Aqueous antirust paint with rust

A rust-proof, water-based technology, used in anti-corrosion coatings, polyester coatings, coatings, etc., can solve problems such as damage to the ecological environment, air pollution, and harm to the health of users, to overcome pollution, save money, reduce The effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

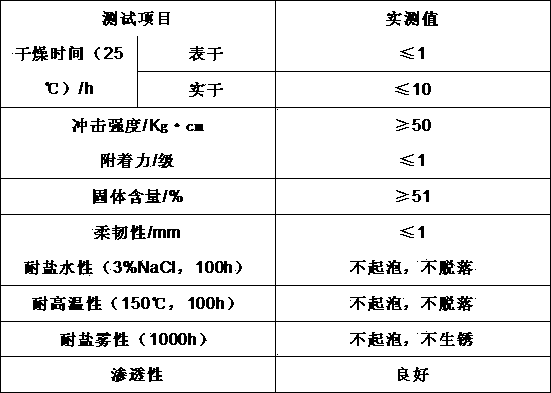

Image

Examples

Embodiment 1

[0014] A water-based antirust paint with rust, comprising the following raw materials in parts by weight: 100 parts of acrylic emulsion, 8 parts of alkyd resin, 6 parts of benzotriazole, 7 parts of basic calcium zinc molybdate, propylene glycol butyl ether 5 parts, 0.1 parts of zinc phosphate, 0.5 parts of citric acid, 0.1 parts of red iron oxide, 0.5 parts of silicon micropowder, 0.1 parts of hydroxypropyl cellulose, 0.1 parts of dibutyltin dilaurate, 0.1 parts of sodium hexametaphosphate, polyether modified 0.1 parts of silicone oil, 4 parts of deionized water.

[0015] The preparation method of the water-based antirust paint with rust of the present embodiment is: (1) acrylic acid emulsion, alkyd resin, benzotriazole, propylene glycol butyl ether, citric acid, hydroxypropyl cellulose, dibutyltin dilaurate , Sodium hexametaphosphate and polyether modified silicone oil are added to water at room temperature and stirred evenly to obtain a slurry; (2) Basic calcium zinc molybda...

Embodiment 2

[0018] A water-based antirust paint with rust, comprising the following raw materials in parts by weight: 120 parts of acrylic acid emulsion, 11 parts of alkyd resin, 8 parts of benzotriazole, 10 parts of basic calcium zinc molybdate, propylene glycol butyl ether 8 parts, 0.3 parts of zinc phosphate, 1 part of citric acid, 0.3 parts of iron oxide red, 5 parts of silicon micropowder, 0.2 parts of hydroxypropyl cellulose, 0.3 parts of dibutyltin dilaurate, 1 part of sodium hexametaphosphate, polyether modified 0.5 parts of silicone oil, 10 parts of deionized water.

[0019] The preparation method of the water-based antirust paint with rust of the present embodiment is: (1) acrylic acid emulsion, alkyd resin, benzotriazole, propylene glycol butyl ether, citric acid, hydroxypropyl cellulose, dibutyltin dilaurate , Sodium hexametaphosphate and polyether modified silicone oil are added to water at room temperature and stirred evenly to obtain a slurry; (2) Basic calcium zinc molybda...

Embodiment 3

[0022] A water-based antirust paint with rust, comprising the following raw materials in parts by weight: 110 parts of acrylic acid emulsion, 9 parts of alkyd resin, 7 parts of benzotriazole, 8 parts of basic calcium zinc molybdate, propylene glycol butyl ether 6 parts, 0.2 parts of zinc phosphate, 0.8 parts of citric acid, 0.2 parts of red iron oxide, 3 parts of silicon micropowder, 0.15 parts of hydroxypropyl cellulose, 0.18 parts of dibutyltin dilaurate, 0.4 parts of sodium hexametaphosphate, polyether modified 0.25 parts of silicone oil, 8 parts of deionized water.

[0023] The preparation method of the water-based antirust paint with rust of the present embodiment is: (1) acrylic acid emulsion, alkyd resin, benzotriazole, propylene glycol butyl ether, citric acid, hydroxypropyl cellulose, dibutyltin dilaurate , Sodium hexametaphosphate and polyether modified silicone oil are added to water at room temperature and stirred evenly to obtain a slurry; (2) Basic calcium zinc m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com