Patents

Literature

94results about How to "Good for the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

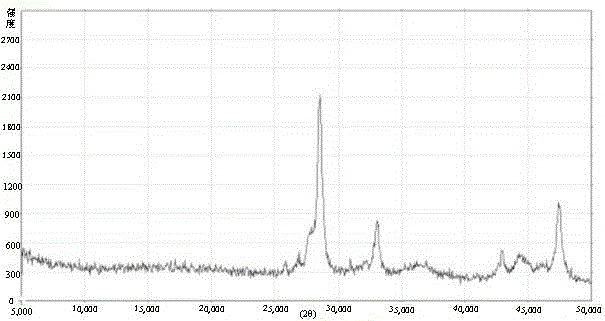

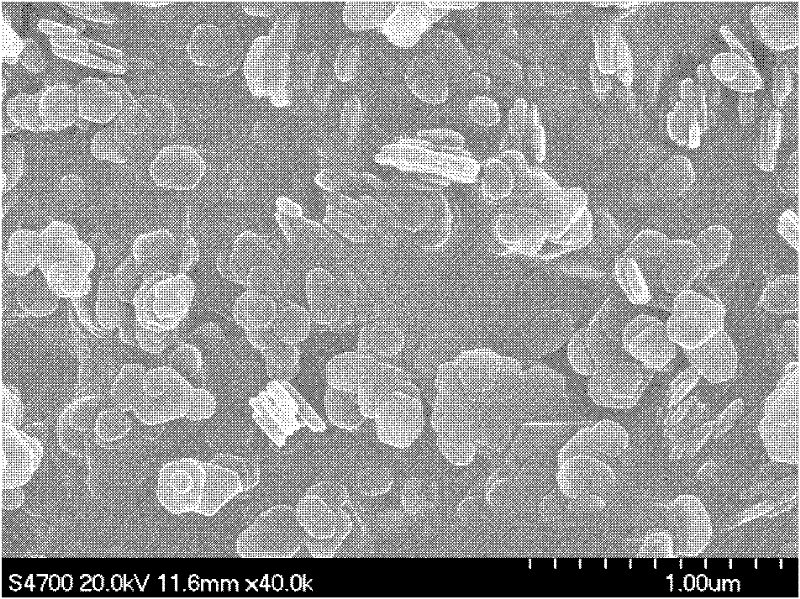

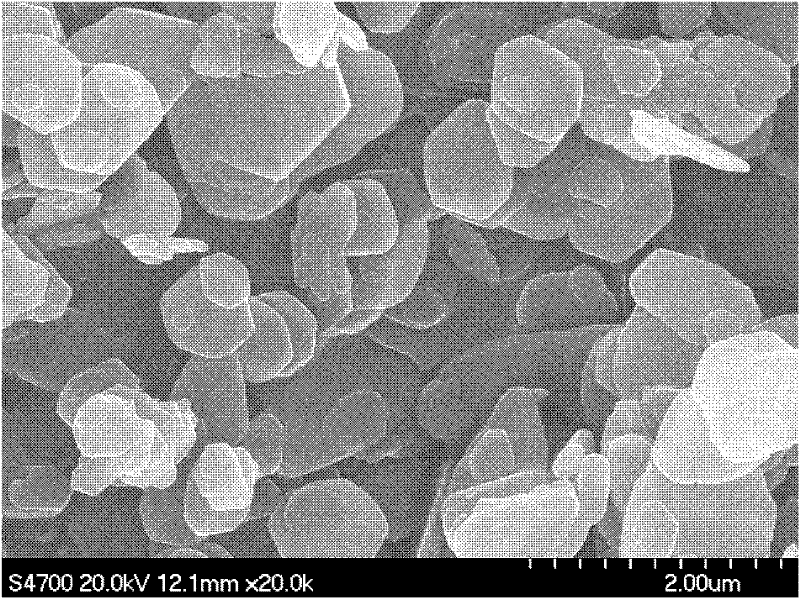

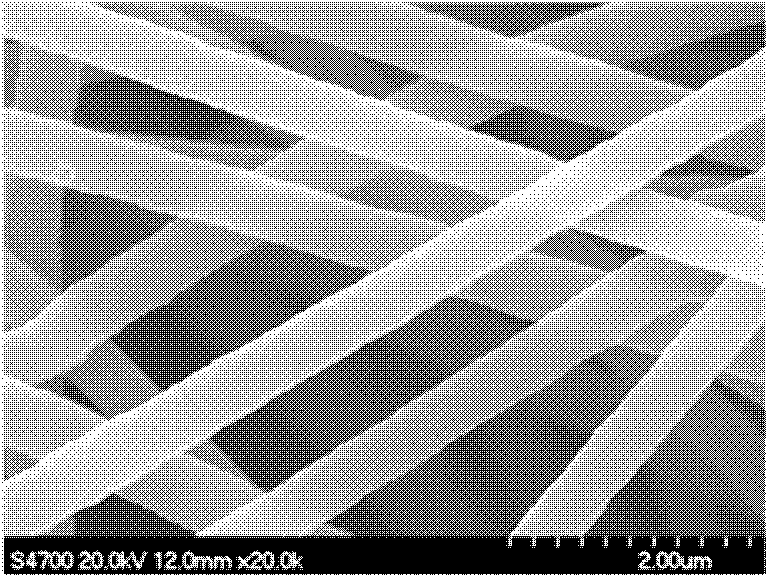

Ceramic diaphragm, and preparation method and application thereof

ActiveCN103579564AReduce VOC emissionsGood for the environmentSecondary cellsCell component detailsFire hazardKetone

The invention discloses a ceramic diaphragm, and a preparation method and application thereof. The ceramic diaphragm comprises a diaphragm material substrate; the surface of the diaphragm material substrate is coated with a protective layer; the protective layer comprises 0.1% to 50% of ceramic particles and 50% to 99.9% of water-based polymer resin in percentage by weight. According to the invention, the water-based polymer resin is adopted to dispersing the ceramic particles, the use of poisonous N-methylpyrrolidine ketone with a high steam point can be avoided, an organic solvent is not required at all in the production process, solvent volatilization is eliminated, the emission of VOC is reduced, environmental protection is facilitated, energy consumed in the ceramic diaphragm production process can be lowered effectively, the risk of fire hazard can be reduced, and the cost can be lowered.

Owner:PANYU NANSHA YAN TIN CHEM

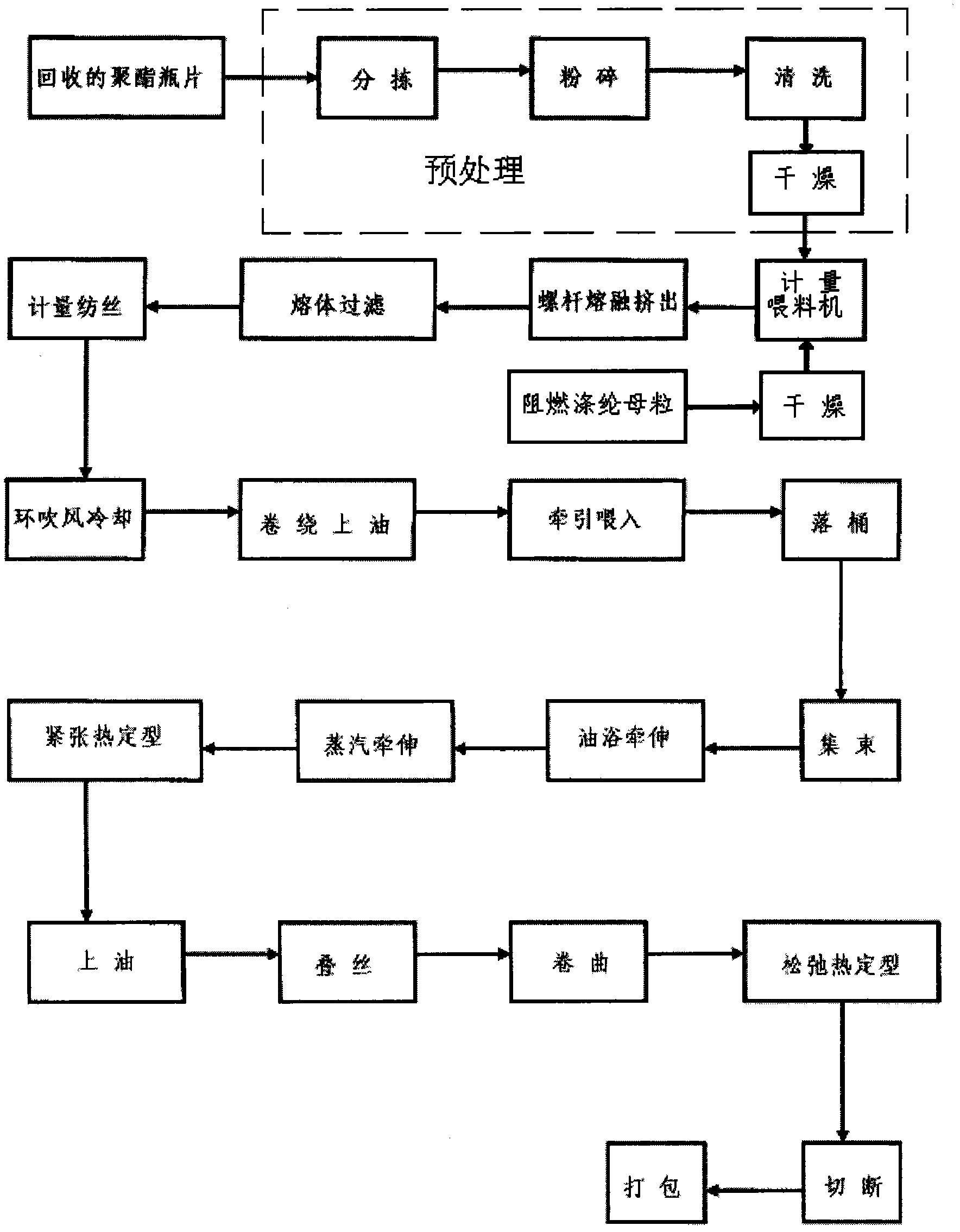

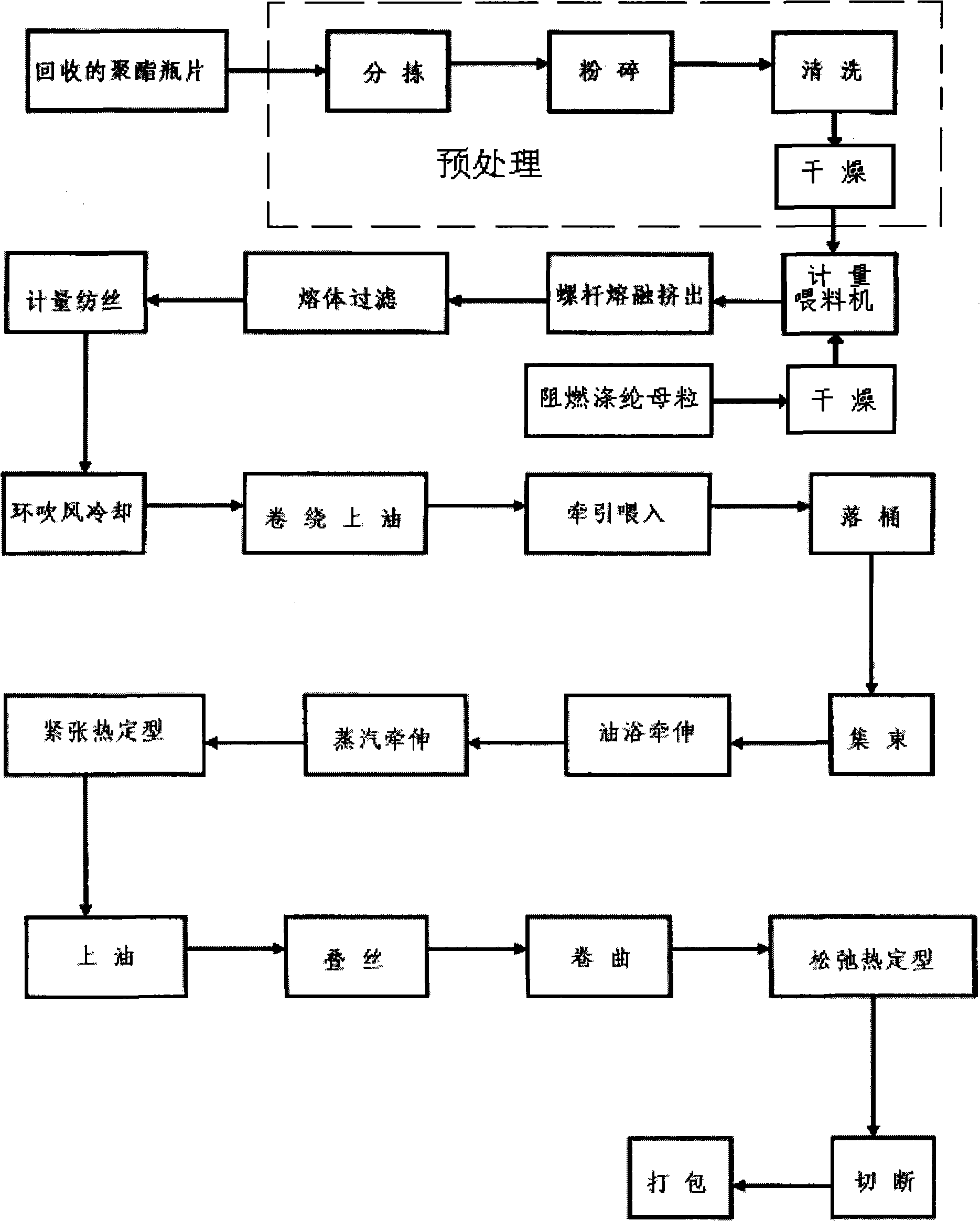

Method for producing flame-retardant polyester staple fibers by utilizing recovered polyester bottle chips

InactiveCN102102241AGood for the environmentReduce manufacturing costFlame-proof filament manufactureNew-spun product collectionPolyesterChemistry

The invention discloses a method for producing flame-retardant polyester staple fibers by utilizing recovered polyester bottle chips, which comprises the following steps: recovered waste polyester bottle chips are pretreated; flame-retardant polyester master batches are dried; the dried polyester bottle chips and flame-retardant polyester master batches are fed into a measuring feeding machine and mixed to obtain the mixed materials, wherein the flame-retardant polyester master batches account for 2 to 5 percent of the total concentration of the mixture; the mixed materials are extruded by screw-melting to obtain a melt; and the melt is subjected to filtration, measurement and spinning, cooling with circularly flowing air, winding and oiling and traction feeding, and yarns are collected and put into barrels; and the yarns in the barrels are bundled, and then subjected to oil bath draft, secondary steam draft, tensioned heat shaping, oiling, overlapping, winding, loose heat shaping, cutting and packaging so as to obtain the flame-retardant polyester staple fiber products. The method for producing flame-retardant polyester staple fibers by utilizing recovered polyester bottle chips has low cost, meets the requirements on performance, reduces harm to environment caused by wastes, and protects environment simultaneously.

Owner:江西富利昌化纤有限公司

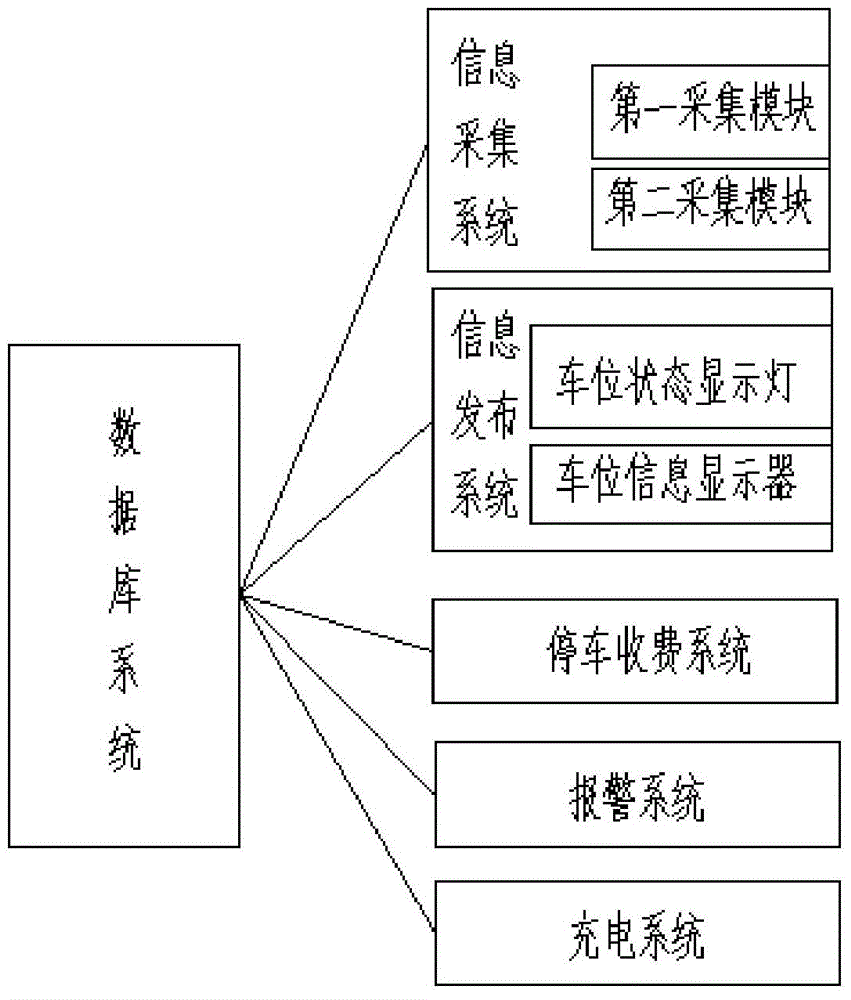

Parking management system with charging management function

InactiveCN104881895AGood for the environmentImplement network managementTicket-issuing apparatusApparatus for hiring articlesCollection systemParking space

The invention discloses a parking management system with a charging management function. The parking management system comprises a database system, an information collection system, an information publishing system, a parking charge system, an alarm system, and a charging system, wherein the information collection system, the information publishing system, the parking charge system, the alarm system and the charging system all communicate with the database system in a wireless transmission mode. Compared with the prior art, the charging module of the system can be used to charge electric energy vehicles, electric bicycles and electric tricycles, which is helpful for the promotion of new energy vehicles. Compared with other parking management systems, the complexity of the system of the invention is simplified, and the overall cost is reduced. In addition, timing is carried out precisely, fee collection for parking spaces is standardized, and electronic management and fee collection is realized. Furthermore, management is easy, each inspector can watch 200-400 parking spaces, and the alarm system makes the whole system easy to maintain.

Owner:BEIJING ZHONGRONG JIAXIN TECH

Method for preparing polyester thermosol

The invention discloses a preparation method of polyester hot melt adhesive, comprising the steps that: (1) A phthalic acid and a dihydric alcohol are mixed and beaten; next an esterification reactor is put into the beaten mixture continuously; a prepolymer of phthalic acid and a dihydric alcohol as well as titanium KEYI tin are added in the esterification reactor in advance; the reaction temperature is between 160 DEG C and 205 DEG C; at the same time, the water generated from the reaction process is discharged, then an esterification process is carried out for the first time; (2) An isophthalic acid, an aliphatic dicarboxylic acid and a diol are mixed and beaten again, next, the beaten mixture is put into an esterification reactor continuously, the reaction temperature is between 185 DEG C and 225 DEG C, then, the esterification process is carried out for the second time, meanwhile, the water generated from reaction process is discharged; after that, a polycondensation catalyst and other auxiliary are added in the esterification reactor for decompression and polycondensation at the temperature between 220 DEG C and 250 DEG C for 0.5 to 1.5 hours ,thereby the thepolyester hot melt adhesive product is obtained. The producing of by-product methanol is avoided and the cost of production is lowered by using the method. By adopting the continuous feeding method of sterification, the stability products are ensured and the discharging of waste water is decreased.

Owner:南通天洋光伏材料科技有限公司

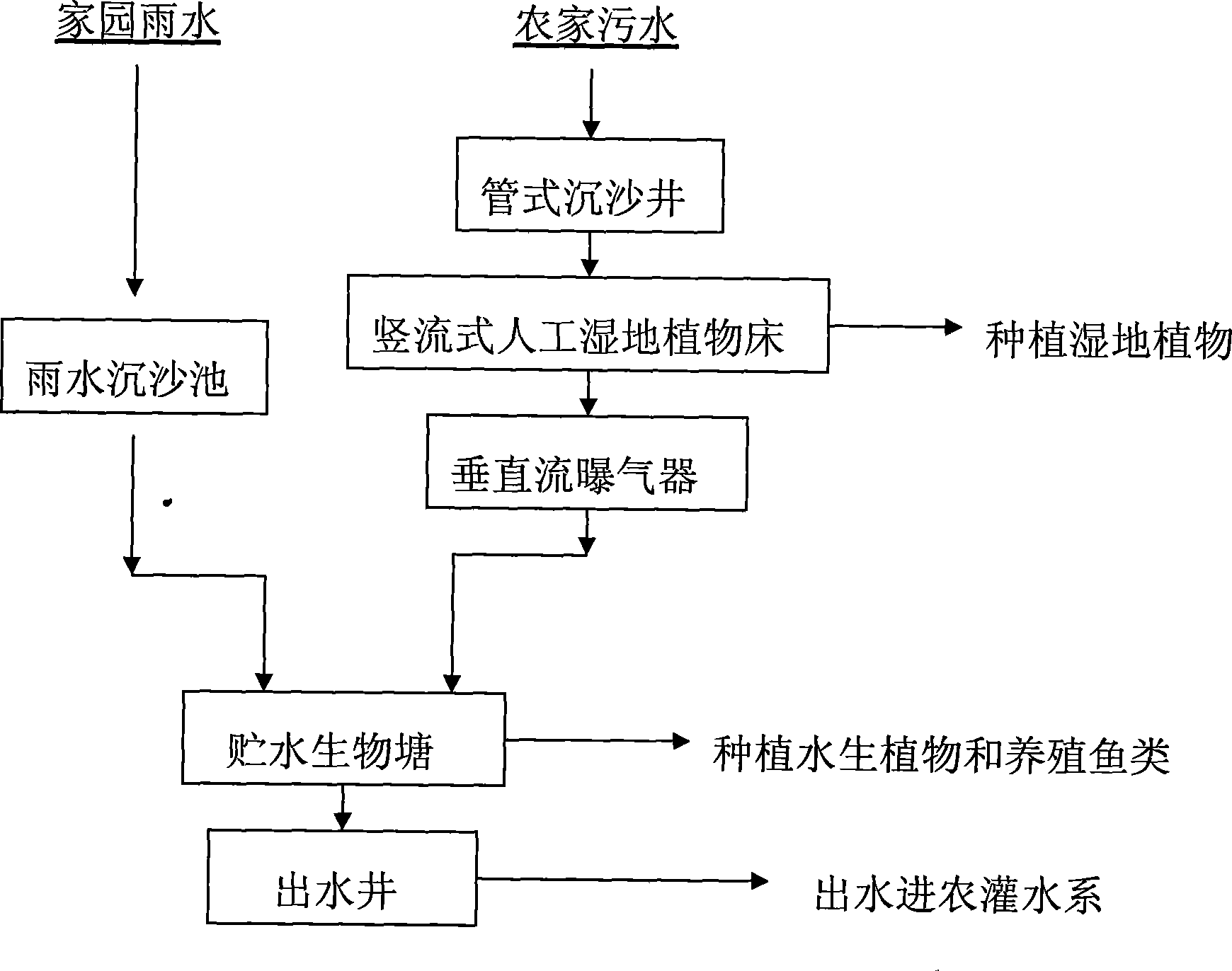

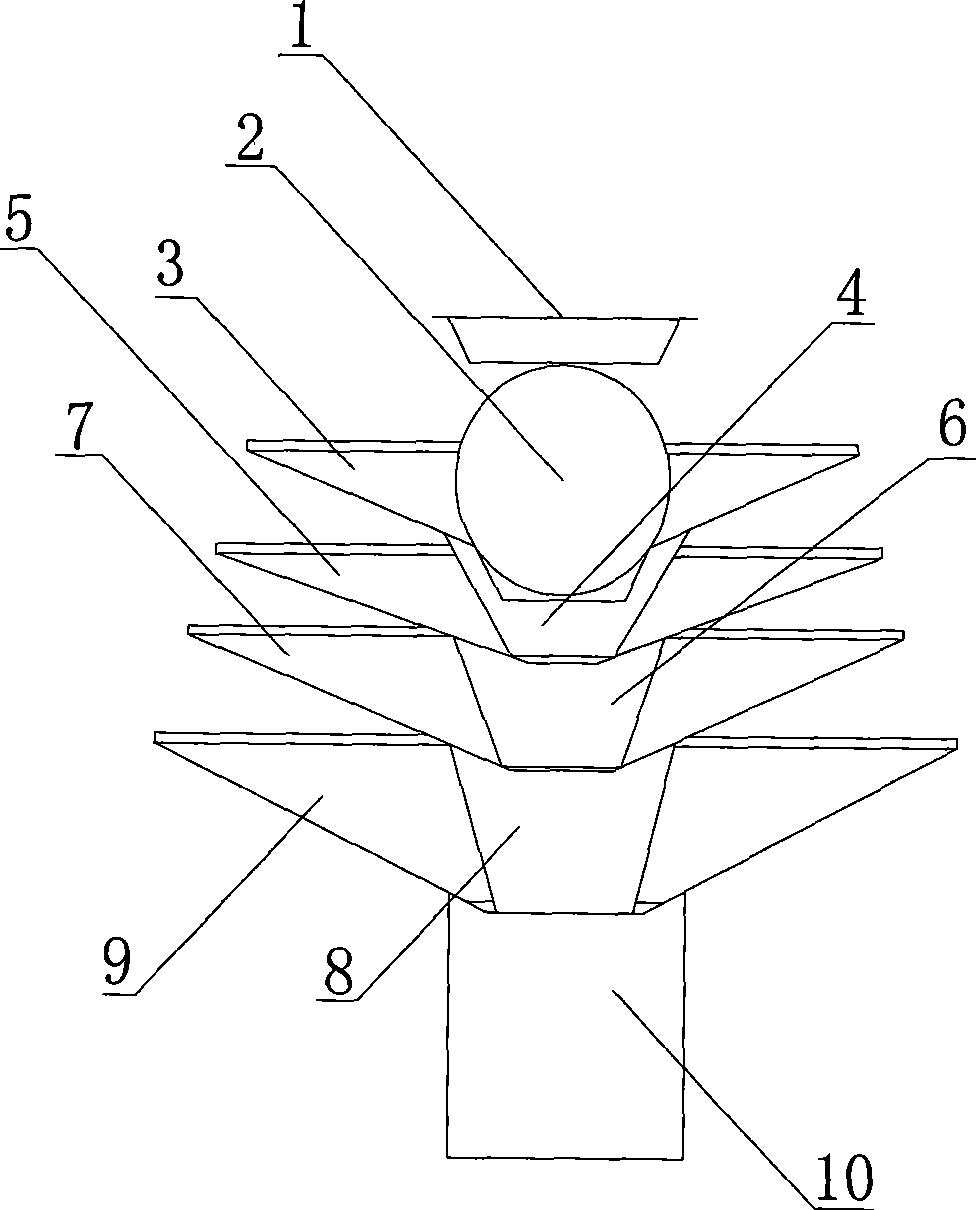

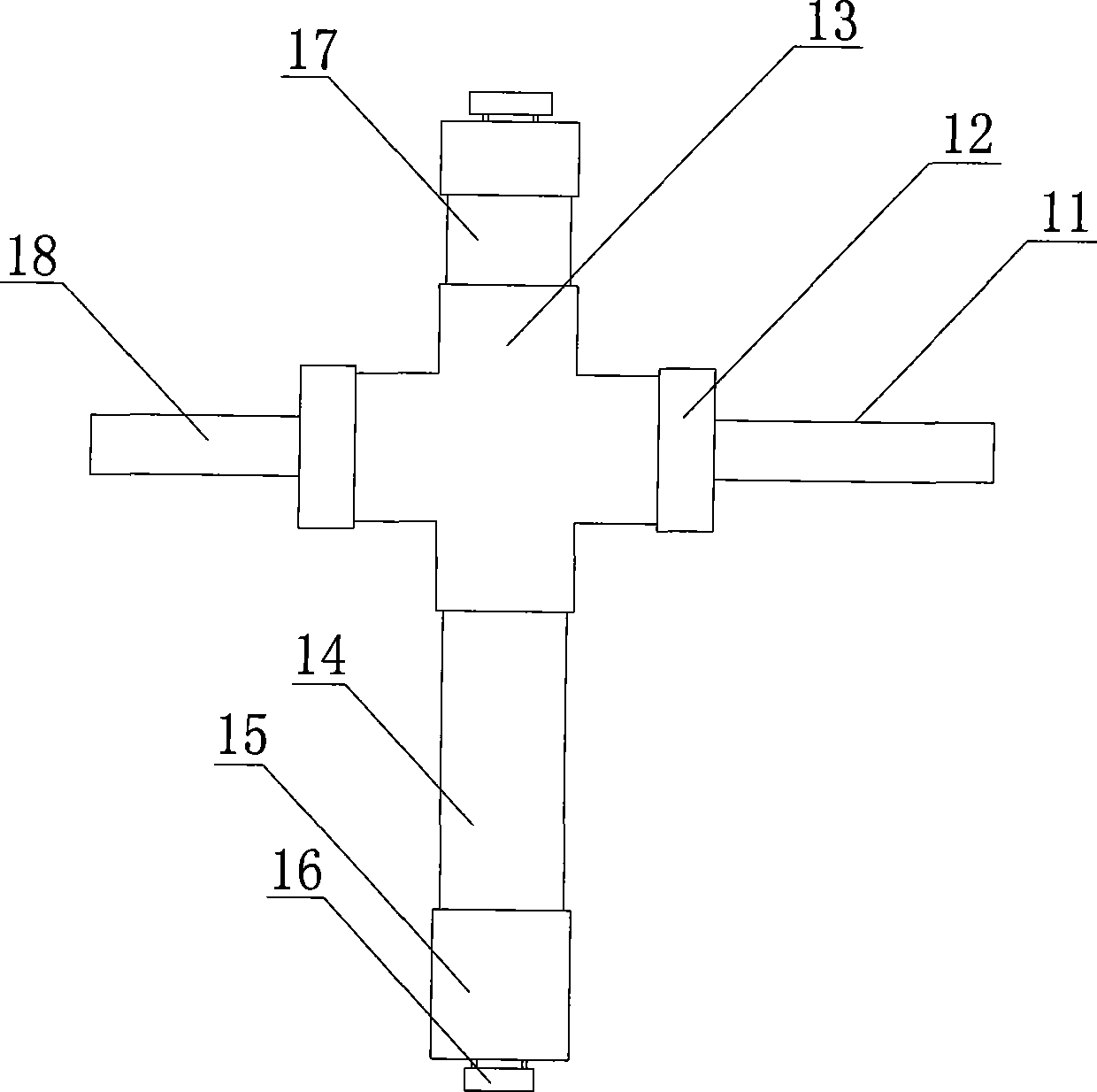

Constructed wetland processing and comprehensive utilization technique for farm household sewage water and rainwater

InactiveCN101503265AGood for the environmentPromote environmental protectionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentElectric energyDitch

The invention relates to a farmholding sewage and rainwater mutual wetland treatment and comprehensive utilization process, which comprises the following steps: collecting farmholding sewage through a drainage pipeline network; transporting the farmholding sewage to a tubular type sand sediment trap; enabling the sewage after being treated by the sand sediment trap to automatically flow into a vertical flow type mutual wetland plant bed; enabling the sweater after being purified by the mutual wetland plant bed and treated by a vertical self-flowing aerator to flow into a water storage biological pond; enabling rainwater collected from house roofs, terraces, water ditches and the like after being subjected to sand settlement treatment by a rainwater sand settling basin to flow into the water storage biological pond; and comprehensively utilizing plants generated by the water storage biological pond, the water storage in the water storage biological pond, the mutual wetland plant bed and the water storage biological pond. In the invention, the farmholding sewage treatment and the rainwater treatment are firstly combined to be stored and recovered; the advanced tubular sand settling basin, the vertical flow type mutual wetland plant bed and the vertical self-flow aerator and the water storage biological pond are applied and combined scientifically, so as to achieve the water purifying requirements; and no electric energy and other resource is consumed during the whole process.

Owner:成都城市河流研究会

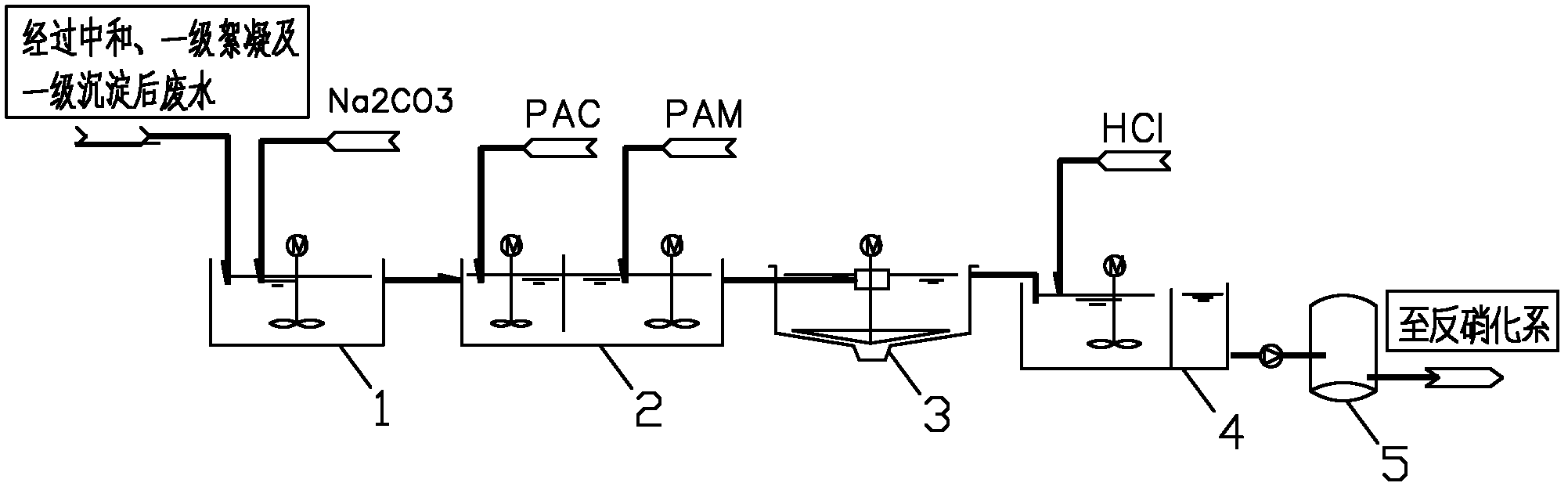

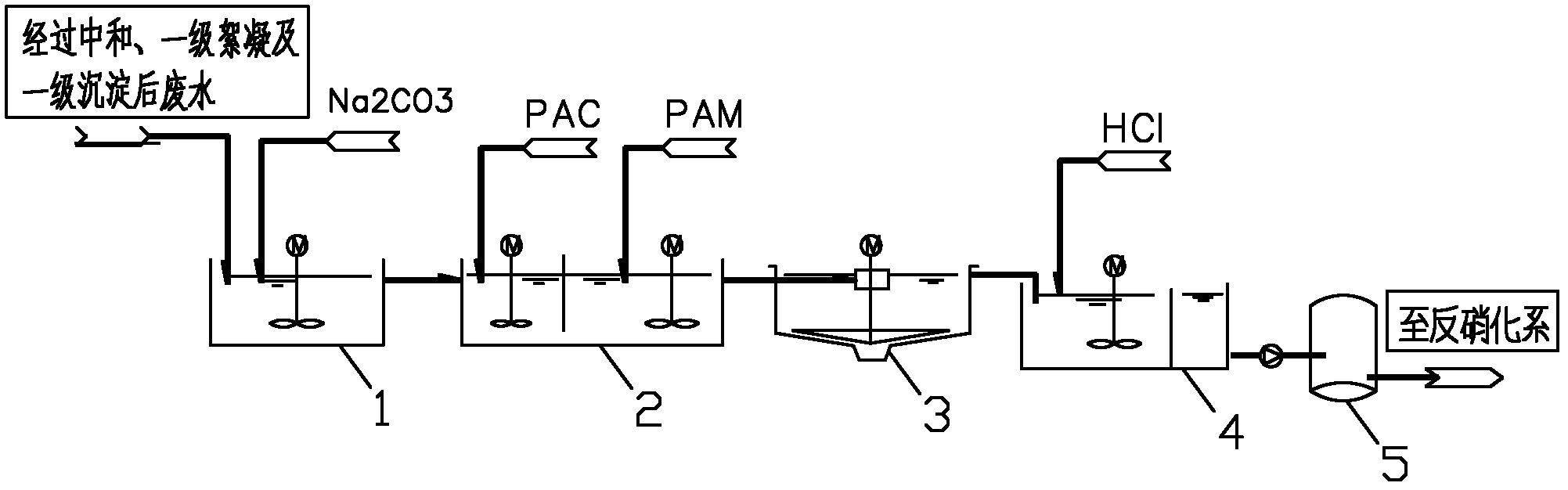

Anti-scaling treatment method for stainless steel acid waste water subsequent treatment

ActiveCN102351348AGood for the environmentReduce manual labor intensityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSand filterEnvironmental chemistry

The invention relates to an anti-scaling treatment method for stainless steel acid waste water subsequent treatment. The method comprises the following steps: (1) residual Ca<2+> in acid waste water which is subjected to lime neutralization, flocculation and precipitation is formed into precipitate of Ca<2+>; (2) flocculation is carried out, wherein the precipitate of Ca<2+> and other sludge formlarge alumen ustum; (3) precipitation is carried out; (4) pH value is regulated, wherein precipitated effluent flows into a final pH regulating pondage, the pH of water quality in the final pH regulating pondage is between 6 and 7 by adding hydrochloric acid; (5) filter is carried out, wherein after the performed steps, the Ca<2+> content in the water in the final pH regulating pondage is less than 150mg / l, SS content is 20mg / l, the effluent can meet the requirement of denitrification and subsequent treatment by utilizing filter of a sand filter, and the effluent is delivered to a denitrification facility for treatment. According to the method, the problems causing scaling and blockage of denitrification system pump and pipeline can be solved, so that the production and environmental-friendliness are facilitated, and the labor intensity of workers is reduced.

Owner:中国冶金科工股份有限公司

Method for recycling sulfur dioxide and butadiene

ActiveCN102407025ASave resourcesGood for the environmentSulfur compoundsVapor condensationChemistrySulfur dioxide

The invention discloses a method for recycling sulfur dioxide and butadiene, relates to a method for recycling the mixed gas of sulfur dioxide and butadiene generated in the process of producing 3-sulfolane, and is mainly used for solving the problem that the sulfur dioxide and butadiene are directly discharged during the production of 3-sulfolane. The method comprises the following steps of: filling a stirred tank for removing sulfur dioxide in the 3-sulfolane with nitrogen, wherein the pressure of nitrogen is 0.05MPa; discharging the 3-sulfolane, sulfur dioxide and butadiene liquid into the stirred tank for removing sulfur dioxide in the 3-sulfolane; introducing the mixed gas of the precipitated sulfur dioxide and butadiene into a compressor through a polymerization inhibitor tank for pressurizing; introducing the mixed gas into a condenser after pressurization for temperature reduction, then introducing the mixed gas into a sulfur dioxide and butadiene recycling and storage tank to be used as the production raw materials; introducing the mixed gas into the stirred tank for removing sulfur dioxide in the 3-sulfolane, the polymerization inhibitor tank, the compressor and the sulfur dioxide and butadiene recycling and storage tank by a pressure retaining valve; and finishing the process when the content of sulfur dioxide in the purge gas is less than 2000ppm. The method has the advantage of being environmentally-friendly.

Owner:GUANGHUA CHEM YINGKOU

Reformed pre-hydrogenation catalyst and preparation method thereof

ActiveCN103143367ALow costGood for the environmentMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsNickel saltActive component

The invention discloses a reformed pre-hydrogenation catalyst which comprises the following components: 2-9wt% of NiO, 1-7wt% of CoO, 15-40wt% of WO3 active component, 40-60wt% of an alumina carrier and 3-10wt% of amorphous FeOOH assistant. The preparation method of the reformed pre-hydrogenation catalyst comprises the steps of: (1) dry-mixing aluminum oxide or an aluminum oxide lead compound with an amorphous FeOOH or regenerated amorphous FeOOH waste desulfurizing agent, subsequently adding into a binder to be kneaded and shaped, and further being dried to obtain the carrier; and (2) adding water into a soluble nickel salt, a soluble cobalt salt and a soluble tungsten salt and mixing up so as to obtain a Ni-Co-W steeping liquid, steeping the carrier into the Ni-Co-W steeping liquid and drying so as to obtain the reformed pre-hydrogenation catalyst. The amorphous FeOOH in the hydrogenation catalyst can adjust and control an active metal into an amorphous structure, so that the absorption of the active metal to a reactant is improved, and furthermore the activity of the catalyst is improved.

Owner:SHENYANG SANJUKAITE CATALYST

Method for preparing novel straw stalk fiber boards

InactiveCN101856834AProtected forest areaGood for the environmentDomestic articlesFlat articlesWork in processMagnesium

The invention relates to a method for preparing novel straw stalk fiber boards. The straw stalk fiber board is prepared from the following components in percentage by weight: 46 to 54 percent of straw stalk powder, 10 to 13 percent of maize straw powder, 5 to 10 percent of talcpowder, 25 to 35 percent of magnesium oxide, 0.2 to 0.6 percent of additive (1) and 0.4 to 0.8 percent of additive (2). The method comprises the following steps of: crushing and pulverizing organic fiber materials such as the straw stalks and the like; stirring and uniformly mixing the organic fiber powder, the maize straw powder, the talcpowder and the magnesium oxide; adding the additive (1) and the additive (2) into the organic fiber powder, the maize straw powder, the talcpowder and the magnesium oxide, adding water into the mixture, and uniformly stirring and mixing the mixture; loading the mixed materials into a mold under the conditions of mediate temperature and humidifying temperature, cold pressing and molding the materials, and removing a mold; trimming the demolded semi-finished products as required in product specification; and loading the demolded and trimmed semi-finished products into a pressure maintaining and curing mold for curing, and warehousing finished products.

Owner:王海燕

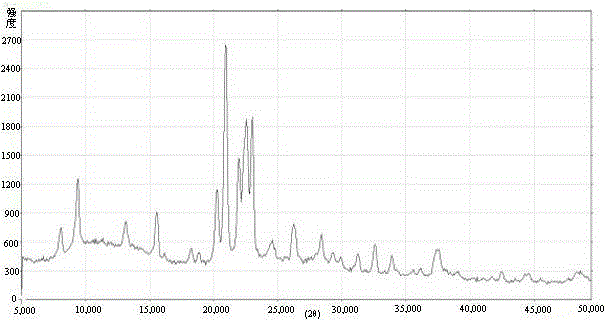

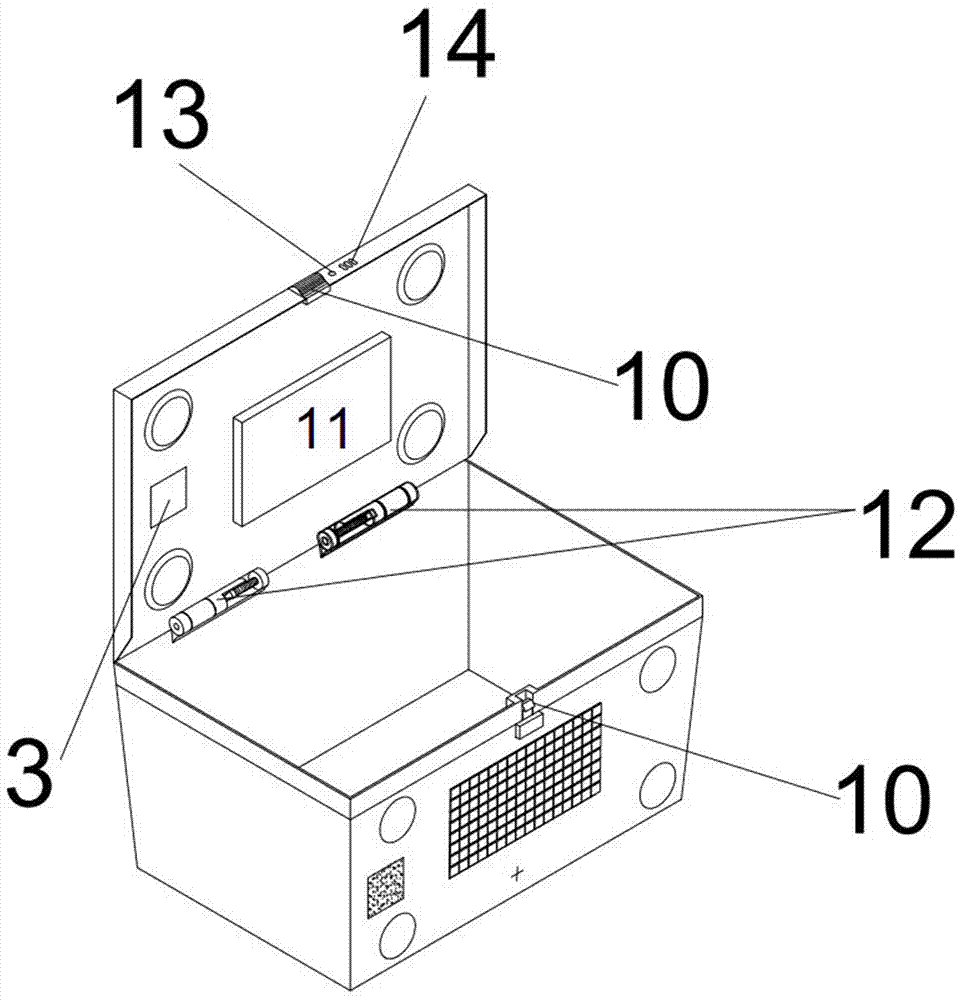

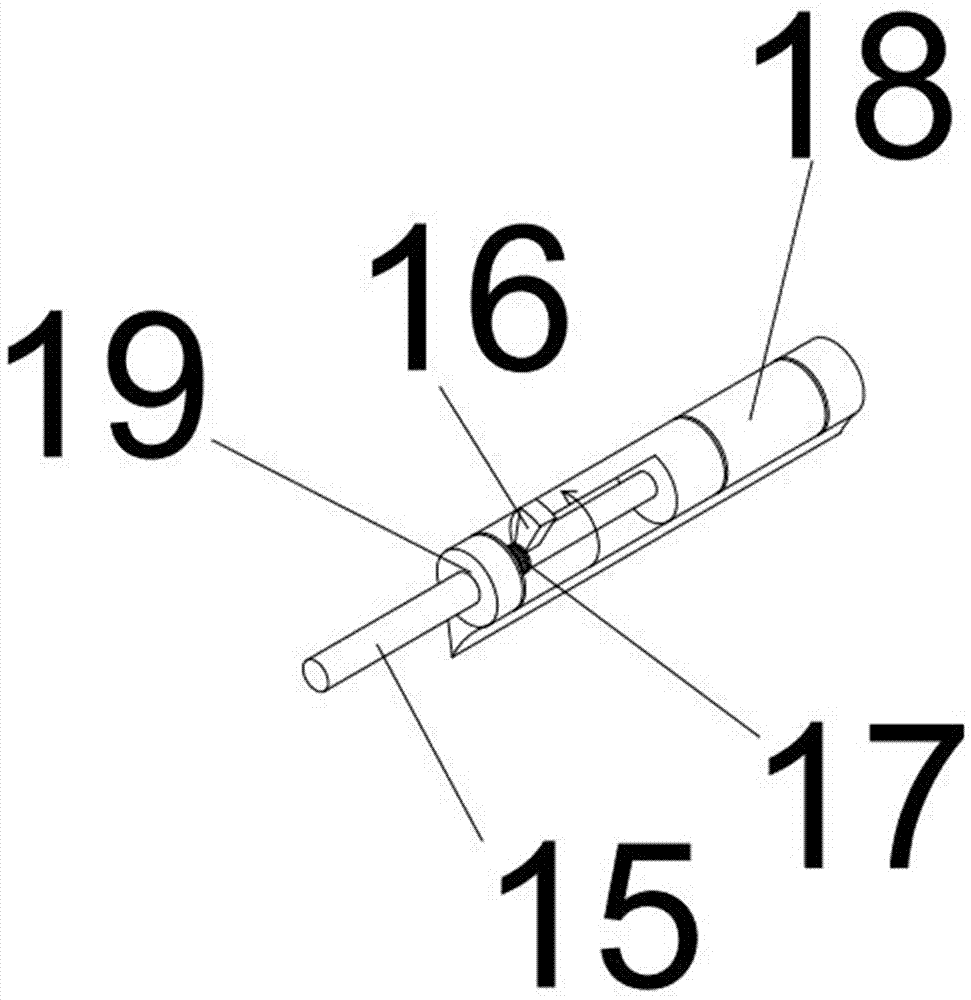

Cyclic utilization intelligent parcel box

PendingCN107380671ASave material and material expenditureGood for the environmentApparatus for meter-controlled dispensingNon-removalbe lids/coversEmbedded systemSmart lock

The invention provides a cyclic utilization intelligent parcel box. The cyclic utilization intelligent parcel box comprises a box cover, a box body, an intelligent lock, a controller, a parcel information screen and an identification tag. The identification tag is used for recording a unique identity recognition code of a parcel box. The intelligent lock is arranged at the box cover and used for controlling opening and closing of the box cover. The controller comprises a control module, a communication interface module, a storage unit and a storage battery. The controller is connected with the intelligent lock and the parcel information screen. The parcel information screen is a low-energy-consumption screen arranged on the cover surface of the box cover. The identification tag is a tag capable of being identified by a mobile device. When the parcel box is in use, the control module acquires delivery information and the sending state of the parcel box from an external management platform through the communication interface module, displays related logistics information through the parcel information screen and enables the intelligent lock to be in an unlocking state when determining a consignee accepts goods after the consignee reads the identification tag of the parcel box through the mobile device. The cyclic utilization intelligent parcel box can be cyclically utilized for logistics and express.

Owner:庄秀宝

Preparation method of flame-retardant magnesium alloy

The invention discloses a preparation method of a flame-retardant magnesium alloy and relates to a magnesium alloy with aluminum as a minor main component. The method comprises the steps of weighing a magnesium ingot, an aluminum ingot, an Mg-Ca master alloy with the calcium content of 20 wt percent and an Mg-Y master alloy with the yttrium content of 25 wt percent as raw materials for feed preparation according to the mass percentage of component elements in the target magnesium alloy, wherein the target magnesium alloy comprises component elements in percentage by weight: 90.7-92.7 percent of Mg, 6.0 percent of Al, 0.3 percent of Mn, 0.5-1.5 percent of Ca and 0.5-1.5 percent of Y, the purity of a magnesium ingot is 99.99 percent, the purity of an aluminum ingot is 99.99 percent, and the purity of a manganese sheet is 99.99 percent; and putting all the raw materials in a gas protection melting furnace, carrying out smelting on the raw materials, then adding a refining agent into the gas protection melting furnace, carrying out refining, pouring the refined raw materials into a cast iron die finally, and carrying out air cooling until room temperature is reached to prepare a flame-retardant magnesium alloy cast ingot of Mg-Al-Mn-Ca-Y. With the adoption of the preparation method, the disadvantages of the flame-retardant magnesium alloy in the prior art that the raw material cost is high, and components contain toxic substances are overcome.

Owner:HEBEI UNIV OF TECH

Micro organism rapid dried sludge dewatered sludge technological process and treatment product

InactiveCN101357816AImprove processing efficiencyGood for the environmentBiological sludge treatmentMicrobial agentRice straw

The invention relates to a microorganism fast drying technology method for sludge and treatment products, and the technology method is as follows: the sludge (treated materials) is sequentially added with microbial agents, fiber, shell powder and rice straws and the products after the treatment to be fully mixed, the obtained mixture is put into a strip-shaped treatment tank to be stirred, with air and materials to be discharged(the proportion of added materials is weight percentage), finally biological fuels (treatment products) are generated. The microorganism fast drying technology method for the sludge and the treatment products according to claim 1 are characterized in that: the generated treatment products can be used as the biological fuels by using the microorganism fast drying technology method for treating the sludge and organic garbage. The microorganism fast drying technology method for the sludge is used for treating the sludge and the similar organic garbage which are generated in a sewage treatment plant, thereby improving the treatment efficiency of the sludge, being beneficial to the environmental protection and allowing the treatment products to have new purpose.

Owner:高军

Method for preparing magnesium hydroxide utilizing light-burned dolomite powder

InactiveCN102259898ASave resourcesGood for the environmentMagnesium hydroxideMagnesium carbonate hydroxideEmulsion

The invention discloses a method for preparing magnesium hydroxide utilizing light-burned dolomite powder. The method comprises the following steps: adding the light-burned dolomite powder to enough water for digestion; introducing a carbon dioxide gas to obtained light-burned dolomite emulsion until the pH value of the reaction product is 6.7-7.0, and filtering the product; adding absolute ethanol to filtrate, heating and controlling the temperature to 50-80 DEG C, and after reaction, filtering, wherein the amount of absolute ethanol is controlled to be 30-40% of the volume of the filtrate; adding hydrochloric acid to obtained solid magnesium bicarbonate until bubbles disappear; adding a base liquid to an obtained magnesium chloride solution; and adding polyvinylpyrrolidone or ethylenediamine to obtained magnesium hydroxide slurry, wherein the amount of polyvinylpyrrolidone or ethylenediamine is equal to 2-6% the volume of the slurry; and then adding the slurry into an autoclave, controlling the temperature at 80-200 DEG C and stirring under constant temperature condition for 10-20 hours. Magnesium hydroxide precipitate prepared by the method disclosed by the invention is in a fibrous or flaky crystal shape and has high purity; and the preparation method is simple to operate, and the reaction conditions are mild and easy to control.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

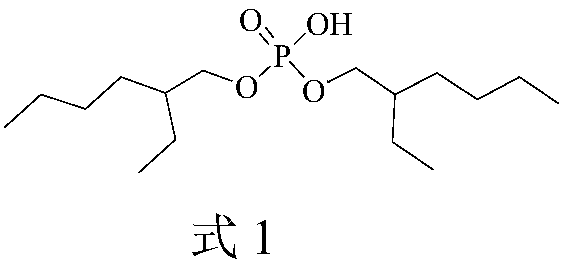

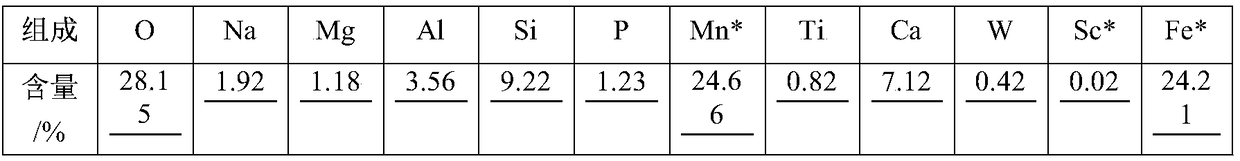

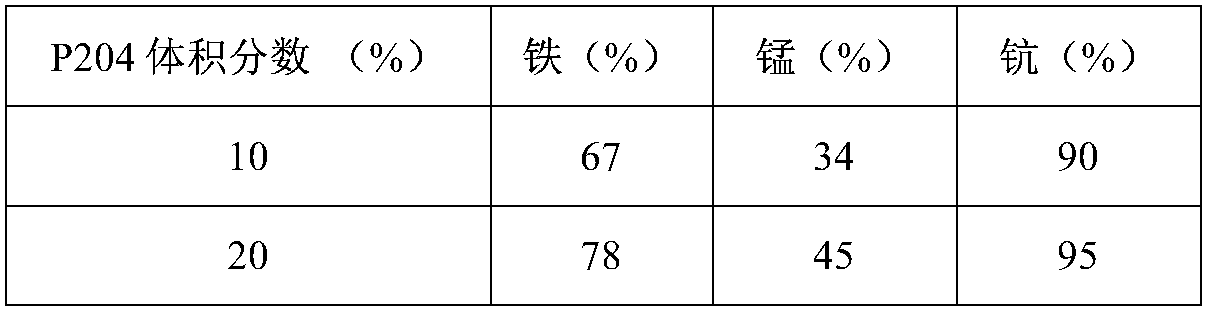

Method for separating and recovering valuable metal iron, manganese and scandium from tungsten slag

ActiveCN109022810AGood for the environmentImprove leaching efficiencyProcess efficiency improvementSlagKerosene

The invention discloses a method for separating and recovering valuable metal iron, manganese and scandium from tungsten slag. The method includes the steps that the tungsten slag is leached with sulfuric acid; valuable metals such as the iron, the manganese and the scandium exist in a leaching solution as Fe<3+>, Mn<2+> and Sc<3+> correspondingly; the Fe<3+>, the Mn<2+> and the Sc<3+> are simultaneously extracted by a P204+ sulfonated kerosene organic phase, the extraction rates are 97%, 95% and 99% correspondingly, and then the manganese, the iron and the scandium in a loaded organic phase are separated and recovered by selective reverse extraction in sequence by using different reverse extraction agents. According to the method, the process is simple, the recovery rate of the valuable metals is high, and the defects such as big acid mist and bad environment in the process of hydrochloric acid leaching are overcome.

Owner:肇庆市珈旺环境技术研究院

Process for producing polyester geotextile with raw material of PET bottle flakes

InactiveCN101724980ALow costGood for the environmentMelt spinning methodsNon-woven fabricsGeotextileBuilding material

The invention relates to a process for producing polyester geotextile with the raw material of PET bottle flakes, belonging to the process for producing the building material. The process for producing the polyester geotextile with the raw material of PET bottle flakes comprises the following steps: drying the recovered PET bottle flakes; tackifing the PET bottle flakes with oligomer; granulating the PET bottle flakes into PET bottle flake granules; screening the PET bottle flake granules; crystallizing and drying the PET bottle flake granules screened out; melting, extruding and spinning the PET bottle flake granules; cooling and stretching the spun filament; swaying and lapping the spun filament; embroidering the spun filament with a needle and strengthening the embroidery; and rolling the embroidery. The invention solves the problems of the high production cost of the product of polyester geotextile and has the advantages of low production cost and obvious social benefit.

Owner:梁本树

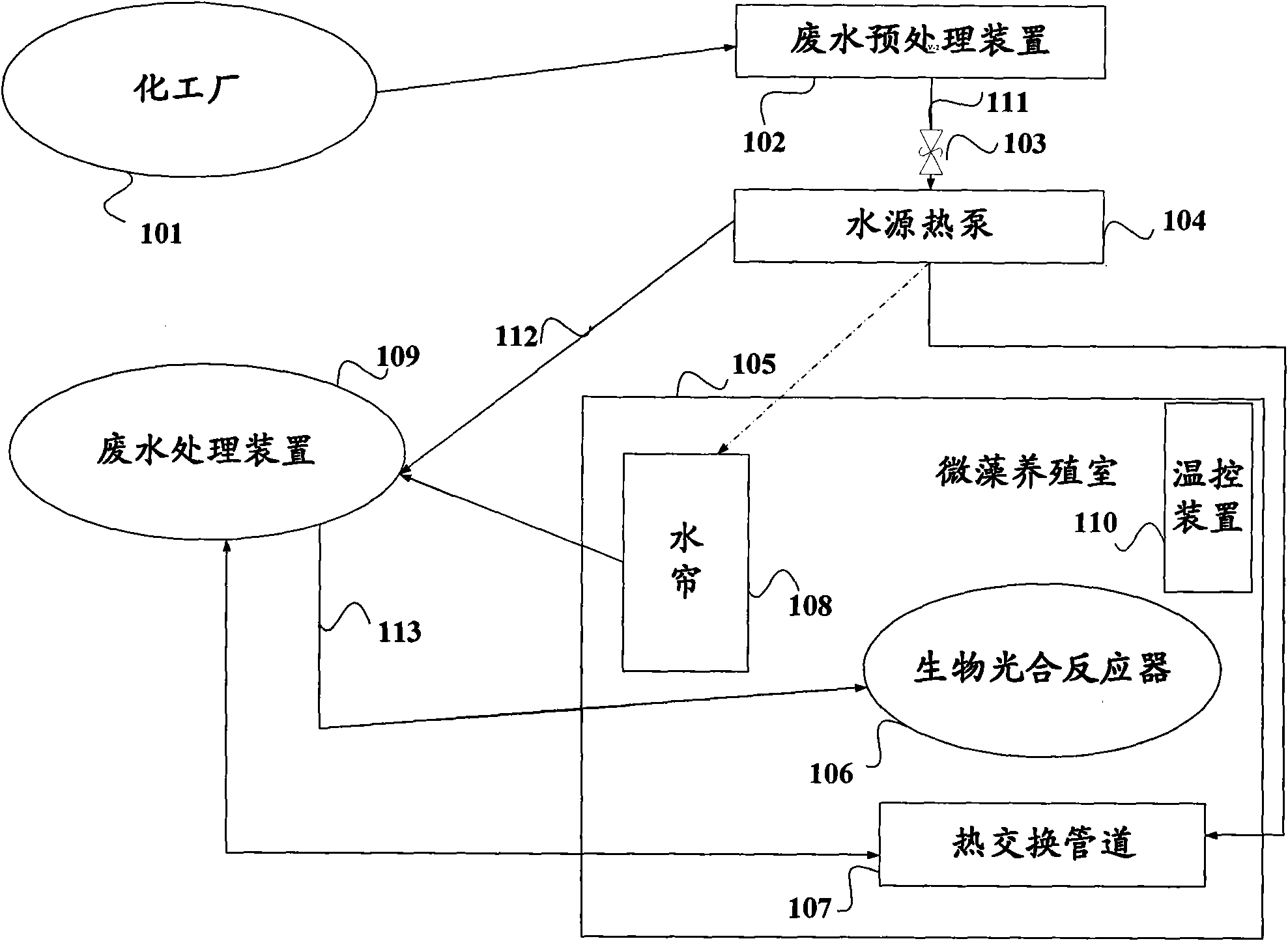

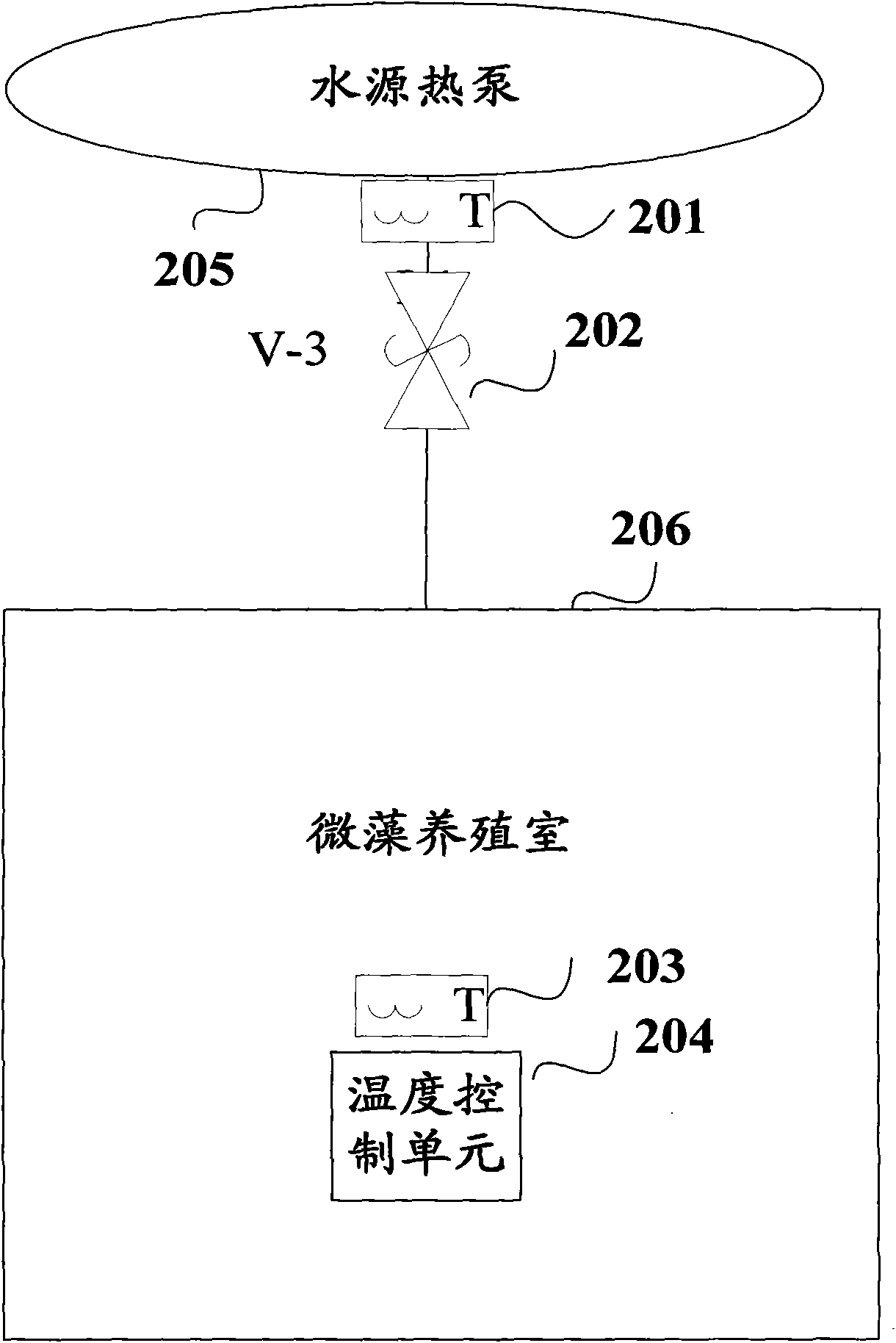

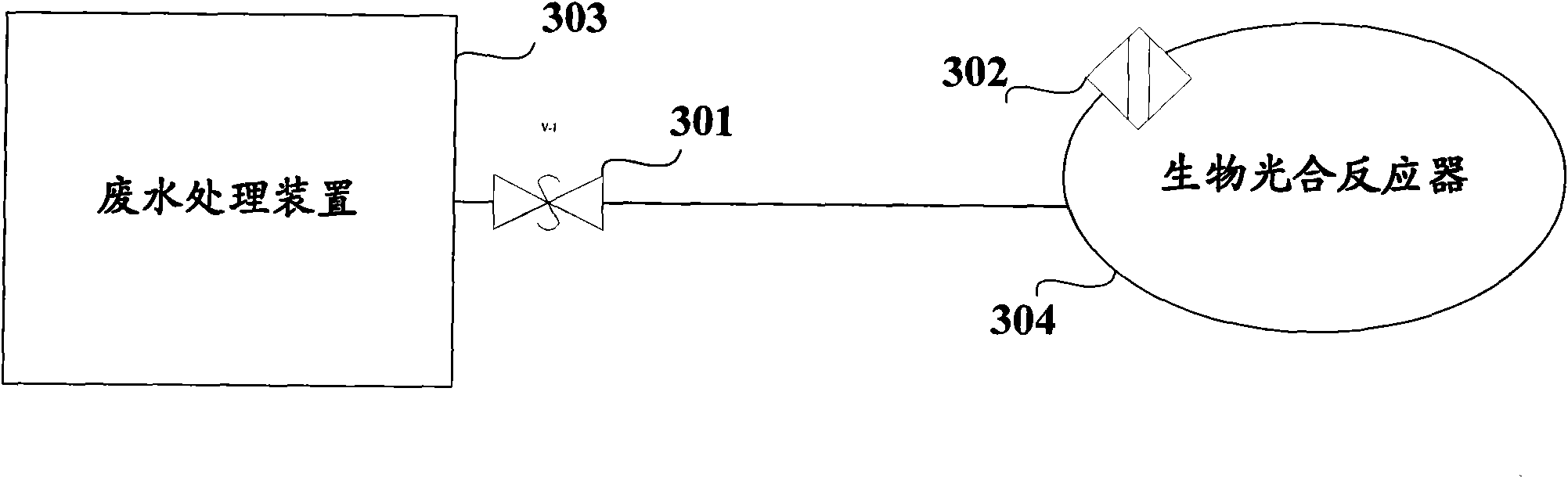

System for cultivating microalgae with waste water

ActiveCN101643699AGood for the environmentSave water and energyBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorThermal energy

The invention discloses a system for cultivating microalgae with waste water, comprising a water source heat pump, a temperature control device, a heat exchange pipeline, and a waste water treatment device, wherein the water source heat pump is used for obtaining heat energy from the input waste water and storing, and the heat energy from the input waste water is used for heating or refrigeratingthe input water; the temperature control device is used for detecting environment temperature of a microalgae cultivation room and effluent water temperature; the heat exchange pipeline is used for accepting the water output by the water source heat pump and carrying out heat exchange with the microalgae cultivation room; and the waste water treatment device is used for carrying out further treatment on the waste water flowing out of the water source heat pump, the heat exchange pipeline and / or a water curtain and inputting to each photobioreactor. The invention realizes utilizing waste waterto control the proper temperature range of microalgae cultivation and inputting to each photobioreactor, and utilizing waste water to provide culture solution for microalgae cultivation.

Owner:ENN SCI & TECH DEV

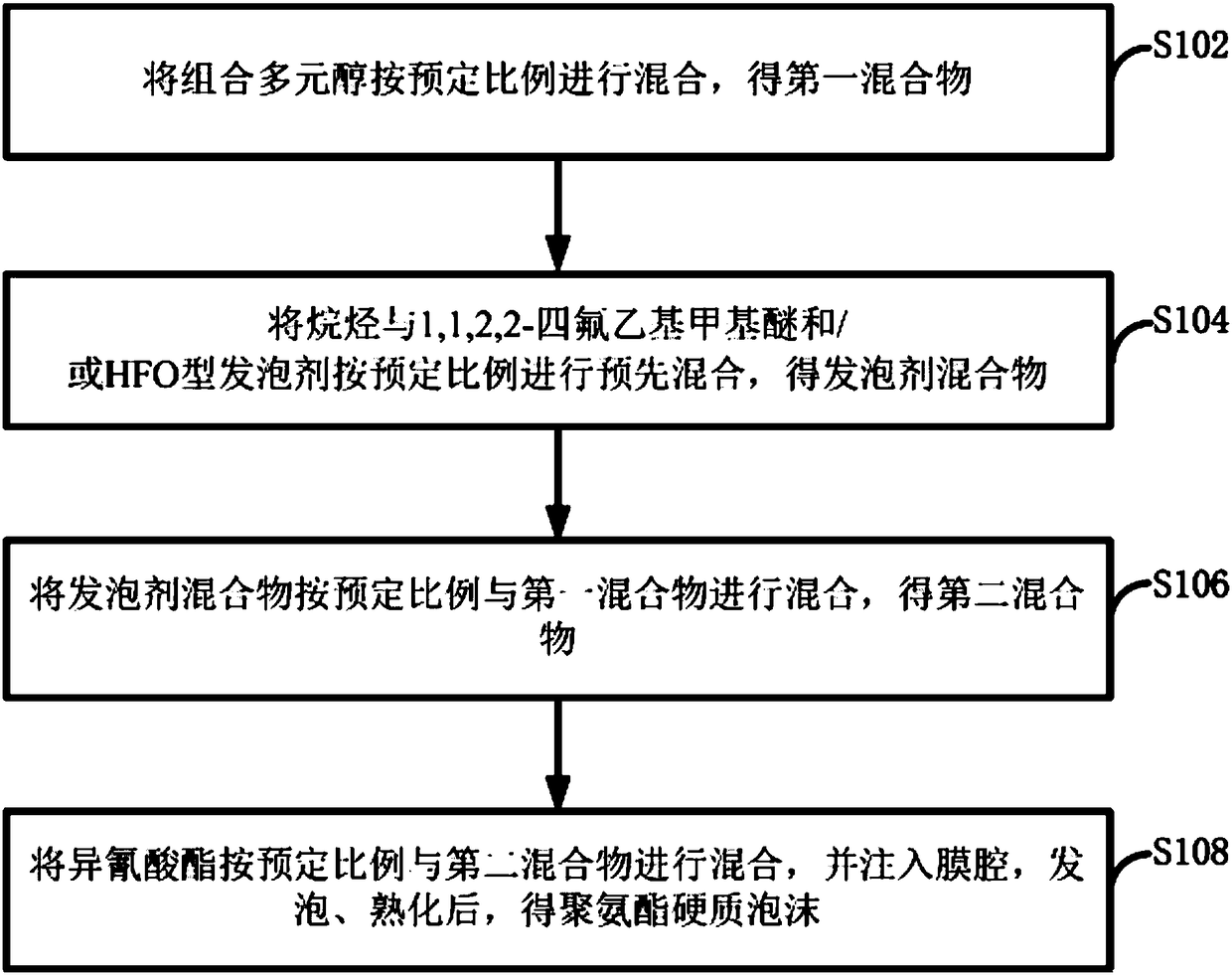

Rigid polyurethane foam plastic and preparation method thereof

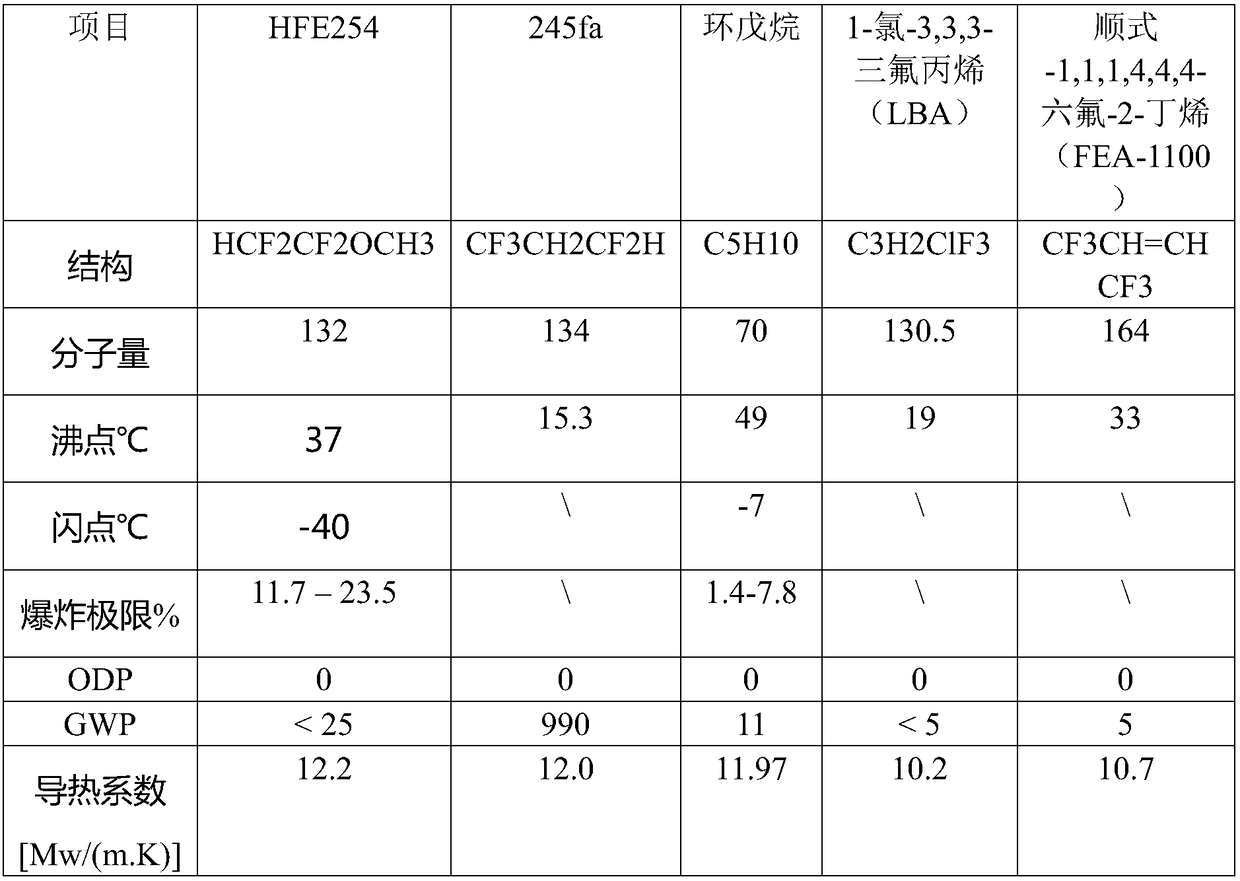

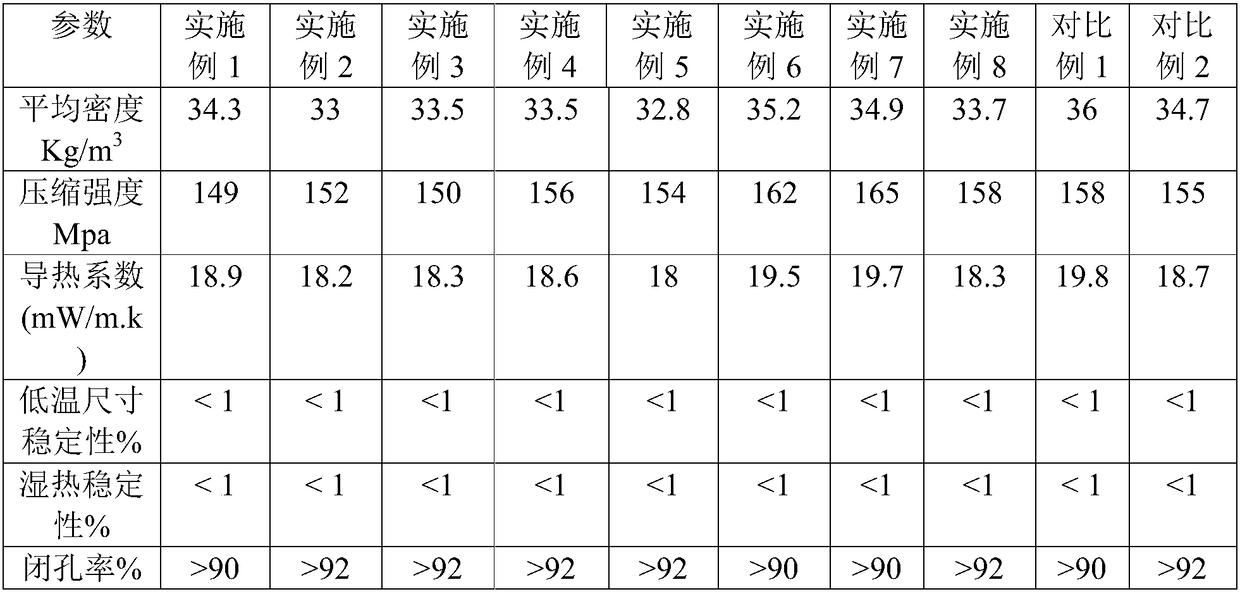

The invention provides rigid polyurethane foam plastic and a preparation method thereof. The rigid foam plastic is prepared from the following components in parts by mass: 100 parts of combined polyol, 10-30 parts of a foaming agent composition and 120-150 parts of isocyanate, wherein the foaming agent composition comprises 10-30 parts of alkane, 10-30 parts of 1, 1, 2, 2-tetrafluoroethylmethyl ether and / or 1-10 parts of a hydrofluoroolefin foaming agent; the alkane comprises one or two of cyclopentane and isopentane; the hydrofluoroolefin foaming agent comprises one or two of 1-chloro-3,3,3-trifluoropropene and cis-1, 1, 1, 4, 4, 4-hexafluoro-2-butene. According to the invention, the more environment-friendly rigid foam plastic is provided, and the overall performance of the rigid polyurethane foam plastic is improved.

Owner:HAIER SMART HOME CO LTD

Silicon fertilizer and production method thereof

The invention relates to a silicon fertilizer and a production method thereof, belonging to the field of plant fertilizers and production methods thereof. The silicon fertilizer contains the followingmaterials in parts by weight: 39.4 parts of bentonite, 30.3 parts of pulverized coal ash, 30 parts of sodium hydroxide liquid caustic soda containing 30 percent of alkali, 0.25 part of catalyst magnesium oxide and 0.05 part of aluminium oxide. The production method of the silicon fertilizer comprises the following steps: processing the pulverized coal ash by an all-powerful pulverizer; putting 50parts of the processed pulverized coal ash, 49.5 parts of sodium hydroxide solutions containing 30 percent of the alkali, 0.416 part of the magnesium oxide and 0.084 part of the aluminium oxide intoa double-helix conical mixer to form soluble silicon fertilizer materials; placing the silicon fertilizer materials into a cement material pool; then putting 60.6 parts of the silicon fertilizer materials and 39.4 parts of the bentonite into a double-shaft horizontal type mixer for mixing, and then putting the mixture into a granulating disc; putting the dried silicon fertilizer into a cooler to enter a sieving machine for being sieved; and circularly producing the silicon fertilizer. The silicon fertilizer enhances the air permeability of soil, regulates the pH value of the soil, plays a soilimprovement role and is suitable for the fertilization of various crops.

Owner:FUXIN WOTIAN FERTILIZER IND

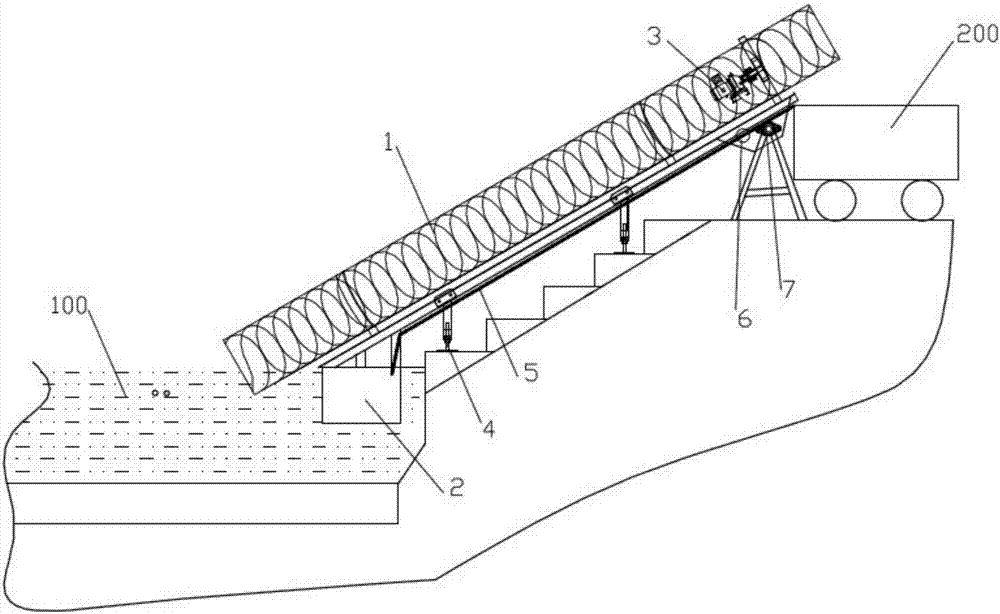

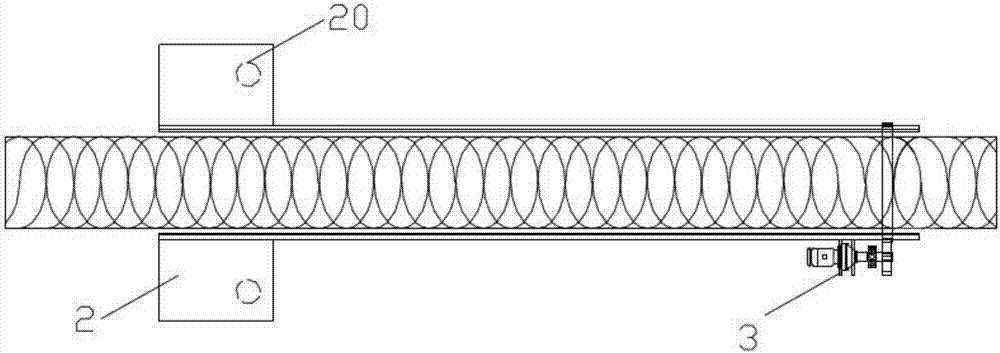

Equipment for recycling solid garbage in water

The invention discloses equipment for recycling solid garbage in water. The equipment comprises a salvaging conveying barrel, a buoyancy adjusting system and a power system. The salvaging conveying barrel is a cylindrical barrel, and a spiral inner blade is arranged in the barrel. The buoyancy adjusting system comprises a buoyancy box, an adjusting support and an automatic air compressor. The buoyancy box is arranged at the bottom of the salvaging conveying barrel and is sealed box, and bottom holes are formed in the bottom of the box and are used for water inflow and water outflow. The power system is used for providing rotation power for the salvaging conveying barrel and comprises a power input engine, a speed reducer and a transmission gear, and a driven gear is arranged on the salvaging conveying barrel so as to be engaged with the transmission gear of the power system. Compared with the prior art, the equipment capable of completely achieving automatic and integrated salvaging is provided, and solid garage in water and above the water surface is automatically and integrally salvaged. Meanwhile, high efficiency and environment friendliness are achieved, the water quality cannot be polluted, and environment friendliness is facilitated.

Owner:刘海飞

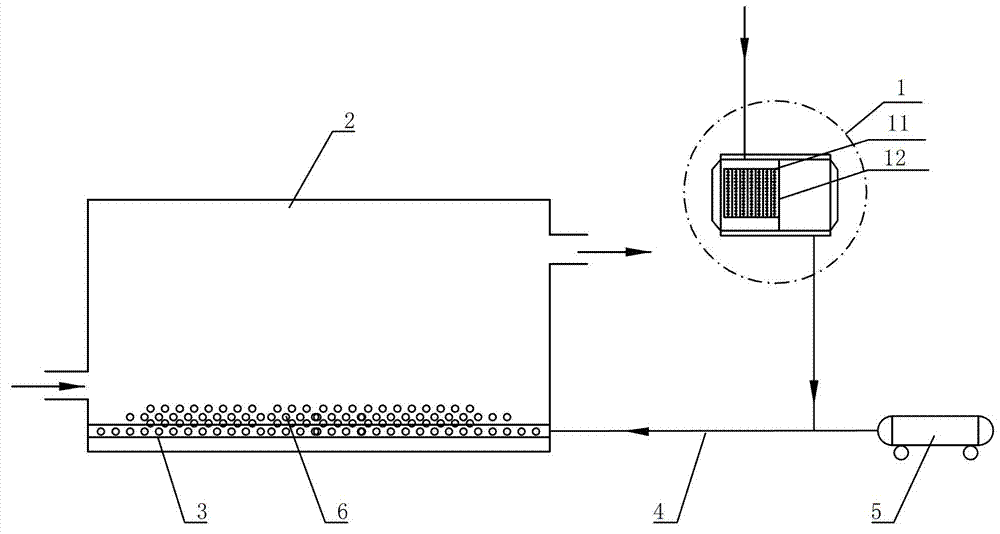

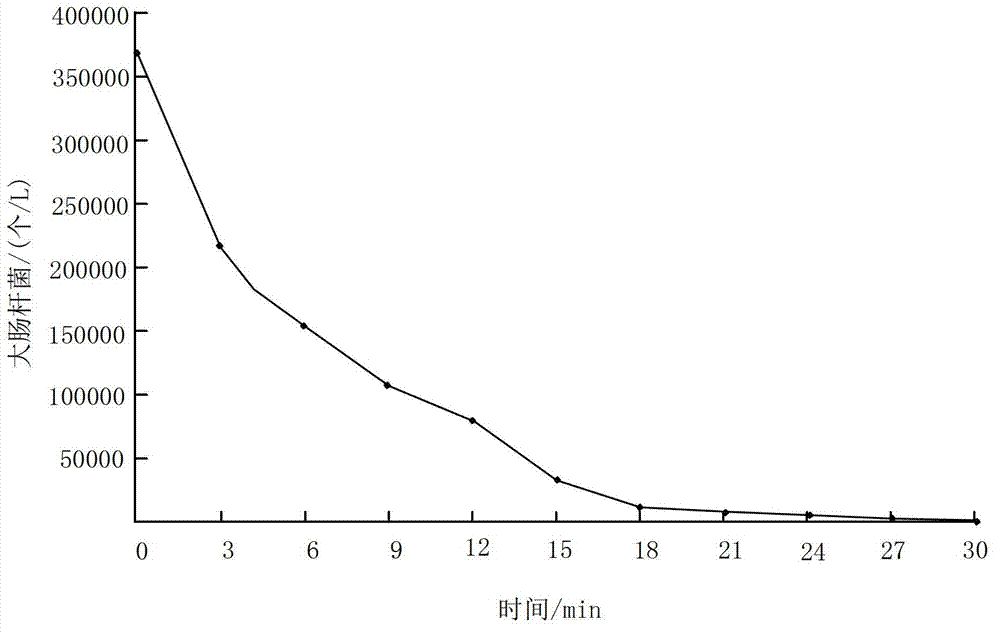

Method for sterilizing and disinfecting sewage by injecting plasma free radicals and device

InactiveCN102765787AReduce energy consumptionGood for the environmentWater/sewage treatment using germicide/oligodynamic-processPollutantImpact ionization

The invention relates to the field of water treatment, in particular to a method for sterilizing and disinfecting sewage by injecting plasma free radicals. Oxygen-containing gas reacts in a plasma generator so as to produce the plasma free radicals, the plasma free radicals are conveyed to bubbling devices in a disinfection container by a conveying device, sewage is fed by the bubbling devices, and then the sewage in the disinfection container is disinfected and sterilized. The invention also relates to a device for treating the sewage by the method. According to the device and the method, the oxygen-containing gas is subjected to dissociation and collision ionization in the plasma generator so as to form the active substances of the plasma free radicals, and the gas containing the active ingredients is injected into the sewage to be treated by the bubbling devices, so that germs and viruses in water are killed by oxidation, and the disinfection and sterilization aim is fulfilled; and due to the adoption of the plasma generator, compared with the conventional ultraviolet disinfection, the method has the advantages that energy consumption is greatly reduced, and after the active substances of the plasma free radicals participate in sewage disinfection, second pollutants are not produced, so that environment can be protected.

Owner:GUANGZHOU PUMA ELECTRICAL

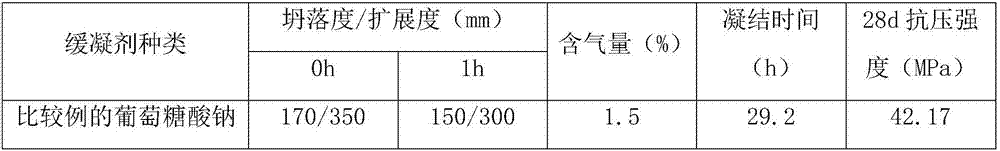

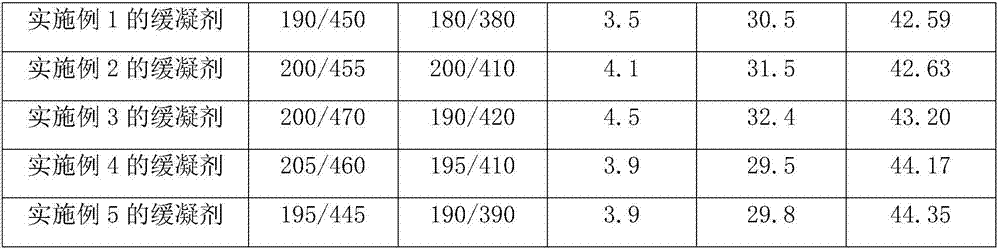

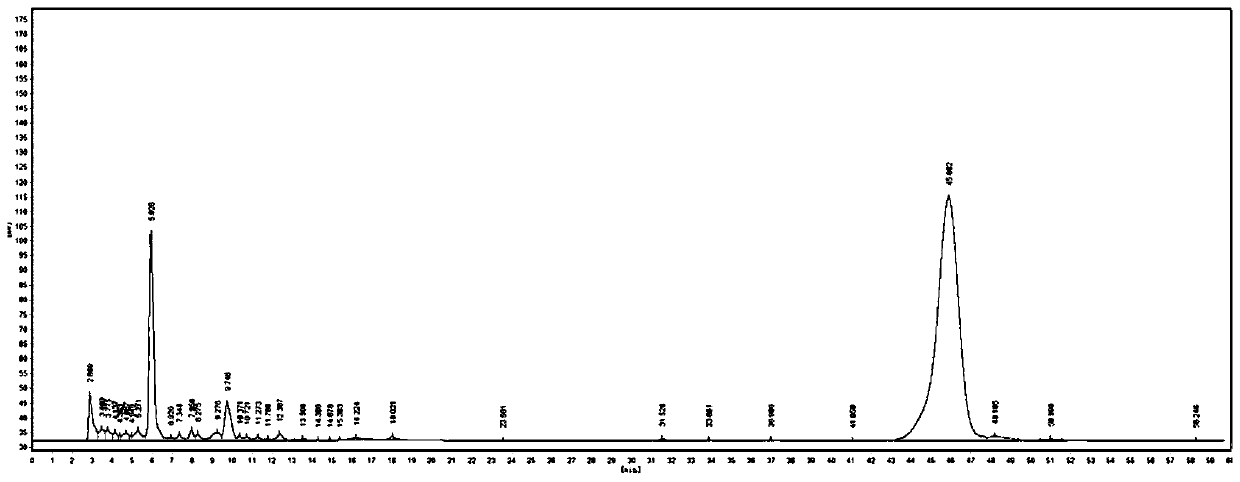

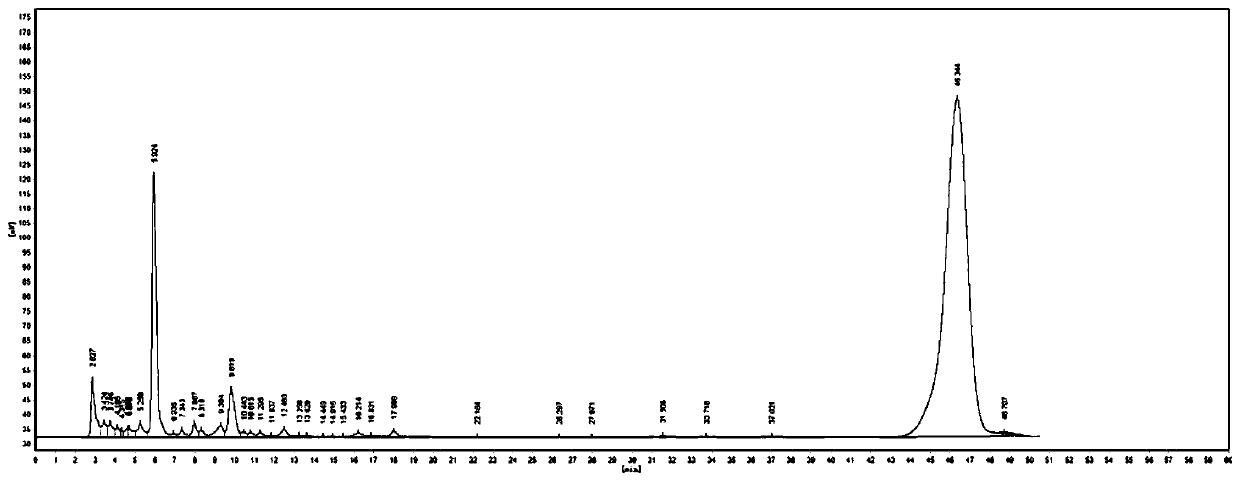

Retarder and preparation method thereof

The invention provides a retarder prepared from corn starch wastewater, wherein a mass ratio of esterified saccharide to proteins and amino acids to starch succinate to soluble cellulose to fatty acid is (3-6): (10-20): (50-100): (20-30): (1-3); modified starch is starch succinate; and the esterified saccharide is a derivative obtained by reacting the hydroxyl groups of saccharide in the corn starch production wastewater with an esterification reagent. A preparation method for the retarder in the invention comprises the following steps: determination of the component contents of the wastewater; heating and concentration; modification of starch and saccharide; and adjustment of a pH value. According to the invention, the corn starch production wastewater is recycled, and the prepared retarder has the advantages of low cost, energy conservation, environmental protection, good dispersibility, good retarding effect, uniform hydration heat release and good air entraining effect, and is especially applicable as a concrete pumping agent.

Owner:武汉新绿博恩科技有限公司

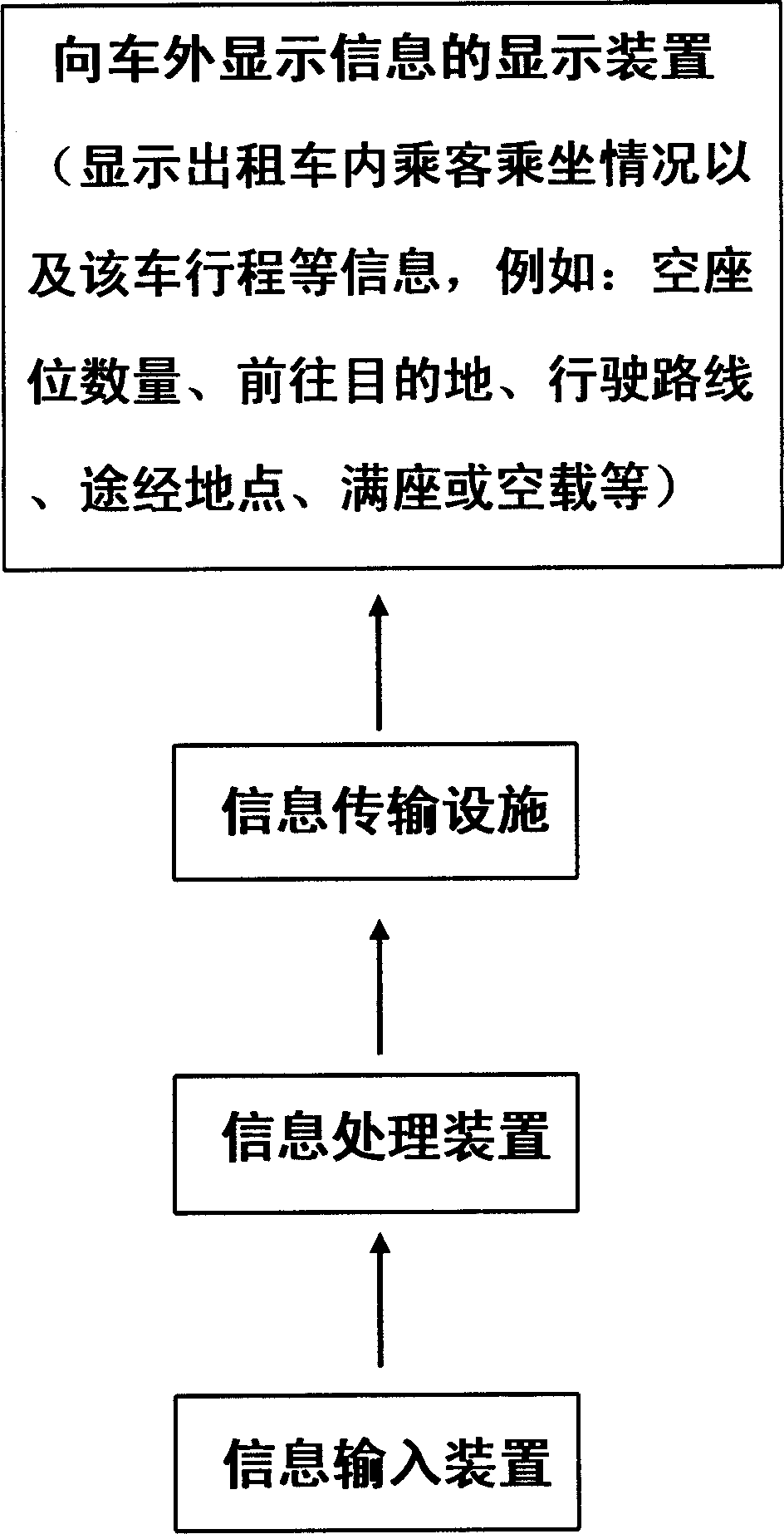

Information display system mounted on taxi

InactiveCN1811872AReduce pollutionGood for the environmentVehicle componentsMobile visual advertisingInformation transferReal-time computing

This invention relates to an information display system mounted on a taxi including: an information input device, an information process device, an information transmission device and a display device for displaying information to the outside, in which, when a car carries passengers, the information display device receives information transmitted by the information input device and displays the journey and situation inside the car( information of destination, the running line, places on the way and vacancies), thus, persons who want to take taxis can take it if the destination of the car is close to his place he wants to go, so that, this kind of taxi can become a public taxi to carry more passengers.

Owner:李建明

Method for extracting ergosterol from distillers'grains

The invention relates to a method for extracting ergosterol from distillers'grains, and belongs to the field of botanical drugs. The extraction method comprises the following steps: extracting distillers'grains by using an ethanol-water solution and a potassium hydroxide solution, extracting the obtained extract solution with n-hexane, and separating the obtained extract product by using a silicagel column to obtain ergosterol. Existing industrially extracted ergosterol is directly obtained by extraction from related fungi, leaching and recrystallization. The ergosterol is extracted from distillers' grains, so that the method is beneficial to the environment and saves the cost.

Owner:宿迁医美科技有限公司

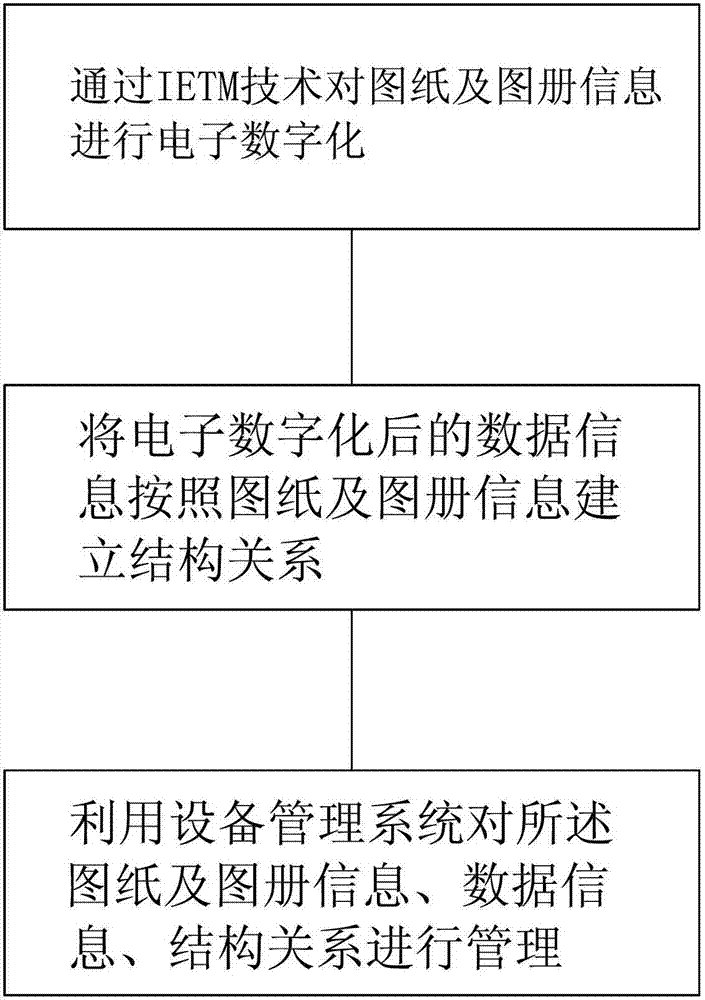

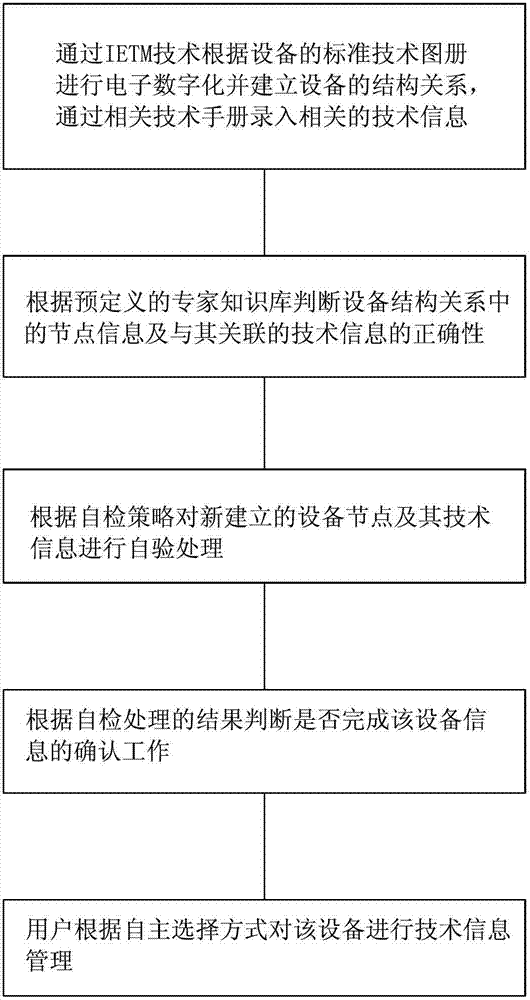

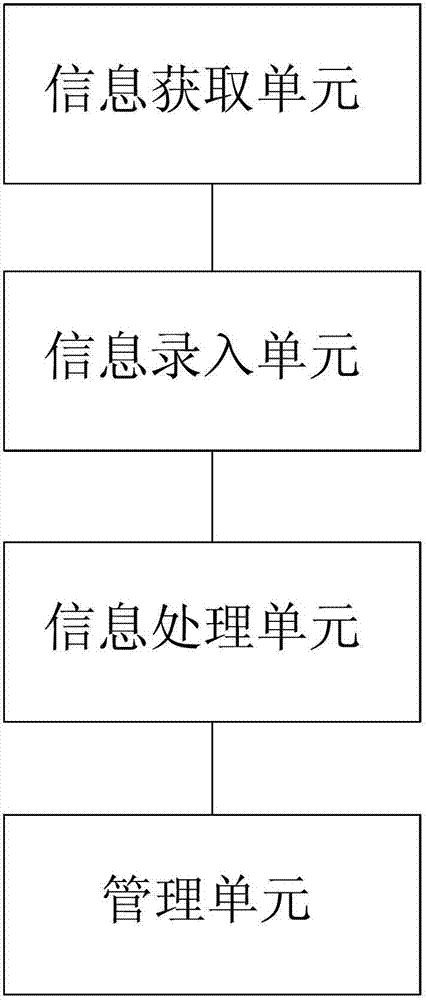

Method and system for providing technical management and technical guidance for equipment

InactiveCN102760254AReduce wood wasteGood for the environmentResourcesInformation technologyTechnical information

The invention relates to the field of information technology, particularly to a method and a system for providing technical management and technical guidance for mechanical industry equipment. The method for providing technical management for equipment, provided by the invention, includes the following steps: step I, performing electronic digitization to drawing and illustrated book information through the IETM technology; step II, building a structural relationship for the data information after the electronic digitization as per the drawing and illustrated book information; and step III, managing the drawing and illustrated book information, the data information and the structural relationship through an equipment management system. The invention further includes a system for providing technical management for equipment corresponding to the method. The method and the system both provided by the invention have the advantages that paperless management substituting the original paper management mode is realized, thereby saving 80% wood, and facilitating the environmental protection; the IETM technology is adopted for managing technical information of equipment, so that the standardability and normalization of technology information of all items can be guaranteed, the information inquiry and management are facilitated, and the working efficiency is improved by 20%; and the standardability, normalization and accuracy are realized.

Owner:NINGBO JINGMA MACHINERY

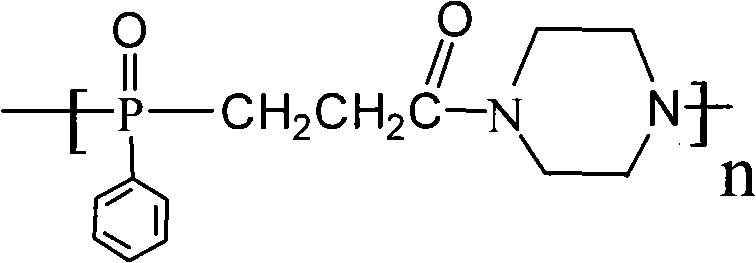

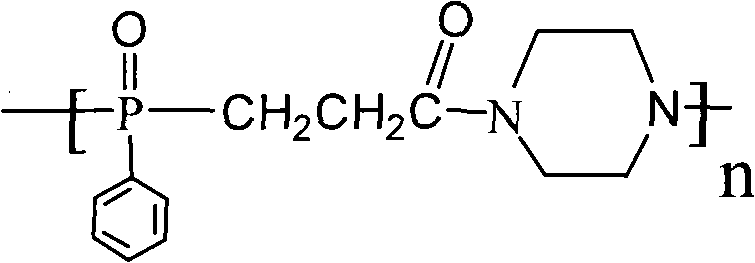

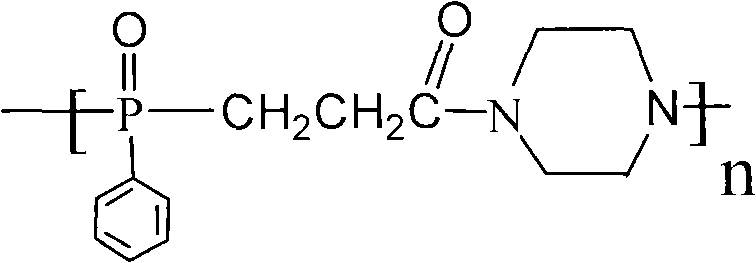

Carboxyethyl phenyl phosphinic acid piperazine polymer and preparation method thereof

InactiveCN101775135AGood compatibilityGood for the environmentGroup 5/15 element organic compoundsPhosphinic AcidsFlame resistance

The invention relates to a carboxyethyl phenyl phosphinic acid piperazine polymer and a preparation method thereof. The structure of the polymer is shown in a formula, wherein n is more than or equal to 1. The preparation method comprises the following steps: directly reacting carboxyethyl phenyl phosphinic acid with piperazine in a molar ratio of 1:0.95-1.05 in a nitrogen atmosphere at the temperature of between 135 and 160 DEG C or continuously reacting the carboxyethyl phenyl phosphinic acid with the piperazine in water or an organic solvent for 4 to 8 hours; and removing water generated in the process of reaction, then purifying and drying the reactant to obtain the carboxyethyl phenyl phosphinic acid piperazine polymer. The carboxyethyl phenyl phosphinic acid piperazine polymer has the advantages of high flame resistance, stable physicochemical property, good intermiscibility with high molecular materials, contribution to environmental protection, diversified synthetic method, simple and easily controlled process, simple needed device, low cost and suitability for scale production of different types of enterprises.

Owner:SUZHOU UNIV OF SCI & TECH

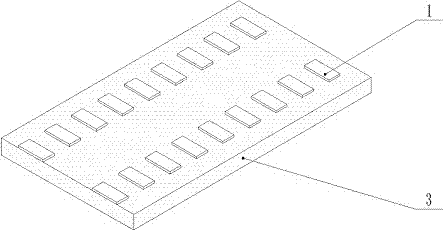

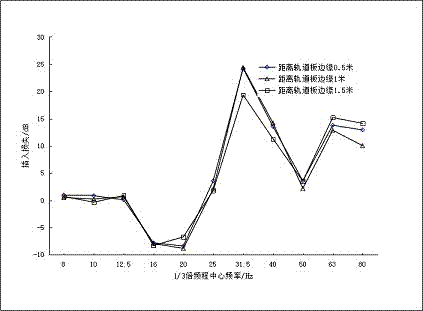

Damping ballastless track slab

The invention belongs to the technical field of track transportation, and particularly relates to a manufacturing material and structure form of a damping ballastless track slab. A track plate layer of the damping ballastless track slab is manufactured through rubber concrete of which rubber particles are treated, and a sleeper is manufactured through common concrete. The treatment method of the rubber particles comprises the step of using a KH 560 type coupling agent to treat the surface of the rubber particles. The doping quantity of the rubber particles is 5% same-volume substitution river sand. In the damping ballastless track slab prepared through the method, the vibration level of the acceleration in the Z direction of the ballastless track slab prepared through the method is obviously lowered, the vibration level of the vibration to the environment is obviously lowered within most frequency bands, moreover, the damping ballastless track slab has the advantages that the cost is low, manufacturing is simple, the intensity is not obviously lowered, and the later maintenance is simple.

Owner:EAST CHINA JIAOTONG UNIVERSITY

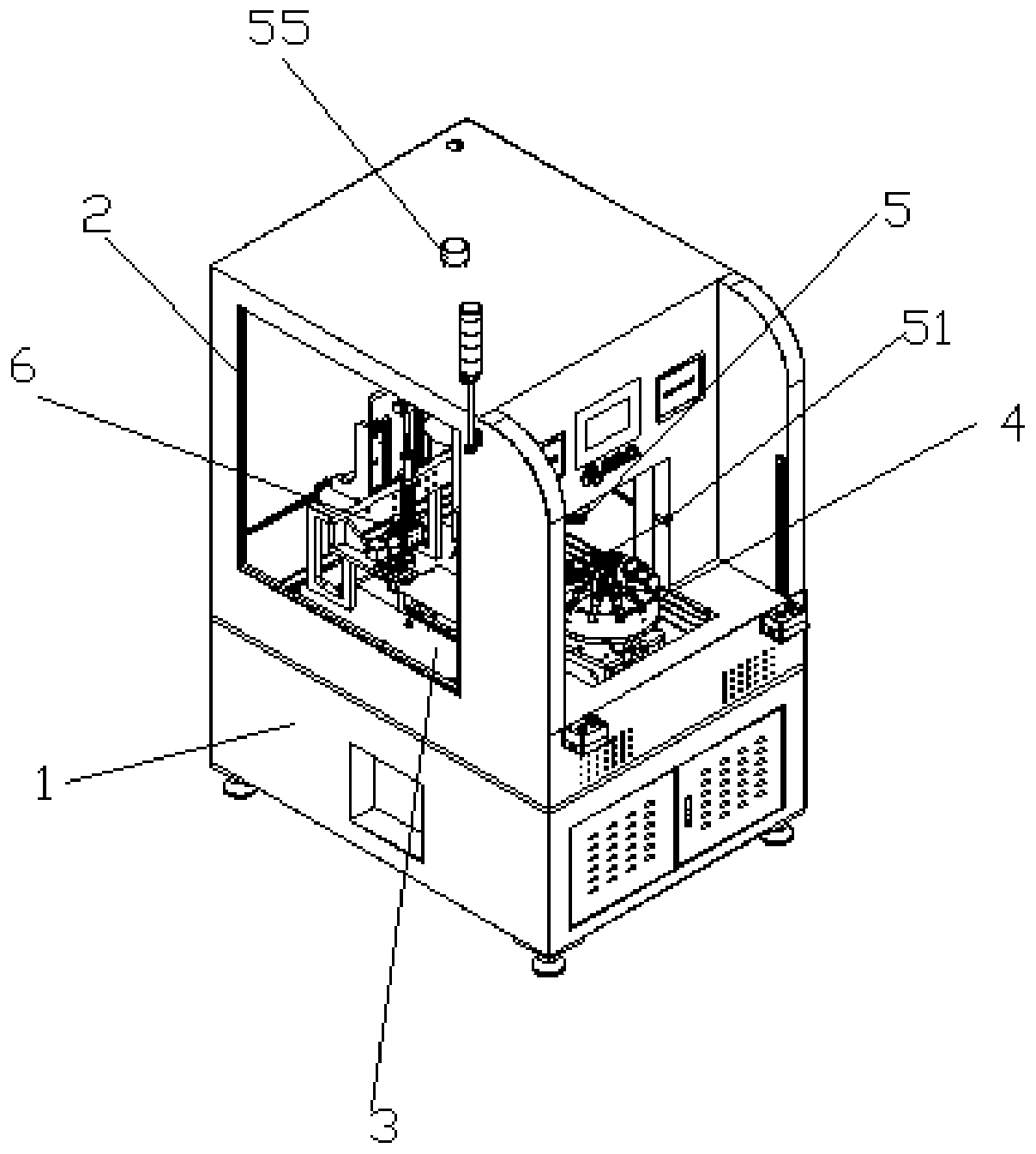

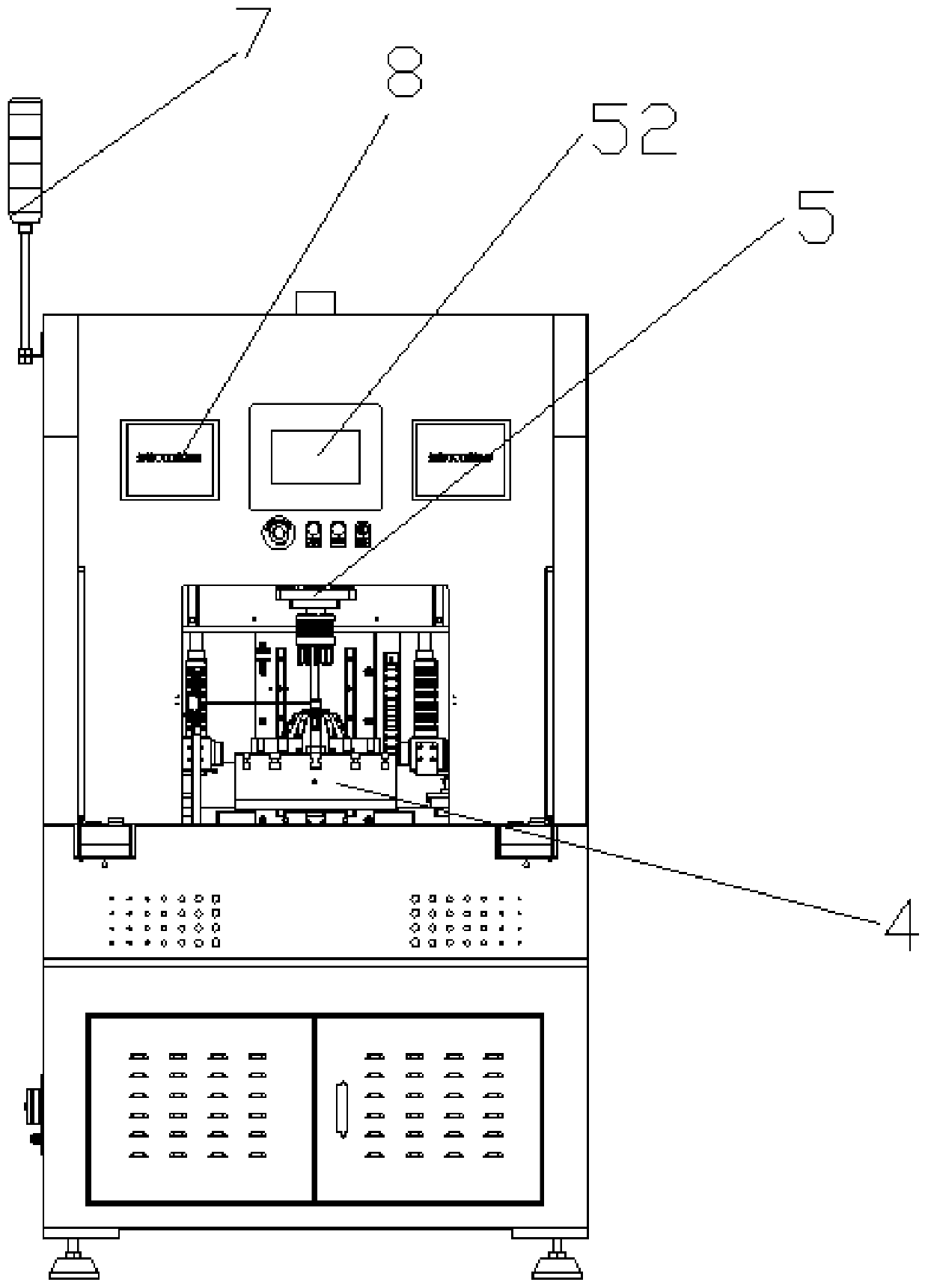

Novel block type circle splicing welding machine for stator iron cores

InactiveCN109877456AIncrease productivityGood for the environmentWelding/cutting auxillary devicesAuxillary welding devicesStatorEngineering

The invention discloses a novel block type circle splicing welding machine for stator iron cores. The machine comprises a case, a safety cover, a worktable top, a stator tightening mechanism, a statorend surface shaping mechanism, a stator welding mechanism, the stator iron cores, an indicator light and a control panel, wherein the case and the safety cover are integrally connected; the stator tightening mechanism, the stator end surface shaping mechanism and the stator welding mechanism are mounted on the worktable top; the control panel controls the stator tightening mechanism, the stator end surface shaping mechanism and the stator welding mechanism to work; the stator tightening mechanism is used for fixing a plurality of stator iron cores; the stator end surface shaping mechanism isused for pressing and aligning the end surfaces of the plurality of stator iron cores; the plurality of stator iron cores are welded into a hole through the stator welding mechanism. According to themachine, the processes from circle splicing, shaping to welding are automatically carried out; the circular degree of an inner circle of the stator iron core subjected to circle splicing completely meets the requirement on the circular degree of an inner circle of a motor; and meanwhile, the production efficiency is greatly improved; and the machine is high in practicability and wide in applicablescope.

Owner:杭州直尚智能设备有限公司

Bamboo-splitting tool capable of removing inner bamboo joints and centering

The invention discloses a bamboo-splitting tool capable of removing inner bamboo joints and centering. The bamboo-splitting tool comprises a tool body and a tool rest. The tool body is arranged on the inner side of the tool rest which is composed of an annular steel ring and a tool handle symmetrically arranged on the outer wall of the steel ring. The bamboo-splitting tool is characterized in that the tool body comprises a joint removing cutter, an annular cutter ring and a plurality of steel blades; the joint removing cutter is of an annular structure coaxial to the cutter ring, the spacing between the joint removing cutter and the cutter ring is slightly larger than the thickness of bamboo wood, and steel blades are arrayed into a scattering structure according to the same included angles among one another; starting ends of the steel blades intersect at the radial center of the inner diameter of the cutter ring, and the terminal ends of the steel blades are fixed on the inner wall of the cutter ring; an axial hollow pipeline is arranged at the center of the intersect center of the starting ends of the steel blades, and a positioning rod capable of moving up and down and penetrating the pipeline is arranged in the pipeline; an internal thread is arranged on the inner side of the steel ring, and an outer thread matching with the inner thread is arranged on the outer side of the cutter ring. The bamboo-splitting tool has the advantages that bamboo splitting and bamboo inner-joint removing are performed simultaneously, the process of removing inner bamboo joints after splitting the bamboo wood into bamboo chips is omitted, the tool body can be replaced conveniently, and centering can be performed automatically during bamboo splitting, so that bamboo chips can be cut evenly, and bamboo splitting efficiency is high.

Owner:江苏广大瑞康农业发展有限公司

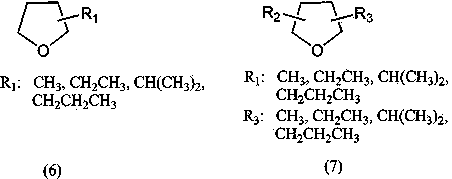

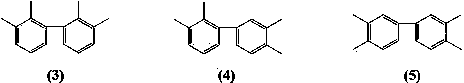

Preparation method of tetramethylbiphenyl isomers

ActiveCN104211559AGood for the environmentIncrease temperatureHydrocarbon from halogen organic compoundsAqueous solubilityOrganic phosphorus

The invention discloses a preparation method of tetramethylbiphenyl isomers. By adopting an alkyl-substituted tetrahydrofuran with a boiling point of above 80 DEG C, low toxicity and non water solubility as a solvent system, halogenated o-xylene as a raw material, magnetism as a reducing agent, and a complex formed by salts of transition metals such as nickel, copper, iron, magnesium or cobalt, or additives such as organophosphorus and organic amine as a catalyst, 3,3'4,4'-tetramethylbiphenyl, 2,3'3,4'-tetramethylbiphenyl and 2,2'3,3'-tetramethylbiphenyl isomers are prepared by adopting a coupled reaction. According to the preparation method, the cyclic utilization rate of the solvent reaches above 90 percent, and the yield of compounds of the tetramethylbiphenyl isomers reaches 85-95 percent.

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com