Deformed steel bar used at low temperature and production process thereof

A production process and rebar technology, applied in the field of rebar, can solve the problems of high cost, complicated process, and many components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

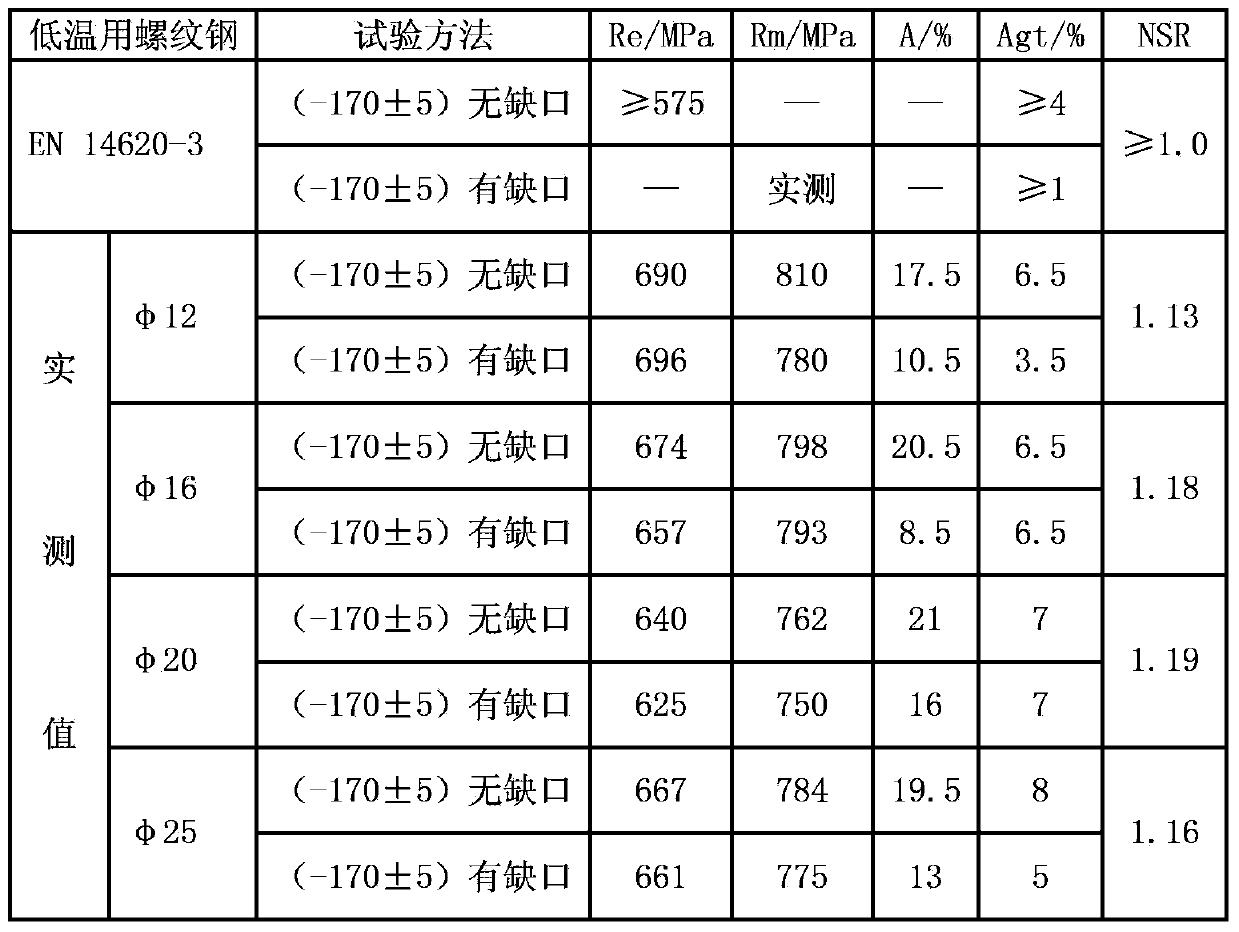

Examples

Embodiment

[0041] A rebar for low temperature use, the chemical composition of the rebar is: C: 0.05-0.10%, Si: 0.20-0.35%, Mn: 1.45-1.60%, S≤0.015%, P≤0.008%, Cr≤0.20 %, Ni: 0.90~1.50%, Cu≤0.20%, Mo≤0.10%, N≤0.0120%, Al: 0.030~0.045%, and the balance is Fe and unavoidable impurities.

[0042] According to the production process of the present invention, the components of various examples of the steel grades of the present invention produced are shown in Table 1.

[0043] Table 1: Chemical composition (wt%) of the examples.

[0044] Example

C

Si

mn

S

P

Cr

Ni

Cu

Mo

N

Al

Example 1

0.05

0.20

1.45

0.015

0.008

0.20

0.09

0.20

0.10

0.0120

0.030

Example 2

0.10

0.35

1.60

0.010

0.007

0.15

1.50

0.15

0.07

0.0115

0.045

Example 3

0.08

0.30

1.50

0.014

0.006

0.18

1.10

0.18

0.05

0.0118

0.035

Exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com