Foil type sensor with function of automatically accumulating resistance

A sensor and foil-type technology, applied in the direction of material resistance, etc., can solve the problems of long service time, structural form, complex stress conditions, and bulky bridge structure, so as to reduce production costs, facilitate large-scale applications, and improve heat resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

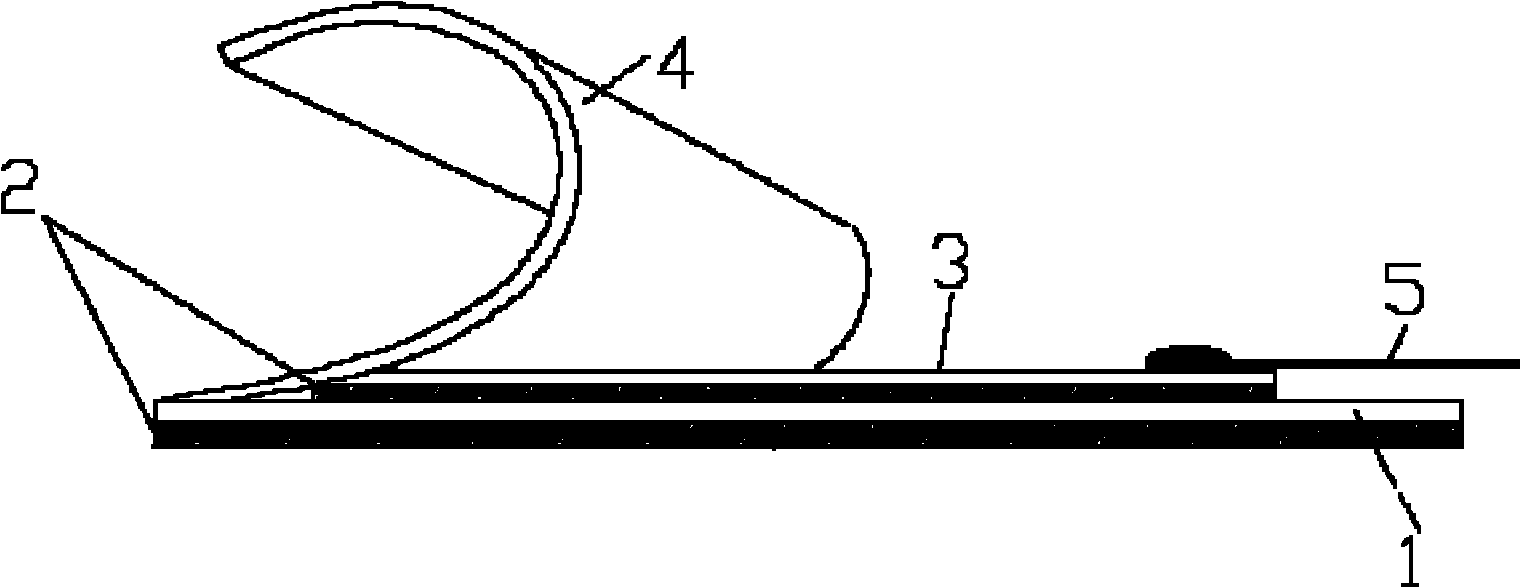

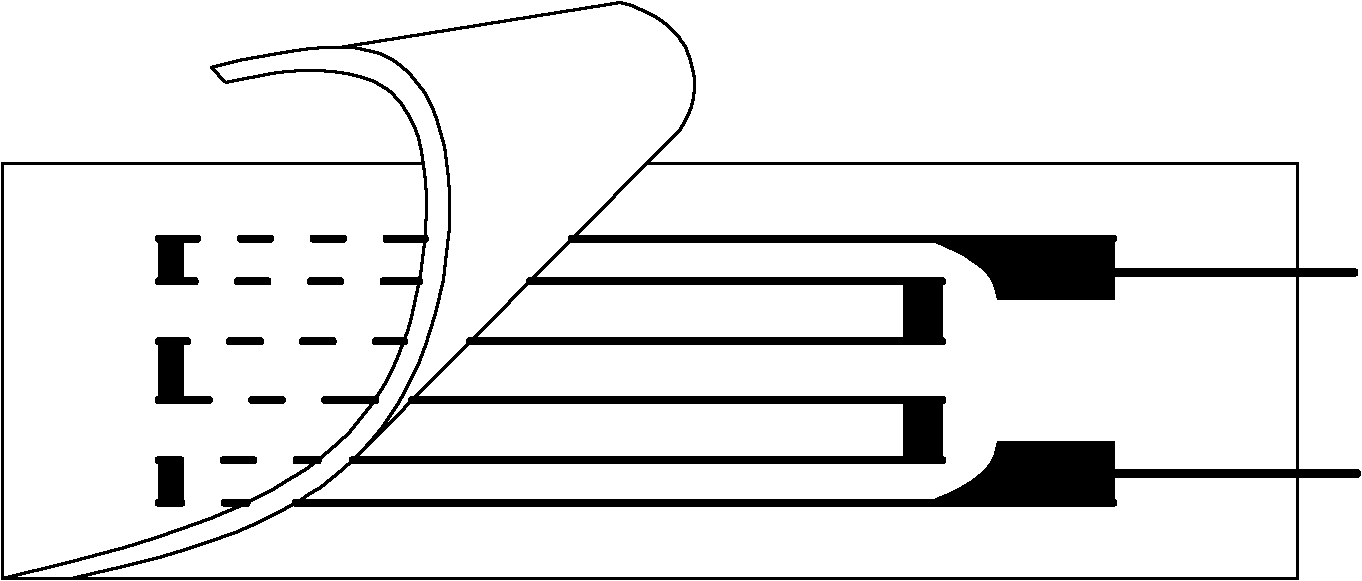

[0039] See attached figure 1 , 2 , a foil sensor with the function of automatic resistance accumulation in the present invention, comprising: a foil sensitive grid 3, a base 1, a covering layer 4, and a lead wire 5, and the foil sensitive grid 3 and the covering layer are sequentially arranged on the surface of the base 1 4. The lead wire 5 is connected to the foil-type sensitive grid 3; the foil-type sensitive grid 3 is made of copper-nickel-manganese-iron-silicon alloy foil by photochemical method according to the designed sensor structure pattern.

[0040] In this embodiment, the foil-type sensitive grid 3 is made of copper-nickel-manganese-iron-silicon precision resistance alloy, and the weight percentage of each component is:

[0041] Ni 43%, Mn 1.8%, Fe 0.1%, Si 0.3%, the balance is Cu, and its thickness is 0.005mm.

[0042] In this embodiment, the lead wire 5 is a constantan wire.

[0043] In this embodiment, the base 1 , the foil-type sensitive grid 3 and the coveri...

Embodiment 2

[0055] The product structure and preparation method prepared in this embodiment are the same as in Example 1, but the weight percentage of each component of the foil-type sensitive grid 3 is:

[0056] Ni 40%, Mn 1.4%, Fe 0.3%, Si 0.3%, the balance is Cu, and its thickness is 0.005mm.

[0057] The performance index of the foil sensor prepared in Example 2 is:

[0058] ΔR / R resistance fatigue cumulative increment: 8.075%,

[0059] Resistance cumulative strain threshold: 750με,

[0060] Temperature coefficient of resistance: 6.272×10 -6 / °C,

[0061] Gauge factor: 2.003.

Embodiment 3

[0063] The structure and preparation method of the product prepared in this embodiment are the same as in Example 1, but the weight percentage of each component of the foil-type sensitive grid 3 is:

[0064] Ni 48%, Mn 1.7%, Fe 0.2%, Si 0.3%, the balance is Cu, and its thickness is 0.005mm.

[0065] The performance index of the foil sensor prepared in Example 3 is:

[0066] ΔR / R resistance fatigue cumulative increment: 8.372%,

[0067] Resistance cumulative strain threshold: 680με,

[0068] Temperature coefficient of resistance: 6.489×10 -6 / °C,

[0069] Gauge factor: 2.057.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gauge factor | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com