A kind of preparation method and application of fluorosilicon modified acrylate emulsion

An acrylate and fluorosilicon modification technology, applied in dyeing, textile and papermaking, etc., can solve the problems of substandard fastness, poor hand feel, large dosage, etc., to improve color fastness and improve apparent color. Quantitative, easy-to-implement effects

Active Publication Date: 2022-06-03

ZHEJIANG SCI-TECH UNIV

View PDF11 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when acrylate emulsion is used to print dark fabrics (generally, the amount of liquid disperse dye is more than 2%), there are problems that the fastness is not up to standard when the amount is small, and the hand feeling is not good when the amount is large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0040]

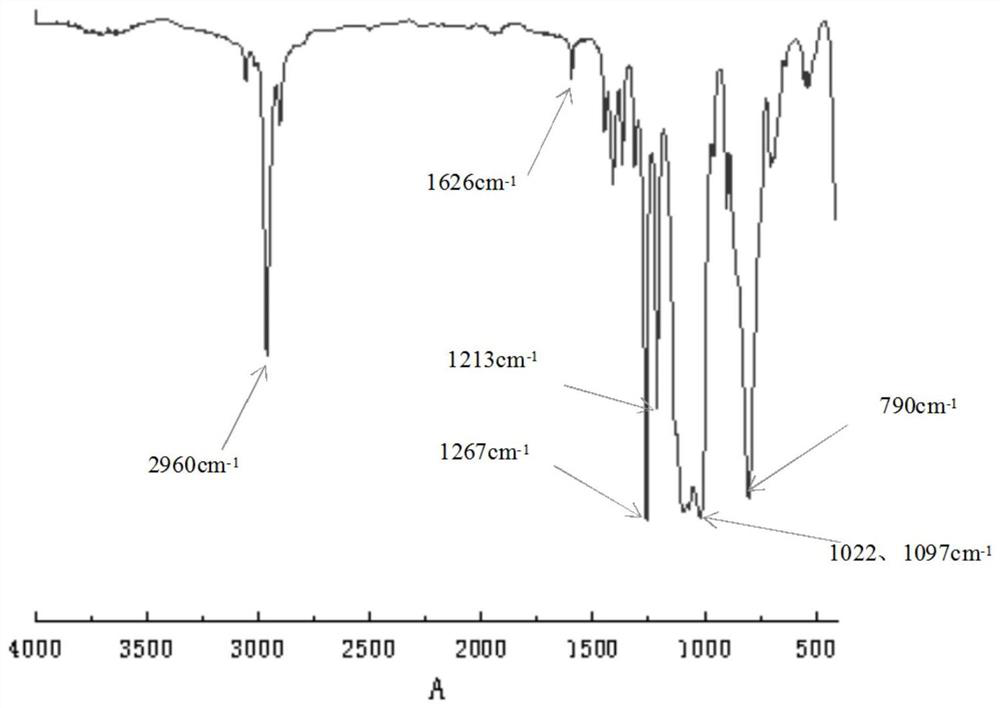

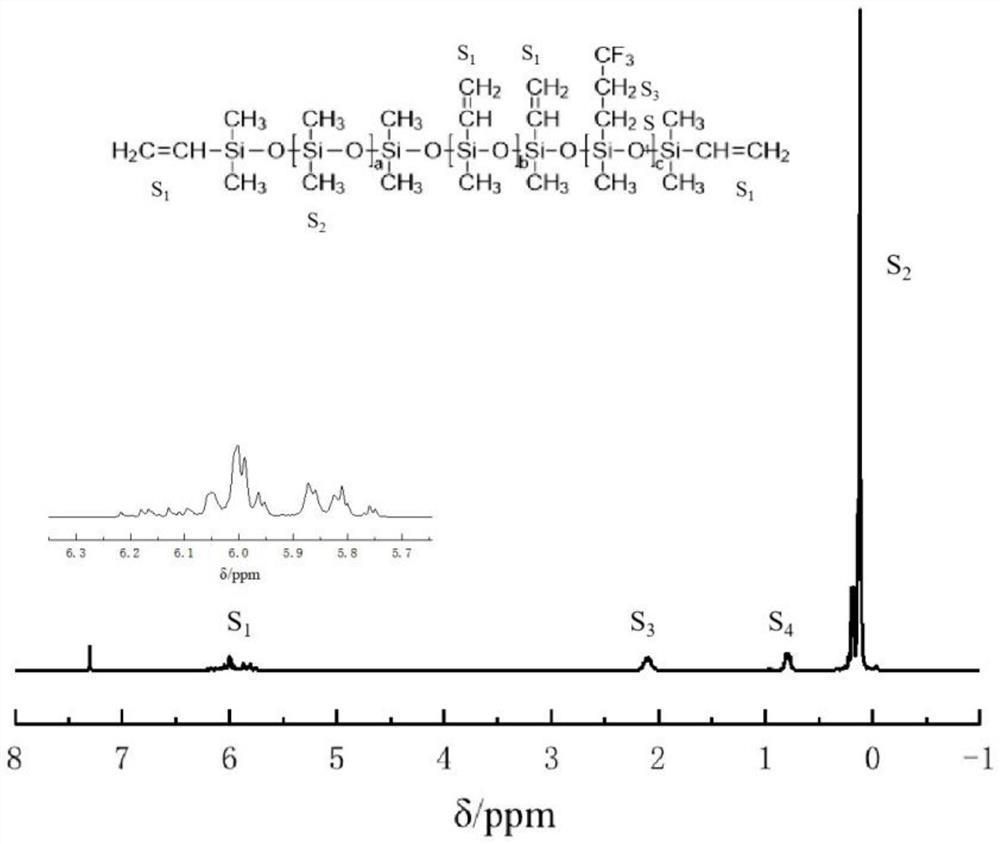

[0043] The infrared spectrogram of the fluorosilicone prepared in Example 1 is shown in Figure 1, and the fluorosilicone infrared analysis is shown in Table 1.

[0045]

[0048]

[0051]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

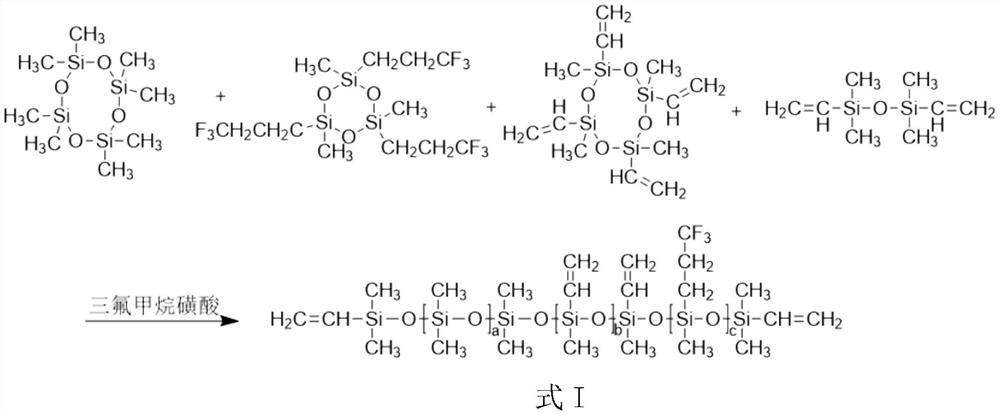

The invention discloses a preparation method of fluorosilicon modified acrylate emulsion and its application in liquid disperse dye printing. The preparation method comprises: (1) synthesis of fluorosiloxane (2) taking isooctyl acrylate, methyl methacrylate, acrylic acid, n-hexadecane and the fluorosiloxane obtained in step (1) and stirring evenly, then adding into the emulsifier aqueous solution to obtain a pre-emulsion; take the pre-emulsion and add it to a reactor as a seed emulsion, add an ammonium persulfate aqueous solution to the seed emulsion for reaction, and cool to obtain a fluorosilicon-modified acrylate emulsion. The method of the present invention introduces fluorine silicon chain segment on the basis of acrylate. The softness of the organic silicon segment can effectively improve the hand feeling of printed fabrics; the short C-F covalent bond and its large bond energy of organic fluorine can improve the hydrophobicity of the film, reduce the solubility parameter and refractive index of the film, and help It is used to improve the color fastness and color yield of fabrics.

Description

A kind of preparation method and application of fluorosilicon modified acrylate emulsion technical field The present invention relates to fluorosilicon modified acrylate emulsion field, be specifically related to a kind of fluorosilicon modified acrylate emulsion Preparation method and application in liquid disperse dye printing. Background technique During disperse dye printing, color paste dyes are mostly powder disperse dyes, which are mainly colored by hot-melting, and then Wash with water to remove various residual auxiliaries and dyes. This process is a serious waste of water resources and sewage damage to the environment. Currently, Liquid disperse dyes appear on the market, and light-colored fabrics are realized after color development by thermal fusion (generally, the amount of dyes is less than 0.5%) The color fastness of medium and dark fabrics is not up to standard after no-wash printing. Therefore, water is still required for medium and dark fabrics af...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F283/12C08F220/18C08F220/14C08F220/06C08G77/08C08G77/24D06P1/16D06P1/52

CPCC08F283/124C08G77/24C08G77/08D06P1/16D06P1/5257C08F220/14C08F220/06

Inventor 姜建堂沈一峰

Owner ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com