Cotton knitted fabric dyeing and finishing method and water bath device

A technology of water bath device and cotton knitted fabric, which is applied in the field of textile dyeing and finishing. It can solve the problems of single hole cover diameter, inability to control temperature at a fixed point and precise temperature control, etc., and achieve a large practical range, improved coloring effect, and clear fabric texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

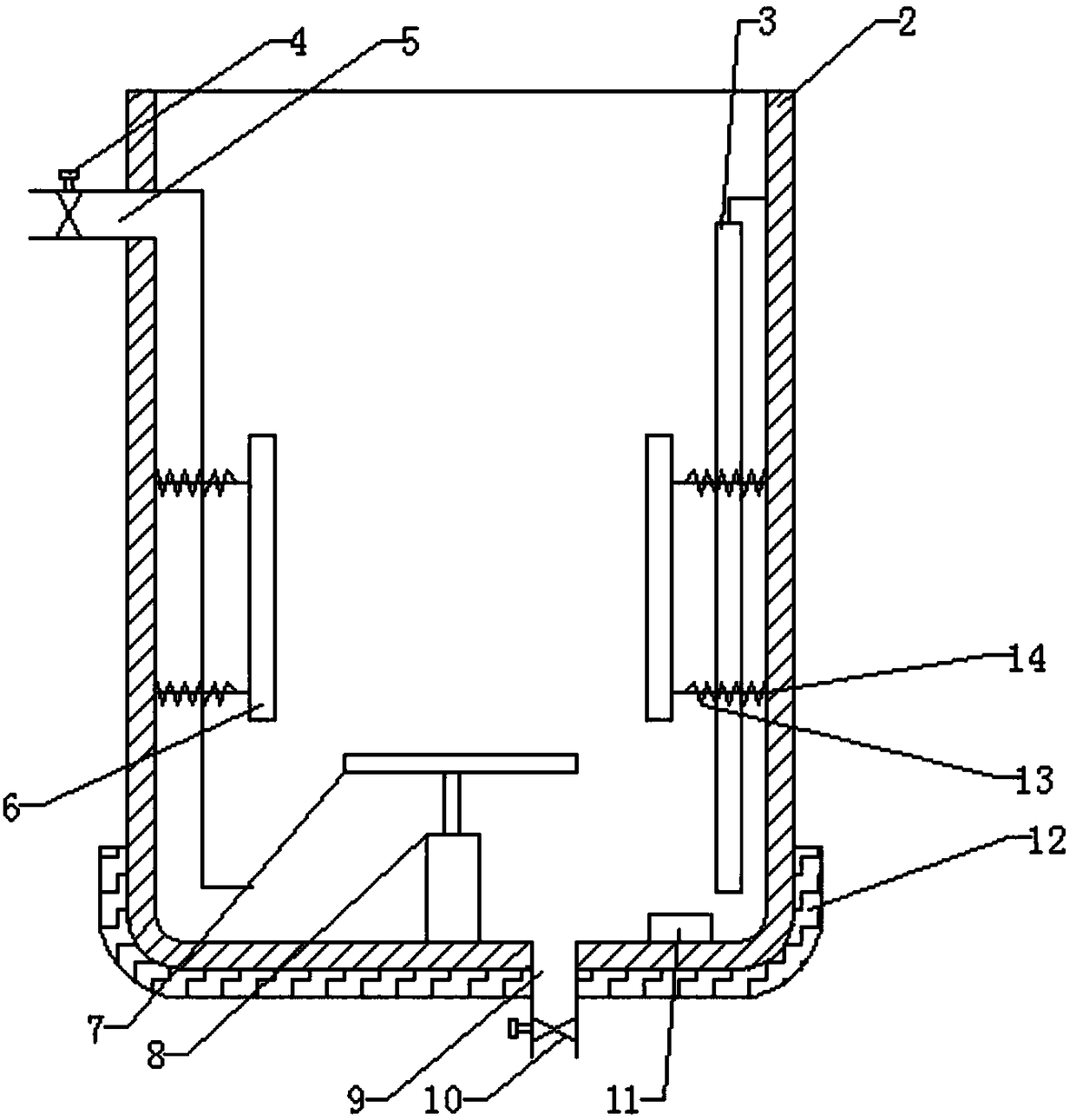

[0030] This specific embodiment discloses a method and device for dyeing and finishing cotton knitted fabrics.

[0031] A method for dyeing and finishing cotton knitted fabrics, the method comprising the following steps:

[0032] Polishing enzyme treatment: immerse the cotton knitted fabric in the bio-polishing enzyme working solution to raise the temperature and keep it warm for a certain period of time, then take out the cotton knitted fabric for inactivation treatment. The components of the biological polishing enzyme working solution include buffer solution, refining penetrant and water. Preferably, the buffer solution is used in an amount of 1.3 g / L, and the refined penetrant is used in an amount of 3 g / L. Preferably, the composition and weight ratio of the refined penetrating agent are: 20% fatty alcohol polyoxyethylene ether, 18% alkyl polyoxyethylene ether, 15% secondary alcohol, and 47% water.

[0033] Dyeing and finishing: After the cotton knitted fabric is boiled a...

Embodiment 2

[0053] This specific embodiment discloses a method for dyeing and finishing cotton knitted fabrics. The difference from Example 1 is that in the polishing enzyme treatment step, the amount of buffer solution in the biological polishing enzyme working solution is 1.5g / L, the amount of scouring penetrant is 4g / L. The composition and weight proportion of the refining penetrant: 30% of fatty alcohol polyoxyethylene ether, 20% of alkyl polyoxyethylene ether, 20% of secondary alcohol, and 30% of water.

[0054] After the cotton knitted fabric is boiled and bleached in the dyeing and finishing process, the dosage of adding sodium bicarbonate to the working solution of bio-polishing enzyme is 80g / L, and the dosage of soda ash is 20g / L.

[0055] In the water bath device, the clamping device and the support device in Embodiment 1 are combined into Figure 5 The improved supporting device shown, the supporting device includes a sleeve 20, a motor 19, a push rod 8 and a fixing device; t...

Embodiment 3

[0058] This specific embodiment discloses a method for dyeing and finishing cotton knitted fabrics. The difference from Example 1 is that in the polishing enzyme treatment step, the amount of buffer solution in the biological polishing enzyme working solution is 1.4g / L, the amount of scouring penetrant is 4g / L. The composition and weight proportion of the refined penetrating agent: 25% of fatty alcohol polyoxyethylene ether, 18% of alkyl polyoxyethylene ether, 18% of secondary alcohol, and 39% of water.

[0059] After the cotton knitted fabric is boiled and bleached in the dyeing and finishing process, the dosage of adding sodium bicarbonate to the biopolishing enzyme working solution is 60 g / L, and the dosage of soda ash is 15 g / L.

[0060] The drape coefficient, weight reduction rate, bursting strength and color yield of the cotton knitted fabric dyed and finished by this specific embodiment all meet the standards, which are respectively 36.47% for the drape coefficient, 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

| drape coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com