Gear transmission apparatus using flexible belts as engagement medium

A technology of gear transmission mechanism and flexible belt, which is applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of high processing and manufacturing costs, difficult re-use of teeth, and influence on gear life, etc., and achieve low cost , Conducive to environmental protection, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

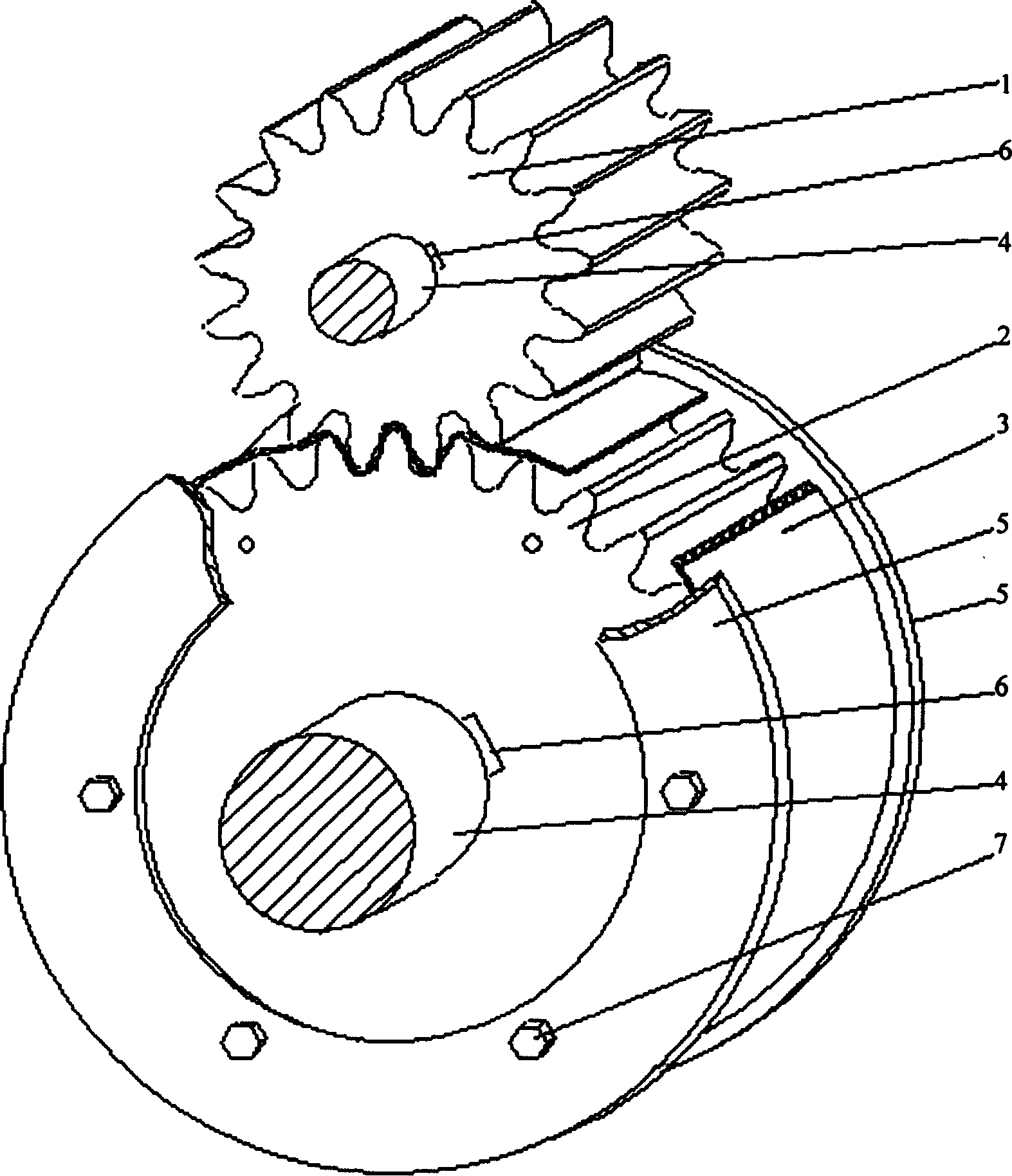

[0026] Such as figure 1 As shown, the gear A1 with the coupling 6 and the gear shaft 4 is conjugately meshed with the gear B2 with the coupling 6 and the gear shaft 4, and the gear teeth of the gear shaft B2 are covered with a movable closed flexible belt 3, which is equipped with a flexible The retaining ring 5 provided on both sides of the gear B2 with 3 is connected with the gear B2 with screws 7 .

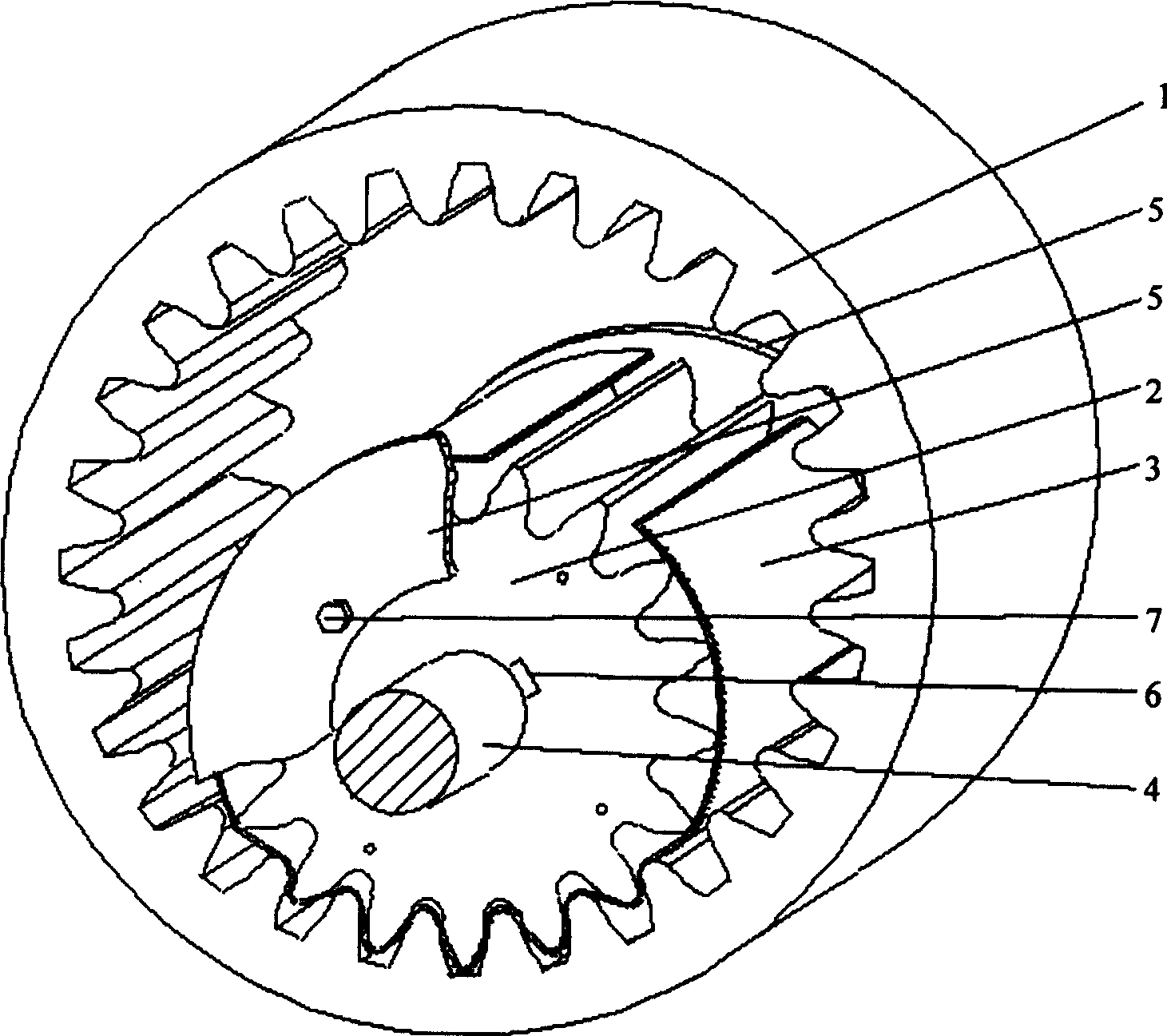

[0027] figure 2 , the gear A1 is conjugately meshed with the gear B2 of the coupling piece 6 and the gear shaft 4, the teeth of the gear B2 are covered with a movable closed flexible belt 3, and the retaining rings 5 arranged on both sides of the gear B2 with the flexible belt 3 Connect with gear B2 with screw 7.

[0028] the above figure 1 , figure 2 Middle: The flexible belt 3 is in a closed ring shape. During operation, the flexible belt 3 is gradually embedded between the two meshing tooth surfaces by the gear A1 without the flexible belt. A piece of easily detacha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com