Patents

Literature

498 results about "PROPYLENE GLYCOL BUTYL ETHER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene Glycol Butyl Ether is the propylene glycol ether of n-butyl alcohol that conforms to the formula: C7H16O2.

Environmentally-friendly high-performance water-based woodware paint and using method thereof

ActiveCN102051096AGood weather resistanceGood quick dryingPolyurea/polyurethane coatingsDiethylene glycol monobutyl etherWater based

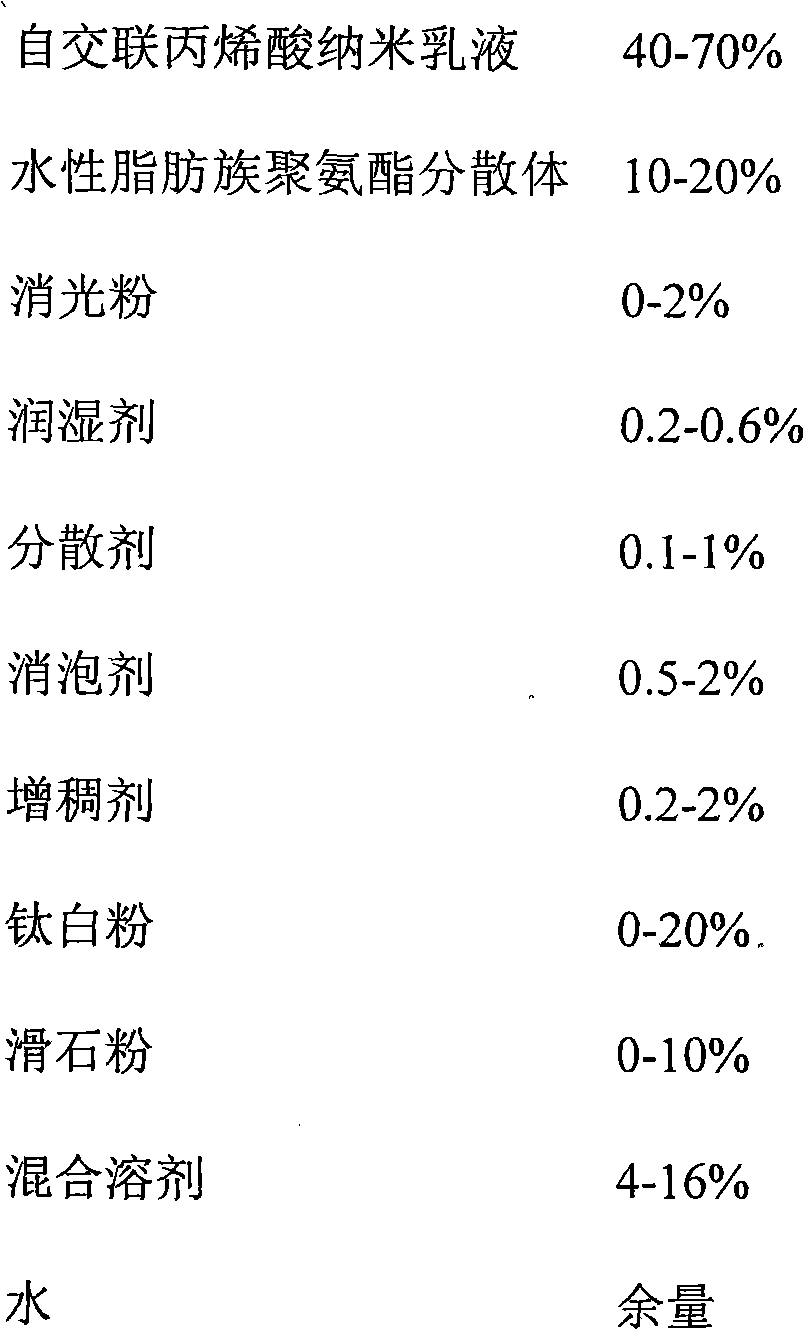

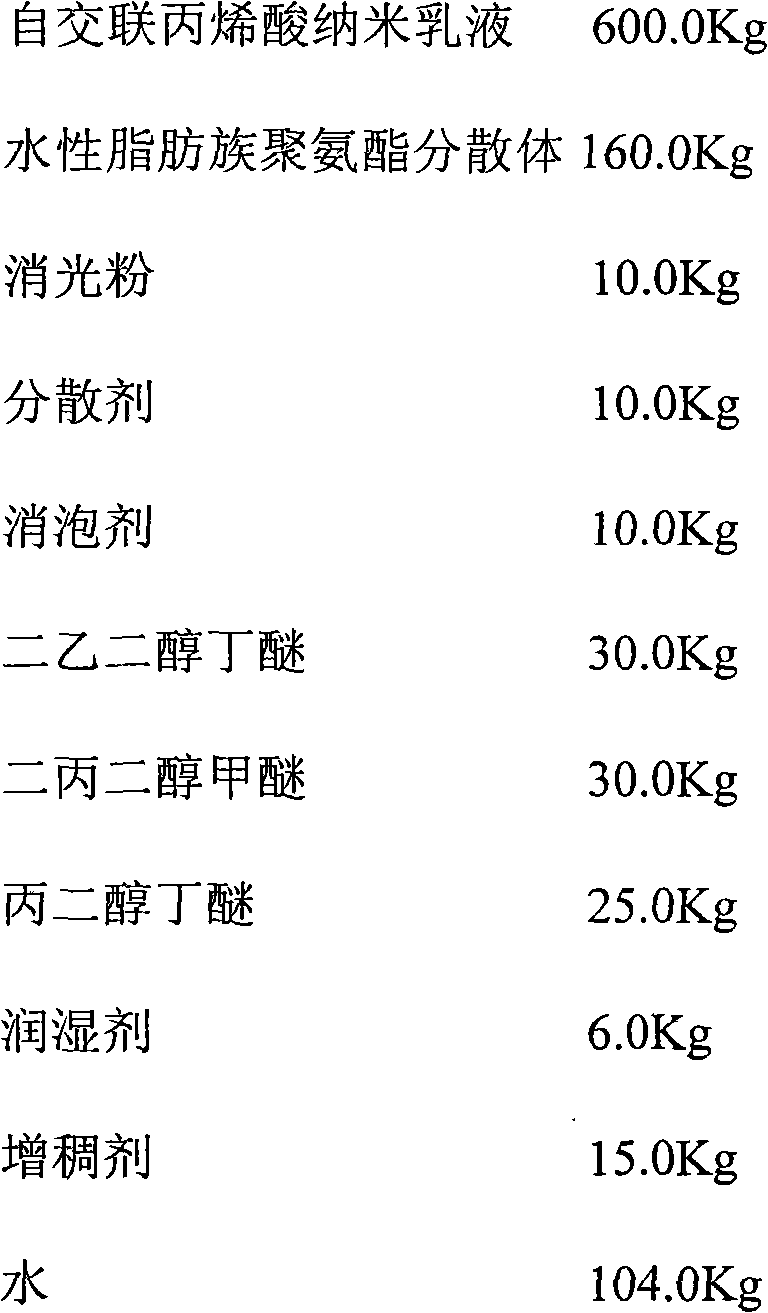

The invention discloses an environmentally-friendly high-performance water-based woodware paint and a using method thereof. The environmentally-friendly high-performance water-based woodware paint comprises 40 to 70 weight percent of self-crosslinking acrylic nano-emulsion and 10 to 20 weight percent of water-based aliphatic polyurethane dispersion. The water-based woodware paint is mainly prepared from the self-crosslinking acrylic emulsion with high triglyceride (Tg) content and weather resistance, so that a paint film has high quick-drying property, chemical resistance and weather resistance, and economy; the self-crosslinking acrylic emulsion is compounded with castor oil modified aliphatic polyurethane dispersion, so that the paint film has high adhesion, hardness, fullness, weather resistance, dry heat resistance and block resistance; and diethylene glycol monobutyl ether is matched with dipropylene glycol methyl ether and propylene glycol monobutyl ether, so that the film forming property of the paint film is ensured, and high drying property is achieved.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Foam extingusher with covering function

InactiveCN1413749AImprove fire extinguishing effectGood anti-reburning effectFire extinguisherPROPYLENE GLYCOL BUTYL ETHERPreservative

A fire-extinguishing foaming chemical with covering function features that it contains F1157N or F1203, F3 or OBS or FC-4, JR-400 or sodium algate or CMC or HEC or cationic starch or chitosan or xanthan gum, CAB or LAB or MZL or K12 or APG, ethanediol butylether or propanediol butylether, glycol or diglycol or propanetriol, urea, anticorrosion agent and water through proportioning and compounding. Its advantages are high fire-extinguishing power, strong covering function and high effect on preventing evaporation of oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Real-stone paint and preparation method thereof

ActiveCN106590268AFast film formationImprove water resistanceAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

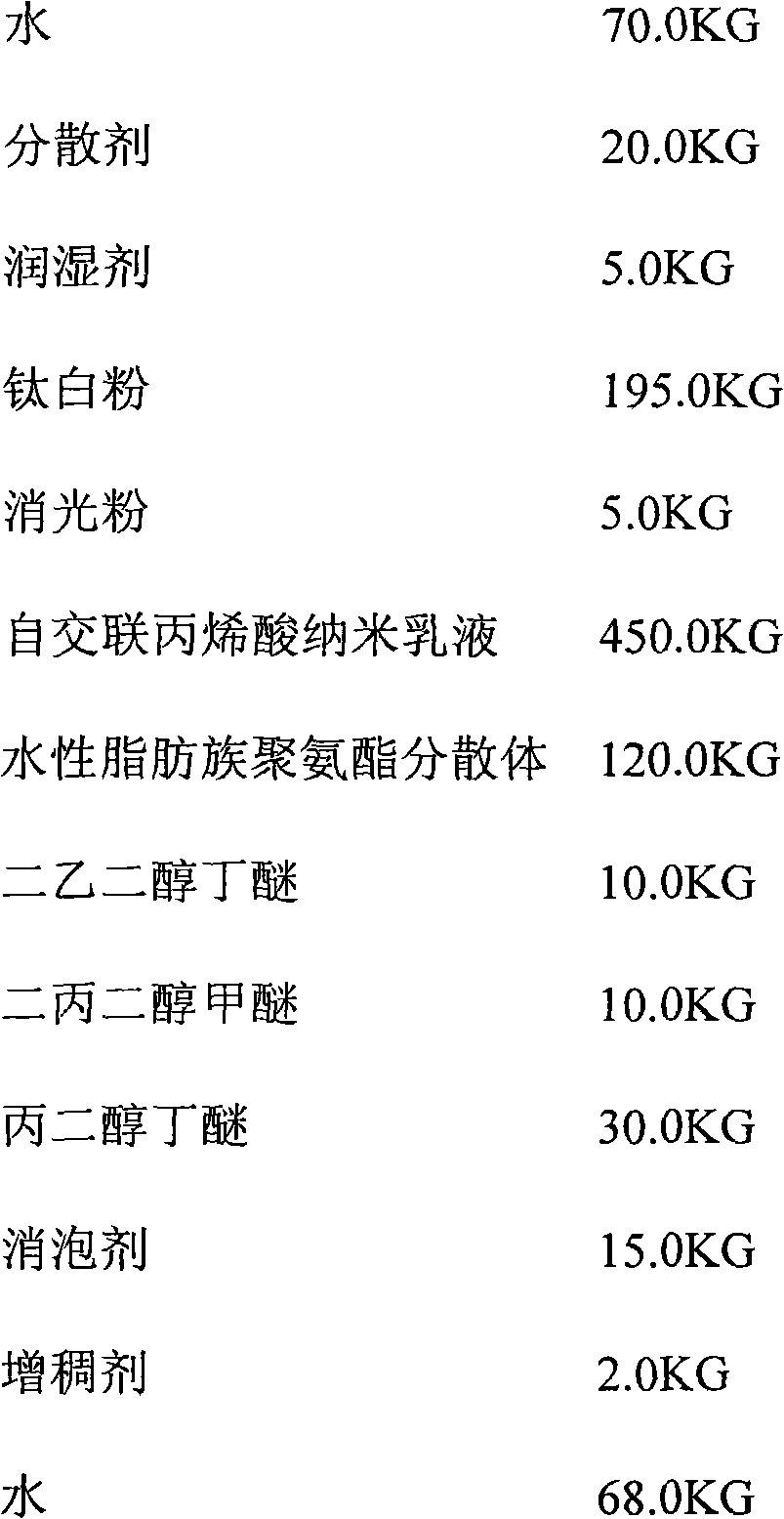

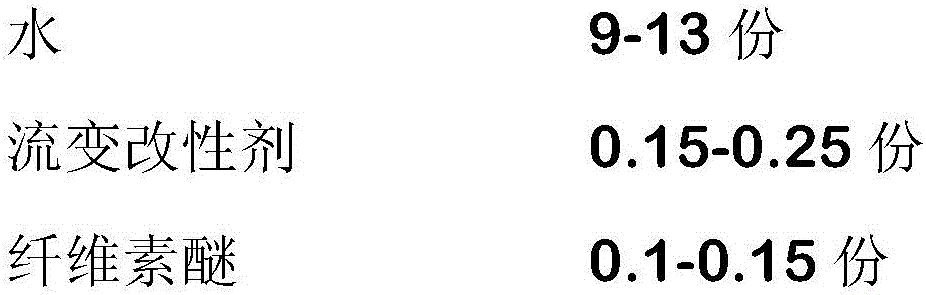

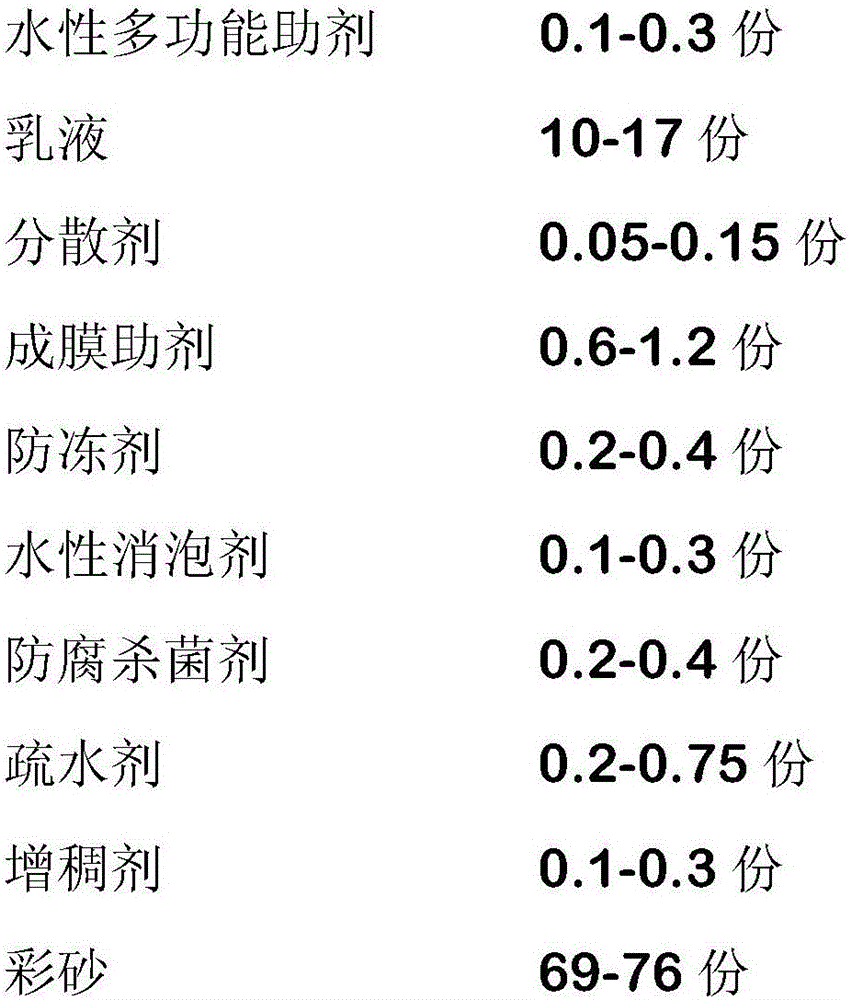

The invention relates to real-stone paint and a preparation method thereof and belongs to the technical field of building decorative materials. Firstly, an inorganic mineral rheological agent and a nonionic water-soluble cellulose ether are combined, so that the two components have the synergistic effect of guaranteeing viscosity of the real-stone paint and excellent constructability, and on the basis hereinabove, the usage amount of cellulose ether, which has water retention effect, in the real-stone paint is reduced, so that a paint film is reduced in the water retention effect and moisture volatilization is improved; secondly, alcohol ester-12 is combined with any one of four film forming additives, comprising ethylene glycol monobutyl ether, propylene glycol butyl ether, diethylene glycol butyl ether and benzyl alcohol, which have high volatile speed, thus accelerating film forming. For solving of a problem of poor antifouling performance of the real-stone paint, through reasonable combination of particle size of color sands and usage of a hydrophobic agent, the real-stone paint can form a compact film and a nano hydrophobic coating layer, which is completely composed of nano hydrophobic particles, is formed on the surface of the paint film, so that the paint film is reduced in surface energy and water absorbency, and is improved in antifouling performance.

Owner:BEIJING SATELLITE MFG FACTORY

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

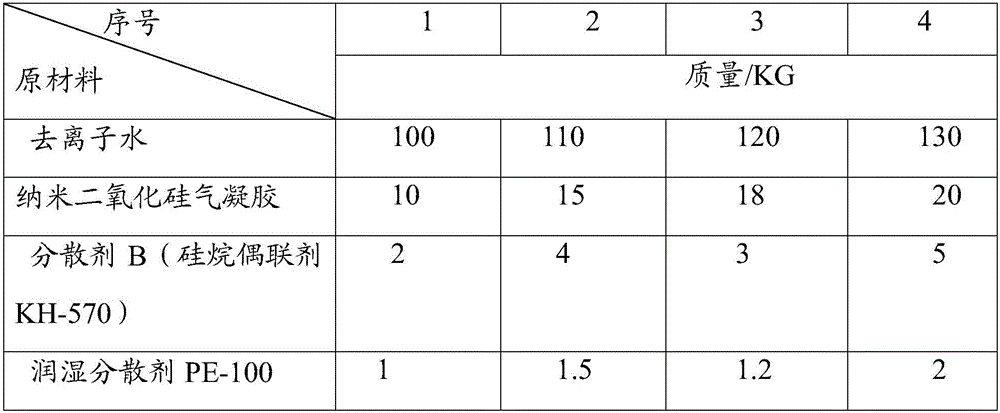

Nano transparent heat-insulating coating and preparation method thereof

ActiveCN105694629AEliminate the problem of easy agglomeration and difficult dispersionLow costCoatingsWater basedAcrylic resin

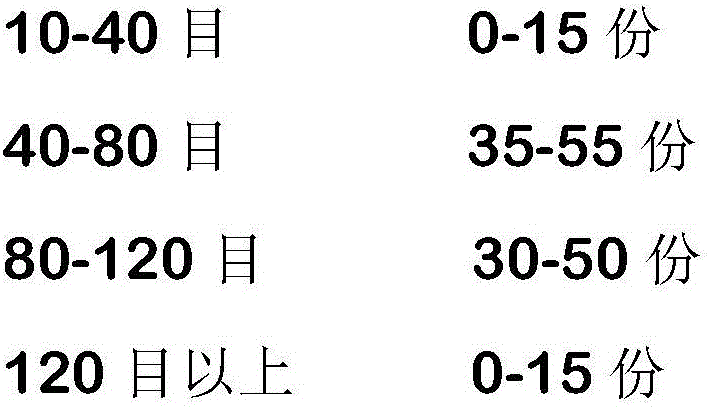

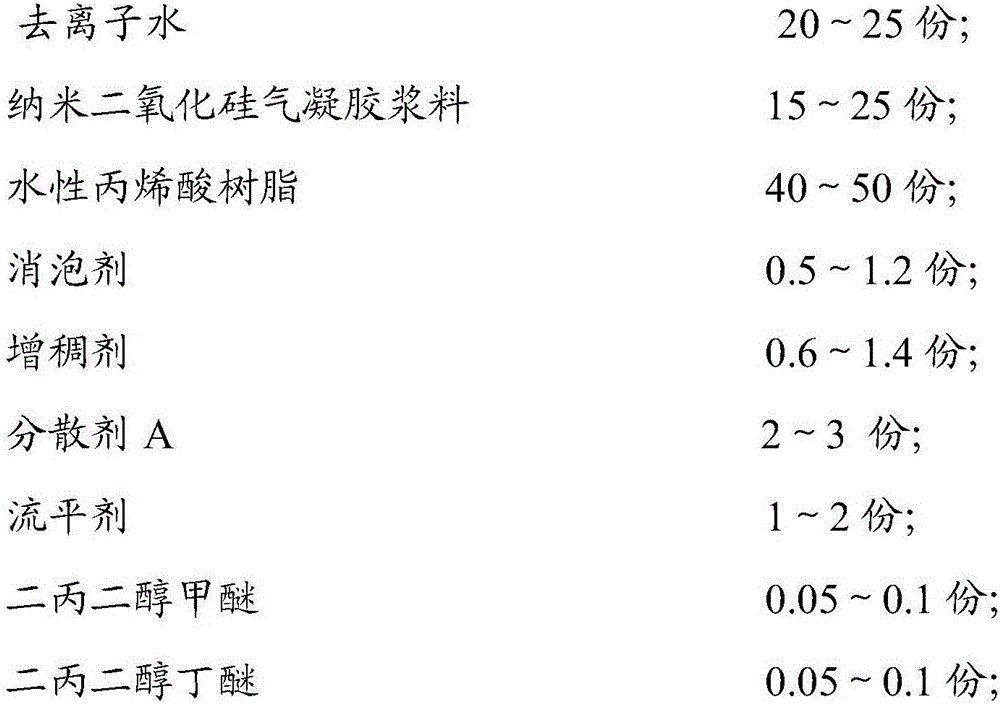

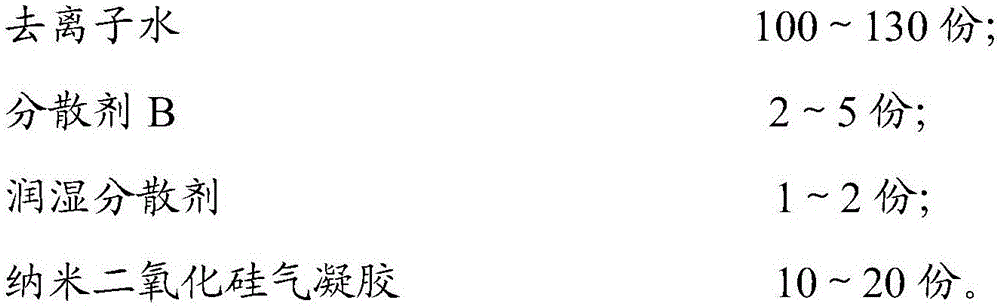

The invention discloses a nano transparent heat-insulating coating and a preparation method thereof. The nano transparent heat-insulating coating comprises raw materials in parts by weight as follows: 20-25 parts of deionized water, 15-25 parts of nano-silica aerogel slurry, 40-50 parts of water-based acrylic resin, 0.5-1.2 parts of a defoaming agent, 0.6-1.4 parts of a thickening agent, 2-3 parts of a dispersing agent A, 1-2 parts of a leveling agent, 0.05-0.1 parts of dipropylene glycol methyl ether and 0.05-0.1 parts of dipropylene glycol monobutyl ether. The single nano-silica aerogel slurry with excellent performance is added to the nano transparent heat-insulating coating and modified with the optimized dispersing agent, the problems that the nano transparent heat-insulating coating is prone to agglomeration and is difficult to disperse are solved, the ideal nano transparent heat-insulating coating is prepared through optimization of the other raw materials, ratio, processing steps, parameters and the like, the cost is saved, and the construction technology is simplified.

Owner:GUANGZHOU BAIYUN CHEM IND

American type water-based coating finish paint and preparation method thereof

InactiveCN102408826AImprove adhesionGood chemical resistancePolyurea/polyurethane coatingsPolymer scienceAziridine

The invention provides an American type water-based coating finish paint and a preparation method thereof. The finish paint comprises the following components in mass percent: 5-25% of self-crosslinking acrylic emulsion, 30-50% of polyurethane modified acrylic emulsion, 5-30% of polyurethane dispersion emulsion, 0.05-0.1% of macromolecular segmented copolymer solution containing pigment affinity groups, 0.1-0.3% of polysiloxane mixture, 0.2-0.5% of organic silicon flatting agent, 0.05-0.2% of primary amine multifunctional additives, 0.5-2% of silica matting powder, 1-4% of dipropylene glycol methyl ether, 3-5% of dipropylene glycol butyl ether, 5-10% of deionized water, 2-4% of polyethylene wax water-based dispersion, 0.2-0.4% of polyether siloxane copolymer emulsion, 0.1-0.3% of non-ionic special polyurethane polymer, 0.1-0.3% of polysiloxane-polyether copolymer and 0.3-3% of one or two of silane coupling agent and aziridine. The finish paint provided by the invention is used for solid wood substrates, is environment-friendly and has excellent performance, and the adhesive force, glossiness and hardness of the finish paint can meet the operating requirements of indoor decoration of wooden furniture.

Owner:KUSN WANSHENG CHEM

Strong absorptive dope of restraining frost

InactiveCN1916094AImprove impact resistanceReduce thicknessAntifouling/underwater paintsLighting and heating apparatusCyclohexanonePROPYLENE GLYCOL BUTYL ETHER

This invention discloses a frost-inhibitive paint with good water absorbency, which comprises: polyacrylic acid absorbent resin 20-40 parts, metal baking paint containing polyacrylic acid resin, amino alkyd resin or polyurethane 40-60 parts, NaCl or KCl crystal particles 20-40 parts, and solvent 20-40 parts. The solvent is cyclohexanone, gasoline, propylene glycol butyl ether, butyl acetate or butanone. The layer painted from the paint has a thickness of 0.06 mm, and an impact strength higher than 50 kg .cm / cm2. The paint has a more obvious frost-inhibitive effect when the humidity is 50%.

Owner:BEIJING UNIV OF TECH

Filmforming foam extinguishant with low viscosity fluid and anti water dissolved

A water-insoluble low-viscosity filming foam-type fire-extinguishing chemical contains perfluoroalkyl betaine or perfluoropolyoxypropene quaternary ammonium salt or perfluoroalkyl sulfonate or perfluoroalkyl sulfate, C12-C16 propylbetaine or C12-C16 ammonium dimethyloxide or C8-C12 sodium alkylsulfate or CX-C10 ammonium dimethyloxide or C8-C12 sodium alkylsulfate or CX-C10 alkyl polyglucoside, ethanediol butylether or propanediol butylether, alcohol-resistant high-molecular matches and water. Its advantage is no environmental pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-wear-resistant antibacterial acrylate paint

InactiveCN106366899AImprove wear resistanceGood solvent resistanceFireproof paintsAntifouling/underwater paintsWear resistantUnsaturated polyester

The invention discloses high-wear-resistant antibacterial acrylate paint. The high-wear-resistant antibacterial acrylate paint is prepared from the raw materials: an aqueous acrylate emulsion, alkyd resin, organosilicon modified unsaturated polyester resin, silica sol, cellulose acetate butyrate, polyvinyl pyrrolidone, modified nano-titania, calcium carbonate whiskers, octadecyl trimethyl ammonium chloride modified montmorillonite, hollow glass beads, zinc oxide, ethylene glycol mono-n-propyl ether, di-propanediol butyl ether, triethylene glycol monoethyl ether, an anti-settling agent, a humectant, an antifoamer, per-methoxylation melamine resin, 3,5-dimethyl-2-aminobenzoic acid, trimethylaniline, a leveling agent, vinyl triethoxysilane and deionized water. The high-wear-resistant antibacterial acrylate paint provided by the invention is high in hardness, good in wear resistance, excellent in antibacterial performance and long in service life.

Owner:ANHUI JINDUN PAINT

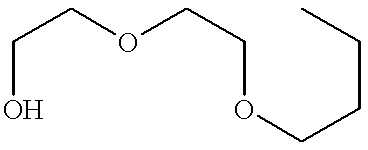

Reducing type concrete fluidity stabilizer preparation method

ActiveCN108047388ALiquidity Stability ControlExcellent initial water reducing rateDiethylene glycol monobutyl etherCarboxylic acid

The invention discloses a reducing type concrete fluidity stabilizer preparation method which comprises the following steps: (1) acylation and esterification reaction; (2) monomer alloying; (3) copolymerization reaction; (4) neutralization reaction. According to the preparation method disclosed by the invention, unsaturated carboxylic acid or unsaturated carboxylic acid anhydride and alcohol amine, diethylene glycol monobutyl ether and / or dipropylene glycol monobutyl ether and compound A are acylated and esterified to prepare unsaturated monomer with an amide structure and an amino structure,unsaturated monomer with an alcohol ether structure and unsaturated monomer with a benzene ring and a carboxylic acid group at the same time; then the unsaturated monomers are copolymerized with excessive unsaturated carboxylic acid and carboxylic acid anhydride, unsaturated sulfonate and polyether macromonomer in acylation and esterification reaction; the monomers are guided into molecule structures, so that the molecule structures have the benzene rings, carboxylic acid groups, sulfonic acid groups, amide groups and amino groups at the same time; thus, a product has an excellent initial water-reducing rate.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Corrosion proof impregnating varnish used for water-based metal components and manufacturing method thereof

ActiveCN101560351ALong-lasting colorHigh hardnessAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a corrosion proof impregnating varnish used for water-based metal components and a manufacturing method thereof. The corrosion proof impregnating varnish is made of de-ionized water, propanediol, dispersant, antifoaming agent, wetting agent, carbon black, iron oxide black, water borne acroid resin, water borne epoxy resin, dipropylene glycol butyl ether, propylene glycol ether and polyaniline water solution, polyaniline carrier particles or polyaniline emulsion. The manufacturing method comprises: the propanediol and the de-ionized water are mixed and stirred, and then added with the dispersant, the antifoaming agent, the wetting agent and the polyaniline water solution or the water solution of emulsion or carrier particles to be evenly mixed together; the carbon black and the iron oxide black are added in to the mixed solution to form uniform pigment paste which is then put into a blending tank after being ground to be evenly stirred; the obtained mixture is added with the water borne acroid resin, the water borne epoxy resin, the dipropylene glycol butyl ether and the propylene glycol ether to be stirred; finally, the stirred mixture is added with the de-ionized water to be diluted and ground. The invention has the advantages of high coating efficiency, stable coating quality, uniform paint film of dip coating, flat and smooth paint film, good hardness, strong adhesive attraction, good corrosion proof performance, excellent painting performance at edges and corners, no leaking painting, good salt mist resistance, environmental protection, low cost, etc.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Aluminum and aluminum alloy cleaning agent and using method thereof

ActiveCN101012411AImprove cleaning rateImprove cleaning efficiencyInorganic/elemental detergent compounding agentsSurface-active detergent compositionsCleansing AgentsPhenol

The invention discloses an aluminium and aluminium alloy abluent, which comprises the following parts: 5-25W% alkyl phenol polyoxyethylene ether, 5-25W% aliphatic alcohol polyoxyethylene ether, 1-10W% cationic modified alkyl phenol polyoxyethylene ether, 2-10W% propanediol butyl ether, 2-8W% glucose, 1-8W% sodium bisilicate and 40-80W% water. The product displays light yellow transparent liquid with density at 1.05+-0.02 g / cm3, which simplifies normal disposal technique.

Owner:DALIAN SANDAAOKE CHEM

Single phase aqueous surfactant-free nontoxic air freshening composition and wick-containing air freshening device using said composition

Described is a single phase aqueous surfactant-free nontoxic air freshening composition containing 30-70% water, 5-20% of a fragrance, at least 60% of the components of which has a C log10P<=2.5 and 30-60 weight percent of a mixture of two glycol ether components:(i) dipropylene glycol methyl ether; and(ii) propylene glycol propyl ether or propylene glycol butyl ether.Also described is an air freshener device comprising a vessel for the aforementioned composition, an emanating surface and a wick for supplying the composition to the emanating surface.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

Ultraviolet light curing coating and production thereof

InactiveCN1778850AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsUltraviolet lightsKetone

A ultraviolet curing coating and its production are disclosed. The coating consists of filming substance, diluent and light initiating agent or assistants. The diluent is a organic solvent which comprises one of several from toluene, acetic ether, acetate butyrin, isobutyl acetate, propyl acetate, alcohol, n-butyl alcohol, ethylene ketone, dimethyl benzene, methyl isobutyl ketone, acetone, methyl ethyl ketone, ethanediol butyl ester and propylene butyl ester. It costs low, has better abrasive-resistance, hardness and adhesion.

Owner:BYD CO LTD

Hard surface cleaning disinfecting wet tissue

InactiveCN102846257AEfficient removalFast evaporationSurface-active non-soap compounds and soap mixture detergentsDomestic applicationsDisinfectantSurface cleaning

The invention discloses a hard surface cleaning disinfecting wet tissue relating to the field of daily necessities. The hard surface cleaning disinfecting wet tissue can solve the problem that a kitchen cleaning agent and a toilet cleaning agent are not applicable for the hard surface cleaning and disinfecting. The hard surface cleaning disinfecting wet tissue comprises a wet tissue solution and a carrier of a wet tissue solution. The hard surface cleaning disinfecting wet tissue is characterized in that the preparation of the wet tissue solution comprises the following raw material components by the weight ratio: 0.1-0.5% of alkyl glucoside, 0.1-0.5% of ethylene diamine tetraacetic acid (EDTA-2Na), 0.1-0.5% of sodium citrate, 0.1-0.5% of citric acid, 5-10% of ethanol, 6-10% of dipropylene glycol n-butyl ether, 5-10% of D-limonene, 0.32-2% of didecyl dimethyl ammonium chloride, 0.3-2% of orthophenylphenol, 0.03-1% of o-benzyl parachlorophenol, and the balance of water. The hard surface cleaning disinfecting wet tissue is compounded by a plurality of chelating agents, and can effectively remove granular dirt and hard water salt; by using dipropylene glycol n-butyl ether and D-limonene, oil dirt and other stubborn stains can be effectively eliminated; by using the biquaternary ammonium salt and phenolic disinfectant, the surface of an object can be cleaned while the pathogenic bacterium can be killed; the product is low in bubble and residue, quick in speed of volatile; after being wiped, the surface of the object does not need to be flushed by water again; and the hard surface cleaning disinfecting wet tissue is applicable to cleaning and disinfecting the hard surface.

Owner:TONGLING JIEYA BIOLOGIC TECH

Method for preparing waterborne plastic toy paint

The invention provides a method for preparing a waterborne plastic toy paint. The paint comprises the following components in percentage by weight: 50 to 70 percent of copolymer emulsion A of butyl acrylate, styrene and acrylonitrile, 10 to 15 percent of copolymer emulsion B of methyl methacrylate, styrene and N-methylol acrylamide, 2 to 5 percent of propylene glycol butyl ether film forming auxiliary agent, 5 to 7 percent of mono-isobutyric acid trimethyl pentanediol ester film forming auxiliary agent, 0.1 to 0.4 percent of polysiloxane and polyester copolymer leveling agent, 0.1 to 0.4 percent of polysiloxane mixture defoaming agent, 0.1 to 0.4 percent of associative type polyurethane thickener, 0.1 to 0.4 percent of 2-amino-2-methyl-1-propanol organic amine neutralizer, 2 to 6 percent of hard polyethylene wax emulsion, 0 to 15 percent of deionized water and 0 to 25 percent of color paste; and the preparation method comprises the following steps of: adding all the acrylic acid emulsion, deionized water, organic amine neutralizer, leveling agent, defoaming agent, film forming auxiliary agents and wax emulsion to a paint mixing kettle with stirring at a rotary speed of 60 to 120rpm, stirring the mixture at a rotary speed of 200 to 300rpm for 10 to 20min, adding the color paste to the mixture at a rotary speed of 60 to 120rpm, stirring the mixture at a rotary speed of 200 to 300rpm for 10 to 20min, adding the thickener until the viscosity of the mixture meets the index of 70 to 110s(paint-1 cup) and the adhesive force of the spraying plate paint film reaches the first grade(by the cut test on an ABS plate), and filtering and packaging.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Aqueous antirust paint with rust

ActiveCN103409017AAvoid pollutionImprove corrosion resistanceAnti-corrosive paintsPolyester coatingsCelluloseDibutyltin dilaurate

The present invention relates to an aqueous antirust paint with rust. The aqueous antirust paint is characterized by comprising the following raw materials, by weight: 100-120 parts of an acrylic acid emulsion, 8-11 parts of an alcoholic acid resin, 6-8 parts of 1H-benzotriazole, 7-10 parts of basic calcium molybdate zinc, 5-8 parts of propanediol butyl ether, 0.1-0.3 part of zinc phosphate, 0.5-1 part of citric acid, 0.1-0.3 part of iron oxide red, 0.5-5 parts of silicon micro-powder, 0.1-0.2 part of hydroxypropyl cellulose, 0.1-0.3 part of dibutyltin dilaurate, 0.1-1 part of a dispersing agent, 0.1-0.5 part of an antifoaming agent, and 4-10 parts of deionized water. The product has characteristics of the conversion type coating material with rust and the stability type coating material with rust, and can be directly sprayed or brushed without a surface treatment during use so as to reduce construction steps and save cost. In addition, the product adopts water as a solvent so as to overcome pollution of the solvent type coating material on the environment.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Waterproof and anticorrosive paint special for marine ships

InactiveCN106318105AAccelerated corrosionImprove water resistanceRubber derivative coatingsAnti-corrosive paintsDimethylaniline N-oxideDefoamer

The invention discloses a waterproof and anticorrosive paint special for marine ships. The paint comprises 60-85wt% of a component A and 15-40wt% of a component B. The component A comprises the following raw materials: epoxy resin, chlorinated rubber, an ethylene chloride-vinyl acetate copolymer, organic fluorine modified acrylic resin, a silane coupling agent, zinc powder, mica powder, iron oxide red, ceramic micro-powder, molybdenum disulfide, propylene glycol butyl ether, propylene glycol methyl ether acetate, a dispersing agent, an organic silicon defoamer, a leveling agent, methyl isobutyl ketone and n-butanol; and the component B includes the following raw materials: poly 2, 3-dimethylaniline modified montmorillonite, a curing agent, ethyl acetate, and butyl acetate. The waterproof and anticorrosive paint special for marine ships provided by the invention has excellent waterproof performance and corrosion resistance, also has excellent impact resistance, abrasion resistance and weather resistance, has good comprehensive performance when used in ship engineering, and has long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Nano silicon dioxide modifying water composite road sign dope and preparation method thereof

InactiveCN101235232AReduce pollutionReduce energy consumptionTraffic signalsRoad signsKetoneSilicon dioxide

The invention discloses nano silica dioxide modified waterborne composite road sign paint and a preparation process. The paint comprises the following components which are counted with parts by mass, 35-44 parts of paint emulsion, 1-3 parts of polyamine polymer, 2-5 parts of film-forming auxiliary agent, 1-4 parts of nano silica dioxide dispersion, 5-8 parts of titanium dioxide, 8-20 parts of heavy calcium carbonate, 5-20 parts of wollastonite, 5-15 parts of silica flour, 5-20 parts of glass bead, 5-20 parts of mica powder, 2-5 parts of propylene glycol butyl ether, 1-3 parts of methyl-ethyl ketone, 1-4 parts of ammonial solution and deionized water which is filled to reach the whole weight of 100 parts. The paint of the invention has the characteristics of quick-drying in normal temperature, self cross-linking, excellent abrasion resistance and water resistance, which is an environment-friendly paint with high property whose organic solvent content is smaller 5%.

Owner:QINGDAO UNIV OF SCI & TECH

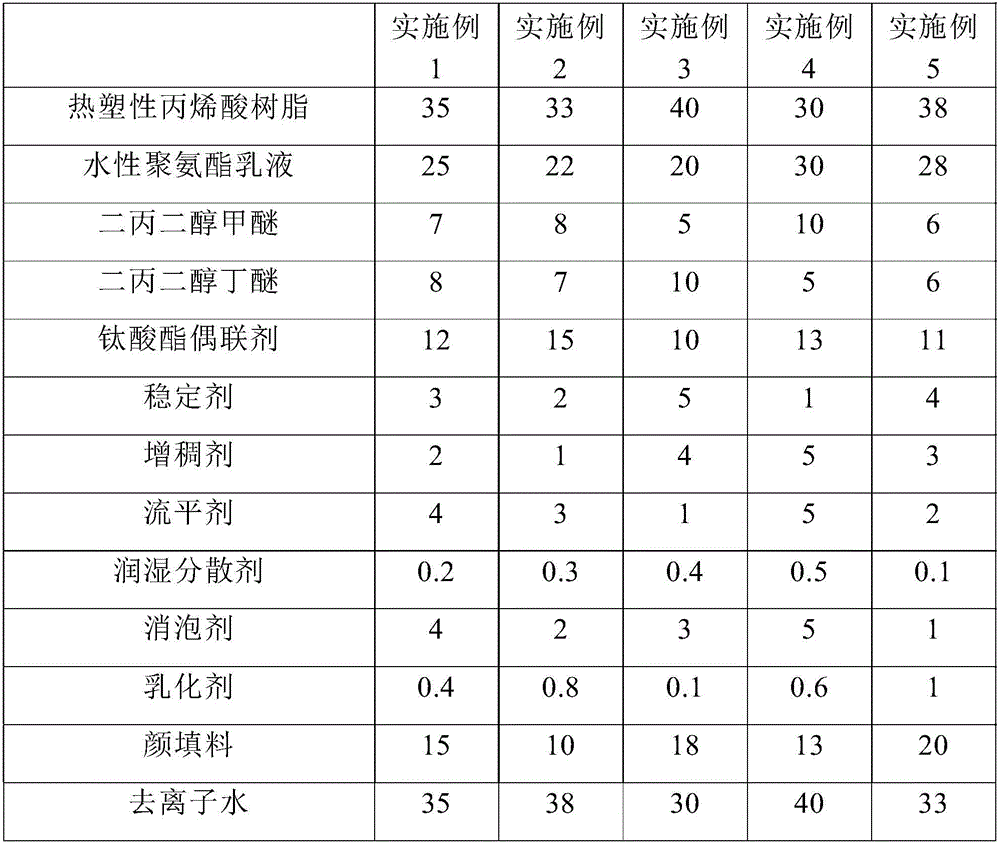

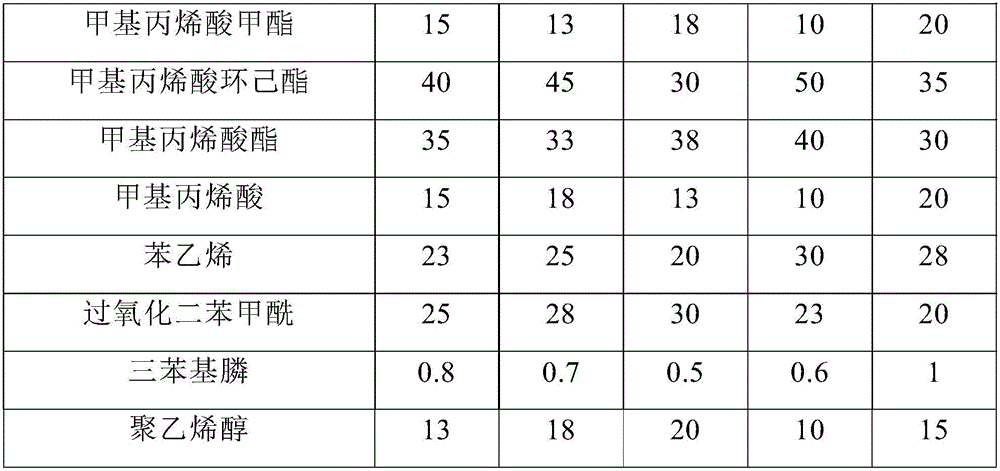

Environmental-friendly luminous abrasion-resisting waterborne plastic paint and preparation method thereof

InactiveCN106085068AHigh hardnessGood for healthPolyurea/polyurethane coatingsEnvironmental resistanceAcrylic resin

The invention provides an environmental-friendly luminous abrasion-resisting waterborne plastic paint and a preparation method thereof. The plastic paint comprises the following ingredients: thermoplastic acrylic resin, waterborne polyurethane emulsion, dipropylene glycol monomethyl ether, dipropylene glycol mono butyl ether, a titanate coupling agent, a stabilizer, a thickener, a leveling agent, a wetting dispersant reagent, a defoaming agent, an emulsifier, pigments and fillers and deionized water. According to the plastic paint, the thermoplastic acrylic resin is used as the main ingredient of the plastic paint and is matched with the waterborne polyurethane emulsion, so that hardness of a paint film of the plastic paint can be effectively improved; the design of the composition ingredients is reasonable; the deionized water is used as a solvent for carrying out dilution and replaces an organic solvent, so that the plastic paint is environmental-friendly; abrasion resistance is improved; the plastic paint has a strong adhesive force, good malleability, high-temperature resistance and a long service life; in the coating process, roller coating is adopted to replace spray coating, so that the production environment is effectively improved, and the plastic paint is beneficial to body health of a worker.

Owner:TAICANG JINXIN PAINT

Oil stain cleaning agent and preparation method thereof

InactiveCN104031755AReduce dosageShort cleaning timeNon-ionic surface-active compoundsOrganic detergent compounding agentsWater basedPolyethylene glycol

Owner:王希贵

Paraffin remover and preparation method thereof

InactiveCN104371685AImprove the difficulty that cannot be usedImprove solubilityDrilling compositionPotassium hydroxideSurface-active agents

The invention provides a paraffin remover and a preparation method thereof. The paraffin remover comprises the following components (in percentage by weight): 15%-25% of alcohol ether, 7%-12% of fatty alcohol-polyoxyethylene ether, 0.15%-0.25% of alkali, 13%-15% of antifreezing fluids, 5%-10% of ethylene glycol and 30%-40% of emulsifying agents, wherein the emulsifying agent is a mixture of oleic acid, linoleic acid, composite vinegar of resin and triethanolamine, the antifreezing fluids comprise propylene glycol butyl ether acetate and ethylene glycol butyl ether acetate, and the alkali is any one of sodium hydroxide or potassium hydroxide. The preparation method of the paraffin remover comprises the following steps: adding the alkali to the fatty alcohol-polyoxyethylene ether to generate a surface active agent; adding the surface active agent to alcohol ether, and stirring under the condition of normal temperature and pressure; and then sequentially adding the antifreezing fluids, the ethylene glycol and the emulsifying agents so as to obtain the paraffin remover. The paraffin remover provided by the invention has the advantages of safety in use, low possibility in ignition and low solidifying point and meets the requirement for usage under the condition of extreme cold.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Automobile brake fluid and preparation thereof

InactiveCN101486943AImprove corrosion resistanceGood compatibilityAdditivesPROPYLENE GLYCOL BUTYL ETHEREther

The invention discloses automobile brake fluid and a preparation method thereof, which is prepared by the raw materials of the following weight percentages: 10 to 38 percent of multi-propandiol butyl ether, 60 to 86 percent of multi-propandiol butyl ether borate, 2 to 7 percent of compound additive, and the preparation method thereof. The automobile brake fluid has avirulence, safe reliability, environmental protection and excellent physical and chemical properties, and becomes a product of low cost and high industrialization, more security and reliable and having competitive advantages in price and quality.

Owner:ZHEJIANG SHENZHOU TECH CHEM IND

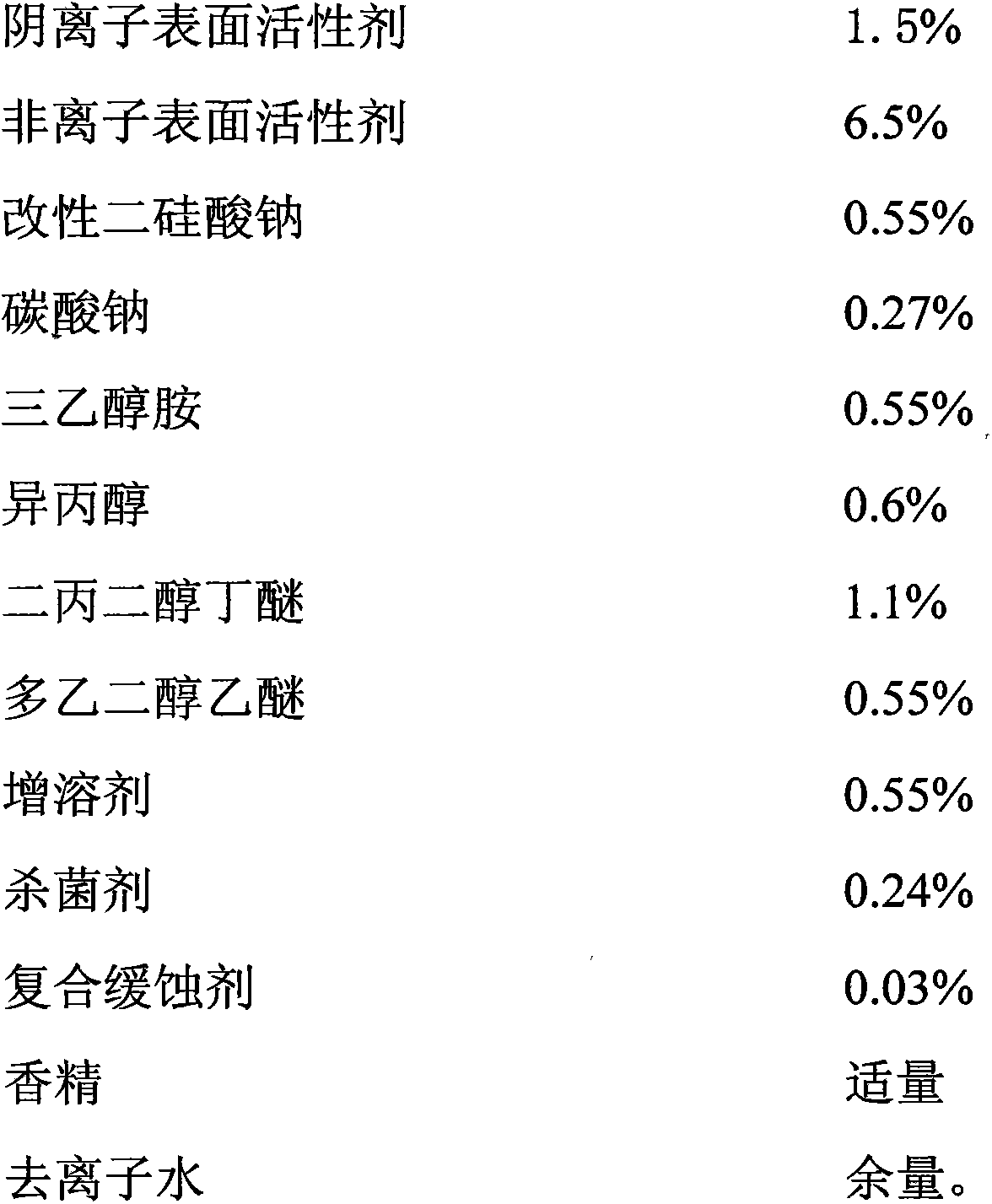

Environmentally-friendly water-based two-component polyurethane coating and preparation method thereof

InactiveCN108165155AGood compatibilityExtended opening hoursPolyurea/polyurethane coatingsWater basedPliability

The invention discloses an environmentally-friendly water-based two-component polyurethane coating and a preparation method thereof. The polyurethane coating is composed of an A component and a B component according to the mass ratio of (2.7-3.0):(0.9-1.0); the A component includes the following materials in percentages by weight: 35-40% of hydroxy acrylate dispersion I, 20%-24% of hydroxy acrylicdispersion II, 0.2%-1.0% of a defoaming agent, 2.0%-3.0% of dipropylene glycol butyl ether, 2.0%-3.0% of ethylene glycol butyl ether, 0.2%-1.0% of a levelling agent, 15%-38% of color paste, and 0.1%-0.3% of a thickener; and the B component includes the following materials in percentages by weight: 30%-33% of propylene glycol diacetate, 43%-49% of polyurethane curing agent I, and 18%-24% of polyurethane curing agent II. The water-based two-component polyurethane coating obtained by the method provided by the invention has better physical and mechanical properties such as hardness, abrasion resistance and flexibility, and performance of water resistance, salt spray resistance, heat and humidity resistance and aging resistance.

Owner:西安经建油漆有限责任公司

Method for synthesizing aqueous hydroxyl polyacrylate dispersoid

InactiveCN104356291AImprove water resistanceGood film weather resistanceCoatingsPROPYLENE GLYCOL BUTYL ETHERWeather resistance

The invention relates to a method for synthesizing aqueous hydroxyl polyacrylate dispersoid. The method comprises the following steps: weighing and adding a certain amount of propanediol butyl ether and tertiary carbonate glycidyl ester into a four-mouth flask with a stirring device, a dripping device, a condensation tube and a heating device, stirring, heating the mixture to the required temperature, dripping a mixed solution containing a part of AA, MMA, St, BA, HEMA and a part of an initiator, keeping the reaction temperature and the stirring speed constant, replenishing a part of the initiator when the temperature is maintained, rapidly replenishing the rest initiator when the temperature is kept, cooling, adding dimethylethanolamine, uniformly stirring, slowly dripping deionized water, emulsifying, filtering, discharging, and obtaining the aqueous hydroxyl polyacrylate dispersoid. The method provided by the invention is simple, low in cost and easy to control, the synthesized aqueous hydroxyl polyacrylate dispersoid is good in water resistance, weather resistance with respect to the paint film, high in light and color maintenance property, high in hardness and rapid to dry.

Owner:重庆市大足区众科管道设备有限公司

Production method of water-based attapulgite conductive paint

InactiveCN102174284ALarge aspect ratioLow densitySilicon compoundsElectrically-conductive paintsWater basedPROPYLENE GLYCOL BUTYL ETHER

The invention discloses a production method of a water-based attapulgite conductive paint. The technical scheme of the invention is characterized in that the production method comprises the following steps: stirring and mixing the ingredients of the water-based attapulgite conductive paint evenly to obtain a mixture; and grinding the mixture in a sanding machine to obtain a semi-finished product, performing vacuum degassing technological treatment on the semi-finished product, and canning to obtain the finished product of the water-based attapulgite conductive paint. The water-based attapulgite conductive paint consists of pasty attapulgite clay, pure acrylic emulsion, a polyaniline / attapulgite nanometer conductive composite, polyethylene glycol, propandiol butyl ether, ethylene glycol, polyoxypropylene glycerin ether and deionized water. The pasty attapulgite clay, polyaniline / attapulgite nanometer conductive composite and pure acrylic emulsion selected by the invention have the advantages of good adhesion, good mechanical properties, better corrosion resistance and excellent mechanical properties; the conductivity of the water-based attapulgite conductive paint with low content is still excellent; and the production method is suitable for the production of the water-based attapulgite conductive paint.

Owner:XUYI BOTU ATTAPULGITE CLAY HIGH TECH DEV +1

Modified polyurethane thermal-insulation composite board

The invention discloses a modified polyurethane thermal-insulation composite board. The composite board sequentially comprises a gypsum board layer, a thermal-insulation board layer and a cement board layer from inside to outside, wherein the thermal-insulation board layer is prepared from modified polyurethane, acrylate, diisocyanate, an alkyd resin, dipropylene glycol monobutyl ether, an organic silicon resin, a melamine formaldehyde resin, chlorinated paraffin, diisocyanate, nitrocellulose, glass fibers, nano calcium carbonate, perlite, fly ash, magnesium oxide, n-octanol, lauryl alcohol, hexadecanol, polymer dibasic alcohol, fluorine-containing polyether dibasic alcohol, a compatilizer, an emulsifier, a foaming agent, a silane coupling agent, a curing agent and silicone oil. The modified polyurethane thermal-insulation composite board has excellent thermal insulation property and excellent heat resistance.

Owner:ANHUI GUANGYAN NEW MATERIAL TECH

High-temperature-resistant high-pressure-resistant water-based wood paint and preparation method thereof

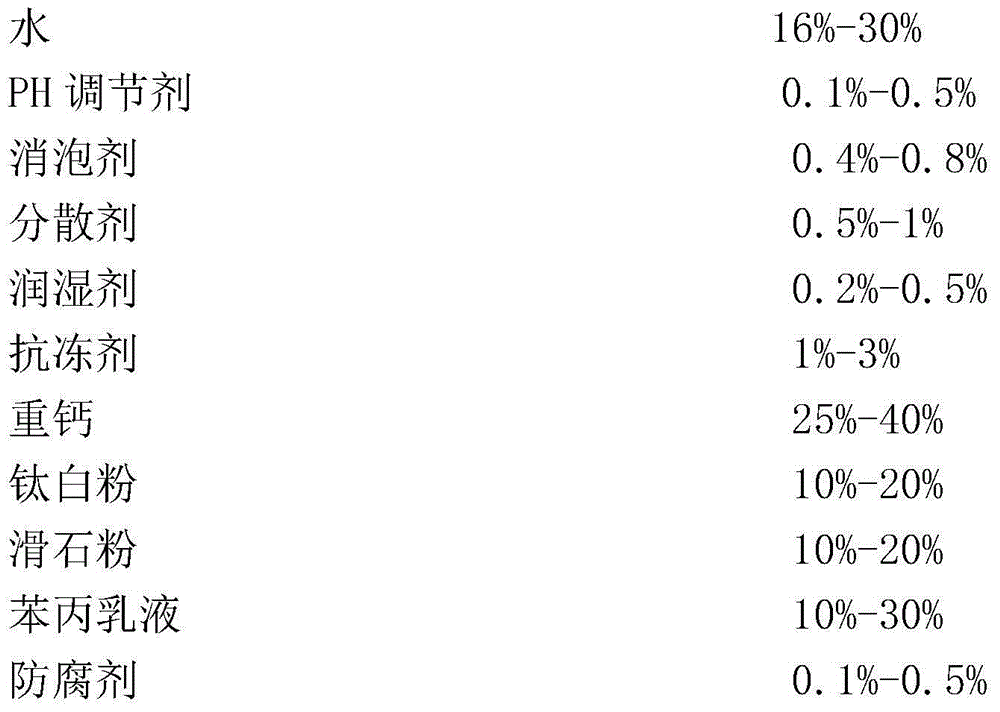

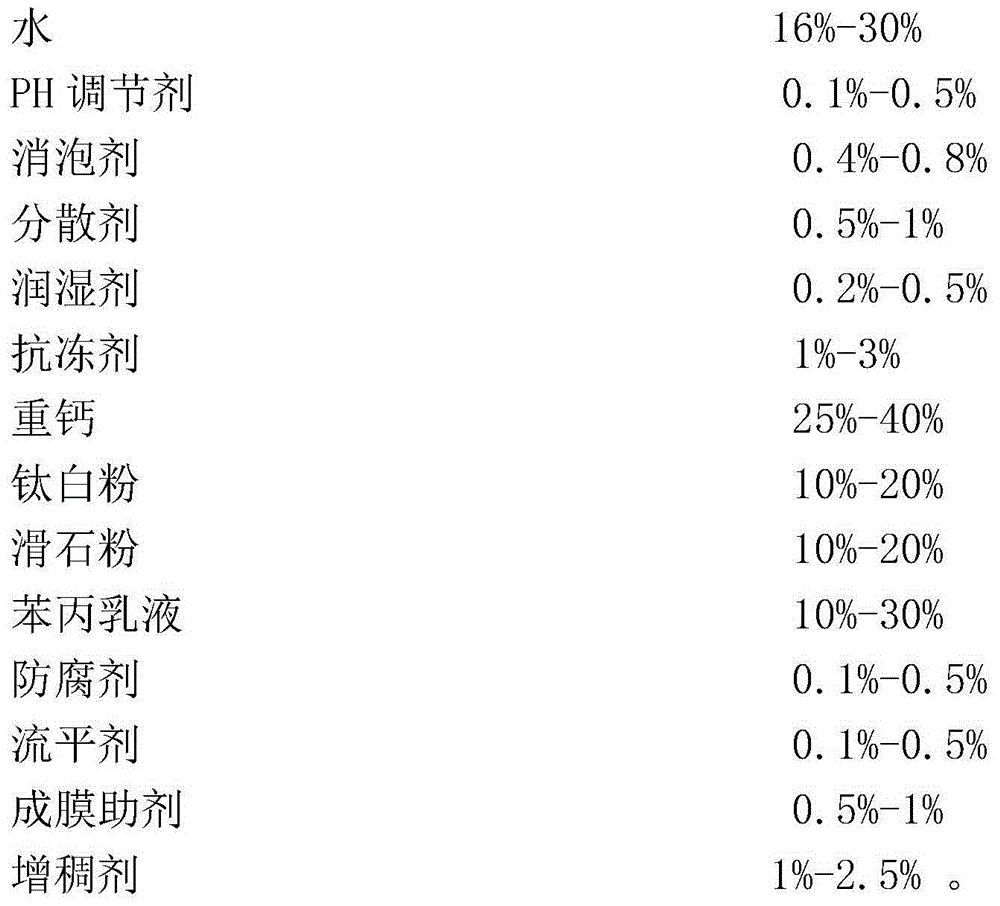

The invention relates to a high-temperature-resistant high-pressure-resistant water-based wood paint and a preparation method thereof. The preparation method comprises the following steps: a. selecting a proper dispersion tank, and adding water; b. adding Aqualon hydroxyethyl cellulose 250HBR; c. adding a pH regulator, a defoaming agent, a dispersing agent, a wetting agent, propanediol, Sannong heavy calcium carbonate 1200, Baiyuying rutile titanium white HTR-668 and Guangxi Longshenghuamei 1250-mesh talcum powder; d. stirring for 10-20 minutes; e. selecting another proper dispersion tank, adding Yizhong Business styrene-acrylic emulsion ER98, and adding ready-made slurry; f. sequentially and slowly adding Thor preservative R-S, Xin'an Business leveling agent XHG-248 and a film forming assistant dipropylene glycol monobutyl ether; g. adding Rohm and Haas thickener ASE60 and Rohm and Haas thickener RM8W; and h. filtering through a 200-mesh screen, and packaging. The water-based wood paint can resist 120-DEG C high temperature and high pressure to satisfy the press fitting technique of the painted semi-finished product material under high-temperature high-pressure conditions, and can not have the phenomena of adhesion and shedding of the paint film due to overhigh local temperature in the high-temperature transportation process.

Owner:SKSHU PAINT

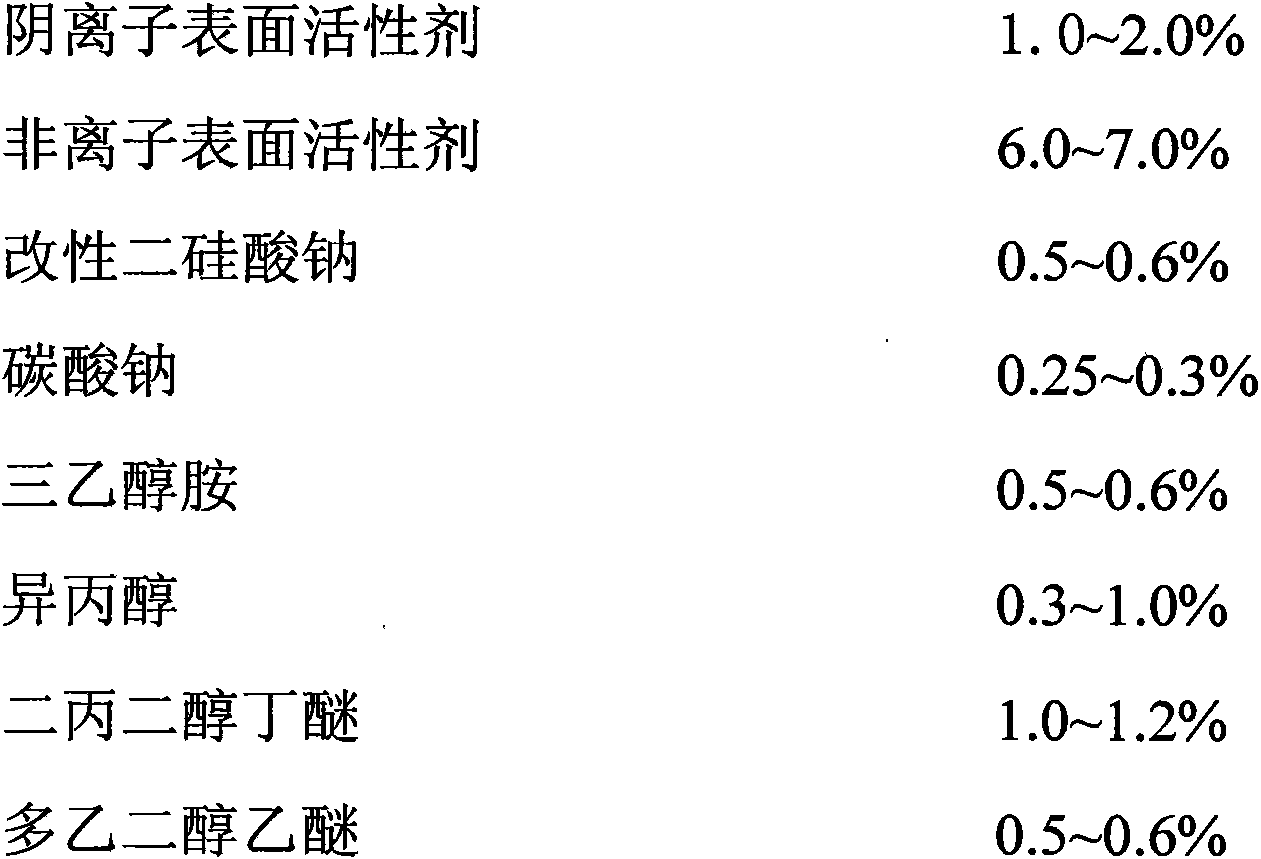

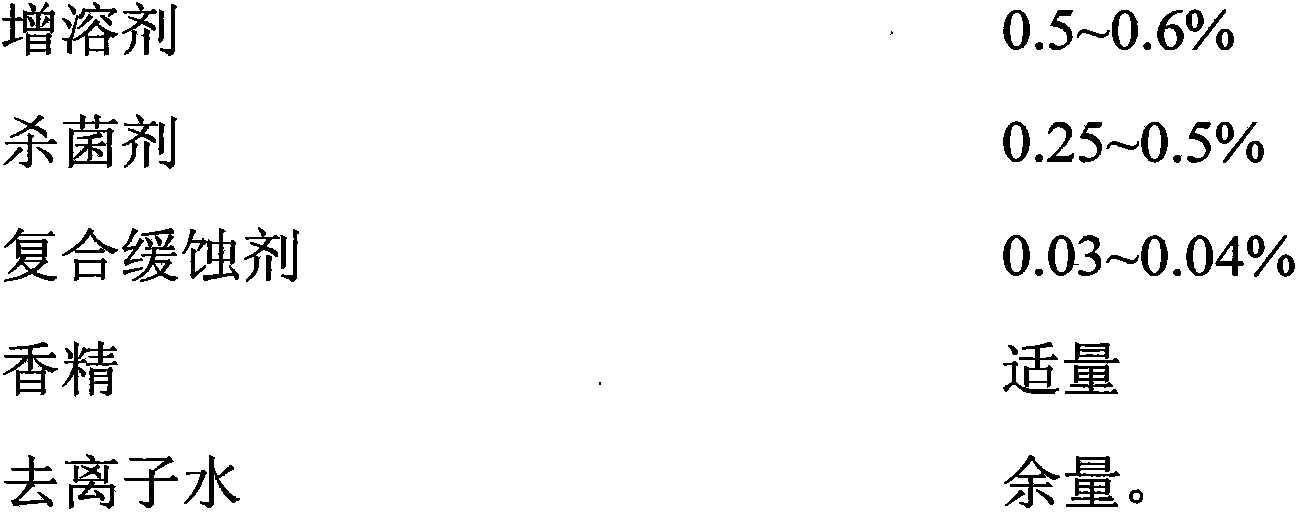

Dry cleaning agent for clothes and preparation method thereof

The invention relates to a dry cleaning agent for clothes and a preparation method thereof. The dry cleaning agent for the clothes takes sodium fatty alcohol-polyoxyethyleneether sulfate (70 percent), fatty alcohol polyoxyethylene ether (9), a modified siloxane surfactant, di-propylene glycol butyl ether, 3-methoxyl-3-methyl-1-butanol, sodium citrate, polyacrylate, citric acid, isothiazolinone, essence, and deionized water as raw materials. The dry cleaning agent for the clothes has the advantages of convenient and quick use, good decontamination effect, and no trace after the use, can meet the demand of removing local stains of the clothes and cloth, and save the energy source consumed by whole cleaning; and a product of the invention is a water-based dry cleaning agent for clothes, does not pollute the environment, ensures that the biodegradation rate reaches more than 90 percent, and is a green environment-friendly washing product.

Owner:北京绿伞科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com