Crease resisting agent for cotton and preparation method and application of crease resisting agent for cotton

A technology of anti-wrinkle agent and condensation reaction, which is applied in the field of anti-wrinkle agent for cotton and its preparation, which can solve the problems that the anti-wrinkle performance of the finished fabric is not involved, and achieve the effects of remarkable anti-wrinkle effect, enhanced firmness, improved wrinkle resistance and washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

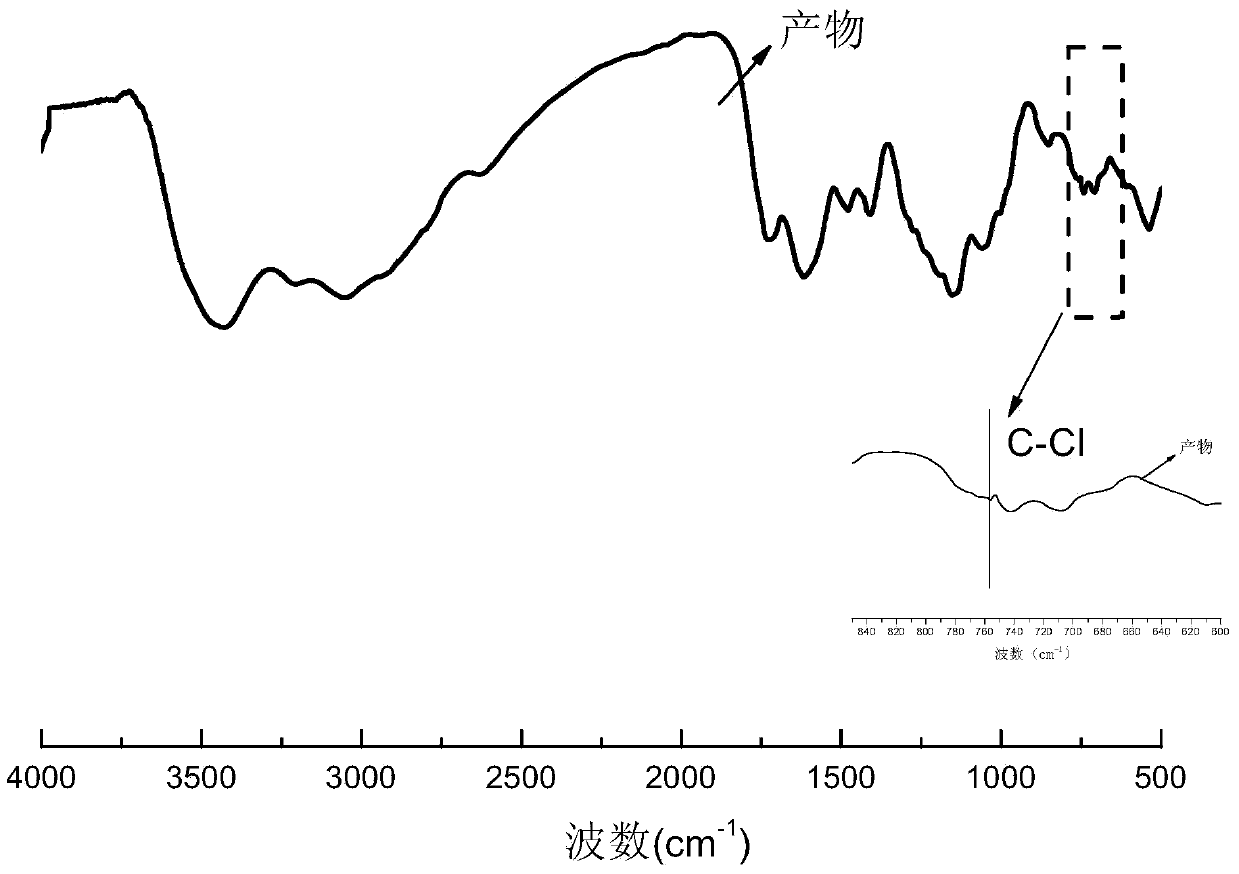

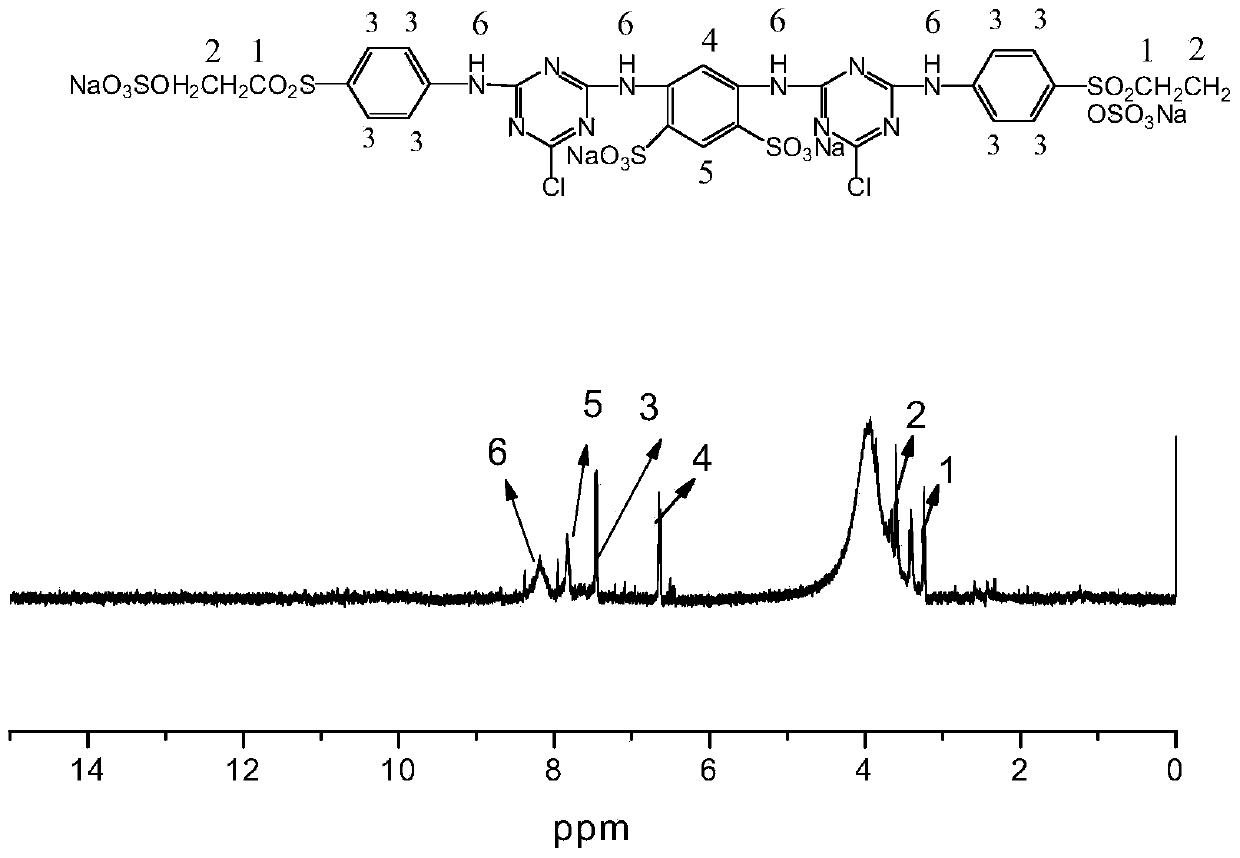

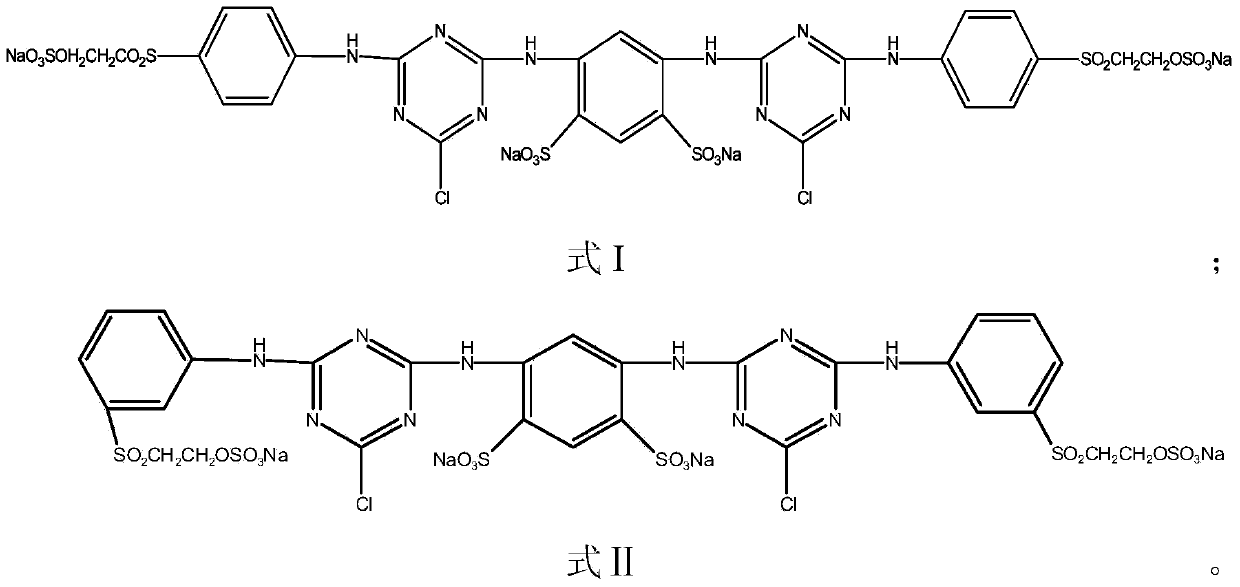

Method used

Image

Examples

Embodiment 1

[0032] 1. Dissolution of cyanuric chloride

[0033] In a reaction flask equipped with a stirrer and a thermometer, add cyanuric chloride [select 20.24g (0.1mol)], and dissolve it with a mixture of acetone and ice water [select 20mL ice water and 10mL acetone] (i.e., acetone aqueous solution) , and mechanically stirred for 10 minutes to promote its full dissolution.

[0034] 2. Add m-phenylenediamine disulphonic acid [choose 13.4g (0.05mol)] into 40mL water, under the condition of stirring, slowly (3min) add sodium carbonate (0.05mol) powder equal to the substance amount, after the sodium carbonate powder is added , and continue to stir for 5 minutes, so that the m-phenylenediamine disulphonic acid becomes sodium m-phenylenediamine disulphonate, and a sodium m-phenylenediamine disulphonate solution is obtained.

[0035] 3. Slowly add m-phenylenediamine disulphonate sodium solution dropwise into the three-necked flask dissolved with cyanuric chloride system to carry out the fir...

Embodiment 2

[0046] 1. Dissolution of cyanuric chloride

[0047] In a reaction flask equipped with a stirrer and a thermometer, add cyanuric chloride [select 20.24g (0.1mol)], and dissolve it with a mixture of acetone and ice water [select 20mL ice water and 10mL acetone] (i.e., acetone aqueous solution) , and mechanically stirred for 10 minutes to promote its full dissolution.

[0048] 2. m-Phenylenediamine disulphonic acid [choose 13.4g (0.05mol)] into 40mL of water, under the condition of stirring, slowly add sodium carbonate (0.05mol) powder of the same amount, after adding the sodium carbonate powder, continue stirring For 5 minutes, the m-phenylenediamine disulphonic acid was converted into sodium m-phenylenediamine disulphonate to obtain a sodium m-phenylenediamine disulphonate solution.

[0049] 3. Slowly add m-phenylenediamine disulphonate sodium solution dropwise into the three-necked flask dissolved with cyanuric chloride system for the first condensation, the reaction temperat...

Embodiment 3

[0054] 1. Dissolution of cyanuric chloride

[0055] In a reaction flask equipped with a stirrer and a thermometer, add cyanuric chloride [select 20.24g (0.1mol)], and dissolve it with a mixture of acetone and ice water [select 20mL ice water and 10mL acetone] (i.e., acetone aqueous solution) , and mechanically stirred for 10 minutes to promote its full dissolution.

[0056] 2. m-Phenylenediamine disulphonic acid [choose 13.4g (0.05mol)] into 40mL of water, under the condition of stirring, slowly add sodium carbonate (0.05mol) powder of the same amount, after adding the sodium carbonate powder, continue stirring For 5 minutes, the m-phenylenediamine disulphonic acid was converted into sodium m-phenylenediamine disulphonate to obtain a sodium m-phenylenediamine disulphonate solution.

[0057] 3. Slowly add m-phenylenediamine disulphonate sodium solution dropwise into the three-necked flask dissolved with cyanuric chloride system for the first condensation, the reaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com