Patents

Literature

369results about How to "Fluffy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepreg applied for multi-layer board of printed electronic circuit

ActiveCN101220160ALow dielectricReduce residual stressSynthetic resin layered productsCircuit susbtrate materialsSolventFilling materials

The invention pertains to the technical field of the copper clad laminate, which more particularly relates to a prepreg applied to a printing circuit multilayer board. The prepreg comprises reinforced materials and resin composite, wherein, the reinforced materials is glass fiber paper, and according to part by weight, the formulation of the resin composite is as follows: 20 to 84 portions of resin, 0 to 35 portions of filling materials, 0.01 to 0.3 portions of curing accelerator and 10 to 45 portions of solvent; the resin composite solvent is soaked in the glass fiber paper for 1 to 5 minutes, and is put in a 140 to 200 DEG C oven for baking for 2 to 10 minutes; after the solvent is removed, the prepreg applied to multilayer PCB processing materials is obtained; white flake and spot problems of base materials during the manufacturing procedures of the multilayer PCB are prevented, problems of de-lamination, shrink resin, holes and crack of the resin and white flake, etc. that come up after the multilayer PCB goes through cold and hot impact are improved, and the prepreg has good reliability and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

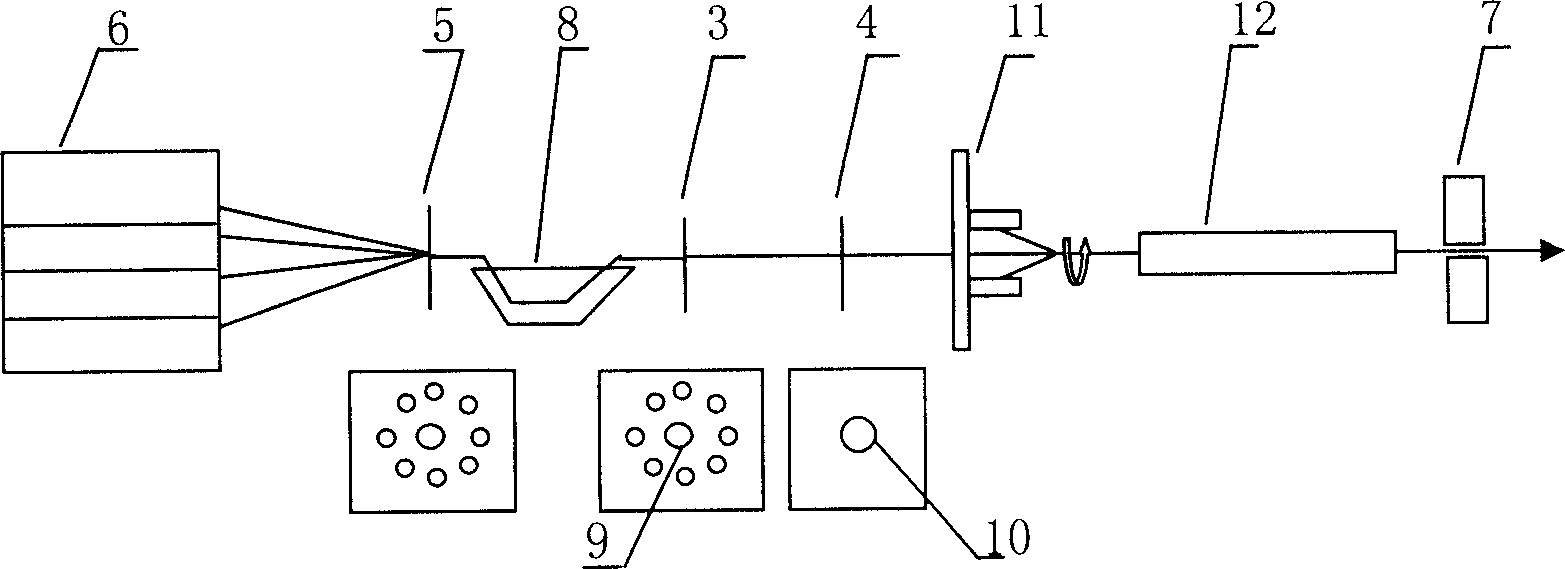

Preparation method for polysiloxanes-amidopolyether block copolymer

InactiveCN102199295ABroad encapsulationWide penetration abilityFibre treatmentPolyelectrolyteEmulsion

The invention discloses a preparation method for a polysiloxanes-amidopolyether block copolymer, comprising the steps of preparation of an intermediate of alpha, omega-hydrosiloxane, preparation of an intermediate of alpha, omega-polysiloxanes diepoxide, and preparation of the polysiloxanes-amidopolyether block copolymer. The polysiloxanes-amidopolyether block copolymer provided in the invention enables a textile finishing agent to be stable under condition of high temperature, a polyelectrolyte, a high pH value or a high shear force without breaking emulsion, sticking to a roller or a cylinder and producing oil marks, allows textiles finished to be returned for repairing, and is widely used in fields like chemical fiber, natural fiber and blended products thereof, etc.

Owner:HANGZHOU MEIGAO HUAYI CHEM

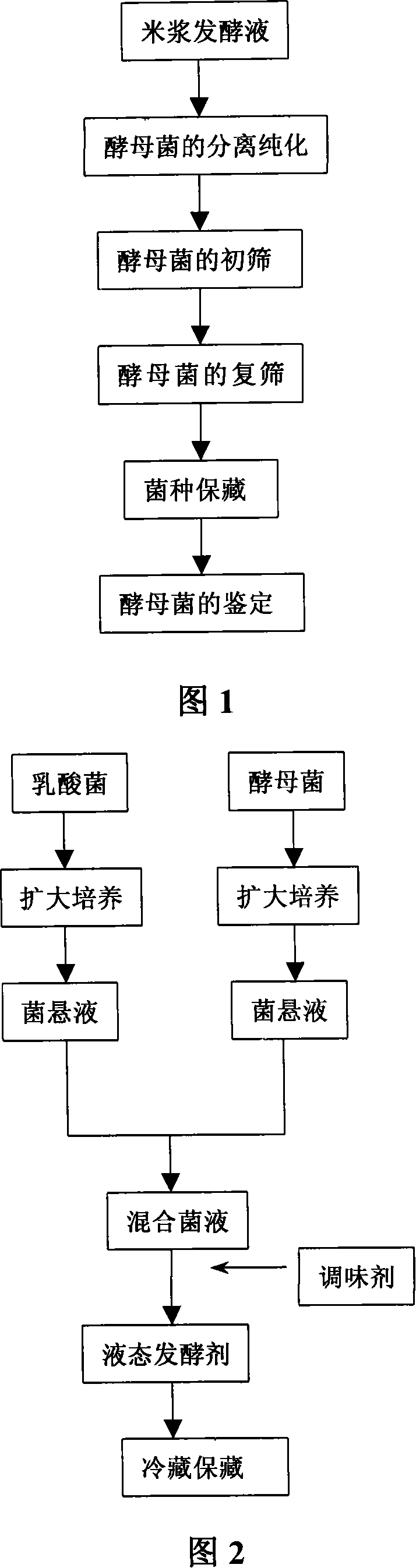

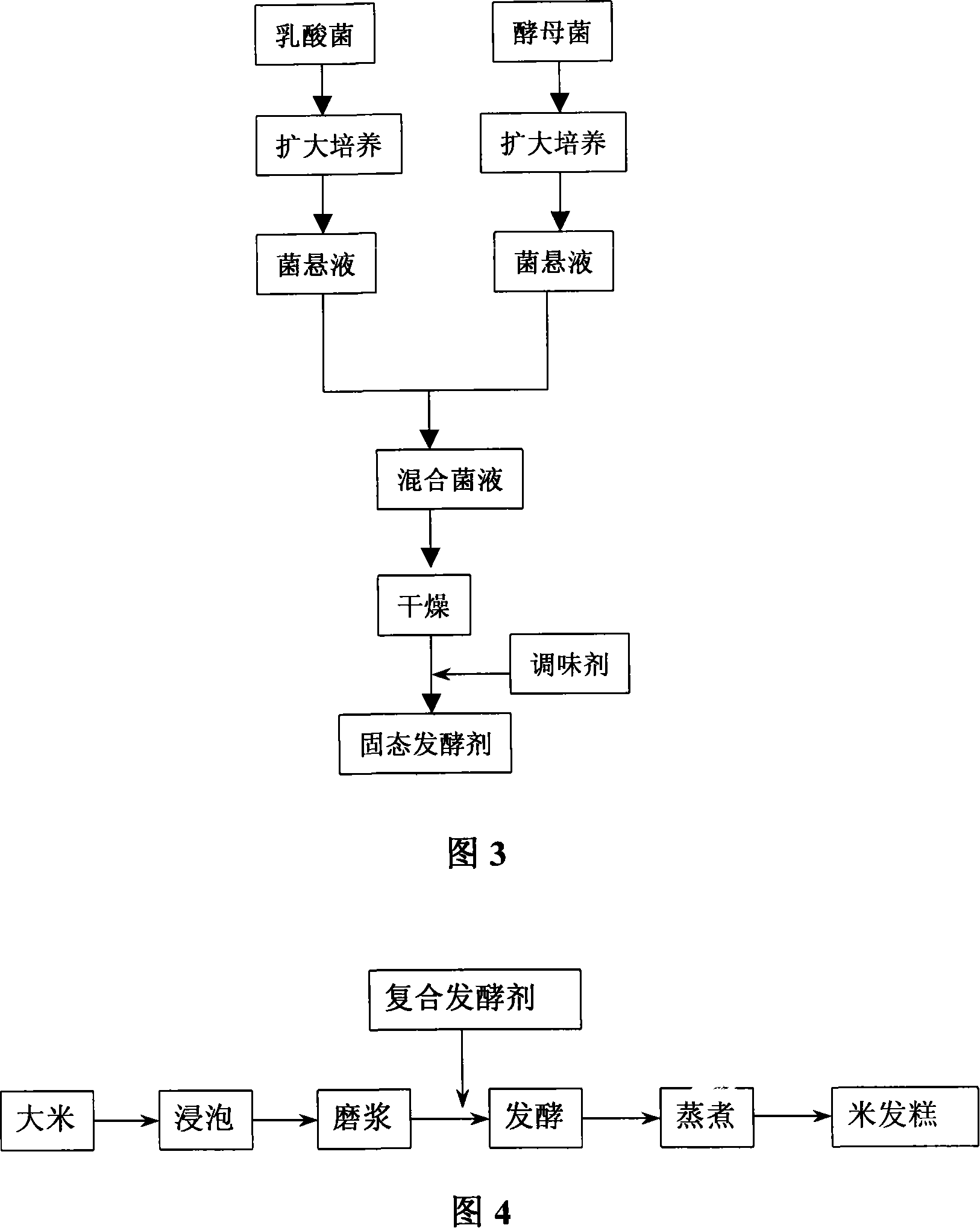

Mycopremna as microorganism leaven, composite leaven containing the mycopremna and application of the same

InactiveCN101173223AShort fermentation timeGood fermentation propertiesFungiMicroorganism based processesBiotechnologyMicroorganism

The invention relates to a strain used as hametz of microorganism, belonging to technical field of processing agricultural microorganism and food, which comprises the strain and the compound hametz ofplant lactocin as well as the application. The invention is characterized in that: the microzyme-Custer bouquet yeast strain can obtain by separating and filtering, which is suitable for fermenting the rice steamed sponge cake; the yeast strain is preserved in Chinese typical culturing and preserving centre and the preserved number is CCTCC NO: M207150. The microorganism compound hametz can be made by the ZSM-001 Custer bouquet yeast strain and AS1.510 plant lactocin (Lactobacillus plantarum), and can be used in rice fermented products, such as rice steamed sponge cakes. The invention has theadvantages of good fermenting performance and easy commercial process, and the products made by the invention have a typical sweet and sour perfume.

Owner:HUAZHONG AGRI UNIV

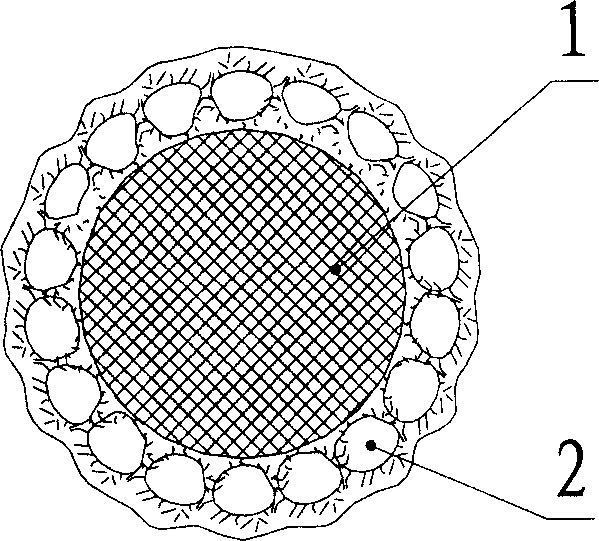

Fiber wall with strong rib material of plastic

The present invention provides a fibre reinforced plastics rib material. It includes fibre reinforced plastics (FRP) core layer and matrix resin impregnating fibre reinforced plastics (FRP), the peripheral surface of said core layer is axially covered with glass fibre bulk yarn reinforced plastics covering layer. Said glass fibre bulk yarn reinforced plastics covering layer can effectively increase roughness of exterior surface of the fibre reinforced plastics rib material core layer, so that the bond stress of said rib material core layer and concrete also can be raised, and the service lift of concrete member also can be raised.

Owner:SINOMA SCI & TECH

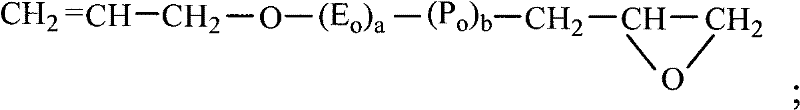

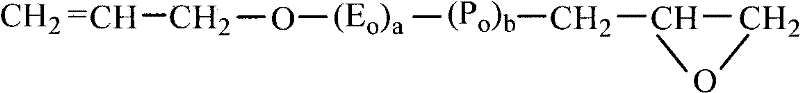

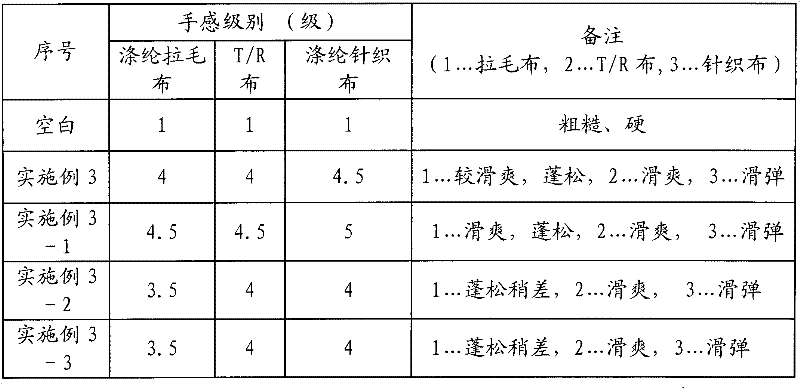

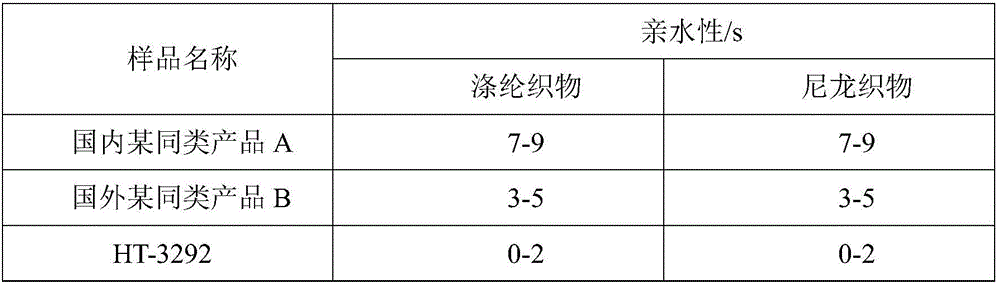

Terpolymer block hydrophilic amino silicone oil and preparation method and application thereof

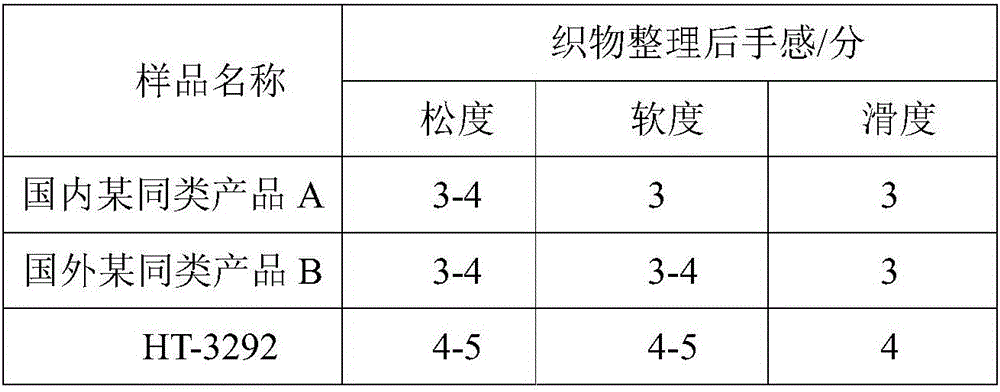

The invention provides terpolymer block hydrophilic amino silicone oil and a preparation method and application thereof. The terpolymer block hydrophilic amino silicone oil is prepared by: reflux-reacting epoxy-terminated polyether silicone oil, amino-terminated polyether and isopropanol at 80-83 DEG C for 8-10 hours, adding a quaternization reagent for modifying, and distilling a modified product under reduced pressure. The terpolymer block hydrophilic amino silicone oil, as a chemical fiber fabric softener, can improve handle characteristics of bulkiness, softness and smoothness to chemical fiber fabric, is good in permeability and can go hydrophilic instantly on nylon fabric; the terpolymer block hydrophilic amino silicone oil has low influence on fabric yellowing and discoloration; the terpolymer block hydrophilic amino silicone oil has excellent chemical stability in resistance to acids, alkalis and salts, has good compounding stability with the aids such as a brightener, saves cost for customers in terms of energy conservation and emission reduction, and provides conveniences.

Owner:HT FINE CHEM CO LTD +1

Terylene comfortable cotton velvet woolen blanket and preparing method thereof

The invention relates to a comfortable cotton velvet blanket and the technical field of the manufacturing method. The polyester comfortable cotton velvet blanket of the invention adopts the DTY polyester yarns of 0.39 to 3.12dtex and the FDY polyester yarns of 55 to 167dtex, and after warp knitting fabric manufacture, the polyester comfortable cotton velvet blanket is manufactured by that the grey cloth is sequentially treated with slitting, combing, ironing and shearing, heat setting, printing or dyeing, post treatment, back fuzzing sorting, and napping typing. The invention selects suitable materials, preparation procedures and equipment, the finished products of the polyester comfortable cotton velvet blanket have stable gram weight and strong stereoscopic impression of the hair side, and the hair height reaches ideal feeling; the suede of the blanket is like cotton, which has soft hand feeling and is fluffy; and the blanket also has very good hydroscopic property and no depilation phenomenon, is mould proofing and moth proofing, is bright in color, and can directly touch the skin, thus being sure to obtain the favour of the people.

Owner:徐建平

Method for printing and dyeing dacron/chinlon/cotton/spandex multi-component fiber fabric

ActiveCN104532611AEliminate potential wrinklesGuaranteed smooth productionBleaching apparatusDyeing processFiberPolymer science

The invention belongs to the technical field of printing and dyeing of textiles and in particular relates to a method for printing and dyeing a dacron / chinlon / cotton / spandex multi-component fiber fabric. The method comprises the following sequential steps: preparing gray fabric, turning seams, rolling enzyme and carrying out cold stacking, bleaching and washing at low temperature, sizing, mercerizing, dyeing and after-finishing. After dyeing, finishing and functional after-finishing, the fabric has fluffy style, and is stiff and smooth and elastic, is capable of absorbing moisture and releasing sweat, and is comfortable and has a close fitting effect; the fabric is integrated with the advantages of a plurality of advantages; the effect of adopting advantages while overcoming disadvantages is exerted; the requirements of superior-quality fabric can be met; meanwhile, the fabric is hydrophilic, and is easy to decontaminate and due to after-finish, the fabric has the characteristic of easiness in cleaning; the quality of the fabric is improved; the enterprise competitiveness is improved.

Owner:HUAFANG

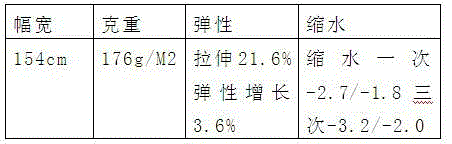

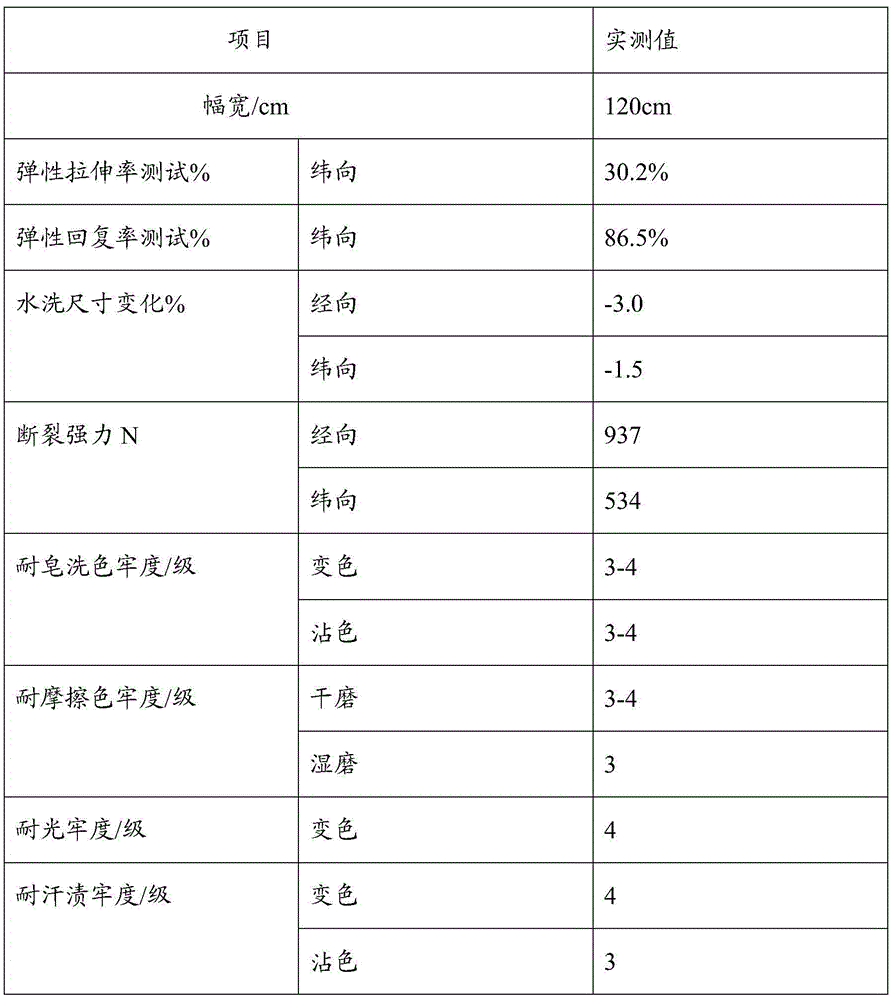

Polyurethane Roman cloth with high stretching resilience and preparation method thereof

The invention relates to polyurethane Roman cloth with high stretching resilience and a preparation method thereof. The Roman cloth is formed by interweaving nylon-coated polyurethane and mucilage glue; the mucilage glue is weaved on the front and back surfaces of a fabric in a cotton wool weaving way; and the nylon-coated polyurethane is used for covering the front and back surfaces of the mucilage glue respectively in an up-down knitting way of a circular knitting machine. The preparation method comprises the following steps: (1) weaving, namely obtaining blanks and performing fabric slitting, curling and finishing; and (2) performing after-finishing on finished fabrics, namely performing open width washing, pre-shaping, dyeing, mellow finishing, dewatering, drying and re-shaping to obtain the polyurethane Roman cloth. The polyurethane Roman cloth has the characteristics of soft hand feel, good elasticity, massiness, good heat retention property, high stretching resilience, fold resistance and the like; the problems of poor stretching resilience and non fold resistance of general Roman cloth are solved; and the practicality of the Roman cloth is improved.

Owner:NINGBO DAQIAN TEXTILE

Preparation process of artificial leather shell material

A rpeparation process of imitation real leather shell fabric with excellent elasticity, air permeability, heat insulating ability, crease-resistance and buckskin effect includes the procedures of warp knitting, grey fabric, pretreatment, drying, raising, opening, dyeing, carding, shearing, grinding and foring, and is characterized by that its raw material is of "islands-in-sea" type fibre, and the technological condition of pretreatment is as follows: adding adjuvant at 120-130 deg.C, treatment time is 30-50 min., the technological condition of raising process is as follows: number of pin-rollers of raising machine is 24, model of card clothing is RA-91, and frame needling for three times; and the condition of opening treatment is that adding sodium hydroxide 10-15 g / l at 100-150 deg.C, heating time is 60-90 min., and the condition of grinding process is that grinding roller speed is 1200 rpm, pressing distance is 3mm and abrasive paper specification is 140-180 meshes.

Owner:JIANGSU HONGDA TEXTILE

Wool semi-worsted spinning technique

InactiveCN101469470AWell mixedWide adaptabilityHeating/cooling textile fabricsCarding machinesCombingWinding machine

The invention relates to a wool semi-worsted spinning process, including fearnaughting, feeding by a FB001 automatic feeding bucket, carding by a FB201 carding machine, drawing by a A272 drawing machine, treating by a A456G fly frame machine, spinning by a A513W spinning machine, cheese winding by an automatic winding machine, twisting by a twisting machine, two-for-one twisting by a two-for-one twisting machine or the like. The manufacturing apparatus is composed by combining a wool spinning apparatus with a cotton spinning apparatus. The process has advantages of: (1) creatively reconfiguring and modifying by introducing cotton spinning apparatus and process, so as to spin woolen short fiber into high count semi-worsted yarn; (2) the spinning process is comparative to ordinary cotton carding, but simplified in process, and lower in cost; (3) drawing process spinning is adopted, cotton material mixing, carding and combined drawing of cotton spinning are introduced, so that spun yarns are uniform in color, mixed uniformly, bright and clean on surface, loose in hand feeling, and soft; feature of the product is between the worsted spinning and the woollen spinning; (4) the process is relatively adaptive to raw material, flexible in yarn number, easy for technology diffusion, low in equipment investment, small in occupation.

Owner:TIANJIN TEXTILE ENG RES INST

Organosilicon emulsion used for hand feel finishing of wool and blended yarn thereof and preparation method and application thereof

The invention provides an organosilicon emulsion used for the hand feel finishing of wool and blended yarn thereof, which comprises 40 to 60% of amino silicon oil emulsion, 30 to 50% of hydroxy silicon oil emulsion and 10% of hydrogen-containing silicone oil emulsion. A preparation method comprises the steps of preparing the amino silicone oil emulsion, the hydroxy silicon oil emulsion and the hydrogen-containing silicone oil emulsion, and then mixing according to the proportion of 40-60%, 30-50% and 10%. The application comprises putting the wool or the blended yarn thereof into the organosilicone emulsion, soaking at the temperature of 40-45 DEG C for 30-60 minutes and drying at the temperature of 85-100 DEG C after dehydration. The effect of the comprehensive hand feeling of smoothness without grease, softness, overhang feel, slip and bulkiness is achieved.

Owner:WACKER DYMATIC SILICONES SHUNDE CO LTD FOSHAN

Elastic towel of untwisted yarn and processing method

InactiveCN101509168AFluffyImprove water absorptionDry-cleaning apparatus for textilesBleaching apparatusEngineeringSoftening

The invention discloses an untwisted yarn elastic towel and a processing method, the towel is subjected to, in accordance with technological parameters, prepared beaming, pirn and weaving to a towel blank by 30-70 wt.% of cotton yarn, 30-70wt.% of untwisted yarn and 5-10 wt.% of spandex covered yarn, subsequently, the towel blank is subjected to desizing, boiling-bleaching, deoxidization, dyeing, soaping, softening, dehydration, soft-drying, finished product cutting and sewing to the towel. The towel has 100-120 yarn / 10cm of warp density and 120-160 yarn / 10cm of weft density, and is 230-250g heavy per square meter; the warp yarns are arrayed such that 20-30 yarns are each circulated with 5-8 yarns of the spandex covered yarns, the weft yarns are arrayed such that 30-40 yarns of cotton yarns are each circulated with 2-3 yarns of the spandex covered yarns, wool yarns are arrayed such that 1 yarn of the cotton yarns and 1 yarn of the untwisted yarns or the whole are the untwisted yarns; compared with normal towels, the product has the characteristics of soft, fluffy and elastic hand feeling, unique appearance in waveform and being stretchable by 30-40%.

Owner:山东好友家纺有限公司

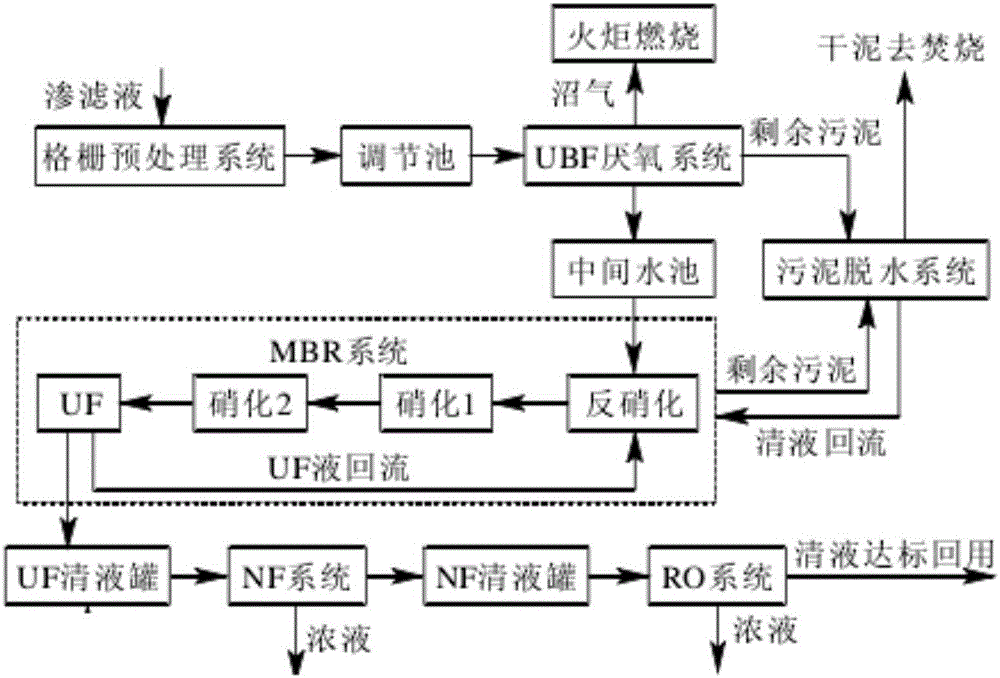

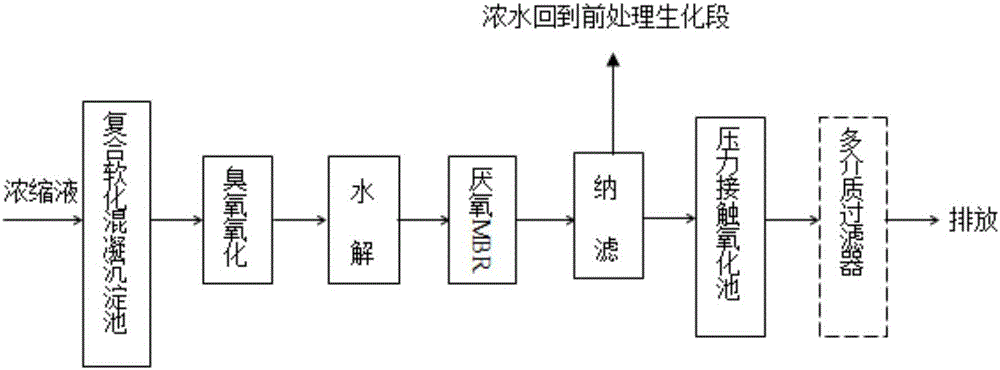

Treatment method of concentrated solution produced from landfill leachate by membrane method

ActiveCN106242163AImprove biodegradabilityReduce processing costsTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationFiltration

The invention discloses a treatment method of a concentrated solution produced from landfill leachate by a membrane method. The treatment method comprises the following steps of enabling the concentrated solution produced from the landfill leachate by the membrane method to sequentially pass through a composite softening coagulation and sedimentation pond, an ozone oxidation reactor, a hydrolyzing pond and an anaerobic MBR pond, and enabling effluent water from the anaerobic MBR pond to enter a nanofiltratoin system; enabling a permeation solution obtained through treatment of the effluent water in the nanofiltratoin system to be treated by a pressure contact oxidation reactor, and directly discharging the treated permeation solution, or after filtering the treated permeation solution by a multi-medium filter, discharging the filtered permeation solution; mixing a concentrated solution obtained after treatment by the nanofiltratoin system with the landfill leachate so as to obtain a mixed solution; and performing concentration treatment on the mixed solution by a biochemical method, an MBR method and the membrane method so as to obtain a concentrated solution, enabling the concentrated solution to enter the composite softening coagulation and sedimentation pond, and performing subsequent operations. The treatment method disclosed by the invention not only is suitable for treatment of the concentrated solution produced from the landfill leachate by membrane filtration, but also is suitable for treatment of other membrane concentrated solutions containing high concentration of organic compounds which are difficult to degrade.

Owner:江苏环保产业技术研究院股份公司

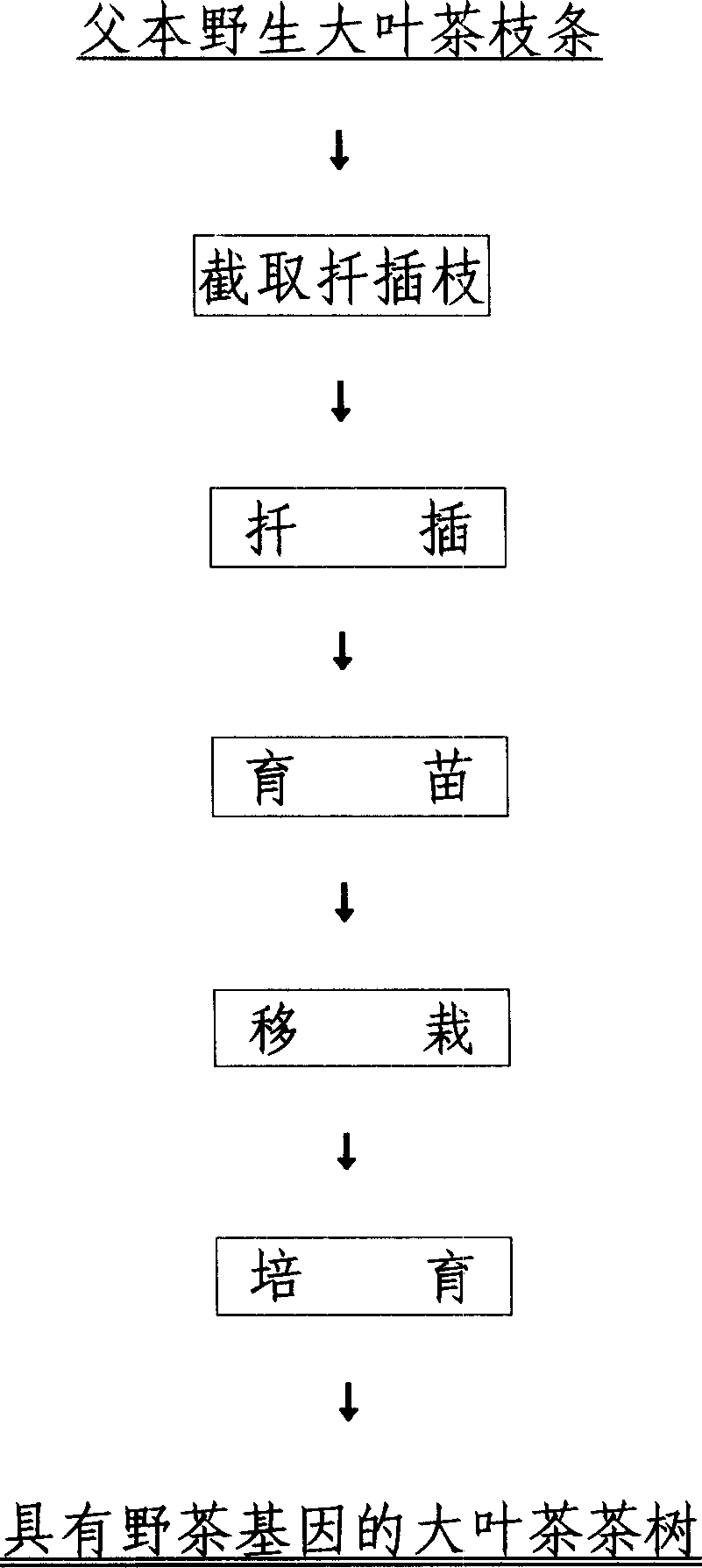

Method for breeding wild tea tree

InactiveCN100998288AYield is not affectedIncrease productionHorticulture methodsPlant tissue cultureTwigReproduction

A method for the reproduction of wild bigleaf tea tree with high yield and quality includes such steps as cutting the wooden twig of wild male-parent bigleaf tea tree to become segments with a leaf to obtain cuttage twigs, rooting, inserting them in nursery bed, arranging sunshade net above the nursery bed, moistening the nursery bed, conventional managing, and transplanting.

Owner:卢万俊

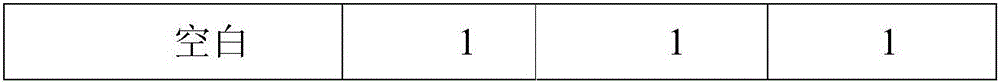

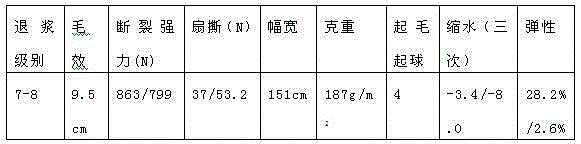

Dyeing and finishing technology for cotton/viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment

ActiveCN105544227ASoft touchFluffyMercerising of indefinite length fabricsTextile storage in wounded formTextile printerRoom temperature

The invention belongs to the technical field of textile printing and dyeing, and in particular relates to a dyeing and finishing technology for a cotton / viscose ammonia multi-fiber stretch fabric employing bio-enzyme low-temperature treatment. The dyeing and finishing technology comprises a pretreatment technology, a dyeing technology and a post-finishing technology. According to the printing and dyeing method for a cotton / viscose stretch fabric, room-temperature stacked desizing is carried out by a biologic desizing enzyme; and an efficient refining agent is selected, so that various pretreatment indexes are effectively improved; soft and fluffy hand feeling of the cotton / viscose stretch fabric is achieved; energy conservation and emission reduction are achieved through low-temperature desizing; potential drapes in the fabric processing process are eliminated; and smooth production of the dyeing procedure is facilitated. A light-colored fabric is dyed from pad dyeing, and a dark fabric is subjected to cold pad-batch dyeing, so that an improvement of various color fastness indexes is met; dyeing process parameters are optimized; and uniform and full dying material quality is obtained. A softening agent is preferably adopted in fabric post-finishing, so that the hydrophilicity of the fabric is achieved; and the wearing comfort of the fabric is achieved.

Owner:HUAFANG

Low-temperature deoiling scouring agent and preparation method thereof

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

Antibacterial comfortable terylene fabric and preparation method thereof

InactiveCN106120317AGood hygroscopicityImprove water absorptionConjugated cellulose/protein artificial filamentsCellulose/protein filament chemical after-treatmentAdditive ingredientGlycerol

The invention discloses an antibacterial comfortable terylene fabric and a preparation method thereof. The terylene fabric is prepared from the following raw materials in parts by weight: 80 to 90 parts of PET slices, 15 to 20 parts of cellulose fiber, 2 to 4 parts of nanometer Al2O3, 6 to 9 parts of glycerol, 8 to 10 parts of PEG-2000 and 3 to 5 parts of antibacterial masterbatches. According to the method, gamma-Al2O3 crystal formation nanometer Al2O3 is added into terylene; a micropore structure is formed in the terylene fabric; meanwhile, through the addition of glycerol with hydrophilic groups and the PEG-2000, the prepared terylene fabric has good moisture absorption performance and water absorption performance, good softness and fluffy feeling. In addition, the terylene fabric achieves the antibacterial effects of inorganic antibacterial agents and antibacterial ingredients in natural traditional Chinese herbal medicine are achieved;dual-directional regulation is performed; high sterilization effects are achieved; the removal rate of various bacteria reaches 99 percent or higher.

Owner:林启东

Bicomponent fiber of polylactic acid and polyethylene butanediol succinate

InactiveCN101694022AFluffyMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer scienceSingle fiber

The invention discloses a bicomponent fiber of polylactic acid and polyethylene butanediol succinate, which is characterized in that the polylactic acid and the polyethylene butanediol succinate are firstly obtained by polymerization; the two different polymers are respectively melted in the process of spinning silk and are combined into a single fiber in the last moment before extrusion to obtain a degradable fiber with puffing performance.

Owner:WUJIANG YINGXIANG CHEM FIBER

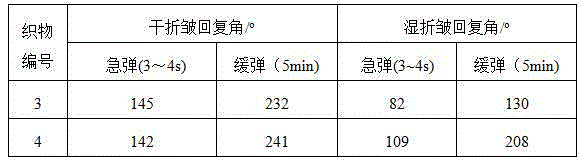

Silicone acrylic emulsion and application of silicone acrylic emulsion as textile finishing agent

The invention discloses silicone acrylic emulsion and the application of the silicone acrylic emulsion as a textile finishing agent. The silicone acrylic emulsion is manufactured by the following raw materials in parts by weight: 24-30 parts of butyl acrylate, 6-14 parts of methyl methacrylate, 0.15-1.0 part of initiator, 42.9-67.7 parts of deionized water, 1.2-6 parts of compound emulsifier, 0.3-0.6 part of pH buffer agent, 1-5 parts of vinyltriethoxysilane and 0.1-0.3 part of ammonium hydroxide. The silicone acrylic emulsion of the invention has the advantages that the composition is simple, the consumption of organosilicone monomer is low, the hydrolyzation of siloxane can be efficiently reduced through the matching of the silicone acrylic emulsion and seed emulsion, the polymerization process and the finally obtained emulsion are stable, and the emulsion is high in solid content, low in viscosity and convenient to use; the emulsion is used as the textile finishing agent so as to enable the textile to gain better weight increment and anti-wrinkle performance under the condition of keeping whiteness and intensity, no methyl aldehyde is realized during finishing, preservation and use, and the emulsion has the characteristics of remarkable effect, environmental protection and low cost.

Owner:SUZHOU UNIV

Microcapsule embedded leavening agent and preparation method thereof

The present invention relates to the technical field of food additives and particularly relates to a microcapsule embedded leavening agent and a preparation method thereof. The microcapsule embedded leavening agent comprises wall materials at a weight percentage of 30%-80% and preservative core materials at a weight percentage of 20%-70%. The core materials of the leavening agent are embedded with the wall materials; the wall materials are at least one of distilled glyceryl monostearate, hydrogenated vegetable oil, diacetyl tartaric acid monoglyceride or diglyceride, polyglycerol fatty acid esters, sodium stearoyl lactate, phospholipids and beeswax; and the core materials of the leavening agent are at least one of sodium bicarbonate, dihydrogen disodium pyrophosphate, calcium hydrophosphate and calcium carbonate. The microcapsule embedded leavening agent is good in use effects, can control the speed of the reaction of the leavening agent, is conductive to releasing in the subsequent baking process, and thereby grants baked food fluffy volume and soft quality.

Owner:GUANGDONG GUANGYI TECH IND

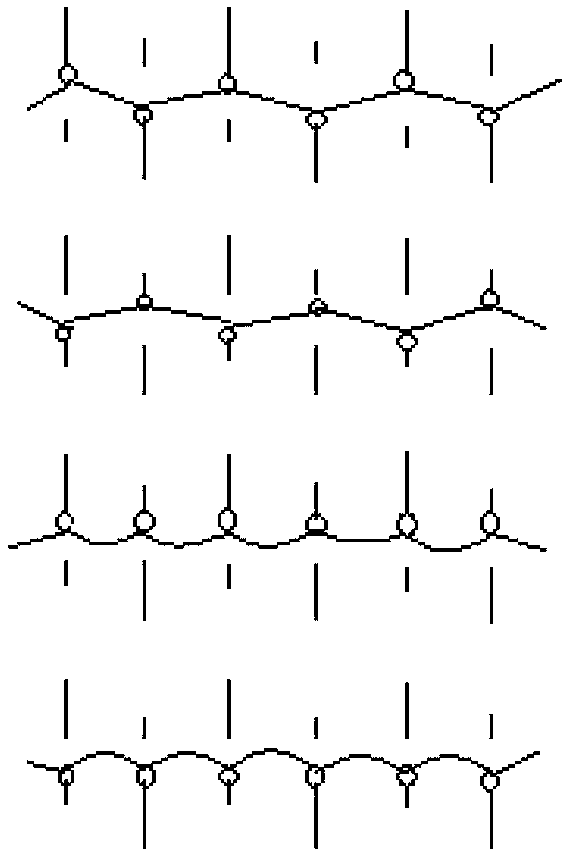

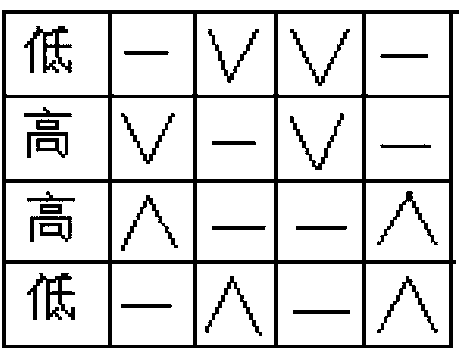

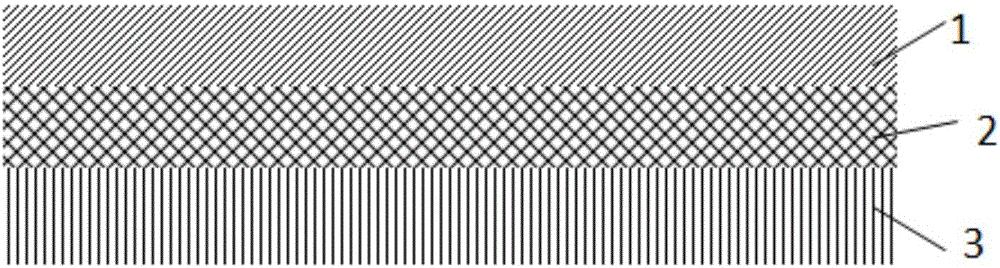

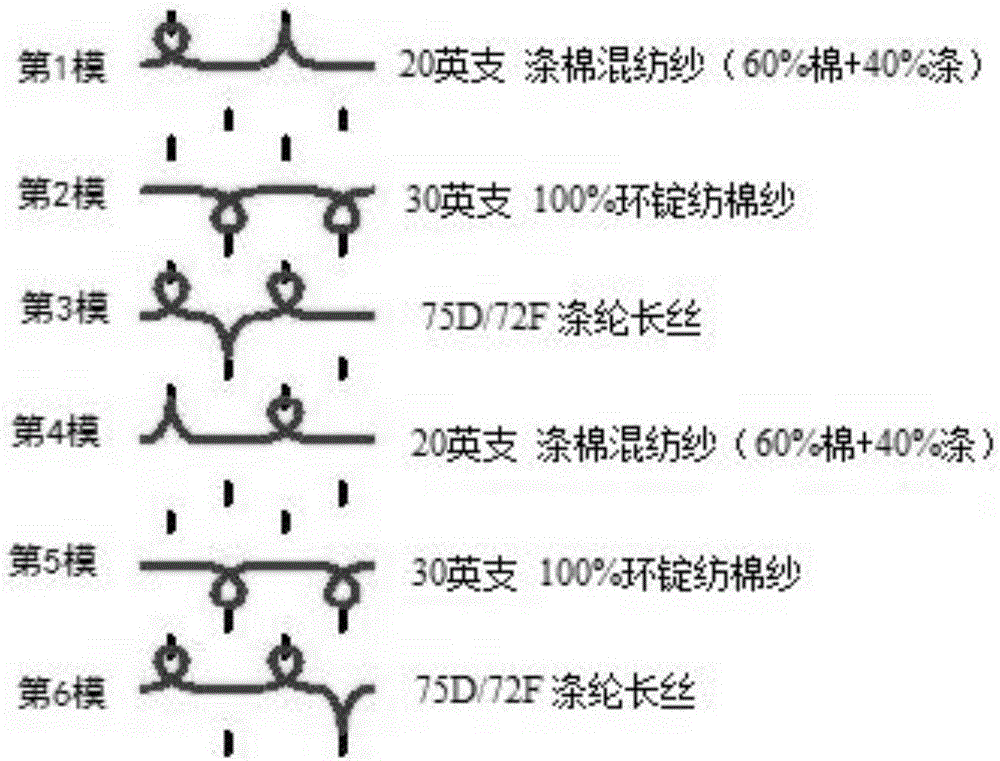

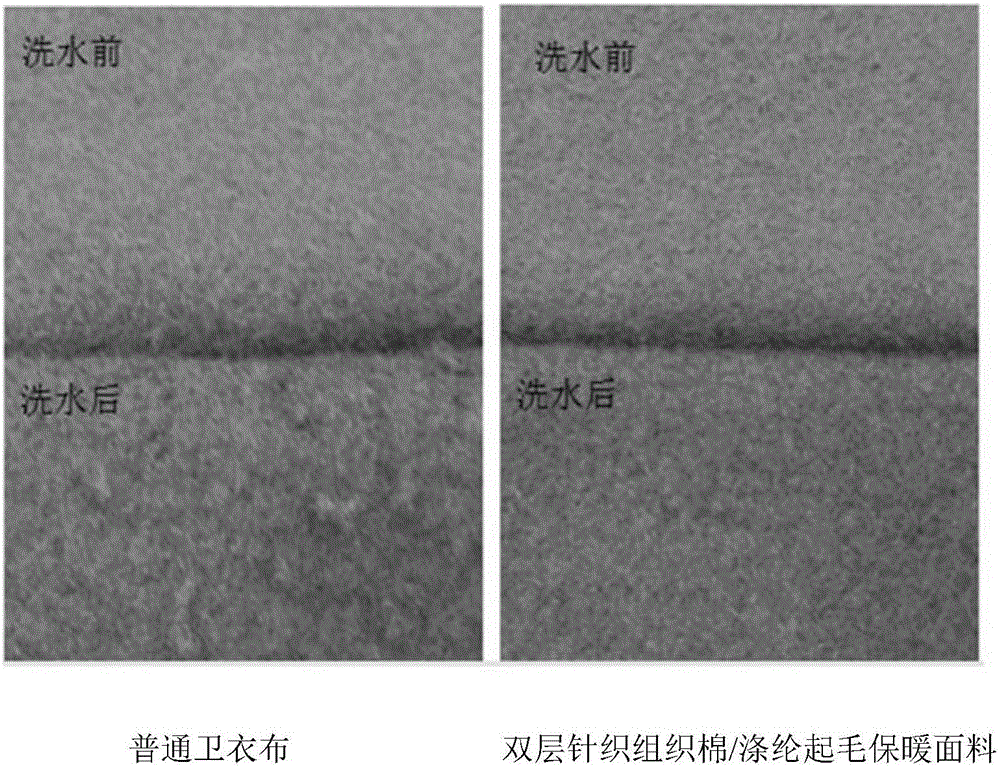

Double-layer knitting stitch type fleece and making method thereof

The invention provides double-layer knitting stitch type fleece and a making method thereof. The double-layer knitting stitch type fleece comprises a surface layer, a middle layer and a bottom layer, wherein the surface layer is made of cotton yarn or cotton blended yarn, the middle layer is made of dacron or nylon, the bottom layer is made of dacron or blended yarn, the surface layer is connected with the bottom layer through the middle layer, and the bottom layer is subjected to fluffing finishing. The invention further provides the making method of the double-layer knitting stitch type fleece. The making method comprises the steps of forming the surface layer and the bottom layer with the knitting double-layer weaving method, connecting the surface layer and the bottom layer into a whole by means of the middle layer to form knitting double-layer gray fabric, and conducting functional after treatment on the knitting double-layer gray fabric to obtain the double-layer knitting stitch type fleece.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

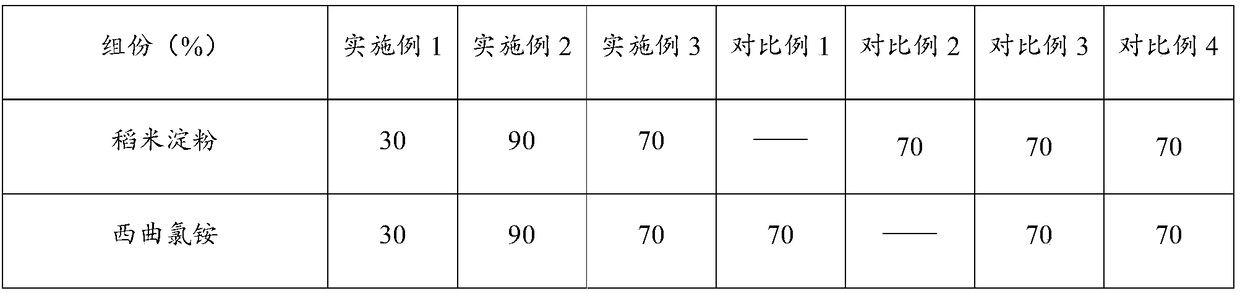

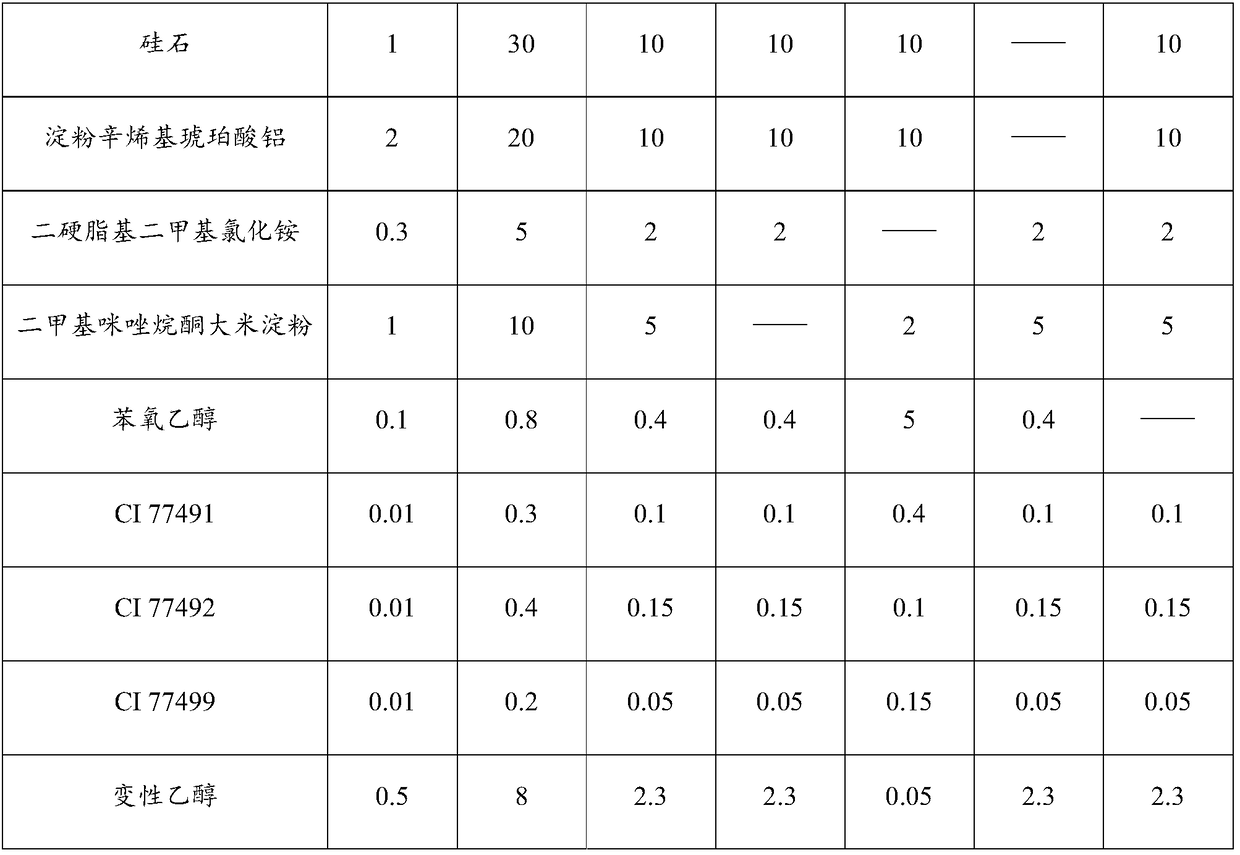

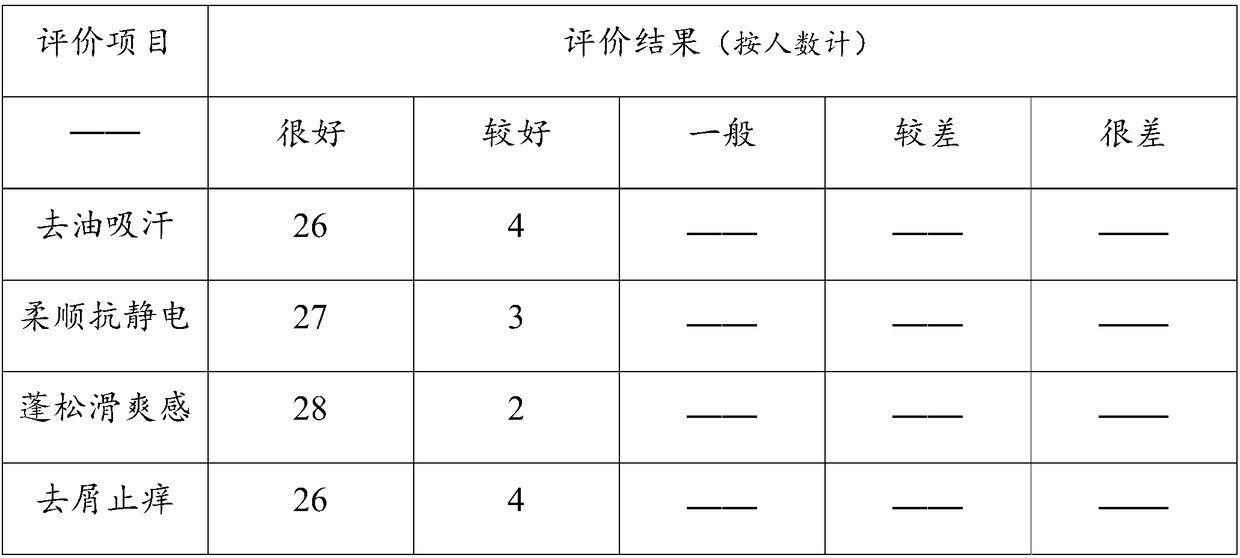

Hair dry cleaning composite and preparation method thereof

InactiveCN108721141AImprove absorbencyAdds volume and textureCosmetic preparationsHair cosmeticsChemistryBrown iron oxide

The invention provides a hair dry cleaning composite and a preparation method thereof. The hair dry cleaning composite is prepared from the following ingredients in parts by weight: 30-90 parts of rice starch, 30-90 parts of cetrimonium chloride, 1-30 parts of silica, 2-20 parts of starch aluminium octenylsuccinate, 0.3-5 parts of distearyl dimethyl ammonium chloride, 1-10 parts of dimethyl imidazolidinone rice starch, 0.1-0.8 part of phenoxyethanol, 0.01-0.3 part of iron oxide red CI77491, 0.01-0.4 part of iron oxide yellow CI77492, 0.01-0.2 part of iron oxide black CI77499 and 0.5-8 parts ofdenatured alcohol. According to the hair dry cleaning composite, grease and sweat on hair can be quickly removed. Compared with a traditional liquid hair washing product, the hair dry cleaning composite disclosed by the invention is almost not in contact with scalp when being used, no irritation is generated for the scalp, and safety is higher.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

Hydrophilic softener for towel fabric

ActiveCN105755829AIncreased versatilityGood antibacterial and deodorizing propertiesFibre treatmentOrganic acidPolyester

The invention relates to a fabric softener, in particular to a hydrophilic softener for towel fabric and belongs to the field of textile softeners.The softener comprises the components according to percent by weight: 10-20% of modified amino siloxane, 5-10% of polyether polyester, 1-8% of quaternary ammonium salt, 5-10% of nonionic emulsifying agent, 0.1-0.5% of an organic acid, and 51.5-78.9% of deionized water.The softener is prepared: according to the above-mentioned ratio, adding the modified amino siloxane and the nonionic emulsifying agent into a variable speed mixer first, mixing well, adding the polyether polyester and the quaternary ammonium salt and stirring, and finally adding citric acid and deionized water according to a ratio for emulsification; stirring well, and packaging.The hydrophilic softener is good in quality stability, can impart fluffy and thick handle to the towel fabric without affecting hydrophilicity and color of the towel fabric and is also functional in inhibiting bacteria and removing odor.

Owner:江西氟聚新材料科技有限公司

Super cotton feeling polyester filament fabric and preparation method thereof

The invention discloses a polyester filament fabric with an ultracotton feeling and a preparation method thereof. At least one of warp yarns used to form the fabric is a cotton-like polyester filament, and the cotton-like polyester filament is air-textured composite yarn taslan. The production method comprises the following steps: firstly, the cotton-like polyester filament taslan which is taken as at least one of the warp yarns is produced into grey cloth, the preparation and weaving of the grey cloth adopt unique preparation and weaving process conditions, and the grey cloth is subjected to post-treatment which comprises steps of soaping, flow dyeing, finishing shaping, calendering, coating, compounding and so on, to obtain a product. The polyester filament yarn fabric with the ultracotton feeling has the terry effect and the fluffiness of outer layers of yarns; and the product produced by the method has light mass, is wear-resistant and easy to wash, and has rich, exquisite and soft appearance and hand feeling superior to those of a cotton fabric. The production method has the advantages that the production method is simple, convenient, and low in cost.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

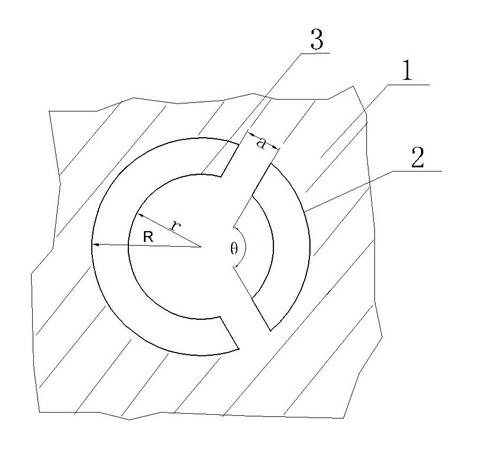

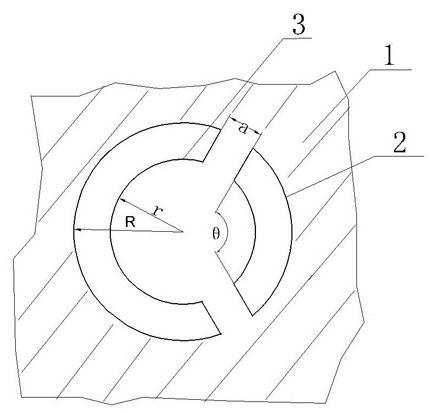

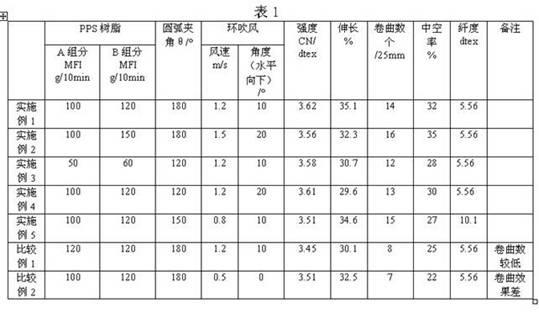

Method for preparing hollow three-dimensional crimped polyphenylene sulfide staple fibers

InactiveCN102162153AAvoid hypothermiaGood operabilityHollow filament manufactureFilament/thread formingMelt spinningWoven fabric

The invention discloses a method for preparing hollow three-dimensional crimped polyphenylene sulfide staple fibers. Two components are adopted in the method, the melt index of linear polyphenylene sulfide is 50 to 150g / 10min, and the melt index difference of the first component and the second component is 10 to 50g / 10min; melt spinning is performed at the temperature of between 300 and 350 DEG C; the spinneret hole of a spinneret plate is a ring consisting of two concentric circles, and the ring is provided with two gaps; the annular blowing cooling air velocity of an annular blowing cylinder is 0.8 to 1.5m / s, and the blowing angle of the upper part of the annular blowing cylinder is horizontal downward 10 to 20 degrees; and the spinning speed is 800 to 1,000m / min, and the hollow polyphenylene sulfide staple fibers are prepared by 2 to 5 times of drafting, cutting and high-temperature heat setting of 180 to 220 DEG C. The polyphenylene sulfide staple fibers have the characteristics of good operability, excellent mechanical property, high hollow ratio and the like, and are particularly suitable for high-temperature resistant protective clothing, heat insulation non-woven fabrics and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Process for manufacturing blended wool yarns

The invention relates to the field of textile technology, in particular to a process for manufacturing blended wool yarns. The process is characterized in that usage boundaries on various traditional spinning devices are broken, and reconfiguration, modification and adjustment are creatively carried out, so that rove staple fibers are spun into separate-count semi-worsted yarns. Yarns are spun by a drafting method, blending and carding of raw wool yarns and doubling drafting of cotton yarns are assimilated, accordingly, colors of spun yarns are uniform, fibers are blended uniformly, surfaces of the yarns are smooth, and the yarns feel fluffy and soft. According to the scheme, the process has the advantages that the process is adaptable to a wide range of raw materials, counts of the yarns can be high or low, the technology is easy to popularize, equipment investment is low, and occupied factory area is small.

Owner:刘自忠

Preparation method of feeds for dark turkeys

InactiveCN101617769AFast growthGood disease prevention performanceFood processingAnimal feeding stuffCalcium biphosphateCorydalis yanhusuo

A preparation method of feeds for dark turkeys adopts the following ingredients by weight percent: 10-14% of corns, 4-6% of bran, 10-20% of soya bean meal, 2-6% of cotton seed cakes, 8-10% of grass seed meal, 10-12% of alfalfa meal, 6-8% of pagoda leaf meal, 10-14% of fish meal, 8-12% of bone meal, 0.5-1% of dicalcium phosphate, 0.5-1% of lysine, 0.5-1% of salt, 0.5-1% of rhizoma corydalis, 1-3% of safflower, 1-3% of tuckahoe, 1-3% of honeysuckle, 1-3% of mulberry leaves, 1-3% of nutgrass and 1-3% of unibract fritillary bulb. The preparation method comprises the following steps: proportionally placing the above meal into a multiplex stirrer to be stirred, taking out the meal to be placed into a ring model grinder to be ground, taking out the meal to be placed into a dryer to be dried, taking out the meal to be placed into a ring model swelling machine to be swelled, taking out the meal to be transferred into a ring model rigid granulator to produce precipitated rigid granulated feeds, sieving the feeds by a 80-mesh sieve to obtain the granules with weight of 0.2g singly and sealing and packing the granules according to the required weight.

Owner:刘学顺

Method for preparing feed for meat pigeons

InactiveCN101617751AFast growthLoud ingredientsFood processingAnimal feeding stuffAnimal scienceCoptis

The invention relates to a method for preparing a feed for meat pigeons. The feed comprises the following components in percentage by weight: 4 to 6 percent of rice albumen powder, 4 to 8 percent of sorghum albumen powder, 2 to 6 percent of soybean albumen powder, 8 to 10 percent of wheat albumen powder, 8 to 11 percent of rice bran, 4 to 6 percent of barley flour, 6 to 10 percent of sunflower seed cake, 12 to 16 percent of fish meal, 3 to 6 percent of eel meal, 4 to 6 percent of seashell meal, 4 to 6 percent of broken rice, 1 to 3 percent of vitamin B complex, 6 to 8 percent of carrot meal, 2 to 4 percent of cod liver oil meal, 1 to 3 percent of cooking salt, 1 to 3 percent of bulbus fritillariae cirrhosae, 1 to 3 percent of coptis root, and 1 to 3 percent of cassia seed. The method for preparing the feed comprises the following steps: taking the powders and meals according to the proportions and putting the same into a multiplex mixer for stirring; taking out the mixture and putting the same into a circular die type crusher for crushing; then taking out the mixture and drying the same in a drying machine; taking out the mixture and bulking the same in a circular die type bulking machine; taking out the mixture and putting the same into a circular die type hard granule machine to produce a deposition hard granulated feed; and screening the feed with a 80-mesh sieve, wherein the each granule of the granulated feed is 0.2 gram so that the feed can be sealed and packaged according to the required weight.

Owner:王嵩

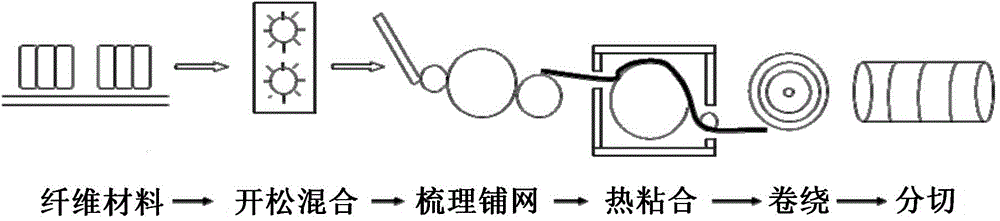

Production method for water-repellent non-woven fabric

InactiveCN104674456AFluffyExcellent water repellencyNon-woven fabricsBandagesEngineeringNonwoven fabric

The invention discloses a novel non-woven fabric and a production method thereof, particularly a production method for a water-repellent non-woven fabric, and the water-repellent non-woven fabric is mainly used as a surface material for personal hygiene care articles. The through-air nonwoven fabric is produced with fibers with water-repellent oil by the through-air method, and has good water-repellent property. The purpose of the design is to overcome the side leakage problem of conventional through-air nonwoven fabrics as the result of long penetration time or insufficient absorbing capacity, and moreover, the visual effect of thin and transparent side edges can be effectively improved. The production method is implemented by using hot air equipment to heat the sheath-core structure or eccentric core structure fibers with the water-repellent oil, and is a novel production method for through-air nonwoven fabrics.

Owner:北京大源非织造股份有限公司

Feed for muscovy ducks

InactiveCN102048045ARich in contentGood preventive and curative effectFood processingAnimal feeding stuffCairina moschataPulverizer

The invention relates to a feed for muscovy ducks, which comprises rapeseed cake flour, wheat flour, rice bran, pumpkin powder, whelk powder, fresh scallop powder, rough fish meal, caterpillar, clam worm powder, egg white powder, starch, cod liver oil, common salt, radix salviae miltiorrhizae powder, boat-fruited scaphium seed powder, lucid ganoderma powder, cochinchnese asparagus root powder, ginkgo seed powder and barbary wolfberry fruit powder. The preparation method comprises the following steps: completely combining the powder agents together according to the proportion, placing in a tandem mixer for stirring for 150 minutes; taking out, then placing in a ring mould type pulverizer for pulverizing into powder; then taking out, placing in a dryer, controlling the dryness of dried substances to be 70%-80%; controlling the drying time to be 40-60 minutes; taking out, cooling, then placing in the tandem mixer for stirring for 160 minutes; taking out, then placing in a ring mould type expander for expanding for 1-2 hours; taking out, then transferring into a ring mould type hard granulation machine for producing the precipitate hard granulated feed, then using an 80-mesh sieve for sieving, keeping the weight of each particle to be 0.2g; and sealing and packaging according to the required weight.

Owner:王嵩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com