Method for separating and recovering valuable metal iron, manganese and scandium from tungsten slag

A technology for separation and recovery of valuable metals, applied in the field of manganese and scandium, tungsten slag treatment, separation and recovery of valuable metal iron, can solve the problems of human and environmental impact, and achieve environmental protection, high leaching efficiency, and efficient separation and recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

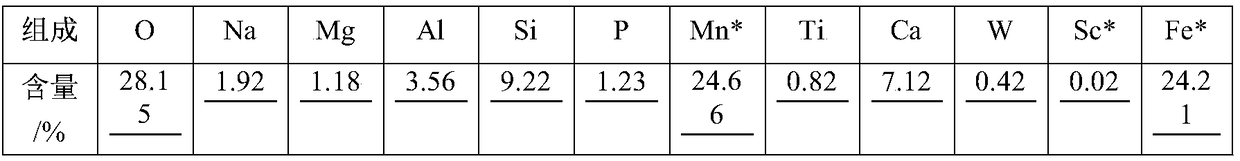

[0034] Use 0.5mol / L, 1mol / L, 2mol / L, 3mol / L, 4mol / L, 5mol / L sulfuric acid solution to leach iron, manganese, and scandium in tungsten slag respectively. The temperature during the leaching process is controlled at 90°C. , the liquid-solid ratio is 5:1, the leaching time is 5h and a certain stirring rate is maintained. After taking the supernatant and diluting it by a certain number of times, analyze the iron, manganese and scandium content in the solution. The analytical instrument is ICP-OES, which is diluted 100 times when analyzing iron, 100 times when analyzing manganese, and 20 times when analyzing scandium. The leaching rate of each element is shown in Table 1.

[0035] Table 1 Effect of different concentrations of sulfuric acid on the leaching rate of valuable metals in tungsten slag

[0036] Sulfuric acid concentration (mol / L)

[0037] It can be seen from Table 1 that at 90°C, the liquid-solid ratio is 5:1. As long as the concentration of sulfuric acid is ...

Embodiment 2

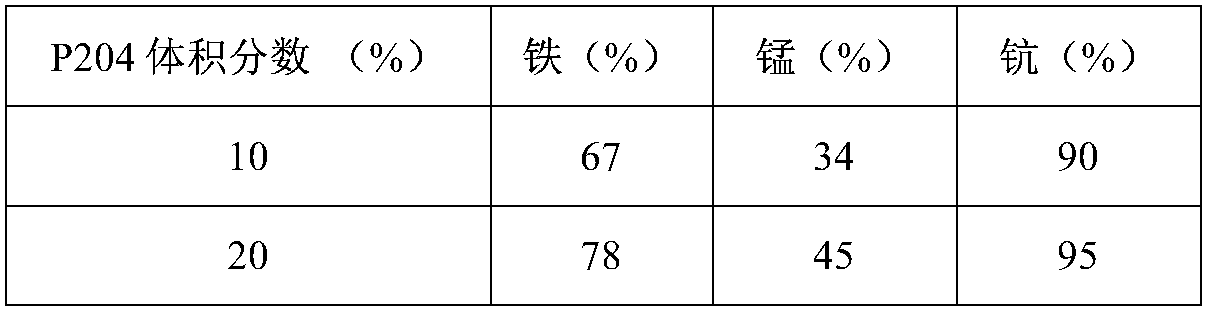

[0039] Respectively adopt 10%, 20%, 30%, 40% and 50% volume fraction of P204 as the extractant to extract iron, manganese, scandium in the leachate. During the extraction process, the control ratio was 1:5, the extraction temperature was 25°C, and the extraction time was 10 minutes. After static phase separation, take the raffinate and dilute it by a certain number of times to analyze the content of iron, manganese and scandium. The analytical instrument is ICP-OES. The extraction rate of each metal was calculated by subtraction method. The results are shown in Table 2.

[0040] Table 2 Effects of different extractant concentrations on the extraction rate of valuable metals in the leachate

[0041]

[0042]

[0043] It can be seen from Table 2 that with the increase of the P204 extractant concentration, the extraction rates of the three metal ions increased significantly. When the extractant concentration reached 30%, the scandium extraction rate was close to 100%, an...

Embodiment 3

[0045] Adopt 2mol / L respectively, the sulfuric acid solution of 7mol / L and the ammoniacal solution of 2mol / L selectivity back-extracts the iron in the loading organic phase, manganese, scandium. The ratio of stripping manganese is 5:1, the ratio of stripping iron is 2:1, and the ratio of stripping scandium is 10:1. The stripping temperature is 25° C., and the stripping time is 30 minutes. The order of selective stripping is manganese>iron>scandium. After phase separation, the stripping solution is removed to analyze the metal content in the stripping solution, and the stripping rate of each metal is calculated by subtraction method. The analysis instrument is ICP-OES. The analysis results are shown in Table 3.

[0046] The stripping rate of each metal of table 3 different stripping agents selective stripping stripping

[0047] stripping agent

[0048] As can be seen from Table 3, the stripping of manganese can be realized with sulfuric acid of lower concentration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com