Hair dry cleaning composite and preparation method thereof

A composition and hair technology, applied in the field of daily necessities, to achieve high absorbency, excellent combability, and increase the effect of volume and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

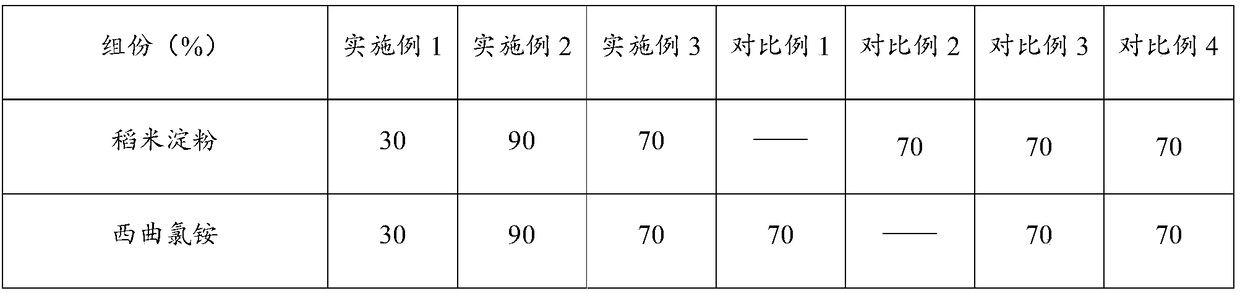

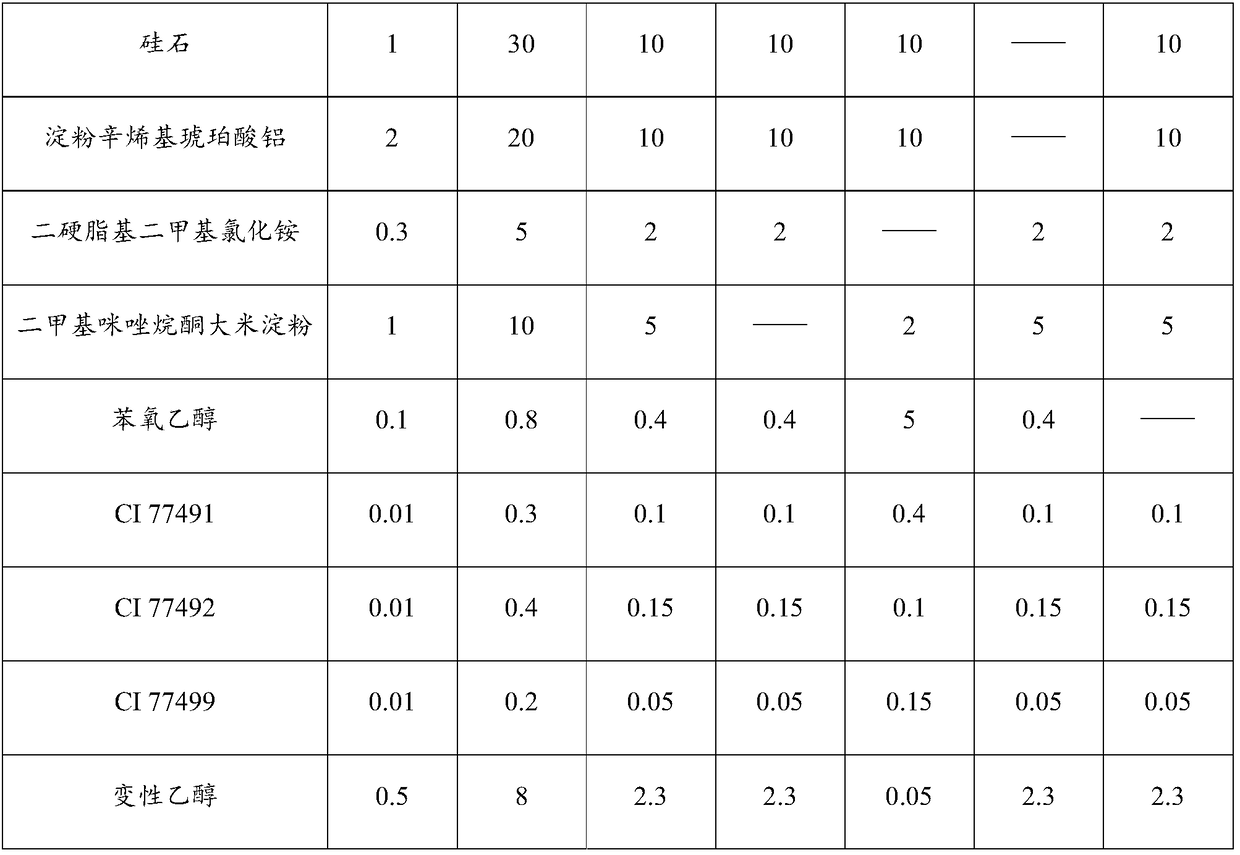

Embodiment 1

[0030] The hair dry-cleaning composition of the present embodiment is made up of following components and mass ratio content:

[0031] Rice Starch 30%

[0032] Cetrimonium Chloride 30%

[0033] Silica 30%

[0034] Aluminum Starch Octenyl Succinate 2%

[0035] Distearyldimethylammonium chloride 5%

[0036] Dimethylimidazolidinone Rice Starch 1%

[0037] Phenoxyethanol 0.8%

[0038] Iron oxide red CI77491 0.01%

[0039] Iron oxide yellow CI77492 0.4%

[0040] Iron oxide black CI77499 0.01%

[0041] Denatured ethanol 0.5%.

[0042] The hair dry-cleaning composition of the present embodiment is prepared by adopting the following method:

[0043] (1) Get silica and iron oxide red CI77491, iron oxide yellow CI77492, iron oxide black CI77499 and mix evenly;

[0044] (2) Mix the mixture of step (1) with rice starch, cetrimonium chloride, aluminum starch octenyl succinate, distearyl dimethyl ammonium chloride, dimethyl imidazolidinone rice starch Put it into the powder mixin...

Embodiment 2

[0050] The hair dry-cleaning composition of the present embodiment is made up of following components and mass ratio content:

[0051] Rice Starch 90%

[0052] Cetrimonium Chloride 90%

[0053] Silica 1%

[0054] Aluminum Starch Octenyl Succinate 20%

[0055] Distearyldimethylammonium chloride 0.3%

[0056] Dimethylimidazolidinone Rice Starch 10%

[0057] Phenoxyethanol 0.1%

[0058] Iron oxide red CI 77491 0.3%

[0059] Iron oxide yellow CI 77492 0.01%

[0060] Iron oxide black CI 77499 0.2%

[0061] Denatured ethanol 8%.

[0062] The hair dry-cleaning composition of this example is prepared by the same method as that of Example 1.

Embodiment 3

[0064] The hair dry-cleaning composition of the present embodiment is made up of following components and mass ratio content:

[0065] Rice Starch 70%

[0066] Cetrimonium Chloride 70%

[0067] Silica 10%

[0068] Aluminum Starch Octenyl Succinate 10%

[0069] Distearyldimethylammonium chloride 2%

[0070] Dimethylimidazolidinone Rice Starch 5%

[0071] Phenoxyethanol 0.4%

[0072] Iron oxide red CI 77491 0.1%

[0073] Iron oxide yellow CI 77492 0.15%

[0074] Iron oxide black CI 77499 0.15%

[0075] Denatured ethanol 2.3%.

[0076] The hair dry-cleaning composition of this example is prepared by the same method as that of Example 1.

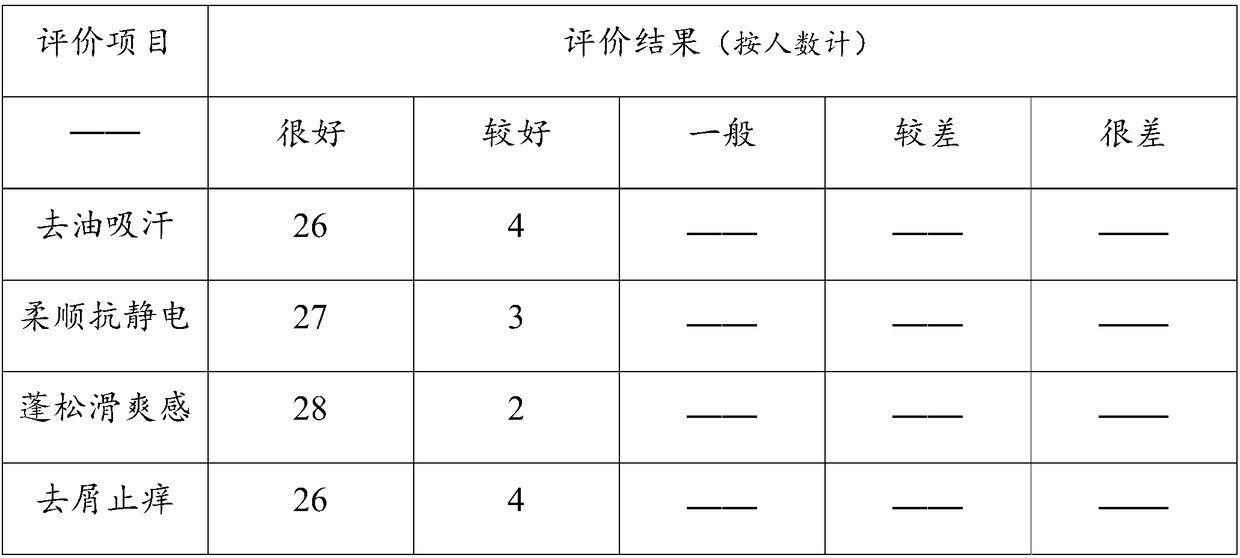

[0077] The product of embodiment is carried out a series of effect evaluation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com