Patents

Literature

31results about How to "Save water and energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

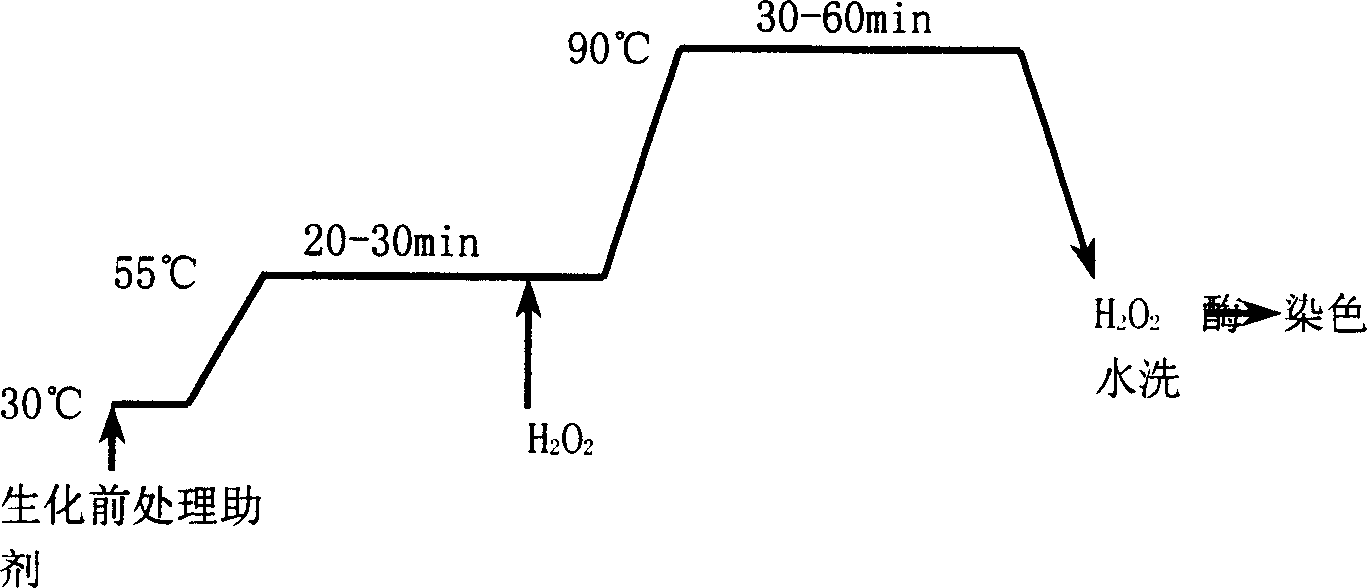

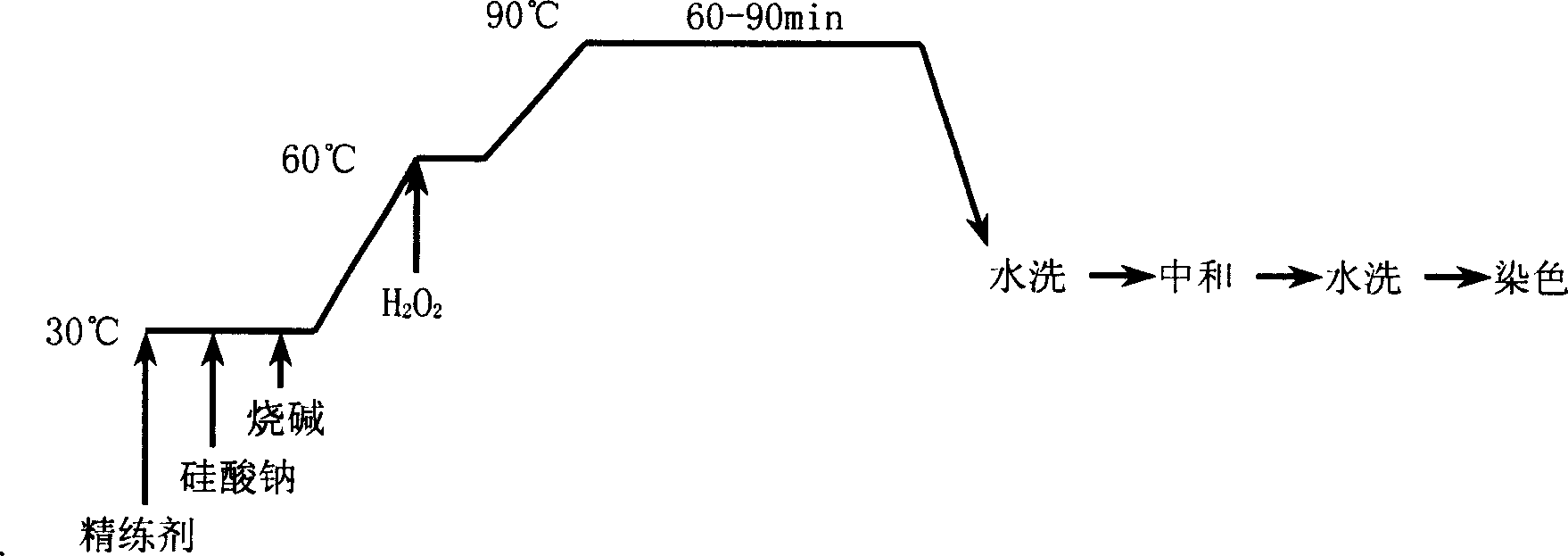

Cellulose fibre, textile assistant for union biochemical pretreatment, perparing method and use

The invention relates to the method to use special biology enzyme (pectic enzyme, fibrin enzyme, lipase, albumen enzyme, lacquer enzyme, xylan enzyme, polysaccharide enzyme, and catalase) and environment-friendly effective surfactant to produce aid fitting the biochemical pretreatment of fibrin fiber, and its fabric, and its processing technology. The aid for short flow of zoology pretreatment made of a host of biology enzyme and environment-friendly surfactant can fit the short flow of zoology pretreatment of fibrin fiber and its fabric. The invention advances the quality of the production. At the same tie, it reduces pollution to the environment, and it achieves the process of pretreatment of fibrin fiber and its fabric with the interreaction with biology enzyme and surfactant. Moreover, thep rocess does little harm to the fiber and it has an effective removement of residue. Additionally, it is friendly to the environment.

Owner:DONGHUA UNIV +1

Intelligent dish washing machine and washing method thereof

PendingCN105455754AFall off quicklyImprove solubilityTableware washing/rinsing machine detailsWater useMicrocomputer

The invention discloses an intelligent dish washing machine and a washing method thereof. To-be-washed tableware is cleaned through the steps of high-pressure water flushing, residue smashing machine cleaning, heating, friction particle dry cleaning and washing, ending processing and the like. The intelligent dish washing machine has the advantages of being simple in structure, safe and reliable and is ingenious in design and low in device cost, all work is controlled through a microcomputer, the process is fed back through a sensor, one-key automatic and intelligent washing can be achieved, and manual labor is thoroughly liberated. According to the intelligent dish washing machine , at the high-pressure water flushing stage, a high-pressure pump pumps clean water from a clean water tank and flushes tableware through a nozzle, residues are smashed in a concentrated mode and discharged, water used at the stage of washing tableware through friction particles is high-temperature water with the temperature of 80 DEG C, the water can conduct disinfection and sterilization and can also soften greasy dirt, dissolution of greasy dirt in water is accelerated, the water can even be recycled, and water and energy are saved.

Owner:郑桂成

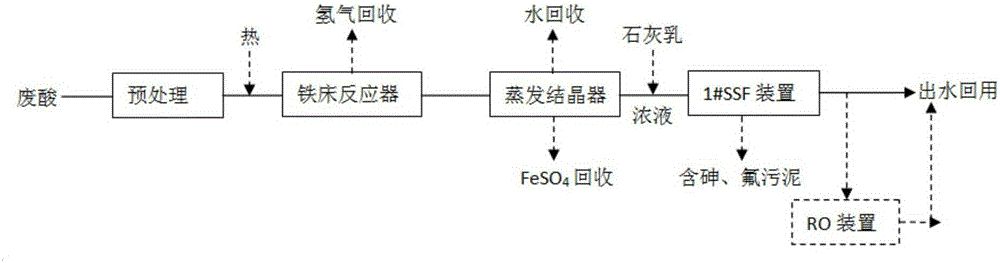

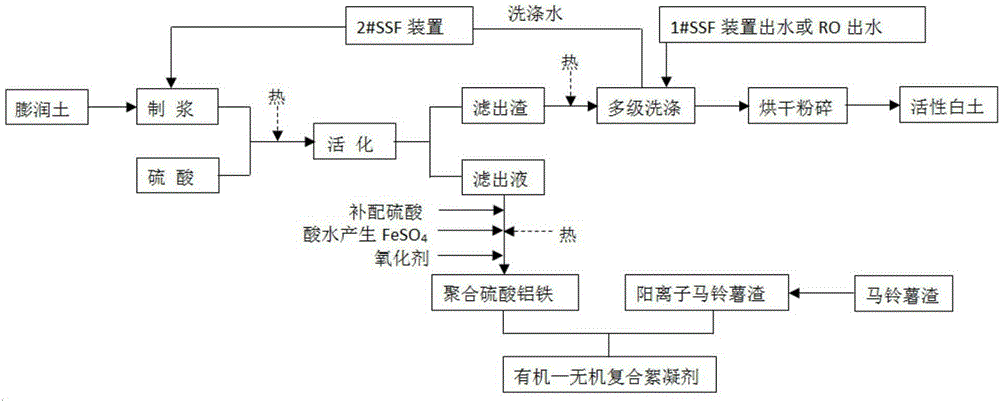

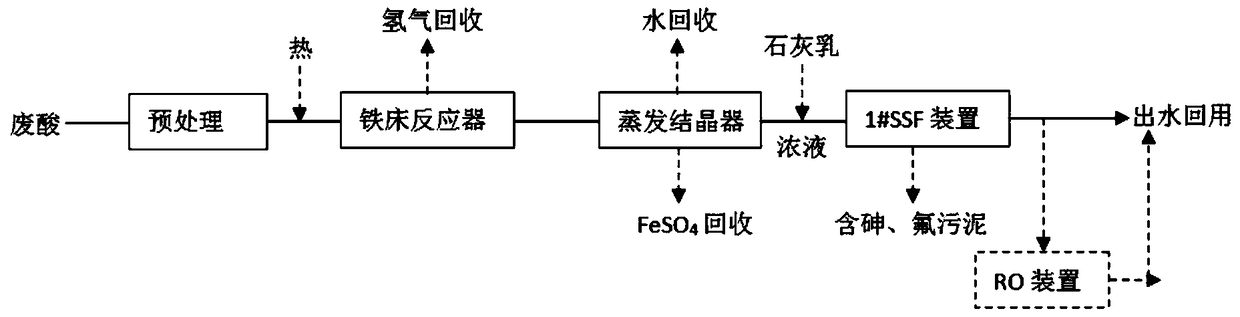

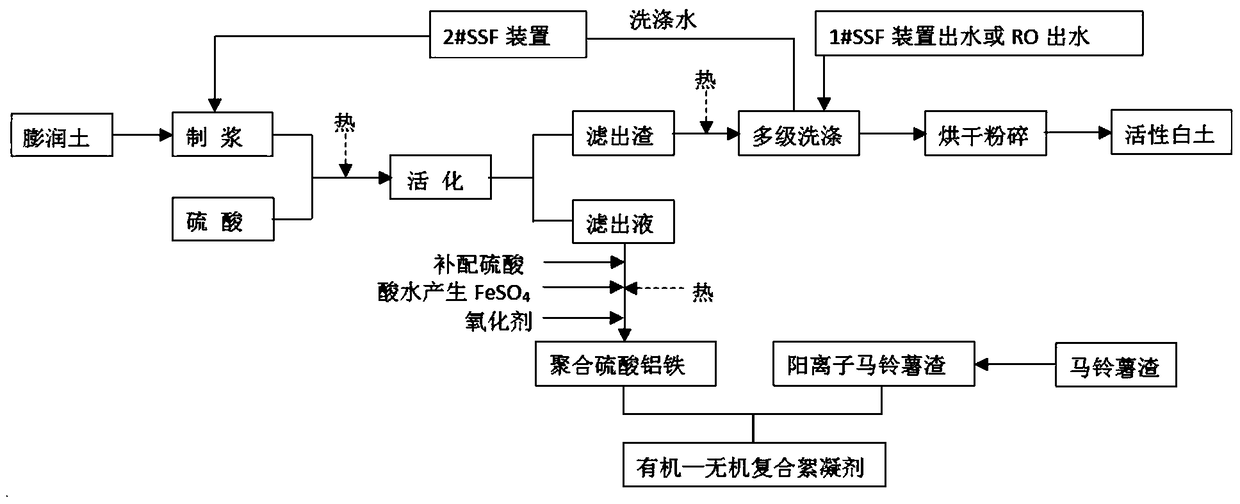

Method for recycling waste acid generated in production of sulfuric acid from smelting flue gas

ActiveCN105217869AReduce processingSolving Seasonal Storage ProblemsEnergy inputMultistage water/sewage treatmentAluminium saltsFlue gas

The invention provides a method for recycling waste acid generated in production of sulfuric acid from smelting flue gas. The method comprises the following steps: reducing waste acid by using Fe, performing evaporative crystallization to obtain FeSO4 crystals, enabling FeSO4 crystals to react with filter liquor, sulfuric acid and an oxidant generated in the activation step of producing activated clay from bentonite, so as to obtain polymeric aluminum ferric sulfate; selectively, enabling polymeric aluminum ferric sulfate to react with an organic flocculating agent, so as to obtain an organic-inorganic composite flocculating agent. According to the recycling method, the waste acid generated in the production process of sulfuric acid from smelting flue gas is adopted as a main raw material, and waste heat of smelting flue gas is utilized to produce the activated clay and the organic-inorganic composite flocculating agent which have broad markets in various industries, so that the problems about recovery of waste heat of high-temperature flue gas, treatment of waste acid, and seasonal storage of by-product sulfuric acid are solved; besides, plenty of valuable industrial products can also be produced; therefore, the method has quite high social benefit, environmental benefit and economic benefit.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Method for rapidly producing viscous wet skin of tofu

The invention provides a method for producing a sticky rice with fillings of bean quickly, which comprises choosing superior lactic acid bacteria lactobacillus plantarum, bending lactobacillus, L.mesenteroides subsp.dextranicum as the bacterial of the leaven, after the bacterial is activated and cultured, adding the bacterial to a seed culture medium for 18-24h with the inoculation amount of 3-5% according to the proportion of 2:2:1, reducing the pH to about 3.2, inoculating waxy corns according to the inoculation amount of 3-5%, fermenting 8-10 days under the condition of 25-28 DEG C, cleaning the waxy corns which are fermented with water, and then drying the moisture, and a completed product of a sticky rice with fillings of bean is made finally after technologies of grinding paste, mixing dough, packaging, stewing, and freezing. The invention can reduce the fermentation periodic time, and can improve the nutrition and local flavor of the product, and is a technology for manufacturing sticky rice with fillings of bean quickly.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

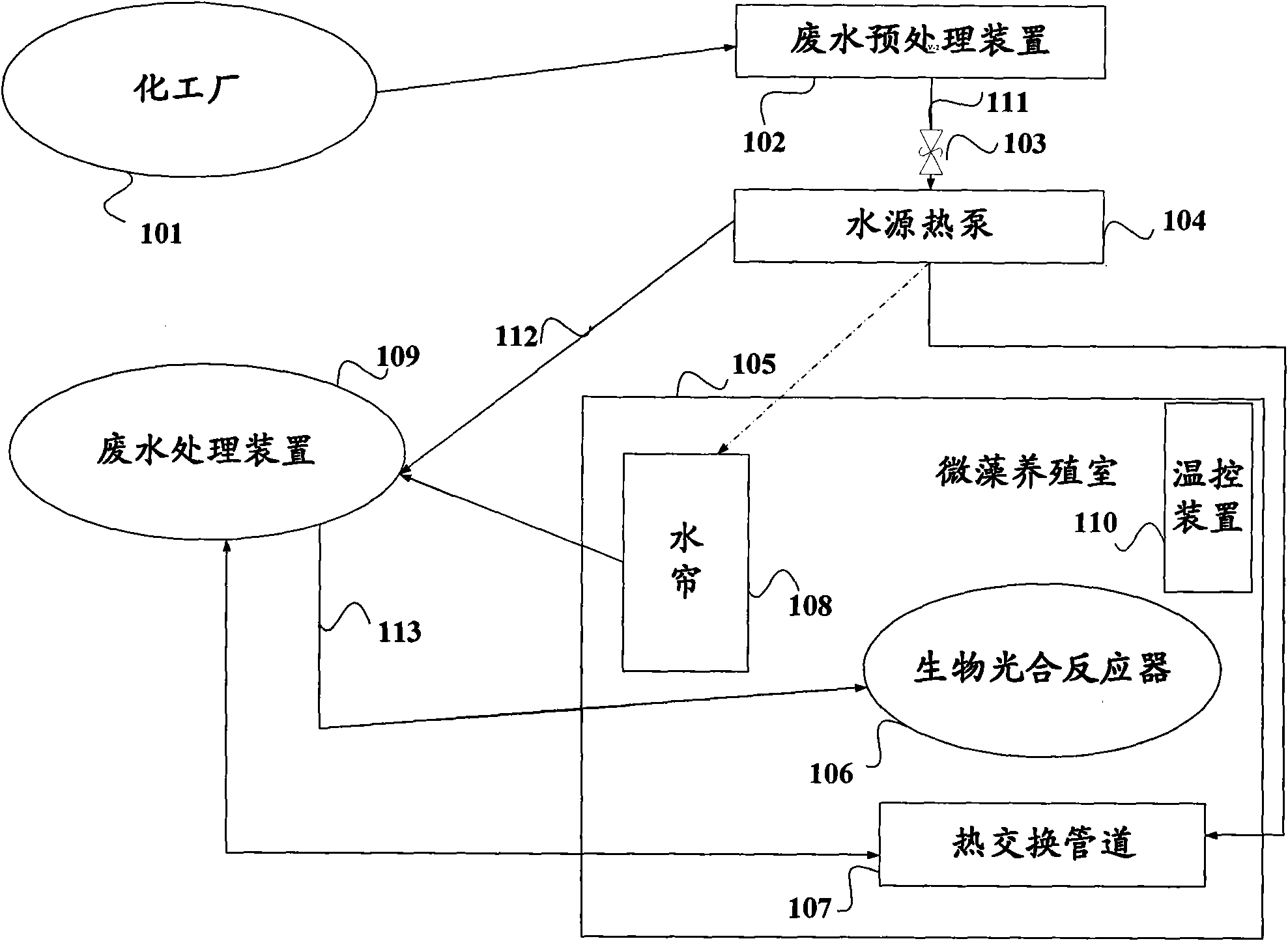

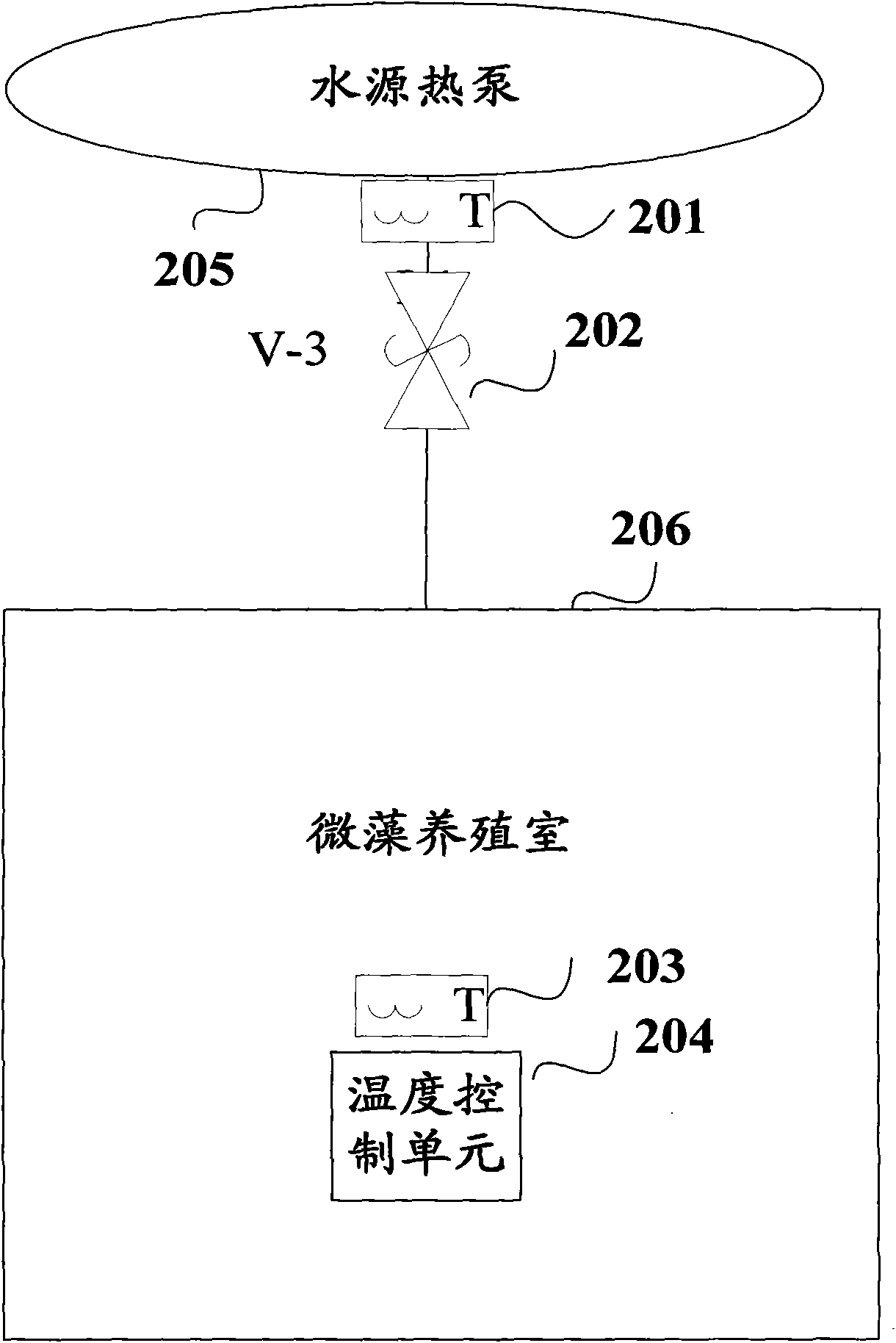

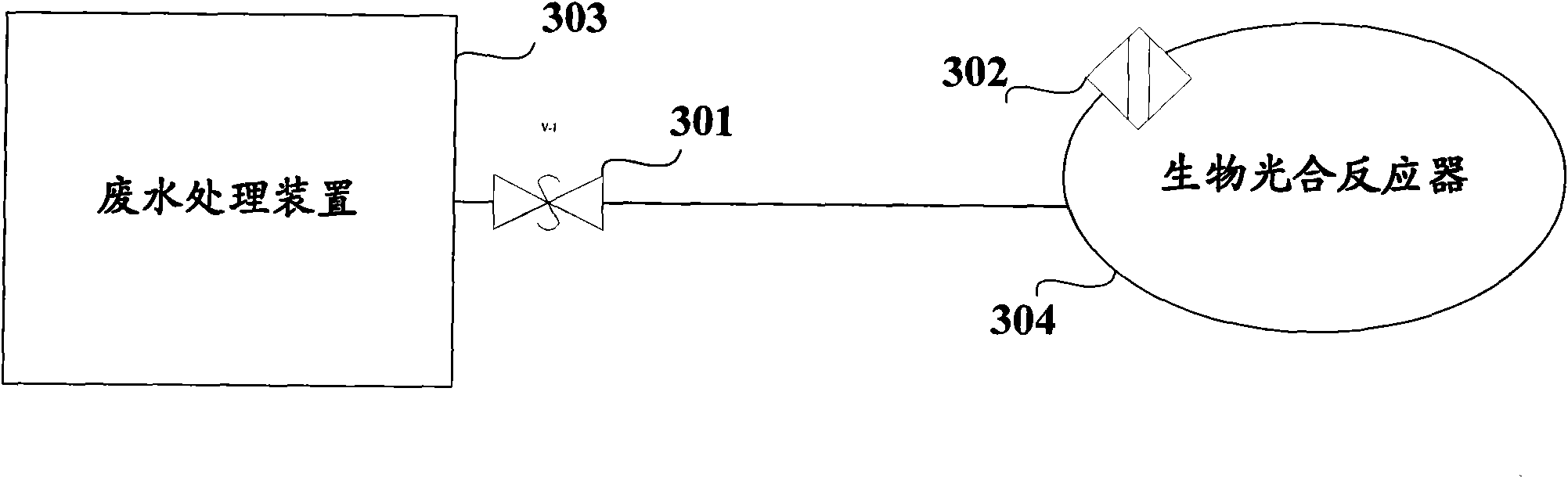

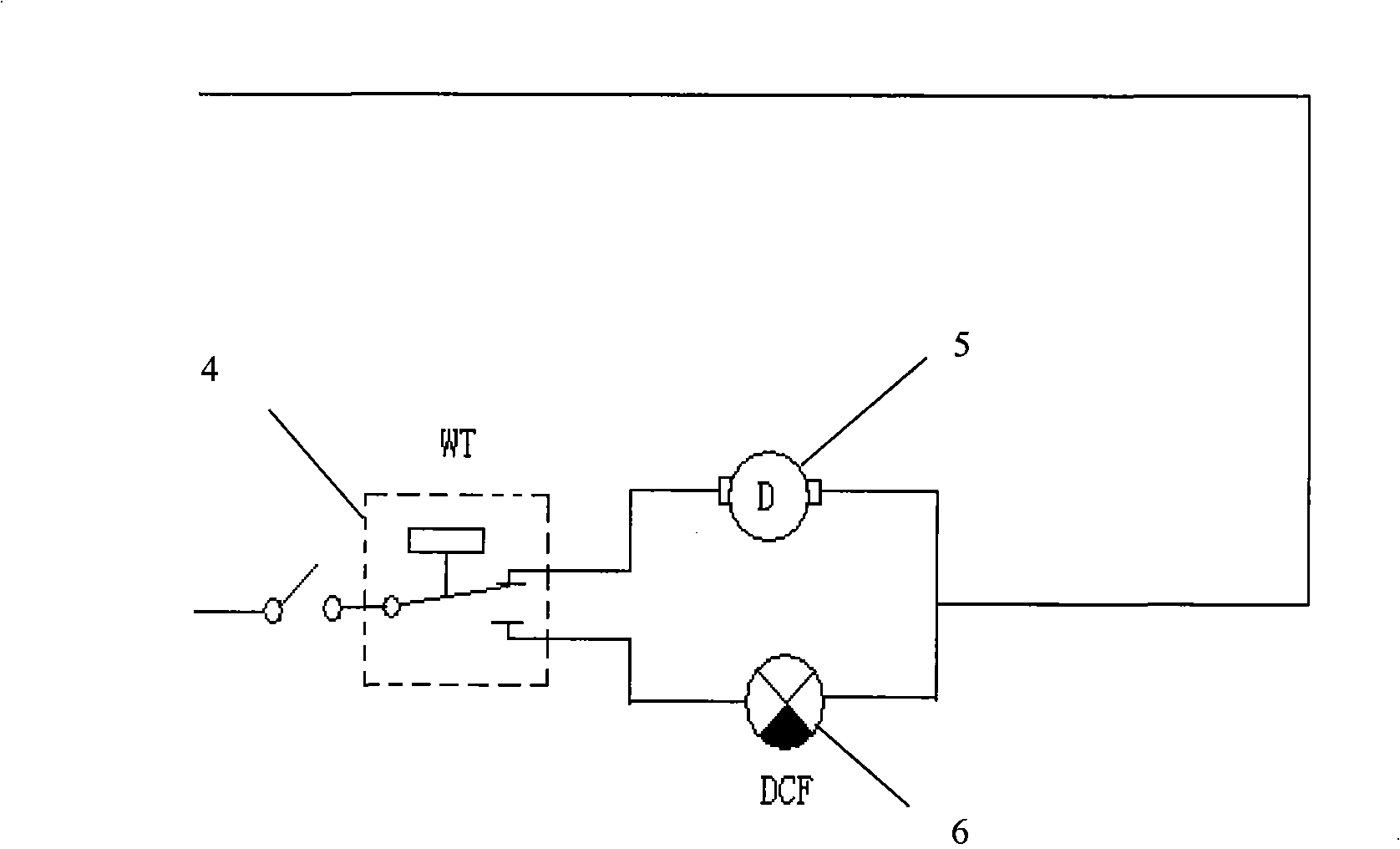

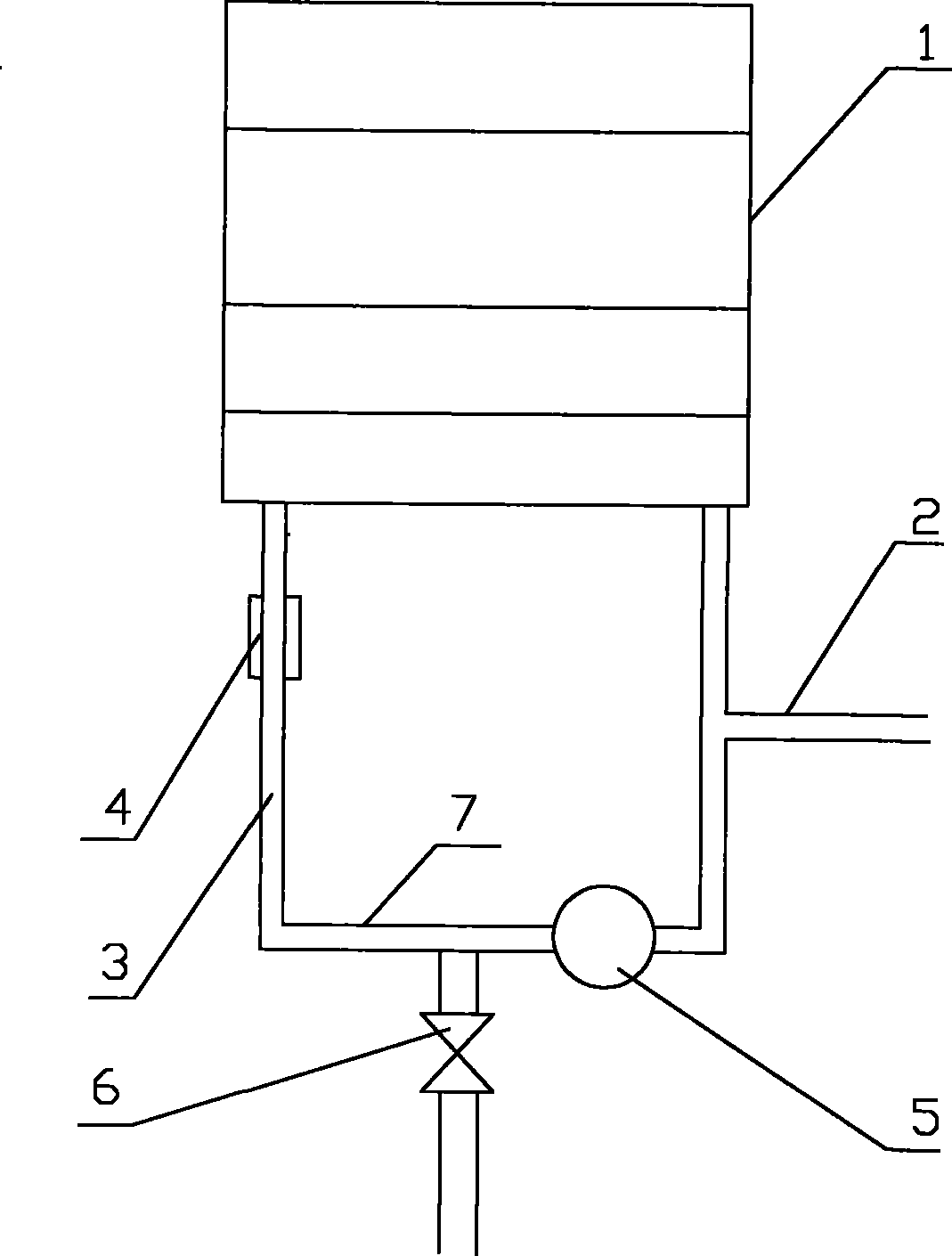

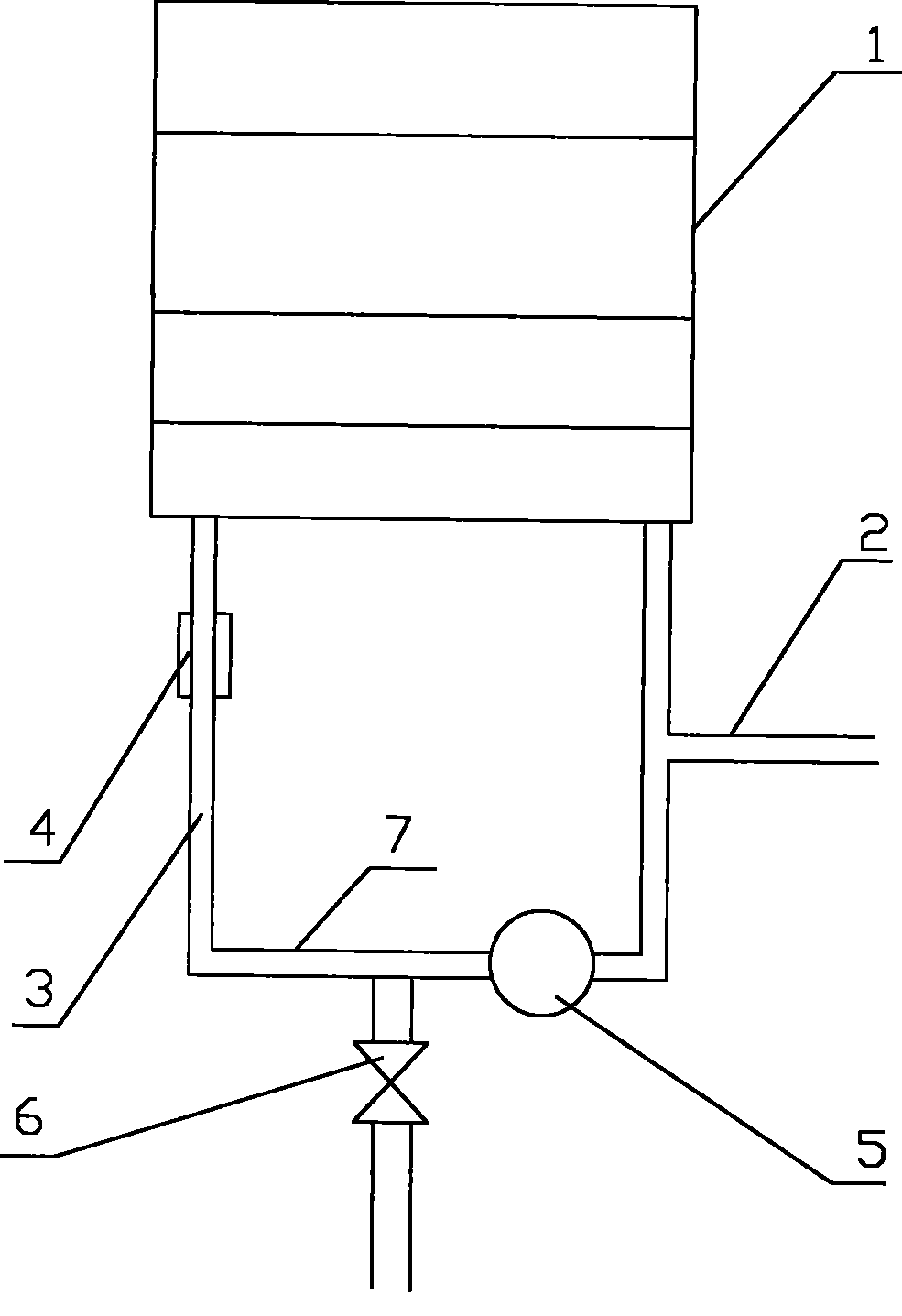

System for cultivating microalgae with waste water

ActiveCN101643699AGood for the environmentSave water and energyBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorThermal energy

The invention discloses a system for cultivating microalgae with waste water, comprising a water source heat pump, a temperature control device, a heat exchange pipeline, and a waste water treatment device, wherein the water source heat pump is used for obtaining heat energy from the input waste water and storing, and the heat energy from the input waste water is used for heating or refrigeratingthe input water; the temperature control device is used for detecting environment temperature of a microalgae cultivation room and effluent water temperature; the heat exchange pipeline is used for accepting the water output by the water source heat pump and carrying out heat exchange with the microalgae cultivation room; and the waste water treatment device is used for carrying out further treatment on the waste water flowing out of the water source heat pump, the heat exchange pipeline and / or a water curtain and inputting to each photobioreactor. The invention realizes utilizing waste waterto control the proper temperature range of microalgae cultivation and inputting to each photobioreactor, and utilizing waste water to provide culture solution for microalgae cultivation.

Owner:ENN SCI & TECH DEV

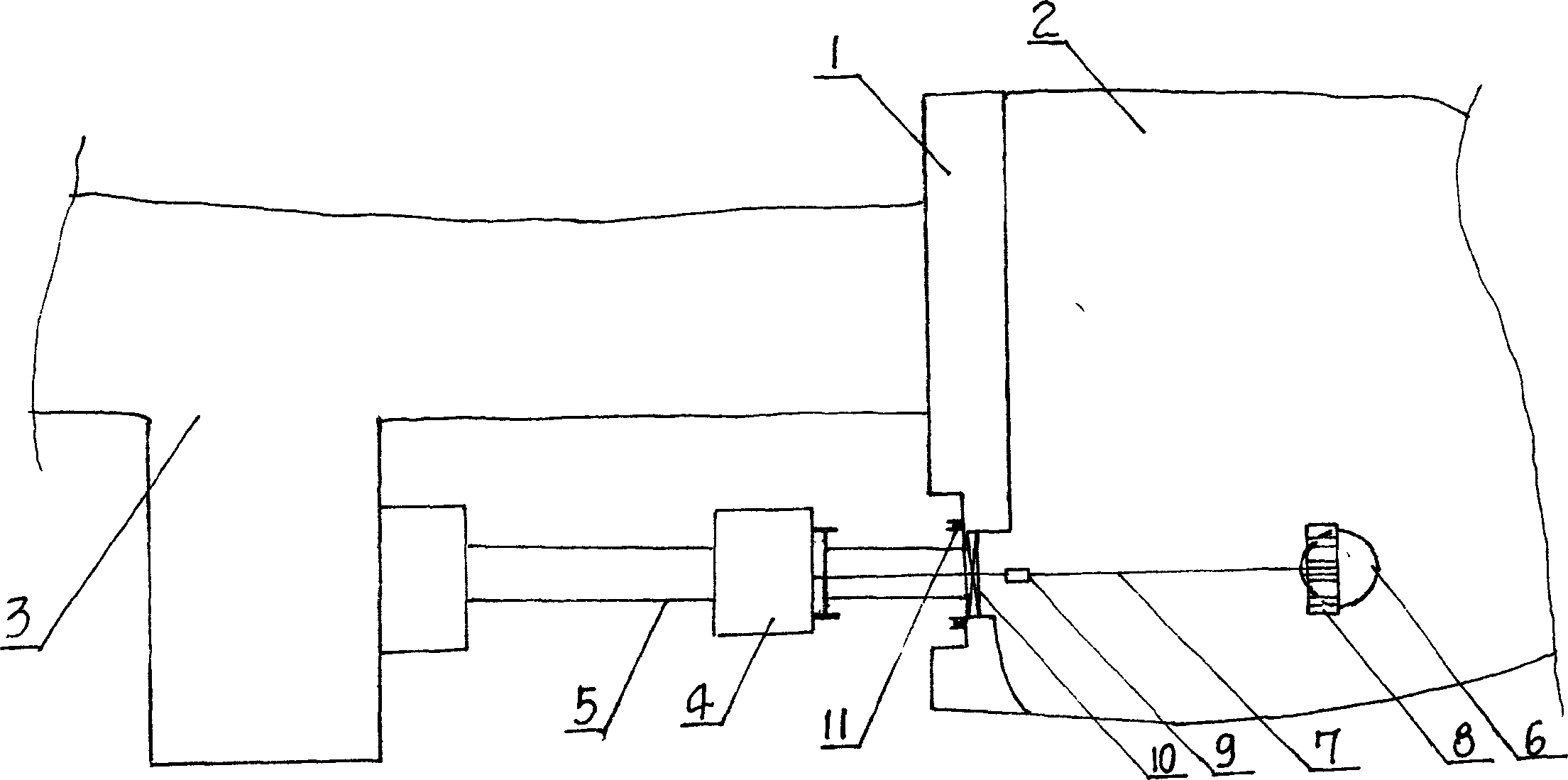

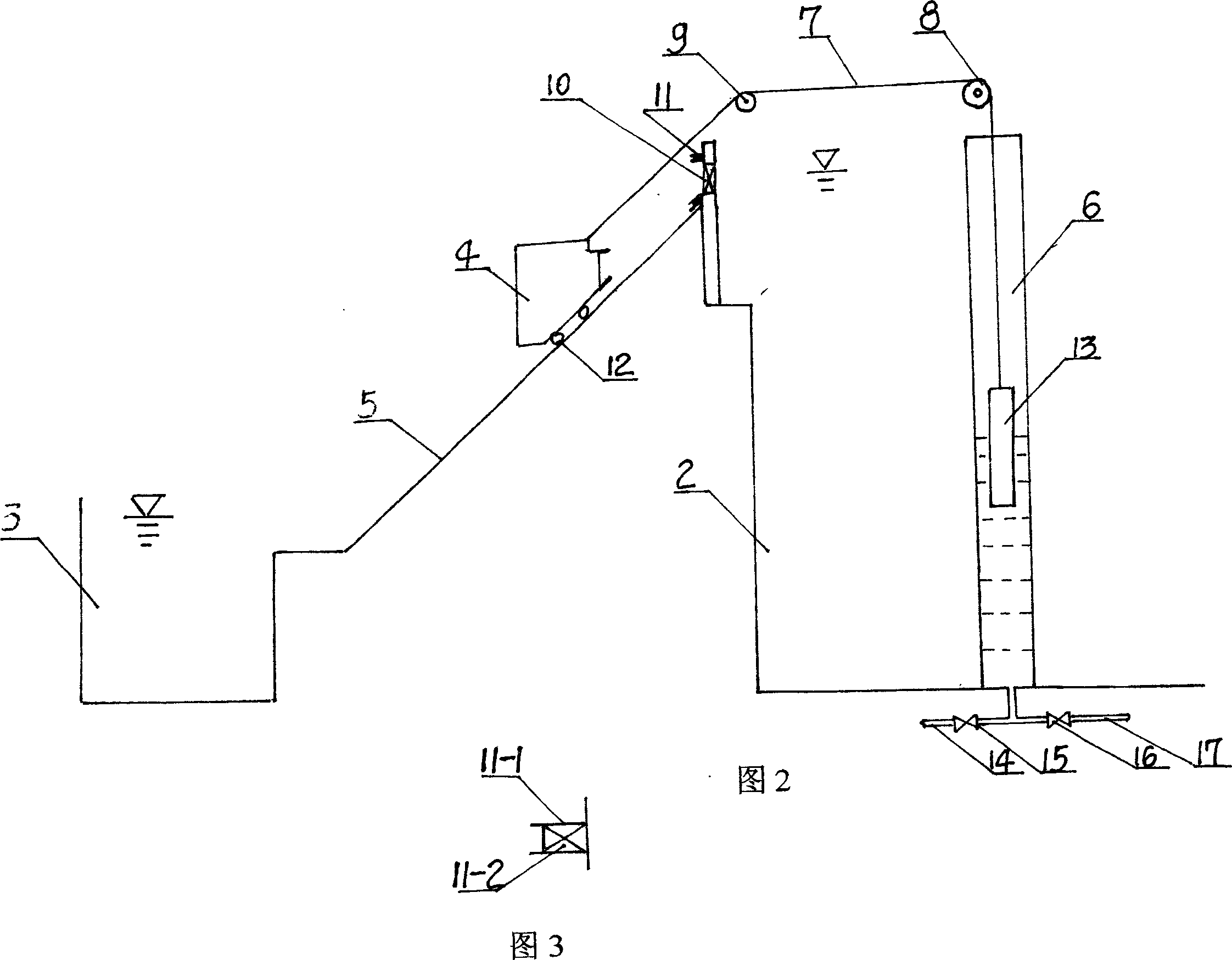

A novel high-efficiency dam-crossing arrangement for ship

InactiveCN1837496APracticalImprove dam crossing efficiencyInclined ship-liftingDry-docksMarine engineeringBuoyancy

Owner:HEBEI AGRICULTURAL UNIV.

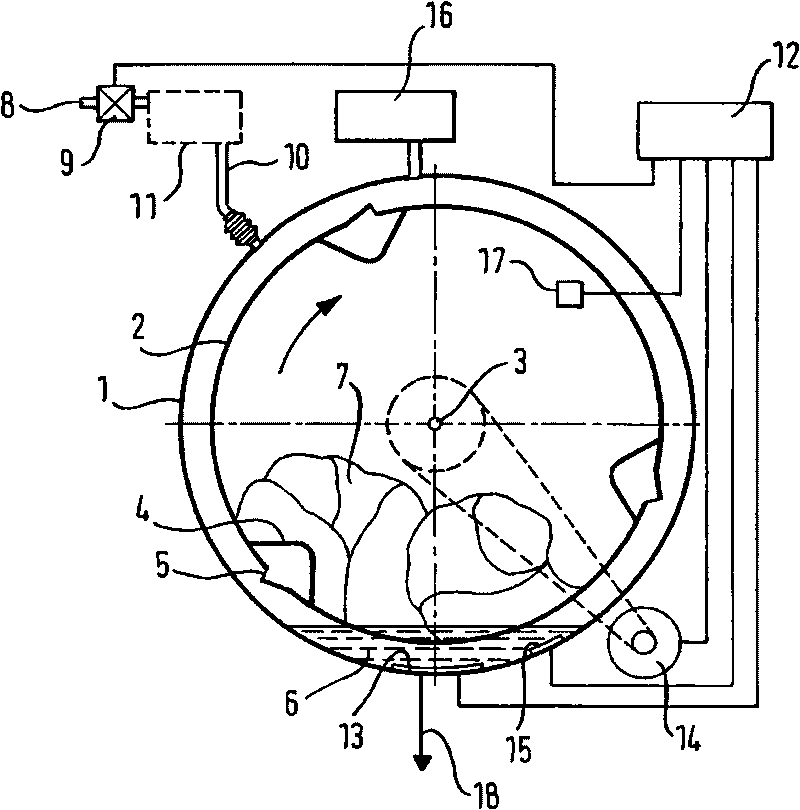

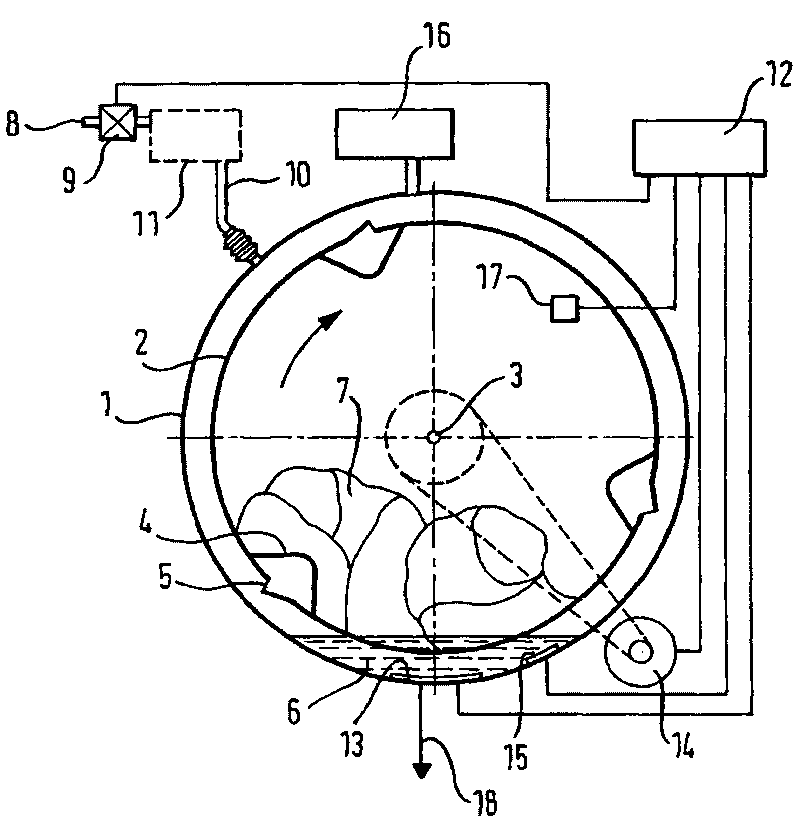

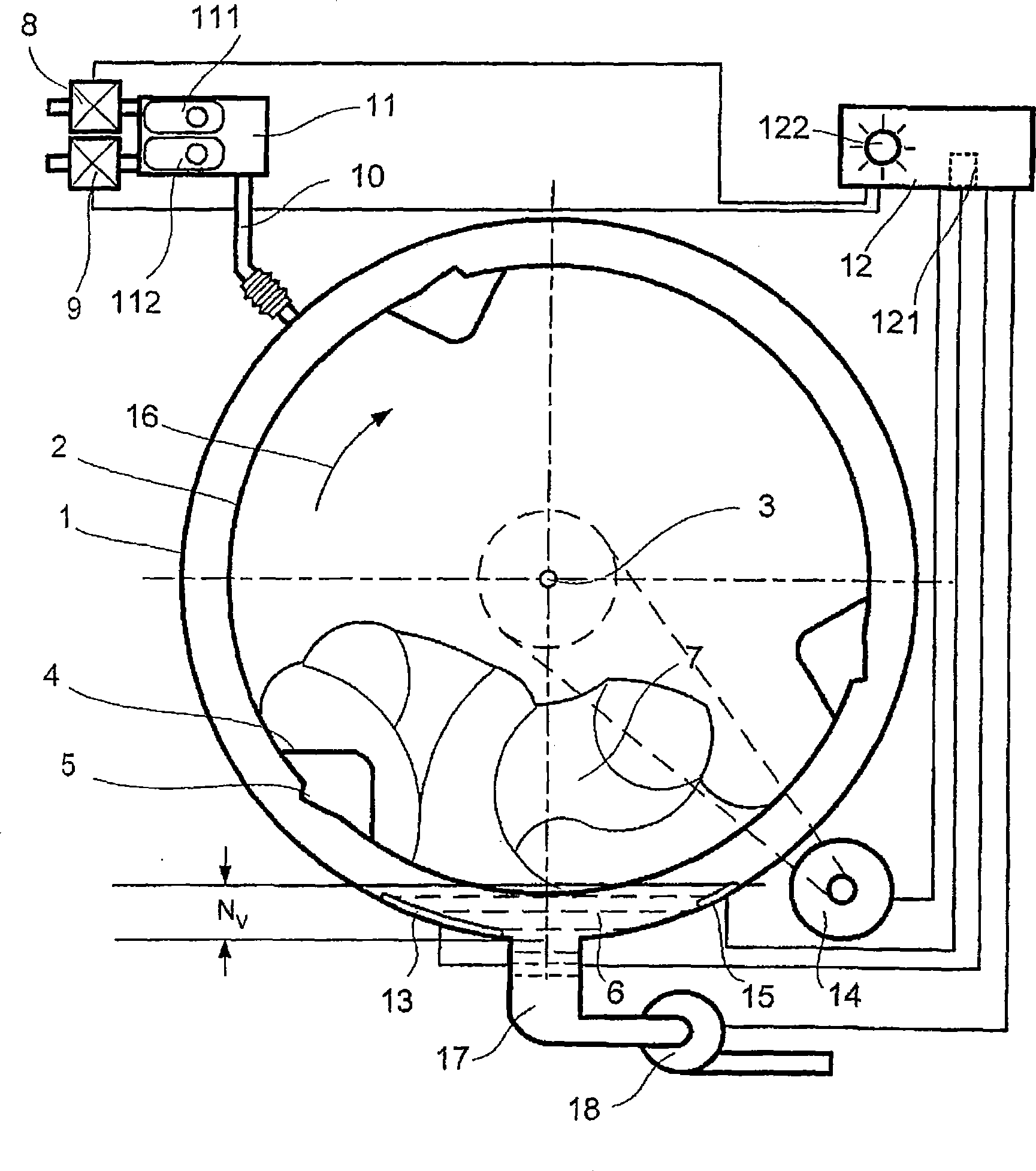

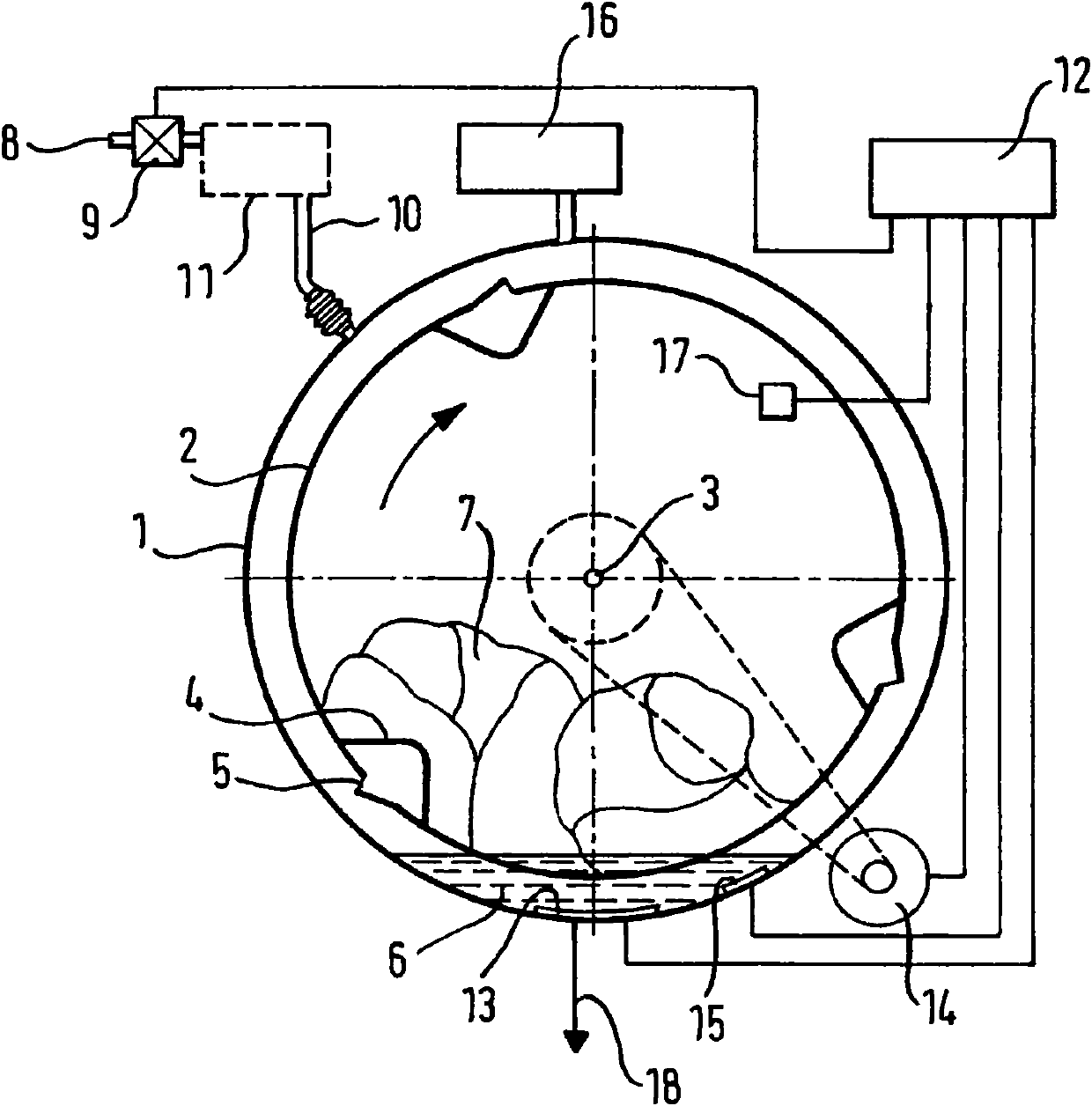

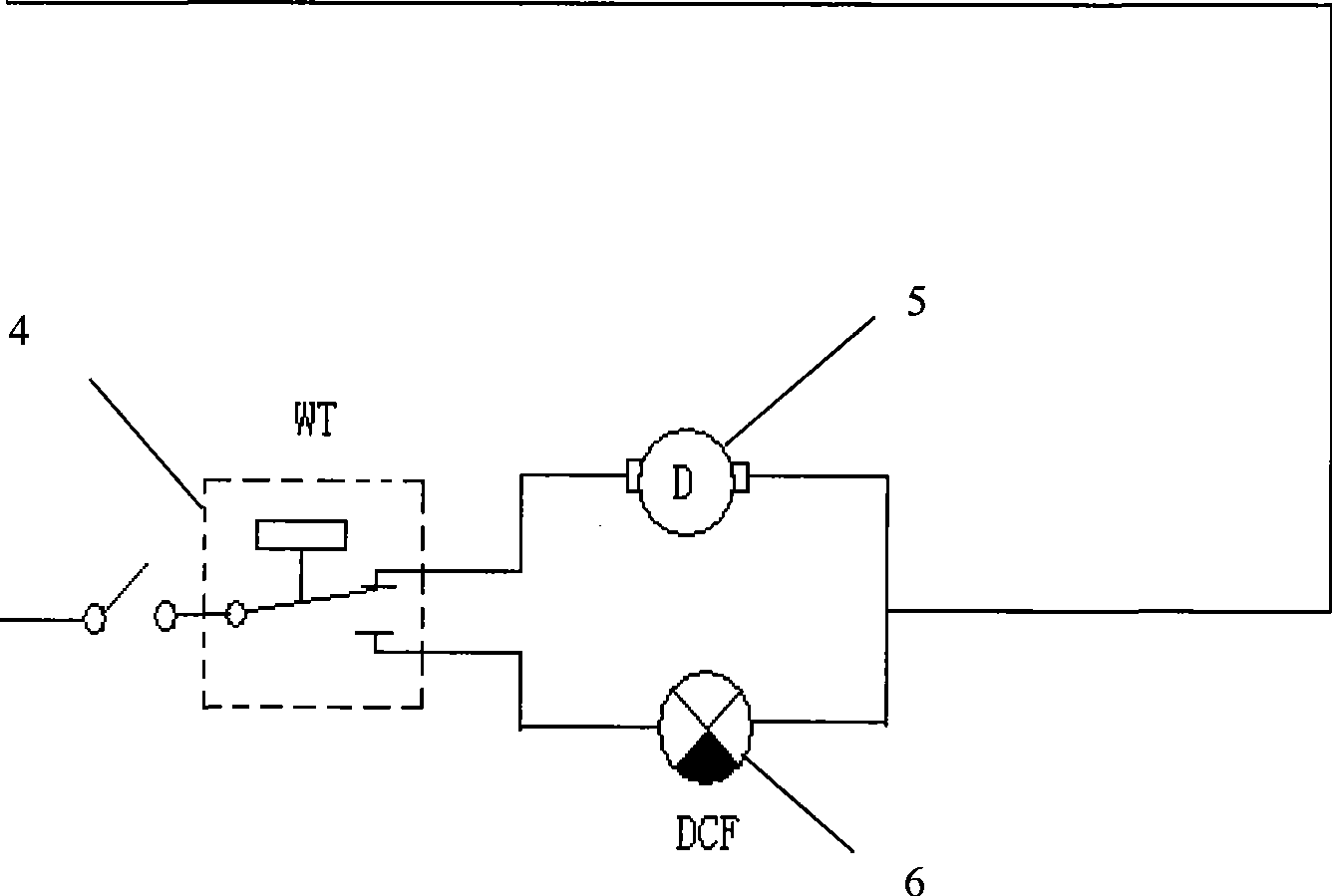

Method for the treatment of laundry, and washing machine suitable for this purpose

ActiveCN101711295ASave water and energyOther washing machinesControl devices for washing apparatusEngineeringLaundry

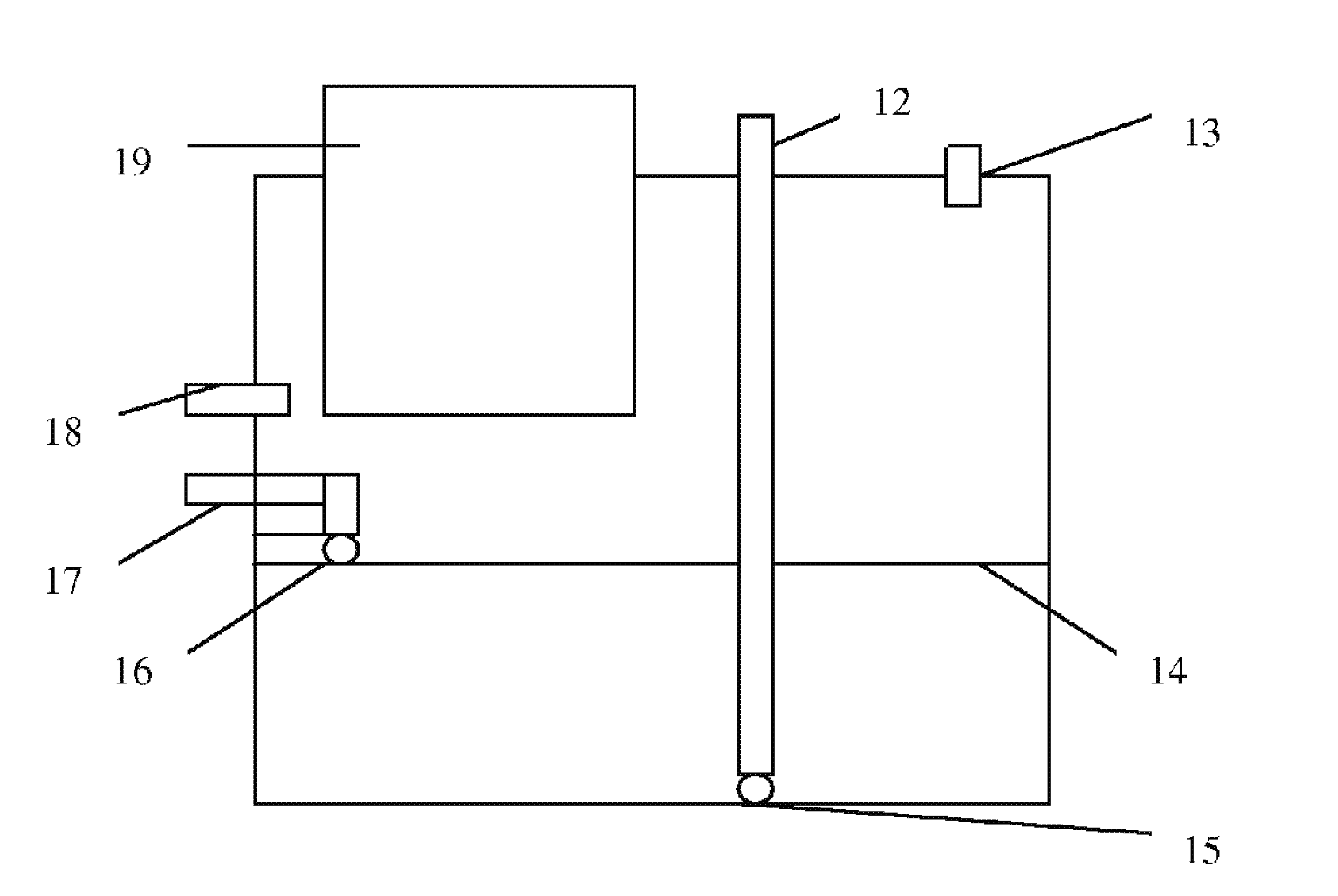

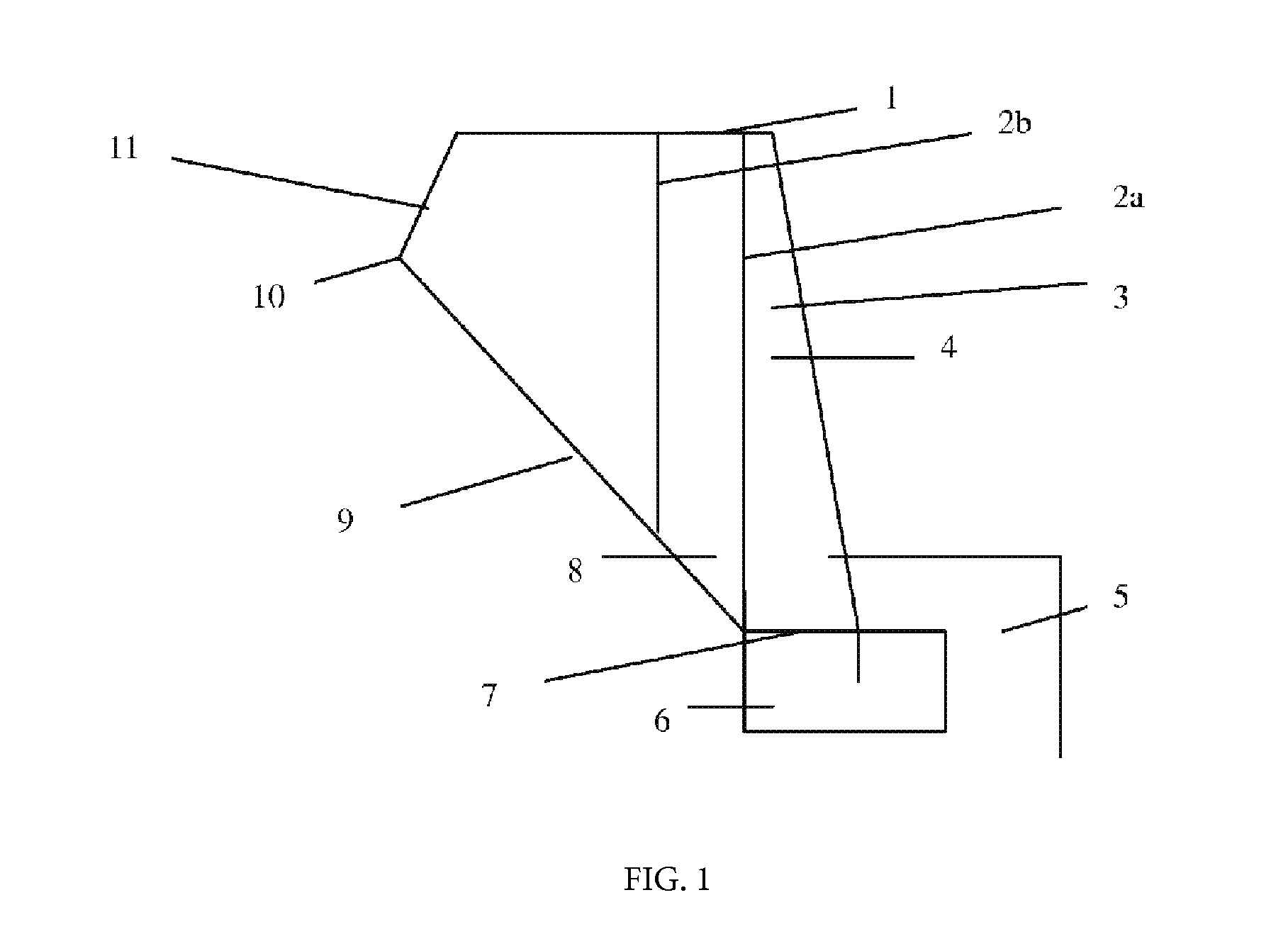

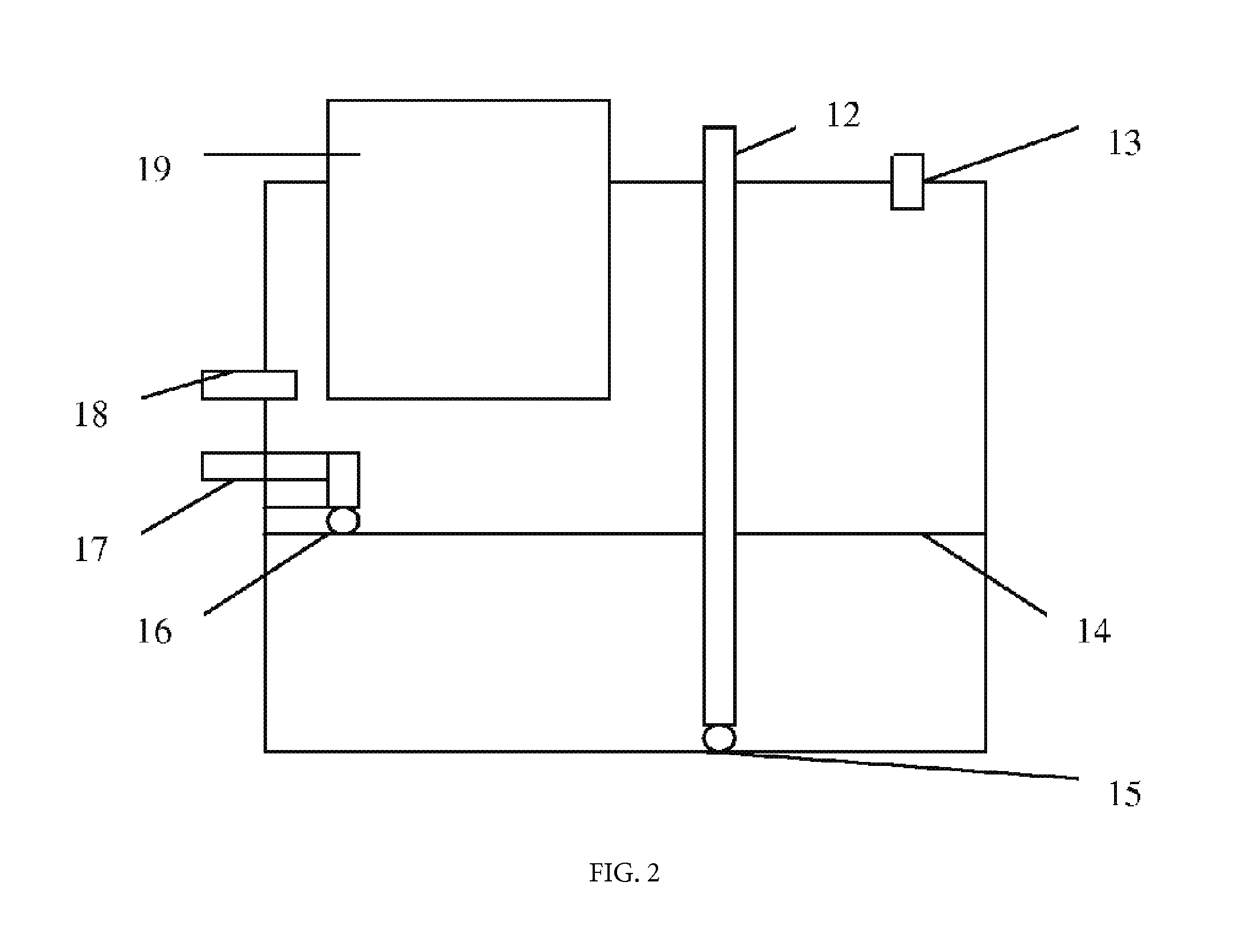

The invention relates to a method for the treatment of laundry (7), having a washing lye in a washing machine comprising a lye discharge system (18) disposed on the base of a lye container (1), a pivotally supported drum (2), and a heating device (13, 16) for the direct heating of a load (a1) of laundry (7) containing the washing lye, the method comprising the steps of: a) adding the washing lye to the load (a1) in an amount (a2) smaller or equal to an amount (a3) required for saturation of the laundry (7) with water ('saturation amount'), and wetting the laundry (7); b) heating the wetted laundry (7) by means of the heating device (13, 16); and c) adding water at a temperature Tw of no more than 40 DEG C for rinsing the washing lye from the laundry (7). The invention further relates to a washing machine suitable for carrying out the method.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

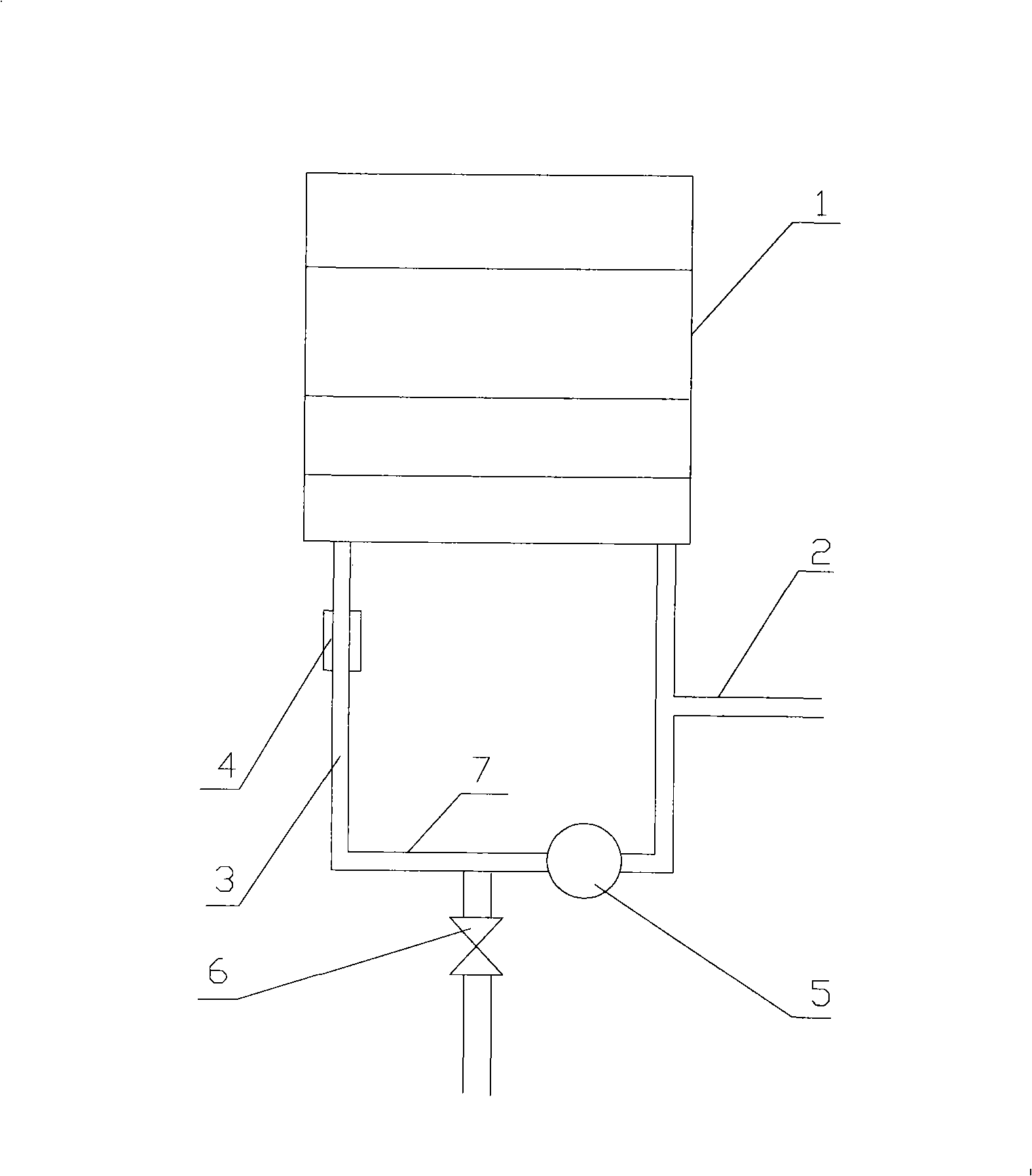

Water heater open-and-heating device

The invention relates to a water heating device, in particular to a water heater. An instant on-and-use device of the water heater comprises a hot water outlet pipe, a cold water inlet pipe, a return pipe communicating the hot water outlet pipe and the cold water inlet pipe, and an outlet valve; a pump is arranged on the return pipe; the device also comprises a double control temperature relay; and the outlet valve is an electromagnetic valve. The device not only can meet the requirement of people on water yield, but also saves electrical power.

Owner:上海友霓节能环保科技发展有限公司

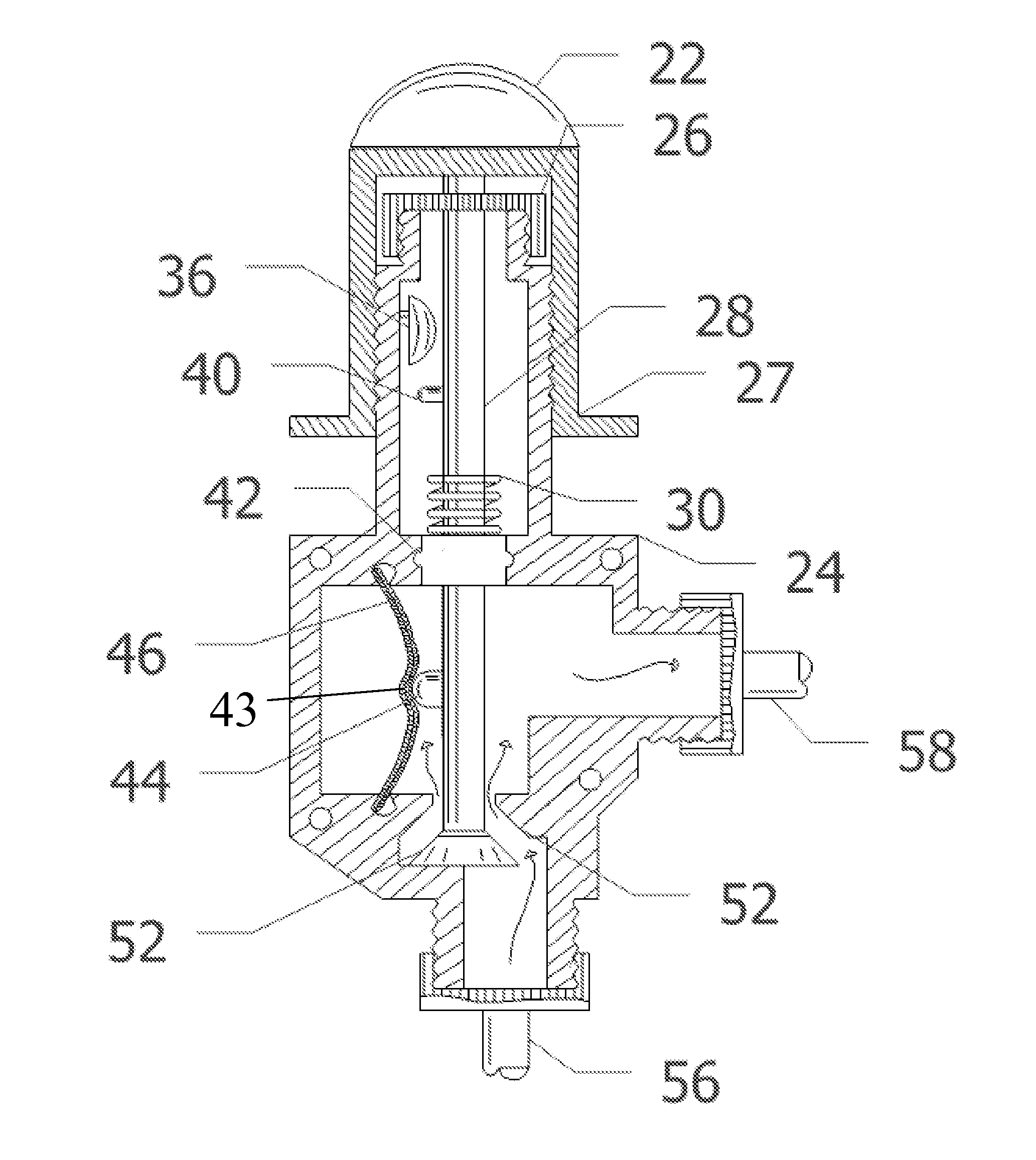

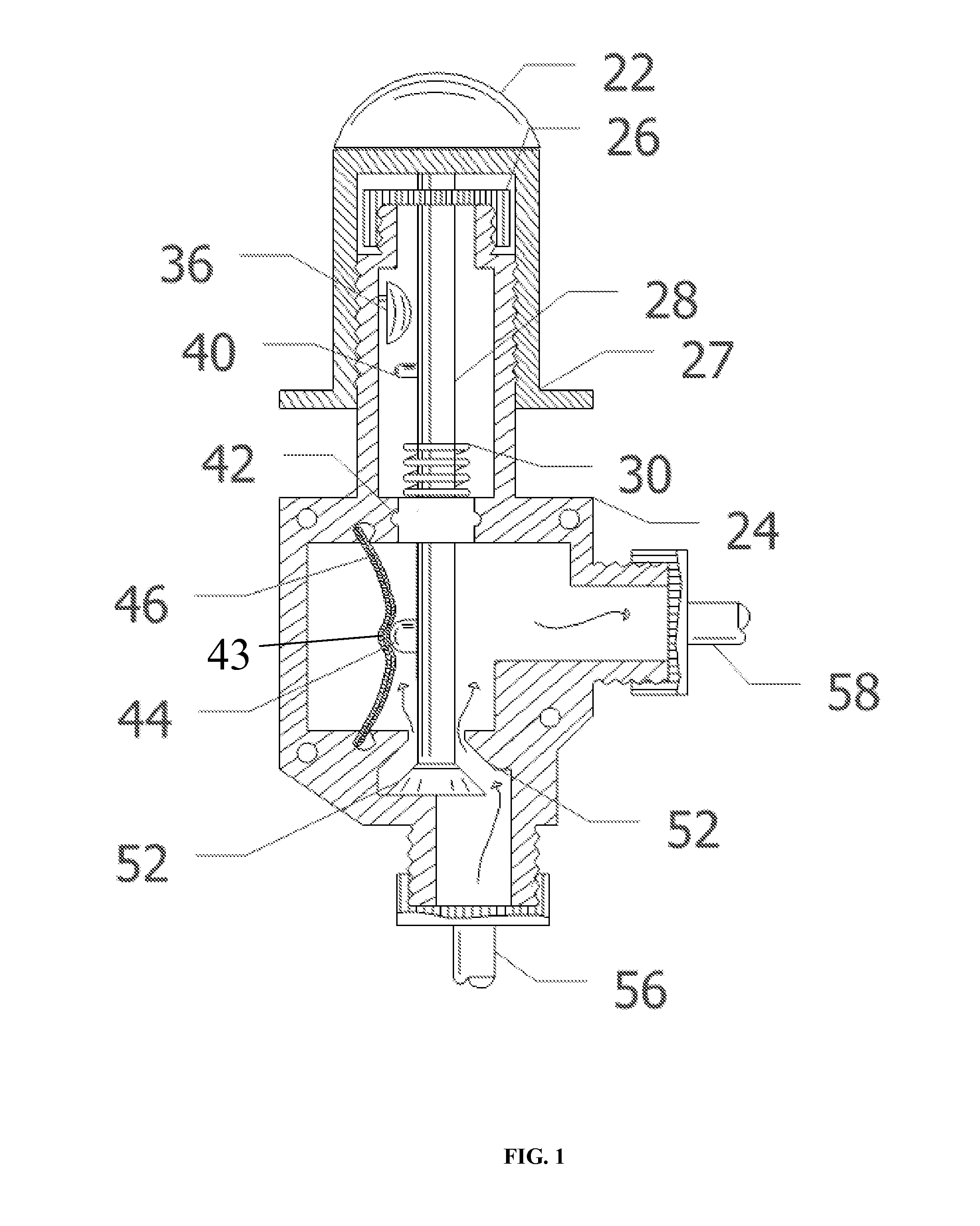

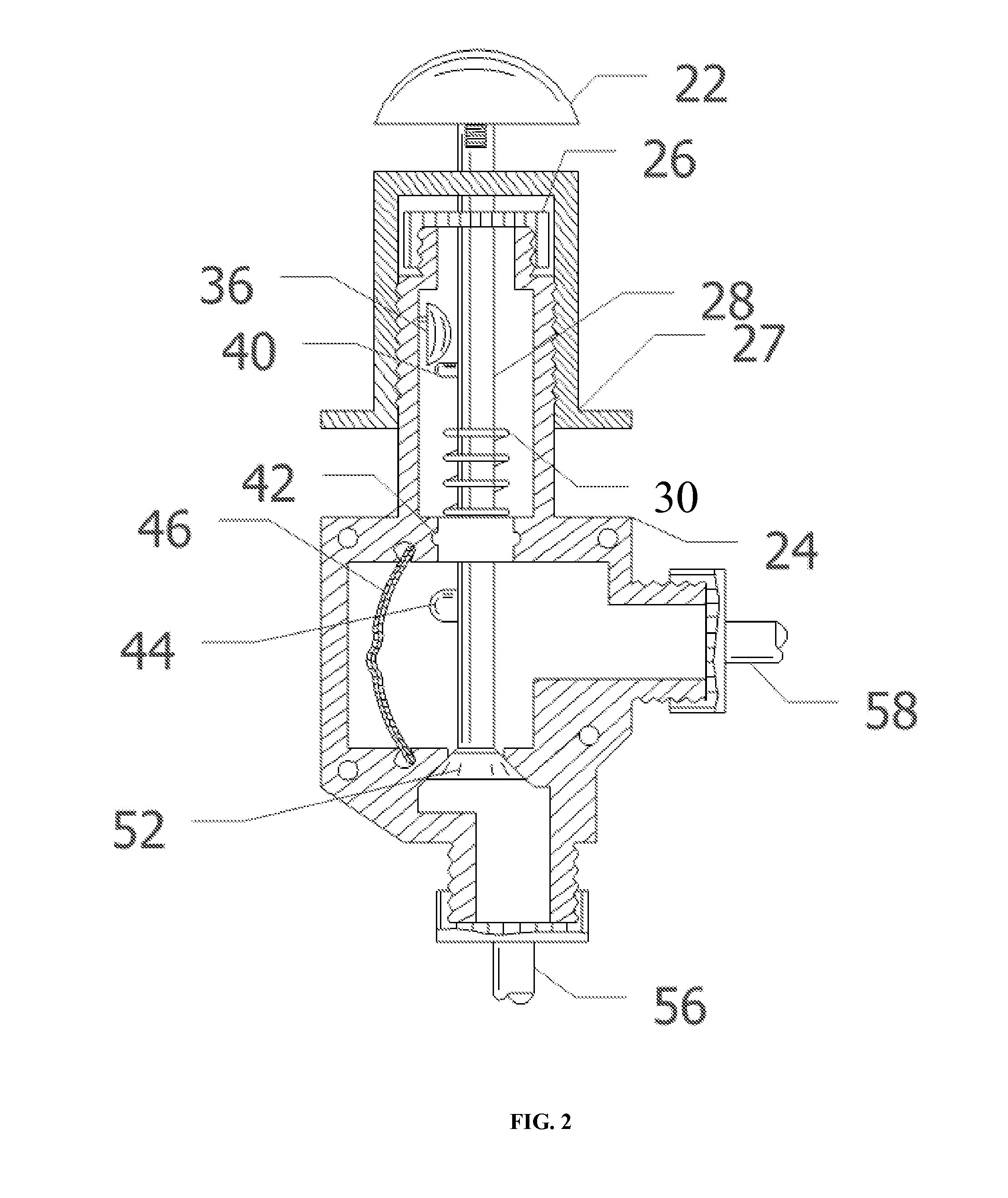

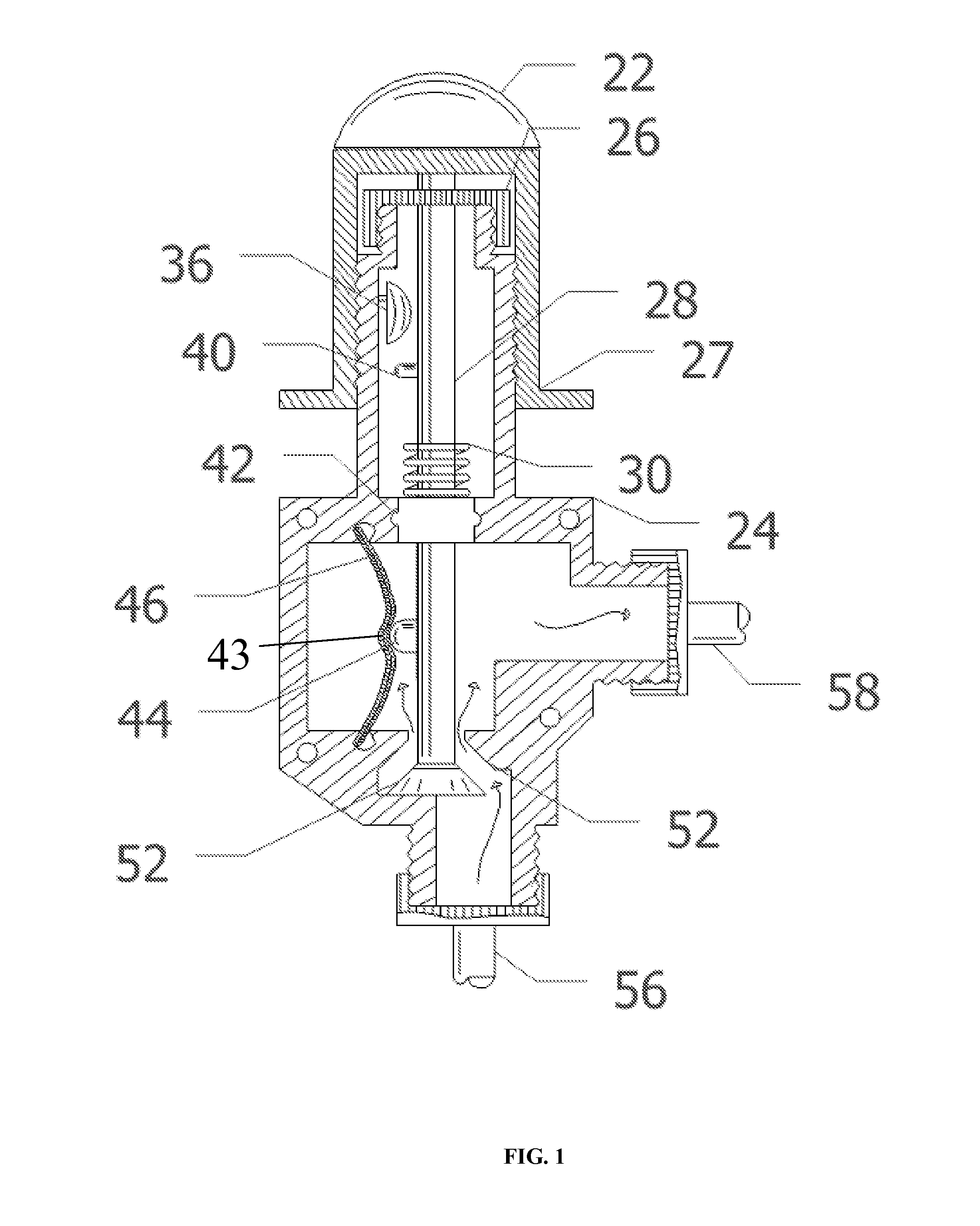

Water conserving domestic hot water purge valve

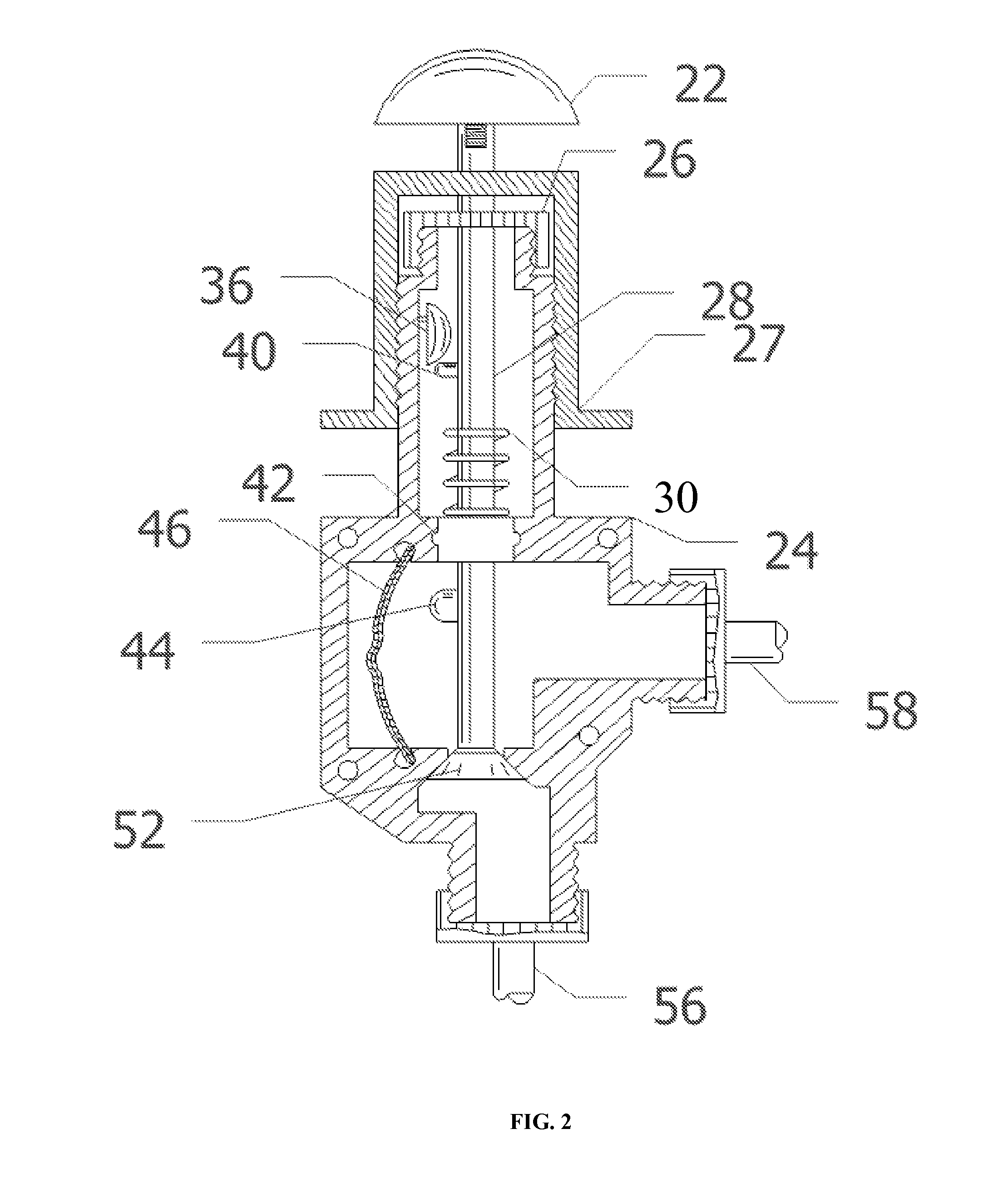

ActiveUS20120012198A1Avoid energy wasteAvoid water wasteWash-standsEqualizing valvesWater flowEngineering

A purge valve comprising a valve body having a valve inlet and a valve outlet and a water flow passage between the valve inlet and the valve outlet; first valve means adapted to set the valve in open position by opening the water flow passage in response to a user's action; second valve means adapted to hold the valve in open position if and until the water flowing through the water flow passage is below a predetermined temperature; third valve means adapted to automatically set the valve in close position when the water flowing through the water flow passage is at the predetermined temperature; and, fourth valve means adapted to alert the user that the valve has closed and water having the predetermined temperature is available at the valve inlet.

Owner:SCHNEIDER AARON

Ultraviolet-resistant fabric and preparation method thereof

ActiveCN107142741AImprove stabilityReduce layeringFireproof paintsPolyurea/polyurethane coatingsBenzotriazoleUv absorber

The invention discloses an ultraviolet-resistant fabric and a preparation method thereof. The fabric comprises a fabric surface layer and an ultraviolet-resistant layer deposited on the fabric surface layer, wherein the ultraviolet-resistant layer is a blending layer of polyurethane, sodium alginate, hydroxyethyl methyl cellulose, hindered amine light stabilizers, hydroxyphenyl benzotriazole ultraviolet absorbents, nano ultraviolet absorbents and rare earth fluorescent compounds. The fabric is excellent in ultraviolet-resistant effect, excellent in moisture absorption property, simple in production process, has resistance to sunlight and perspiration and does not need to be washed with water; a lot of water and energy can be saved; the fabric coated with the ultraviolet-resistant coating is soft, tough, washable and durable, and is excellent in properties.

Owner:嘉兴市俊发喷织有限公司

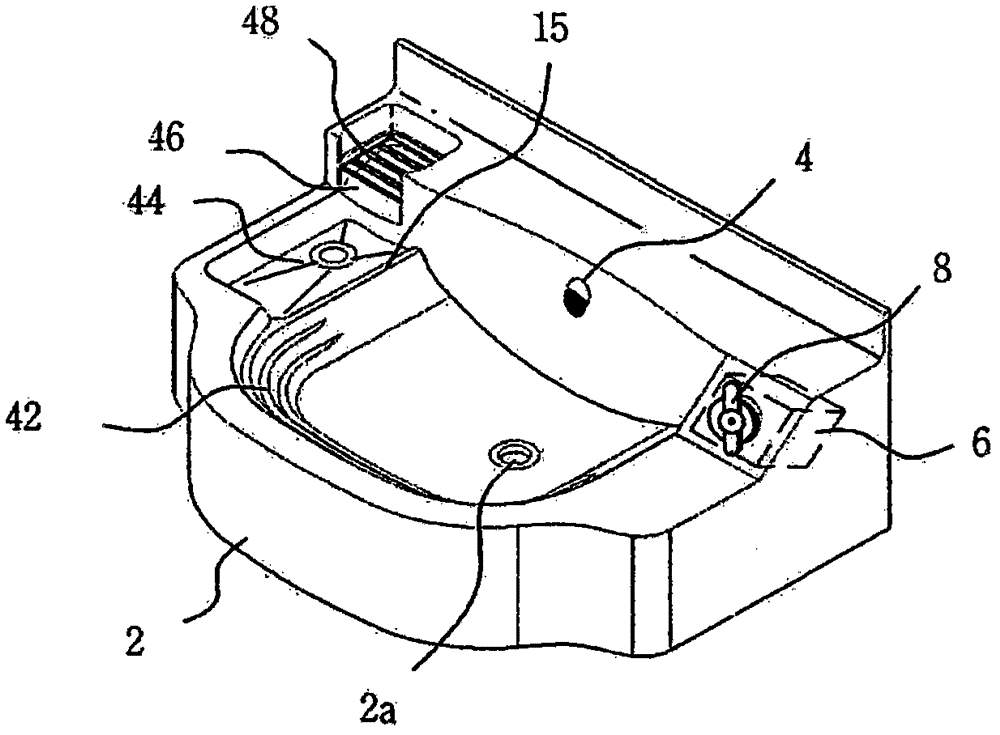

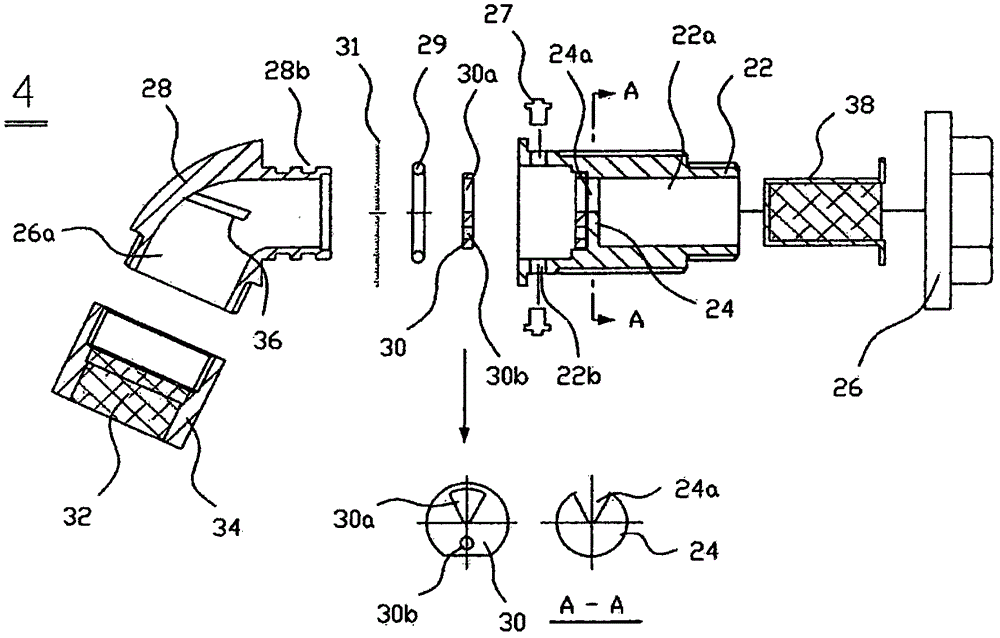

Bathroom Sink

InactiveCN102802481AWide wash spaceEasy to useWash-standsJoints with sealing surfacesWater dischargeEngineering

The present invention relates to a bathroom sink which is adapted to have a water retaining space as large as possible and enables a user to wash his or her hair therein or to rinse his or her mouth easily, even without using a separate cup, after brushing. Accordingly, the present invention provides the bathroom sink, comprising: a main body, which has a water retaining space for use as a water receptacle, an insertion aperture formed on the front surface in a downward inclined direction and an outlet formed on the bottom surface; a water supply nozzle, which passes through the insertion aperture from the rear end of the main body and is protruded outside of the water retaining space, with the protruded portion being rotatable in a direction the user desires to have water discharged in an amount that is regulated according to the rotation; a cold / hot water feed valve, which is embedded on an edge side of the main body and connected to the water supply nozzle through the medium of a pipe; and a cold / hot water selection lever, which is installed on the top surface of the cold / hot water feed valve and selectively supplies cold / hot water towards the water supply nozzle.

Owner:金石镇 +1

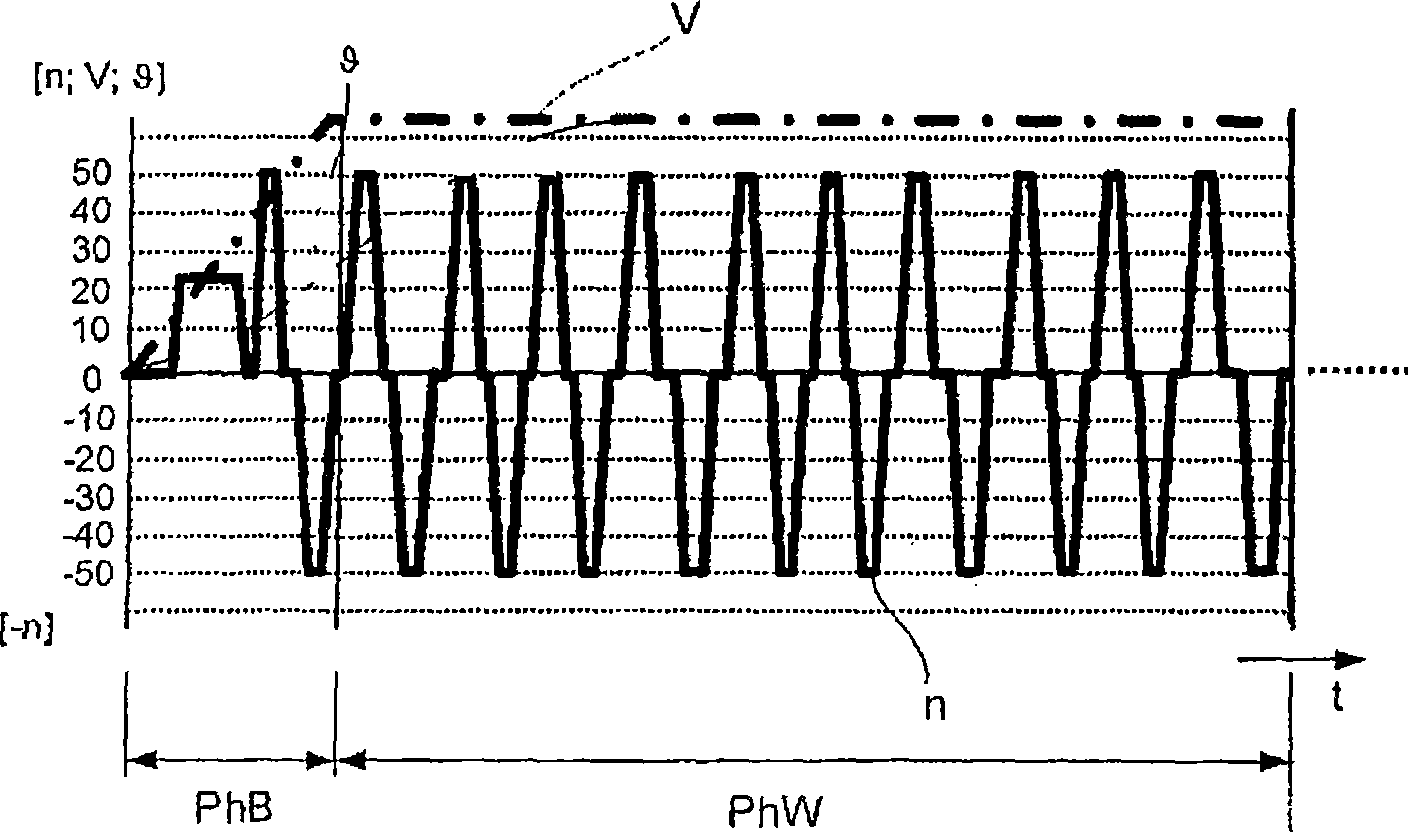

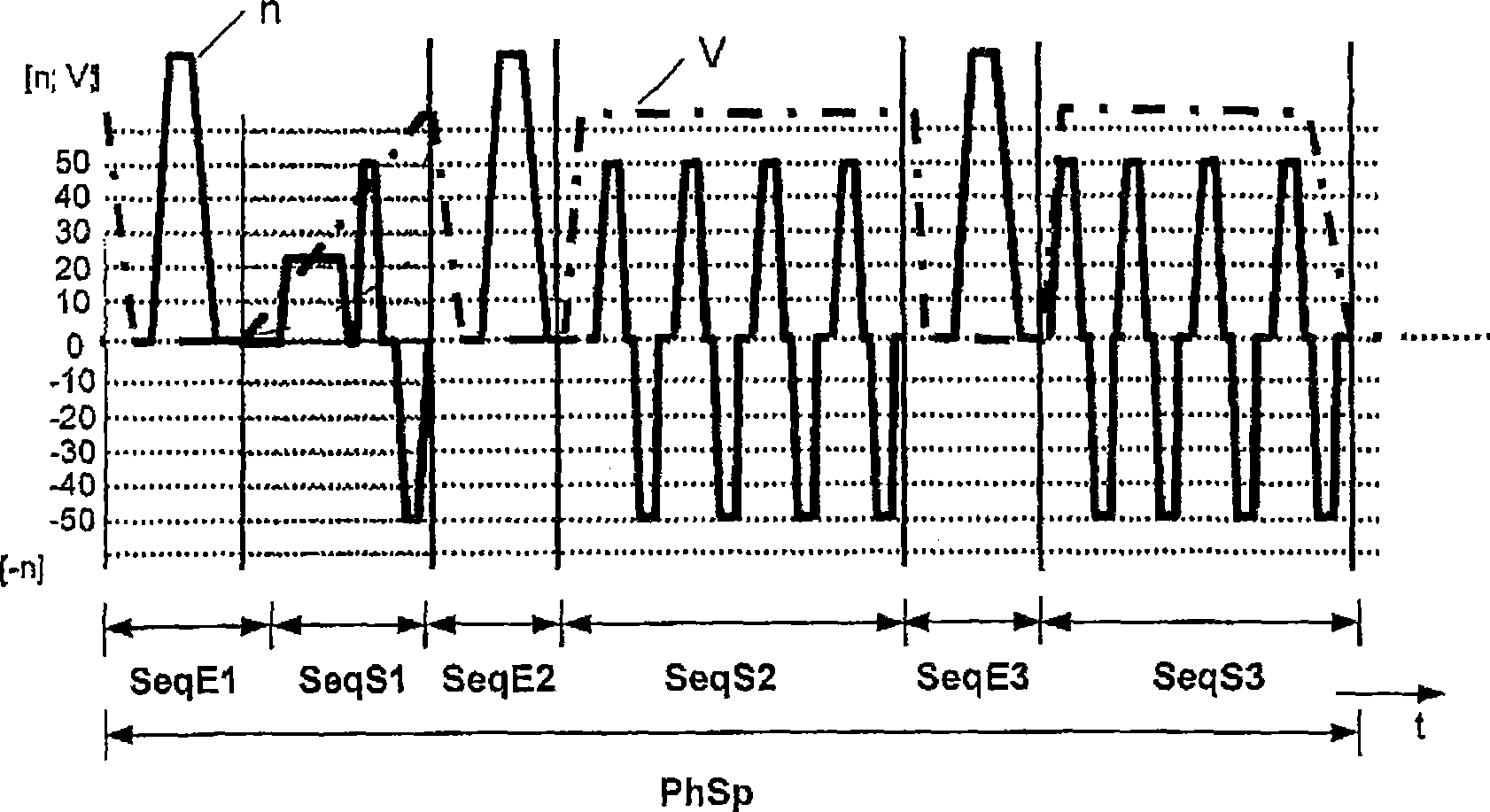

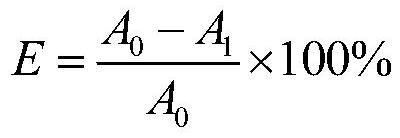

Determination of the water storage capacity of textiles in a washing machine, and corresponding washing machine

ActiveCN101479420AIncrease moisture contentDetermination of moisture contentOther washing machinesTextiles and paperWater storageEngineering

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Water conserving domestic hot water purge valve

ActiveUS8235306B2Avoid wastingAvoid delayTemperature control without auxillary powerWash-standsWater flowEngineering

Owner:SCHNEIDER AARON

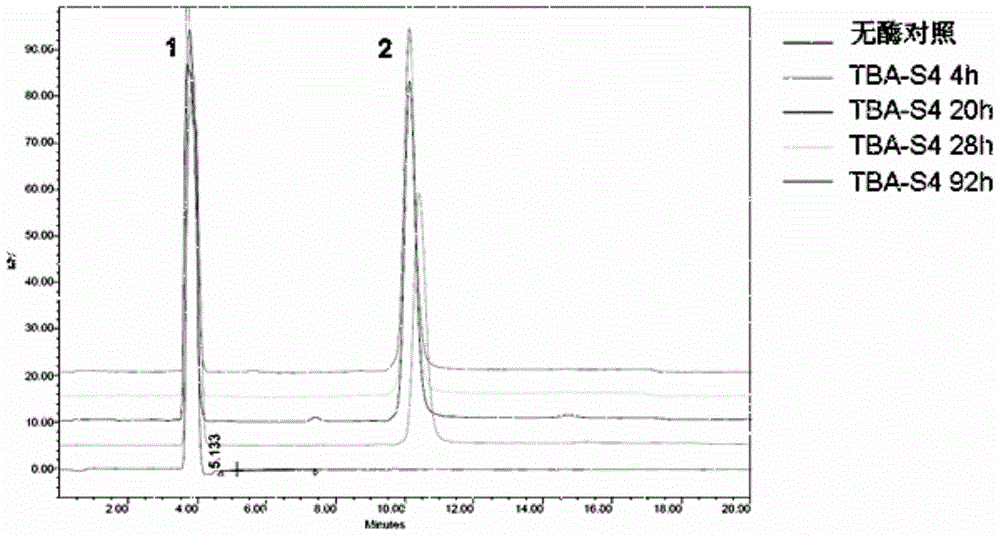

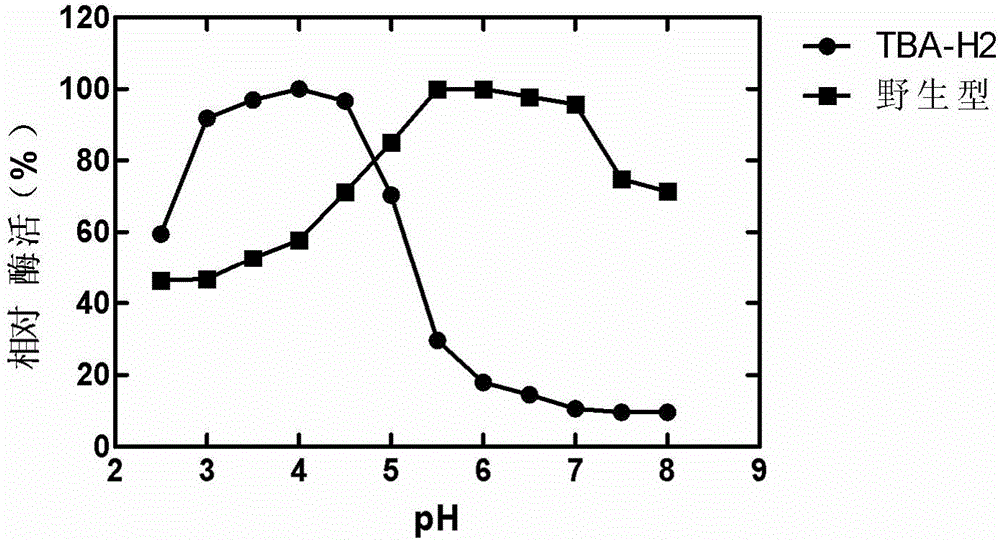

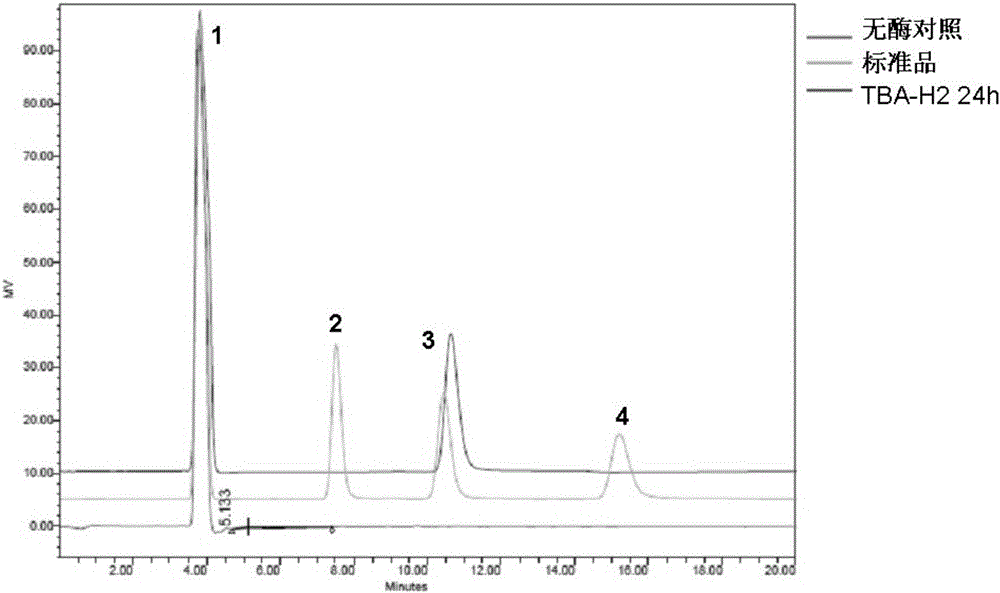

Mutant TBA-H2 of acid and high temperature resistant beta-amylase and application thereof

The invention provides a mutant TBA-H2 of acid and high temperature resistant beta-amylase and an application thereof. The amino acid sequence of the mutant is shown in SEQ ID NO:1 in a sequence table. Relative to enzymes before mutation, the mutant has an optimum pH value of acid and a higher function of generating maltose. The mutant TBA-H2 of high temperature resistant beta-amylase can be used for degrading starchy materials and is especially suitable for degrading starch under acidic conditions to generate maltose.

Owner:南宁邦尔克生物技术有限责任公司

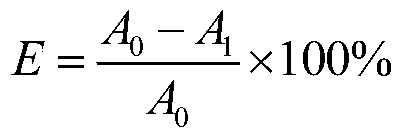

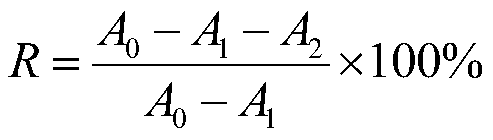

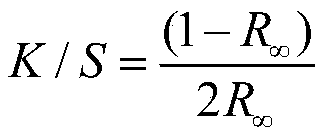

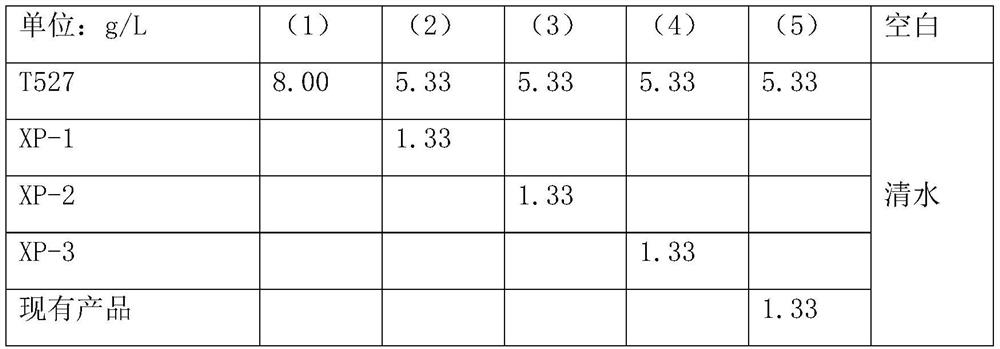

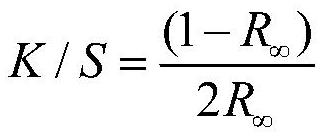

Method for improving fixation rate of reactive dye in alcohol organic solvent-water system

ActiveCN110258141AImprove apparent color yieldHigh color fixing rateDyeing processOrganic solventAlcohol

The invention discloses a method for improving the fixation rate of a reactive dye in an alcohol organic solvent-water system. The method includes modifying a pre-dyed cotton textile by adopting a treatment method that an alkali liquor and a cation modifier are in the same bath, and then directly dyeing in the alcohol organic solvent-water system; remarkably improving the affinity between the cotton textile and the reactive dye through the synergistic effect of alkali liquor pre-swelling and cation modifier modification treatment, so as to improve the fixation rate of salt-free dyeing of the cotton textile and the K / S value after soaping; and meanwhile, placing the cotton textile in the alcohol organic solvent-water system, performing alkali liquor pre-swelling, and then performing cationic modification. on one hand, the alkali liquor is used as a nucleophilic reagent combined with the cation modifier and the cotton textile, on the other hand, the alkali liquor is used as a fixing agent for dyeing the modified cotton textile, and the modified cotton textile is directly dyed without water washing, so that the fixing rate of the reactive dye in the alcohol organic solvent-water system is obviously improved.

Owner:WUHAN TEXTILE UNIV

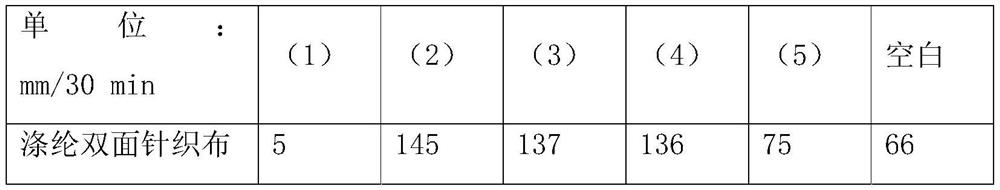

Preparation method of polyester fabric moisture absorption and sweat releasing finishing agent containing naphthalene structure

The invention relates to a preparation method of a polyester fabric moisture-absorbing and sweat-releasing finishing agent containing a naphthalene structure, which comprises the following steps: by taking dimethyl 1, 8-naphthalate, ethylene glycol, polyethylene glycol and a catalyst as raw materials, carrying out transesterification, and then carrying out polycondensation to synthesize a polyester-polyether copolymerization type moisture-absorbing and sweat-releasing finishing agent suitable for polyester fabrics. The method is high in synthesis efficiency, the finished fabric is good in hydrophilicity and hand feeling, the moisture absorption and sweat releasing agent and silicone oil can be subjected to one-bath finishing, the hydrophilic performance is excellent after one-bath finishing, and the after-finishing efficiency of the fabric is greatly improved.

Owner:DYMATIC CHEM

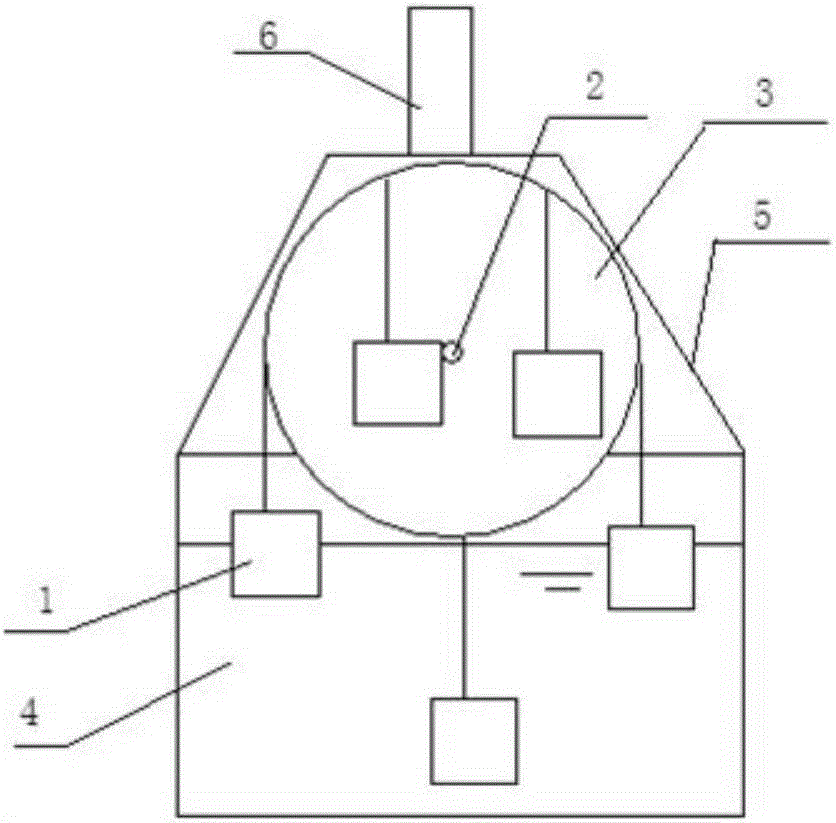

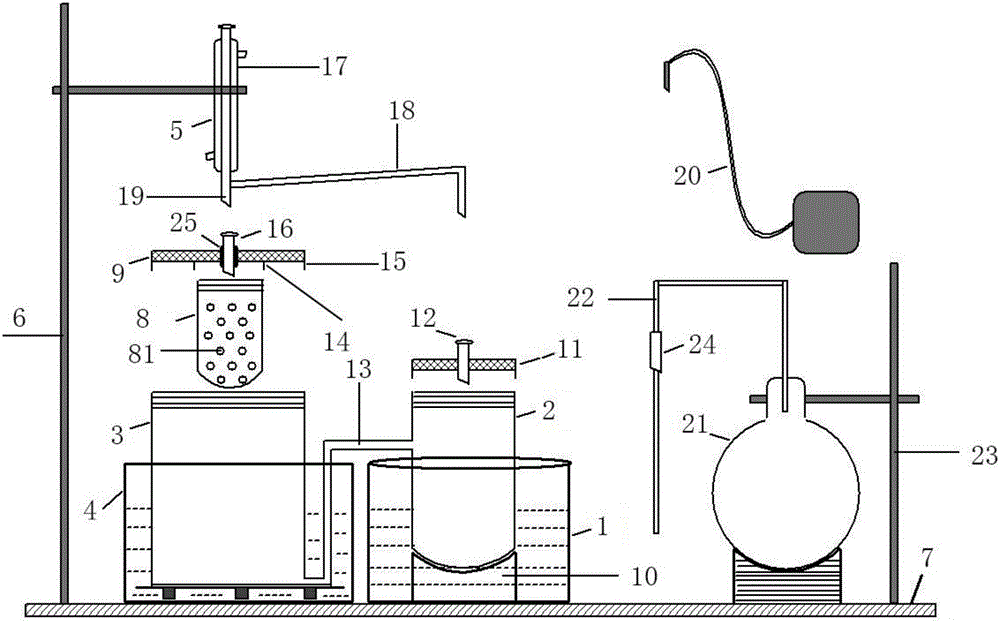

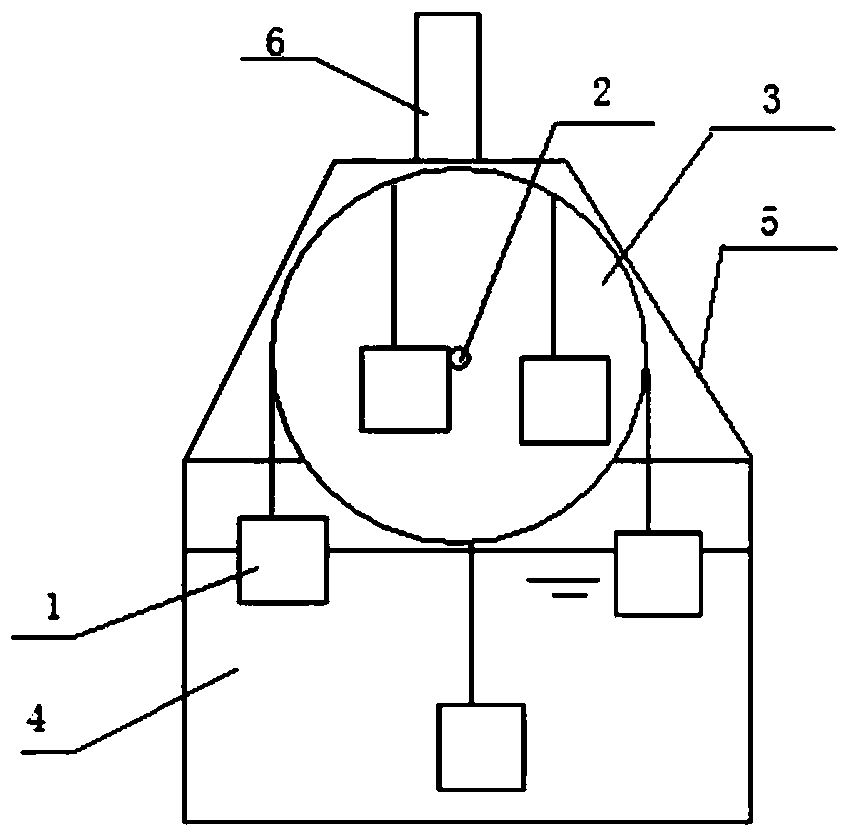

Full-automatic closed-circuit circular extraction device

InactiveCN106334339AShorten the timeSave water and energyEvaporationSolid solvent extractionWater bathsMicrowave

The invention discloses a full-automatic closed-circuit circular extraction device. The device comprises a magnetic stirring water bath pot, an evaporation kettle, an extraction kettle, ultrasonic / microwave auxiliary equipment, a condenser, a support frame, a horizontal support, an extraction container and a dual-sealing cover; a support is arranged at the pot bottom; the evaporation kettle is arranged in the pot; a sealing cover and a steam pipe are arranged on the top of the evaporation kettle; a flow guide pipe is arranged between the evaporation kettle and the extraction kettle; the dual-sealing cover comprises an inner cover and an outer cover; the outer cover is fixedly connected with the extraction kettle in a sealing mode; the extraction container is connected with the inner cover in a sealing mode; mesh holes are formed in the extraction container, and a return pipe is arranged on the inner cover; the condenser is fixed to the support frame and comprises a water cooling part, a natural cooling part and a drainage pipe; the drainage pipe is detachably connected with the return pipe in a sealing mode; the natural cooling part is detachably connected with the steam pipe in a sealing mode; the support frame, the magnetic stirring water bath pot and the ultrasonic / microwave auxiliary equipment are arranged on the horizontal support. The whole device is a closed-circuit system, no solvent is lost in the extraction process, and steam in the evaporation kettle serves as driving force for achieving automatic circulation of the whole system.

Owner:ZHENGZHOU UNIV

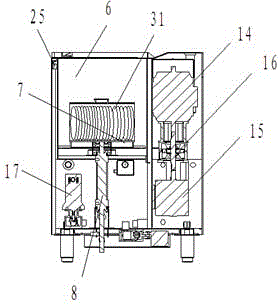

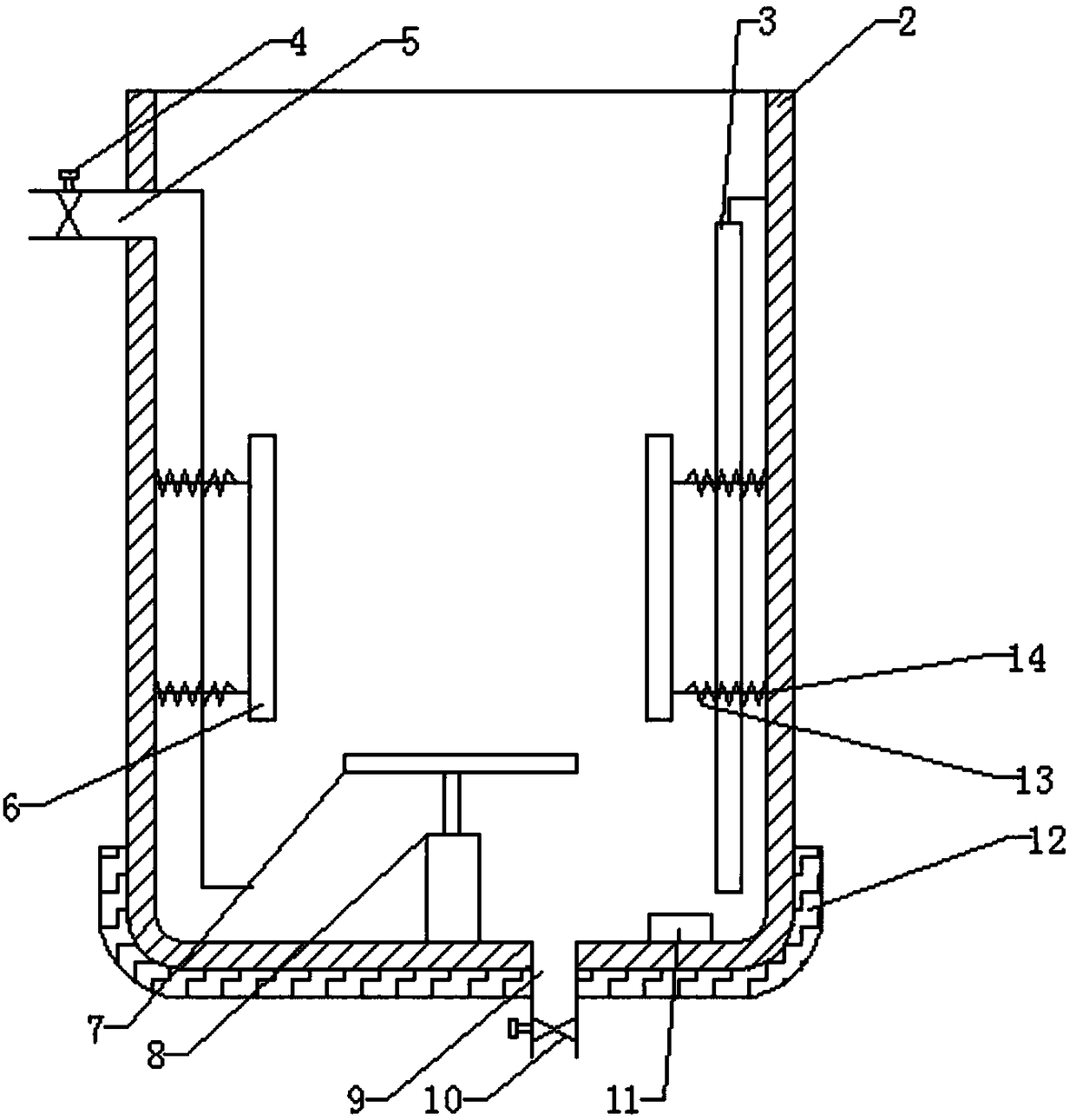

Cotton knitted fabric dyeing and finishing method and water bath device

ActiveCN106283665BImprove qualityShorten the timeTextile treatment containersTextile treatment machine arrangementsWater bathsTemperature control

The invention provides a cotton knitted fabric dyeing and finishing method and a water bath apparatus. The method comprises: carrying out polishing enzyme inactivation treatment: dipping a cotton knitted fabric in bio-polishing enzyme working solution, firstly heating up, then carrying out heat preservation, and taking out the cotton knitted fabric to carry out inactivation treatment; carrying out dyeing and finishing treatment; after scouring and bleaching the cotton knitted fabric, adding a dye, anhydrous sodium sulphate and sodium carbonate into the bio-polishing enzyme working solution to carry out biological enzyme polishing and dyeing one-bath treatment. The apparatus used by the dyeing and finishing method comprises a pot body and an independent constant-temperature water bath unit in the pot; the constant-temperature water bath unit comprises a water bath tank, a clamping device, a supporting device, a heating device and a control panel. The cotton knitted fabric dyeing and finishing method and the water bath apparatus have the beneficial effects that by the method provided by the invention, a high-quality product can be produced; the apparatus used by the dyeing and finishing method provided by the invention can implement accurate temperature control and is applicable to various diameters of containers.

Owner:南通海林集团有限公司

Method for the treatment of laundry, and washing machine suitable for this purpose

ActiveCN101711295BSave water and energyOther washing machinesControl devices for washing apparatusCelsius DegreeProcess engineering

A method for treating laundry with washing lye uses a washing machine having a lye discharge system disposed on a base of a lye container, a pivotally supported drum, and a heating device for the direct heating of a load of laundry containing the washing lye. The method includes adding the washing lye to the load in an amount smaller or equal to an amount required for saturation of the laundry with water (“saturation amount”), wetting the laundry, and heating the wetted laundry via the heating device. Water is added at a temperature of no more than 40 degrees Celsius for rinsing the washing lye from the laundry. A washing machine is also configured to be suitable for carrying out the method.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

A kind of method for improving color fixation rate of reactive dyes in alcoholic organic solvent-water system

The invention discloses a method for improving the color fixation rate of reactive dyes in an alcoholic organic solvent-water system, which is to modify pre-dyed cotton textiles and then directly Dyeing in an alcohol organic solvent-water system, the affinity between cotton textiles and reactive dyes is significantly improved through the synergistic effect of alkali solution pre-swelling and cationic modifier modification, so that cotton textiles can be dyed without salt. The color rate and the K / S value after soaping are improved; at the same time, the present invention adopts placing cotton textiles in an alcoholic organic solvent-water system to carry out lye pre-swelling and then carry out cationic modification. On the other hand, it is used as a color-fixing agent for the dyeing of modified cotton textiles, and the modified cotton textiles are directly dyed without washing, which significantly improves the ability of reactive dyes in alcohol organic solvent-water Fixation rate in the system.

Owner:WUHAN TEXTILE UNIV

A kind of resource utilization method of waste acid produced in smelting flue gas to produce sulfuric acid

ActiveCN105217869BSolve waste heat recoverySolve processing problemsEnergy inputMultistage water/sewage treatmentResource utilizationEvaporation

The invention provides a resource recovery method for waste acid produced in the production of sulfuric acid from smelting flue gas. The method is as follows: reducing the waste acid with Fe, obtaining FeSO4 crystals through evaporation and crystallization, and combining the FeSO4 crystals with bentonite to prepare activated clay. The filtrate produced in the activation step reacts with sulfuric acid and an oxidant to obtain polyaluminum ferric sulfate. Optionally, the polyaluminum ferric sulfate is reacted with an organic flocculant to obtain an organic-inorganic composite flocculant. The resource recovery method uses the waste acid produced in the process of producing sulfuric acid from smelting flue gas as the main raw material, and utilizes the waste heat of smelting flue gas to produce activated clay and organic-inorganic composite flocculants that have a broad market in various industries, solving the problem of high temperature Flue gas waste heat recovery and waste acid treatment problems, while solving the seasonal storage problem of by-product sulfuric acid, can also produce a large number of valuable industrial products, with high social, environmental and economic benefits.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

High-pressure water-saving closestool

A high-pressure water-saving closestool for the places such as washrooms comprises a high pressure air generator (19), a high pressure water generator, a high pressure air tank and a closestool body. All the parts are enclosed and are capable of bearing the pressure and impact force of high pressure air or high pressure water without damage. The high pressure air generator (19) is used for pressurizing the water in the high pressure water generator or inflating the high pressure air tank, and then the kinetic energy generated by the high pressure water or high pressure air is used for clearing the dirt. The high-pressure water-saving closestool saves water and energy, and is sanitary and generates less noise.

Owner:TONG JIANLUN

A kind of anti-ultraviolet fabric and preparation method thereof

ActiveCN107142741BSimple structureImprove UV protection effectFireproof paintsPolyurea/polyurethane coatingsFluorescenceUltraviolet

The invention discloses an ultraviolet-resistant fabric and a preparation method thereof. The fabric comprises a fabric surface layer and an ultraviolet-resistant layer deposited on the fabric surface layer, wherein the ultraviolet-resistant layer is a blending layer of polyurethane, sodium alginate, hydroxyethyl methyl cellulose, hindered amine light stabilizers, hydroxyphenyl benzotriazole ultraviolet absorbents, nano ultraviolet absorbents and rare earth fluorescent compounds. The fabric is excellent in ultraviolet-resistant effect, excellent in moisture absorption property, simple in production process, has resistance to sunlight and perspiration and does not need to be washed with water; a lot of water and energy can be saved; the fabric coated with the ultraviolet-resistant coating is soft, tough, washable and durable, and is excellent in properties.

Owner:嘉兴市俊发喷织有限公司

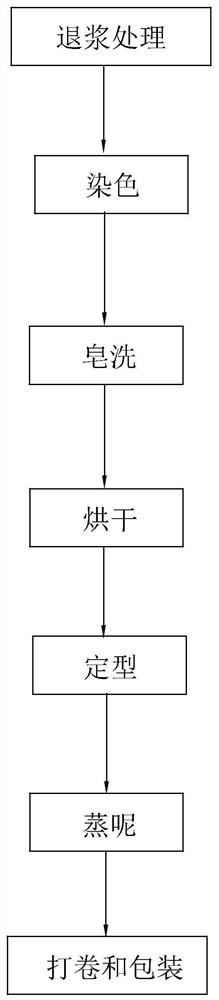

A printing and dyeing process of diacetate fiber and corn fiber high elastic fabric

ActiveCN109629268BLittle strengthCompensation for wicking propertiesDry-cleaning apparatus for textilesWrinkle resistant fibresColour fastnessFiber

The invention discloses a printing and dyeing process of diacetate fiber and corn fiber high-elastic fabric, relates to the technical field of printing and dyeing, and solves the technical problems of poor dyeing uniformity and poor hand feeling of the fabric. It mainly includes the following steps: desizing treatment, dyeing, soaping, drying, setting, steaming and rolling packaging, wherein the fabric is made of acetate fiber for the warp and corn fiber for the weft. The fabric has the advantages of high color fastness, uniform dyeing and excellent fabric performance.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

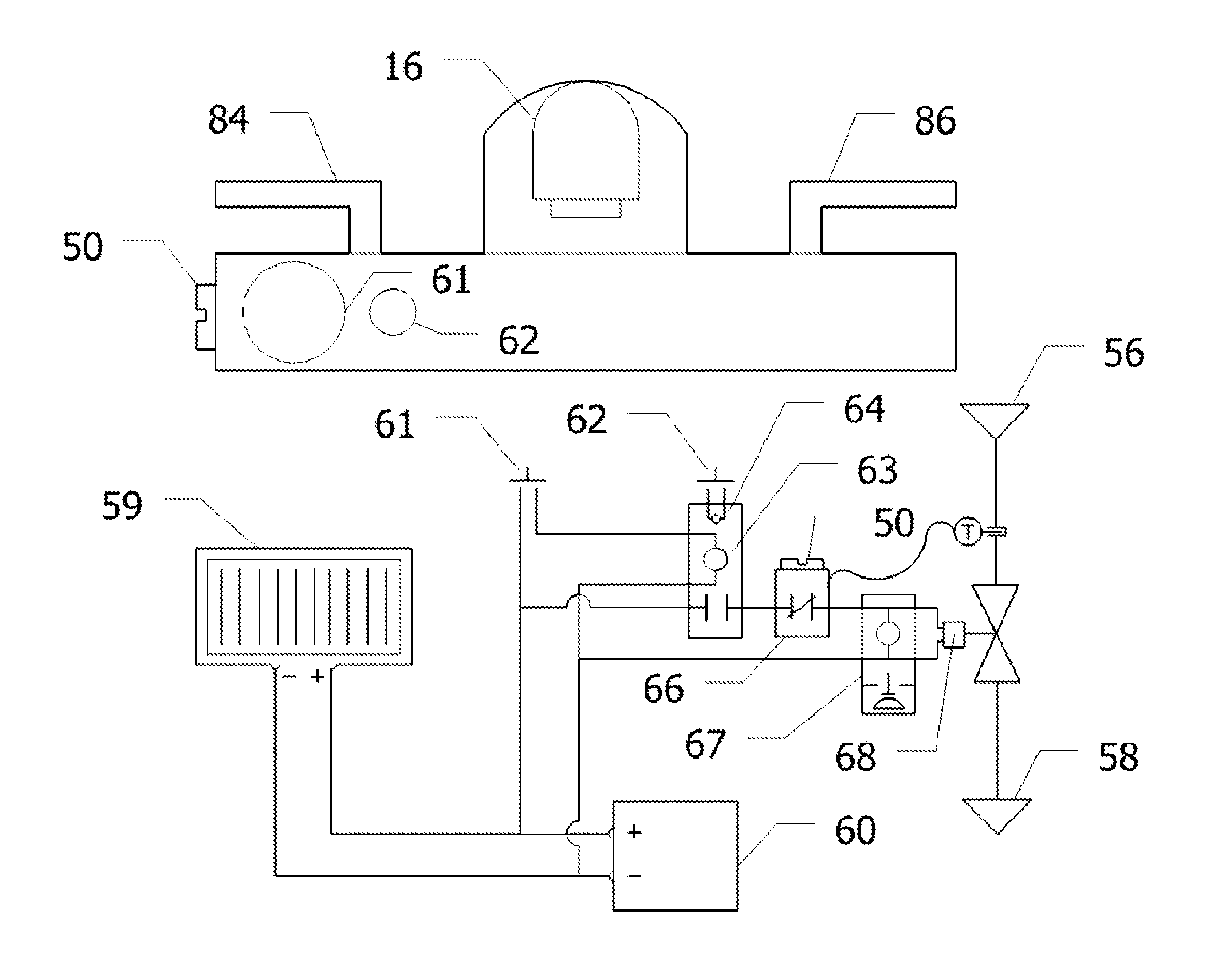

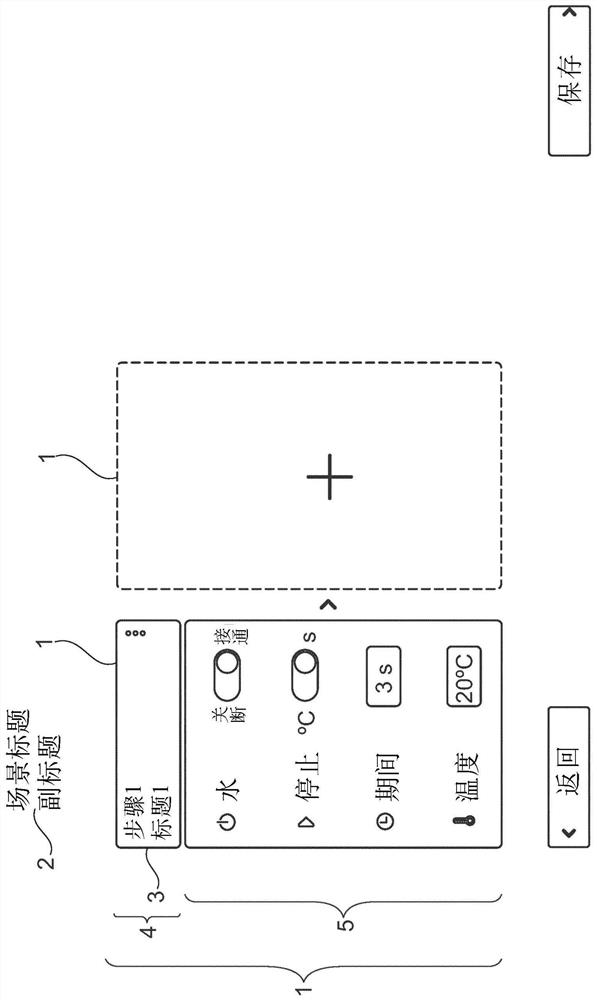

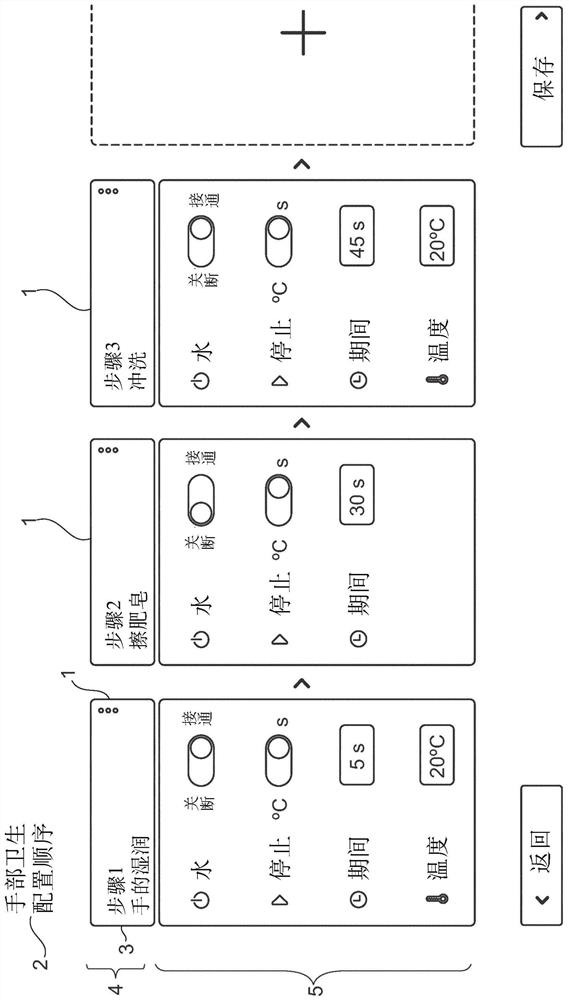

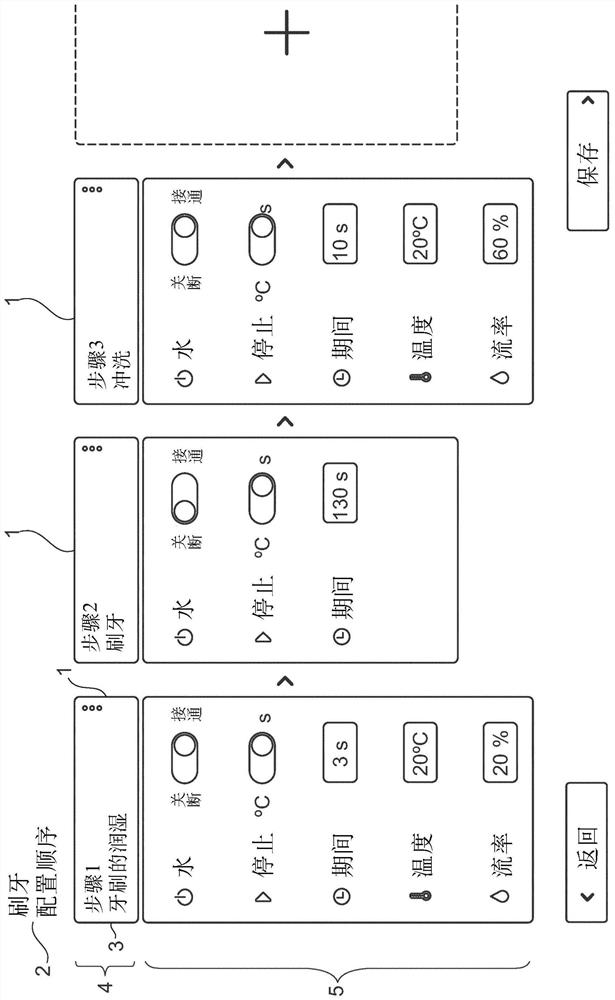

Sequence controller for extraction points

PendingCN113039328ASimple configurationSave water and energyProgramme controlDomestic plumbingSequence controlLiquid medium

A programmable sequence controller for extraction points and peripheral devices associated therewith for controlling sequences having individual sequence steps comprising open-loop-controlled and / or closed-loop-controlled dispensing of liquid media, the controller comprising a control unit for data processing and for storing and executing selectable sequence programs (2), having a display and a possibility for sequence program selection and a control panel for inputs, as well as interfaces for sensors and interfaces for actuating control members connectable to the control unit. In order to configure and edit the selectable sequence programs (2), the sequence controller has a modular programming surface with module boxes (1) for the individual sequence steps (3), into which settings and criteria for the extraction point in question and peripheral devices associated therewith as well as desired properties of the liquid medium that is to be dispensed or breaks in the dispensing procedure can be input for each sequence step in a corresponding module box (1) via the control panel, and the sequence steps can be strung together in the form of the corresponding module boxes (1) to form a sequence program (2) for the sequence. The invention additionally comprises a method for configuring such a sequence controller, and uses of the programmable sequence controller.

Owner:OBLAMATIK AG

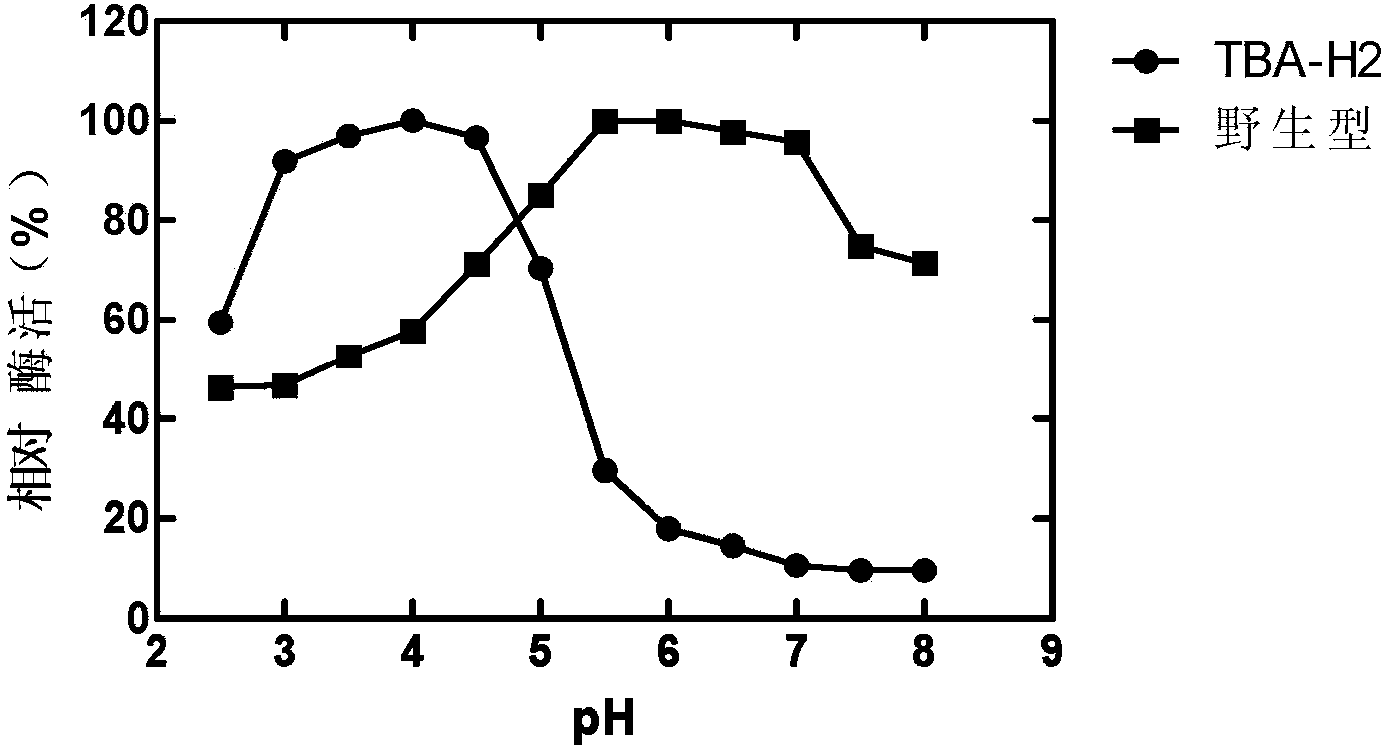

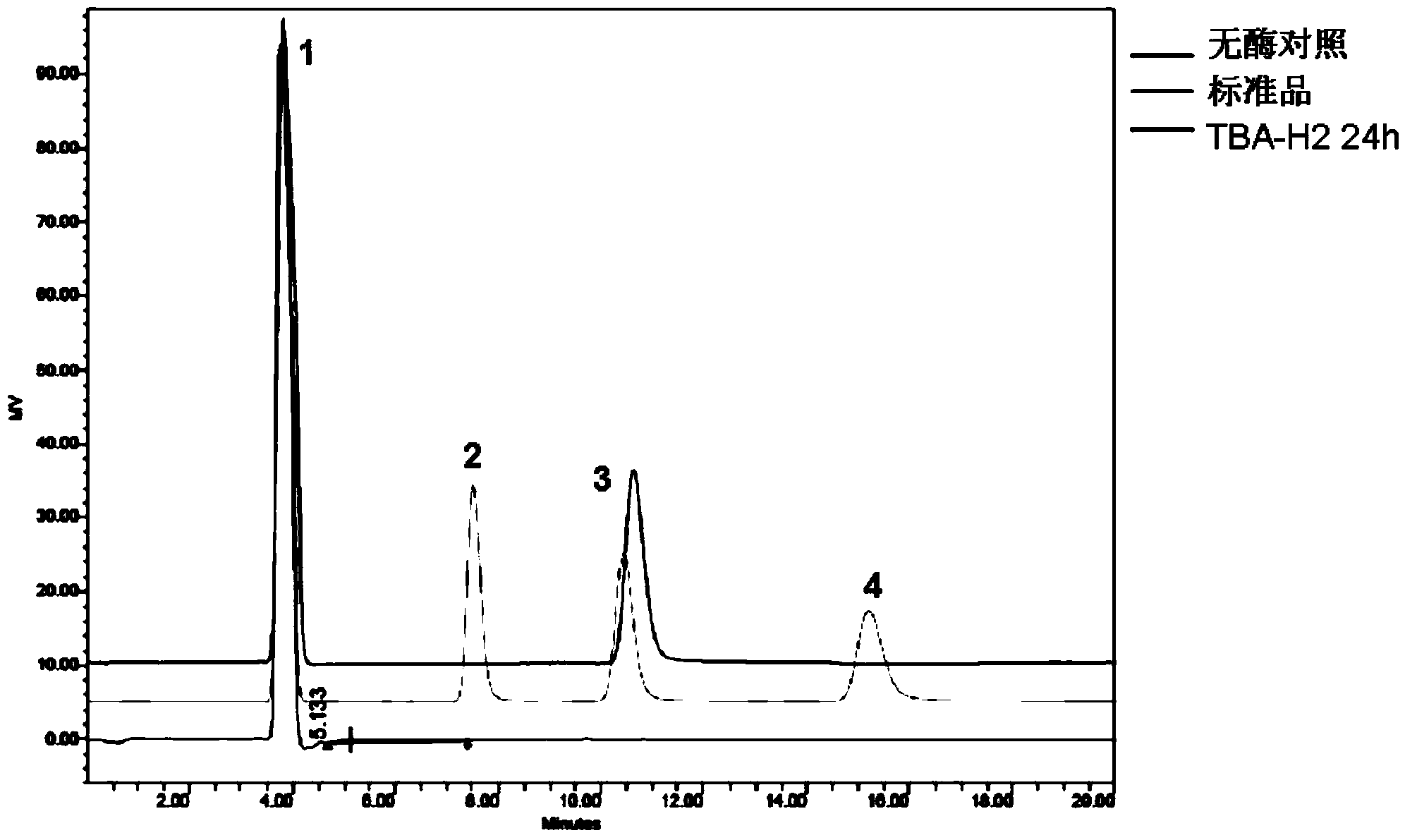

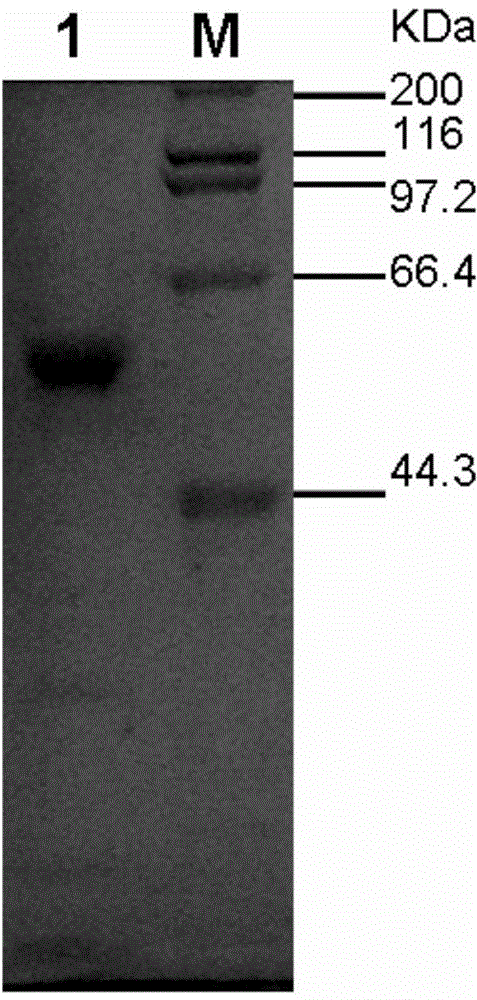

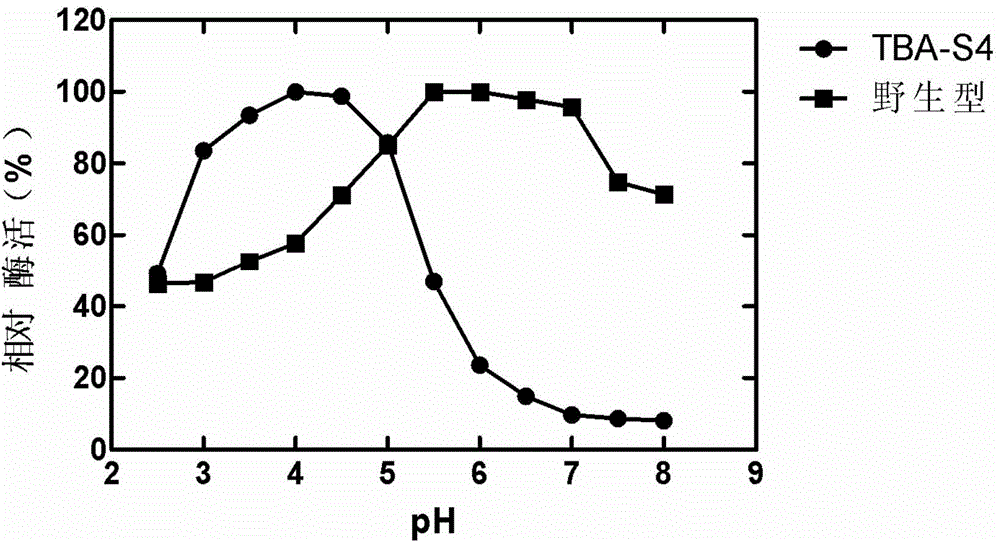

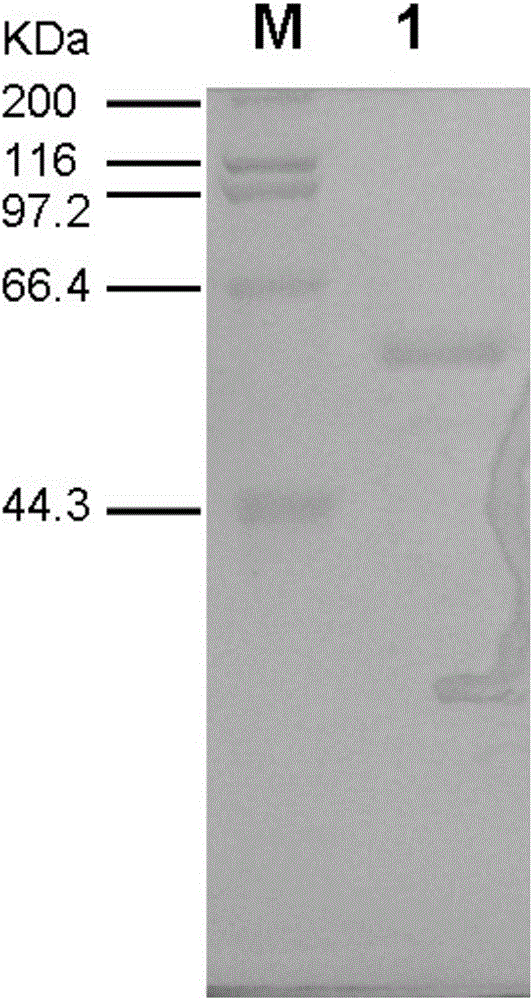

A kind of acid-resistant high-temperature beta-amylase mutant and its application

ActiveCN103695386BEfficient degradationSignificant progressMicroorganism based processesFermentationAcid-fastHydrogen

The invention discloses an acid-resistant and high-temperature-resistant beta-amylase mutant and an application thereof. Small amino acid nearby a catalytic functional domain, including 115-site cysteine, 312-site alanine, 351-site threonine and 354-site cysteine is reconstructed into serine by taking thermoanaerobacterium thermosulfurigenes high-temperature beta-amylase as a parent and by adopting a molecular enzyme engineering technique, and the acid-resistant and high-temperature-resistant beta-amylase mutant particularly comprises an SEQ ID NO:1 (sequence identifier number 1) amino acid sequence. The obtained beta-amylase mutant keeps a temperature resistance characteristic, an optimum pH (power of hydrogen) value is lowered to 4.0 from 6.0 of parent enzyme, the activity is improved by 1.4 times, and the acid-resistant and high-temperature-resistant beta-amylase mutant more facilitates industrial production of the starch industry in comparison with a wild beta-amylase mutant.

Owner:南宁邦尔克生物技术有限责任公司

A mutant tba-h2 of acid-resistant high-temperature beta-amylase and its application

The invention provides a mutant TBA-H2 of acid and high temperature resistant beta-amylase and an application thereof. The amino acid sequence of the mutant is shown in SEQ ID NO:1 in a sequence table. Relative to enzymes before mutation, the mutant has an optimum pH value of acid and a higher function of generating maltose. The mutant TBA-H2 of high temperature resistant beta-amylase can be used for degrading starchy materials and is especially suitable for degrading starch under acidic conditions to generate maltose.

Owner:南宁邦尔克生物技术有限责任公司

Environment-friendly discharge printing technology and printing paste used by same

InactiveCN102535204ASave water and energyIn line with the concept of low-carbon economyDyeing processSolventEnvironmental resistance

The invention discloses an environment-friendly discharge printing technology which comprises the specific steps of: performing pre-treatment on knitted cloth; then performing rotary screen printing; and finally adopting one of high-temperature roasting and high-temperature steaming. Printing paste used for the environment-friendly discharge printing technology comprises components in percentages by weight as follows: 10-20% of leucotrope, 12-50% of a solvent, 20-30% of a paste material and the balance water. The printing paste disclosed by the invention does not contain odor from free formaldehyde and free sulfur, so that the environment-friendly discharge printing technology which uses the printing paste does not need water-washing and soap-washing. Thus, the environment-friendly disperse dye printing technology is not only environment-friendly, but also saves plenty of water and energy, and is in accordance with a principle of low carbon economy.

Owner:江苏AB集团股份有限公司

Water heater open-and-heating device

The invention relates to a water heating device, in particular to a water heater. An instant on-and-use device of the water heater comprises a hot water outlet pipe, a cold water inlet pipe, a return pipe communicating the hot water outlet pipe and the cold water inlet pipe, and an outlet valve; a pump is arranged on the return pipe; the device also comprises a double control temperature relay; and the outlet valve is an electromagnetic valve. The device not only can meet the requirement of people on water yield, but also saves electrical power.

Owner:上海友霓节能环保科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com