Environment-friendly silicon-acrylate emulsion and preparation method thereof

A silicone acrylic emulsion, an environmentally friendly technology, applied in dyeing, textiles and papermaking, etc., can solve problems such as hard hand feeling, and achieve the effect of increasing color yield, increasing viscosity, and excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

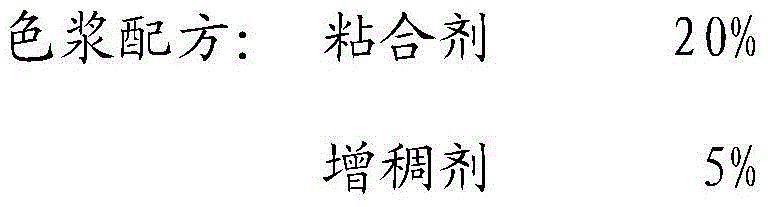

Image

Examples

Embodiment 1

[0030] 1.0 grams of acrylic acid, 8.0 grams of ethyl methacrylate, 2.0 grams of diallyl phthalate, 1.0 grams of hydroxypropyl acrylate and 1.0 grams of methacryloxypropyl tripropropoxysilane, 10.0 grams of vinyl Pyrrolidone, 12.0 grams of vinyl silicone oil, 1.0 grams of sodium acrylate-2-ethylsulfonate, 0.15 grams of n-dodecanethiol, 0.05 grams of sodium bicarbonate, and 150 grams of deionized water were placed in an emulsification cup, and pre-treated at room temperature. Emulsified for 0.5 hours to form a stable white pre-emulsion.

[0031] The pre-emulsion obtained above is transferred to a four-neck flask equipped with devices such as stirring, nitrogen ventilation, condensation, and temperature measurement. Under the protection of nitrogen, stir, heat up, and add 0.4 g of ammonium persulfate at 50 ° C. After 15 minutes of reaction, an obvious blue light appears. After 2.5 hours of heat preservation, the temperature can be lowered to obtain a white emulsion with blue fluo...

Embodiment 2

[0033] 6.0 grams of maleic acid, 12.0 grams of styrene, 5.0 grams of divinylbenzene, 3.0 grams of hydroxyethyl methacrylate and 3.0 grams of methacryloxypropyl tripropoxysilane, 14.0 grams of vinylpyrrolidone, 12.0 grams Vinyl silicone oil, 1.5 grams of sodium styrene sulfonate, 0.3 grams of n-dodecyl mercaptan acetate, 0.1 grams of potassium bicarbonate, and 170 grams of deionized water were placed in an emulsification cup, and pre-emulsified at room temperature for 0.5 hours. A stable white pre-emulsion was formed.

[0034] The pre-emulsion obtained above is transferred to a four-neck flask equipped with devices such as stirring, nitrogen ventilation, condensation, and temperature measurement. Under the protection of nitrogen, stir, heat up, and at 55°C, add 0.5 g of potassium persulfate. After 12 minutes of reaction, a clear blue light appears. After 2.5 hours of heat preservation, the temperature can be lowered to obtain a white emulsion with blue fluorescence.

Embodiment 3

[0036] 2.0 grams of acrylic acid, 2.0 grams of itaconic acid, 20.0 grams of lauryl (meth)acrylate, 5.0 grams of ethylene glycol diacrylate, 5.0 grams of allyl glycidyl ether and 5.0 grams of methacryloxypropyl tri Isopropoxysilane, 12.0 grams of vinylpyrrolidone, 10.0 grams of vinyl silicone oil, 0.5 grams of sodium tetradecyl propyl sulfonate maleate, 0.1 grams of succinic acid mono-n-dodecyl mercaptan, 0.06 One gram of sodium carbonate and 200 grams of deionized water were placed in an emulsification cup, and pre-emulsified at room temperature for 0.5 hour to form a stable white pre-emulsion.

[0037] The pre-emulsion obtained above is transferred to a four-neck flask equipped with devices such as stirring, nitrogen ventilation, condensation, and temperature measurement. Under the protection of nitrogen, stir, heat up, and add 0.75 g of AIBN at 60 ° C, after 11 minutes of reaction, there will be obvious blue light, and after 2.5 hours of heat preservation, the temperature ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com