Aqueous silver powder amino baking paint and preparation method thereof

An amino baking paint, water-based technology, applied in the coating and other directions, can solve the problems of the preparation method of low water-based silver powder amino baking paint, the serious conflict of the painter, the lack of VOC content, etc. The effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

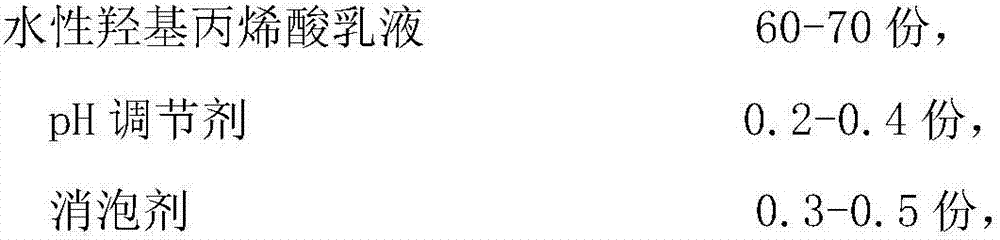

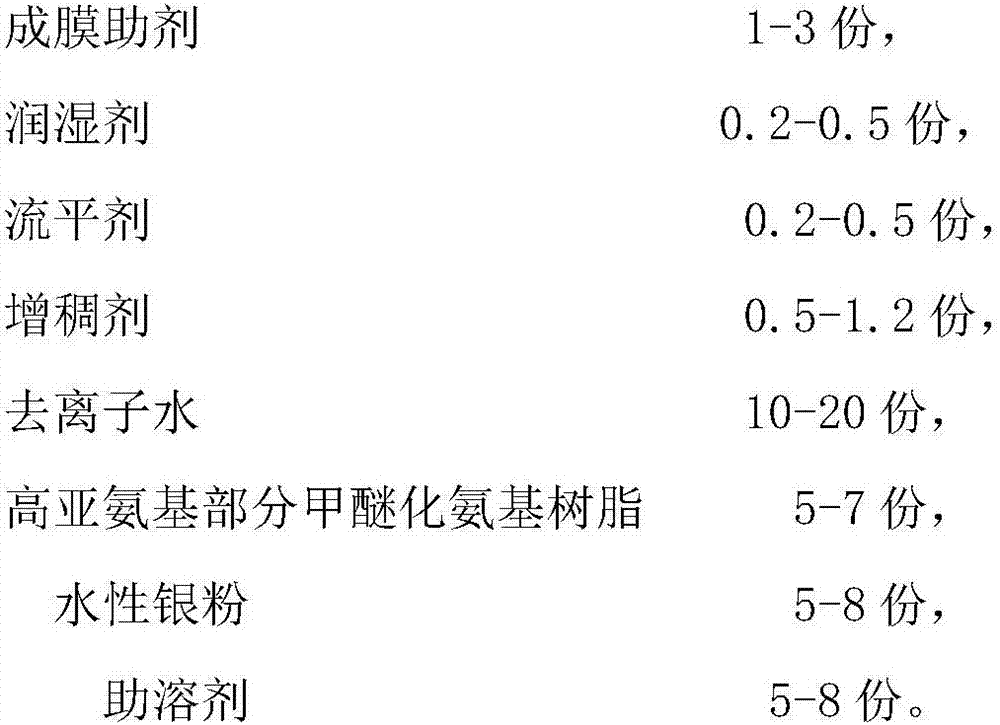

[0029] A kind of water-based silver powder amino baking varnish of the present invention, described water-based silver powder amino baking varnish consists of the following components in parts by mass:

[0030]

[0031]

[0032] Described water-based hydroxyacrylic acid emulsion is Yantai Wanhua's 0678; the pH regulator is a combination of dimethylethanolamine and ammonia water. The defoamer is an acrylic defoamer; the coalescent is a combination of propylene glycol methyl ether and propylene glycol butyl ether.

[0033] The wetting agent and the leveling agent are both acrylic polymers. The thickener is a combination of two types of cellulose thickener and alkali-swellable thickener.

[0034] The amino resin is a high imino part methylated melamine formaldehyde resin, such as MR-625 of Changchun Chemical Industry.

[0035] The water-based silver powder is a combination of W8030 of Wuxi Yuanfeng Chemical Industry and WS220 of Suzhou Boca.

[0036] The preparation me...

Embodiment 2

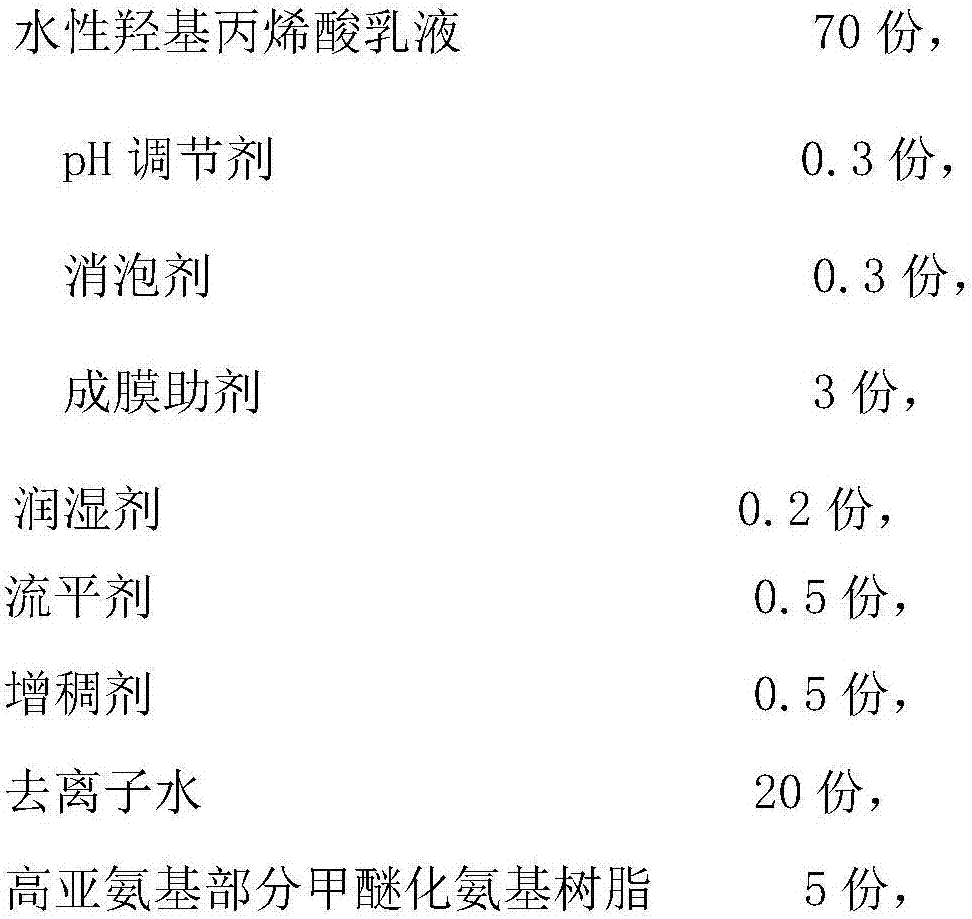

[0044] The difference between embodiment 2 and embodiment 1 is:

[0045] A kind of water-based silver powder amino baking varnish of the present invention, described water-based silver powder amino baking varnish consists of the following components in parts by mass:

[0046]

[0047]

[0048] The pH regulator is dimethylethanolamine. The defoamer is an acrylic defoamer; the coalescent is propylene glycol methyl ether. The thickener is a combination of three types of cellulose thickeners, alkali-swellable thickeners and associative thickeners.

[0049] The preparation method of water-based silver powder amino baking varnish of the present invention, comprises the steps:

[0050] In step (1), add the water-based silver powder and co-solvent into the stock preparation pot successively according to the components in the parts by weight, stir at a low speed for 20 minutes, then soak for 1 hour statically, and set aside;

[0051] In step (2), add the water-based hydroxyacr...

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is:

[0057] A kind of water-based silver powder amino baking varnish of the present invention, described water-based silver powder amino baking varnish consists of the following components in parts by mass:

[0058]

[0059]

[0060] The pH regulator is ammonia water. The film-forming aid is a combination of two kinds of propylene glycol methyl ether and propylene glycol butyl ether. The thickener is a cellulose thickener.

[0061] The water-based silver powder is a combination of three types of W8013 of Wuxi Yuanfeng Chemical Industry, W8030 of Wuxi Yuanfeng Chemical Industry and WS220 of Suzhou Boca.

[0062] The preparation method of water-based silver powder amino baking varnish of the present invention, comprises the steps:

[0063] In step (1), add the water-based silver powder and the cosolvent into the stock pot successively according to the components in the parts by weight, stir at a low speed for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com