Method for preparing high purity zirconium by calcium in situ distillation-deoxidation

A high-purity, in-situ technology, applied in the field of metal smelting, can solve the problems of contaminated zirconium products, difficult to control uniformity, and unsatisfactory zirconium oxygen content of less than 0.14wt%, to achieve high solubility, reduce energy consumption, and reduce activity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

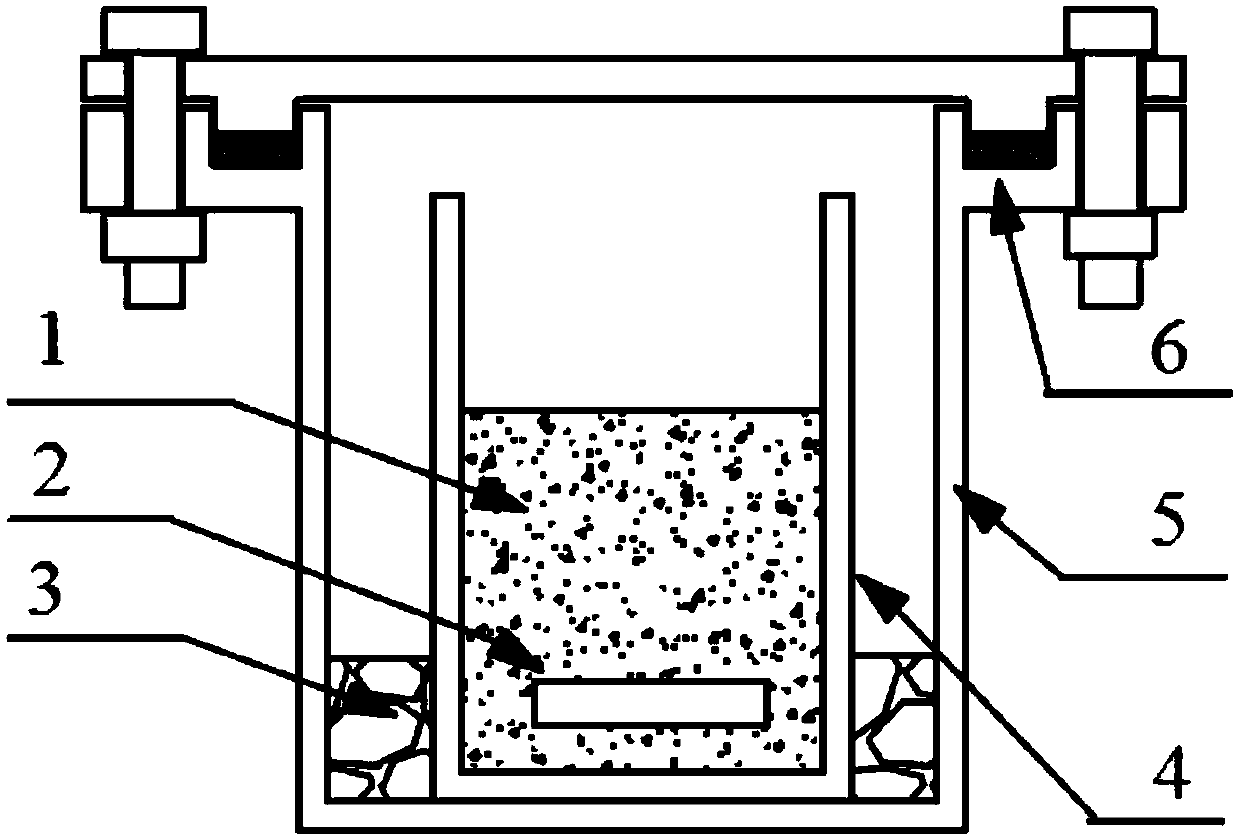

[0034] Get 1 metal zirconium block 10g, the oxygen content in the metal zirconium block is 730ppm, press (CaCl 2 ): m(Zr) = 5:1 Weigh 50g of anhydrous calcium chloride (dehydrated at 500°C for 18 hours before use), and weigh 8g of high-purity calcium chips (at 900°C, calcium in anhydrous calcium chloride molten salt 2.5 times the saturation solubility), metal zirconium and anhydrous calcium chloride are filled in the zirconium crucible, high-purity calcium chips are filled in the gap between the zirconium crucible and the stainless steel crucible, and then the stainless steel crucible is sealed with a high-temperature sealing gasket. Specific as figure 1 shown.

[0035]Put the sealed crucible into a vacuum tank heated by a resistance furnace, cover the furnace cover, vacuumize to 0.1Pa, and then wash with argon. Under the protection of argon, heat up to 900°C at a heating rate of 5°C / min, and keep at 900°C for 44 hours. After the heat preservation is completed, the furnace i...

Embodiment 2

[0037] Get 1 metal zirconium block 15g, the oxygen content in the metal zirconium block is 720ppm, press (CaCl 2 ): m(Zr) = 25:1 Weigh 375g of anhydrous calcium chloride (dehydrated at 300°C for 36 hours before use), and weigh 120g of high-purity calcium chips (at 1000°C, calcium in anhydrous calcium chloride molten salt 5 times the saturation solubility), metal zirconium and anhydrous calcium chloride are filled in the zirconium crucible, high-purity calcium chips are filled in the gap between the zirconium crucible and the stainless steel crucible, and then the stainless steel crucible is sealed with a high-temperature sealing gasket. Specific as figure 1 shown.

[0038] Put the sealed crucible into a vacuum tank heated by a resistance furnace, cover the furnace cover, vacuumize to 0.5 Pa, and then wash with argon. Under the protection of argon, the temperature was raised to 1000°C at a rate of 5°C / min, and kept at 1000°C for 26 hours. After the heat preservation was compl...

Embodiment 3

[0040] Get 1 metal zirconium wire, quality is 12g, oxygen content 840ppm in the metal zirconium wire, press (CaCl 2 ): m(Zr)=30:1 Weigh 360g of anhydrous calcium chloride (dehydrated at 600°C for 12 hours before use), weigh 288g of industrial calcium chips (at 1300°C, calcium saturated in anhydrous calcium chloride molten salt 4 times the solubility), metal zirconium and anhydrous calcium chloride are filled in the zirconium crucible, industrial calcium chips are filled in the gap between the zirconium crucible and the high-temperature alloy crucible, and then the high-temperature alloy crucible is sealed with a high-temperature sealing gasket. Specific as figure 1 shown.

[0041] Put the sealed crucible into a high-temperature alloy vacuum tank heated by a resistance furnace, cover the furnace cover, evacuate to 0.2 Pa, and then wash with argon. Under the protection of argon, heat up to 1300°C at a heating rate of 5°C / min, and keep at 1300°C for 12 hours. After the heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com