Patents

Literature

126results about How to "Good deoxygenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

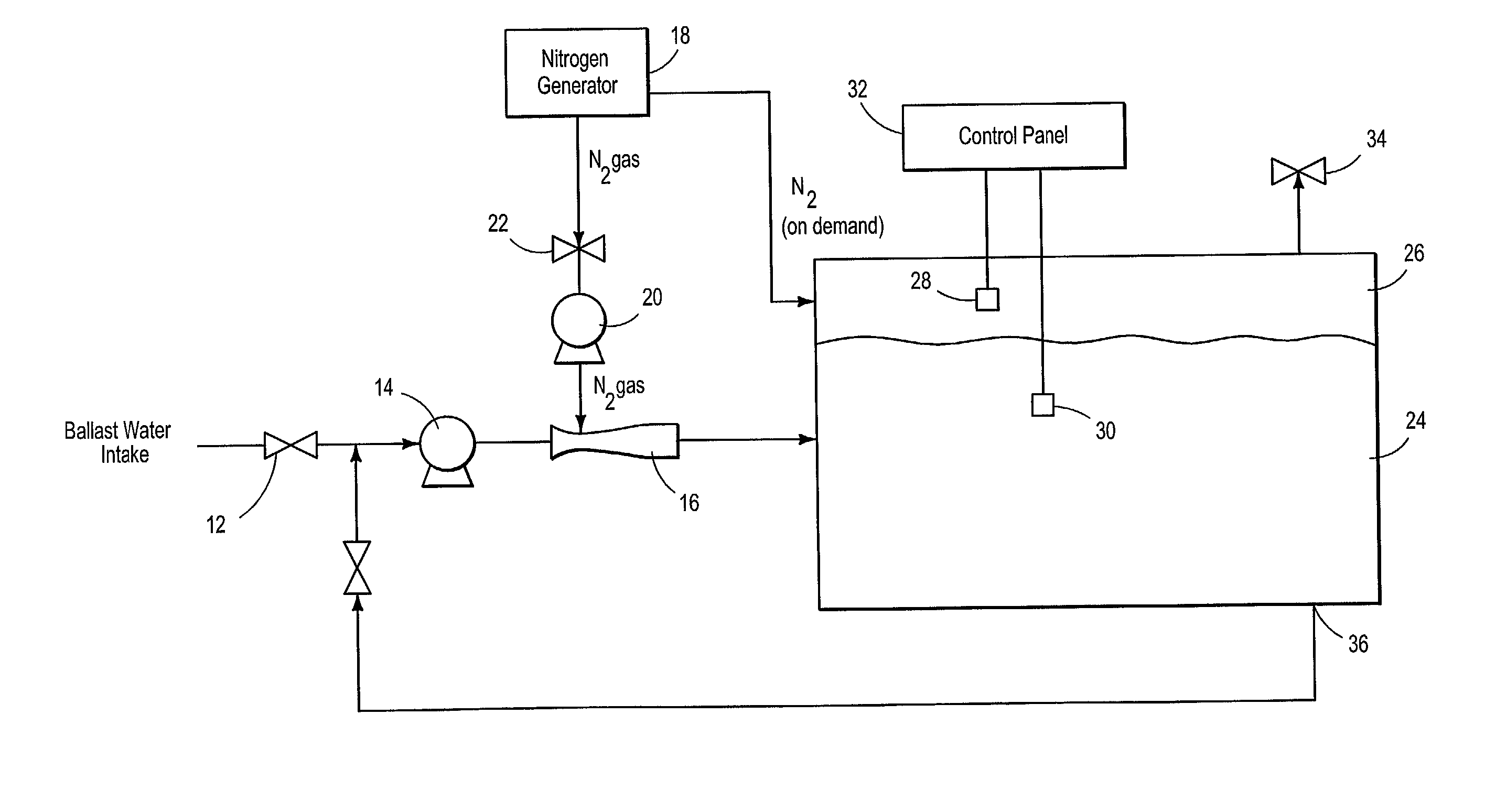

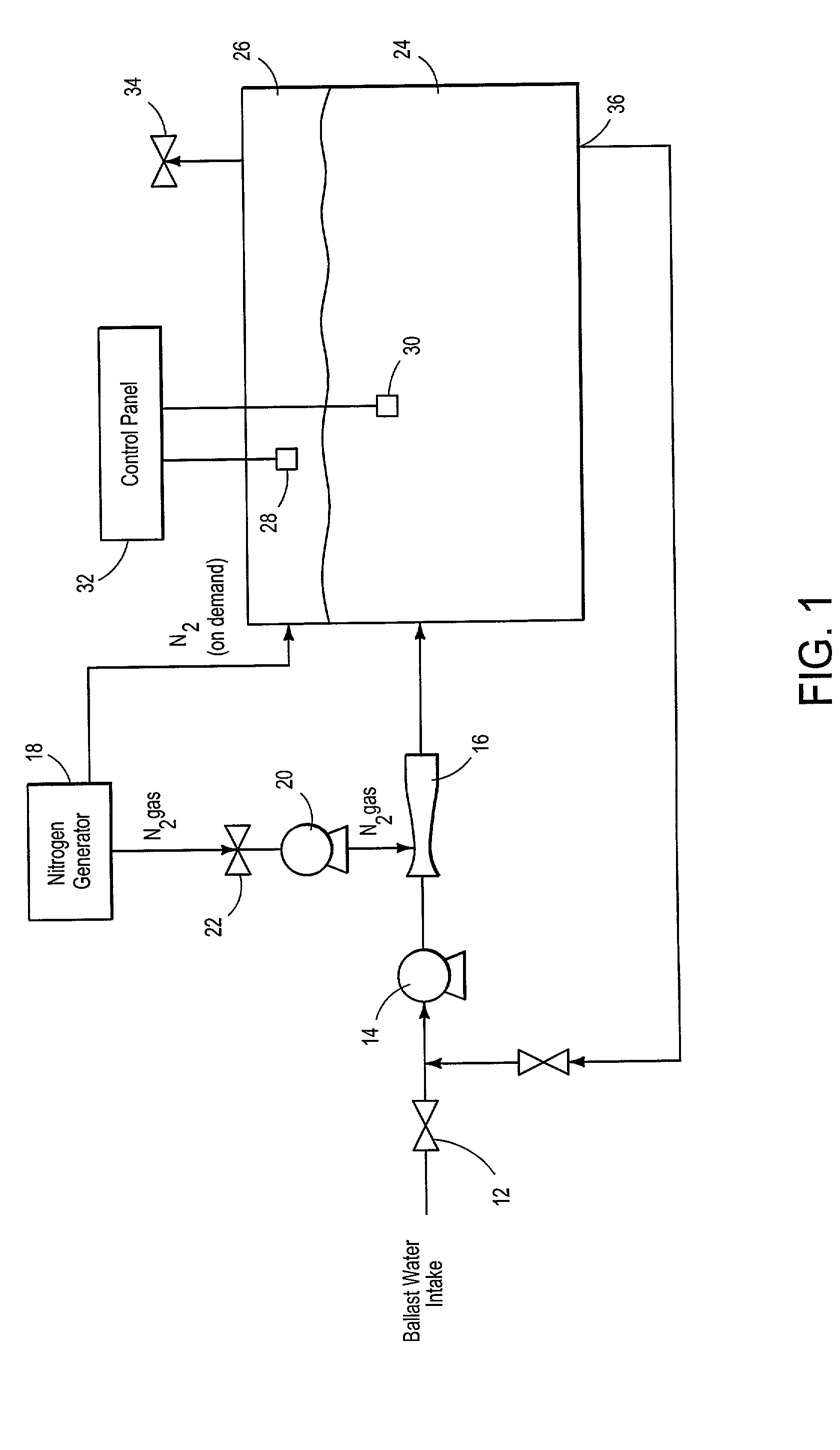

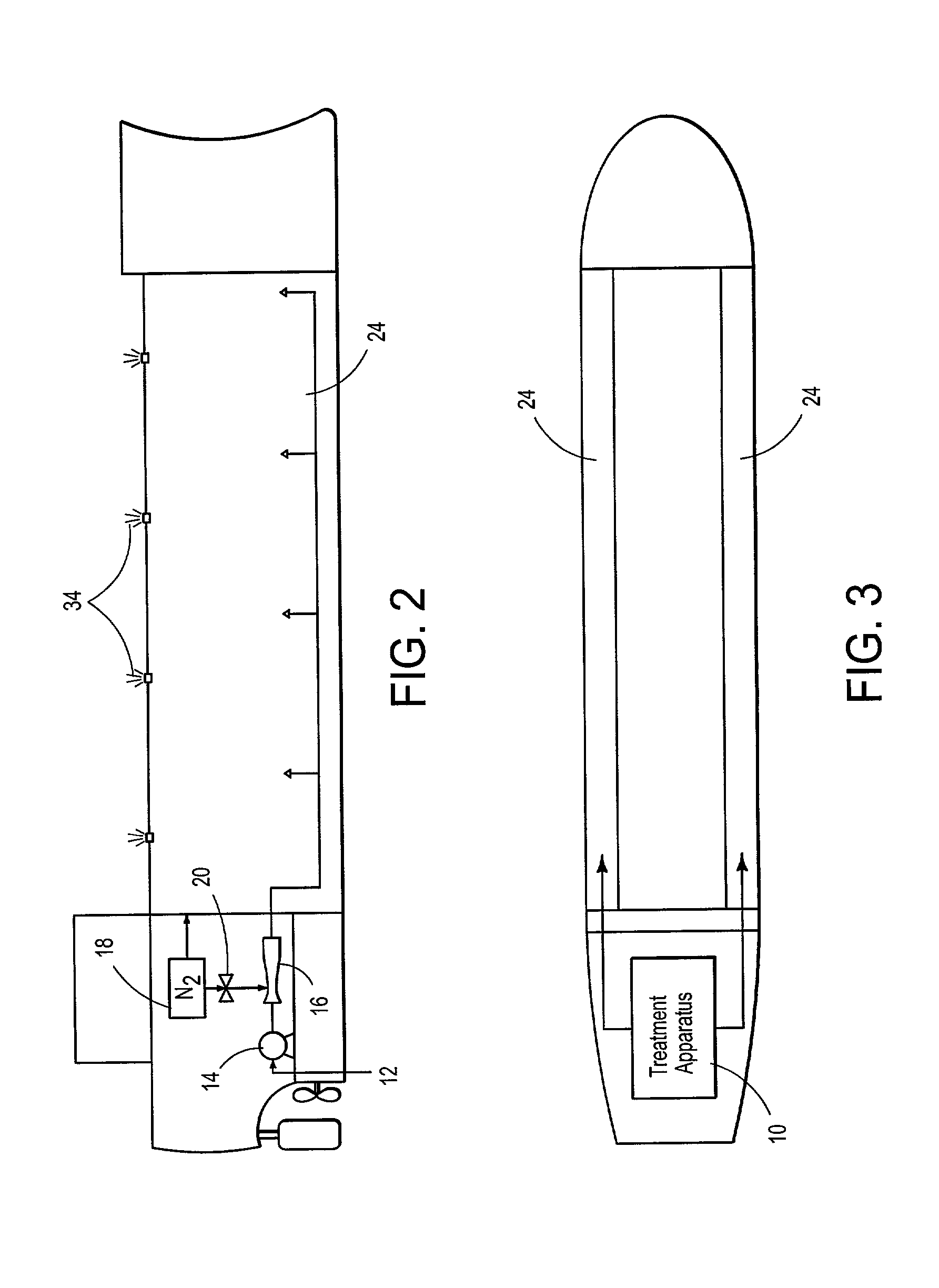

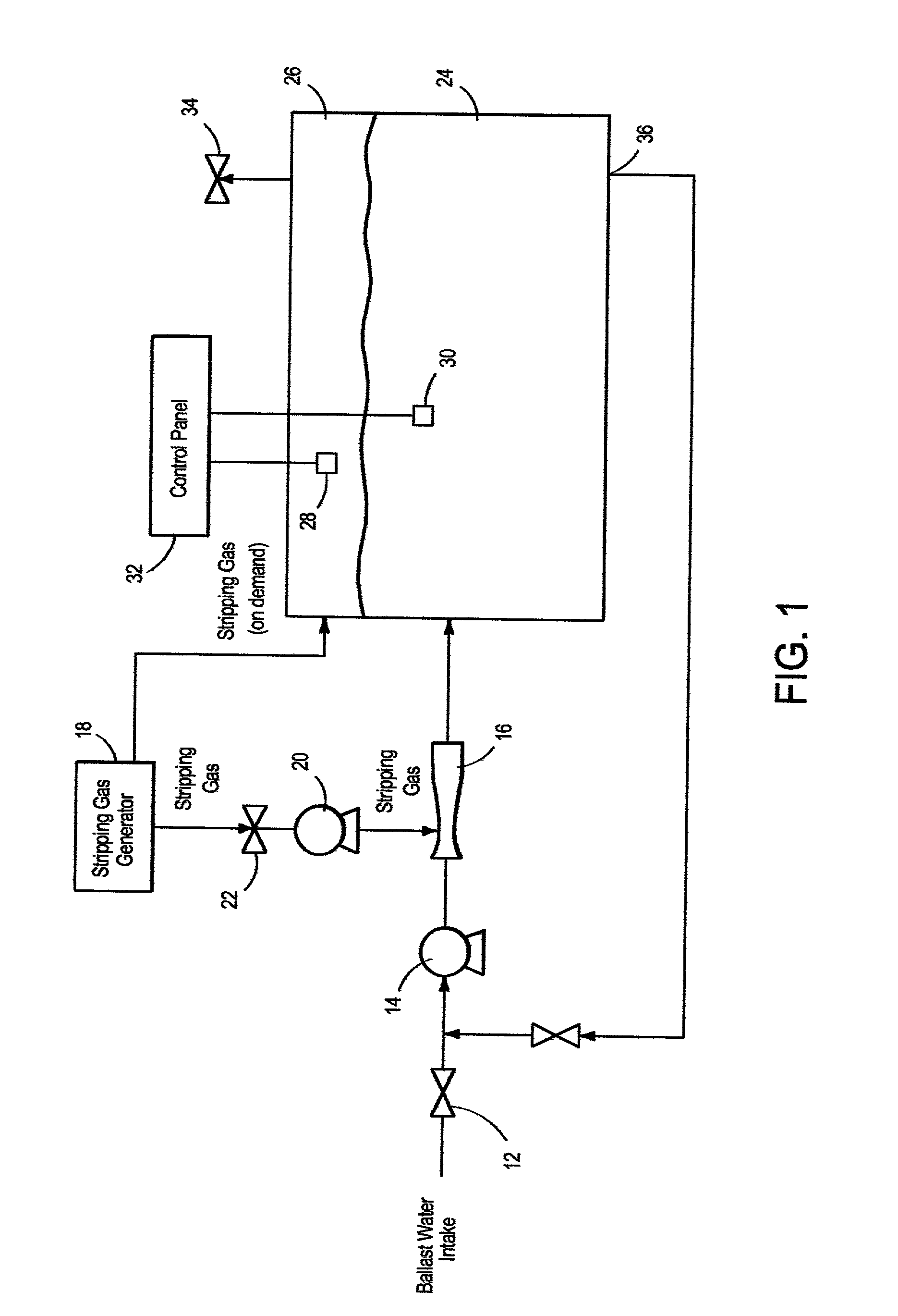

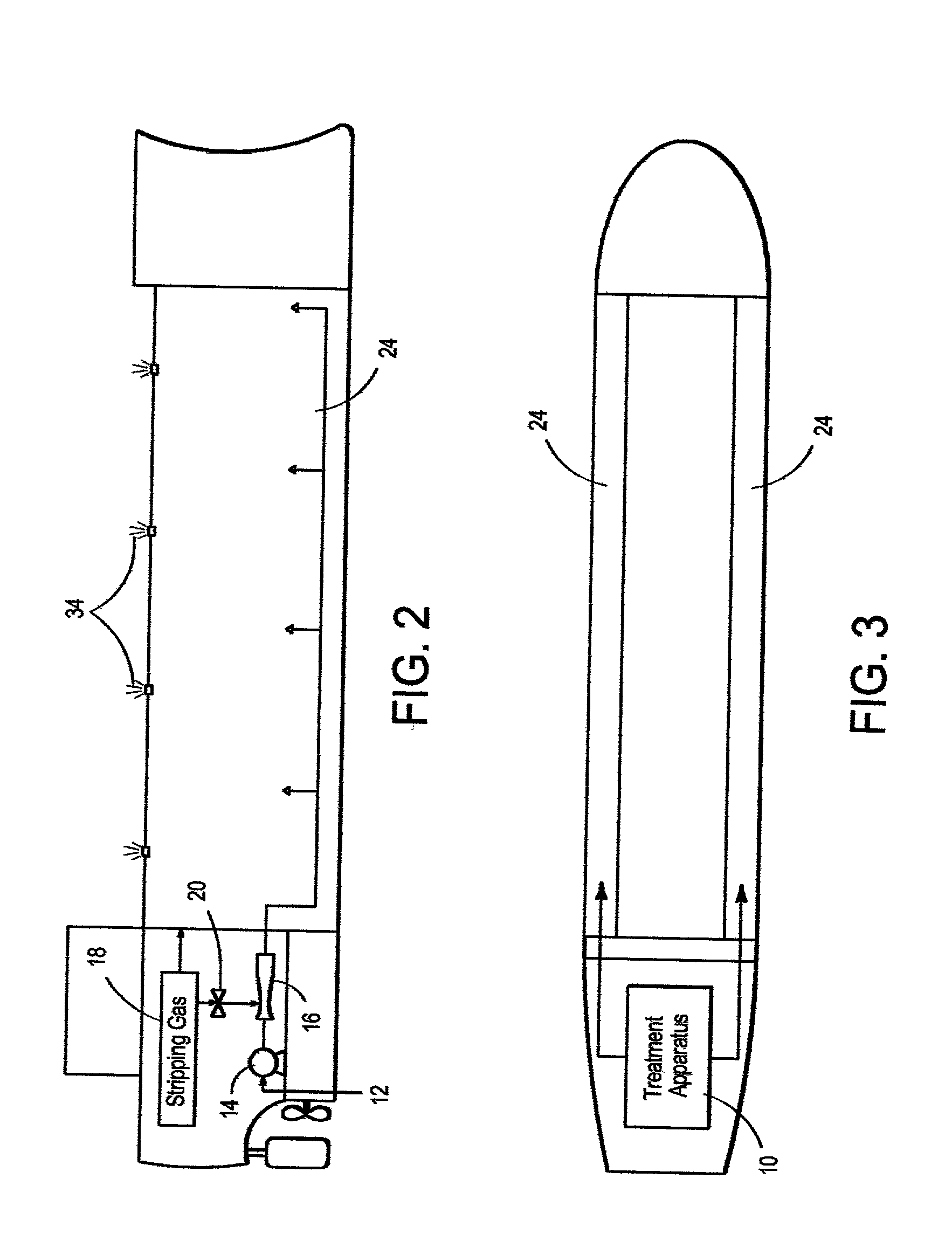

System and method of water treatment

InactiveUS20030205136A1Good deoxygenationEffective treatmentLiquid degasification with auxillary substancesSpecific water treatment objectivesWater treatment systemEngineering

The present invention generally offers a system and a method that allows a vessel to treat water while providing corrosion inhibition. A nitrogen source produces nitrogen gas that may be pumped directly to, preferably but optionally, a venturi injector, or may first be pumped into an empty tank and then delivered to the injector means. Water being pumped through the injector via a transfer piping means comes into contact with the nitrogen, and dissolved oxygen in the water transfers to micro-fine nitrogen bubbles generated by the injector. The water and the micro-fine bubbles are pumped from the injector and into the tank, where the micro-fine bubbles float to the surface, and the oxygen is released into the tank's headspace. The deoxygenated water may be re-circulated through the system for additional deoxygenation or released from the tank into the surrounding waterways.

Owner:MCNULTY PETER DRUMMOND

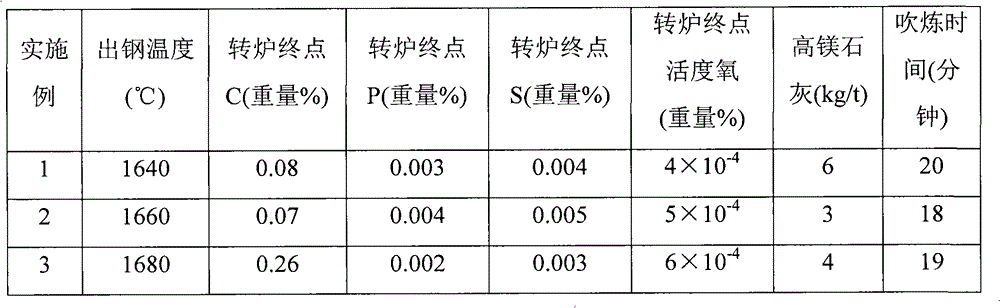

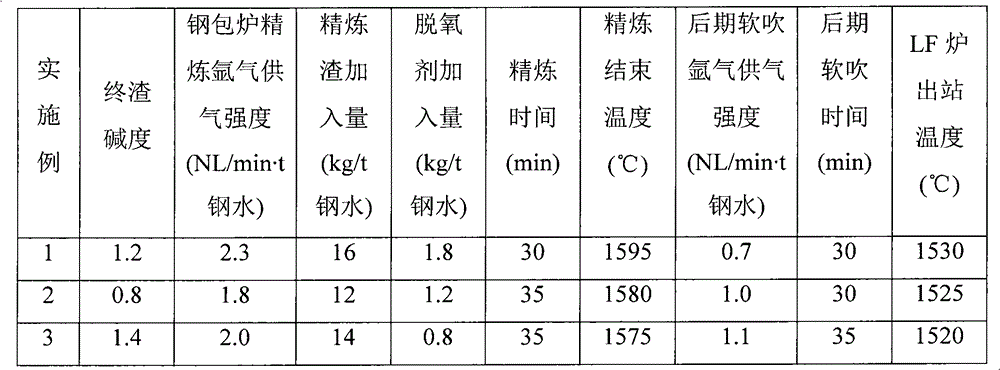

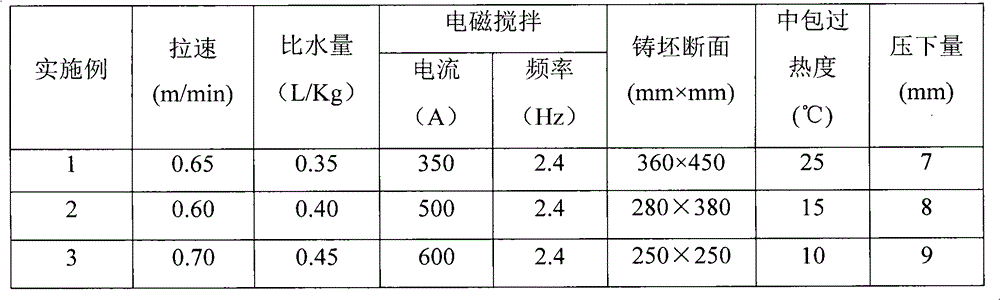

Method for smelting tire cord steel and method for continuously casting tire cord steel

ActiveCN103060513ARealize clean productionInclusion deformable strongManufacturing convertersIngotOxygen content

The invention discloses a method for smelting tire cord steel and a method for continuously casting tire cord steel; the methods comprise the following steps of: (1), carrying out primary smelting on molten iron or semi-steel by converter top-bottom blowing, and tapping into a steel ladle without deoxidization; (2), carrying out recarburization and pre-alloying on the molten steel in the tapping process, so on the basis of the total weight of the molten steel, the activity oxygen content in the molten steel is 0.004-0.008wt%, the C content is 0.64-0.68wt% and the Al content is less than 0.4wt%; (3), blowing argon to the molten steel in the steel ladle after tapping, and carrying out vacuum refining and alloy fine adjustment; and (4), carrying out ladle furnace refining on the molten steel which is subjected to the vacuum refining by using the manner of bottom blowing argon, adding refining slags batch by batch and adding deoxidizing agents batch by batch, so the total content of FeO and MnO in the steel ladle top slag is less than or equal to 10wt%. In the methods, the tire cord steel is produced by using the technological process consisting of converter primary smelting, vacuum refining and steel ladle furnace refining and cogged ingot continuous casting pouring, and thus the clean production of tire cord steels is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

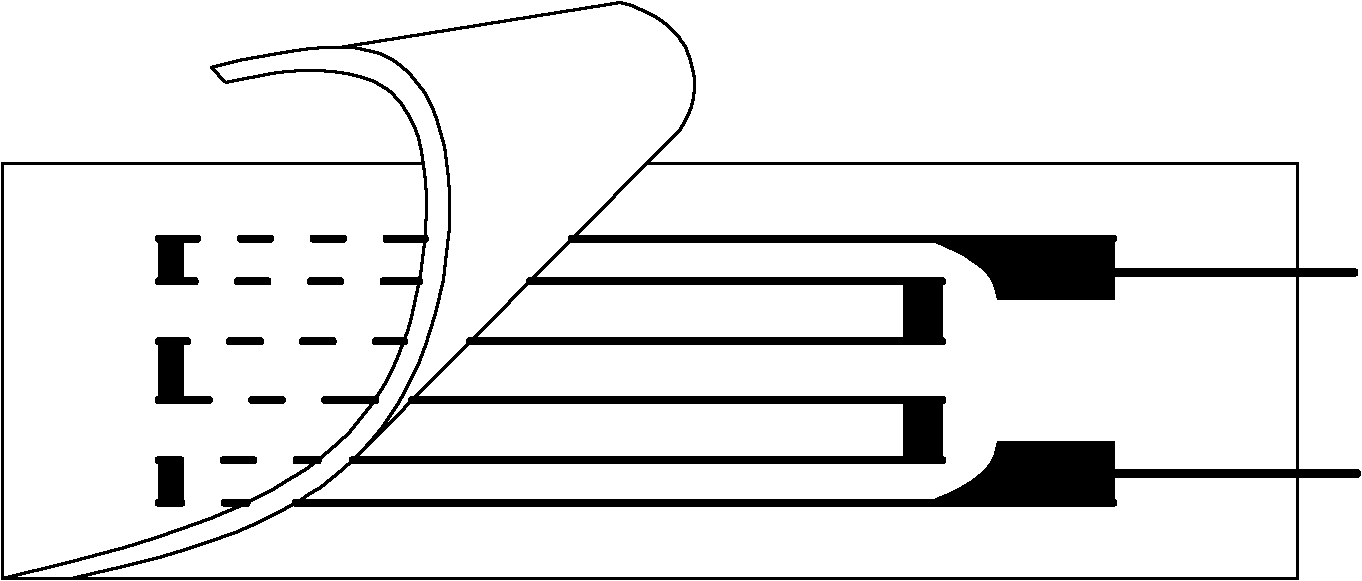

System and method of water treatment

InactiveUS20030205135A1Good deoxygenationEfficient deliveryLiquid degasification with auxillary substancesSpecific water treatment objectivesWater treatment systemProduct gas

The present invention generally offers a system and a method that allows a vessel to treat water while providing corrosion inhibition. An oxygen stripping gas source produces oxygen stripping gas that may be pumped directly to, preferably but optional a venturi injector, or may first be pumped into an empty tank and then delivered to the injector means. Water being pumped through the injector via a transfer piping means comes into contact with the oxygen stripping gas, and dissolved oxygen in the water transfers to micro-fine stripping gas bubbles generated by the injector. The water and the micro-fine bubbles are pumped from the injector and into the tank, where the micro-fine bubbles float to the surface, and the oxygen is released into the tank's headspace. The deoxygenated water may be re-circulated through the system for additional deoxygenation or released from the tank into the surrounding waterways.

Owner:HRL LAB +1

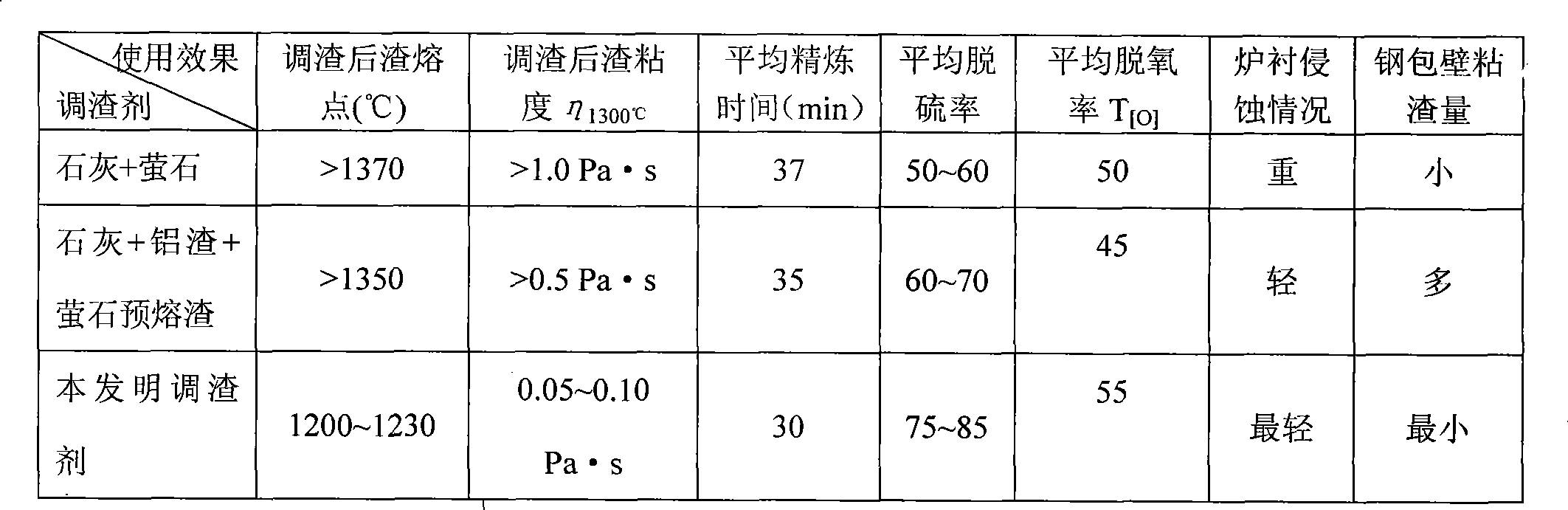

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Smelting process of steel for high-titanium alloy welding wire

ActiveCN102586685AGood deoxygenationImprove purityElectric furnaceProcess efficiency improvementFerrosiliconTitanium alloy

The invention relates to a production process of steel, in particular to a smelting process of steel for a high-titanium alloy welding wire. The smelting process comprises the following steps of: in an electric furnace smelting step, adding molten iron and waste steel and tapping molten steel, wherein the molten iron accounts for 50-60% the total amount of the furnace charge, and the tapping temperature is not lower than 1630 DEG C; in a refining furnace refining step, adding silicon-aluminum-calcium deoxidant in a refining furnace for manufacturing white slag through diffusion deoxidization, and adding low-carbon ferromanganese and ferrosilicon according to steel grade component requirements and sampling component analysis to regulate components of the molten steel so as to reach temperature of 1630-1650 DEG C matching vacuum treatment; in a vacuum furnace degassing step, keeping the temperature for 10-15min under a low vacuum degree of 1 millibar, and carrying out secondary refining after vacuum breakage; and in a secondary refining step, adding low-aluminum ferrotitanium to regulate titanium content at the refining temperature of 1585-1600 DEG C, stirring for 1-2min, adding iron sulfide, stirring for 1-2min, taking a lollipop sample to analyze, continuously keeping static stirring, carrying out soft argon blowing for 15-40min after all components are qualified and carrying out continuous casting when the temperature is up to 1565-1585 DEG C. The smelting process disclosed by the invention can effectively control purification degree of the molten steel, ensures stability of titanium in the molten steel and improves the surface quality of a cast blank.

Owner:NANJING IRON & STEEL CO LTD

Steel for linear guide rail and hot-rolling production method for steel

ActiveCN109182901ALow content of harmful elementsPrevention of large-scale generation of inclusionsProcess efficiency improvementNon-metallic inclusionsWear resistance

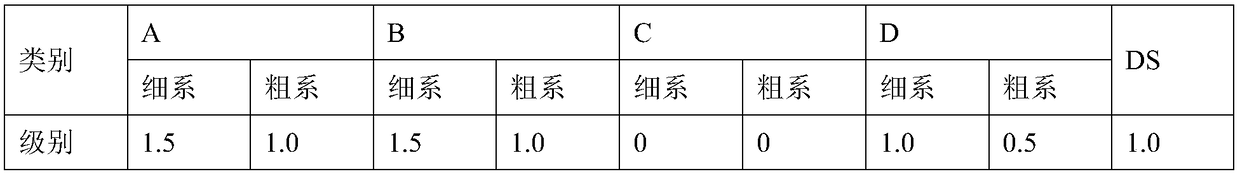

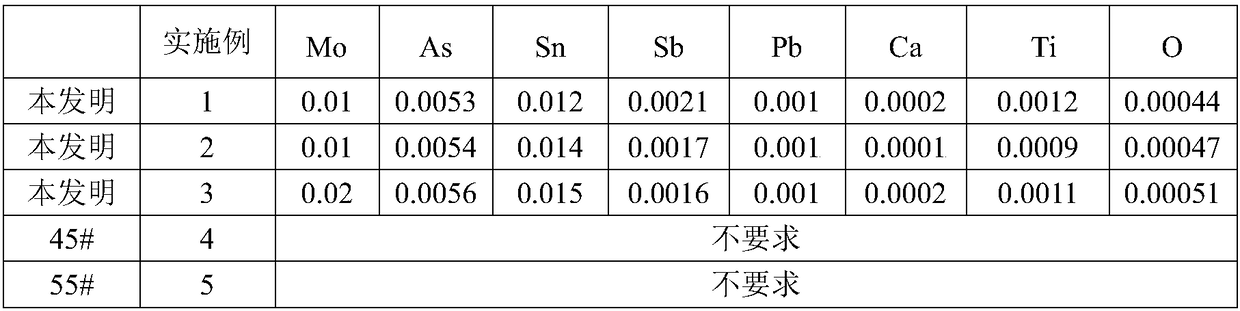

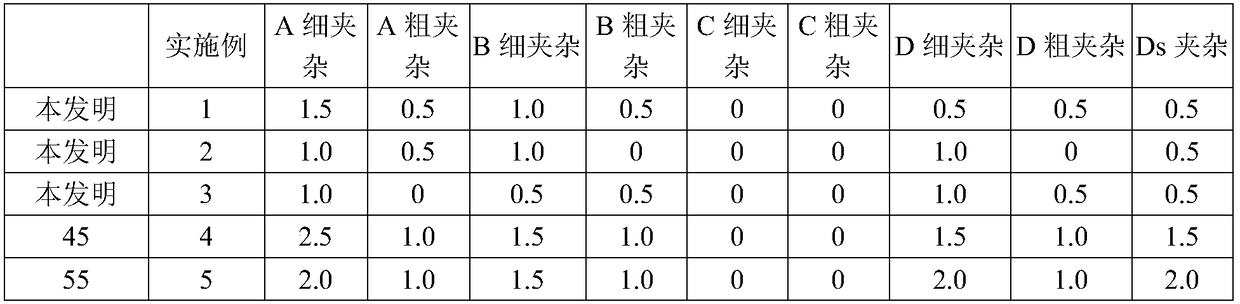

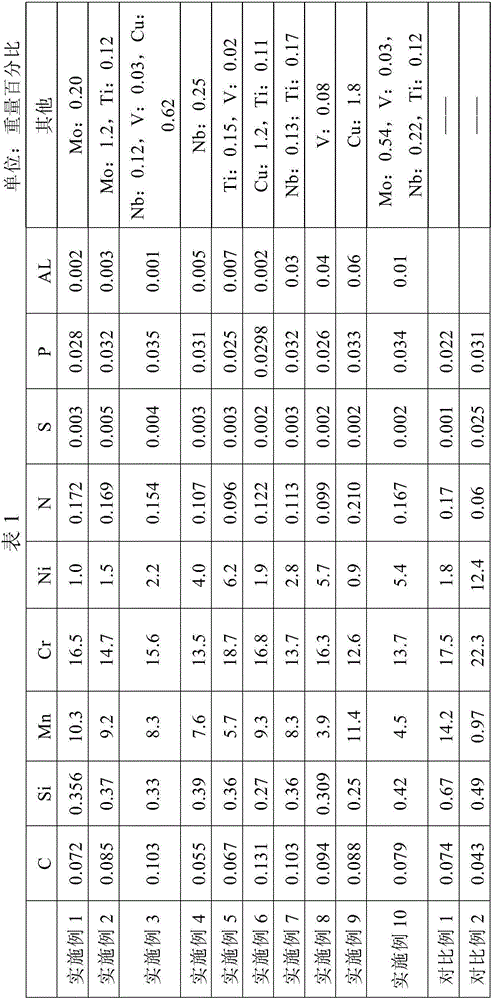

The invention relates to steel for a linear guide rail. The steel is prepared from the following chemical components in percentage by weight: 0.40-0.70% of C, 0.15-0.40% of Si, 1.30-1.80% of Mn, 0.30-0.60% of Cr, 0.005-0.030% of S, less than or equal to 0.025% of P, less than or equal to 0.25% of Ni, less than or equal to 0.30% of Cu, less than or equal to 0.10% of Mo, less than or equal to 0.05%of Al, less than or equal to 0.0010% of Ca, less than or equal to 0.003% of Ti, less than or equal to 0.0010% of O, less than or equal to 0.04% of As, less than or equal to 0.03% of Sn, less than or equal to 0.005% of Sb, less than or equal to 0.002% of Pb, and the balance of Fe and inevitable impurities. After being subjected to quenching and tempering, the steel has yield strength higher than orequal to 785 MPa, tensile strength higher than or equal to 930 MPa, ductility higher than or equal to 12%, and Charpy impact work AKU higher than or equal to 50 J at the normal temperature. Non-metalimpurities meet the following relationship: A-series fine system less than or equal to 1.5, A-series rough system less than or equal to 1.0, B-series fine system less than or equal to 1.5, B-series rough system less than or equal to 1.0, C-series fine system equal to 0, C-series rough system equal to 0, D-series fine system less than or equal to 1.0, D-series rough system less than or equal to 0.5, Ds-series less than or equal to 1.0. Main process comprises electric furnace or converter-external refining-VD or RH vacuum degassing-continuous casting-continuous rolling-stack cooling. By optimizing chemical components of a steel plate, hardenability, strength and wear resistance of the steel are remarkably improved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

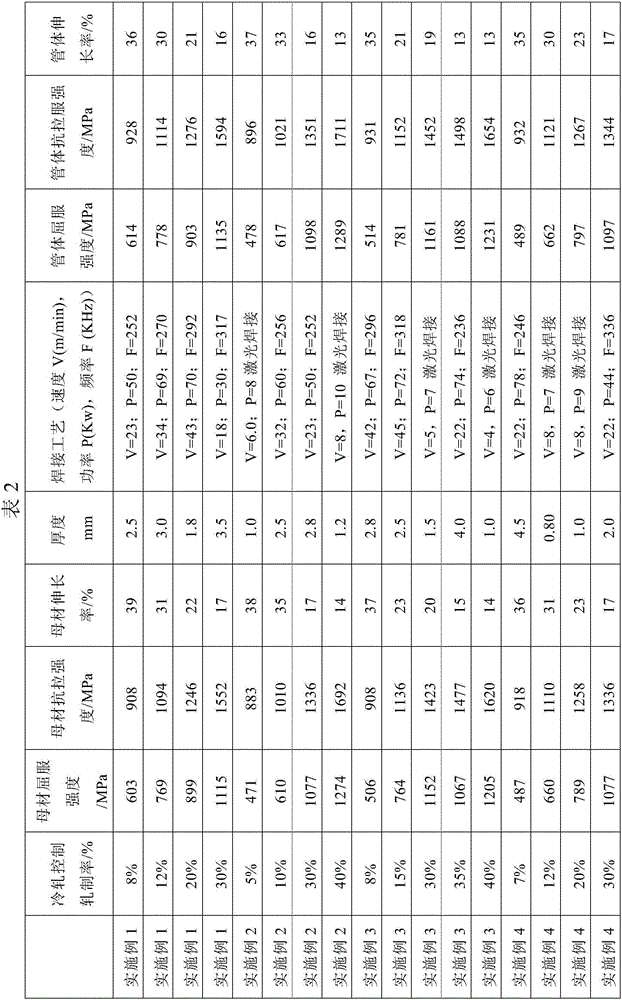

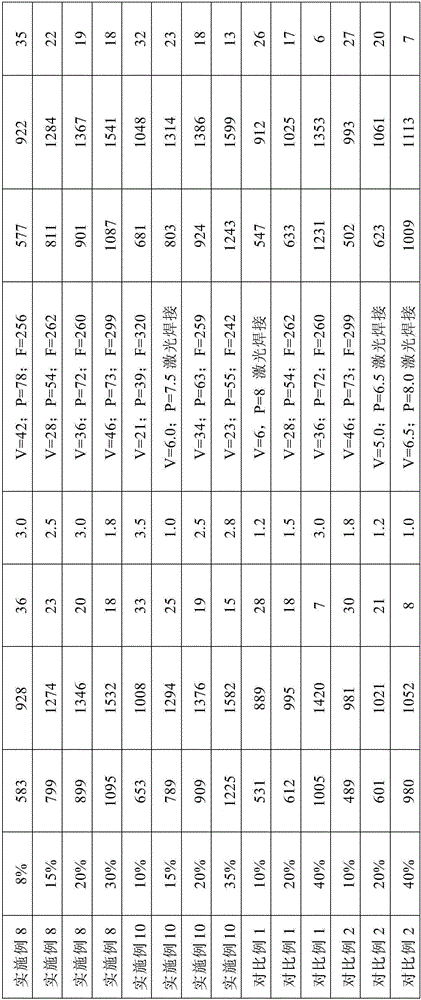

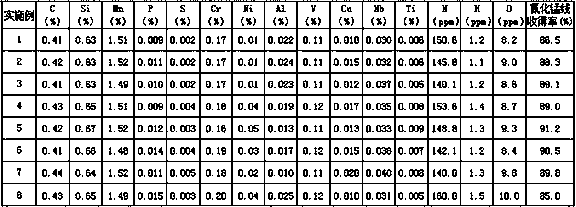

Low-cost and high-strength stainless steel and manufacturing method of welding pipe thereof

Provided are low-cost and high-strength stainless steel and a manufacturing method of a welding pipe of the low-cost and high-strength stainless steel. The high-strength stainless steel is prepared from, by weight percent, 0.02%-0.15% of C, not larger than 0.6% of Si, 2%-15% of Mn, 12%-20% of Cr, 0.5%-7.0% of Ni, not larger than 0.04% of P, not larger than 0.03% of S, 0.02%-0.20% of N, 0.5%-2.0% of Cu, 0.001%-0.08% of AL, 0.001%-0.10% of V and the balance Fe and inevitable impurities, and the total quantity of the impurities does not exceed 0.05%. Meanwhile, the formula 12.5<=100*(0.5*Mn+Ni+30*N)<=22 needs to be met. The tensile strength of the high-strength stainless steel ranges from 700 MPa to 1,800 MPa, the yield strength of the high-strength stainless steel ranges from 400 MPa to 1,200 MPa, and the ductility of the high-strength stainless steel ranges from 50% to 12%. The requirements for car weight reduction, high safety performance, good corrosion resistance and the like are met, and a part and other products manufactured through the welding pipe have delaying and cracking resisting capacity.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

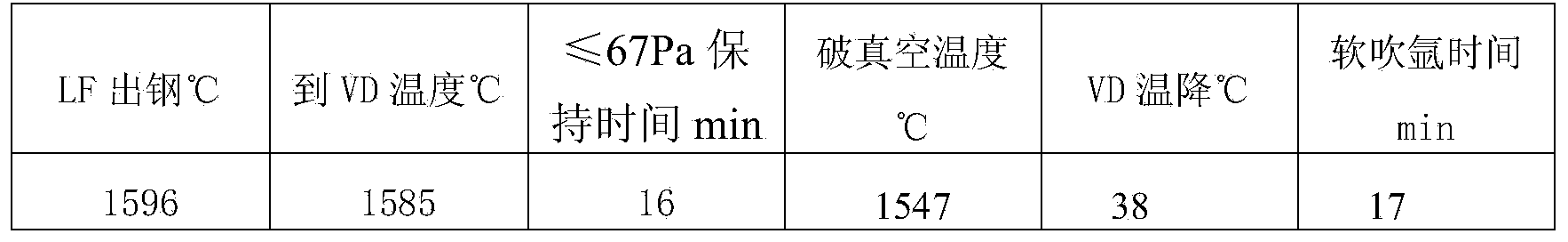

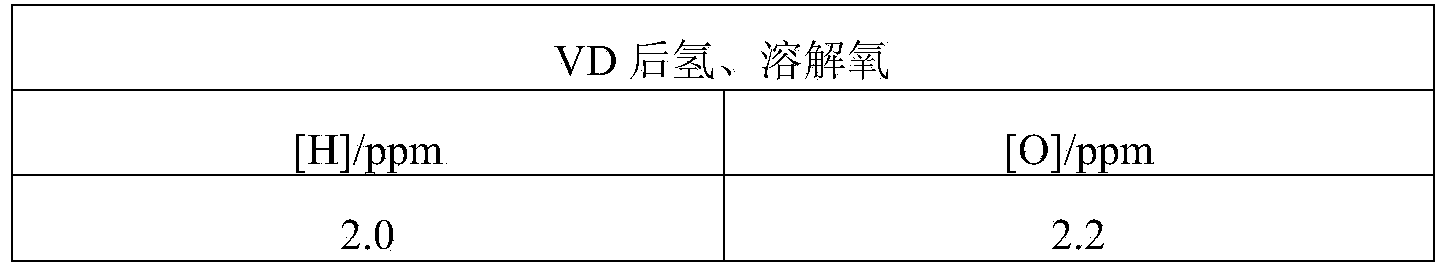

Smelting method of non-quenched and tempered steel

ActiveCN110055450AImprove purityReduced activityManufacturing convertersProcess efficiency improvementSmelting processCalcium cyanamide

The invention discloses a smelting method of non-quenched and tempered steel. The smelting method comprises the working procedures of converter smelting, LF refining, VD vacuum treatment and continuous casting, and comprises the specific technological steps that (1) nitrogen is blown at the bottom in the whole converter smelting process, and converter high-carbon drawing and tapping is carried out; (2) diffusion deoxidation is carried out in the LF refining process, good deoxidation and desulfurization effects are guaranteed, and the N content of molten steel after LF finishing is 75-90ppm; (3) VD vacuum treatment is carried out, wherein the content of N in the molten steel after hollow breaking is 50-60 ppm, after hollow breaking, soft blowing time is larger than or equal to 30 min, and argon flow is smaller than or equal to 25 L / min; and (4) continuous casting adopts crystallizer stirring and tail-end stirring, medium-high carbon tundish covering agent and medium-carbon crystallizercovering slag are used, and continuous casting billets are cooled slowly in an off-line mode. According to the smelting method of the non-quenched and tempered steel, the nitrogen content yield is stable, the performance of the non-quenched and tempered steel is good, calcium cyanamide (CaCN2) is not adopted, environmental pollution is small, the feeding amount of the manganese nitride wire is small, and the production cost is low.

Owner:石钢京诚装备技术有限公司

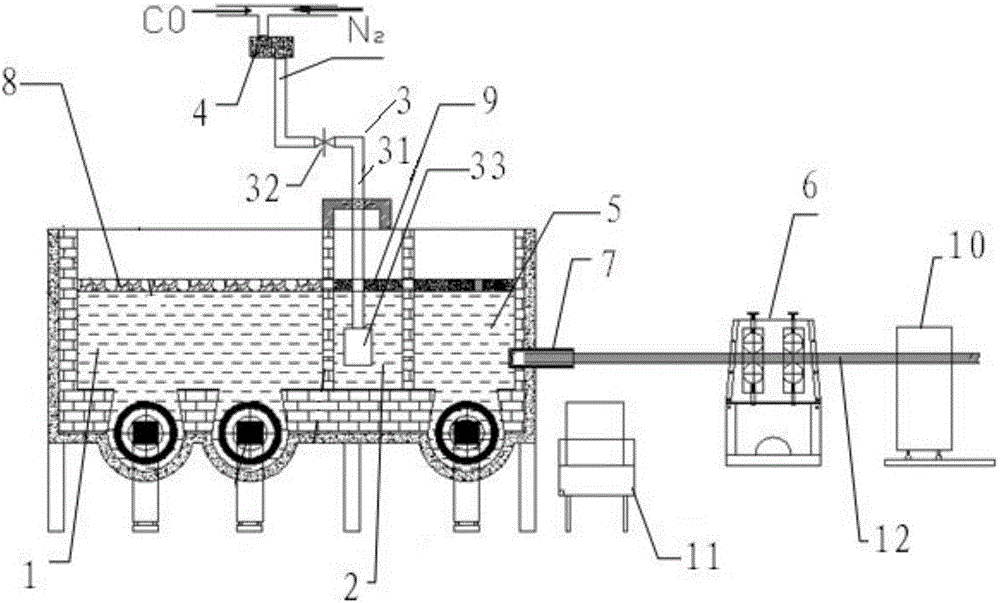

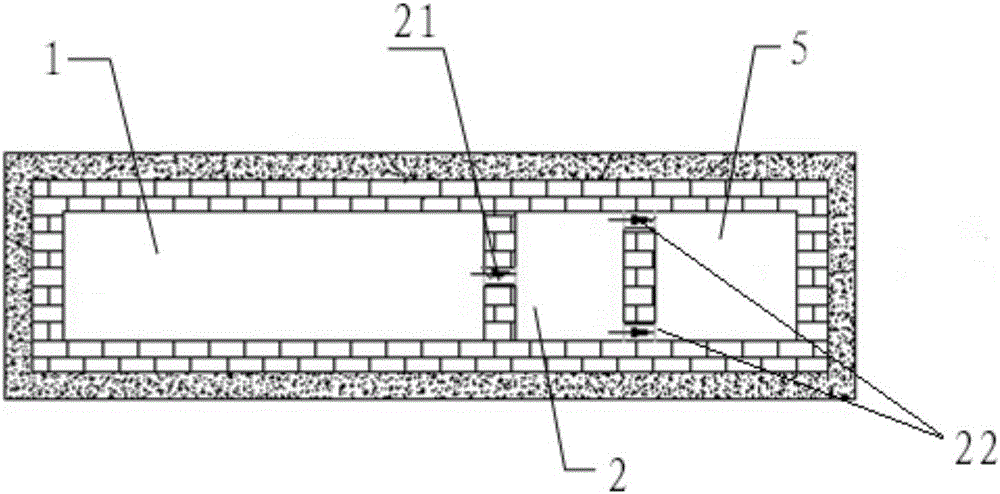

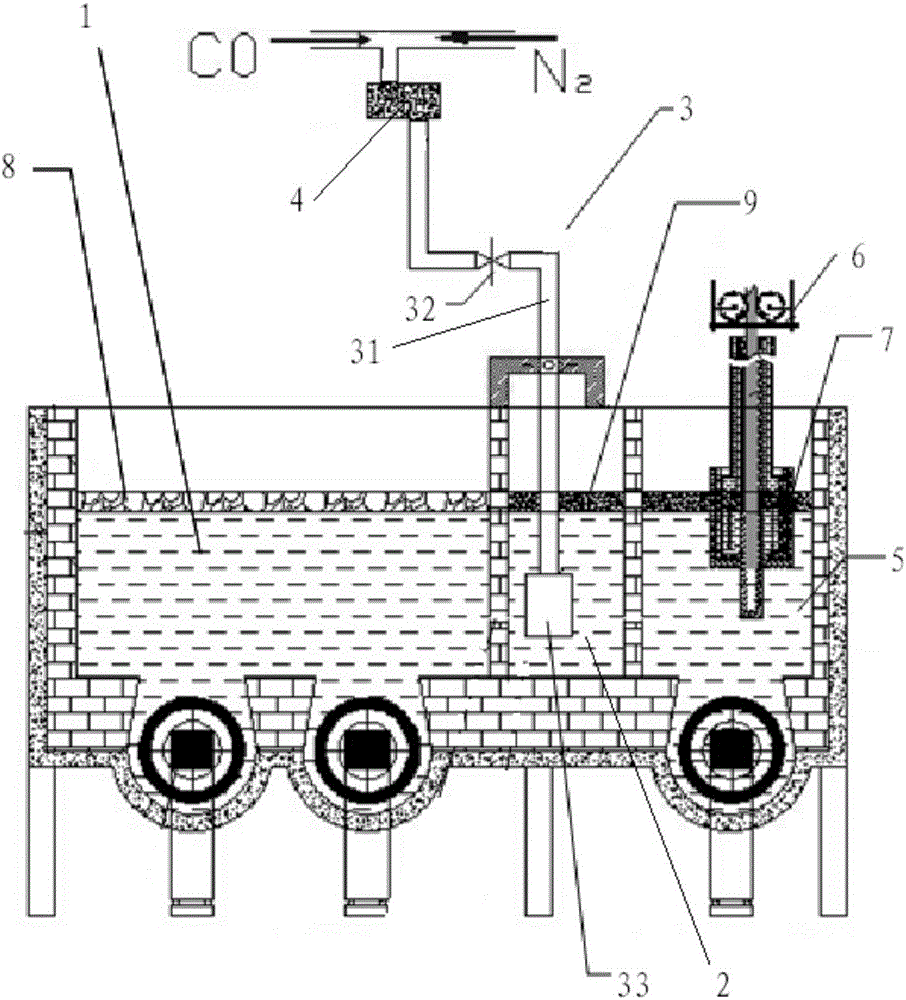

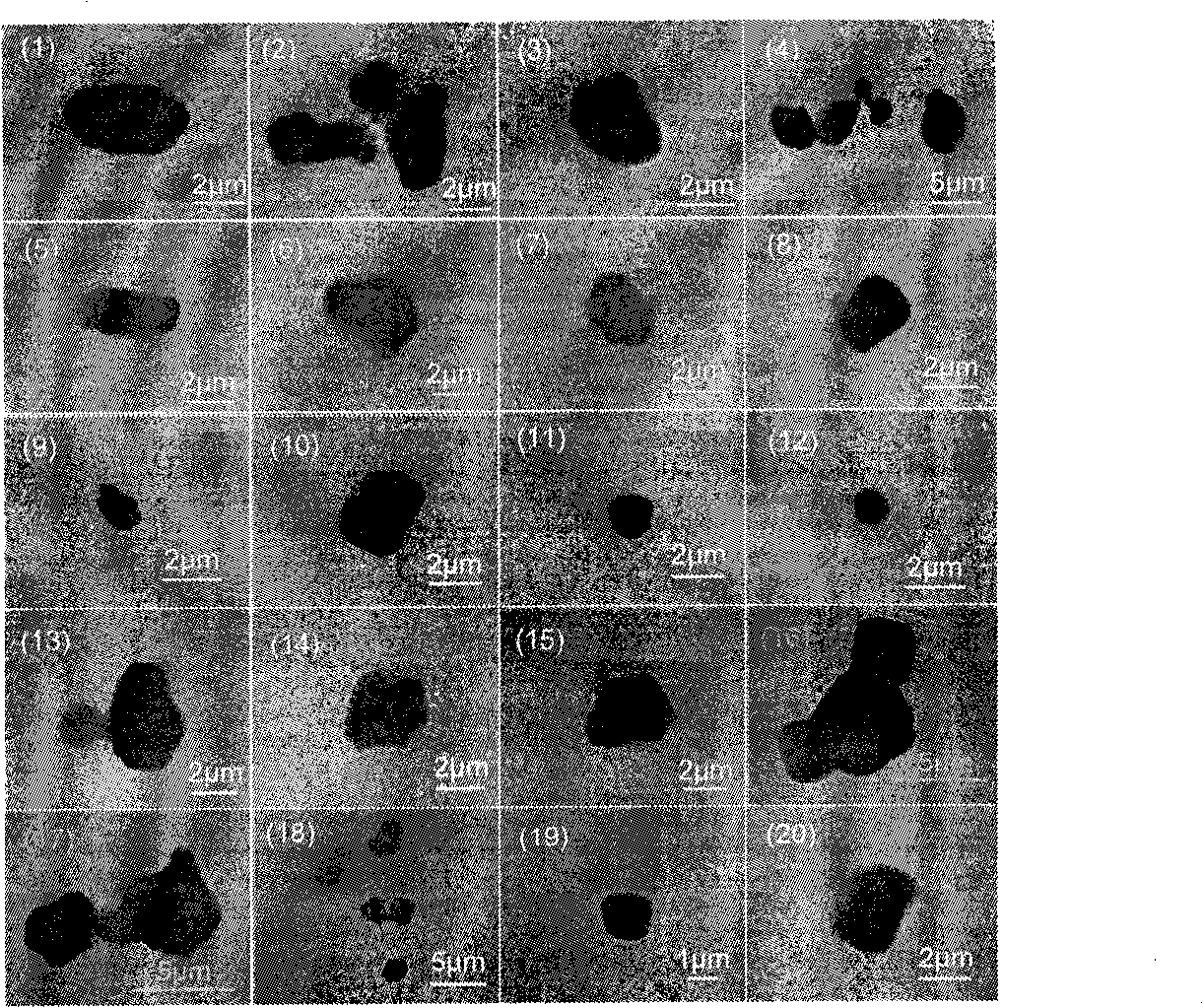

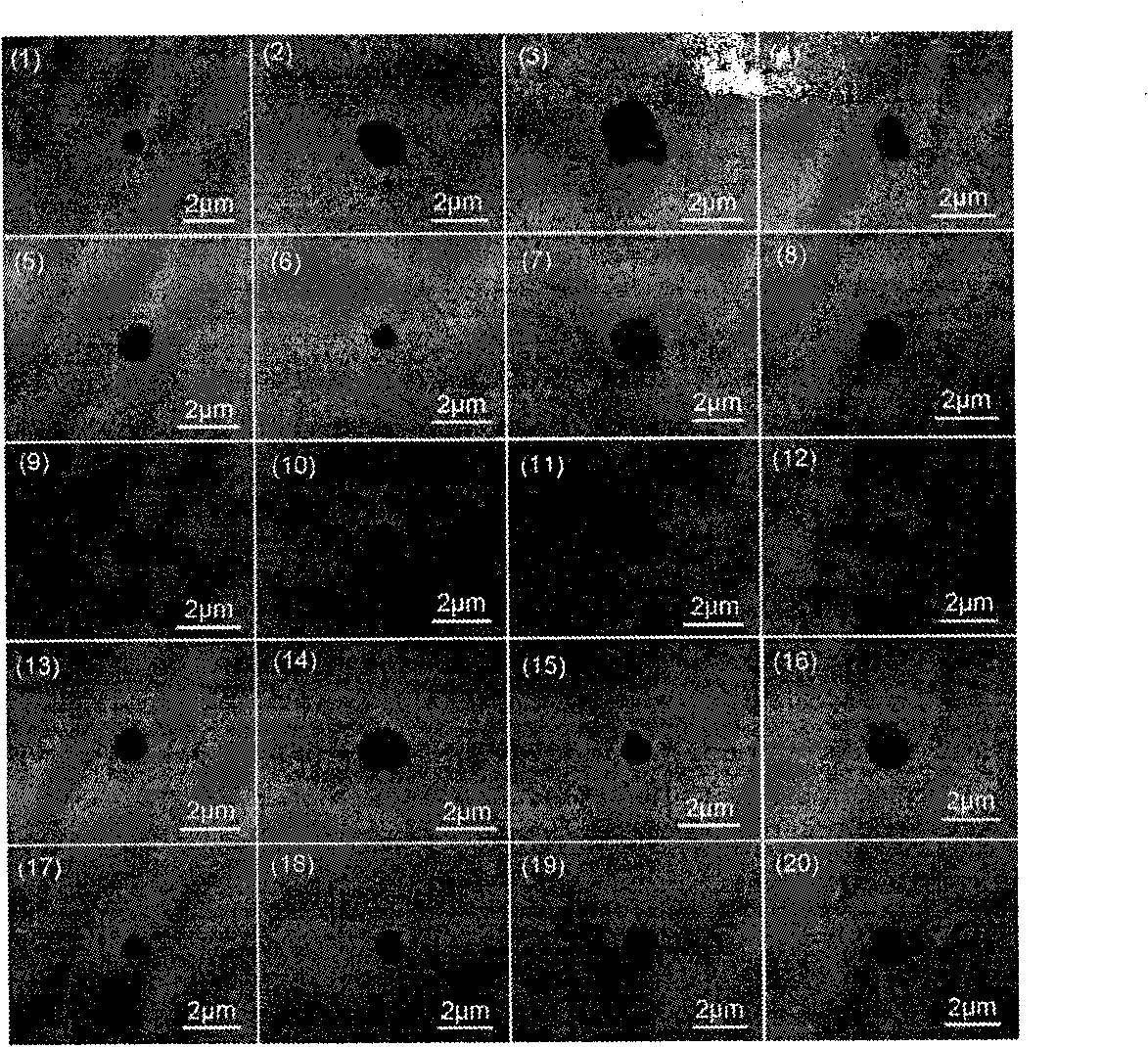

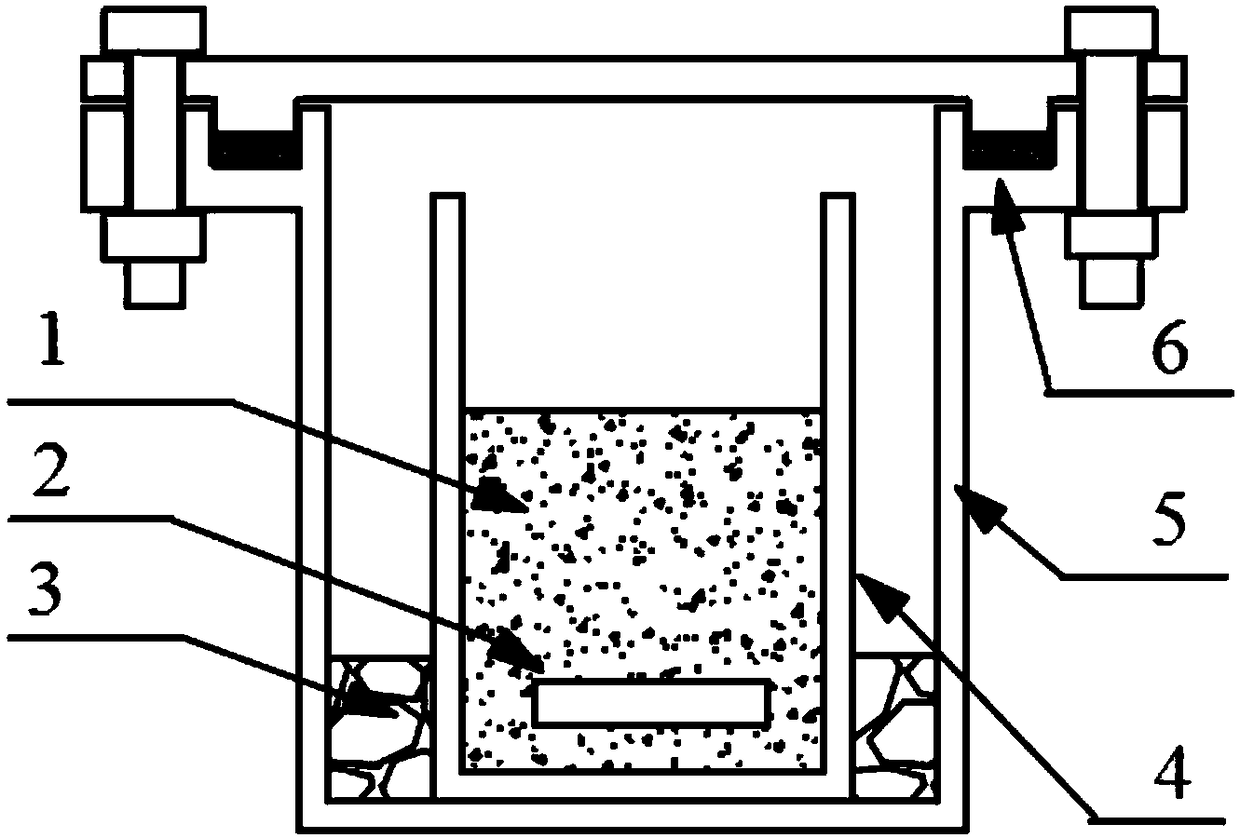

Production device and method of high-purity oxygen-free copper ingot billet

The invention provides a production device of a high-purity oxygen-free copper ingot billet. The device comprises a melting furnace, a partition bin and a heat preservation furnace which are sequentially communicated, the partition bin is further provided with a deoxygenator, the deoxygenator comprises a gas conveying pipe used for conveying deoxygenation gas and an air exhaust cover which is located in the partition bin and connected with the outlet end of the gas conveying pipe, and a plurality of air exhaust holes with the diameter of 0.5 mm to 1 mm are formed in the air exhaust cover; the melting furnace and the partition bin are connected through a liquid inlet hole, the air exhaust cover right faces the liquid inlet hole, and the distance between the air exhaust cover and the liquid inlet hole ranges from 10 mm to 40 mm; in the flowing direction of molten copper, the projection of the air exhaust cover is larger than the projection of the liquid inlet hole; the invention further provides a method capable of adopting the device for producing the oxygen-free copper ingot billet. By the adoption of the method, the oxygen-free copper ingot billet which is good in production compactness and low in oxygen content can be produced.

Owner:JIANGXI GUANGXIN COPPER IND

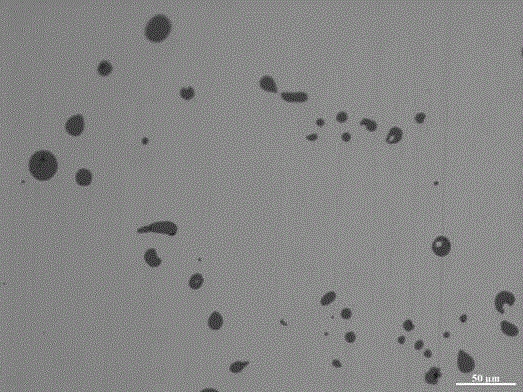

Method for controlling non-metallic inclusion in pipeline steel

ActiveCN101492758AGood deoxygenationImprove desulfurization effectProcess efficiency improvementAlkalinitySlag

A method for controlling non-metal inclusions in pipe line steel belongs to the refining controlling field of steel making. The method comprises a step of controlling the following chemical components of non-metal inclusions of oxides in pipe line steel casts: 20wt%-35wt% of CaO, 10wt%-20wt% of MgO, 30wt%-60wt% of Al2O3 and not more than 5wt% of others. Sulfide inclusions in the pipe line steel casts comprise 90wt%-100wt% of CaS and not more than 10wt% of others, and no MnS inclusion exists in the pipe line steel casts. In the LF refining process, reaction between molten steel and high-alkalinity furnace slag is used to control contents of Ca, Mg and S in the molten steel, and Ca dosage in the calcium treatment process, so as to control melting point of the non-metal inclusions in the molten steel to be between 1500 DEG C and 1650 DEG C. The method has the advantage that deformation index of the non-metal inclusions in post rolling process is controlled to be not more than 0.5 while good oxidizing and desulfurizing effects of the molten steel are achieved, thus avoiding cracks caused in use process of the pipe line steel by linear or stripe-shaped non-metal inclusions after being rolled.

Owner:SHOUGANG CORPORATION

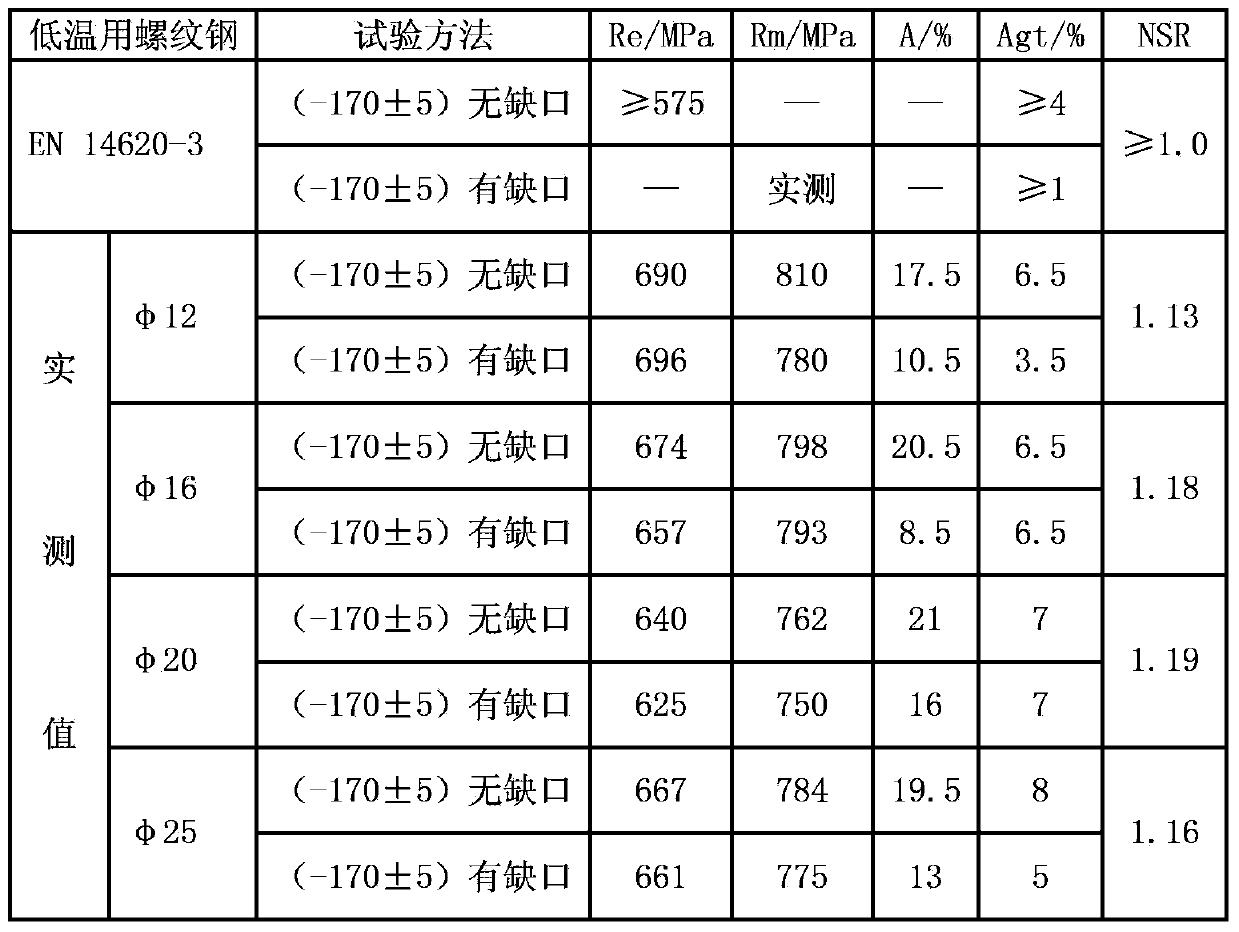

Deformed steel bar used at low temperature and production process thereof

ActiveCN103422033AGood deoxygenationImprove purityProcess efficiency improvementElectric furnaceChemical compositionSteel bar

The invention discloses a deformed steel bar used at a low temperature and production process thereof. Particularly, the deformed steel bar can be used at a low temperature, and comprises the following chemical components by weight percentage: 0.05-0.10 percent of C, 0.20-0.35 percent of Si, 1.45-1.60 percent of Mn, no more than 0.015 percent of S, no more than 0.008 percent of P, no more than 0.20 percent of Cr, 0.90-1.50 percent of Ni, no more than 0.20 percent of Cu, no more than 0.10 percent of Mo, no more than 0.0120 percent of N, 0.030-0.045 percent of Al, and Fe and unavoidable impurities in balancing amount. The production process of the deformed steel bar comprises the procedures of electric furnace smelting, refining furnace refining, vacuum furnace deaeration, and continuous casting and pouring. According to the invention, the components are reasonably designed, the production process and the operation process are easy to control; molten steel deoxygenation is good, the purity is good, the continuous casting and pouring is smooth, and the quality of surface of casting billet is better; the finished deformed steel bar has good quality and can satisfy low-temperature (no more than minus 1650 DEG C) use demand.

Owner:NANJING IRON & STEEL CO LTD

Wear-resistant flux-cored wire for stainless steel

InactiveCN106514047AHigh strengthHigh hardnessWelding/cutting media/materialsSoldering mediaWear resistantRare earth

The invention discloses a wear-resistant flux-cored wire for stainless steel. The wear-resistant flux-cored wire consists of a flux core and a stainless steel sheath coating the outer side of the flux core, wherein the flux core comprises the following raw materials in parts by weight: 15-22 parts of chromium powder, 1-4 parts of titanium powder, 0.5-2 parts of nickel powder, 1-4 parts of silicon calcium alloy, 1-4 parts of magnalium, 4.5-7 parts of ferromanganese, 2-5 parts of ferromolybdenum, 2-4 parts of ferrocolumbium, 4-8 parts of rare earth ferroalloy, 4-8 parts of vanadium-nitrogen alloy, 6-9 parts of carbonate, 3-6 parts of graphite and 100-150 parts of iron powder. The wear-resistant flux-cored wire for stainless steel has favorable wear resistance, corrosion resistance, heat resistance and mechanical property; a deposited metal structure is compact, pore-free and crack-free; and the wear-resistant flux-cored wire for stainless steel can be favorably combined with a base material and is stable in performance.

Owner:天长市通联焊业有限公司

Method for preparing high-purity titanium through calcium in-situ distillation-deoxygenation

The invention discloses a method for preparing high-purity titanium through calcium in-situ distillation-deoxygenation, and belongs to the technical field of metal smelting. The method comprises the steps that a raw material system A and a calcium reducing agent are placed in a closed reaction vessel in a partitioned manner, heating is carried out in an inert atmosphere, calcium in the calcium reducing agent is dissolved to enter molten salt in the raw material system A in the form of high-purity calcium gas, deoxygenation of a titanium raw material is achieved, and the high-purity titanium with the oxygen content being smaller than or equal to 0.10% by weight is prepared; the raw material system A is a mixture of the titanium raw material and anhydrous calcium chloride, the raw material system A contains or does not contain one or two of alkali metal halide or alkaline earth metal halide, and the titanium raw material is titanium metal or titanium oxide; the calcium reducing agent ismetal calcium or a calcium alloy; and partitioned regions for partitioned containing are separated from each other and are in gas phase communication. The method is simple and easy to perform, has thegood oxygen and nitrogen removing effect, can meet the using requirements in the fields of aerospace, national defense military and the like.

Owner:有研资源环境技术研究院(北京)有限公司

Magnesium-calcium alloy cored wire for ferrous metallurgy and preparation method of magnesium-calcium alloy cored wire

The invention discloses a magnesium-calcium alloy cored wire for ferrous metallurgy and a preparation method of the magnesium-calcium alloy cored wire. The magnesium-calcium alloy cored wire is composed of a core material and a sheath. The core material is composed of magnesium, calcium and silicon and is prepared from 6%-38% of Mg, 5%-30% of Ca and the balance silicon and inevitable impurity elements during raw material preparation; and preferably, the mass ratio of Mg to Ca is controlled to be between 5:3 and 7.5:3. For gear steel, free-cutting steel and non-quenched and tempered steel, the morphology of Al2O3 inclusion and MnS inclusion and the cleanliness of molten steel can be improved through Ca, and the morphology of the inclusion and the cleanliness of the molten steel can also be improved through Mg; the functions of inclusion denaturation and molten steel purification can be achieved at the same time through magnesium-calcium composite treatment; and the effective function of Ca can be remarkably improved through Mg, and the yield of Ca can be remarkably increased through Mg. The cored wire is fed during refining, and the functions of deoxidization, inclusion modification, molten steel purification and steel performance improving can be achieved.

Owner:SHANGHAI UNIV

Wear-resisting and high-hardness flux core wire

InactiveCN107252994AHigh hardnessHigh strengthWelding/cutting media/materialsSoldering mediaSilicon alloyRare earth

The invention discloses a wear-resisting and high-hardness flux core wire. The wear-resisting and high-hardness flux core wire is composed of a flux core and a low-carbon cold-rolling steel tape sheath wrapped on the outer side of the flux core. The flux core comprises, by weight, 20-25 parts of low-carbon ferrochromium, 1.5-3 parts of titanium powder, 1-2 parts of nickel powder, 5-8 parts of calcium-silicon alloys, 2-4 parts of magnesium-aluminum alloys, 3-5 parts of electrolytic manganese, 1-2 parts of ferromolybdenum, 2.5-4 parts of ferroniobium, 1-2 parts of ferrovanadium, 3-5 parts of rare earth iron alloys, 3-5 parts of carbonate, 3-4 parts of graphite, 120-150 parts of iron powder, 0.5-1.5 parts of tungsten powder and 2-4 parts of calcium fluoride. The wear-resisting and high-hardness flux core wire has good welding performance, deposited metal tissue is compact, air holes and cracks are avoided, combination with base metal is good, performance is stable, and deposited metal has good wear resistance, corrosion resistance, high hardness and other performance.

Owner:天长市通联焊业有限公司

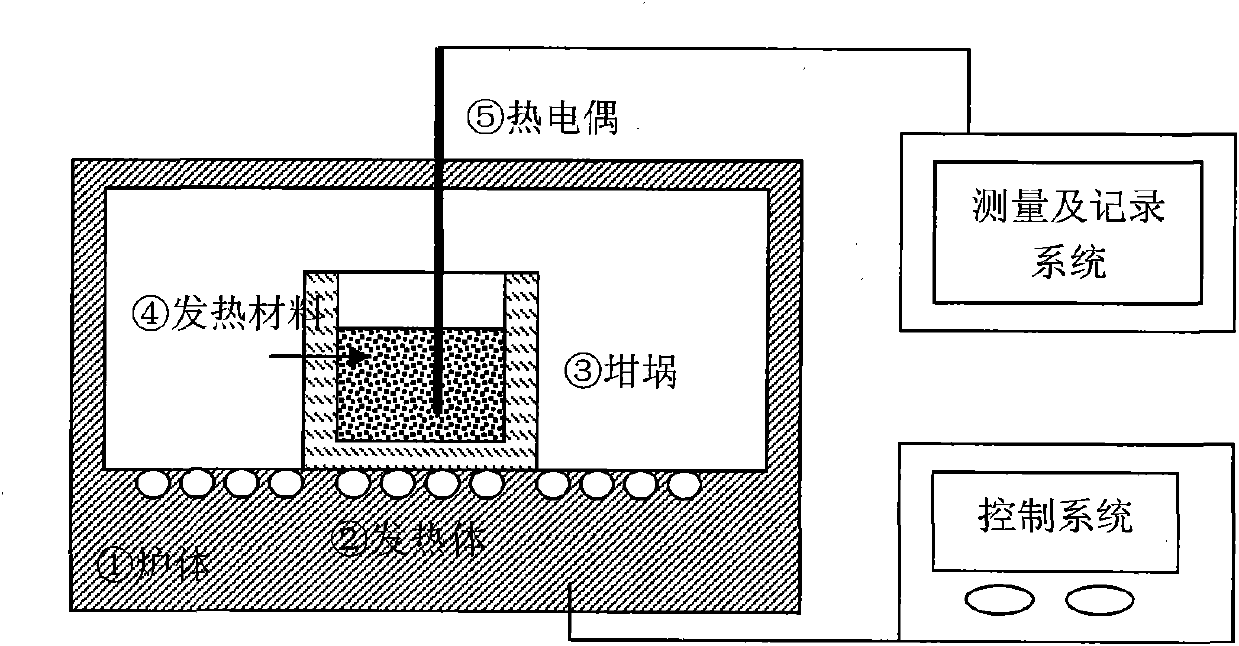

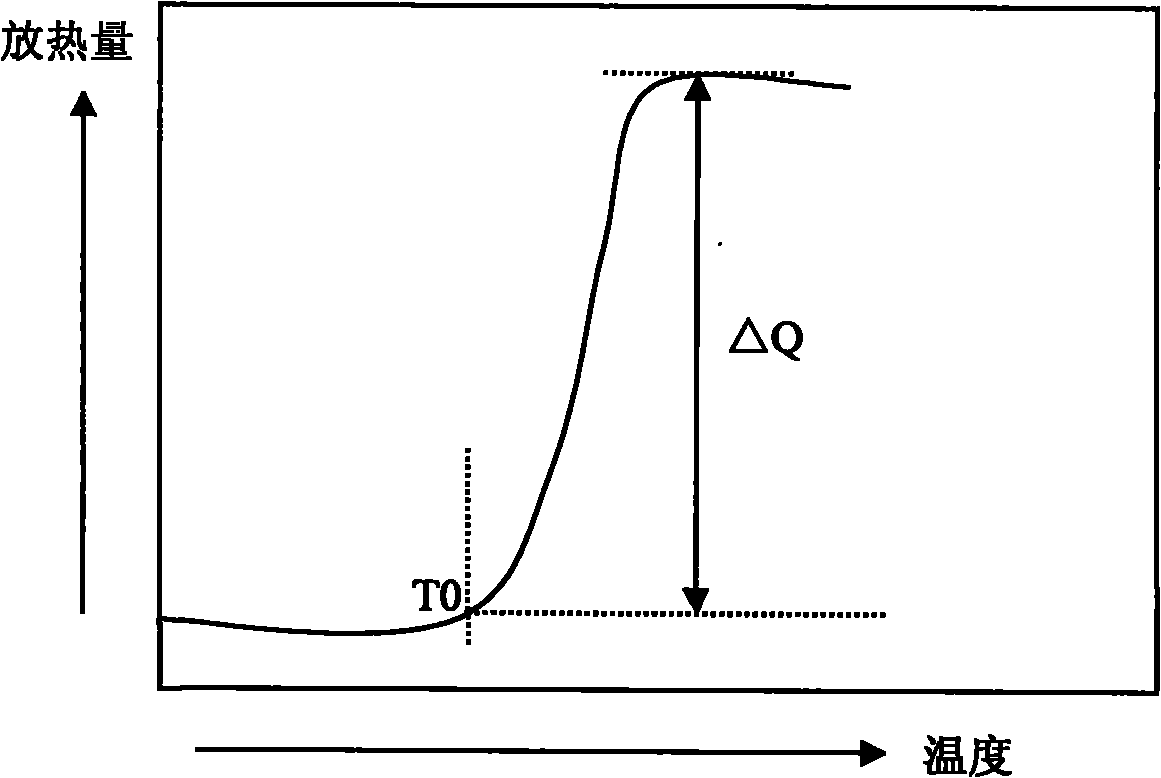

Method for preparing high-performance heat-generating agent

The invention relates to a method for preparing a heat-generating agent. The technical scheme is that: the heat-generating agent is prepared from the following raw materials in percentage by mass: 10 to 60 percent of aluminum metal powder, 10 to 60 percent of silicon / calcium oxides, 5 to 30 percent of graphite, 2 to 20 percent of ferric oxide and 1 to 10 percent of rare earth oxides, wherein the purity of the aluminum metal powder is over 90 percent; the particle diameter of silicon / calcium oxide micro powder is less than 0.074mm; the mol ratio of calcium oxide to silicon oxide is 1 to 5; the silicon / calcium oxide micro powder contains 0.5 to 9 mass percent of impurities, such as magnesium oxide and the like; the purity of the expanded graphite is over 90 percent; the purity of the ferric oxide is over 60 percent; and the rare earth oxides contain more than 30 mass percent of cerium oxide. The heat-generating agent with high performance can be prepared by uniformly mixing the raw materials according to the proportion in mixing equipment. The heat-generating agent has the characteristics of low combustion starting temperature, high heat productivity, good heat-preservation effect. Moreover, the process is simple, and the method is applicable for large-scale production.

Owner:沈阳东大高温材料有限公司

Copper-nickel system precision resistor alloy foil and preparation method thereof

The invention provides copper-nickel system precision resistor alloy foil which comprises the following components in percentage by weight: 40-48% of Ni, 1.4-1.8% of Mn, 0.1-0.3% of Fe, 0.3% of Si and balance of Cu. The preparation method comprises the steps of homogenizing treatment, hot forging, face milling, hot rolling, pickling, cold rolling in steps and annealing of finished products. The technical method is simple and convenient to operate, and the prepared foil is 0.005mm thick, can meet the operating requirements of a sensitive grid of a bridge fatigue life gauge, and can be used as a material of the sensitive grid of a bridge fatigue life gauge.

Owner:CENT SOUTH UNIV

Kalzium metal for deoxidization during steel making

The invention discloses a kalzium metal for deoxidization during steel making, comprising the following components by weigh percent: 40% of metallic aluminium grains, 15% of silicon carbide, 10% of limestone and 35% of silicate slag, wherein the deoxidized product of the kalzium metal is calcium aluminate with low melting point, which is easy to remove by aggregation and upward flotation. Therefore, the kalzium metal has the capabilities of removing dissolved oxygen from smelting steel and removing mixed oxygen by adsorption simultaneously, and has the capability of rapid white slag formationand strong desulfuration. The kalzium metal utilizes strong deoxidizing elements aluminum and calcium to deoxidize, thus promoting limestone to melt rapidly to form white slag to realize high-efficiency desulfuration, meanwhile, the deoxidized product of calcium aluminate with low melting point can well mild the desulfurized product CaS, thus being conducive to adsorbing the desulfurized product to discharge molten steel, so as to reach high desulfuration efficiency. The invention has stable metallurgical effect and strong operability.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Method for controlling aluminum component in steel

InactiveCN102021276AReduce entryReduce deoxygenation burdenProcess efficiency improvementMolten steelMolten slag

The invention belongs to the technical field of ferrous metallurgy and relates to a method for controlling an aluminum component in steel. In order to solve technical problems, the invention provides the method for precisely and stably controlling the aluminum component in steel, particularly the aluminum component in low-carbon aluminium steel. The control method comprises the following steps of: A, smelting in an electric furnace or a converter, wherein the primarily smelted molten steel is deoxidized by aluminum after the molten steel is discharged; B, low-frequency (LF) refining; and C, continuous casting. The control method is characterized in that: in the LF refining process, the adding amount of slag is 12 to 14Kg per ton of steel during slagging; and based on 100 weight parts, the slag mainly comprises the following components in part by weight: 60 to 68 parts of CaO, 15 to 20 parts of Al203, more than zero part and less than or equal to 5.0 parts of SiO2, more than zero part and less than or equal to 3.0 parts of MgO and 10 to 15 parts of CaF2. When the control method is used, the activity of SiO2 in the slag can be reduced, and the probability of reaction between aluminum in the steel and SiO2 in the slag can be reduced, so that the aluminum component in the molten steel is precisely controlled and the desulfurization rate of the molten slag is also improved at the same time.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

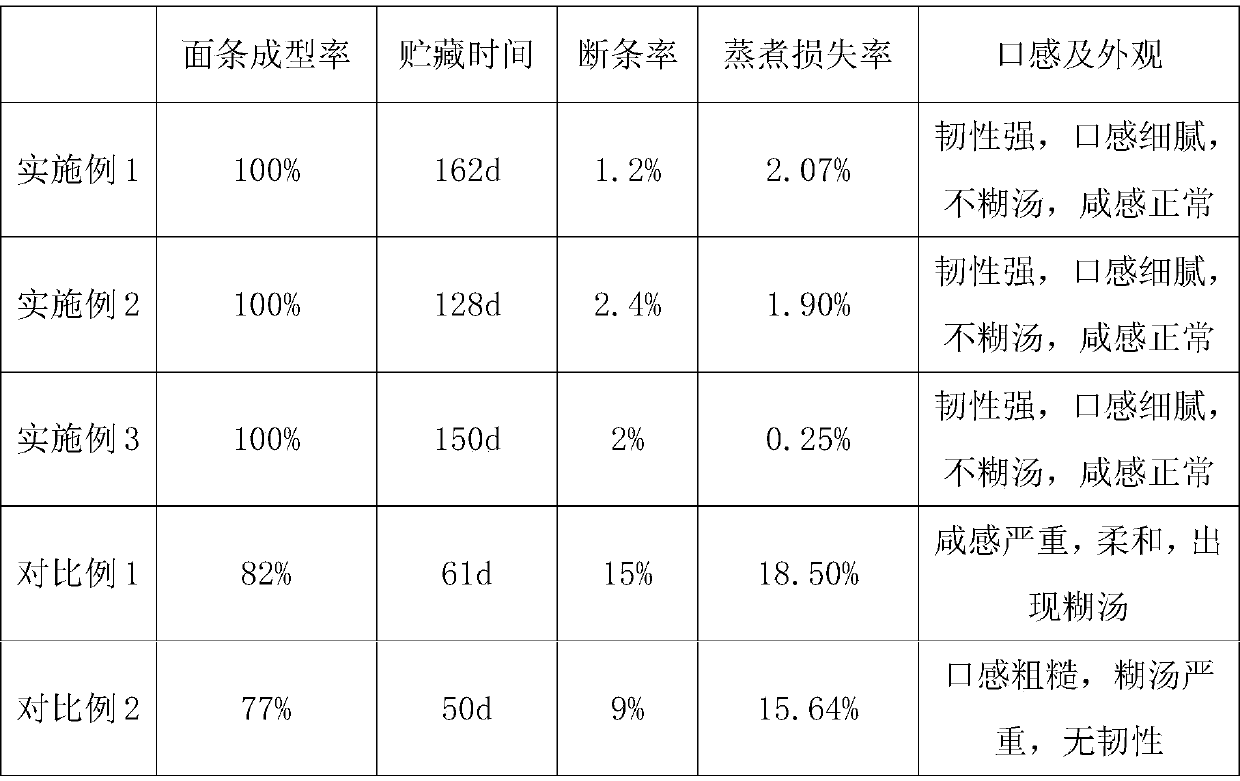

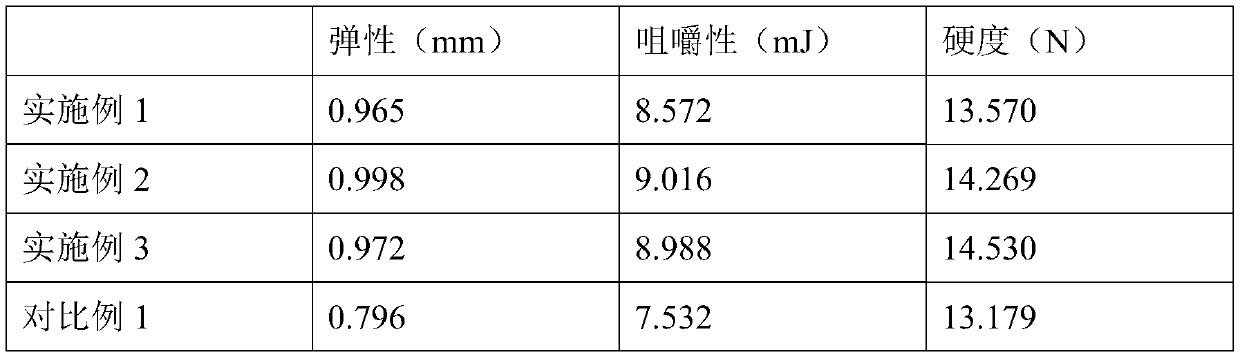

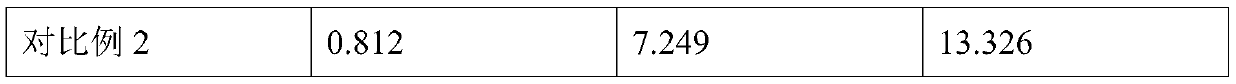

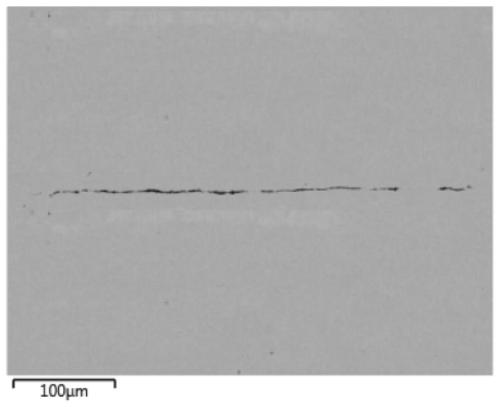

Convenient instant fresh wet noodle and preparation method thereof

The invention discloses a convenient instant fresh noodle and a preparation method thereof, and relates to the field of food processing. The convenient instant fresh wet noodle is mainly composed of high-gluten wheat flour, modified starch, vital gluten and salt. The addition of additives reduces indicator degradation of color, texture and microorganisms during storage. The noodle adopts an extrusion molding curing process to ensure long shelf life by pickling, modified atmosphere packaging and irradiation sterilization.

Owner:湖北戴氏食品科技股份有限公司

Process method for smelting high purity steel through VD vacuum treatment device

ActiveCN111378811AReduce slaggingGood removal effectManufacturing convertersSlagNon-metallic inclusions

The invention provides a process method for smelting high purity steel through a VD vacuum treatment device. The method comprises the following steps of KR molten iron desulfuration, wherein it is ensured that before putting into a furnace, S in molten iron is smaller than or equal to 30 ppm; top and bottom combined blowing converter blowing, wherein the mass percent omega [C] of converter tappingC is larger than or equal to 0.08%; external refining and argon refining, wherein in the full process, weak stirring is carried out, and calcium aluminum silicon series slag with the basicity being 2.0 to 4.5 is adopted; and VD treatment, wherein 20 to 35 min VD treatment is adopted, high-vacuum holding of strength is achieved, in the treatment process, according to the strong-weak-strong mode, the bottom stirring argon strength is controlled in a time interval manner, after VD vacuum breaking, a manner that soft blowing is adopted, large-particle inclusions are removed, molten steel is subjected to standing, and small particle inclusions are removed is adopted for further improving the molten steel purity. It is known that through the particular VD treatment process stirring control modeis adopted for assisting with a proper refining slag system and a soft blowing operation method, molten steel slag entrapment can be effectively reduced, the removing effect of non metal inclusions can be improved, and the method is suitable for production of various low, middle and high carbon steel with the carbon content being 0.15 to 1.05%.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

Bactericidal dehydration and deoxidation preserving agent and its preparation method

InactiveCN101199360ADoes not affect flavorImprove the bactericidal effectFruit and vegetables preservationEdible seed preservationEthyl hydroxybenzoateFlavor

The invention discloses a sterilizing, dehydrating and oxygenating antistaling agent and its preparation method. Current oxygenating and antistaling agents have the double functions of oxygenating and sterilizing, but have heavy irritating odor, which greatly influences the flavor of the food, thus not suitable for industrial application. The antistaling agent of the invention is made up of the following materials in weight ratio: ferrous powder 55-81%, active carbon1.5-4.0%, absorbent resin0.5-2.5%, quick lime0.5-5%, the mixture of ethyl p-hydroxybenzoate and ethyl p-hydroxypropyl formate0.05-0.30%, hydrosulphite0.6-1.25% and the rest is silica gel. The invention integrates the functions of sterilizing, dehydrating and oxygenating and has good effects; the invention is strong in antibacterial action and light in odor, and hardly influences the flavor of the food, thus the invention is suitable for industrial application.

Owner:新昌县群星实业有限公司

Method for preparing high purity zirconium by calcium in situ distillation-deoxidation

The invention belongs to the technical field of metal smelting, and discloses a method for preparing high purity zirconium by calcium in situ distillation-deoxidation. The method includes the steps that a raw material system A and a calcium reducing agent are separately placed in a sealed reaction container and heated under an inert atmosphere, calcium in the calcium reducing agent is dissolved into molten salt in the raw material system A in the form of high pure calcium gas, deoxidation of a zirconium raw material is realized, and the high purity zirconium with the oxygen content less than or equal to 0.10 wt% is prepared; the raw material system A is a mixture of the zirconium raw material and anhydrous calcium chloride, the raw material system A contains or does not contain one or twoof an alkali metal halide and an alkali earth metal halide, and the zirconium raw material is zirconium metal, a zirconium alloy or zirconia; the calcium reducing agent is calcium metal or a calcium alloy; and separately placed separated regions are isolated from each other and communicate through the gas phase. The method for preparing the high purity zirconium by calcium in situ distillation-deoxidation is simple and practicable, has the good effect of oxygen removal, and can meet the use requirements of aerospace, nuclear industries and other fields.

Owner:有研资源环境技术研究院(北京)有限公司

Wet pan gear and manufacturing method thereof

ActiveCN101899610AReduce the amount addedLow costPortable liftingGearing elementsRare earthFerrosilicon

The invention relates to a long-life wet pan gear and a manufacturing method thereof. The wet pan gear is chemically made from 3.4-3.8% of C, 2.2-2.6% of Si, 0.6-0.9% of Mn, not more than 0.06% of P, not more than 0.03% of S, 0.4-0.7% of Cu, 0.05-0.2% of Mo, 0.4-0.6% of Cr and the balance of Fe. The manufacturing method comprises the following steps of: making a mold, smelting, casting, smelting into an alloy liquid at 1480-1500 DEG C, adding rare earth ferrosilicon magnesium alloy nodulizer, uniformly mixing, and pouring into the mold to cast a gear blank; thermally treating the blank at 900-920 DEG C for 2-4 h, heating the tooth part of the blank to 280-310 DEG C, and tempering for 2-3 h; and processing by a lathe so that the surface roughness Ra of the gear reaches 6.3-12.5. The strength and the wear resistance of the product are increased by 2-3 times higher than those of common spheroidal graphite cast iron, the tensile strength is 780-810 MPa, the yield strength is 580-610 MPa, the hardness HRC of the tooth part reaches 40-48, and the average service life of the product is long.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

Composite alloy of Al - Mg - Ca - Fe with lower carbon, silicon, phosphor, and sulfur in use for final steelmaking deoxidizer

This invention relates to a final deoxidizer for steelmaking, which is low-C, low-Si, low-P and low-S Al-Mn-Mg-Ca-F alloy. The alloy can be used as the final deoxidizer for steelmaking with good effect, and does not need further refinery of steel. The alloy comprises: C less than or equal to 0.2 wt.%, Si less than or equal to 1.0 wt.%, P less than or equal to 0.02 wt.%, S less than or equal to 0.02 wt.%, Al 40-50 wt.%, Mn 1.0-10 wt.%, Mg 0.1-10 wt.%, Ca 0.1-10 wt.%, and Fe as balance. This invention adopts main frequency induction furnace smelting to produce the final deoxidizer. The final deoxidizer has such advantages as high specific gravity, low melting point, no pulverization, good deoxidation and desulphurization effects, high yield, high fluidity of deoxidized molten steel, no nodulation, easy suspension of deoxidized product, low inclusion total content, high molten steel purity, good steel quality, fine grains, good mechanical properties, and long service life.

Owner:李兴有

Foil type sensor with function of automatically accumulating resistance

InactiveCN102023179AImprove heat resistanceEasy to joinMaterial resistanceFatigue damageElectrical resistance and conductance

The invention relates to a foil type sensor with a function of automatically accumulating resistance. The senor comprises a foil type sensitive grid, a base, a covering layer and a lead, wherein the surface of the base is sequentially provided with the foil type sensitive grid and the covering layer, and the foil type sensitive grid is connected with the lead; and the foil type sensitive grid is made of a foil material of copper-nickel-manganese-iron-silicon alloy through a photochemical method according to the designed sensor structure. Under the effect of fatigue loading, the sensor has the function of automatically accumulating resistance, is suitable for monitoring the accumulation of fatigue damages of a bridge structure, has the capacity of temperature self-compensation and is suitable for complicated and variable climatic environments of bridge structures. The sensor has larger resistance accumulation increment and excellent fatigue service life and can be guaranteed to work for a long time without being frequently changed. The sensor also has a lower resistance accumulation strain threshold value and can be directly bonded on the surface of a structure for use. The sensor has low production cost and can be industrially applied in a large scale.

Owner:CENT SOUTH UNIV

Submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel

InactiveCN103143856AGood crack resistanceGood impact toughnessWelding/cutting media/materialsSoldering mediaSubmerged arc weldingCorrosion resistant

The invention relates particularly to a submerged-arc welding wire for CO2 (Carbon Dioxide) corrosion resistant high-strength pipeline steel. The technical scheme is that the submerged-arc welding wire for the high-strength pipeline steel comprises the following chemical components: 0.02-0.06 wt% of C, 0.20-0.40 wt% of Si, 1.20-2.00wt% of Mn, 3.00-8.00wt% of Cr, and 0.20-0.40wt% of Cu, 0.04-0.10 wt% of (V+Ti+B), not more than 0.001 wt% of S, not more than 0.002 wt% of P, and the remain of Fe and inevitable impurities. The submerged-arc welding wire for the high-strength pipeline steel provided by the invention is matched with an SJ101-G soldering flux for use, requirements of intensity, tenacity and CO2 corrosion resistance of a welding joint formed by the welded submerged-arc welding wire for the CO2 corrosion resistant high-strength pipeline steel can be met by mechanical property and corrosion resistance of formed weld metal; moreover, the property of the welding joint is matched with base metal, so that technical requirements of oil and gas pipelines prepared by welding can be met; and the welding joint is good in CO2 corrosion resistance.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com