Preparation method of spun yarn fabric for enhancing thermoplastic resin

A technology for enhancing thermoplasticity and thermoplastic resins, which is applied in fiber processing, plant fibers, textiles and papermaking, etc. It can solve the problem of difficult entry of molten resin in spun yarns, achieve improved mechanical properties, low cost, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

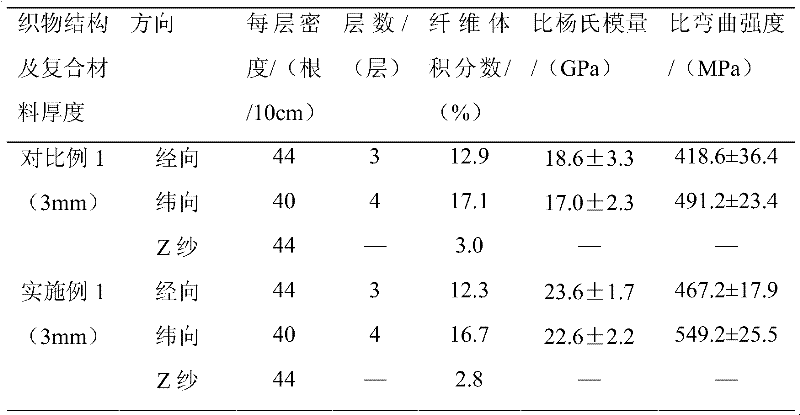

Embodiment 1

[0018] The spun yarn fabric is a three-dimensional orthogonal ramie woven fabric. Warp and weft yarn fineness is 560tex, warp density: 44 threads / 10cm, weft density: 40 threads / 10cm, width: 35cm, warp yarn 3 layers, weft yarn 4 layers, fabric thickness 3mm, according to the size required for hot pressing (30cm×30cm) cutting. Use a glass transition temperature of 90°C (the resin is composed of 88% by weight of methyl methacrylate, 3% of acrylic acid and 9% of butyl acrylate), and an emulsion of 4% thermoplastic resin relative to the weight of the spun yarn fabric , the ramie woven fabric is completely submerged, the emulsion of the thermoplastic resin is immersed in the fabric for 20 minutes, the fabric soaked in the emulsion of the thermoplastic resin is taken out, the excess emulsion is pressed off, and dried to obtain the ramie fabric infiltrated with the thermoplastic resin.

[0019] Then lay the fabric and PP film at intervals, hot press with a flat vulcanizer at a temper...

Embodiment 2

[0021] Spun yarn fabric is linen plain weave fabric. The warp and weft fineness is 3850tex, warp density: 6 threads / 10cm, weft density: 5 threads / 10cm. Use the resin that glass transition temperature is 110 ℃, (resin is made up of the methyl methacrylate of 87%, the methyl acrylate of 8%, the methacrylic acid of 4% and the N-methylol acrylamide of 1% by weight percentage Potentially cross-linked), with respect to the emulsion of 2% thermoplastic resin by weight of spun yarn fabric, the linen plain woven fabric is completely submerged, the emulsion of thermoplastic resin is immersed in the fabric for 15 minutes, the fabric soaked in the emulsion of thermoplastic resin is taken out, pressed Remove excess lotion and dry to obtain resin-impregnated linen.

[0022] Observing the yarn section in the fabric with an optical microscope, it was observed that resin was contained inside the flax yarn, which confirmed that the resin had entered the inside of the flax yarn.

Embodiment 3

[0024] The spun yarn fabric is a cotton weft knitted fabric. Yarn fineness is 90tex, machine number E36, uses the resin (resin is made up of the styrene of 22% by weight percentage, the acrylic acid of 5% and the butyl acrylate of 73% that glass transition temperature is 40 ℃), relative to short fiber Submerge the cotton weft-knitted fabric completely with an emulsion of 8% thermoplastic resin by yarn fabric weight, and soak the emulsion of thermoplastic resin in the fabric for 10 minutes, take out the fabric soaked in the emulsion of thermoplastic resin, press off excess emulsion, dry, That is, the cotton weft-knitted fabric infiltrated with resin is obtained.

[0025] The cotton yarn section in the fabric was observed with an optical microscope, and it was observed that resin was contained inside the cotton yarn, which confirmed that the resin had entered the inside of the yarn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com