Patents

Literature

529results about How to "Reduce formulation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

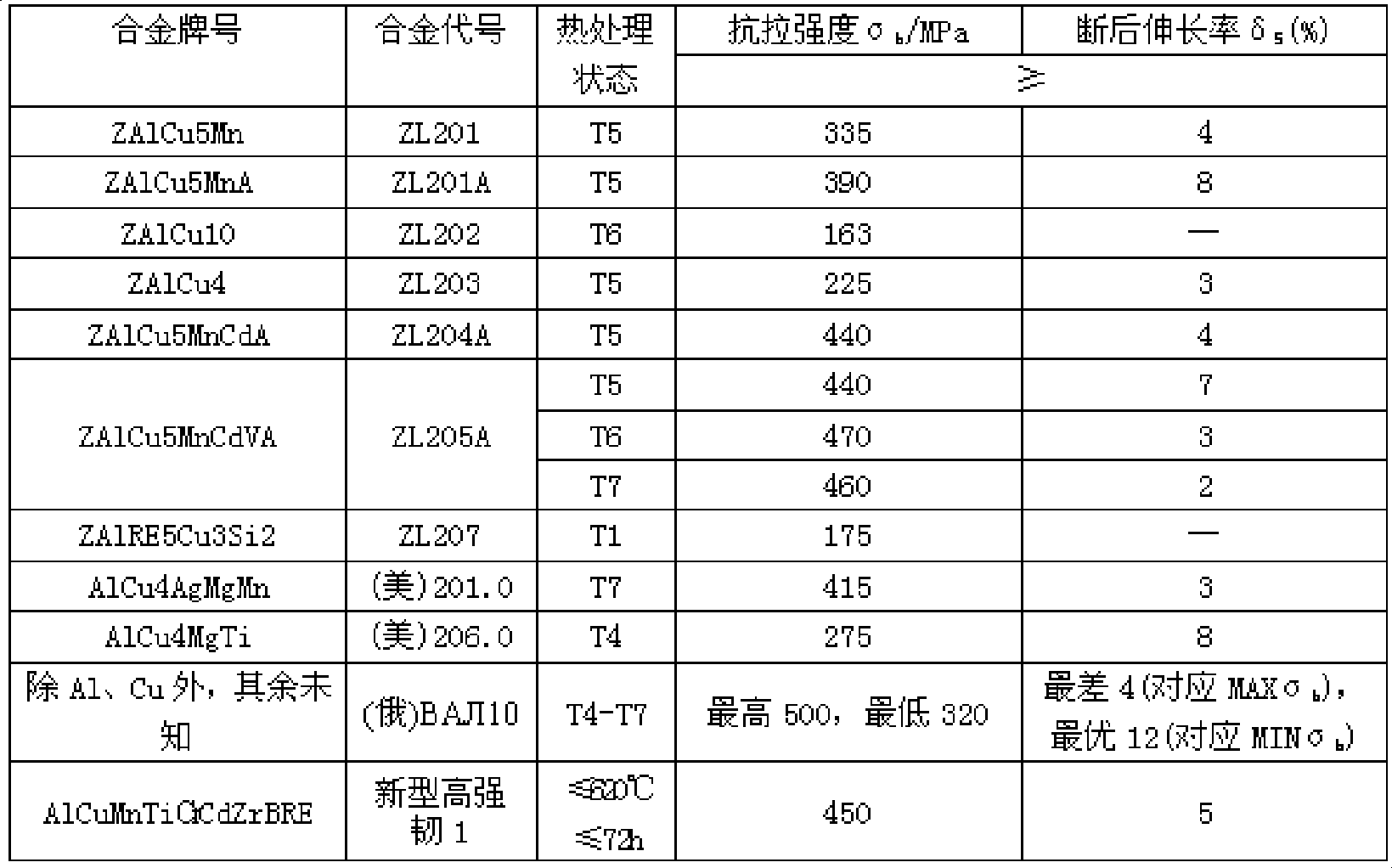

High-strength cast aluminium alloy material

The invention discloses a high-strength cast aluminum alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of mixed rare earth RE, Al and microimpurity elements. The material adopts the advanced design of alloy components and the microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, the mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:GUIZHOU UNIV +2

High-strength cast aluminium alloy material

The invention discloses a high-strength aluminum casting alloy material which comprises the following components by weight percentages: 2.0-6.0% of Cu, 0.05-1.0% of Mn, 0.01-0.5% of Ti, 0.01-0.2% of Cr, 0.01-0.4% of Cd, 0.01-0.25% of Zr, 0.005-0.04% of B, 0.05-0.3% of Ce, Al and other microimpurity elements. The material adopts the advanced design of alloy components and microalloying design. Based on the Al-Cu-Mn as the major components, rational microalloy elements (the Ti, the Cr, the B, the Zr, mixed rare earth, etc.) are found and the ranges thereof are determined, which can realize the function of substituting the precious rare metals Ag, V, and the like, thus lowering the formula cost by 5-10%.

Owner:贵州铝厂有限责任公司 +2

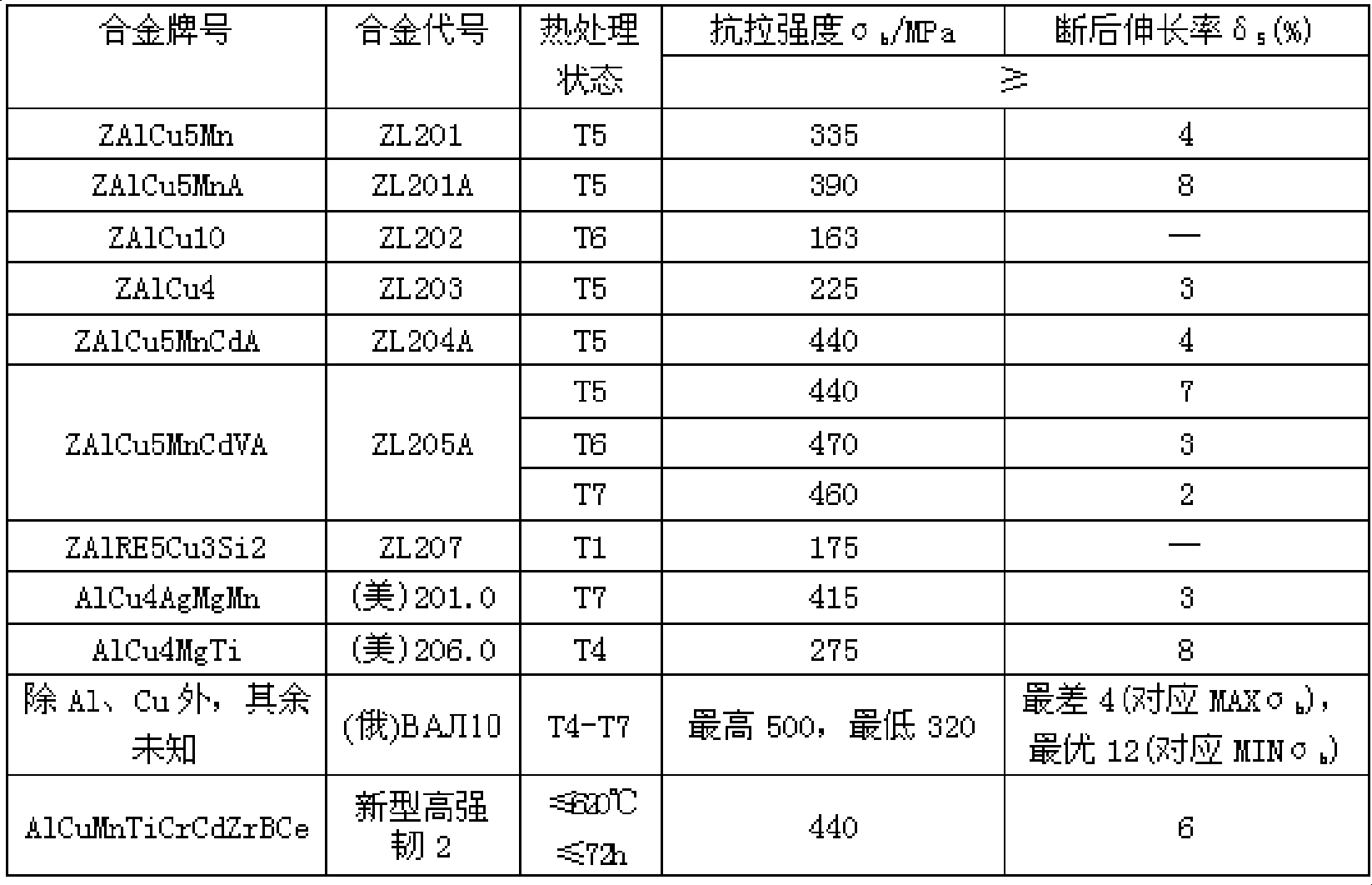

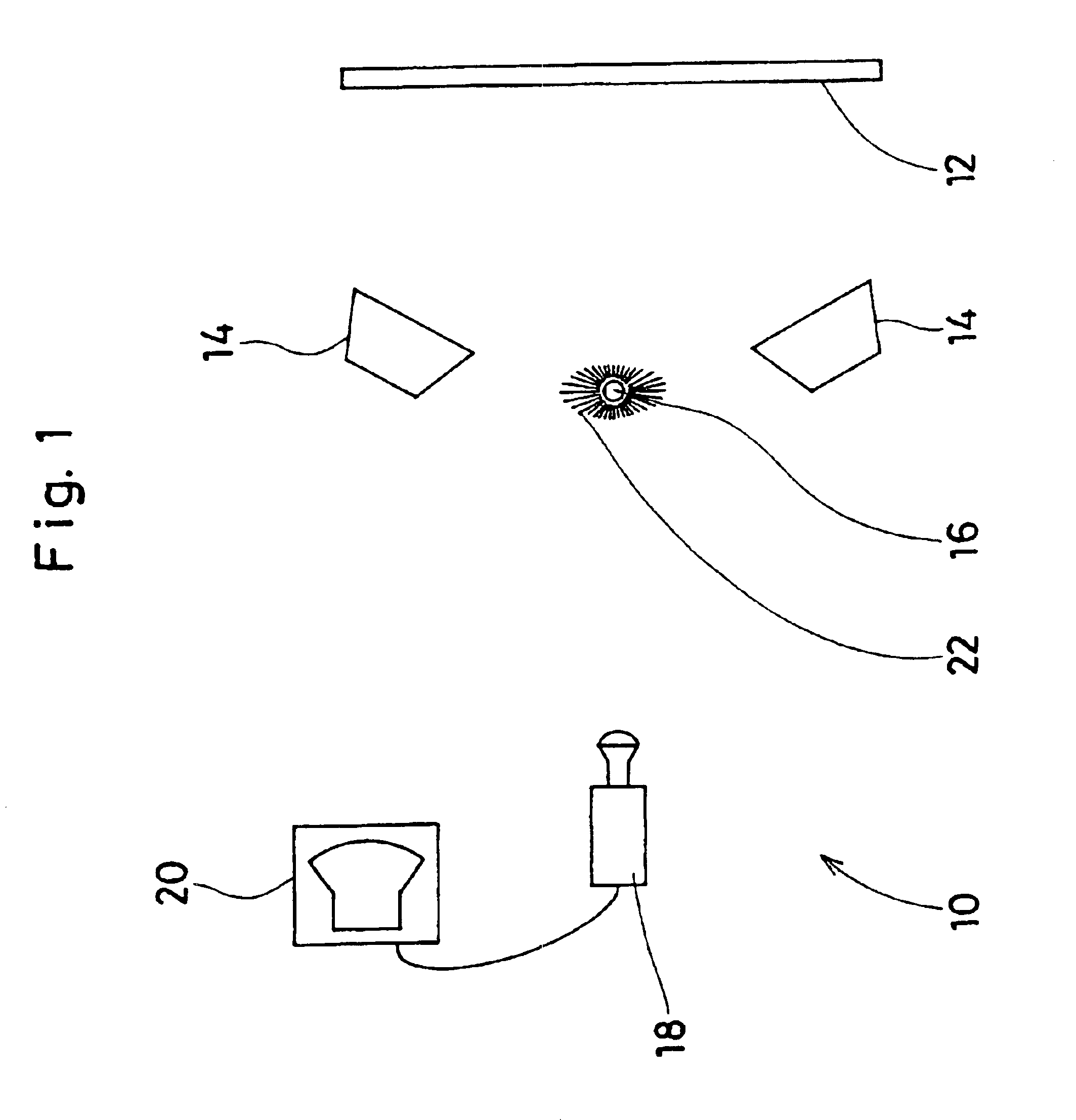

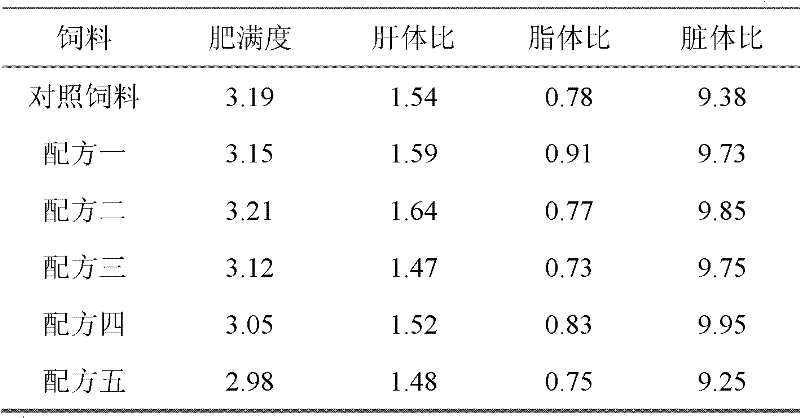

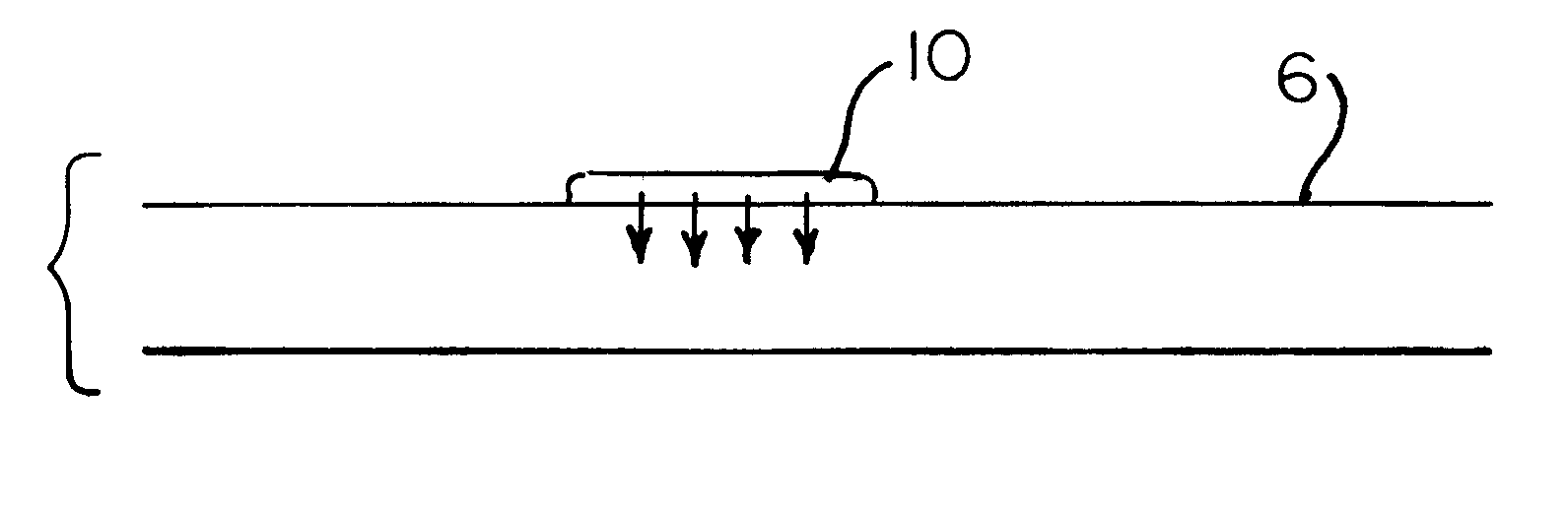

Mounting mat for mounting monolith in a polution control device

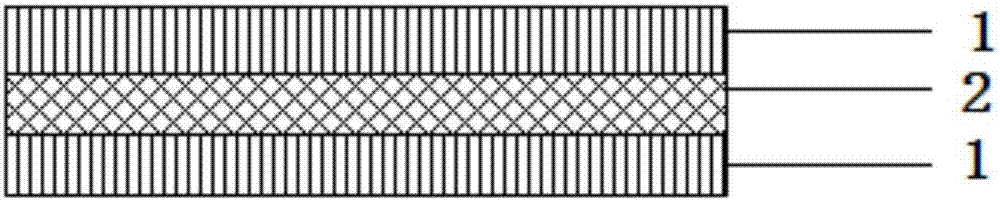

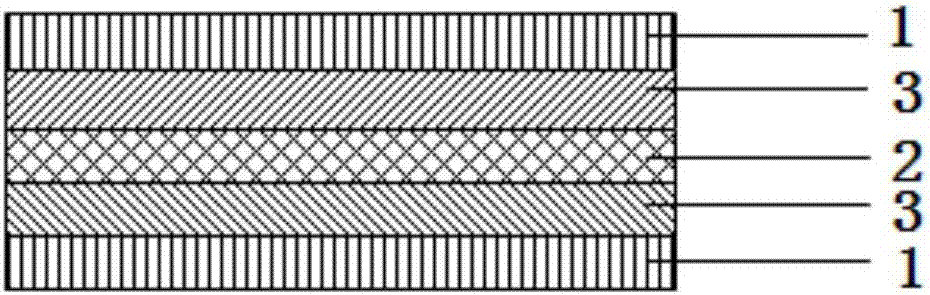

InactiveUS20060154040A1Good and excellent pressureReduce formulation costsInternal combustion piston enginesLayered productsControl theoryThin walled

The present invention provides a multilayer mounting mat for mounting a pollution control element. The mounting mat comprises a layer of intumescent material between two non-intumescent layers defining opposite major sides of the mounting mat. The mounting mat in accordance with the present invention is suitable for mounting a pollution control element in a pollution control device and is in particular suitable for mounting fragile monolith such as thin-wall and ultra thin-wall monoliths. Also, the mounting mats conveniently exhibit a good or excellent holding pressure over a wide temperature range and can be formulated in an inexpensive way. The invention also provides a pollution control device comprising a pollution control element arranged in a casing with the mounting mat disposed between the casing and pollution control element.

Owner:3M INNOVATIVE PROPERTIES CO

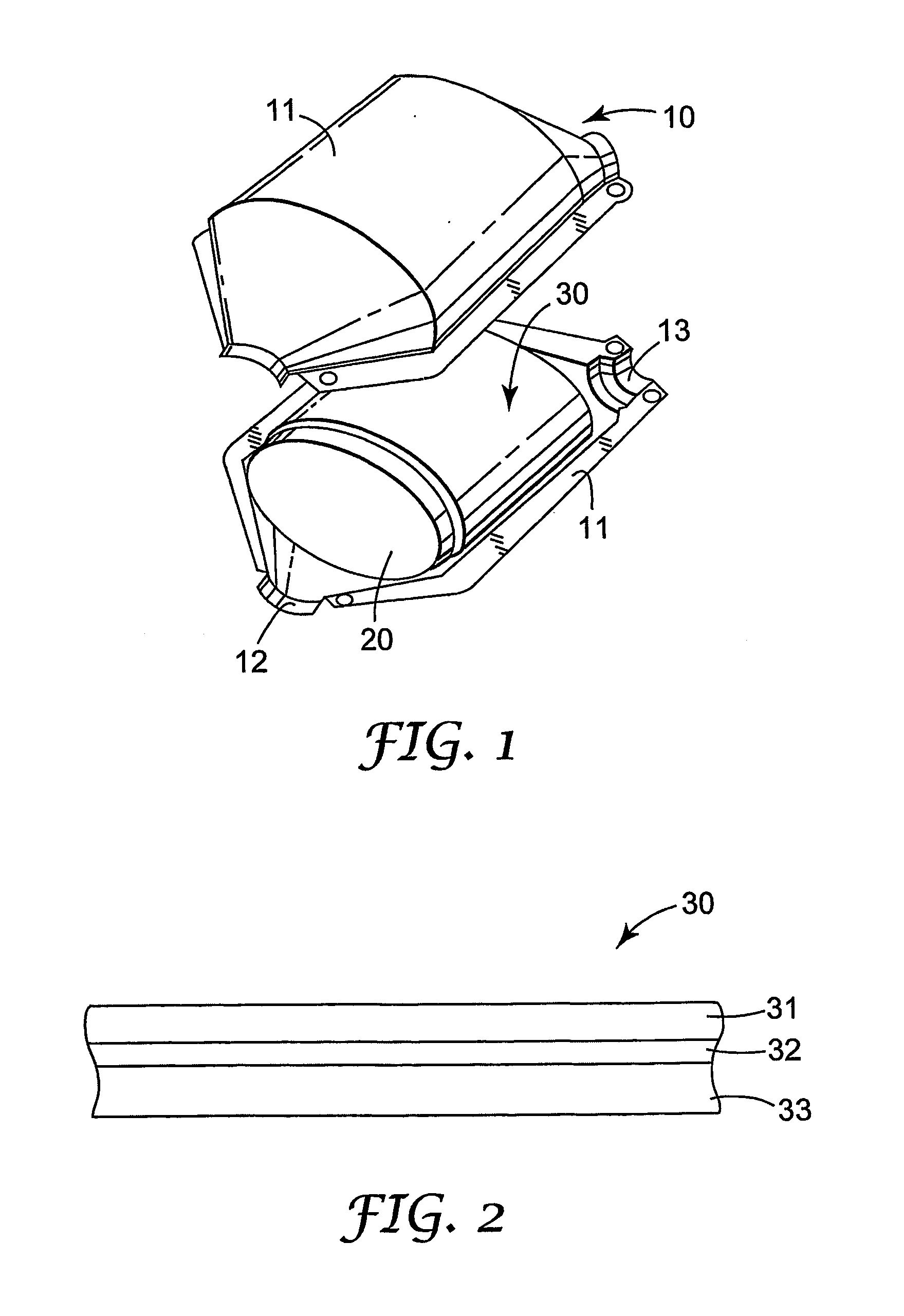

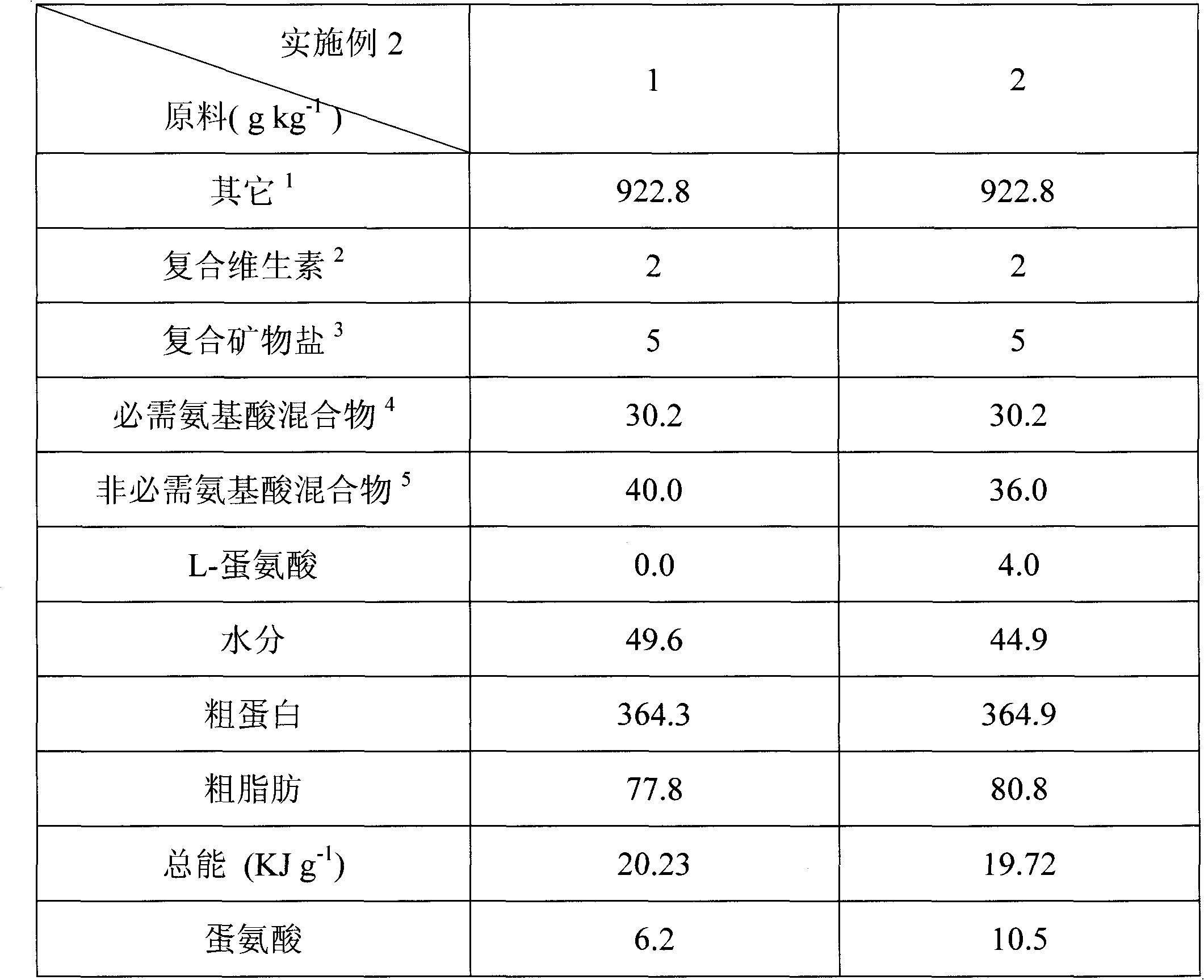

High-efficacy environment-friendly compound feed for layer hens

InactiveCN101606634AIncrease profitEmission reductionFood processingAnimal feeding stuffEconomic benefitsNitrogen

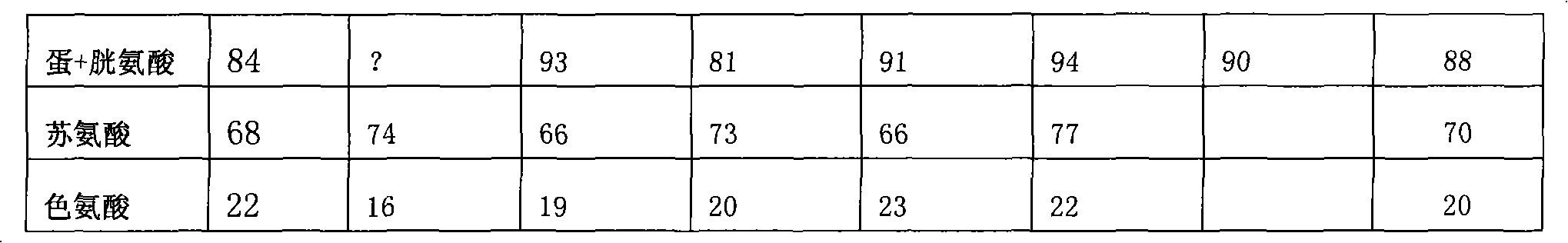

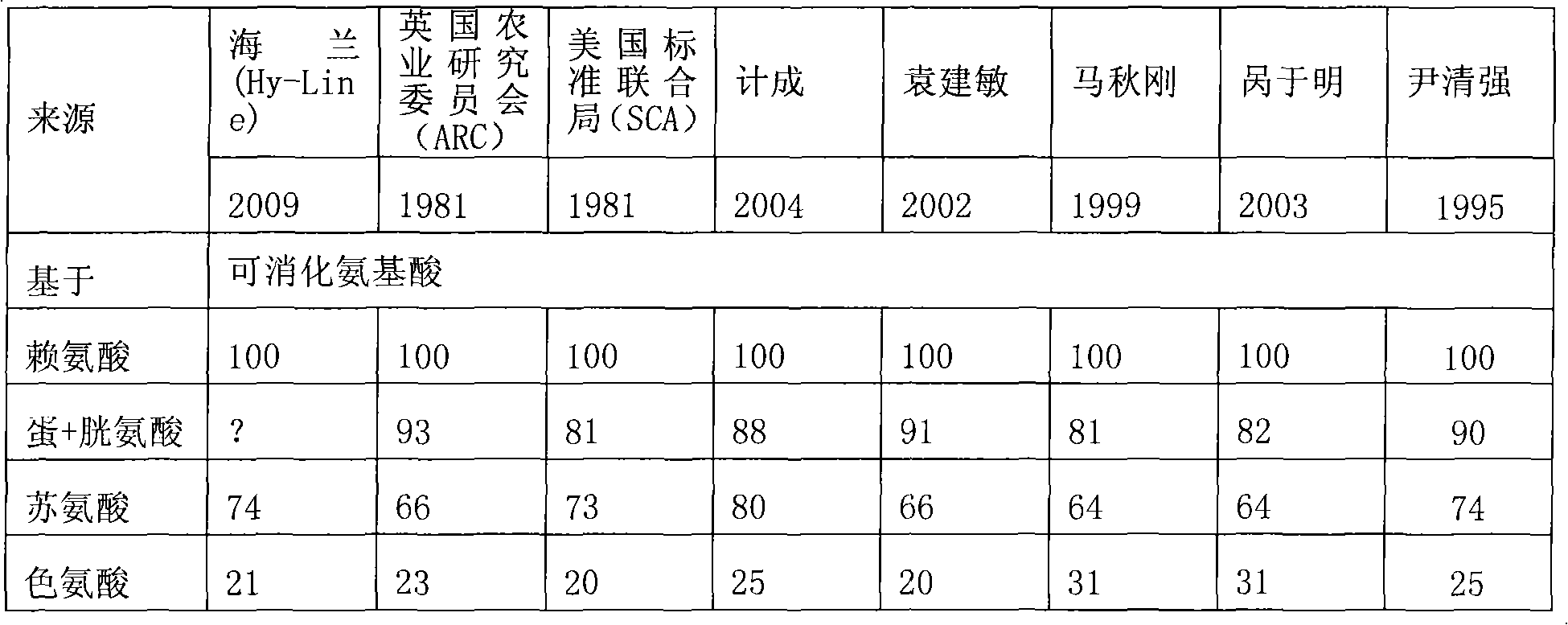

The invention relates to a high-efficacy environment-friendly compound feed for layer hens, fundamentally solving the problems of high content of crude protein, poor quality of protein and large discharge of nitrogen and phosphorus in the prior feed formulation. In the material composition of the compound feed, the balance model of digestible lysine: digestible methionine+ digestible cystine: digestible threonine: digestible tryptophan is 100:87:71:18. The invention has the advantages of reasonable design, environment protection, energy saving, improvement of laying rate, reduction of feed-egg ratio, reduction of the discharge of fecal nitrogen and fecal phosphorus and improvement of the economic benefits of enterprises.

Owner:LIAONING ZHONGYOU FEED

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

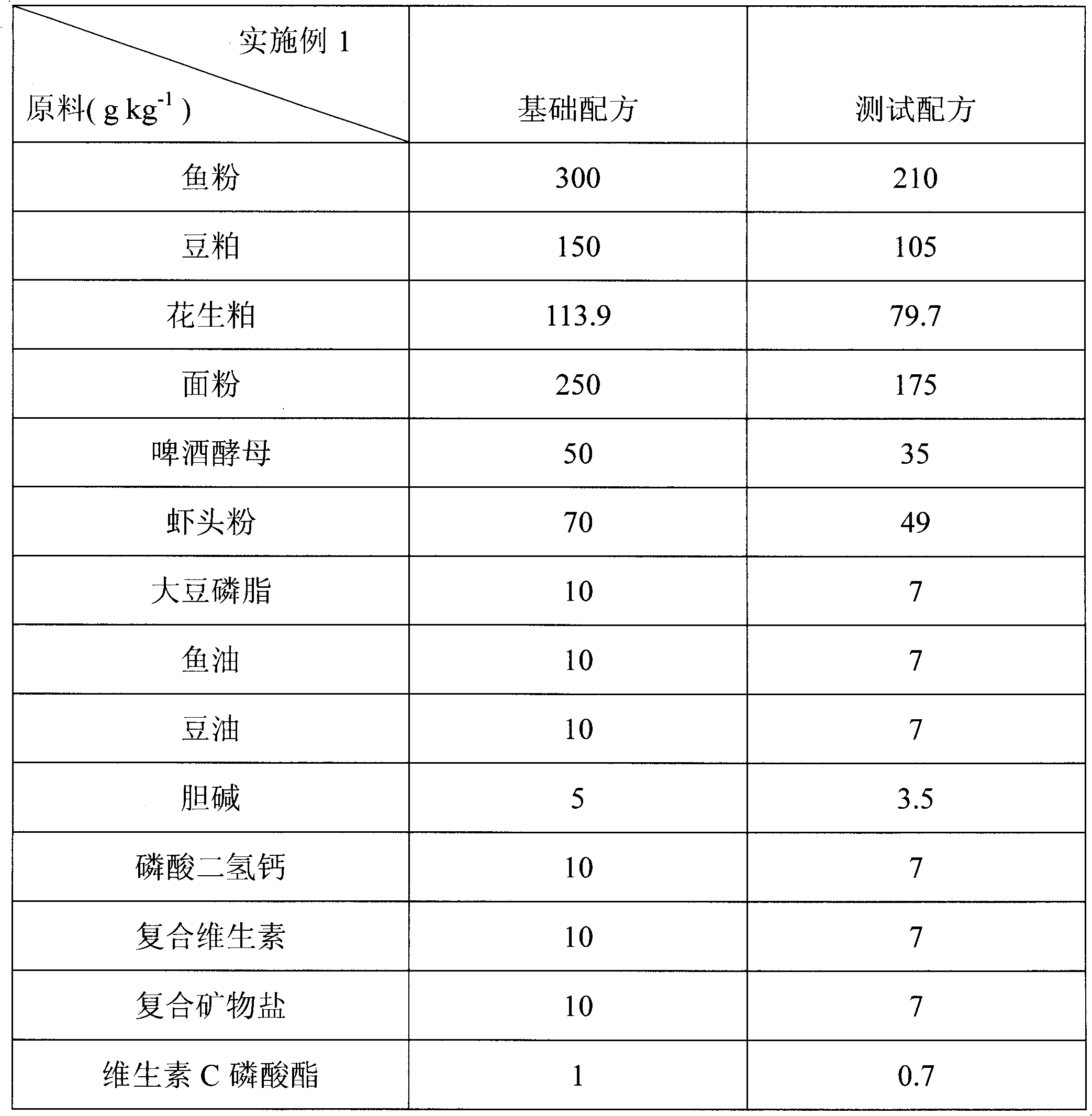

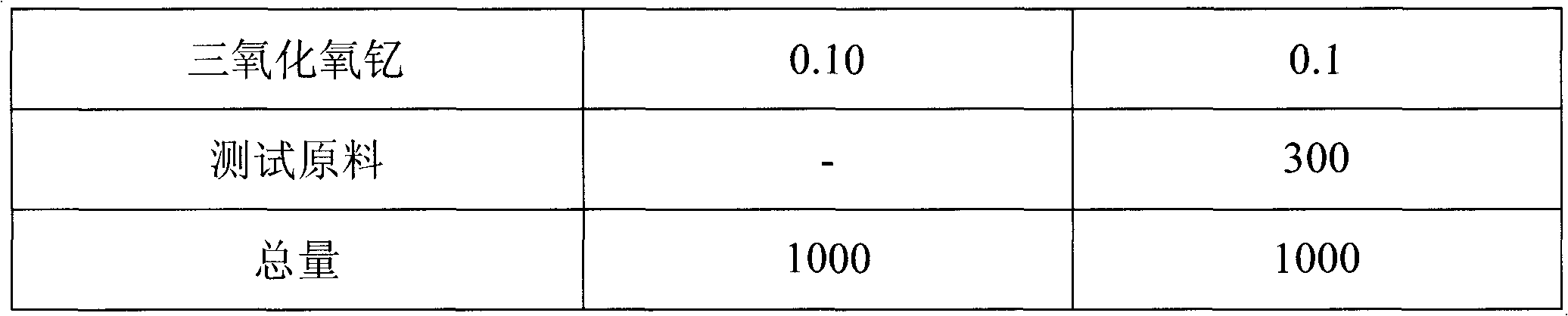

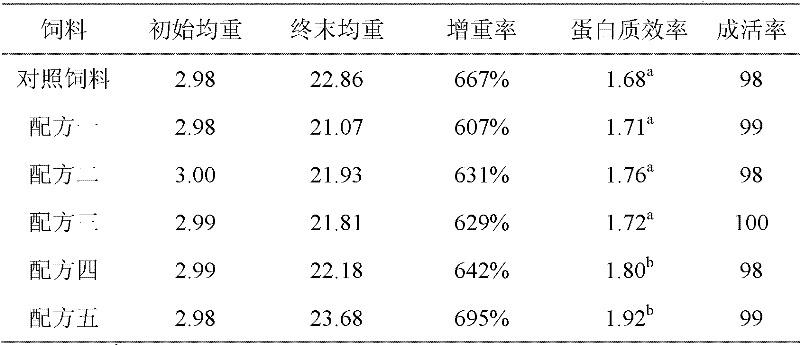

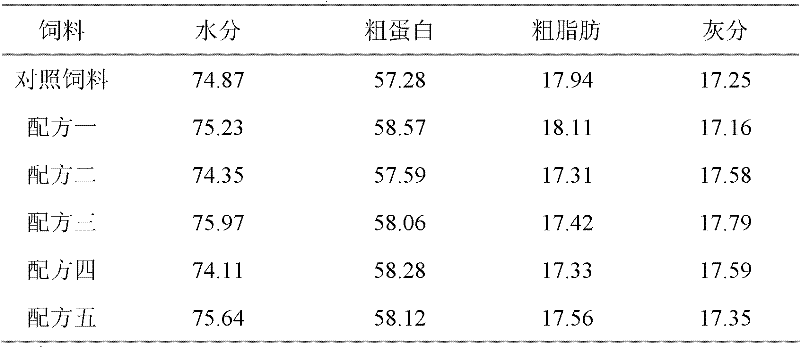

Feed for litopenaeus vannamei

InactiveCN101828644AMeeting nutritional needsImprove digestion and absorption rateAnimal feeding stuffProtein levelPollution

The invention discloses a feed for litopenaeus vannamei, which comprises the following nutrition compositions by mass percent: 25-35% of proteins, 4-9% of fat, 7-12% of ash contents, 40-55% of carbohydrates and 3-11% of water. The feed can meet the nutrient requirement of litopenaeus vannamei for best growth, and effectively solves the traditional problems of high protein level of a compound feedand severe environmental pollution in the process of culturing litopenaeus vannamei; the industrial profit is increased, and the pollution and the damage to a water environment in the process of culturing are reduced; and the sustainable development of litopenaeus vannamei culturing industry is realized.

Owner:SUN YAT SEN UNIV

High-polylactic acid-content film and preparation method thereof

The invention relates to a high-polylactic acid-content film and a preparation method thereof, belonging to the technical field of high-polymer materials. The high-polylactic acid-content film is prepared from the following raw materials in parts by weight: 50-65 parts of polylactic acid, 35-50 parts of toughener, 1-10 parts of plasticizer, 0.1-2 parts of chain extender, 0.1-4 parts of antioxidant and 0.5-5 parts of anti-block agent. The polylactic acid content is dominant in the film content and is higher than that in the existing film; and meanwhile, the raw material formula cost is lowered, and the market competitiveness is enhanced. The prepared film is completely biodegradable, and thus, is beneficial to environment protection.

Owner:JILIN COFCO BIOCHEM +2

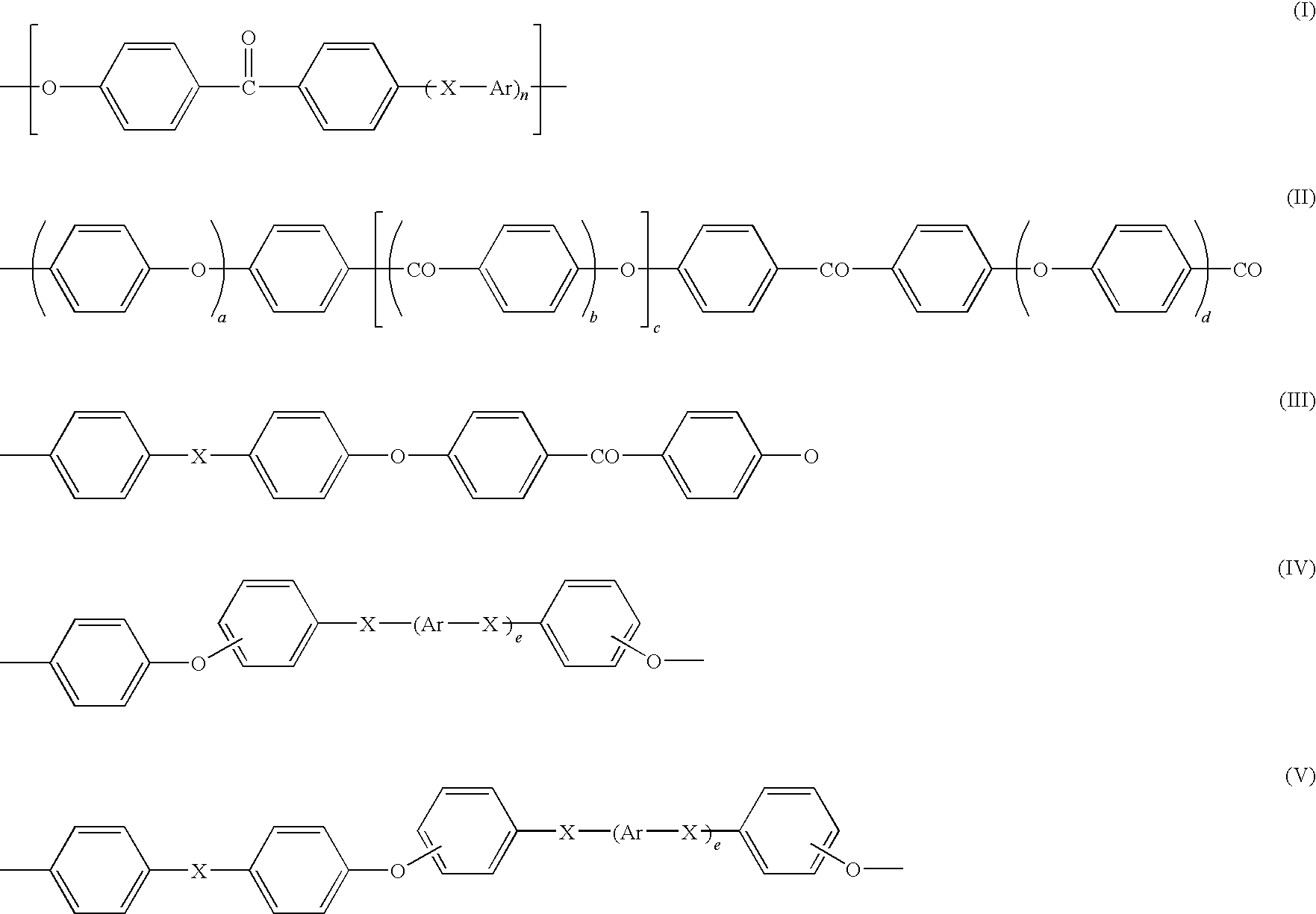

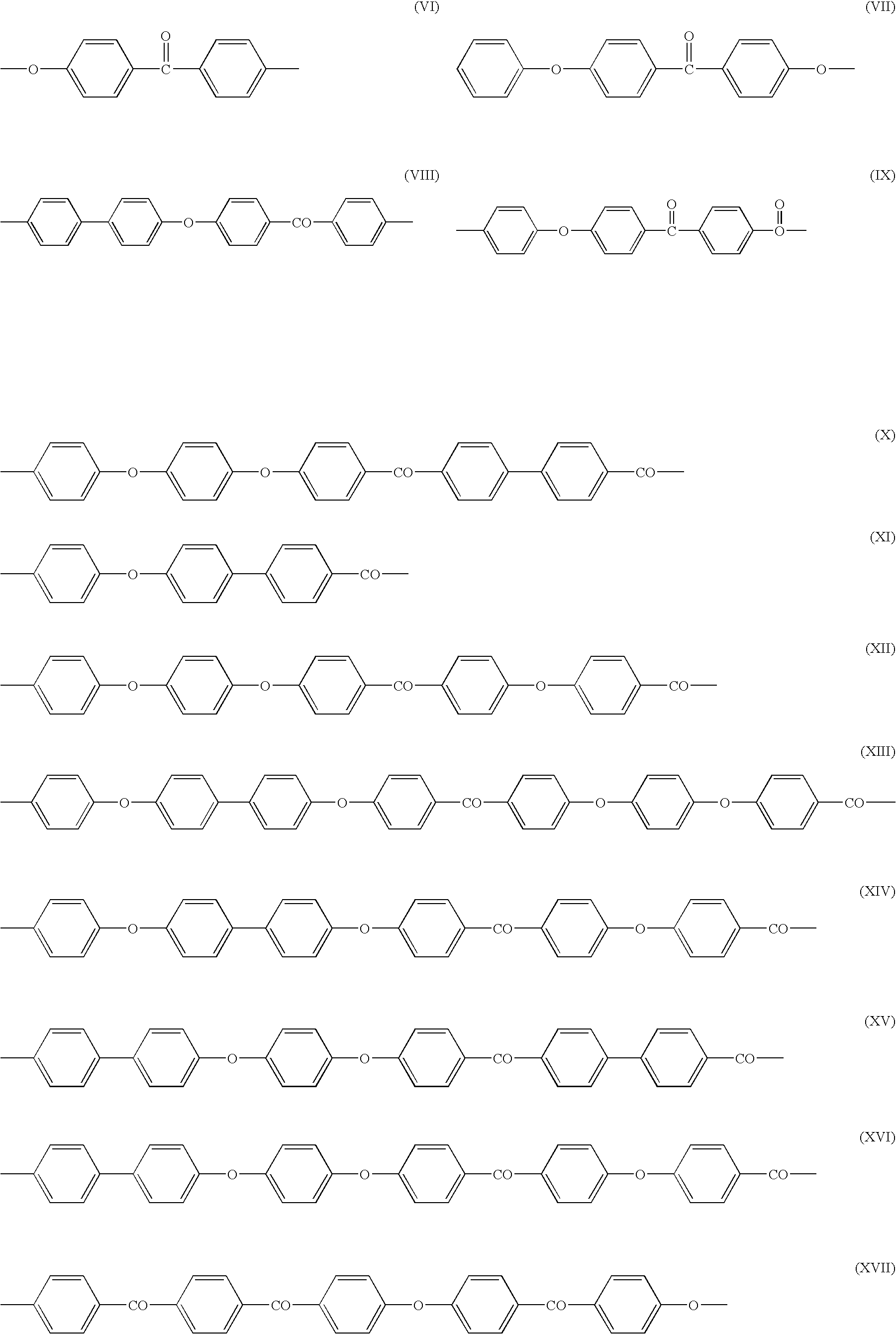

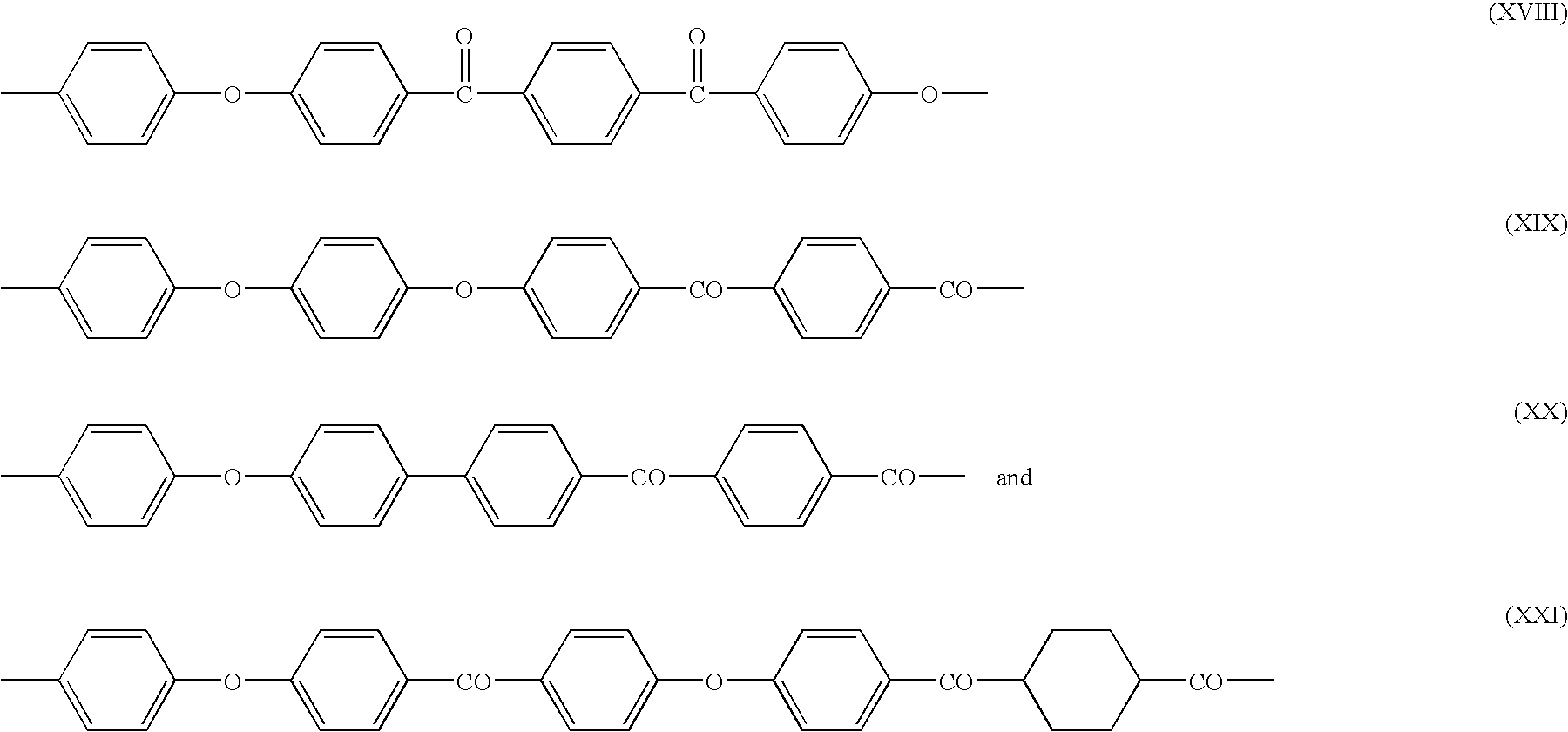

Thermoplastic polymer mixtures, and applications thereof

Thermoplastic polymer mixture (M) comprising at least one poly(aryl ether ketone) (P1), at least one poly(arylene sulfide) (P2), and between 0 and 25 wt. % of the total weight of the thermoplastic mixture (M), of a thermoplastic polymer material (P3) consisting of (i) at least one poly(biphenyl ether sulfone) (P3a), and / or (ii) at least one poly(ether imide) (P3b), and / or at least one poly(ether imide sulfone) (P3c), wherein: the combined weight amount of the poly(aryl ether ketone) (P1) and the poly(arylene sulfide) (P2), based on the total weight of the polymer mixture (M), is of at least 30%, and the weight amount of the poly(aryl ether ketone) (P1), based on the combined weight of the poly(aryl ether ketone) (P1) and the poly(arylene sulfide) (P2), is of at most 90%.

Owner:SOLVAY ADVANCED POLYMERS LLC

Environment-friendly type feed for river crab

InactiveCN101258900AIncrease profitReduce churnClimate change adaptationAnimal feeding stuffCalcium biphosphatePhytase

The invention discloses an environment friendly river crab feed, which consists of fish meal, blood meal (AP301), cuttlefish cream, soybean meal, peanut cake, rapeseed meal, cottonseed meal, wheat, strong flour, granulesten, defatted rice bran, corn gluten feed (DDGS), malt root, fish oil, vegetable oil, phytase, calcium biphosphate and special phagostimulant for the river crab. The utilization rate of the feed for the river crab can be improved by adopting the environment friendly river crab feed of the invention, thereby promoting the benefit of breeding, reducing the loss of nitrogen and phosphorus in the feed and improving the water quality of the breeding.

Owner:SUZHOU UNIV

Method for preparing solvent-free aqueous polyurethane dispersion

InactiveCN102702471ALow viscosityEase of neutralization, emulsification and chain extensionPolyurethane dispersionSolvent free

The invention relates to a method for preparing solvent-free aqueous polyurethane dispersion, and aims to provide the method for preparing the aqueous polyurethane dispersion without using complex solubilizer and solvent during the preparing process; the technical key points of the method sequentially comprises the following steps of: 1) preparing prepolymer which contains end isocyanate group; 2) adding 20-50% of hot water at the temperature of 60-90 DEG C, and stirring for 3-10 minutes; 3) uniformly mixing tertiary amine which accounts for 1-5% of the mass of the prepolymer with water which accounts for 40-60% of the mass of the prepolymer, adding the material which is obtained in step 2) under the stirring condition, and continuously stirring for 10-30 minutes; and 4) uniformly mixing amine chain extender which accounts for 1-5% of the mass of the prepolymer with the water which accounts for 5-15% of the mass of the prepolymer, adding the material which is obtained in the step 3) into the mixture under the stirring condition, and stirring for 60-120 minutes at the temperature of 40-60 DEG C, thus obtaining the solvent-free aqueous polyurethane dispersion. The method belongs to the technical field of the production of a chemical disperse system.

Owner:惠州市汉诺新材料有限公司

Grain-saving growing and fattening pig feed and preparation method thereof

ActiveCN102524587ARelieve stressSave raw materialsAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses a grain-saving growing and fattening pig feed and a preparation method of the grain-saving growing and fattening pig feed. The grain-saving growing and fattening pig feed comprises the following components by mass percentage: 0-35% of rice bran meal, 0-35% of wheat middling, 0-30% of bran, 0-8% of rice bran, 0-15% of corns, 0-25% of wheat, 3-18% of soybean meal, 0-3% of fermented soybean meal, 0-1% of fish meal, 0.5-2% of grease, 0-3% of silicate mineral feed, 0.3-1% of mountain flour, 0-0.8% of calcium hydrophosphate, 0.2-0.5% of salts, 0.5-1% of premix compound and 0.05-0.3% of compound additives. In the feed of the invention, a great amount of grain processing by-products are used to replace the corns and wheat, the nutrition ingredient proportioning is rational, a plurality of kinds of compound additives are used, and the processing technique improvement is combined to improve the feed utilization rate; and compared with the daily ration which takes the corns and the wheat as main energy feed, the grain-saving growing and fattening pig feed does not affect the growth property of pigs and the meat quality, and can reduce the formula cost and improve the comprehensive economic benefit.

Owner:哈尔滨众诚牧业有限公司

PVC (Poly Vinyl Chloride) wood-plastic foaming composite and preparation method thereof

ActiveCN102501506AGood weather resistanceReduce formulation costsSynthetic resin layered productsASA-polymerWeather resistance

The invention discloses a PVC (Poly Vinyl Chloride) wood-plastic foaming composite and a preparation method of the wood-plastic foaming composite. The PVC wood-plastic foaming composite comprises a PVC wood-plastic foaming base material layer and an ASA (Acrylonitrile Styrene Acrylate) layer which is co-extruded and formed on at least one side of the PVC wood-plastic foaming base material layer, wherein the PVC wood-plastic foaming base material layer comprises the following components in parts by weight: 100 parts of PVC, 50-100 parts of paddings, 1-1.5 parts of coupling agents, 5-7 parts of compound stabilizers, 1.0-1.5 parts of compound foaming agents and 6-8 parts of blowing promoters. The PVC wood-plastic foaming composite disclosed by the invention has the characteristics of light weight, high specific strength, water prevention, corrosion prevention, heat preservation, good weather resistance, low formula cost and low material density, and can be widely used in outdoor product markets such as exterior decoration of buildings, garden landscapes, fences, plank ways and the like.

Owner:北京欧尼克新型材料有限公司

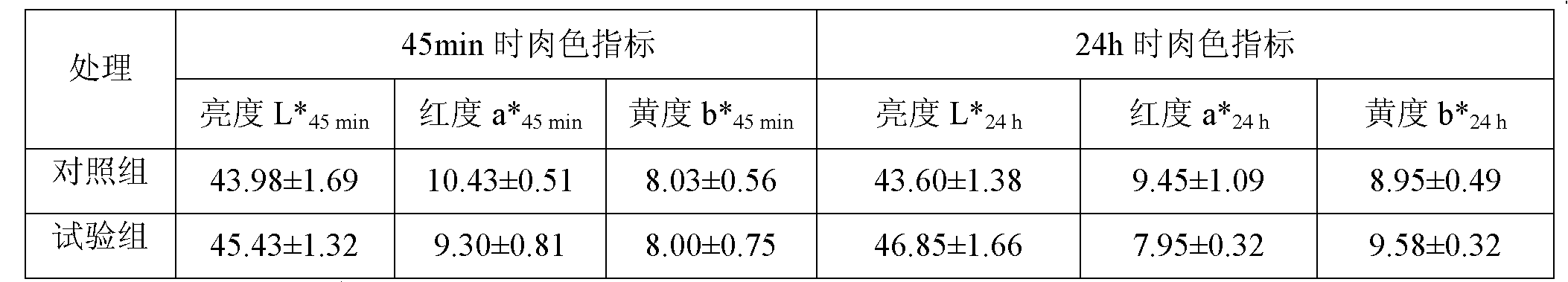

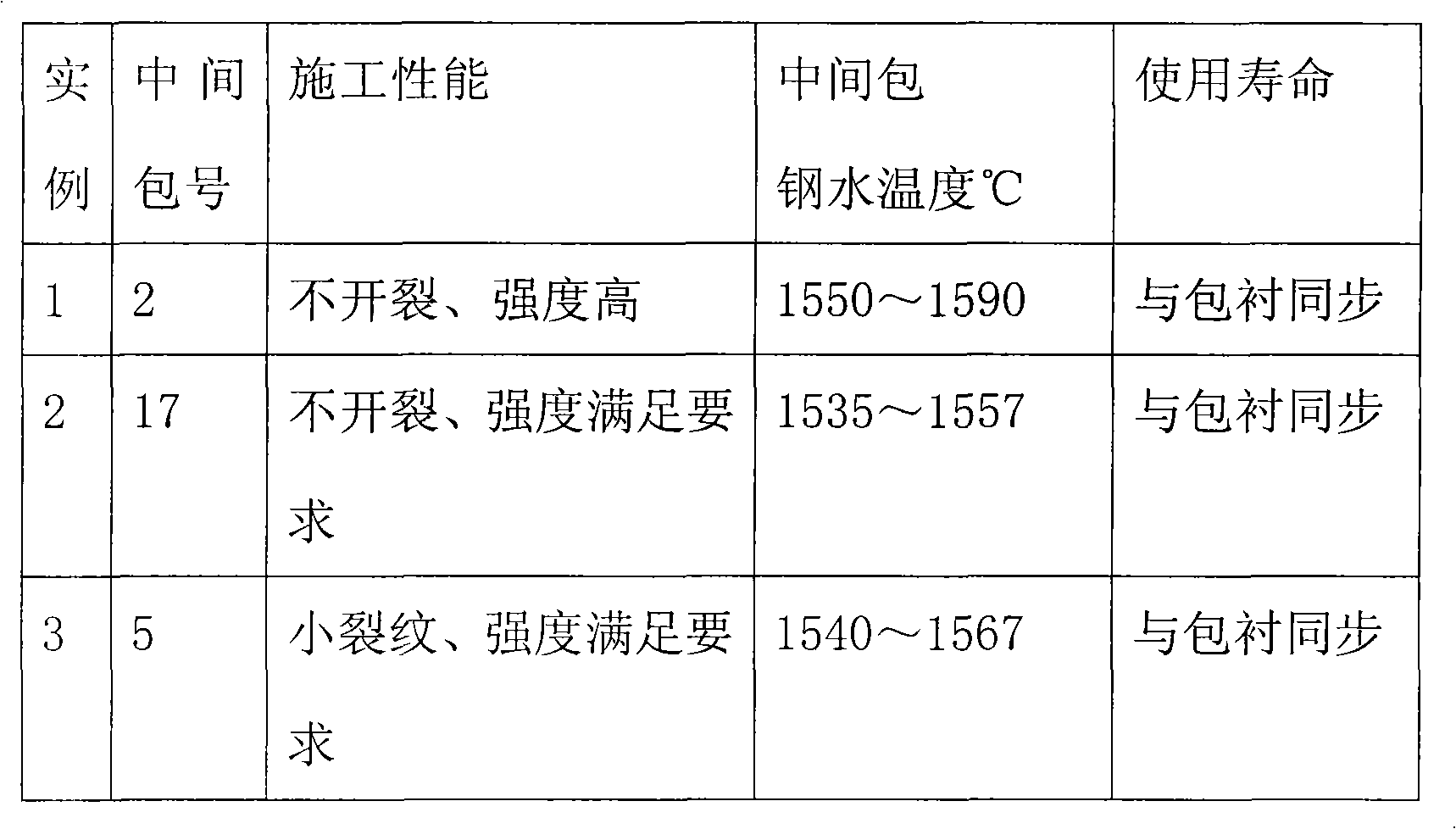

Pouring material for forsterite tundish slag stop wall and production process thereof

The invention discloses a pouring material for a forsterite tundish slag stop wall and a production process thereof. The pouring material is prepared from the following raw materials in part by weight: 5 to 70 parts of forsterite, 15 to 85 parts of magnesium sand, 5 to 15 parts of corundum powder, 3 to 5 parts of composite additive, 0.1 part of organic fiber and 1 part of steel fiber. The production process comprises the following steps of: adding aggregates in the raw materials into a stirrer and mixing and stirring the aggregates uniformly, then adding the fine powder and the composite additive into the mixed aggregates and stirring the mixture for 2 to 3 minutes, adding water into the mixture and stirring the mixture for 2 to 3 minutes when all the materials are mixed and stirred uniformly, and performing discharge, vibration molding, curing, drying and packing. The formula cost of the product is reduced by adopting combined action of the forsterite and the magnesium sand; and the construction performance and the use performance of the product are ensured at the same time of improving the strength of the product by adopting the composite additive, organic fiber, steel fiber andthe like with good performance.

Owner:WUGANG REFRACTORY CO LTD

Plasticizers from less branched nonyl alcohols

ActiveUS6969736B1Easy to processReduce volatilityPlastic/resin/waxes insulatorsYarnAlcoholPlasticizer

Less branched C9 alcohols are used to provide plasticizer esters particularly suitable for high temperature applications such as wire and cable insulation.

Owner:EXXONMOBIL CHEM PAT INC

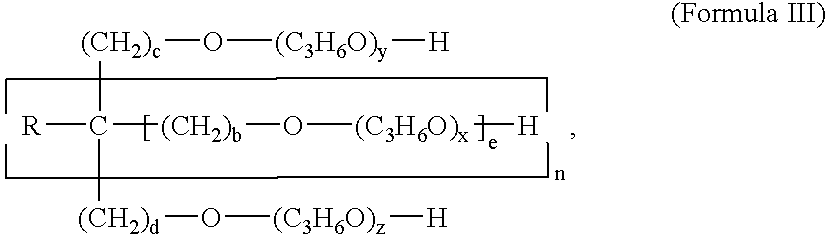

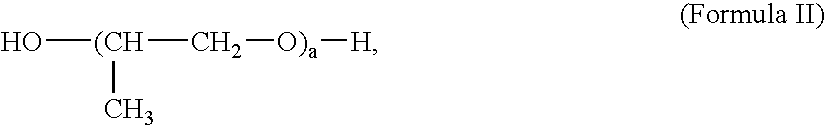

Hair care composition comprising a polypropylene glycol

InactiveUS6849252B1Improved look and feelReduce formulation costsCosmetic preparationsCationic surface-active compoundsPolypropylene glycolPropylene glycol

A hair care composition includes a polypropylene glycol and a gel matrix. The polypropylene glycol is selected from a single-polypropylene glycol-chain segment polymer, a multi-polypropylene glycol-chain segment polymer, and mixtures thereof. The single-polypropylene glycol-chain segment polymer is of the formula (I): HO—(C3H6O)Ha, wherein a is a value from about 20 to about 100. The multi-polypropylene glycol-chain segment polymer is of formula (I), wherein n is a value from about 0 to about 10, each R is independently selected from the group consisting of H, and C1-C30 alky, each b is independently a value from about 0 to about 2, c and d are independently a value from about 0 to about 2, b+c+d is at least about 2, each e is independently a value of 0 or 1, each x, y, and z is independently a value of from about 7 to about 100, and x+y+z is greater than about 20. Te gel matrix includes a cationic surfactant, a solid fatty compound and water.

Owner:THE PROCTER & GAMBLE COMPANY

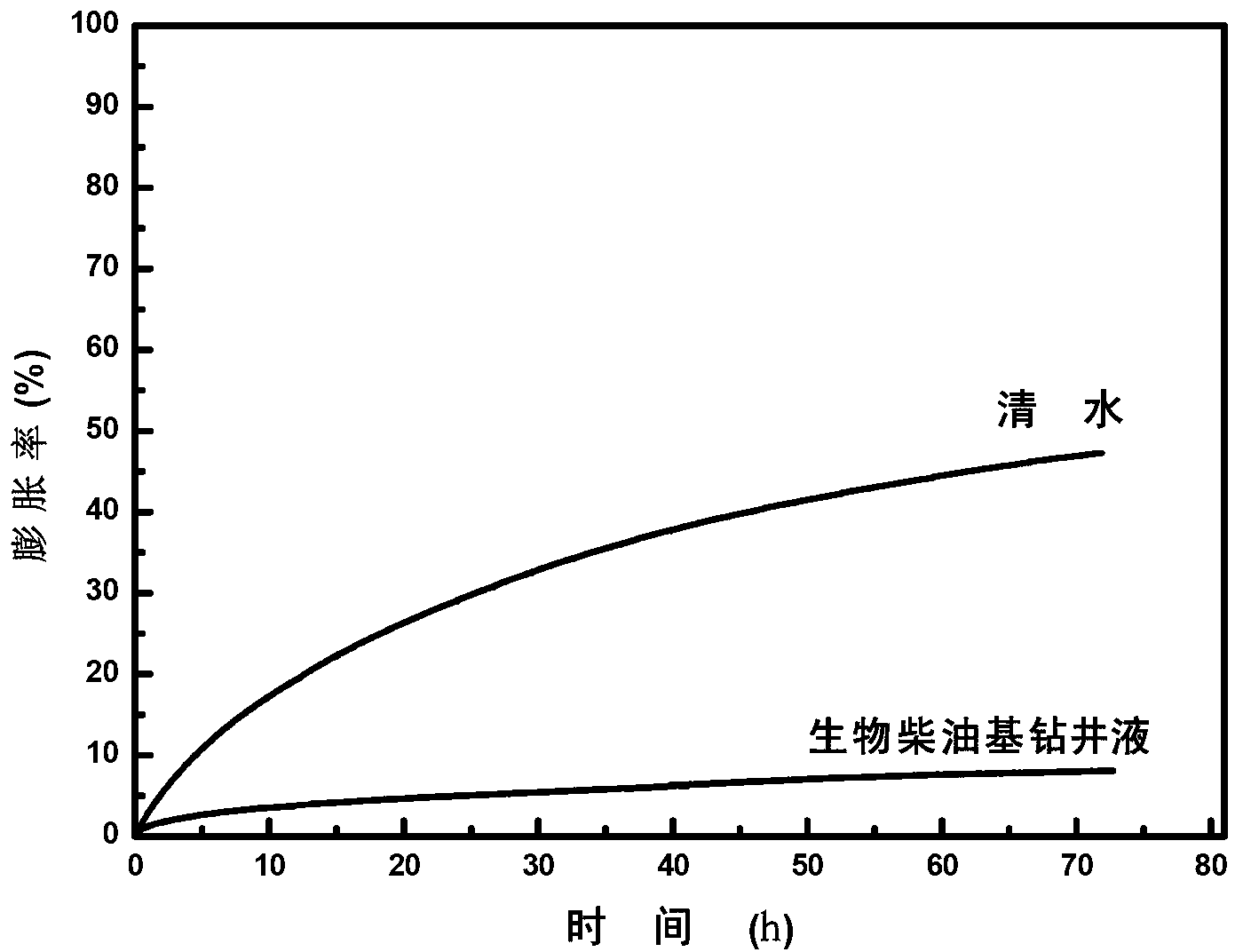

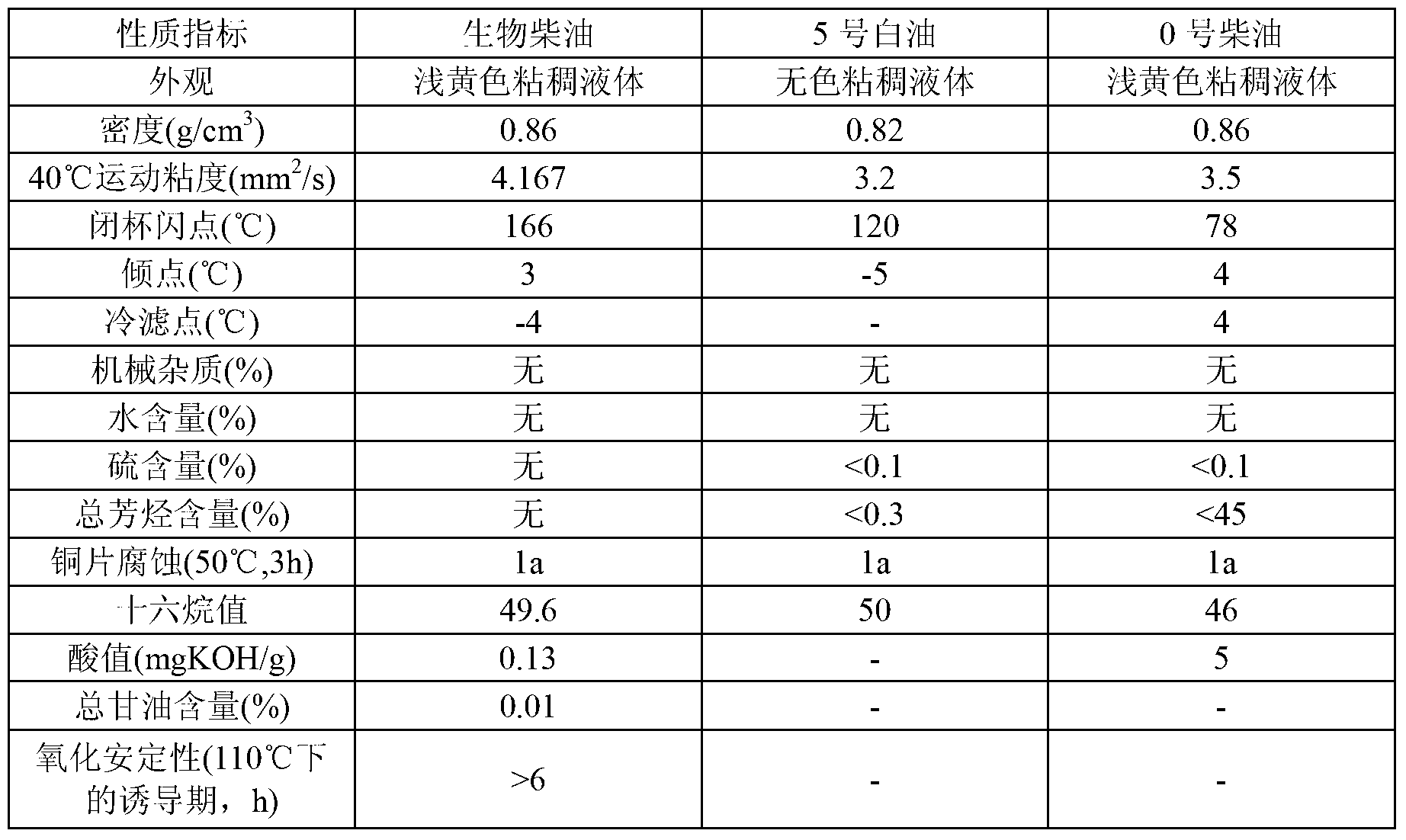

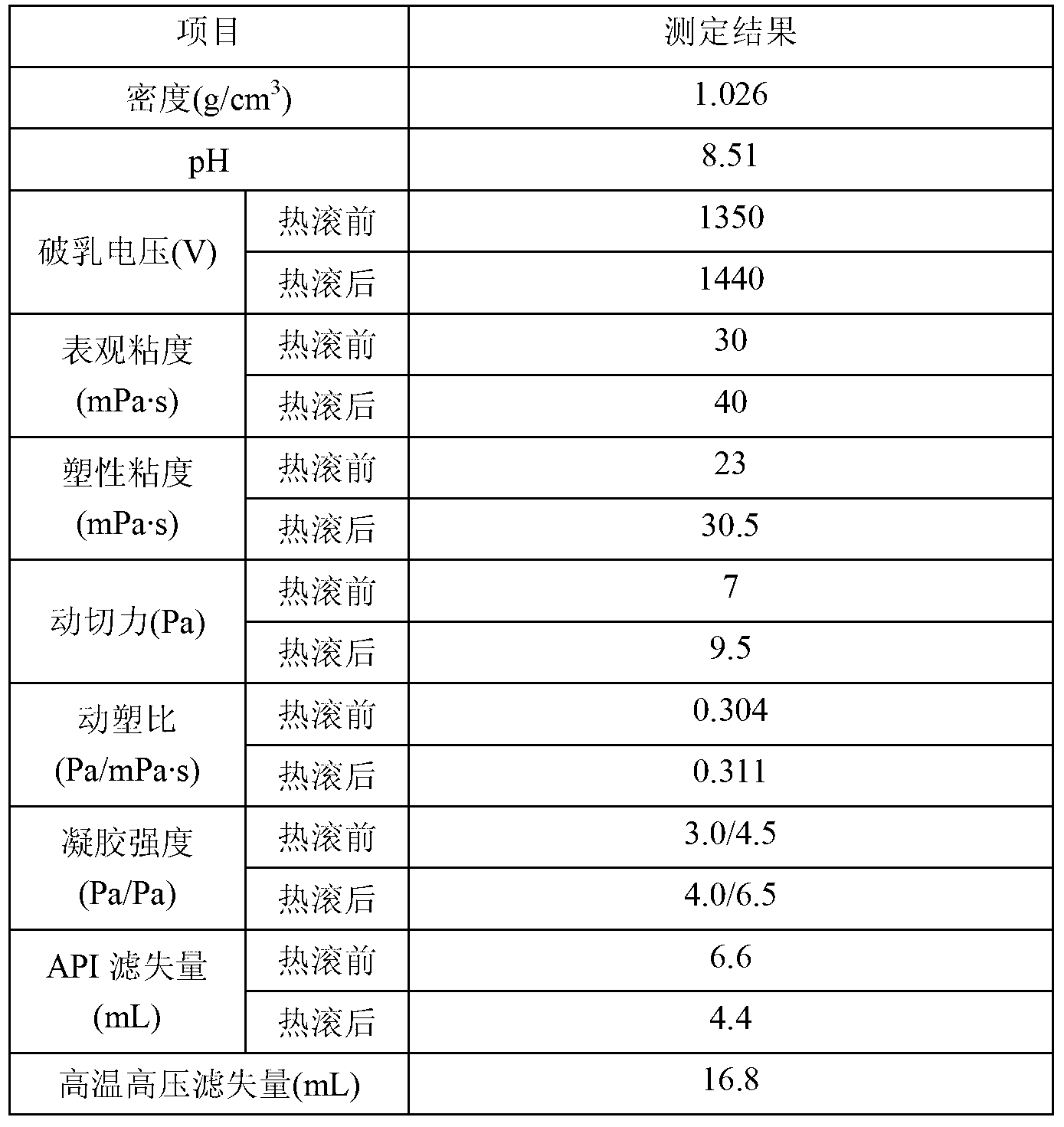

Water-in-oil-type biodiesel-based drilling fluid and preparation method thereof

ActiveCN103320104ASource requirements relaxedInhibit migrationDrilling compositionOil and greaseBiodiesel

The invention discloses a water-in-oil-type biodiesel-based drilling fluid and a preparation method thereof. The drilling fluid comprises the following components in parts by volume: 70 to 90 parts of biodiesel prepared by taking waste oils as a raw material, and 10 to 30 parts of calcium chloride aqueous solution. Based on the total volume of the biodiesel and the calcium chloride aqueous solution, the drilling fluid further comprises the following components in mass-volume ratio: 2% to 6% of calcium oxide, 1% to 6% of organic soil, 2% to 8% of emulsifier, 2% to 8% of wetting agent, 2% to 6% of filtrate reducer and 0% to 200% of weighting material. The drilling fluid disclosed by the invention has the characteristics of good operating performance, low cost, strong collapse-resisting inhibiting performance, excellent lubricating performance and excellent biological degradability.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

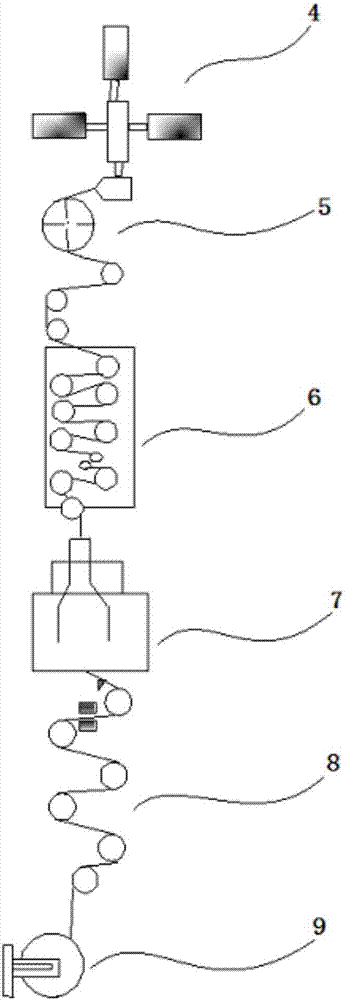

Biodegradable multilayer co-extrusion material and preparation method thereof

ActiveCN107031153APromote degradationWith natural propertiesSynthetic resin layered productsFlat articlesPolybutyleneMedical product

The invention provides a biodegradable multilayer co-extrusion material. The material is characterized by comprising two surface functional layers and a middle layer located between the two surface functional layers, components of the surface functional layers and the middle layer include biodegradable materials, and the biodegradable materials refer to one or more of polybutylene succinate, polylactic acid, polyhydroxyalkanoate and polybutylene adipate-polybutylene terephthalate. The invention further discloses a preparation method of the material. The biodegradablity of four selected master batches of the multilayer co-extrusion material is good, and adopted inorganic minerals are natural, so that the co-extrusion material has completely biodegradable properties and can be widely used in various types of food packages, medical products, environmental protection labels, advertisements and all kinds of environmental-protection products.

Owner:齐庆德

A high-sugar and low-protein tilapia feed

InactiveCN102265983AIncrease dosageLow in proteinFood processingClimate change adaptationRapeseedVitamin B6 synthesis

The invention discloses a high-sugar and low-protein tilapia feed. Based on the total mass fraction of 100%, it consists of the following components: fish meal: 0-3%, soybean meal: 16-20%, rapeseed meal: 18-21%, cotton meal: 12-16%, secondary meal: 39- 42%, soybean oil: 2-3%, choline chloride: 0.2-0.5%, sodium chloride: 0.1-0.5%, calcium dihydrogen phosphate: 1-2%, vitamin B1: 0.004-0.006%, vitamin B6: 0.002-0.004%, zinc sulfate: 0.02-0.04%, chromium chloride: 0.0001-0.0003%, vitamin premix: 0.1-0.2% and mineral premix: 0.5-1%. The invention maximizes the amount of secondary powder in the feed, adds several plant protein sources to overcome the problem of amino acid imbalance of a single protein source, and at the same time significantly reduces the amount of fish meal. By optimizing and adjusting the feed formula, supplementing suitable vitamin and mineral premixes to adjust the sugar utilization ability of tilapia, so that the tilapia can make good use of the sugar compound of the present invention, avoiding the damage of fish liver caused by high sugar, Fatty liver is formed, and even the fish body becomes obese, and the symptoms of "big belly" appear.

Owner:广东省农业科学院畜牧研究所 +1

Method and ink for producing waterproof markings on plastic surfaces

InactiveUS6602334B1Low production costOverheating of the ink jet printerDecorative surface effectsDuplicating/marking methodsPlastic materialsPolymer chemistry

An ink and a method are disclosed for producing waterproof- and smudge-proof markings and printing on plastic surfaces with an ink formulated to contain a low-volatile solvent with a vapor pressure of less than 20 mbar at 20° C. and a dye dissolved in the solvent which when applied to a plastic material surface absorbs the low-volatile solvent and embeds the dye into the plastic material.

Owner:KAUFMANN RAINER

Method for preparing high-stability heat-resistance and salt-tolerance air foam oil displacing agent

InactiveCN104059625AReduce formulation costsEasy to useDrilling compositionFoaming agentApparent viscosity

The invention discloses a method for preparing a high-stability heat-resistance and salt-tolerance air foam oil displacing agent. According to the method, a nanometer and nanometer modification technology is adopted, and nanometer hectorite is used as a foam stabilizer and a high-temperature stabilizer to prepare the high-stability heat-resistance and salt-tolerance air foam oil displacing agent. The technology includes the following steps that the hectorite is added into deionized water at the temperature of 50-90 DEG C, stirred and dispersed evenly, cooled to the room temperature and stewed and aged for a period of time to obtain hectorite aqueous dispersion, quantitative cationic surface active agents are added, evenly stirred, stewed and aged, finally, foaming agents are added, high-speed stirring is conducted on a high-speed emulsification machine, and the high-stability heat-resistance and salt-tolerance air foam oil displacing agent is obtained. The foam half-life period reaches up to 768 hours, the high foam stability is achieved, the foam half-life period reaches up to 70 hours under the condition that the degree of mineralization is 30000 mg / L, the good salt tolerance is achieved, the apparent viscosity reaches up to 2000 mPa.s, the heat resistance performance reaches 90 DEG C, the high foam strength and the heat resistance are achieved, the shearing rate is 170 per second, the foam apparent viscosity reaches 800 mPa.s after shearing is conducted for 60 minutes, the good shearing performance is achieved, and the method is suitable for exploration and development of conventional and unconventional oil fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

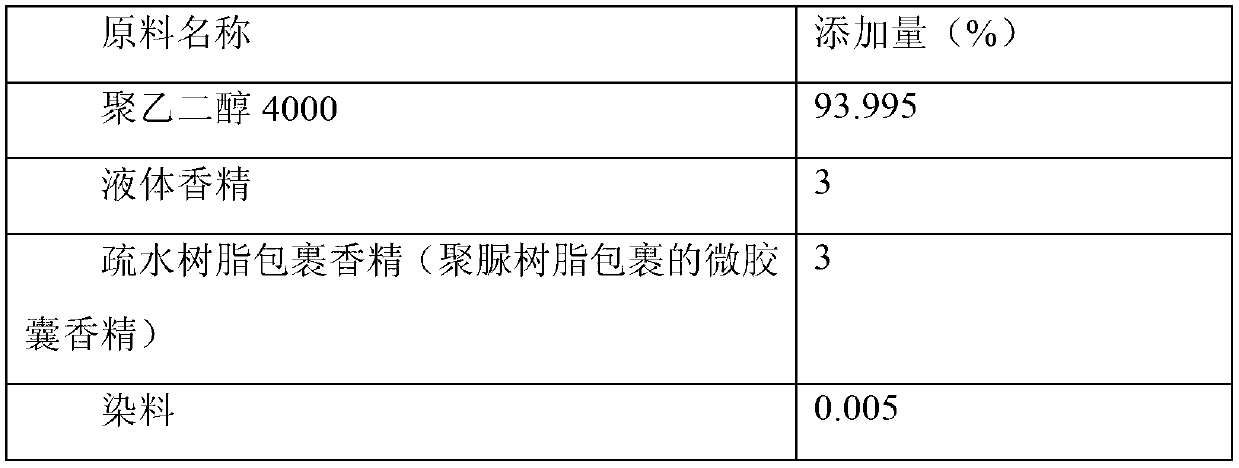

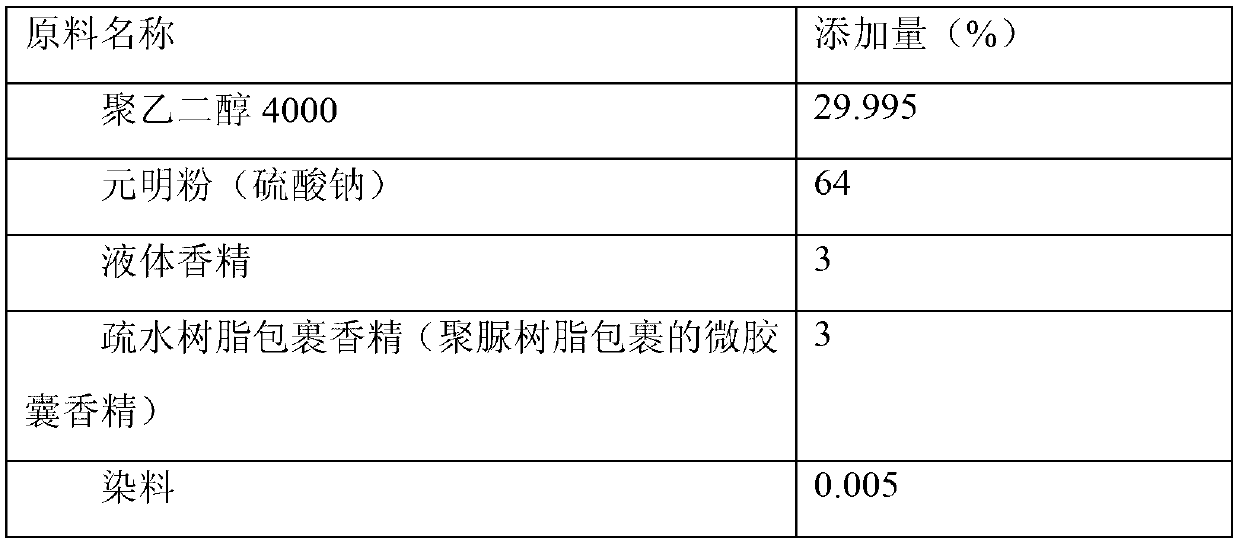

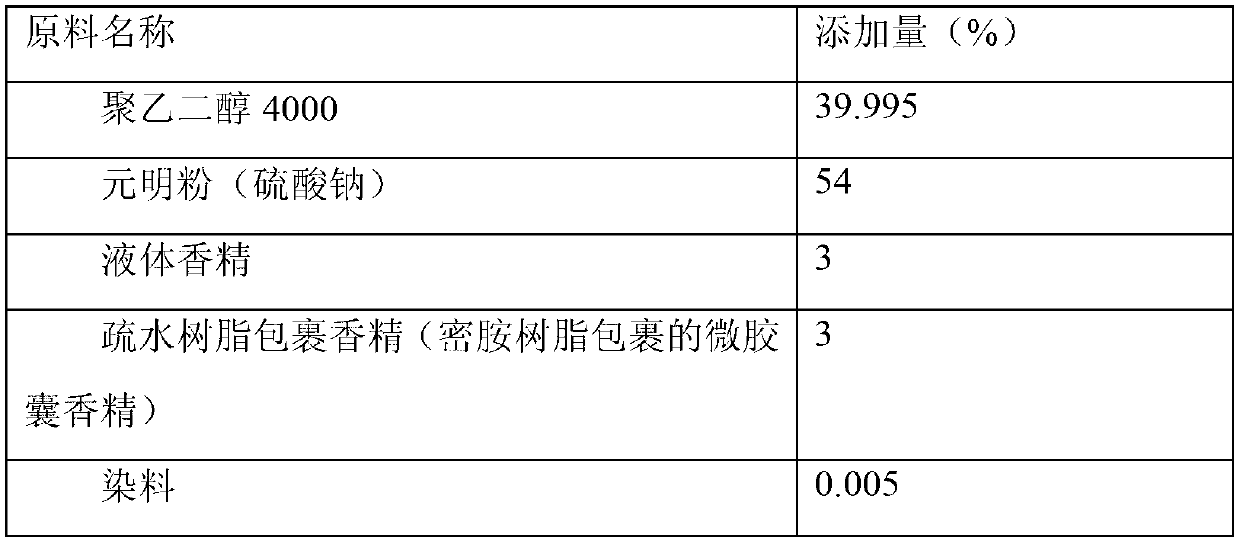

Cloth fragrant granule and preparation method thereof

ActiveCN103205328ALow costImprove solubilityOrganic detergent compounding agentsDetergent perfumesSolubilityPolyethylene glycol

The invention discloses a cloth fragrant granule and a preparation method thereof. The clothing fragrant granule is prepared from the following raw materials by weight: 10-79% of polyethylene glycol, 18-89% of water-soluble salt, 0.1-3% of a liquid essence, 0.1-3% of a hydrophobic resin coated essence and 0.5-2% of other assistants. The cloth fragrant granule prepared by the invention has the advantages of low cost and good water solubility.

Owner:GUANGZHOU LIBY

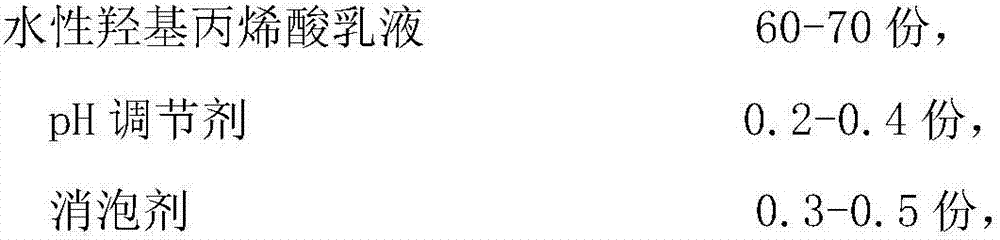

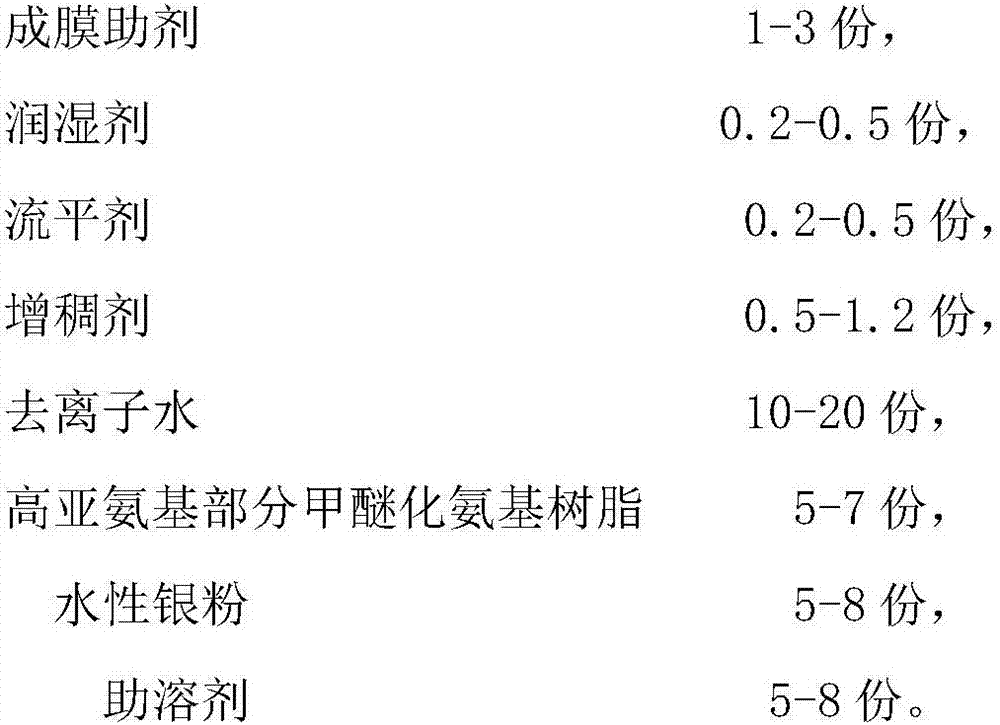

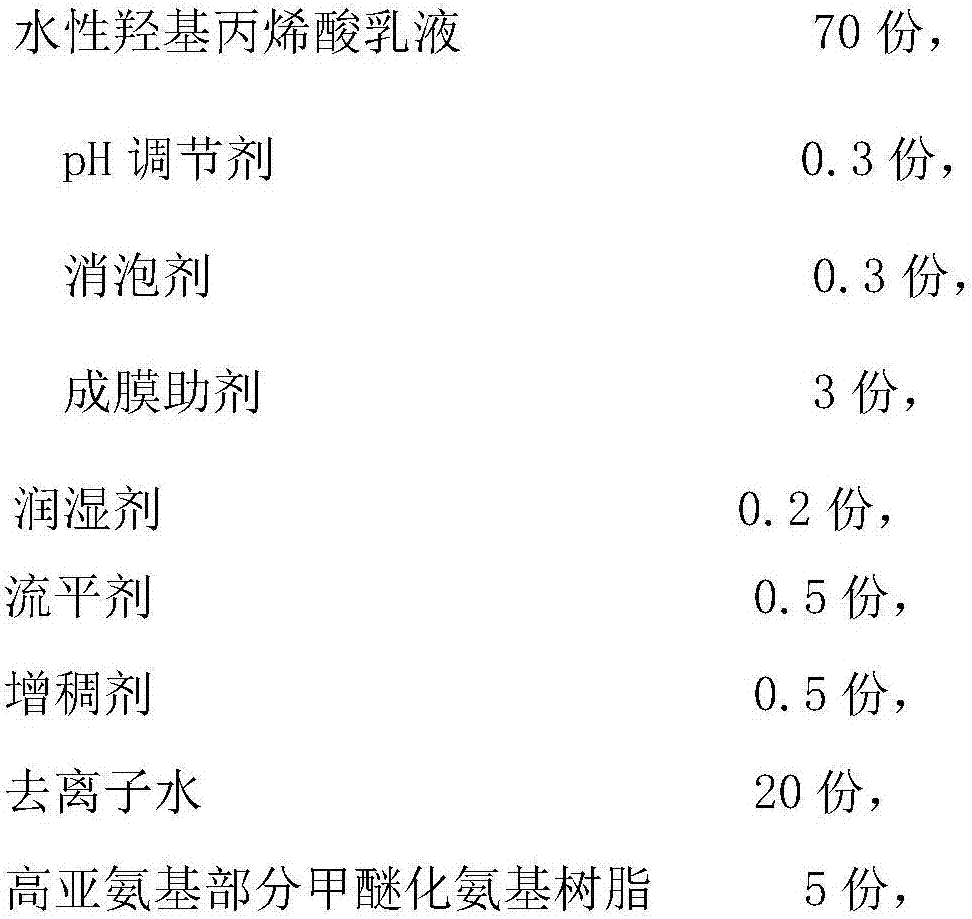

Aqueous silver powder amino baking paint and preparation method thereof

The invention discloses aqueous silver powder amino baking paint and a preparation method thereof. The aqueous silver powder amino baking paint is prepared from the following components in parts by mass: 60 to 70 parts of aqueous hydroxyl acrylic emulsion, 0.2 to 0.4 part of a pH regulator, 0.3 to 0.5 part of an anti-foaming agent, 1 to 3 parts of film-forming auxiliaries, 0.2 to 0.5 part of a wetting agent, 0.2 to 0.5 part of a leveling agent, 0.5 to 1.2 parts of a thickening agent, 10 to 20 parts of deionized water, 5 to 7 parts of gonyar amino part methylated amino resin, 5 to 8 parts of aqueous silver powder, and 5 to 8 parts of co-solvents. The aqueous silver powder amino baking paint is safe and environment-friendly, has low VOC content, is high in drying speed, and is good in glossiness; and the paint film is good in glossiness and has a good metal effect.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

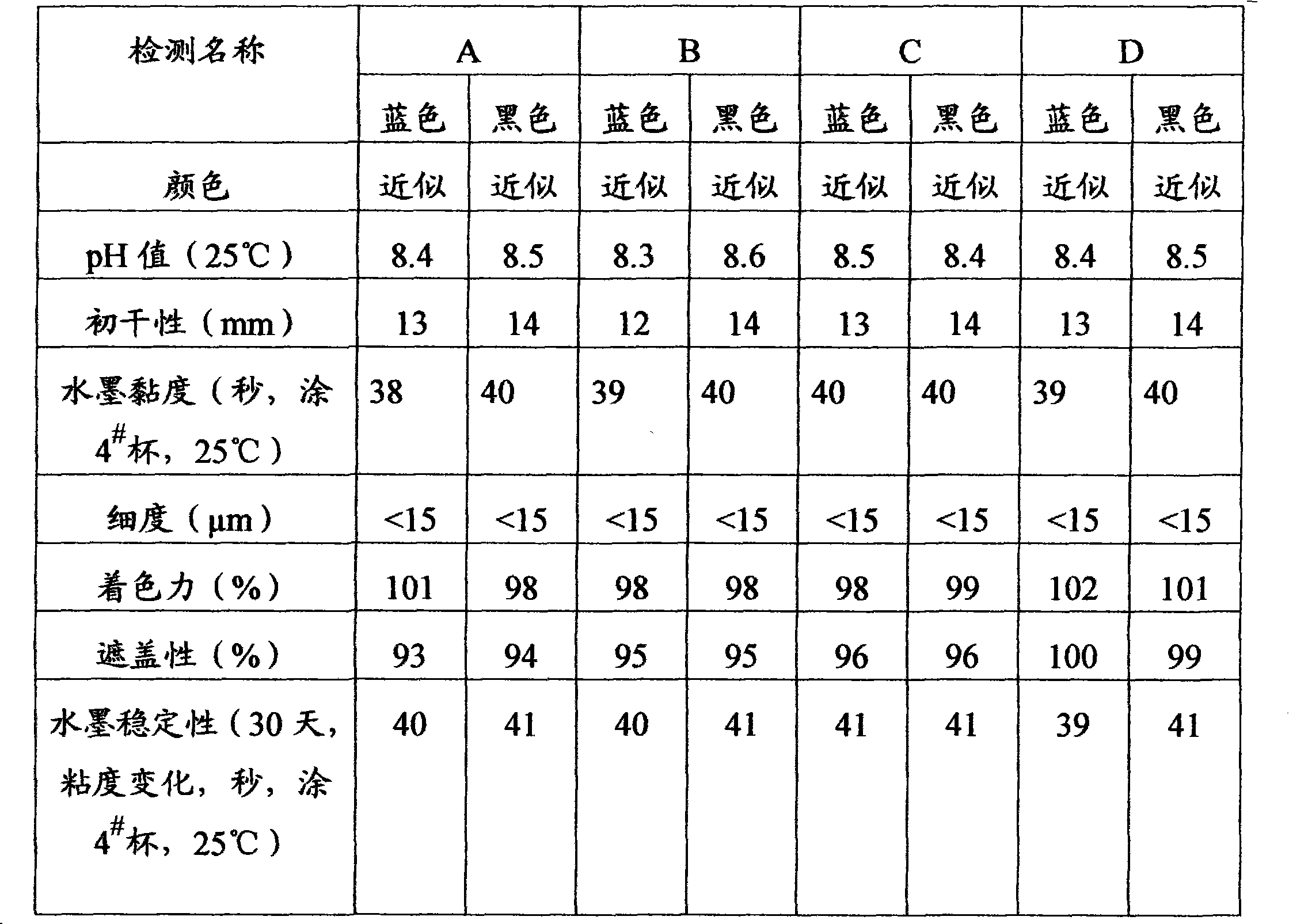

High-covering-power styrene-acrylate emulsion, synthesis method thereof and use thereof in aqueous printing ink

The invention relates to the field of printing ink and discloses high-covering-power styrene-acrylate emulsion, a synthesis method thereof and use thereof in aqueous printing ink. The preparation method comprises: mixing deionized water, an initiator, a lacquer and a composite emulsifier to obtain solution A; regulating the pH value; introducing nitrogen to remove oxygen; mixing a monomer with a molecular weight regulator to obtain solution B; dripping solution B into solution A to perform a chemical reaction; regulating the pH value of shell emulsion and heating to prepare shell emulsion; adding a composite emulsifier and an initiator into the synthesized shell emulsion; dripping a vinyl monomer to synthesize core-shell emulsion; and cooling, regulating the pH value and filtering to obtain the styrene-acrylate emulsion. The invention also provides aqueous printing ink using the high-covering-power styrene-acrylate emulsion. The preparation process is very simple, the reaction processis simple and easy to control, the operability is high, and the method is suitable for large-scale production. The aqueous printing ink disclosed by the invention is high in resolubility, is insusceptible to crusting and blocking printing plate and has high printing adaptability.

Owner:广东天龙油墨有限公司

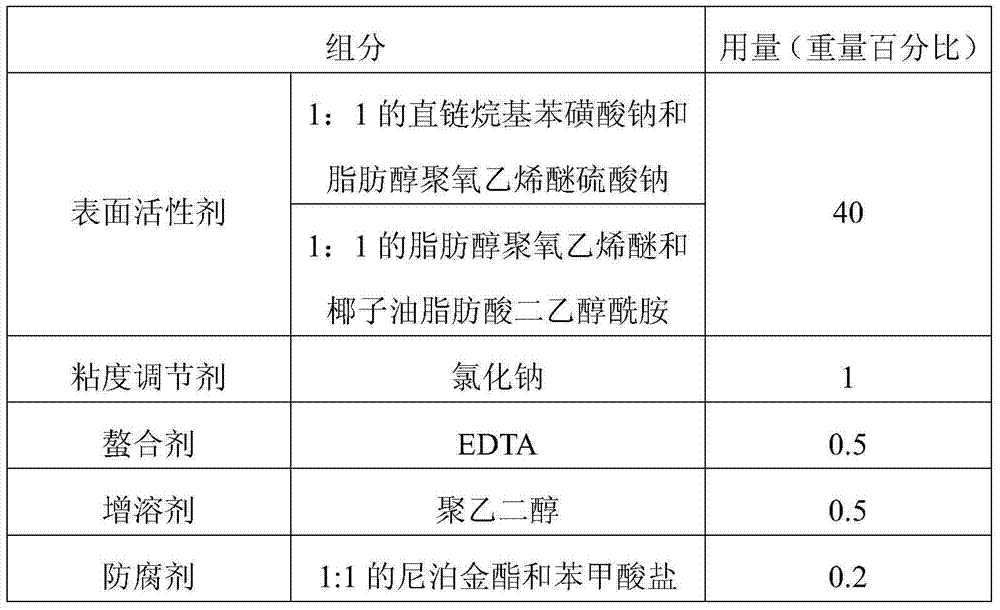

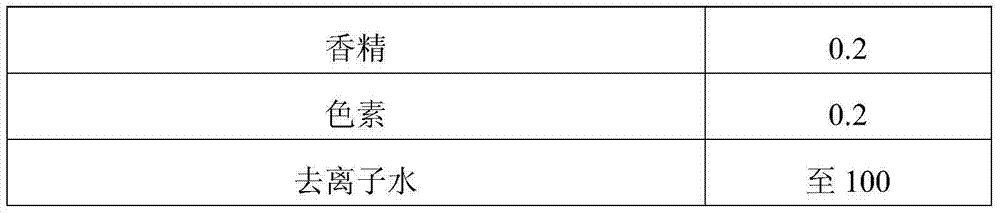

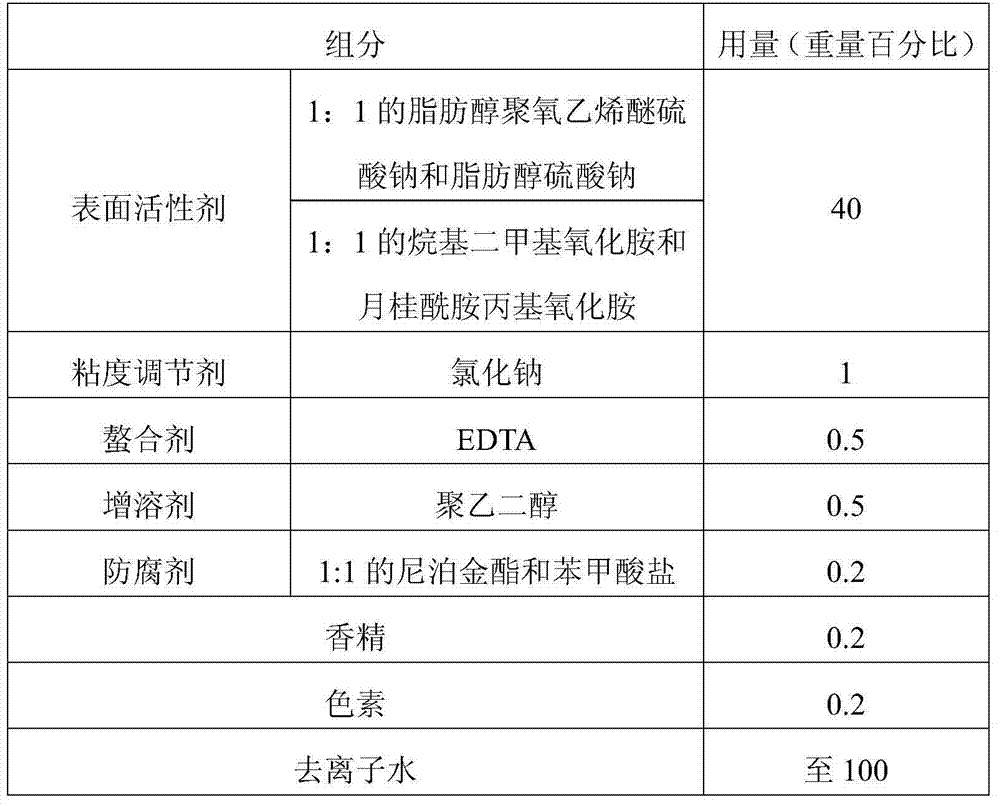

Pesticide residue removing liquid detergent

InactiveCN103540436AReduce stimulationWide variety of sourcesNon-ionic surface-active compoundsDetergent compounding agentsMicroorganismPesticide residue

The invention discloses a pesticide residue removing liquid detergent comprising the following components in percentage by weight: 20-50% of surfactant, 0.1-10% of viscosity modifier, 0.1-5% of chelating agent, 0.1-5% of solubilizer, 0.1-1% of preservative, 0.1-10% of essence, 0.1-10% of pigment and the balance of deionized water. The liquid detergent disclosed by the invention has the advantages of reasonable formula, mild nature, less skin irritation and strong cleaning property and is capable of removing pesticide residue and more than 80% of pesticide and killing residual microorganisms such as bacteria. The liquid detergent disclosed by the invention is wide in raw material source, low in preparation cost, convenient for use, storage and transportation and easy in popularization and application.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

Environmentally-friendly black chrome-silver-free zinc-plating passivation solution and preparation method thereof

InactiveCN101876071AReduce formulation costsHigh film forming efficiencyMetallic material coating processesSodium silicateCopper salt

The invention provides black passivation solution for zinc-plating post treatment. 1 liter of black passivation solution consists of 10 to 20g of sodium silicate, 20 to 30g of copper sulfate, 0.5 to 1.5g of nickel sulfate, 0.5 to 1.5g of ferrous sulfate, 1 to 3g of sodium acetate, 20 to 40mL of glacial acetic acid, 3 to 7mL of sulfuric acid (98 percent) and the balance of water. A zinc-plating material processed by the passivation solution has a uniform, bright and black appearance and high corrosion resistance, is free of rust for over 200h through a neutral salt spray test and can achieve the same effect as that achieved by the conventional black chrome-silver-contained passivation process in appearance and performance. The passivation solution has the advantages of thoroughly solving the problem of environment pollution caused by a chromium salt used by the conventional black zinc-plating passivation process, eliminating the use of a silver salt at the same time and greatly reducing the cost thereof by substituting silicate for the chromium salt as a main film-forming material and a copper salt, a nickel salt and a ferric salt for the silver salt as a blackening agent, along with stability and reliability and high film-forming efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Liquid detergent dedicated for underwear

ActiveCN101993793AStrong decontaminationPenetrate fastAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsStaphylococcus aureusCocamidopropyl betaine

Owner:SHANGHAI SOAP FACTORY

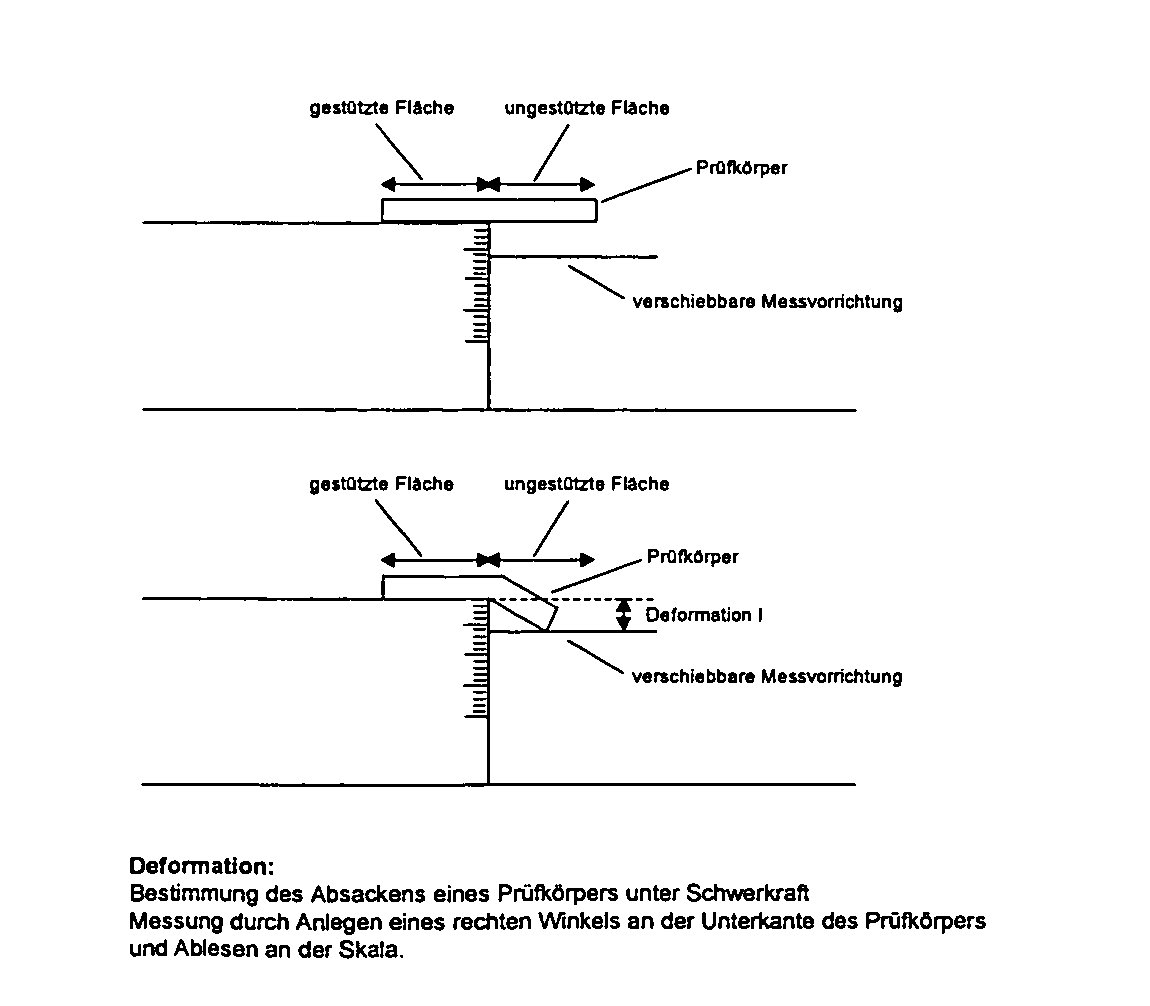

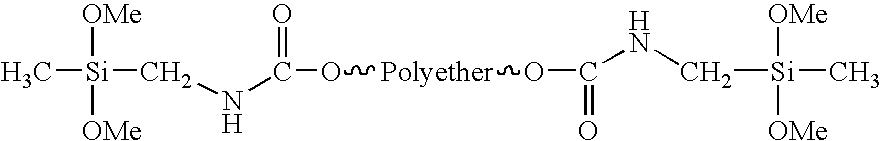

Condensation-crosslinked dental material hardening to dimensionally stable casts

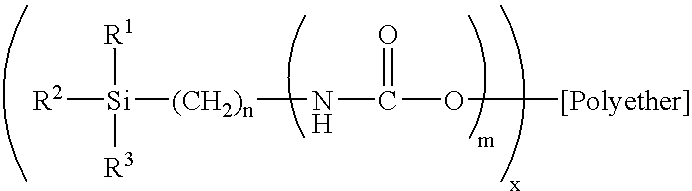

InactiveUS20070004821A1Minimize intermolecular interactionLow viscosityImpression capsDental impression compositionsSolubilityDentures

Condensation-crosslinked dental materials based on alkoxysilyl-functional and / or hydroxysilyl-functional polyethers are useful in dentistry for taking tooth impressions, bite registration, denture rebasing, or as temporary and permanent dental cement, temporary closure material, or dental prosthodontic material. The dental material has a composition containing at least one alkoxysilyl-functional and / or hydroxysilyl-functional polyether a), at least one catalyst b), and optionally water c) and at least one acidic compound d) that has a water solubility (20° C.) of no more than 150 g / l.

Owner:KETTENBACH GMBH & CO KG

Electrochemical corrosion resistant inner ply compound formula

InactiveCN101423638AGood physical and mechanical propertiesExtended service lifeFlexible pipesPolyethylene glycolStearic acid

The invention relates to an inner hose formula for an electrochemical corrosion resistant hose, which comprises the following compositions in portion by weight: 30 to 70 portions of low-mooney ethylene propylene diene rubber, 70 to 30 portions of high-mooney ethylene propylene diene rubber, 60 to 80 portions of semi-reinforcing carbon black, 60 to 90 portions of silica fume, 1.2 to 1.8 portions of bi-thiuram tetrasulfide, 1.7 to 2.3 portions of zinc dibutyl dithiocarbamate, 0.5 to 0.8 portion of tetramethyl thiuram disulfide, 3 to 5 portions of zinc oxide, 1 to 3 portions of polyethylene glycol, 1.5 to 2.0 portions of morphine disulfide, 0.3 to 0.6 portion of sulfur, 50 to 60 portions of paraffin oil, 1 to 3 portions of stearic acid and 2 to 4 portions of 2, 2, 4-trimethyl-1, 2-biquionlyl dihydride polymers. Compared with the prior product, the inner hose formula for the electrochemical corrosion resistant hose has obvious differences; the tensile strength is 12.0 MPa; the volume resistivity is 1X10<12> omega.cm and 1X10<5> omega.cm higher than that of the prior product; the service life of the electrochemical corrosion resistant hose is greatly improved; and the inner hose formula for the electrochemical corrosion resistant hose can well meet the demands of heat resistance and electrochemical corrosion resistance of a radiator hose of a motor vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

Method for inhibiting freeze-clumping of aggregate materials

InactiveUS6878308B2Less corrosiveReduce formulation costsLiquid surface applicatorsSolid waste managementD-GlucoseGlucose polymers

Owner:NATURAL ALTERNATIVES

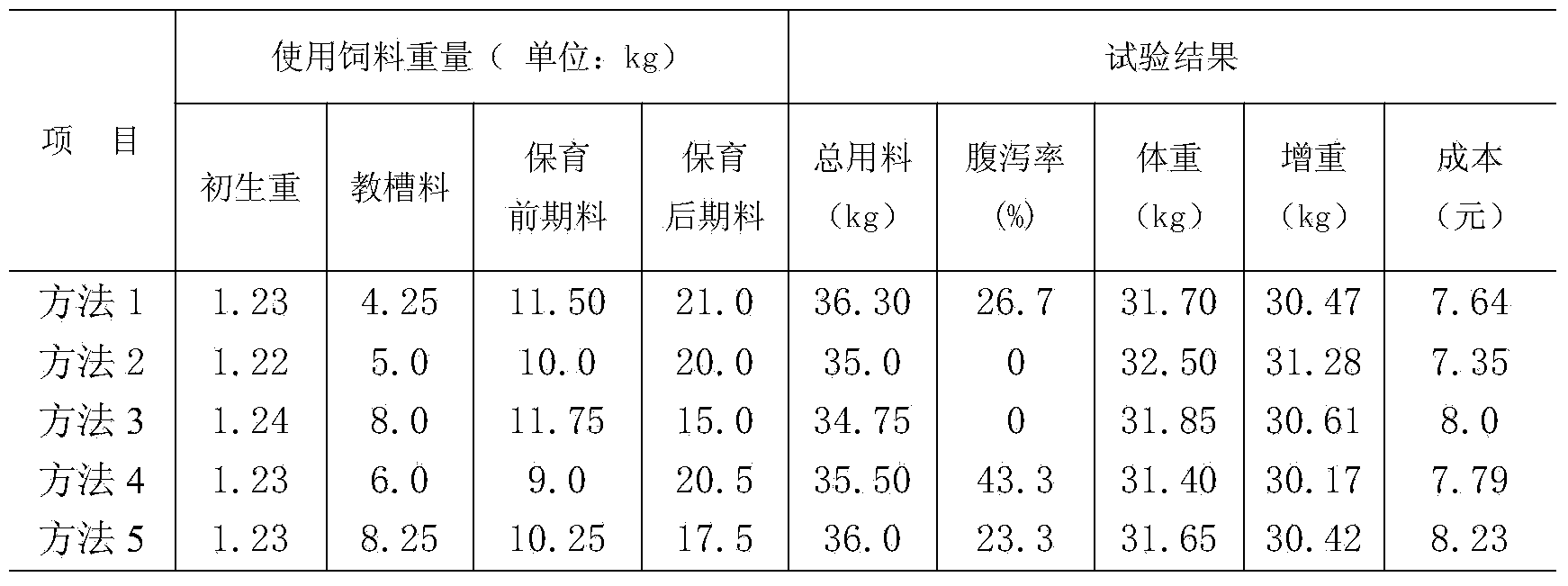

Large scale farming feed for piglets and feeding method thereof

InactiveCN104222639AEat balanced and adequateReduce formulation costsAnimal feeding stuffMethionine biosynthesisSOYBEAN SEED OIL

The invention relates to a large scale farming feed for piglets and a feeding method thereof. The feeding method comprises feeding milk replacer at a lactation stage, feeding at the earlier stage of nursing, and feeding at the later stage of nursing, wherein the milk replacer at a lactation stage is prepared from corns, bean pulp, extruded soybeans, whey powder, imported fish meal, phospholipids powder, whole milk powder, glucose, cane sugar, calcium hydrophosphate, threonine, zinc oxide, threonine, methionine, choline chloride, an acidifier, and 1% piglet core material; the feed for the earlier stage of nursing is prepared from corns, bean pulp, extruded soybean, whey powder, soybean oil, calcium hydrophosphate, mountain flour, cane sugar, lysine, threonine, methionine, choline chloride, an acidifier, a complex enzyme, phytase, a sweetening agent, montmorillonite, salt and 1% piglet premix; and the feed for the later stage of nursing is prepared from corns, bean pulp, extruded soybeans, soybean oil, calcium hydrophosphate, mountain flour, cane sugar, lysine, choline chloride, an acidifier, a complex enzyme, phytase, a flavoring agent, salt and 1% piglet premix.

Owner:LINYI UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com