Preparation method and application of fluorine-silicon modified acrylate emulsion

A technology of acrylate and fluorosilicone modification, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of substandard fastness, poor hand feeling, and low dosage, so as to improve color fastness and appearance. The effect of color quantity and synthesis process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

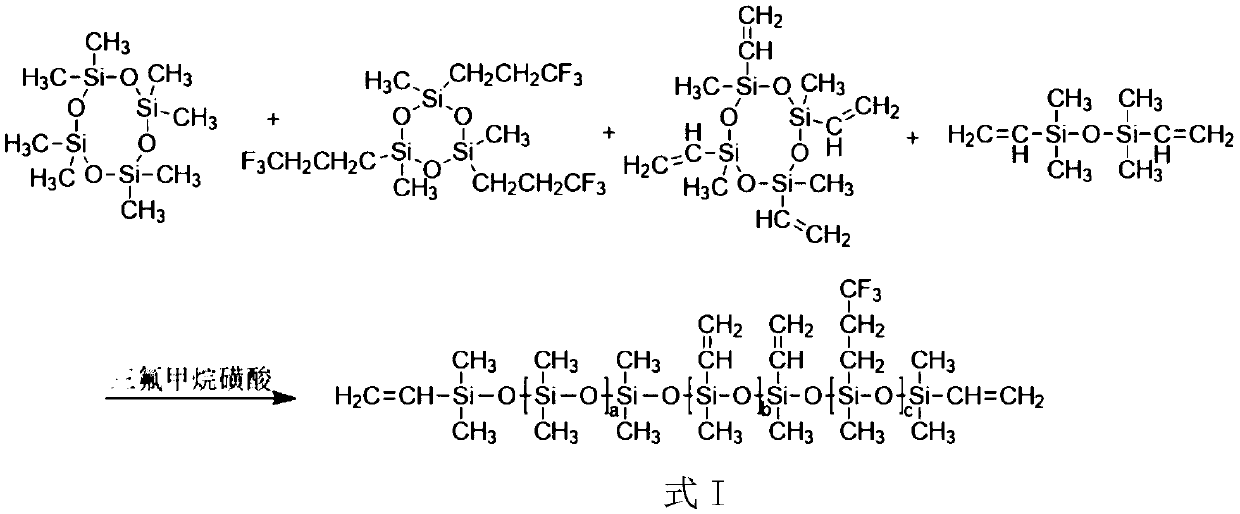

[0039] (1) Synthesis of fluorosilicone:

[0040]

[0041] Weigh a certain amount of octamethylcyclotetrasiloxane (D 4 ), 1,3-divinyl-1,1,3,3-tetramethyldisiloxane (DVMS), methyltrifluoropropylcyclotrisiloxane (D 3 F) and tetramethyltetravinylcyclotetrasiloxane (D 4 Vi) Stir magnetically at 65°C for about 40 minutes and mix well, then take 0.15% trifluoromethanesulfonic acid as a catalyst, react at 65°C for 7 hours, add anhydrous sodium carbonate to neutralize to a pH value of about 6- 7. Bake in a vacuum oven at 120° C. for 5 hours to remove unreacted monomers and small molecule polysiloxanes.

[0042] Description: Monomer D n (D 4 +D 3 F): D 4 The molar ratio of Vi:DVMS is 17:1:1 where D 3 The molar content of F is 20%, and the fluorosiloxane with the molecular weight of 7916 is synthesized, and the yields are all over 90%.

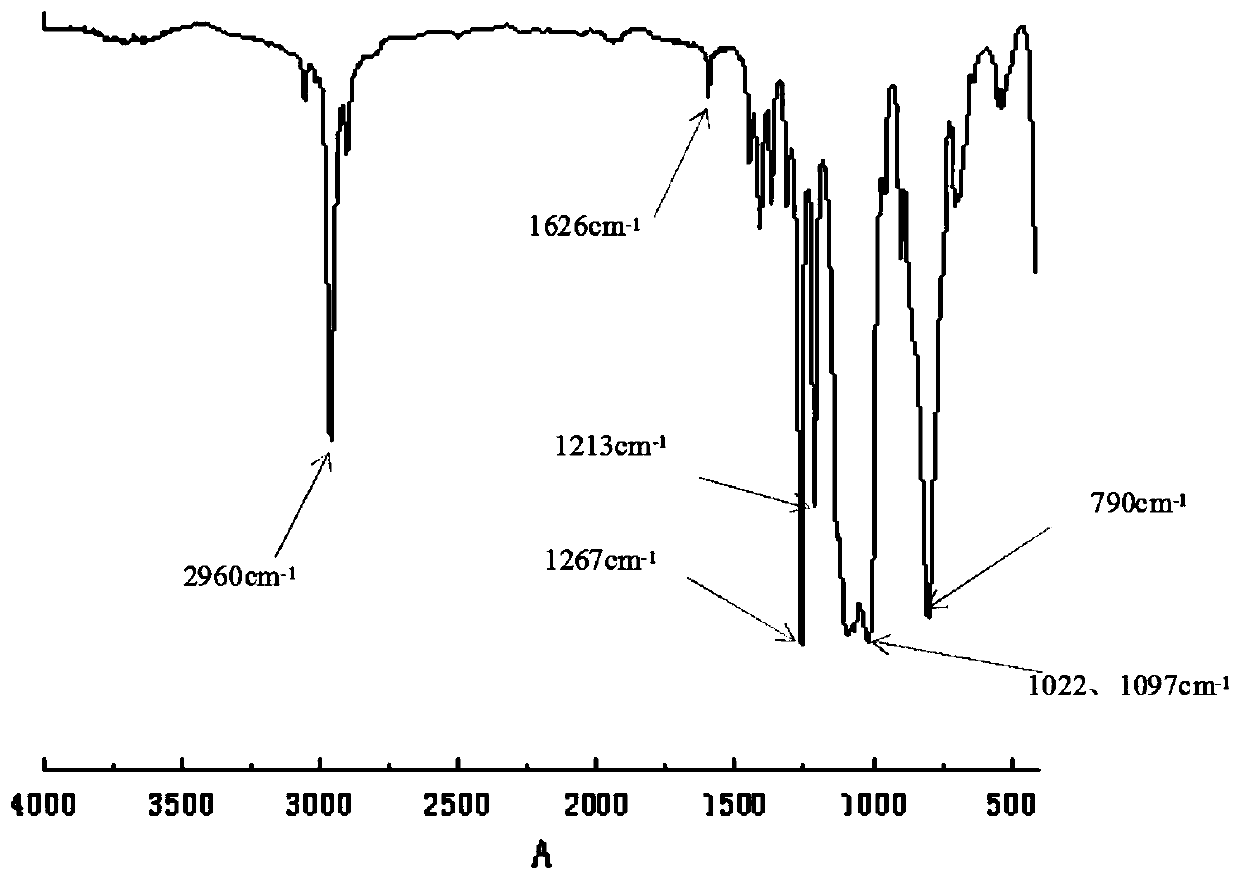

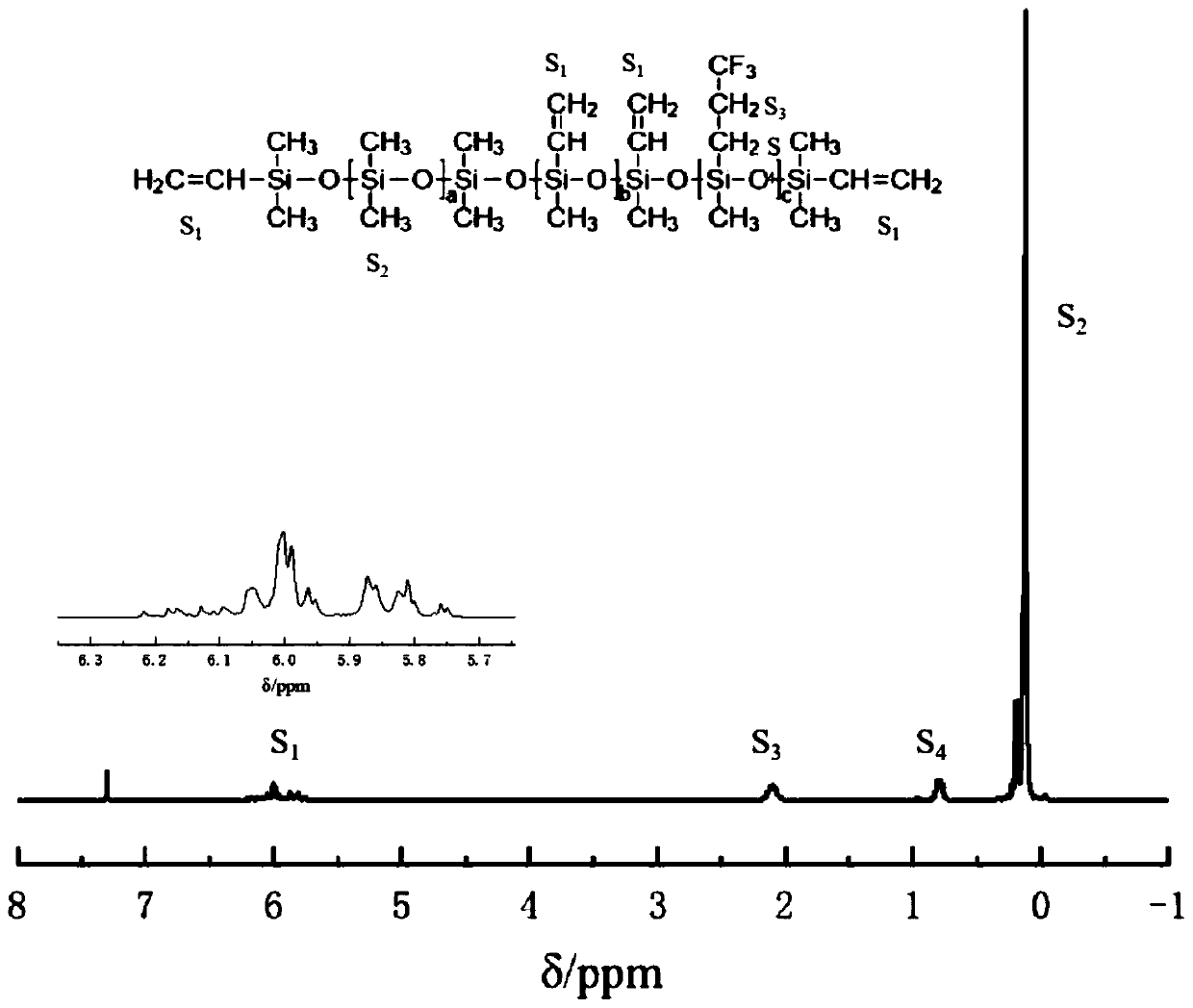

[0043] The infrared spectrogram of the fluorosiloxane prepared in embodiment 1 is as follows figure 1 As shown, the infrared analysis of fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com