Convenient instant fresh wet noodle and preparation method thereof

A production method and convenient technology, applied in food science, food preservation, application, etc., can solve problems such as unfavorable noodle preservation and increased water content of noodles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

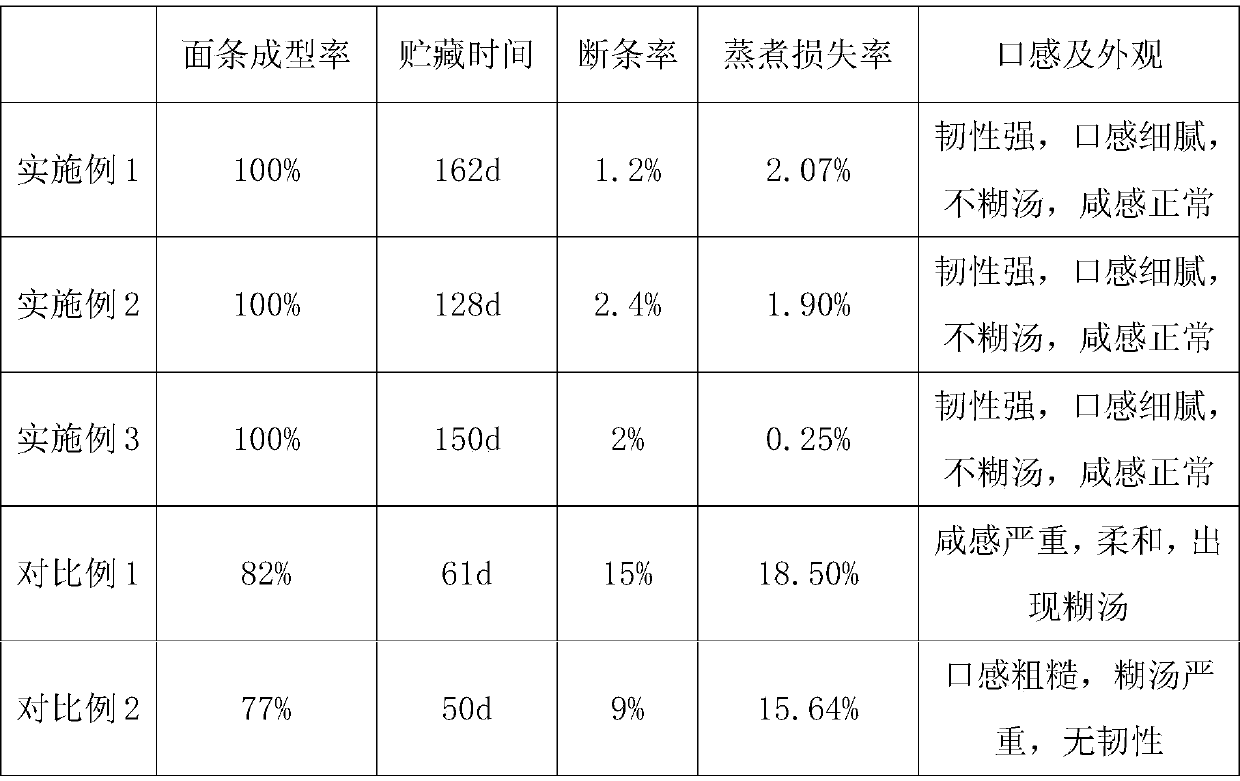

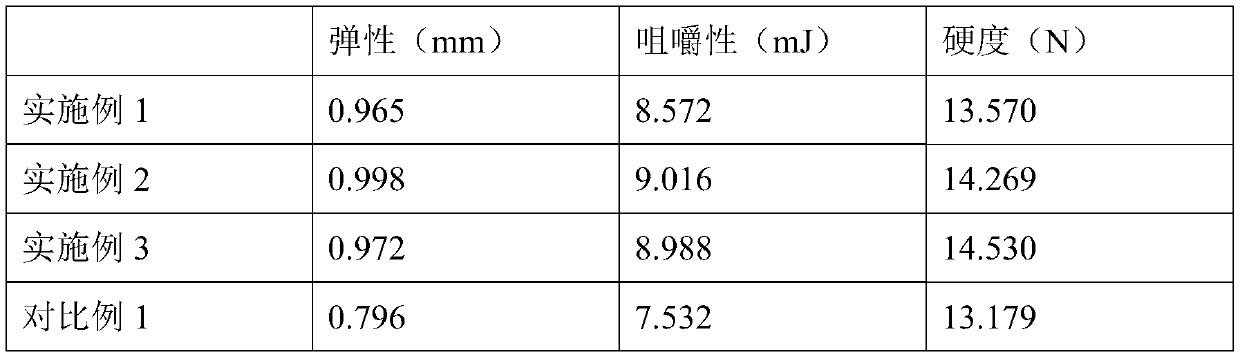

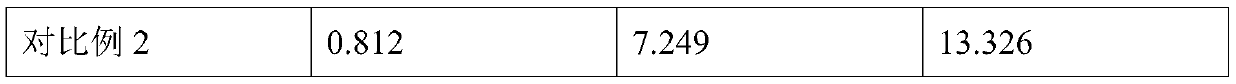

Examples

Embodiment 1

[0024] Take 75 parts of high-gluten wheat flour, 3 parts of modified starch, 8 parts of gluten powder, 2 parts of edible salt, 0.01 part of nisin, 0.1 part of sodium alginate, 0.2 part of sodium stearoyl lactylate, 0.2 Part tea polyphenol, 0.1 part glycerol, 0.1 part sodium erythorbate, 0.05 part glucose oxidase, 0.01 part lipase. Add sterile water with 30% of the weight of the ingredients, mix the above ingredients in the dough mixer, and knead the dough. After kneading the dough, it will be proofed in a proofing box at a temperature of 35°C for 30 minutes; Extrusion, molding and aging in the machine, the extrusion temperature is 100°C, the extrusion screw speed is 100r / min, the gelatinization degree of the noodles after extrusion is greater than 75%; the extruded noodles are pickled with 1% lactic acid solution for 120s; The washed noodles are packaged in modified atmosphere, and the packaging bag is filled with a mixed gas of nitrogen and carbon dioxide at a ratio of 2:3. I...

Embodiment 2

[0026] Take 90 parts of high-gluten wheat flour, 10 parts of modified starch, 5 parts of gluten powder, 1 part of edible salt, 0.01 part of nisin, 0.2 part of sodium alginate, 0.5 part of sodium stearoyl lactylate, 0.5 part of Part tea polyphenol, 0.05 part glycerol, 0.1 part sodium erythorbate, 0.01 part glucose oxidase, 0.05 part lipase. Add 40% of the weight of the ingredients aseptic water, mix the ingredients in the dough mixer, knead the dough, and proof the dough for 20 minutes in a proofing box at a temperature of 40°C after mixing the dough; Extrusion, molding and aging in the machine, the extrusion temperature is 110°C, the extrusion screw speed is 70r / min, the gelatinization degree of the noodles after extrusion is greater than 75%; the extruded noodles are pickled with 3% lactic acid solution for 60s; Washed noodles are packaged in modified atmosphere, and the package is filled with a mixed gas of nitrogen and carbon dioxide at a ratio of 2:4. In addition, the mixe...

Embodiment 3

[0028] Take 80 parts of high-gluten wheat flour, 10 parts of modified starch, 2 parts of gluten powder, 1 part of edible salt, 0.01 part of nisin, 0.2 part of sodium alginate, 0.1 part of sodium stearoyl lactylate, 0.1 part of Part tea polyphenols, 0.1 part glycerol, 0.1 part sodium erythorbate, 0.05 part glucose oxidase, 0.05 part lipase. Add 33% of the weight of the ingredients aseptic water, mix the ingredients in the dough mixer, knead the dough, and proof the dough for 40 minutes in a proofing box at a temperature of 30°C after mixing the dough; Extrusion, molding and aging in the machine, the extrusion temperature is 70°C, the extrusion screw speed is 140r / min, the gelatinization degree of the noodles after extrusion is greater than 75%; the extruded noodles are pickled with 2% lactic acid solution for 95s; The washed noodles are packaged in modified atmosphere, and the packaging bag is filled with a mixed gas of nitrogen and carbon dioxide at a ratio of 2:1. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com