Method for improving fixation rate of reactive dye in alcohol organic solvent-water system

An organic solvent and reactive dye technology, applied in the field of textile printing and dyeing, can solve the problems of affecting dye diffusion, many processing steps, poor thermal stability, etc., and achieve the effects of improving color yield, shortening process flow, and reducing salt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for improving the color fixation rate of reactive dyes in ethanol-water system, comprising the steps:

[0050] S1. Lye treatment of cotton textiles:

[0051] 2g of cotton yarn to be dyed is placed in 15g / L sodium carbonate solution, bath ratio is 1:20, 60 ℃ dipping treatment 10min; Wherein, the solvent of described sodium carbonate solution is the volume ratio is 5% ethanol and 95% water mixed solution;

[0052] S2. Cationic modification of cotton textiles:

[0053] Add 1g 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHTPAC) cationic modifier in the lye described in step S1, make 3-chloro-2-hydroxypropyltrimethylammonium chloride cationic The concentration of the modifier is 25g / L, and the treatment is continued at 60°C for 50 minutes, and the liquid carrying rate is finally controlled to 100%;

[0054] S3, dyeing:

[0055] The cotton textiles treated in step S2 are placed in reactive red 195 dyeing solution with a concentration of 1% o.w.f., the bat...

Embodiment 2-13

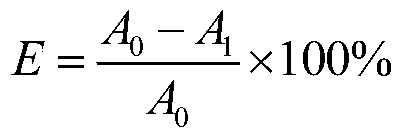

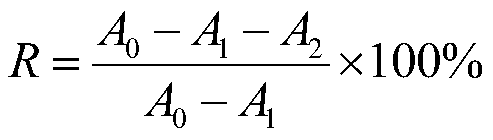

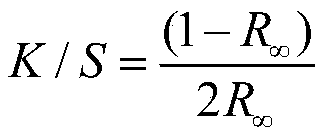

[0059] Embodiment 2-13 provides a kind of method for improving the fixation rate of reactive dyes in ethanol-water system, compared with embodiment 1, difference is that in step S2, change 3-chloro-2-hydroxypropyltrimethyl The concentration of ammonium chloride (CHTPAC) cationic modifier, except the above-mentioned difference, other operations are all the same, no longer repeat them here; 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHTPAC) cationic The specific amount of agent used, the dye uptake rate of cotton yarn, the K / S value before and after soaping, and the test results of color fixation rate are shown in the table below.

[0060]

[0061]

[0062] From the results in the above table, it can be seen that with the increase of the concentration of 3-chloro-2-hydroxypropyltrimethylammonium chloride (CHTPAC) cationic modifier, the dye uptake rate of modified cotton yarn without salt dyeing, the dyeing rate before and after soaping The K / S value and color fixa...

Embodiment 14-17

[0065] Embodiments 14-17 provide a method for improving the fixation rate of reactive dyes in an ethanol-water system. Compared with Example 1, the difference is that the modification treatment temperature in step S2 is changed. In addition to the above differences, other operations They are all the same, so I won’t go into details here; the specific modification temperature conditions, the dye uptake rate of cotton yarn, the K / S value before and after soaping, and the test results of color fixation rate are shown in the table below.

[0066]

[0067] Comparing the results of Example 1 and Examples 14-17, it can be seen that as the modification treatment temperature increases from 30°C to 60°C, the dye uptake rate of modified cotton yarn without salt dyeing, the K / S value before and after soaping, and the color fixation The rate increases gradually, which may be due to the fact that within a certain temperature range, the increase in temperature is conducive to the grafting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com