Method for treating decomposed gas by low resistance vertical calandria type absorptive condenser

A condenser and tube-and-tube technology is applied in the absorption field of ammonia and carbon dioxide mixed gas, which can solve the problems of difficult heat balance and water volume control, high investment cost, and high equipment investment in the circulating absorption part, and achieves good application prospects and condensation heat. Effective, absorptive capacity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

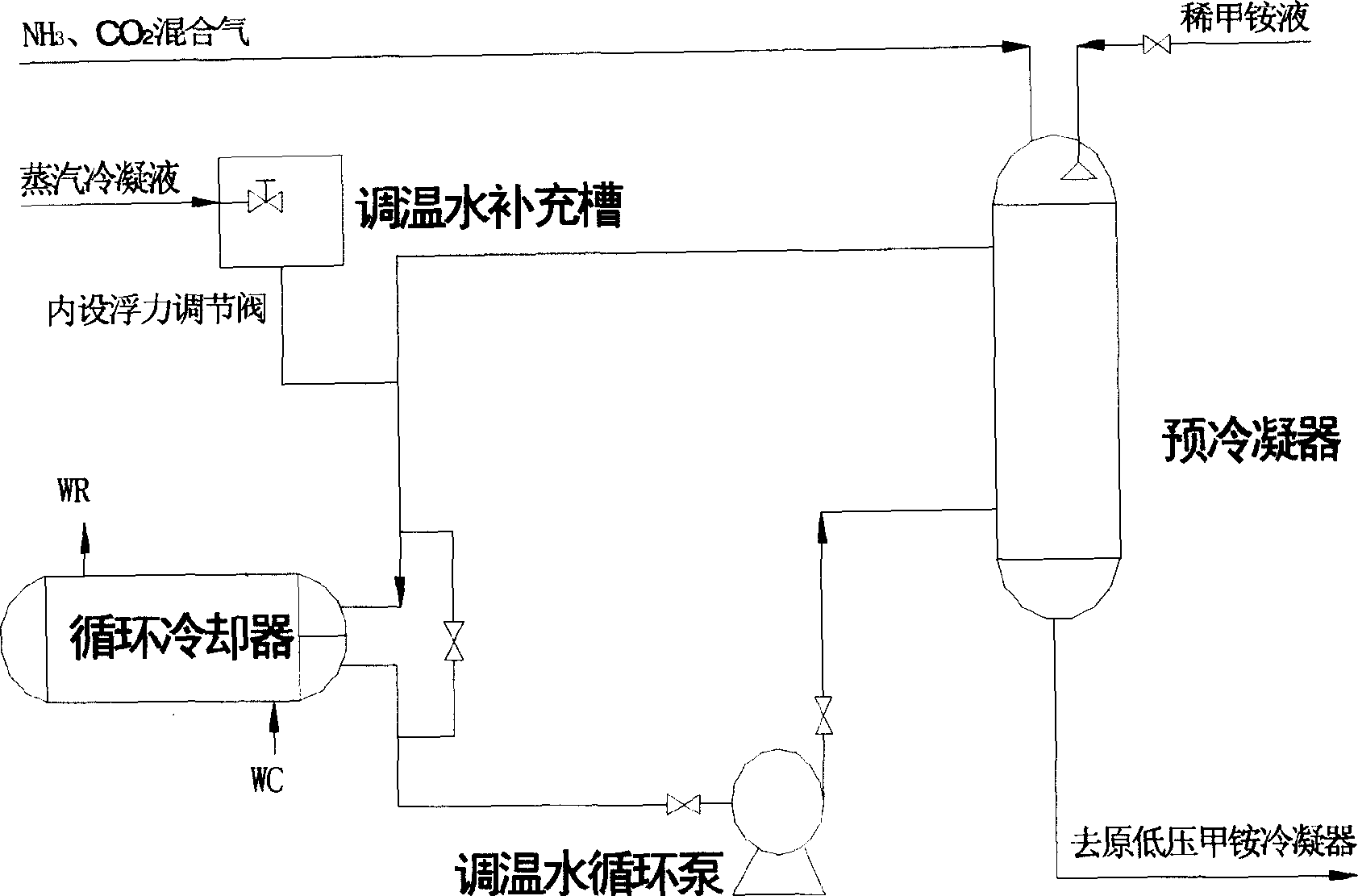

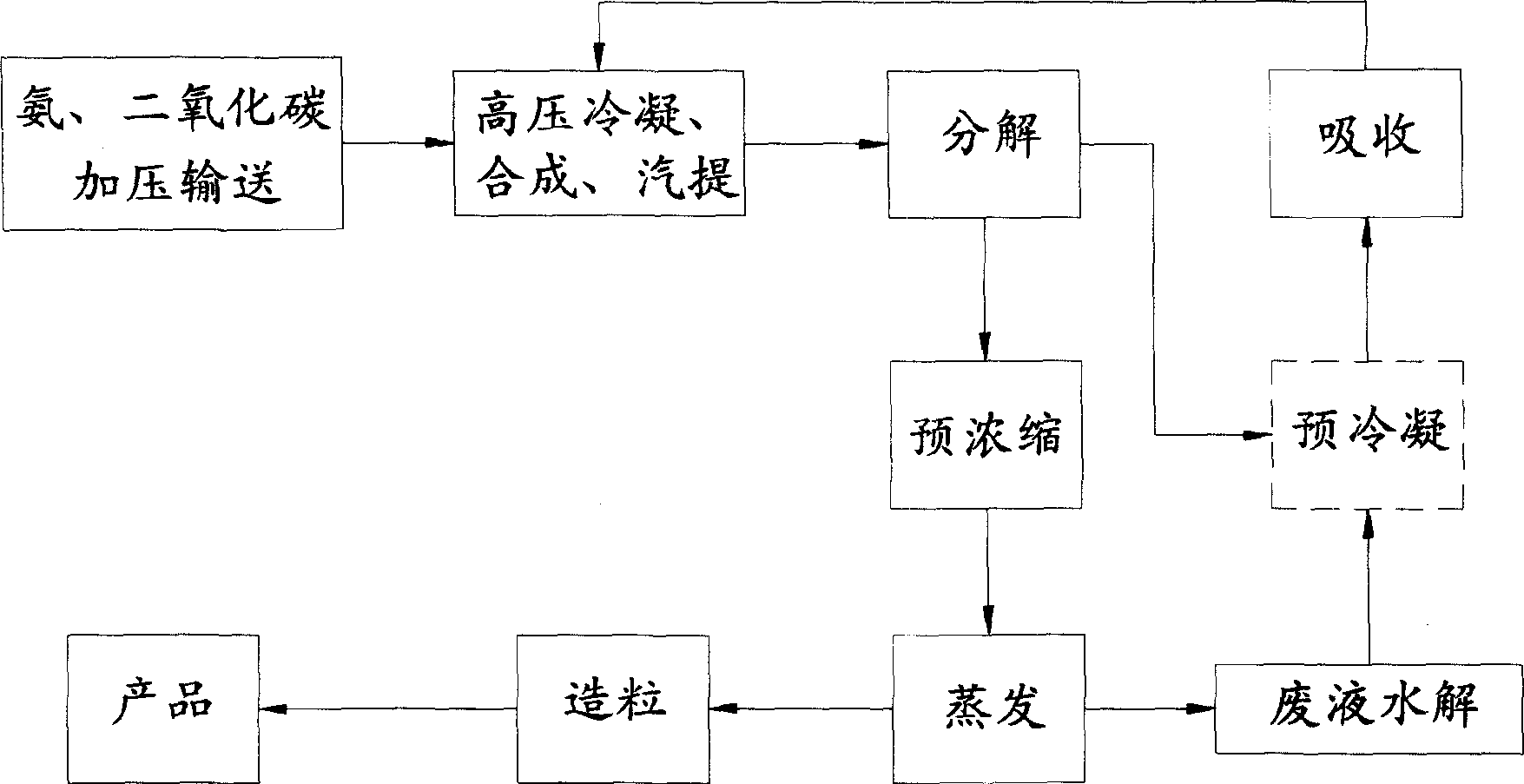

[0011] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the temperature from the rectification tower is 105-112°C, the decomposed gas containing about 34% ammonia, about 51% carbon dioxide, and the rest is water vapor is introduced into the upper tube box of the pre-condenser and distributed to the For each row of tubes, the dilute methylammonium solution with a total concentration of 47-53% is evenly distributed by the nozzles, and the spray angle of the nozzles for spraying the absorbent dilute methylammonium solution is 90-120° to evenly spray each row of tubes. During the top-down flow of the gas-liquid mixture, part of the ammonia and carbon dioxide are absorbed into the liquid phase, and release heat of dissolution and chemical reaction heat, and the gas-liquid mixture out of the pre-absorption condenser is controlled at a temperature not lower than 75°C, and then further condensed and absorbed by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com