Ink jet printing reactive dye ink, preparation method thereof and printing and dyeing process of ink

A technology of reactive dyes and inkjet printing, applied in dyeing methods, chemical instruments and methods, textiles and papermaking, etc., can solve the problems of long process flow, large energy and water consumption, and restrictions on industrial application, and achieve simple process flow, Improve the color fixing rate and the overall effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

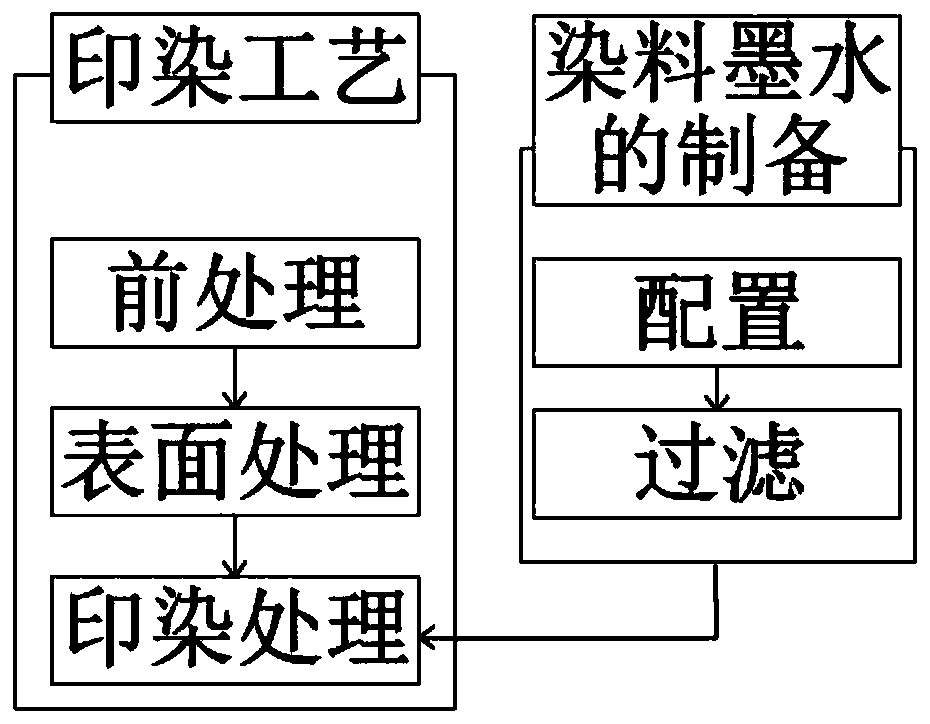

Image

Examples

Embodiment A1

[0032] S1) Accurately weigh 4 parts by weight of a chloro-s-triazine reactive dye, 0.1 part of 2,3-epoxypropyltrimethylammonium chloride as a cationic modifier, and 0.4 part of sodium dodecylsulfonate as a Surface tension regulator, 10 parts of ethylene glycol as viscosity regulator, 0.1 part of ammonia as pH regulator, 0.2 part of 5-chloro-2-methyl-4-isothiazolin-3-one as fungicide, 3 parts of N -Methyl-2-pyrrolidone as a humectant, 1 part of dyeing aid, 2 parts of ethanol as a leveling agent, 1 part of ethylenediamine as a softener and 40 parts of deionized water, wherein the dyeing aid includes 25 parts of ethylene phthalate, 3 parts of ethyl 2,4,6-trimethylbenzoylphenyl phosphonate and 2 parts of ethyl 4-dimethylaminobenzoate;

[0033] According to the order of deionized water, moisturizing agent, surface tension regulator, viscosity regulator, pH regulator, bactericide, dyeing aid, leveling agent, softener, reactive dye and cationic modifier, put them into the stirring co...

Embodiment A2

[0036] S1) Accurately weigh 20 parts by weight of dichloro-s-triazine reactive dye, 0.3 part of 2,3-epoxypropyltriethylammonium chloride as cationic modifier, and 2.5 parts of sodium lauryl sulfate as surface Tonicity regulator, 40 parts of ethylene glycol benzyl ether as viscosity regulator, 1.5 parts of monoethanolamine as pH regulator, 1.2 parts of benzoic acid as fungicide, 11 parts of ethylene glycol as humectant, 3 parts of dyeing aid, 5 parts Polyvinyl alcohol as a leveling agent, 10 parts of diethylenetriamine as a softener and 80 parts of deionized water, wherein the dyeing assistant includes 30 parts by weight of ethylene phthalate, 2,4,6- 5 parts of ethyl trimethylbenzoyl phenylphosphonate and 4 parts of ethyl 4-dimethylaminobenzoate;

[0037] According to the order of deionized water, moisturizing agent, surface tension regulator, viscosity regulator, pH regulator, bactericide, dyeing aid, leveling agent, softener, reactive dye and cationic modifier, put them into ...

Embodiment A3

[0040] S1) Accurately weigh 12 parts of vinylsulfone type reactive dyes, 0.2 parts of 3-chloro-2-hydroxypropyl trimethyl ammonium chloride as cationic modifier, 1.5 parts of dodecyl trimethyl bromide Ammonium as a surface tension regulator, 25 parts of diethylene glycol ether as a viscosity regulator, 0.8 parts of diethanolamine as a pH regulator, 0.7 parts of potassium sorbate as a fungicide, 7 parts of propylene glycol as a humectant, 2 parts of dyeing aids, The mixture of 3 parts of ethanol and polyvinyl alcohol is as leveling agent, 5 parts of triethylenetetramine as softening agent and 60 parts of deionized water, wherein, dyeing assistant comprises 28 parts of ethylene phthalates by weight, 4 parts of ethyl 2,4,6-trimethylbenzoylphenylphosphonate and 3 parts of ethyl 4-dimethylaminobenzoate;

[0041] According to the order of deionized water, moisturizing agent, surface tension regulator, viscosity regulator, pH regulator, bactericide, dyeing aid, leveling agent, softene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com