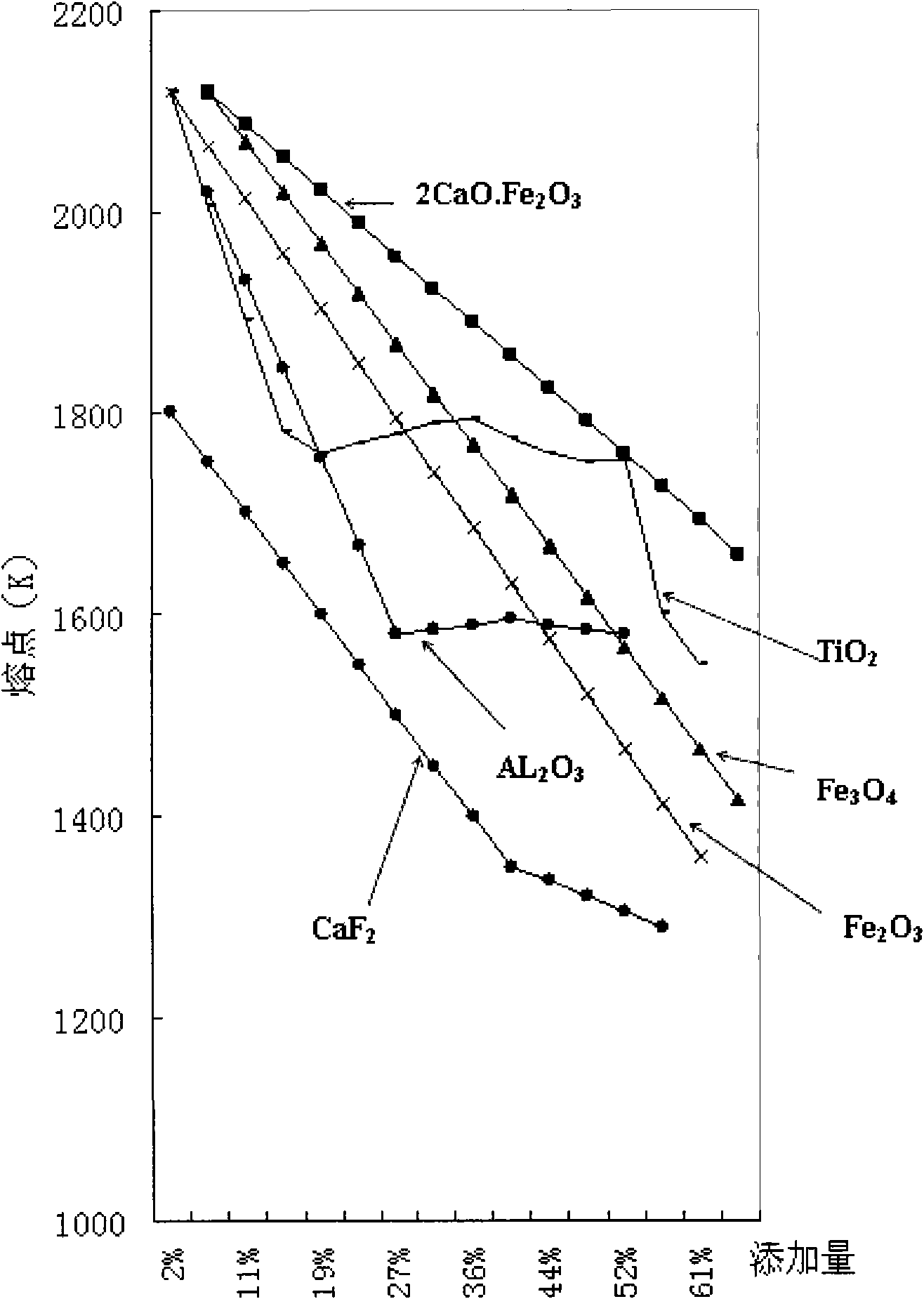

Exothermic agent for converter molten iron with low heating value

InactiveCN101988137AAdjust alkalinityPlay the role of supplementing molten iron [Si]Manufacturing convertersSlagSilicon

The invention discloses an exothermic agent for converter molten iron with a low heating value, which comprises the following components in percentage by weight: 31-44 percent of carbonaceous material, 35-48 percent of siliceous material, 6-14 percent of bauxite, 4-10 percent of iron granules or scrap iron and 4-8 percent of binder, and the bulk specific weight of the exothermic agent is 2.2-3.5ton / m<3>. The exothermic agent for the converter molten iron with the low heating value has the characteristic of raising the temperature obviously and promoting slagging for low-silicon and low-temperature molten iron, and can improve the dephosphorizing capability of converter slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Chinese medicament preparation with sobering-up, blood fat-reducing, liver-protecting and cardio-cerebrovascular-protecting functions

ActiveCN101485861AHas the function of harmonizing the spleen and stomachReduce lipid peroxidation damageNervous disorderMetabolism disorderFormularyNutmeg extract

The invention relates to a traditional Chinese medicine preparation having functions of neutralizing the effect of alcoholic drink, reducing blood fat and protecting the liver and cardio-cerebral blood vessels, which comprises the following compositions: 20 to 80 percent of pollen pini, 10 to 70 percent of kudzu root extract, 5 to 50 percent of nutmeg extract and 5 to 30 percent of auxiliary materials. The traditional Chinese medicine preparation is health-care food prepared from pure natural food, namely the pollen pini, kudzu roots and nutmeg which are taken as main raw materials by a reasonable formula, specially aims to people suffering from chronic alcohol drinking, fat people and patients suffering from hypertension, hyperlipemia and hyperglycemia and chronic diseases, and achieves the aim of protecting chemical liver damage by protecting the liver and resisting lipid overoxidation damage of the liver caused by alcoholism. The pollen pini contains rich antioxidative substances, and can lighten lipid overoxidation damage of alcohol on the liver, strengthen metabolism of fatty acid in hepatocyte, and reduce fat deposition in the hepatocyte; the nutmeg has the function of regulating spleen and stomach; and the kudzu roots also have the function of relieving cerebral vasospasm, so that the traditional Chinese medicine preparation achieves the aim of relieving symptoms such as headache, stomach upset, dyspepsia and poor health after drinking.

Owner:承德畅达生物科技有限公司

Method for preparing benzaldehyde through phenylcarbinol oxidation

InactiveCN102719844ALow selectivityHigh selectivityElectrolysis componentsElectrolytic organic productionSupporting electrolyteElectrolysis

The invention provides a method for preparing benzaldehyde through phenylcarbinol oxidation. According to the method, ionic liquid serves as a supporting electrolyte, acetonitrile serves as a cosolvent, a high-pressure reactor provided with electrodes is used for performing electrochemical electrolysis in a supercritical CO2 environment with a reaction temperature of 25-70 DEG C (system pressure is 10-25MPa), and the phenylcarbinol is converted to the benzaldehyde through selective oxidation. According to the method, features of the supercritical CO2 such as small viscosity, zero surface tension and friendly environment are utilized, advantages of the ionic liquid such as stable physicochemical properties and high electrical conductivity are combined, a constant potential electrolysis technology is adopted to control the efficient selective oxidation of the phenylcarbinol to the benzaldehyde effectively, and the yield and the selectivity of the benzaldehyde can reach above 99.8% under an optimum condition.

Owner:BEIJING UNIV OF CHEM TECH

Biological-source nutritional preservative for seafood

InactiveCN106070538AStrong Broad Spectrum ResistanceEnhanced inhibitory effectStrepto/lacto-coccusNatural extract food ingredientsPropolisRosmarinus

The invention relates to a biological-source nutritional preservative for seafood. The biological-source nutritional preservative is characterized in that each liter of the distilled water of the biological-source nutritional preservative contains 0.4-0.6g of lysozyme, 2.5-3.5g of tea polyphenols, 20-28g of carboxymethyl chitosan, 10-14g of nisin, 17-23g of sodium alginate, 20-30g of lactobacillus, 1.5-2.5g of propolis extract and 10-14g of spice extract, wherein the spice extract is made of rhizoma galangae, garlic, onion, cinnamon, clove and rosemary. The biological-source nutritional preservative has the advantages that the biological-source nutritional preservative is compound by biological preservatives and is safe, nontoxic, simple in preparation and application method, outstanding in microorganism inhibition effect, good in preservation effect, capable of greatly prolonging the shelf life of the seafood and high in industry value.

Owner:黎建波

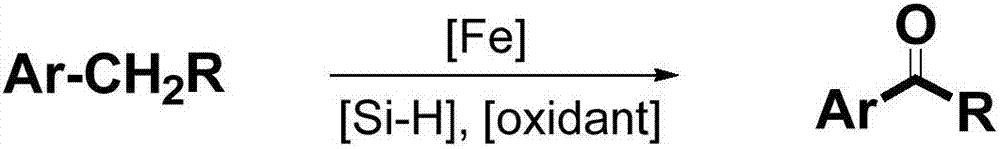

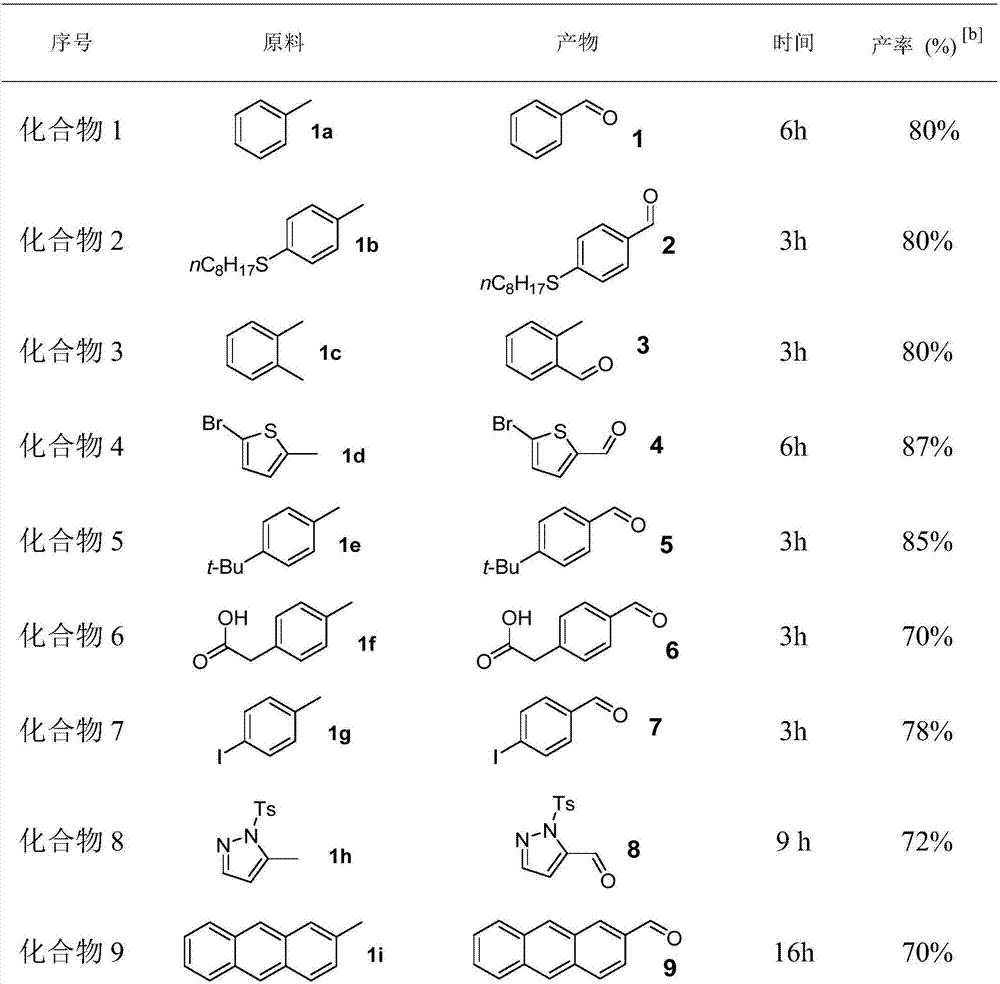

Method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing alkyl aromatic compound by iron

ActiveCN107216242ABroad compatibilityGood compatibilitySugar derivativesOrganic compound preparationSide chainCatalytic oxidation

The invention discloses a method for synthesizing aromatic aldehyde, aromatic ketone and aromatic ester through catalytically oxidizing an alkyl aromatic compound by iron, and belongs to the technical field of catalytic synthesis. According to the method, a low-cost and environment-friendly iron catalyst is used under a normal pressure; under the action of hydrogen and silicon reagents serving as an accelerant and an oxidant, a side chain of an aromatic hydrocarbon is oxidized into a carbonyl group for generating the corresponding aromatic aldehyde, aromatic ketone and aromatic ester. The method for preparing the aromatic aldehyde, the aromatic ketone and the aromatic ester through a catalytic oxidation reaction, which is provided by the invention, has numerous advantages that a catalyst, reaction raw materials, the oxidant and a silicon reagent are wide in sources and good in stability and is low-cost and environment-friendly; the alkyl aromatic compound is metered to participate in a reaction; the reaction condition is mild; the compatibility of functional groups is good; the scope of application is wide; the reaction selectivity is good; in an optimized reaction condition, the separation yield of a target product can be up to approximately 95 percent.

Owner:NANJING NORMAL UNIVERSITY

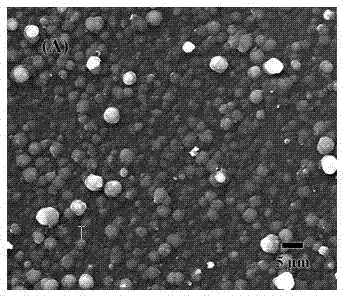

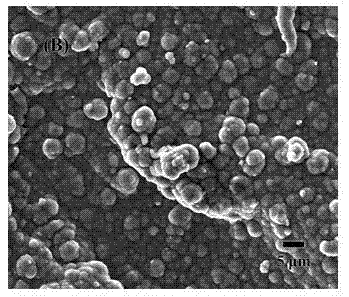

Preparation method for electroactive polypyrrole film

ActiveCN102817042AGood reproducibilitySimple preparation processElectrolysis componentsElectrolytic organic productionPolypyrroleAqueous solution

The invention discloses a preparation method for an electroactive polypyrrole film. The preparation method comprises the following steps of: preparing an aqueous solution of single pyrrole, an electrolyte solution and a protonic acid solution; secondly, mixing the three solutions; and obtaining a polypyrrole film electrode material on a conducting substrate by using a unipolar pulse electric polymerization. According to the preparation method disclosed by the invention, the operation is simple; products are easily obtained; no oxidant is needed; and the secondary pollution caused by the oxidant is avoided. The polypyrrole film electrode material prepared by the method in a neural solution has higher discharging stability.

Owner:TAIYUAN UNIV OF TECH

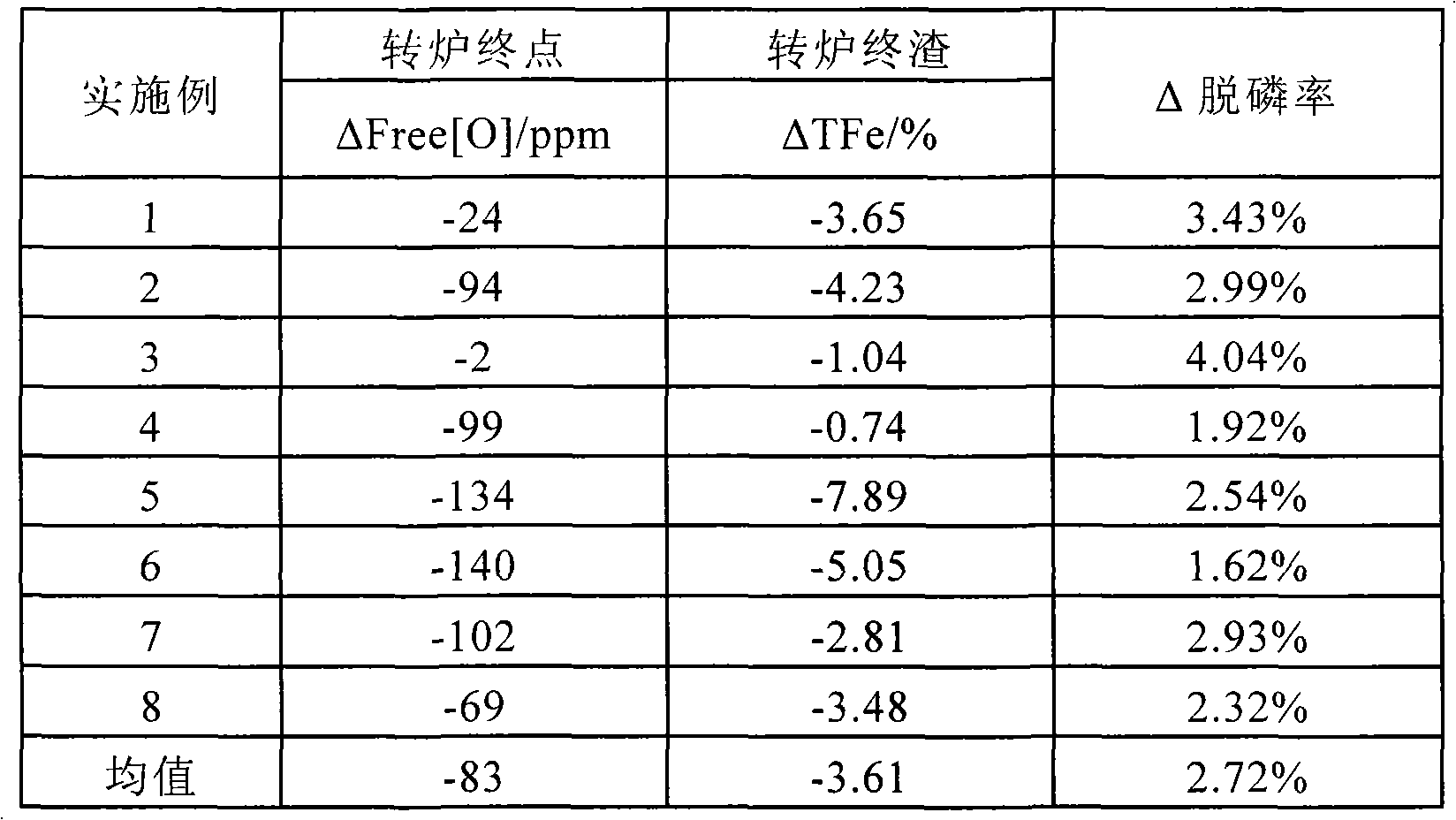

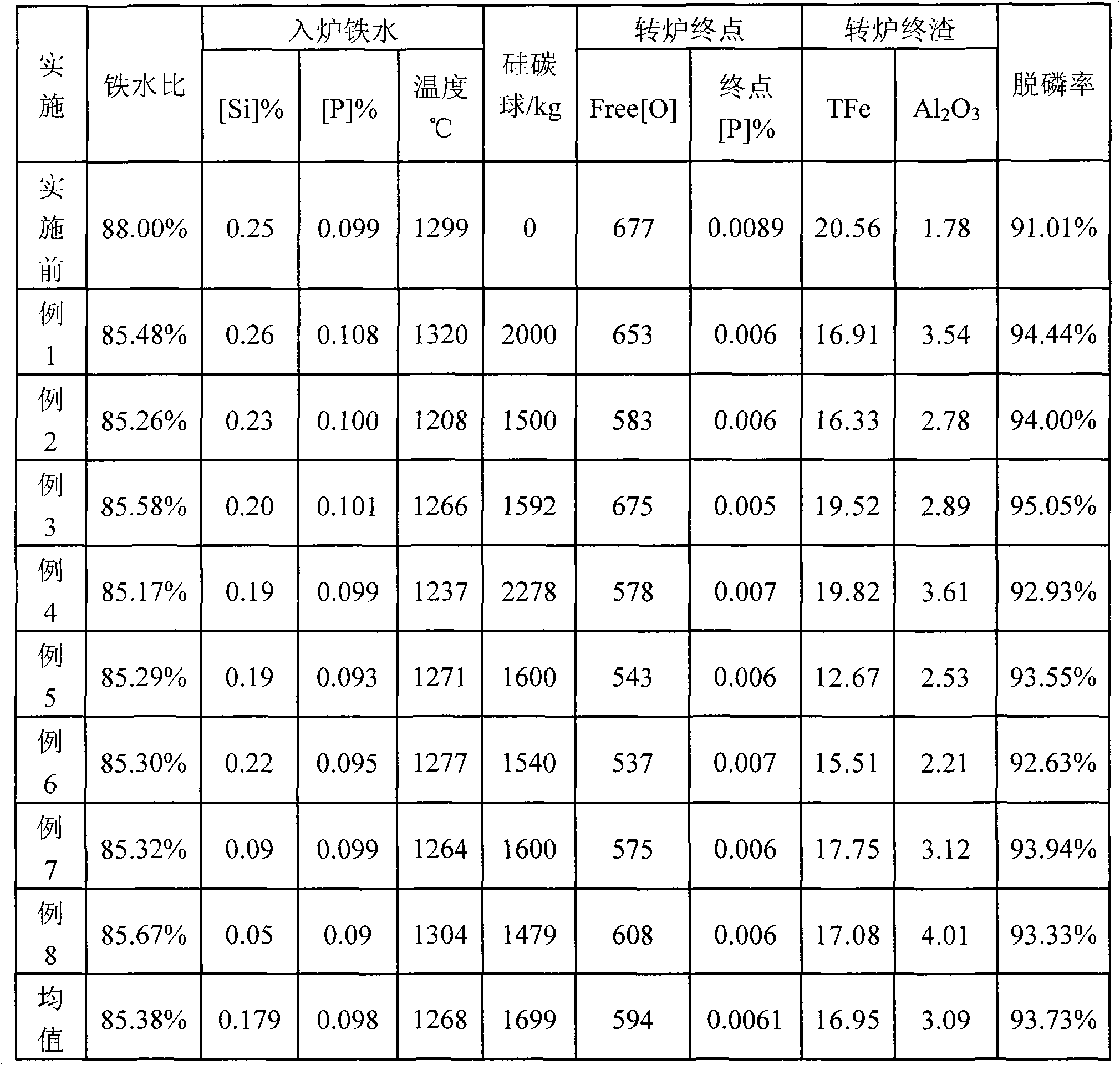

Method for dynamically controlling steelmaking process of bottom blowing O2-CO2-CaO converter

ActiveCN111500815AExtend your lifePromote reaction balanceSteel manufacturing process aspectsIncreasing energy efficiencySteelmakingProcess engineering

The invention discloses a method for dynamically controlling the steelmaking process of a bottom blowing O2-CO2-CaO converter, and belongs to the technical field of steelmaking. The method is suitablefor the steelmaking process of the 30-300t bottom blowing O2-CO2-CaO converter. According to a steelmaking process of the bottom blowing O2-CO2-CaO converter, O2 is adopted as top blowing gas, O2+CO2mixed gas is adopted as bottom blowing gas, lime powder is sprayed into the converter from a bottom blowing spray gun, and molten steel ingredients of the converter steelmaking process are predictedbased on material conservation in combination with the ingredient data of molten iron in the converter and waste steel, converter blowing process converter gas ingredient data and bottom blowing equipment work conditions; the top blowing oxygen amount, the bottom blowing gas ratio and the lime powder flow are dynamically adjusted by stages according to the blowing end point target ingredient requirements; while the fire blowing point area temperature is reduced, the converter molten pool stirring effect is enhanced, conduction of slag metal reaction balance is promoted, and the carbon contentand phosphorus content of molten steel are reduced; meanwhile, peroxidation of a converter blowing end point is avoided, deoxidizing alloy consumption is reduced, the number of occluded foreign substances in steel is reduced, and the quality of the molten steel is improved; and on the basis of an efficient metallurgy reaction, the metal yield is increased again, the production cost is reduced, andthe smelting period is shortened.

Owner:UNIV OF SCI & TECH BEIJING

Traditional Chinese medicine composition with effects of removing freckles and whitening and preparation and application methods thereof

InactiveCN107737272AEasy to useUse naturalCosmetic preparationsAnthropod material medical ingredientsSide effectBletilla striata

The invention discloses a traditional Chinese medicine formula with effects of removing freckles and whitening and a preparation method thereof and belongs to the technical field of human health careproducts. The traditional Chinese medicine formula contains the following raw materials: 4-18 parts of ganoderma lucidum, 9-36 parts of tricholoma matsutake, 3-12 parts of ginseng, 1-4 parts of bearberry leaf extract, 3-12 parts of rhizoma polygonati, 3-12 parts of bighead atractylodes rhizome, 1-6 parts of bletilla striata, 3-12 parts of white paeony root, 3-12 parts of ampelopsis japonica, 3-12parts of silkworm larva, 4-12 parts of poria cocos, 1-6 parts of angelica sinensis, 3-9 parts of paeonia lactiflora, 3-12 parts of astragalus, 1-5 parts of almond, 2-10 parts of semen coicis, 1-5 parts of fructus kochiae, 1-5 parts of cortex dictamni, 1-5 parts of liquorice and 2-6 parts of mint. The whitening and freckle removing skin care product provided by the invention is mild and non-irritating, can be applicable to population with sensitive skin, is simple and convenient to use, natural and zero in side effect and has excellent application prospects.

Owner:TONGJI UNIV

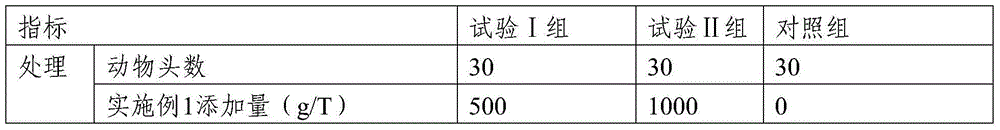

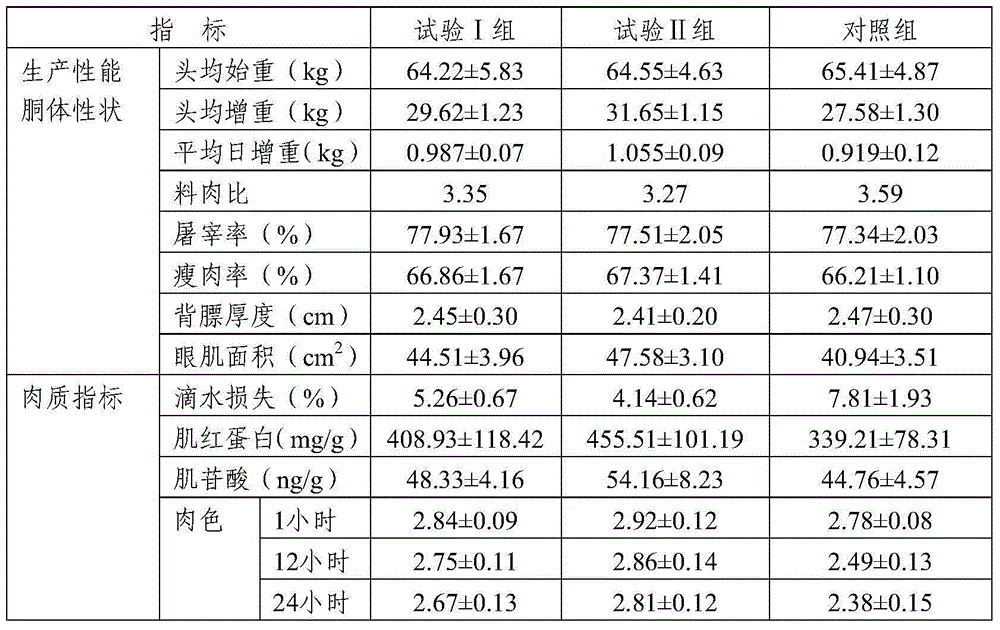

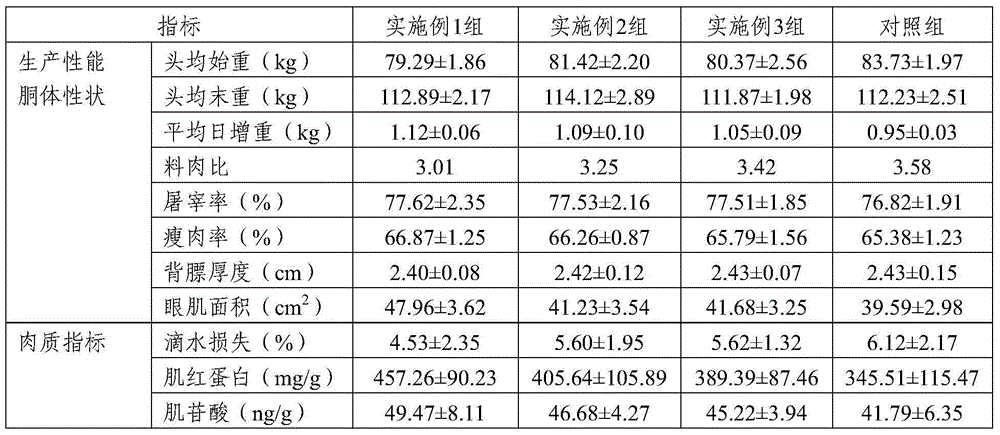

Feed additive for improving quality of animal meat

ActiveCN104431333AInhibit peroxidationStable structureAnimal feeding stuffBiotechnologyVitamin E Acetate

The invention relates to a feed additive for improving the quality of animal meat. The raw materials of the feed additive for improving the quality of animal meat are composed of radix salvia extract, pilose asiabell root extract, angelica extract, rosemary extract, schisandra extract, aloe extract, alfalfa extract, liquorice extract, vitamin E acetate and selenium yeast. The feed additive for improving the quality of animal meat is based on modern Chinese veterinarian theories, adopts a regulating scheme of integrating gene expression regulation and anti-lipid oxidation and is elaborately developed by selecting various natural plant extracts and combining functional trace elements and vitamins. Meanwhile, the safe and efficient plant feed additive for improving the quality of animal meat is relatively complex in composition and stable and comprehensive in effects.

Owner:BEIJING AILV BIOTECH

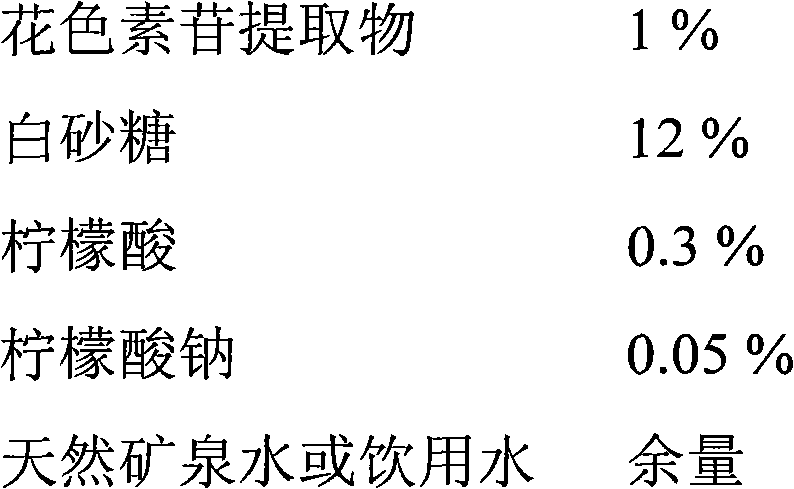

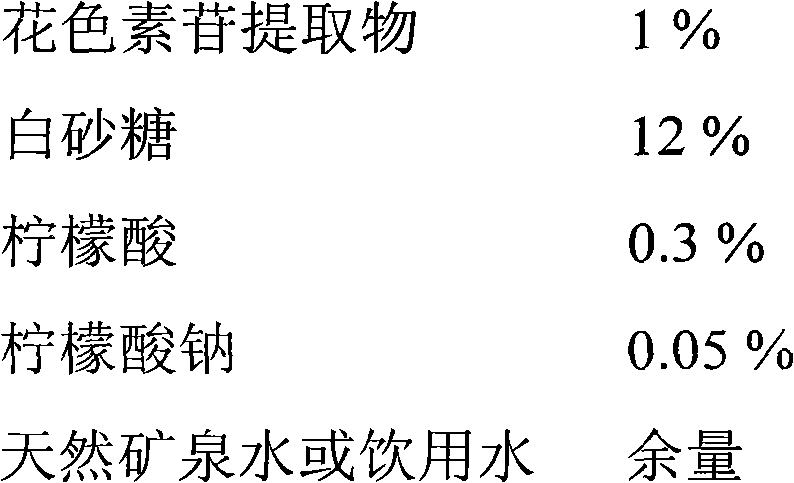

Functional drink with function of relieving visual fatigue and preparation method thereof

InactiveCN104256817AReduce extraction timeImprove extraction efficiencyTea substituesFood ingredient functionsLuteinSugar

The invention provides a functional drink with a function of relieving visual fatigue and a preparation method thereof, belonging to the technical field of functional drinks. The functional drink with the function of relieving the visual fatigue is prepared from five raw materials of lutein, medlar, chrysanthemum, white granulated sugar and citric acid, wherein the lutein is extracted from marigold; the functional drink is prepared by adopting a series of steps of pretreating raw materials, extracting, blending and the like. The functional drink prepared by adopting the preparation method is safe and reliable in raw materials; meanwhile, no caffeine, preservative and artificial color are added, and the functional drink has functions of improving the eyesight and relieving the visual fatigue.

Owner:河南福森药业有限公司

Novel anthocyanin functional beverage

The invention relates to health care functional beverage, in particular to health care beverage taking black rice anthocyanin as a main functional component. The novel anthocyanin functional beverage is formed by mixing and preparing main ingredients, i.e. anthocyanin, cane sugar, citric acid and the like according to a certain proportion, is higher in nutritional value and can satisfy the demands of enhancing the oxidation resistance of an organism and promoting the immune function of the organism. Meanwhile, the novel anthocyanin functional beverage has the effects of adjusting the blood fat, reducing the cholesterol and the like, is suitable for various crowds and has the health care function.

Owner:WENZHOU MEDICAL UNIV

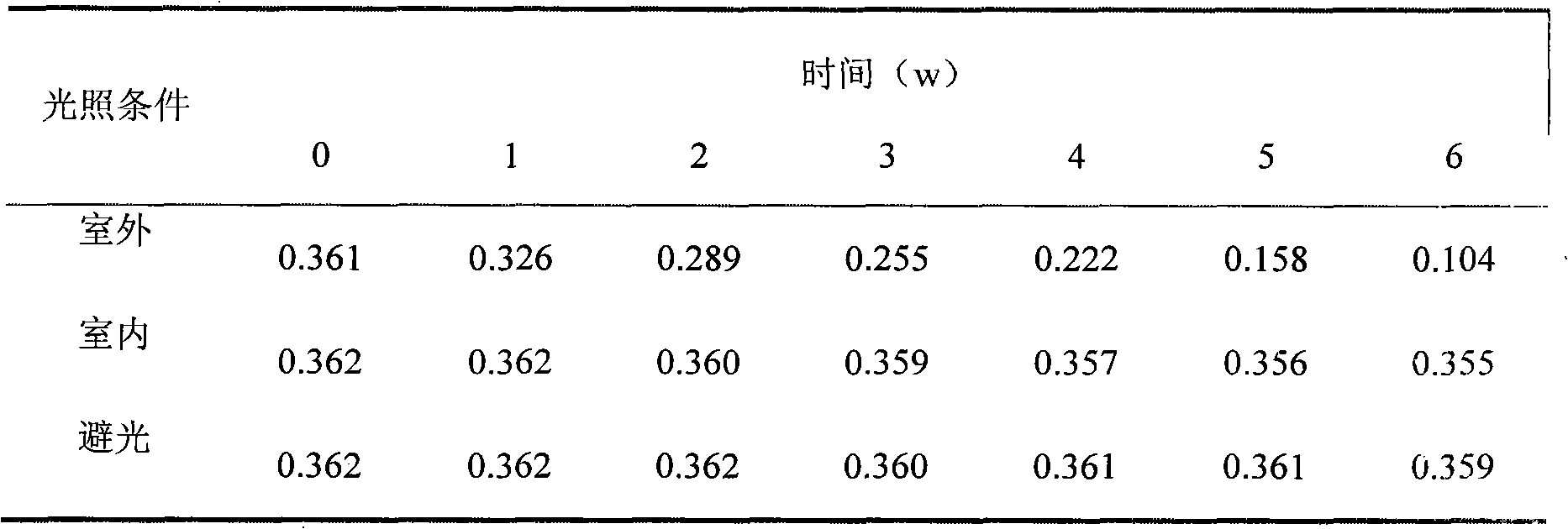

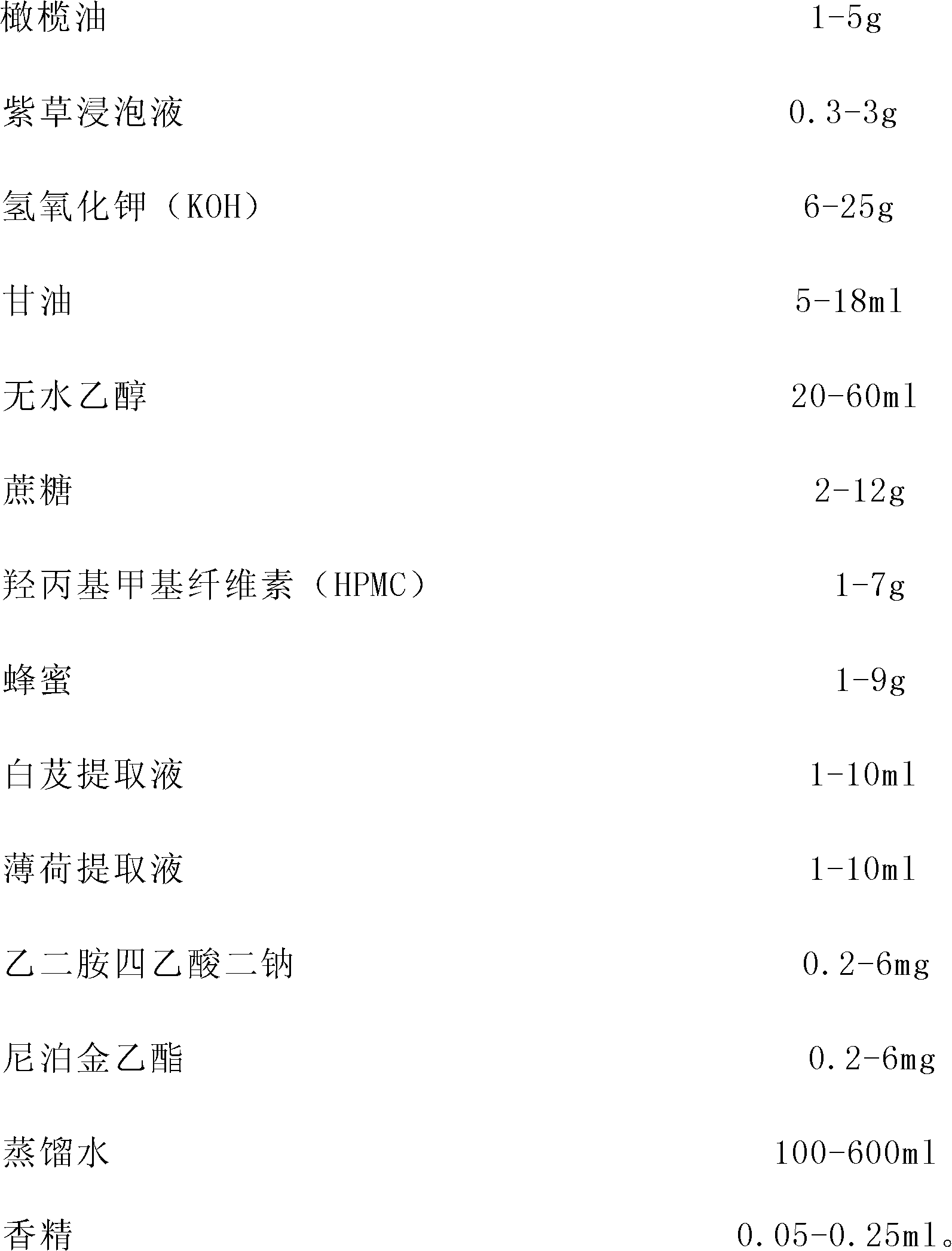

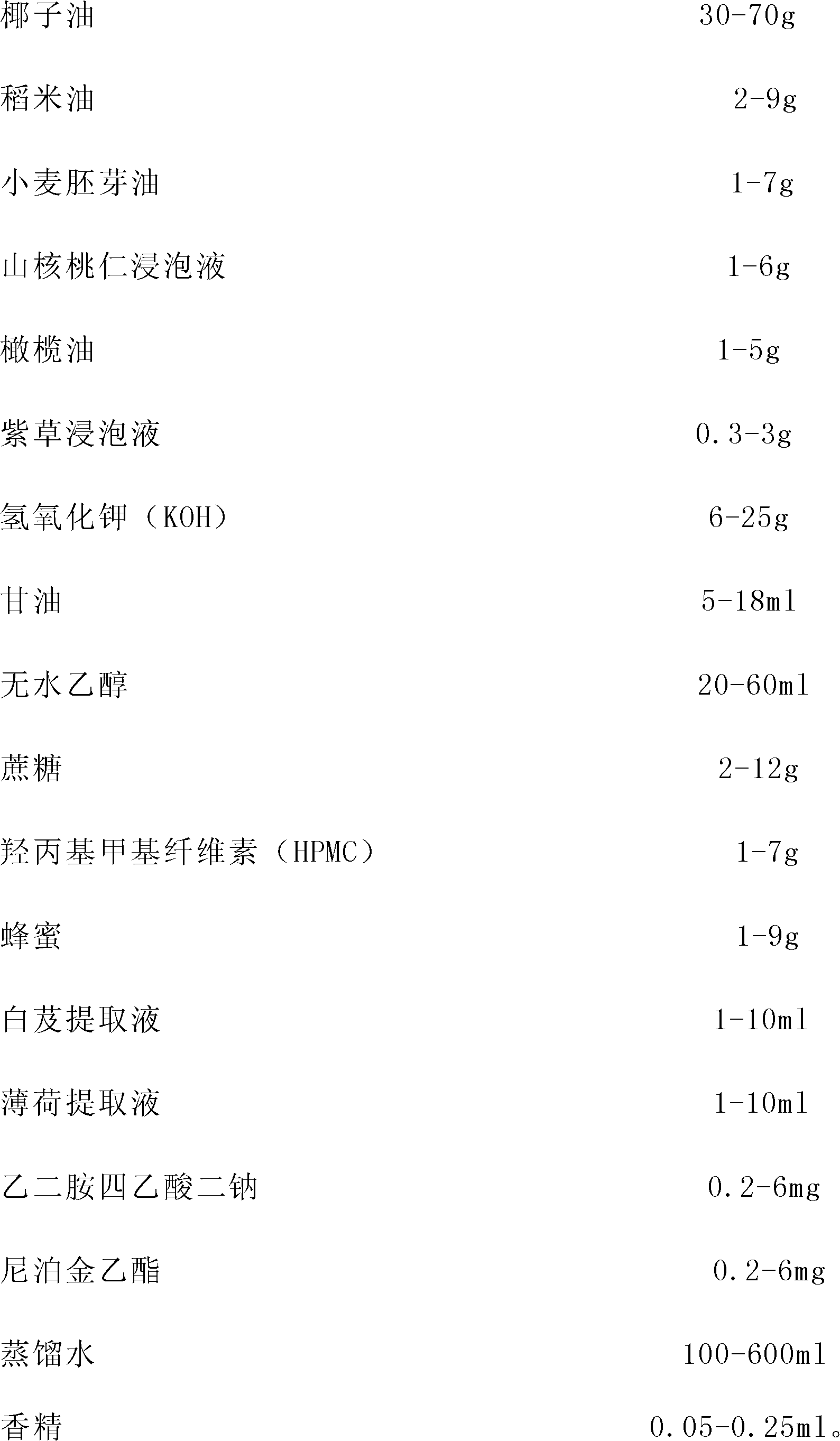

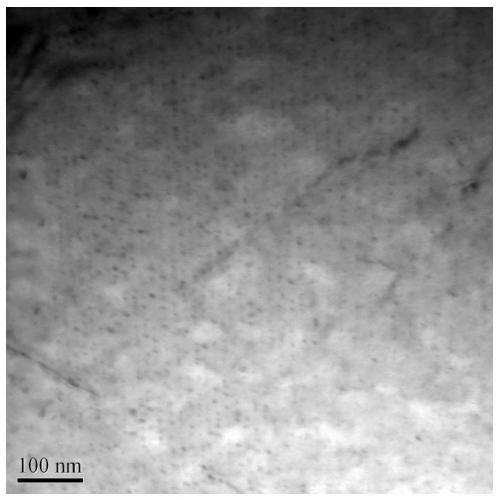

Health-care bath foam and preparation method thereof

ActiveCN102302439AFree from damageInhibit peroxidationCosmetic preparationsToilet preparationsSucroseUltraviolet

The invention discloses health-care bath foam and a preparation method thereof. The bath foam contains the following substances: coconut oil, rice oil, wheat germ oil, hickory kernel soaking liquid, olive oil, lithospermum soaking liquid, potassium hydroxide, glycerol, absolute ethanol, sucrose hydroxypropyl methyl cellulose, honey, bletilla extract, mint extract, ethylene diamine tetraacetic acid, ethylparaben, distilled water and essence. Compared with the prior art, the health-care bath foam has the advantages of inhibiting melanin, resisting ultraviolet, achieving the effect of removing freckles, supplementing nutrient and moisture required by the skin, preventing dry skin, ageing and various skin infections, improving the blood circulation of the skin, promoting metabolism and makingthe skin elastic and soft.

Owner:广州康芙莱生物科技有限公司

Method for extracting active polysaccharide from seaweed

InactiveCN109608559AGood cell wall breaking effectImprove leaching rateAntinoxious agentsAntineoplastic agentsChemistryPrecipitation

The invention discloses a method for extracting an active polysaccharide from the seaweed, which comprises the steps of seaweed cleaning, seaweed crushing treatment, seaweed degreasing treatment, enzymolysis treatment, super extraction, concentration, protein removal treatment, decolorization treatment, alcohol precipitation and the like. The method for extracting an active polysaccharide from theseaweed comprises the following steps of: firstly carrying out superfine grinding on the seaweed, extracting the polysaccharide of the seaweed by adopting a mode of combining microwave-assisted enzymolysis and super extraction, thereby achieving a good cell wall breaking effect, effectively improving the leaching rate of the polysaccharide and the extraction efficiency is greatly improved, the process route is simple, and the production cost is low. The method for extracting an active polysaccharide from the seaweed is simple and feasible, the extraction conversion rate and the purity of thepolysaccharide are higher, the industrial production is easy with higher safety, and the economic value of the seaweed is greatly improved., The method has mild deproteinization and decolorization processes, shortens the process flow, reduces the energy consumption and the consumption of organic solvents, which is more suitable for large-scale production and application.

Owner:GUANGDONG OCEAN UNIVERSITY

Steel for hot-rolling ribbed high-strength steel bars of 700 Mpa or above and production method of high-strength steel bars

The invention discloses steel for hot-rolling ribbed high-strength steel bars of 700 Mpa or above and a production method of the high-strength steel bars and belongs to the technical field of hot-rolling ribbed steel bars. The steel for the hot-rolling ribbed high-strength steel bars contains the chemical components including, by mass, 0.20-0.50% of C, 0.80-1.20% of Si, 1.00-1.50% of Mn, 0.10-0.25% of V, 0.015-0.025% of N, 0.40-1.00% of Cr, 0-0.025% of P, 0-0.010% of S, and the balance Fe and inevitable impurity elements. By means of the microalloying design, converter (or electric-arc furnace) steel-making and bar low-temperature temperature-controlling rolling technology, under the conditions of existing technology equipment of steel enterprises and proper 10% increase of motor power, large-scale industrial production of the steel bars of 700 Mpa can be achieved, and thus the demands of high-rise and long-span reinforced concrete building structures in China are met.

Owner:MAANSHAN IRON & STEEL CO LTD

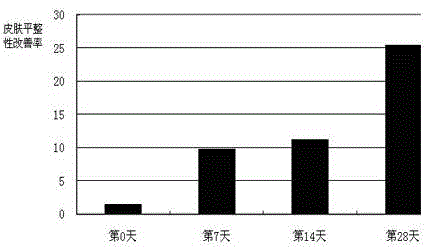

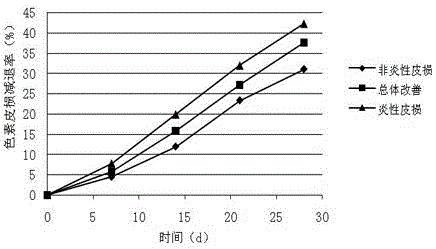

Multieffect skin-smoothing cream and preparation method thereof

InactiveCN106309246AImprove permeabilityGood effectCosmetic preparationsToilet preparationsCentella asiatica extractBetaine

The invention belongs to daily cosmetics, and relates to a multieffect skin-smoothing cream which is prepared from the following components in parts by weight: 30-70 parts of deionized water, 3-8 parts of butanediol, 3-8 parts of glycerol, 1-4 parts of dimethyl siloxane cyclopolymer, 0.3-2 parts of betaine, 1-5 parts of squalane, 1-3 parts of palmitoylhexapeptide-12, 1-10 parts of centella extract, 1-10 parts of rosemary extract, 1-10 parts of gold camomile extract, 2-10 parts of giant knotweed root extract, 3-10 parts of liquorice extract, 3-10 parts of licorice root extract, 1-10 parts of tea extract, 0.1-0.8 part of ammonium acryloyldimethyl taurate / VP copolymer, 0.1-1 part of cetostearyl alcohol, 0.1-1 part of phenoxyethanol, 0.05-0.5 part of methylparaben, 0.05-0.5 part of ethylparaben, 0.1-0.5 part of ethylhexyl glycerol, 0.1-1 part of PEG-100 sterin, 0.1-1 part of allantoin and 0.03-0.5 part of hyaluronic acid. The multieffect skin-smoothing cream is used for various types of sensitive skin, can repair various types of sensitive skin in the aspects of red, swelling, heat, itches, peeling and the like, can smooth the face and resist aging, and has favorable treatment and repair effects on damaged cuticles.

Owner:大连苗谣青颜生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com