Reformed pre-hydrogenation catalyst and preparation method thereof

A catalyst and pre-hydrogenation technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of low catalytic efficiency and weak adsorption capacity of catalysts, Achieve the effects of environmental protection, energy saving, and catalytic efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

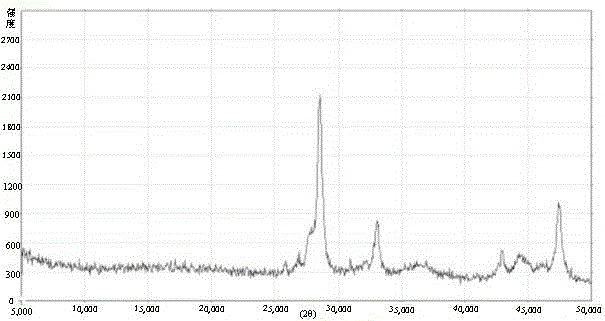

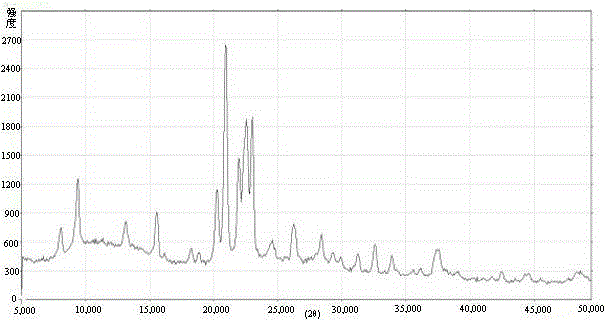

Image

Examples

Embodiment 1

[0042] (1) After dry mixing 100g of alumina and 3g of amorphous FeOOH, add 25g of attapulgite and 20g of water, mix uniformly and knead into 1×4cm strips, and dry the strips at 90℃ for 1.5h to obtain 128g carrier;

[0043] (2) Add 12.8g of water to 2.56g of nickel nitrate, 1.28g of cobalt nitrate and 10.24g of ammonium metatungstate to mix to obtain a Ni-Co-W impregnation solution, and place the prepared carrier in the Ni-Co-W impregnation solution Impregnated for 5 hours, and then dried at 60° C. for 3 hours to obtain reforming prehydrogenation catalyst 1.

[0044] The reforming prehydrogenation catalyst 1 contains 5wt% NiO, 4wt% CoO, and 25wt% WO 3 , 6wt% amorphous FeOOH and 60wt% alumina.

Embodiment 2

[0046] (1) After dry mixing 100g pseudo-boehmite and 10g amorphous FeOOH, add 60g sesame powder and 20g water, mix uniformly and knead into 1×4cm strips, dry the strips at 60℃ for 3h, Get 150g of carrier;

[0047] (2) Add 60 g of water to 15 g of nickel sulfate, 12 g of cobalt sulfate and 67.5 g of ammonium tungstate to obtain a Ni-Co-W impregnation solution, and immerse the prepared carrier in the Ni-Co-W impregnation solution for 1.5 hours, Then, it was dried at 90°C for 1.5 hours to obtain a reforming prehydrogenation catalyst 2.

[0048] The reforming prehydrogenation catalyst 2 contains 9wt% NiO, 7wt% CoO, and 40wt% WO 3 , 4wt% amorphous FeOOH and 40wt% alumina.

Embodiment 3

[0050] (1) After dry mixing 100g of boehmite and 6g of amorphous FeOOH, add 40g of nitric acid to mix uniformly and knead into 1×4cm strips, and dry the strips at 80℃ for 2h to obtain 100g carrier;

[0051] (2) Add 20g of water to 5g of nickel chloride, 6g of cobalt acetate and 30g of sodium tungstate and mix to obtain a Ni-Co-W impregnation solution. The prepared carrier is immersed in the Ni-Co-W impregnation solution for 3h, then After drying at 70°C for 2.5 hours, a reforming prehydrogenation catalyst 3 was obtained.

[0052] The reforming pre-hydrogenation catalyst 3 contains 2wt% NiO, 1wt% CoO, and 28wt% WO 3 , 10wt% amorphous FeOOH and 59wt% alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com