Patents

Literature

100results about How to "Reduce construction links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

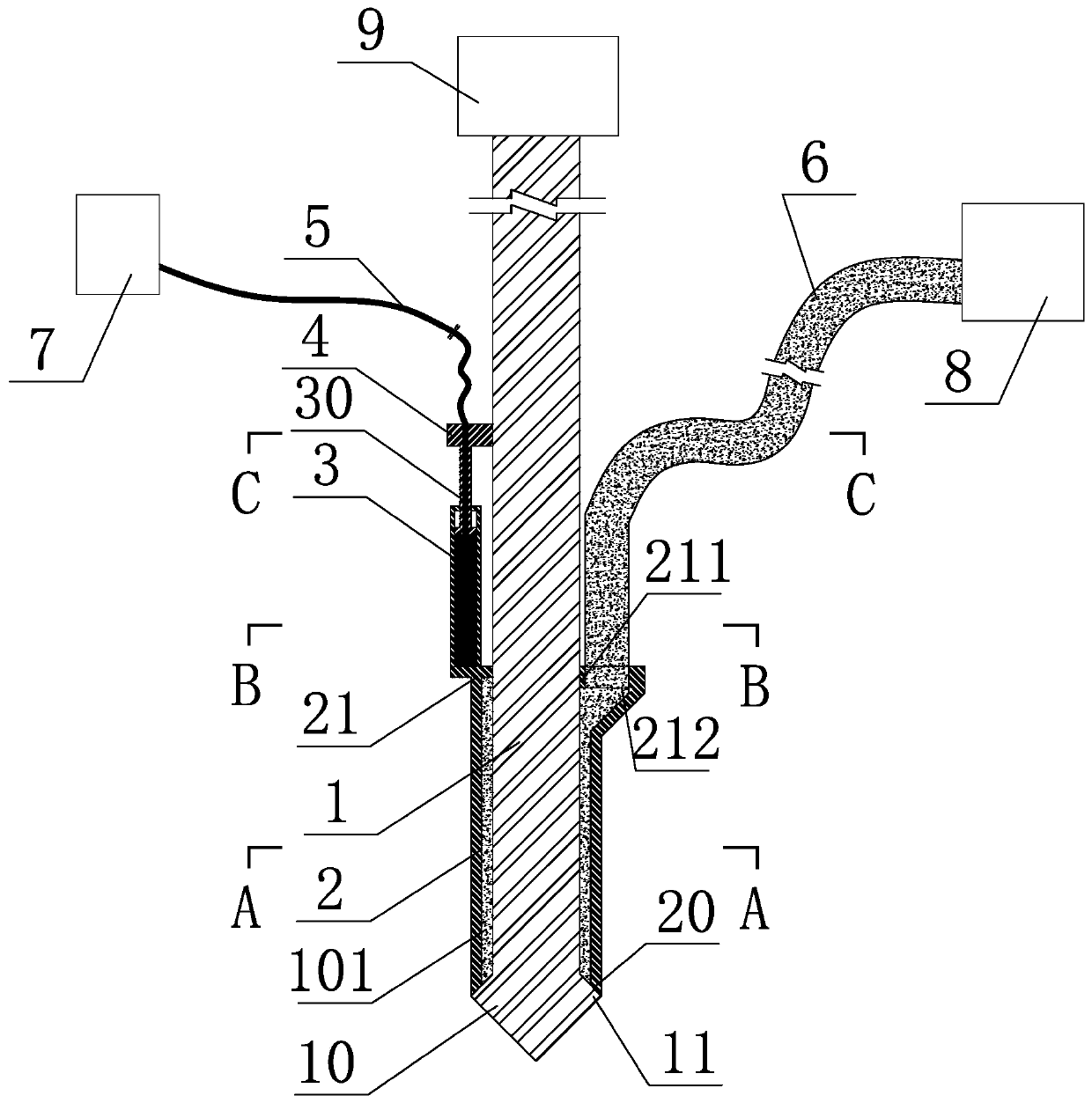

Steel pipe column concrete jacking construction method

ActiveCN103643740AEasy to operateReduce construction costsStrutsBuilding material handlingSocial benefitsArchitectural engineering

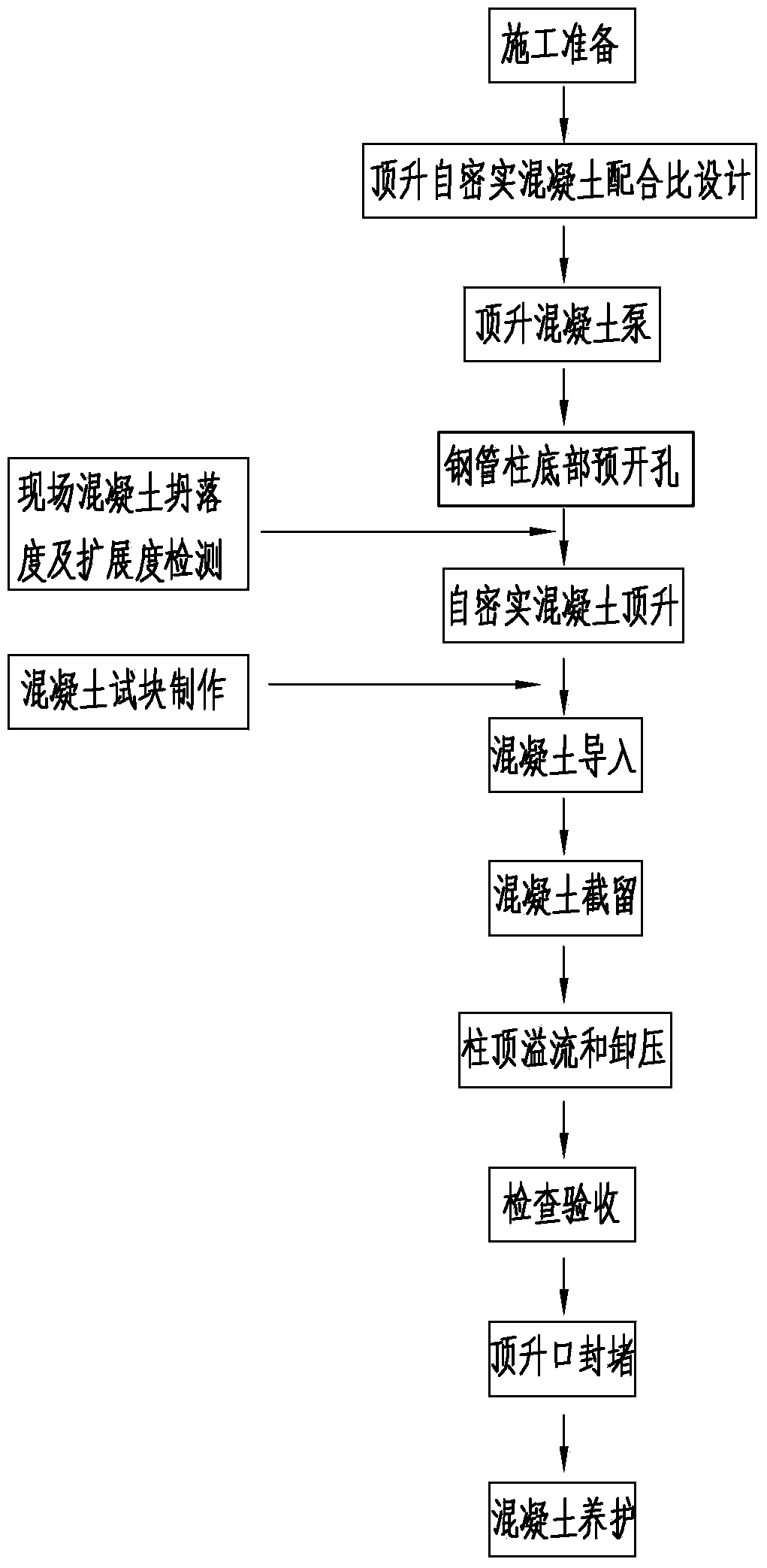

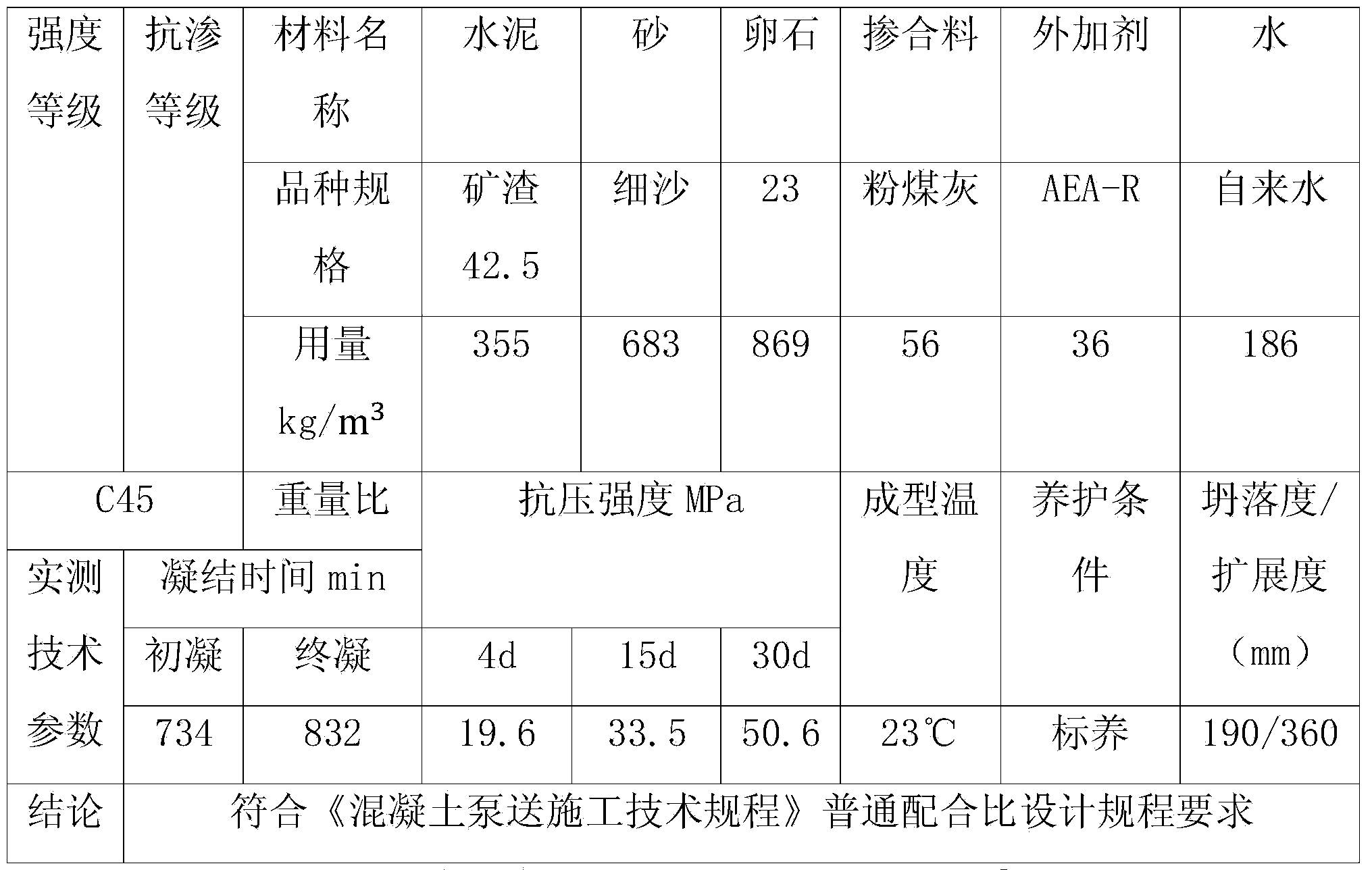

The invention discloses a steel pipe column concrete jacking construction method which comprises the following steps of (1) construction preparing, (2) jacking self-compacting concrete design, (3) concrete pump jacking, (4) steel pipe column bottom hole performing, (5) self-compacting concrete jacking, (6) concrete guiding in, (7) concrete retaining, (8) column top overflow and pressure relief, (9) examining and accepting, (10) jacking opening sealing and (11) concrete curing. Concrete core filling is carried out in a steel pipe column, mechanical characteristics of a steel structure and concrete are well combined, steel materials are saved, construction technologies such as corresponding closure, overflow and pressure relief device and self-compacting concrete application are combined, concrete does not need vibration self-flow compacting, construction efficiency is high, the construction period is short, concrete one-time jacking concrete in the high steel pipe column is achieved, accordingly, construction links are reduced, construction speed is accelerated, construction quality is guaranteed, and economic benefit and social benefit are obvious.

Owner:ZHEJIANG JIANGNANCHUN CONSTR GRP

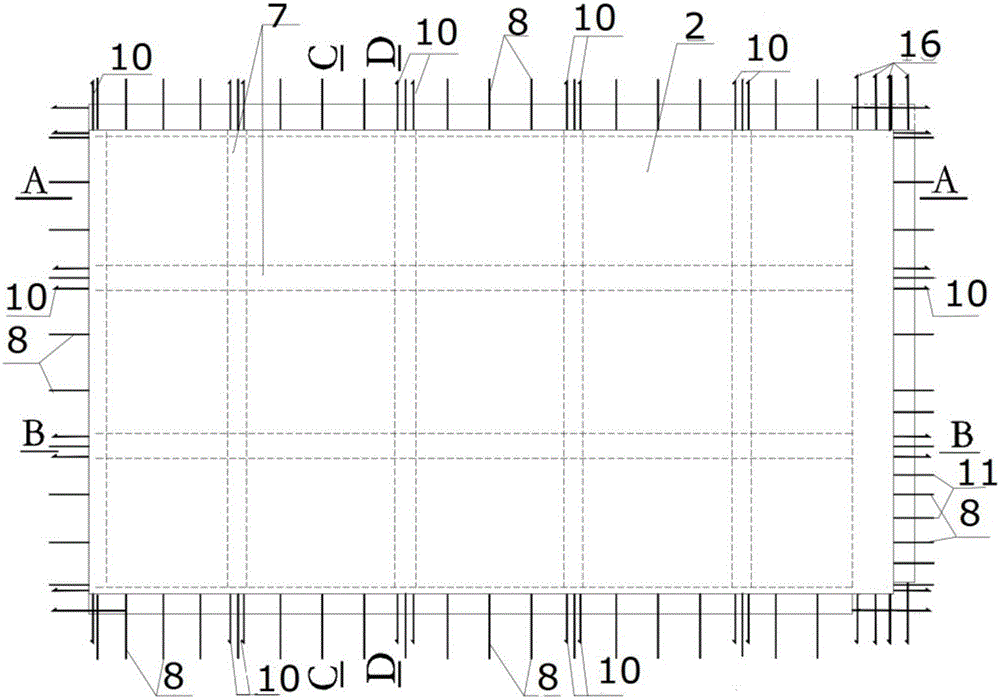

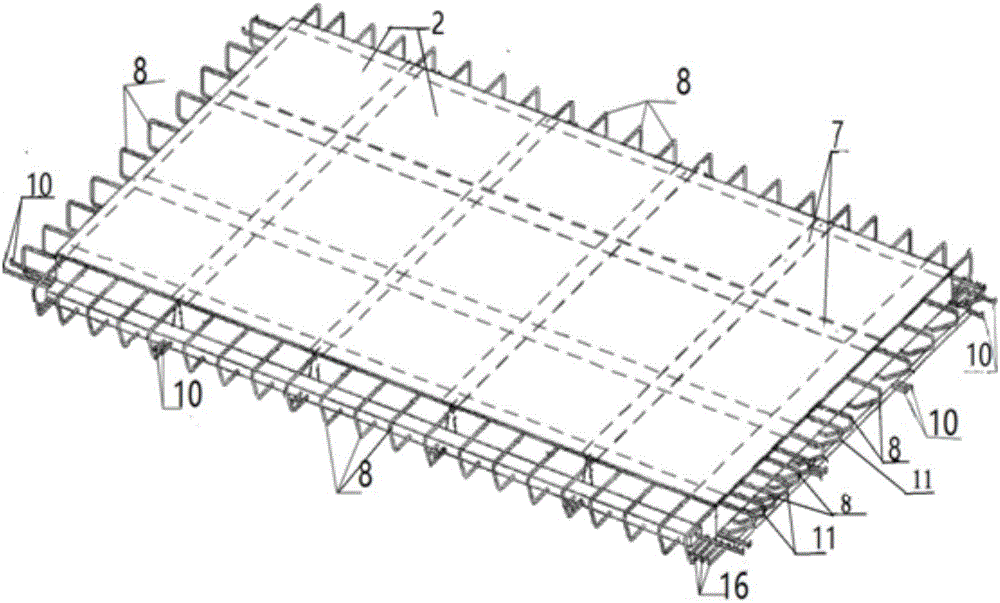

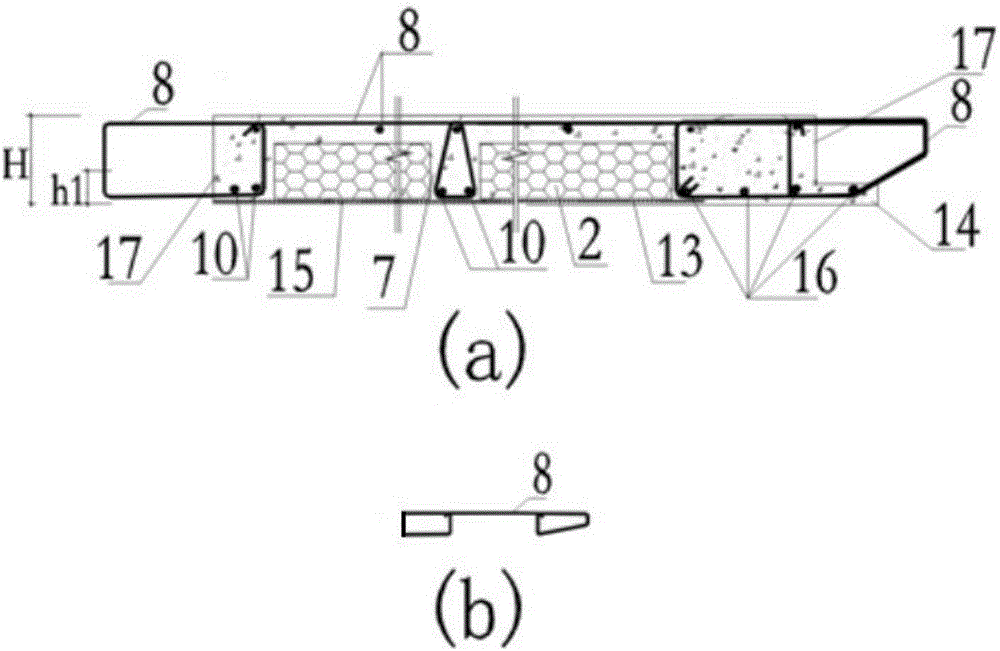

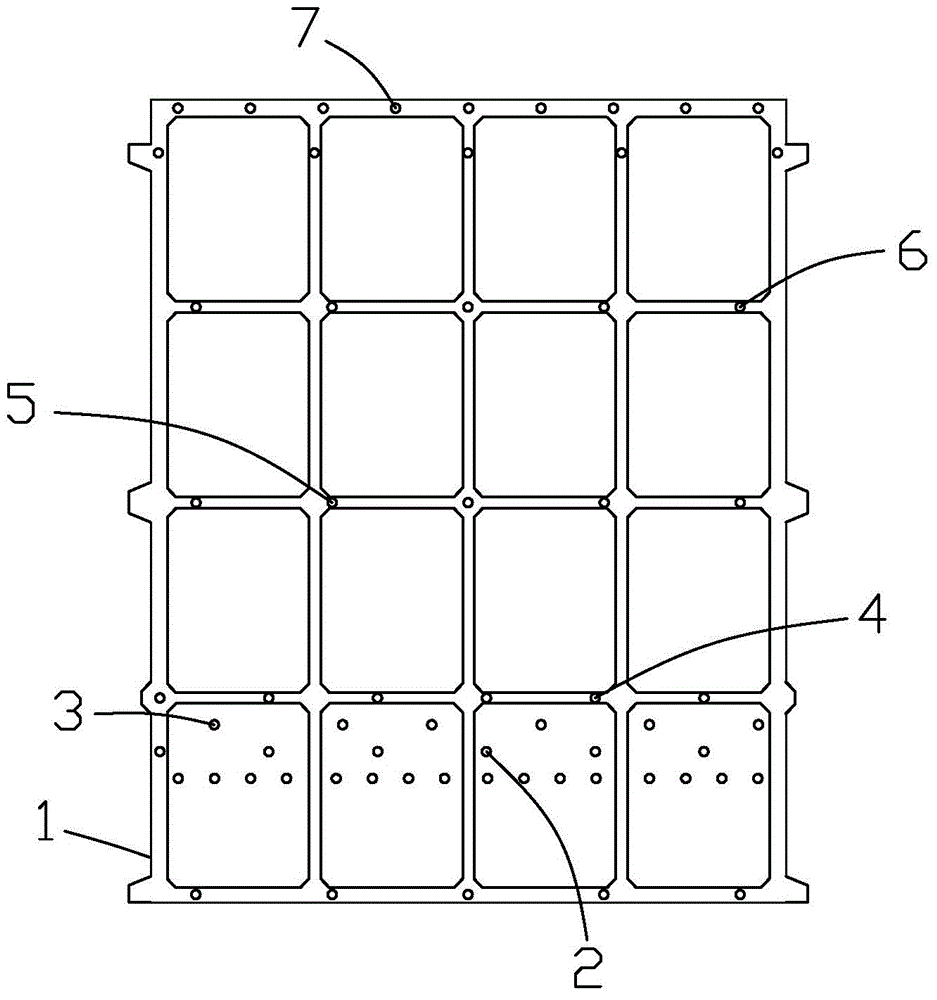

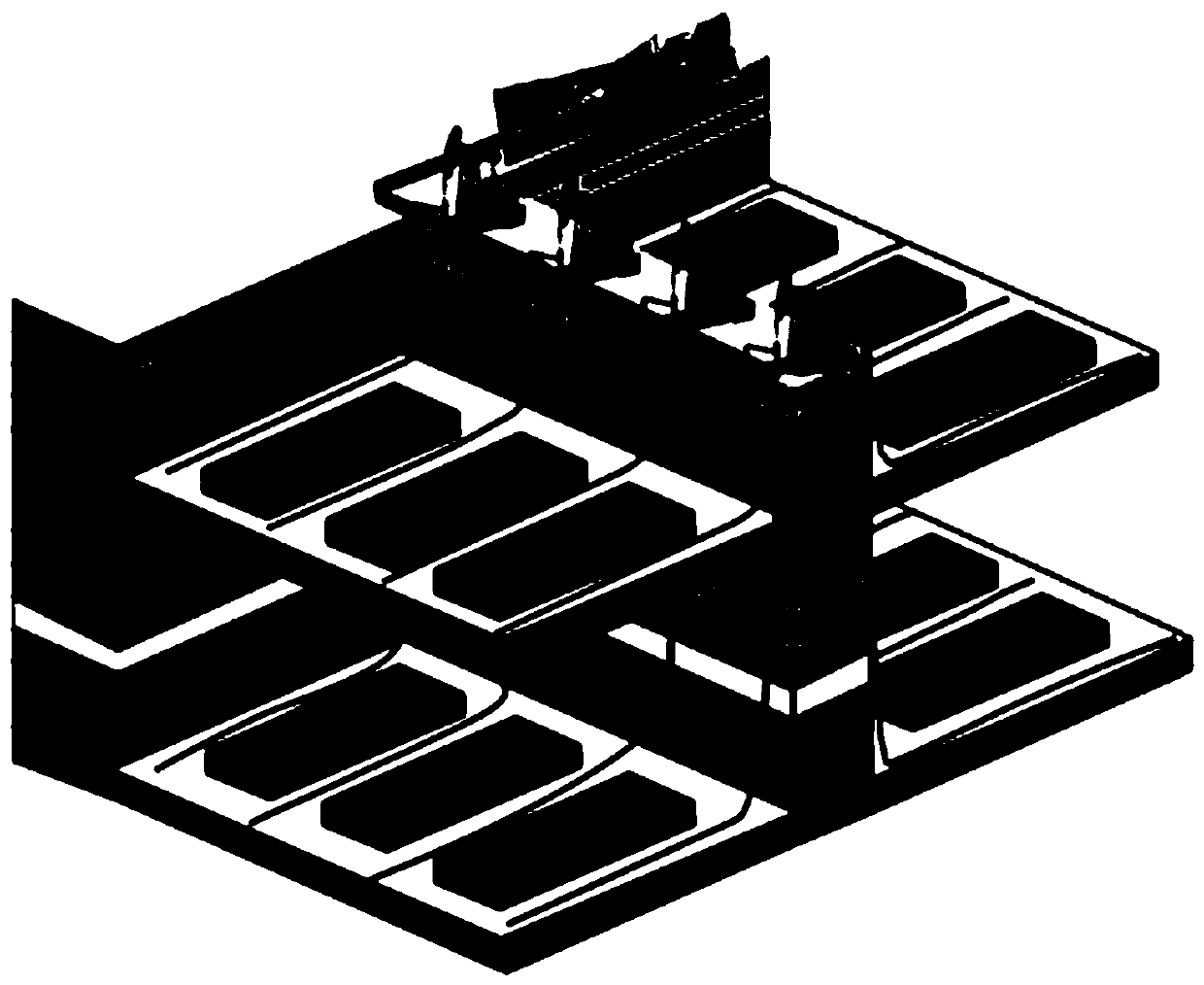

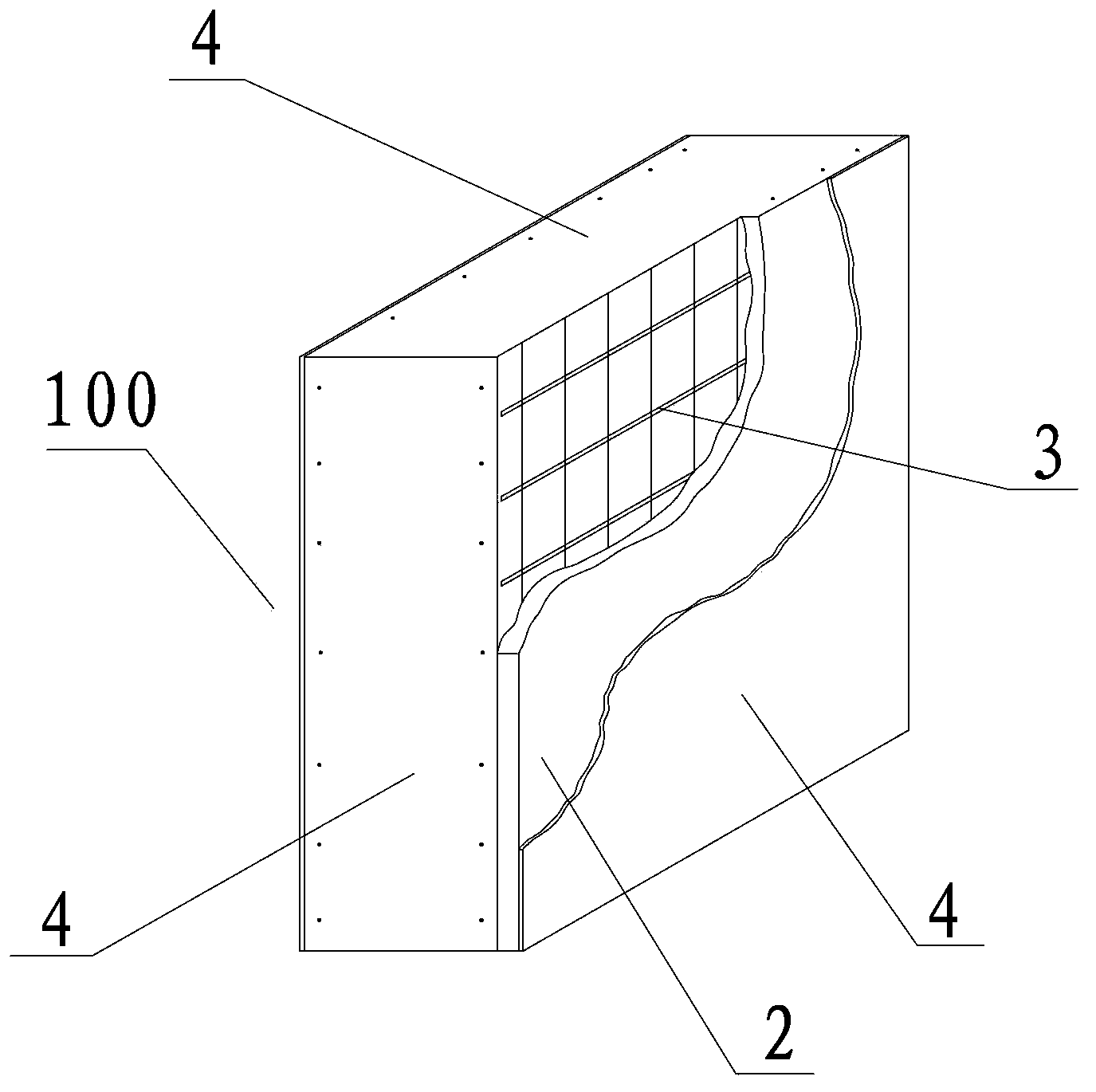

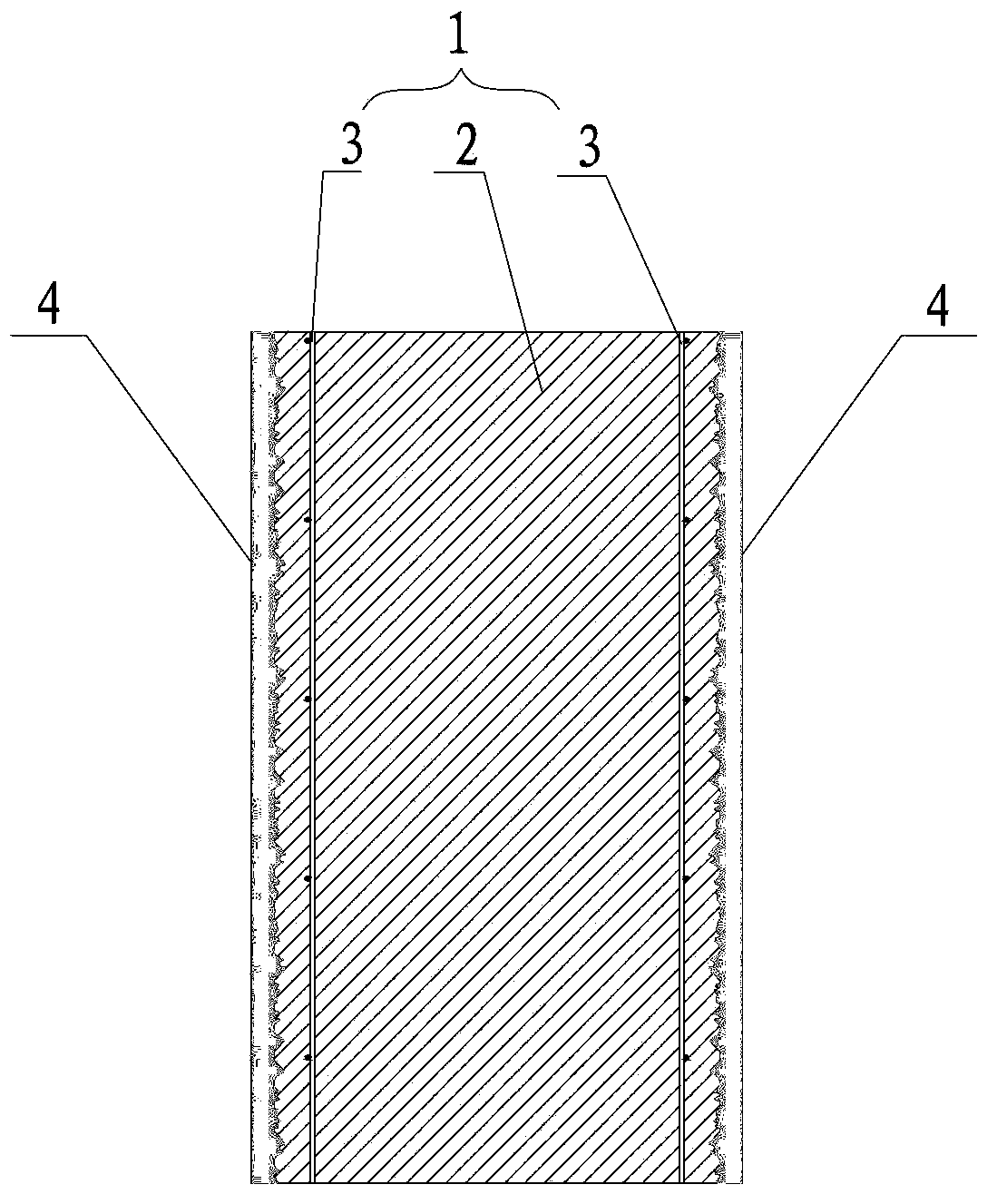

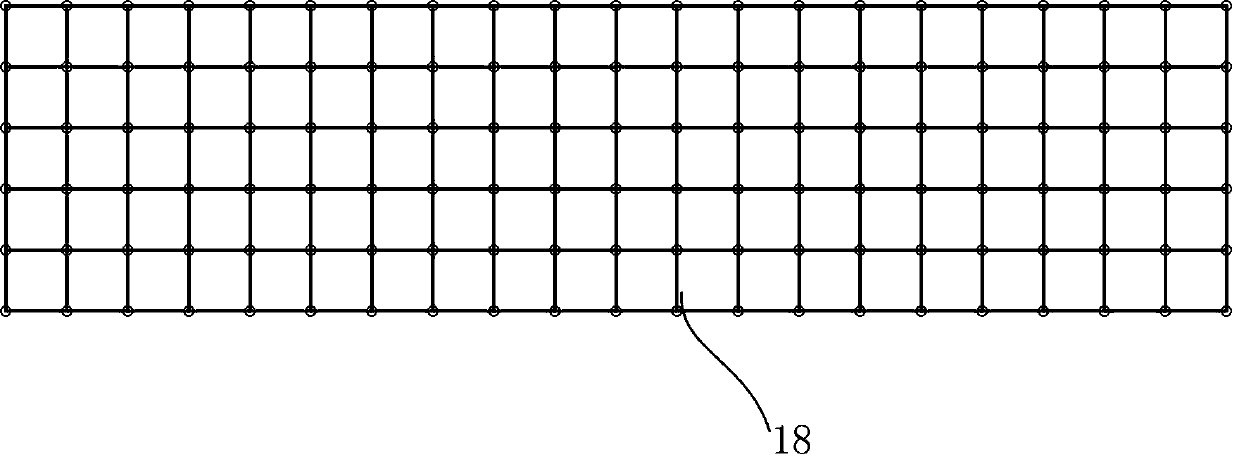

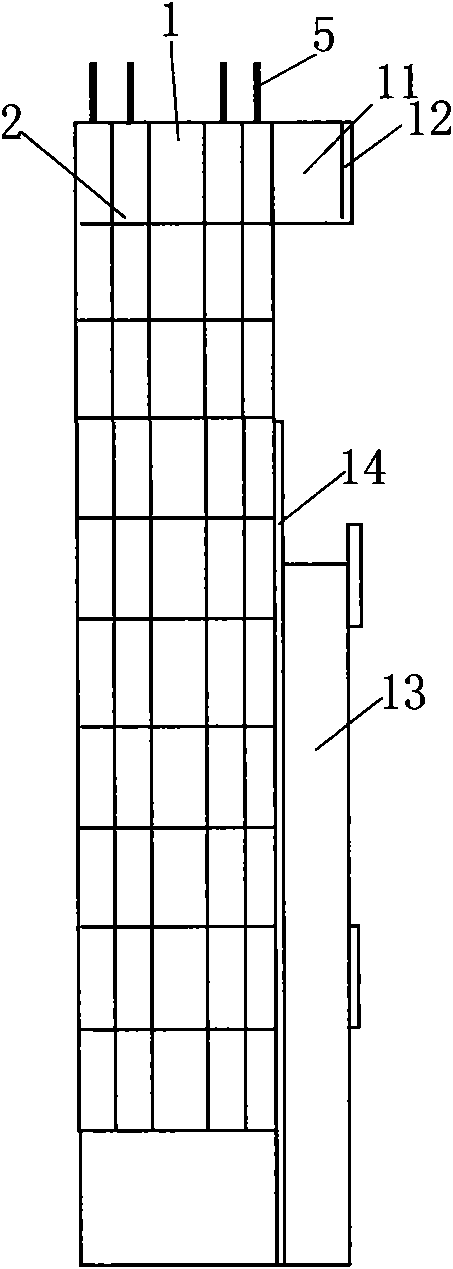

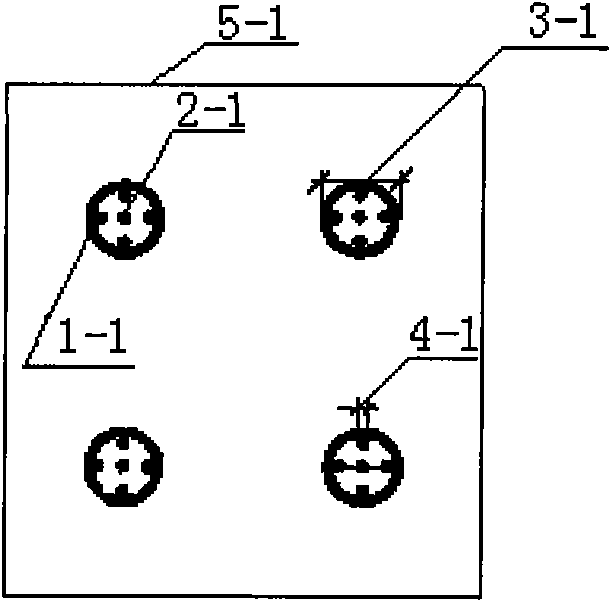

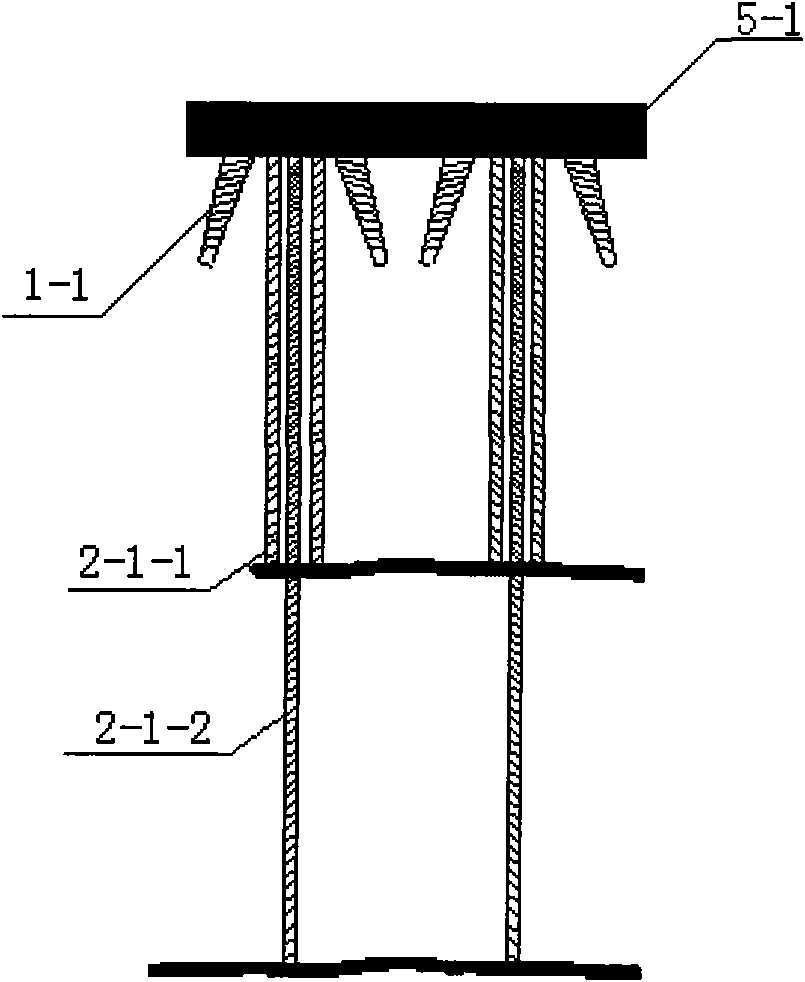

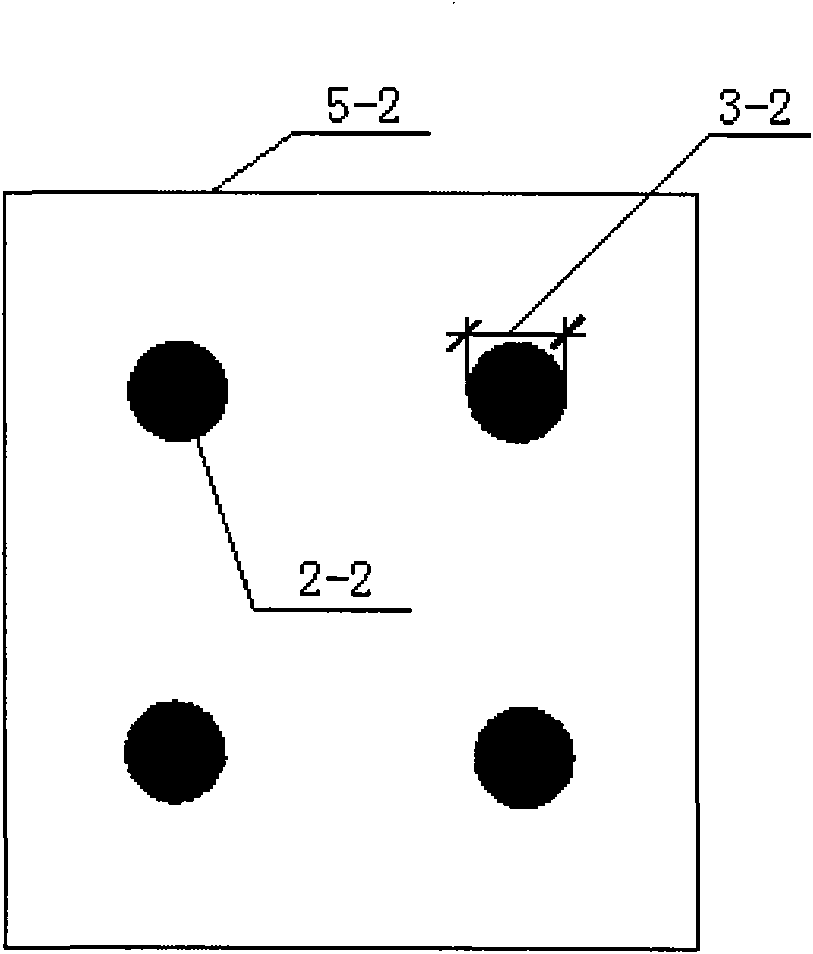

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

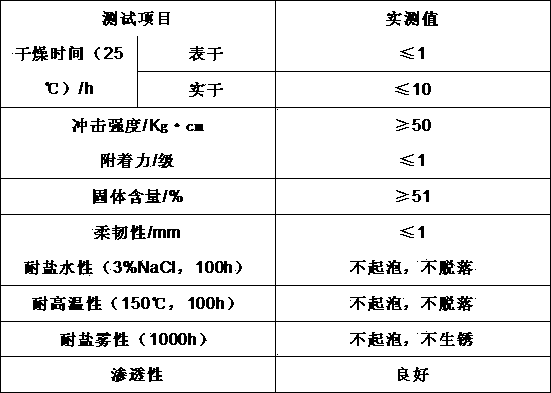

Aqueous antirust paint with rust

ActiveCN103409017AAvoid pollutionImprove corrosion resistanceAnti-corrosive paintsPolyester coatingsCelluloseDibutyltin dilaurate

The present invention relates to an aqueous antirust paint with rust. The aqueous antirust paint is characterized by comprising the following raw materials, by weight: 100-120 parts of an acrylic acid emulsion, 8-11 parts of an alcoholic acid resin, 6-8 parts of 1H-benzotriazole, 7-10 parts of basic calcium molybdate zinc, 5-8 parts of propanediol butyl ether, 0.1-0.3 part of zinc phosphate, 0.5-1 part of citric acid, 0.1-0.3 part of iron oxide red, 0.5-5 parts of silicon micro-powder, 0.1-0.2 part of hydroxypropyl cellulose, 0.1-0.3 part of dibutyltin dilaurate, 0.1-1 part of a dispersing agent, 0.1-0.5 part of an antifoaming agent, and 4-10 parts of deionized water. The product has characteristics of the conversion type coating material with rust and the stability type coating material with rust, and can be directly sprayed or brushed without a surface treatment during use so as to reduce construction steps and save cost. In addition, the product adopts water as a solvent so as to overcome pollution of the solvent type coating material on the environment.

Owner:WUJIANG JUNDA ELEVATOR PARTS

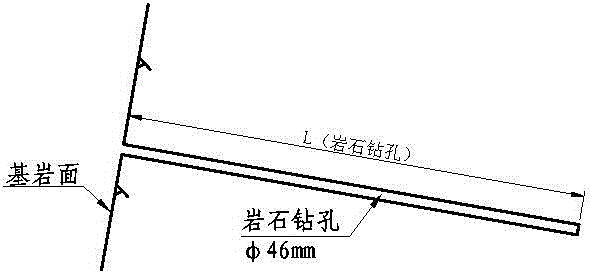

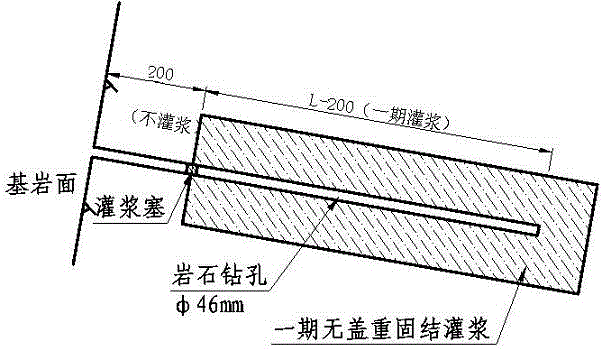

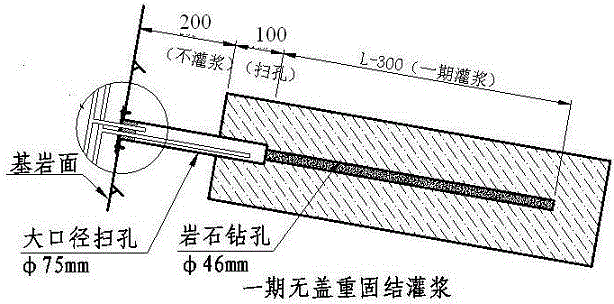

High-mountain narrow-valley arch dam foundation segmented and staged grouting method

The invention relates to a high-mountain narrow-valley arch dam foundation segmented and staged grouting method, and belongs to a foundation treatment method of a rock surface of a high steep bank slope foundation of a high-mountain narrow-valley arch dam foundation. The high-mountain narrow-valley arch dam foundation segmented and staged grouting method comprises the following steps: carrying out consolidation grouting and drilling after acceptance of excavation of the arch dam foundation; carrying out first-stage consolidation on the inside of a consolidation grouting hole; drilling a residual contact segment by the distance of 1 m with a phi 75 mm drilling sleeve after first-stage consolidation grouting is finished; burying a grouting system; pouring dam body concrete after first-stage consolidation grouting is finished; after joint grouting of a dam body is finished or while joint grouting of the dam body is carried out, carrying out second-stage consolidation on a consolidation grouting contact segment of the dam foundation. Consolidation of a bed rock contact segment and contact grouting are combined together, meanwhile, effects of contact segment consolidation and contact grouting are achieved, the work amount of the contact grouting system is reduced, the construction period is shortened, a construction technology is simplified, foundation treatment purposes of a high steep bank slope of the dam foundation of simplicity and convenience in construction, reliable technology, economy and reasonableness of grouting treatment of the high steep bank slope are achieved, and the problems encountered in foundation treatment of a dam segment of a bank slope are solved.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

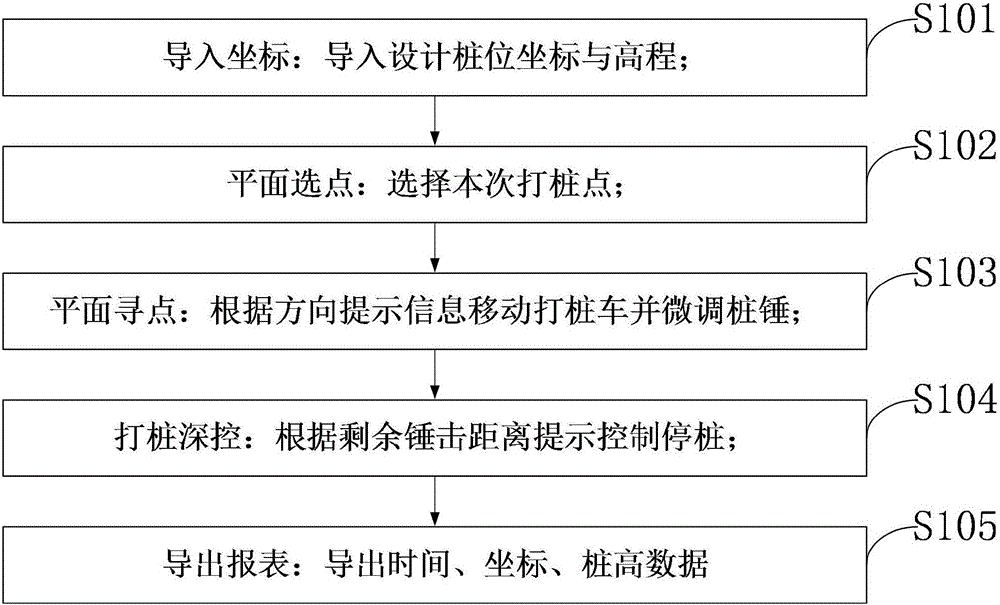

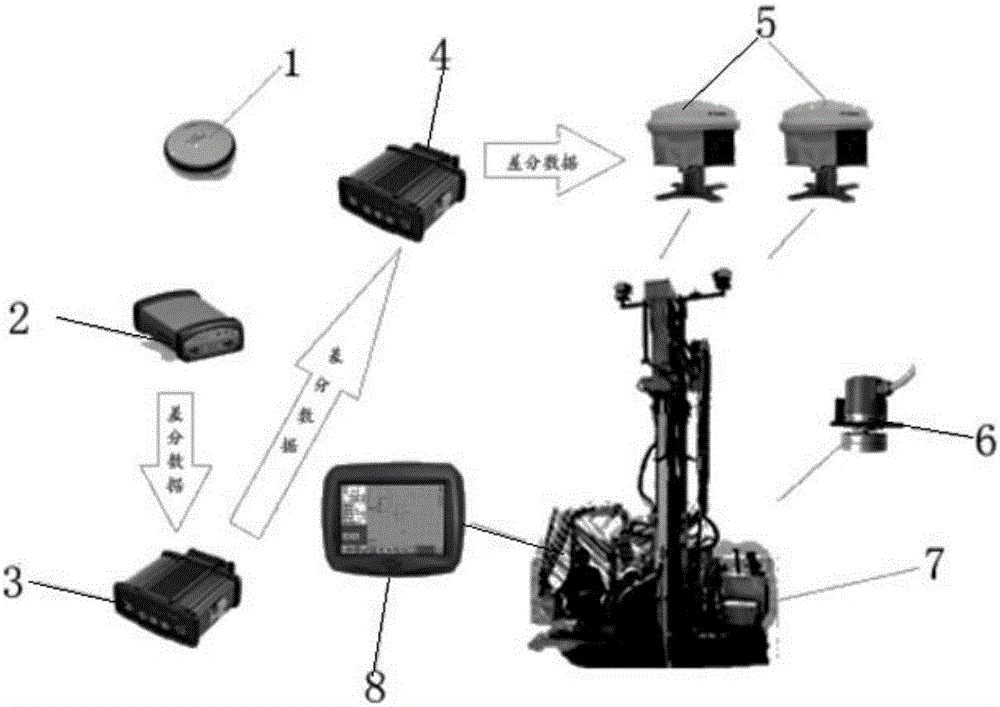

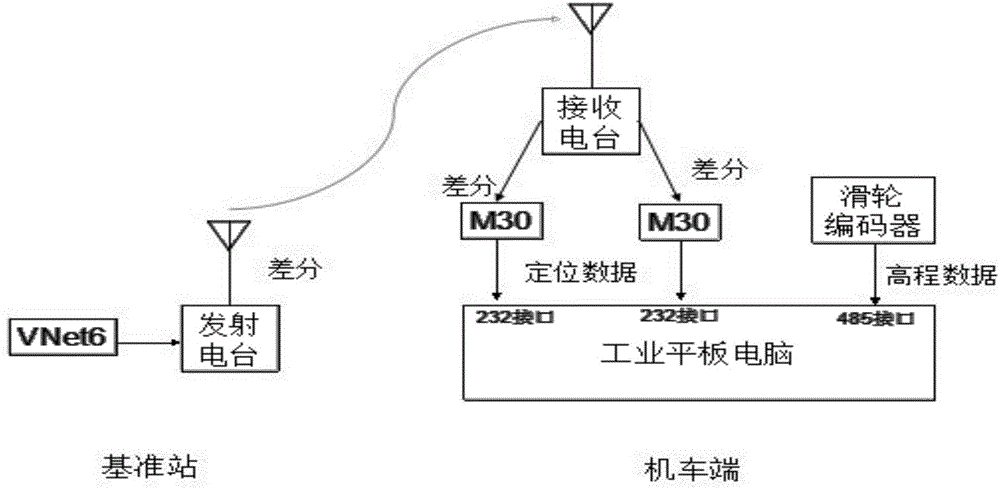

Land piling system and method precisely guiding driver to look for piling points

InactiveCN106592589AImprove reliabilityMeet centimeter-level high-precision positioning requirementsBulkheads/pilesEngineeringHamming distance

The invention discloses a land piling system and method precisely guiding a driver to look for piling points. The method comprises the steps: importing coordinates: importing designed pile site coordinates and elevations; selecting points in a plane; selecting the piling point this time; looking for the point in the plane: moving a piling trolley according to direction prompt information and micro-turning a piling hammer; piling depth control: prompting to control pile stop according to a residual hamming distance; and exporting a report form: exporting time, coordinate, pile height data. The invention discloses the land piling system precisely guiding driver to look for piling points as well. A high-precision positioning GNSS positioner product designed for conditions of a severe construction environment and strong vibration of engineering machinery, the high-precision positioning GNSS positioner product supporting Beidou satisfies centimetre-level high-precision positioning requirements of machinery such as mining machinery, earthwork machinery, construction positioning machinery, piling machinery, transporting machinery, locomotives and the like. The product is the first mechanical positioner at home and is high in reliability.

Owner:王强

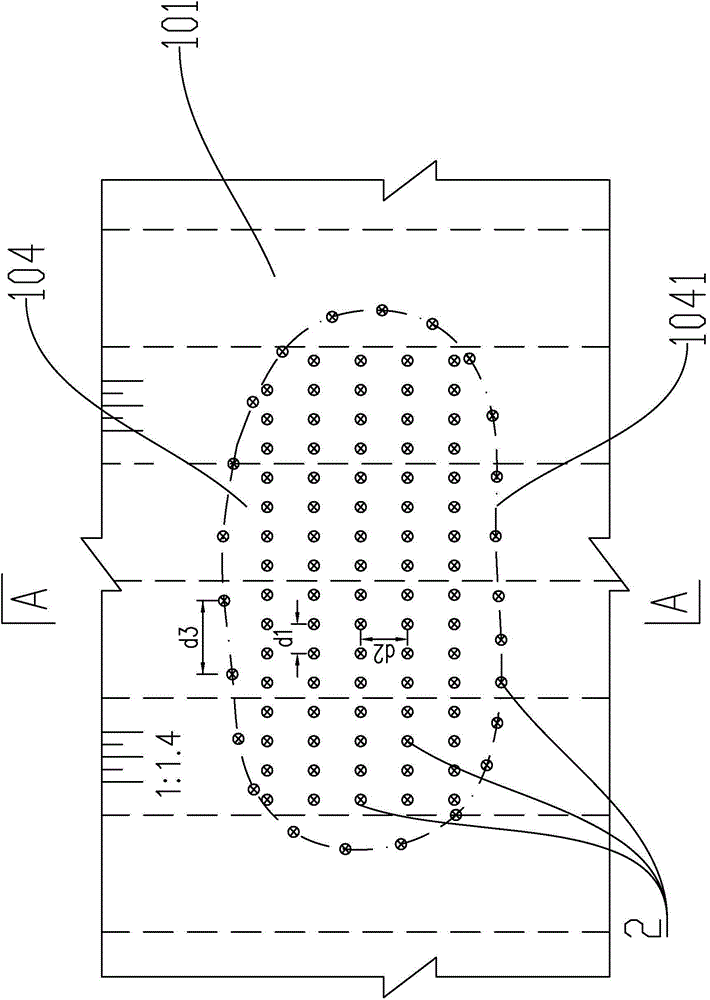

Concrete panel void repairing method

InactiveCN104912039AEnsure safetyEasy to operateFoundation engineeringEarth-fill damsHot weatherQuincunx

The invention relates to a concrete panel void repairing method. The purpose is to improve the efficiency of concrete anti-leakage panel void repairing and enhance the safety and reliability of engineering operation. According to the technical scheme, the method includes the steps that a, void region detection is performed, LTD ground penetrating radar is adopted for detecting a panel void region and determining the panel void region, and void depth information is collected; b, grouting hole positions are arranged inside the panel void region, the distance d1 between grouting holes is equal to 2 m-3 m, the row distance d2 is equal to 2 m-4 m, and quincunx-type arrangement or rectangular arrangement can be performed; c, drilling is performed according to the arrangement of the grouting hole positions; d, grouting starts to be performed upwards step by step from the lower portion of a panel in the grouting process; e, after two hours from grouting, cement mortar is adopted for plugging the grouting holes, the plugging height is larger than the height of the panel by about 3 mm-5 mm, and the surface of the panel is polished to be flat after standing for about 8 hours; f, in hot weather, water should be sprayed to the void repairing region for maintenance.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

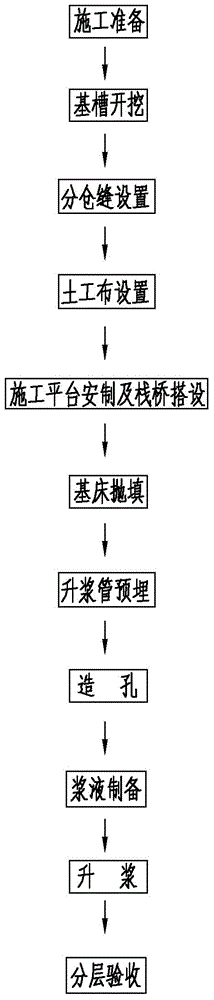

Grouting-to-stop-water construction method of underwater rubble bed

InactiveCN104153371AEasy to makeEasy constructionFoundation engineeringSocial benefitsEconomic benefits

The invention discloses a grouting-to-stop-water construction method of an underwater rubble bed. The method includes the steps of (1) construction preparation, (2) base slot excavation, (3) points warehouse seam arrangement, (4) geotextile arrangement, (5) construction platform installation and trestle setting up, (6) bed dump-filling, (7) grouting pipe embedding, (8) pore-forming, (9) grout preparation, (10) grouting and (11) layer-by-layer inspection and acceptance. The method has the advantages that a vibratory grouting formation method is adopted for construction, rubble is not required for concrete mixing, water in coarse aggregate gaps can be completely replaced with mortar during underwater construction, a mixer is not needed for mixing aggregate, construction is facilitated, construction progress is quickened beneficially, the pumping technology is improved as compared with that of normal concrete, construction links are decreased, and economic benefit and social benefit are obvious.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

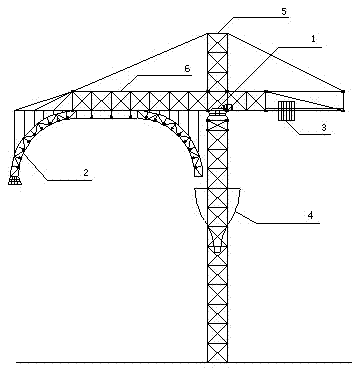

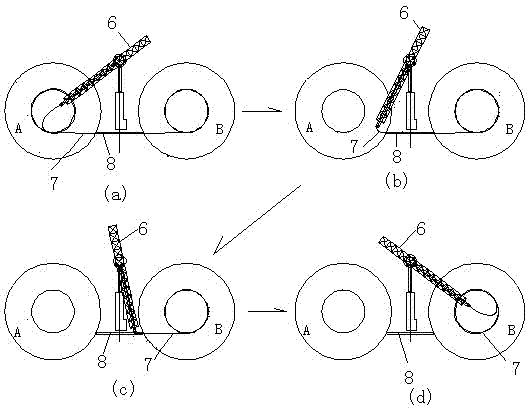

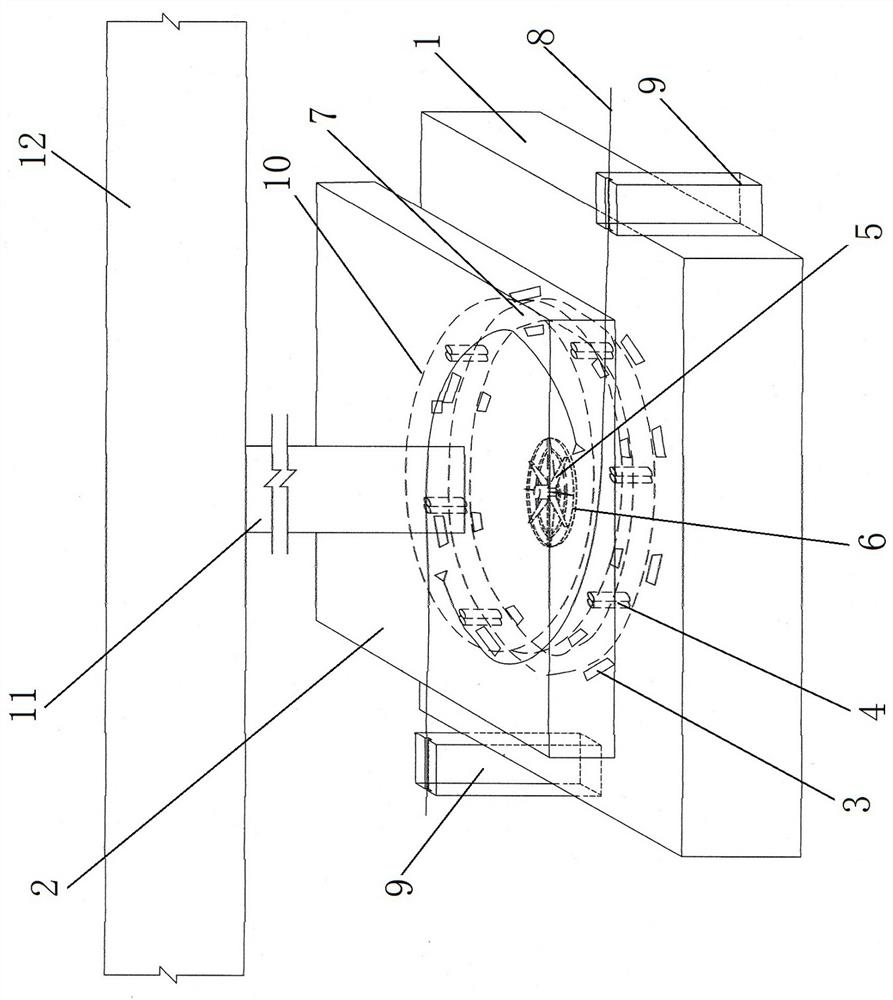

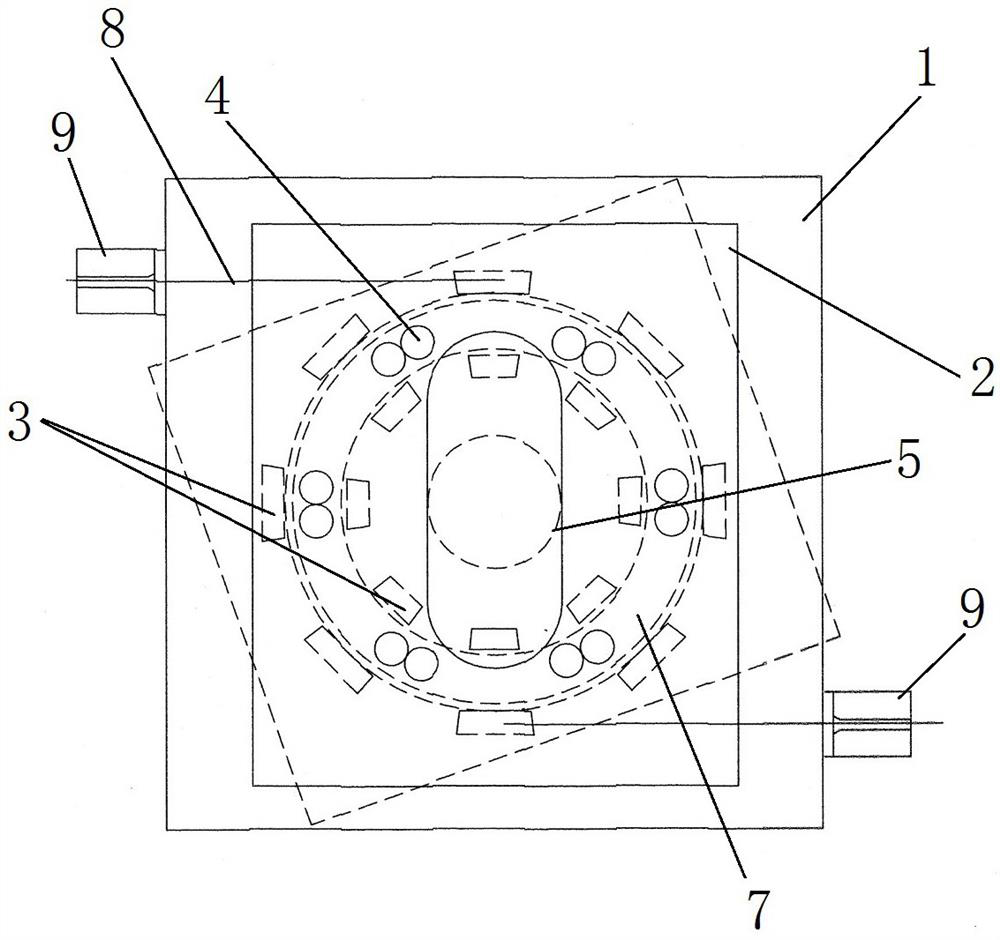

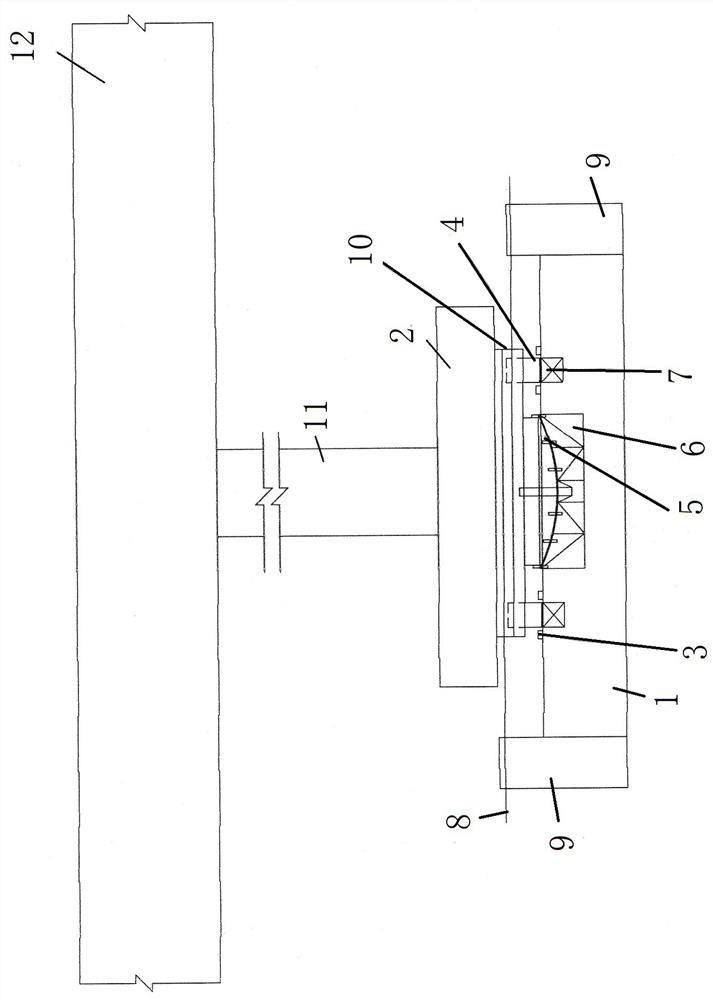

Rotary untwisting rack with double cable reels

ActiveCN102832573AIncrease carrying capacityWork lessApparatus for laying cablesEngineeringSubmarine cable

The invention relates to a rotary untwisting rack with double cable reels. The rotary untwisting rack comprises a rotating mechanism, a cable bracket, an untwisting rack upright column and a rotary untwisting rack crossbeam. The rotary untwisting rack crossbeam is connected to the upper surface of the untwisting rack upright column by the rotating mechanism, the cable bracket is disposed on the rotary untwisting rack crossbeam, and the cable bracket at the front end of the rotary untwisting rack crossbeam rotates along a preset track via the rotating mechanism, can be fixed to upper sides of two cable storage rings respectively, collects cables from the two cable reels and guides the cables into an untwisting rack, so that continuous untwisting and laying construction can be carried out. Uninterrupted untwisting operation for stacking a single cable behind two cable carrying areas can be realized by rotation of the untwisting rack crossbeam, so that the single ultra-long submarine cable can be stored by the two cable reels, and can be subjected to normal untwisting and laying construction, and a series of problems that a cable is required to be cut into sections, and then cut sections of the cable are abutted, sealed and then are laid due to limitation of the traditional untwisting equipment are avoided.

Owner:SHANGHAI FOUND ENG GRP

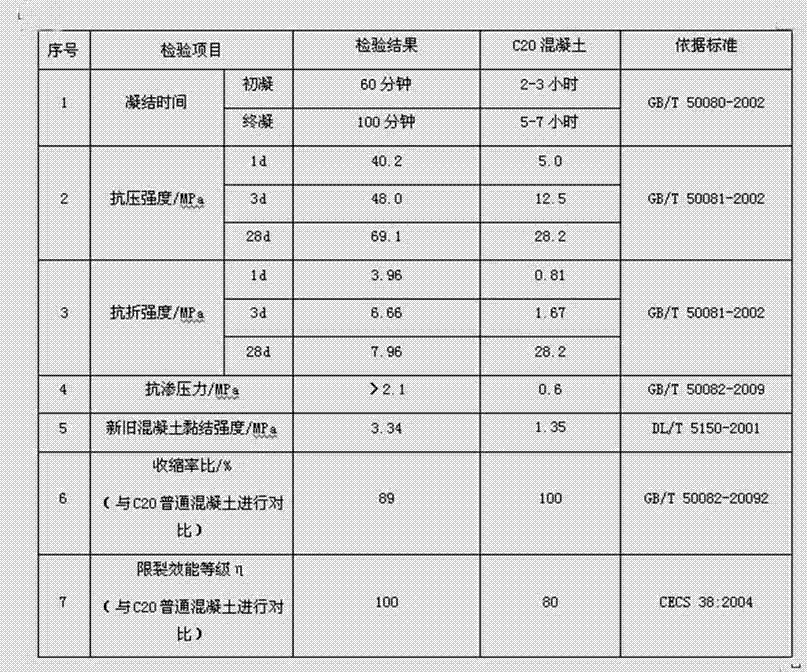

Waterproof anti-permeable agent and waterproof anti-permeable concrete prepared by utilizing same

The invention discloses a waterproof anti-permeable agent which comprises the following materials by weight ratio: cement:coagulating agent:expanding agent:coal ash:polypropylene fiber=(1:0.004-0.006):(0.07-0.097):(0.01-0.025):(0.0035-0.0055). The invention also discloses waterproof anti-permeable concrete which adopts the waterproof anti-permeable agent. The waterproof anti-permeable concrete comprises the following materials by weight ratio: the waterproof anti-permeable agent:gravels: water=(1:0.8-1.5):(0.2-0.3). The anti-permeable anti-cracking concrete prepared from the waterproof anti-permeable agent can be used as a cushion layer by being directly mixed with fine stones, thereby decreasing the construction link; the anti-permeable anti-cracking concrete disclosed by the invention has large adhesive force with a substrate without being shrunk and desquamated, thereby being very suitable for the plugging of the holes of pipelines, the water proofing of floors and the like in the toilets, kitchens and wash rooms of an office building and a residential building; and the anti-permeable anti-cracking concrete disclosed by the invention has the advantages of low cost, simple construction process and high operability and is nontoxic, non-combustible and nonexplosive.

Owner:黎彦廷

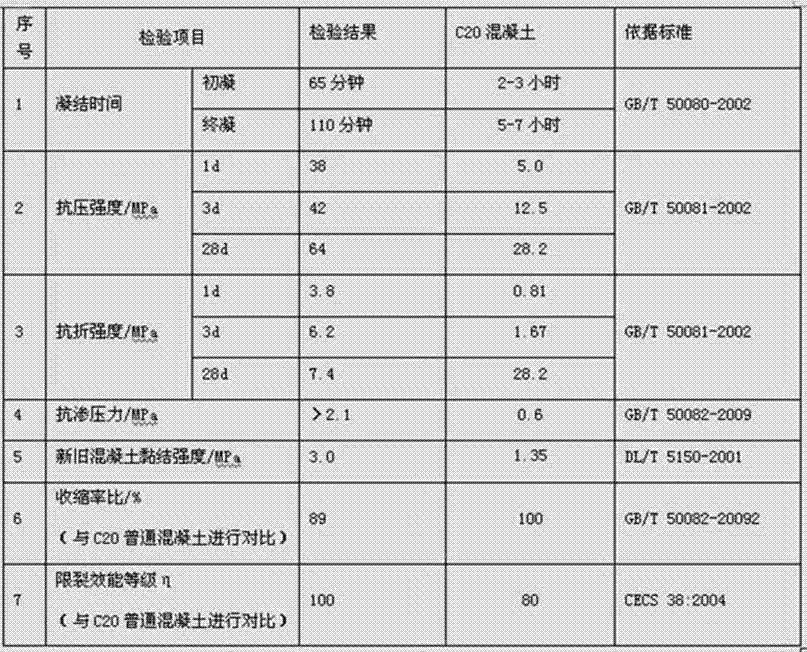

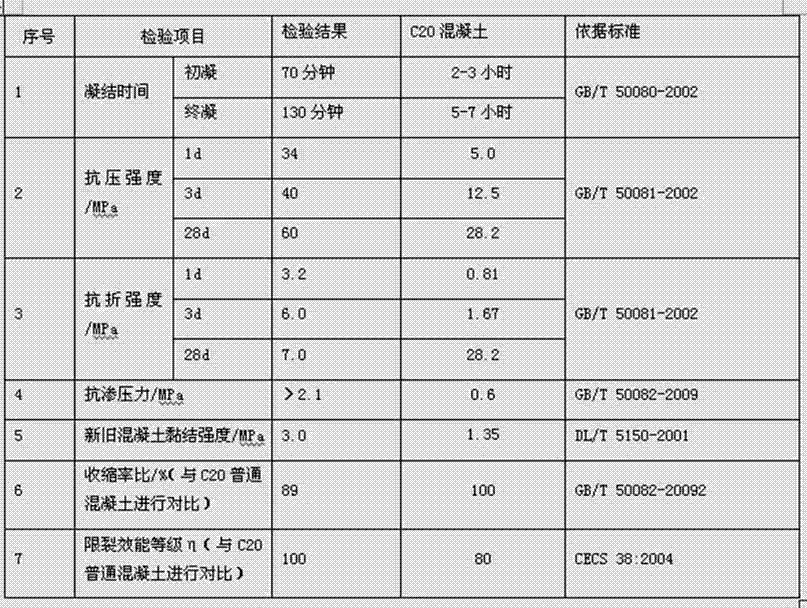

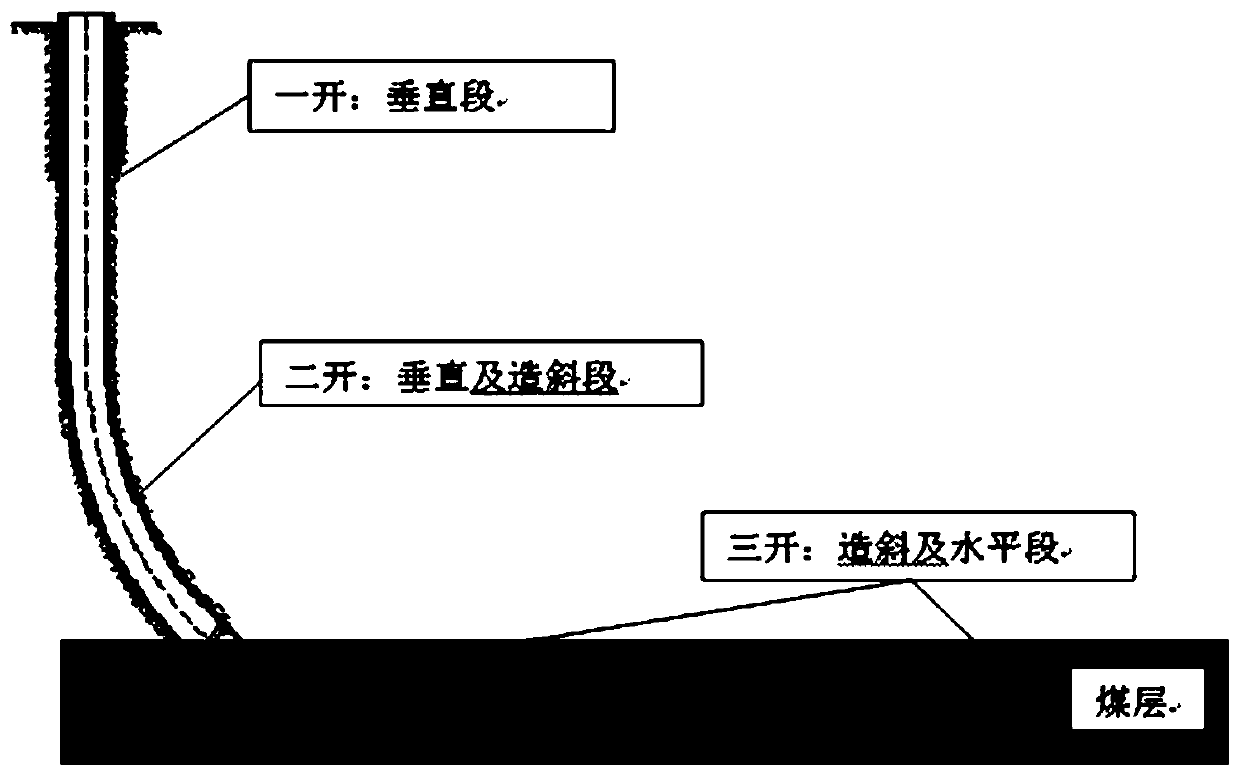

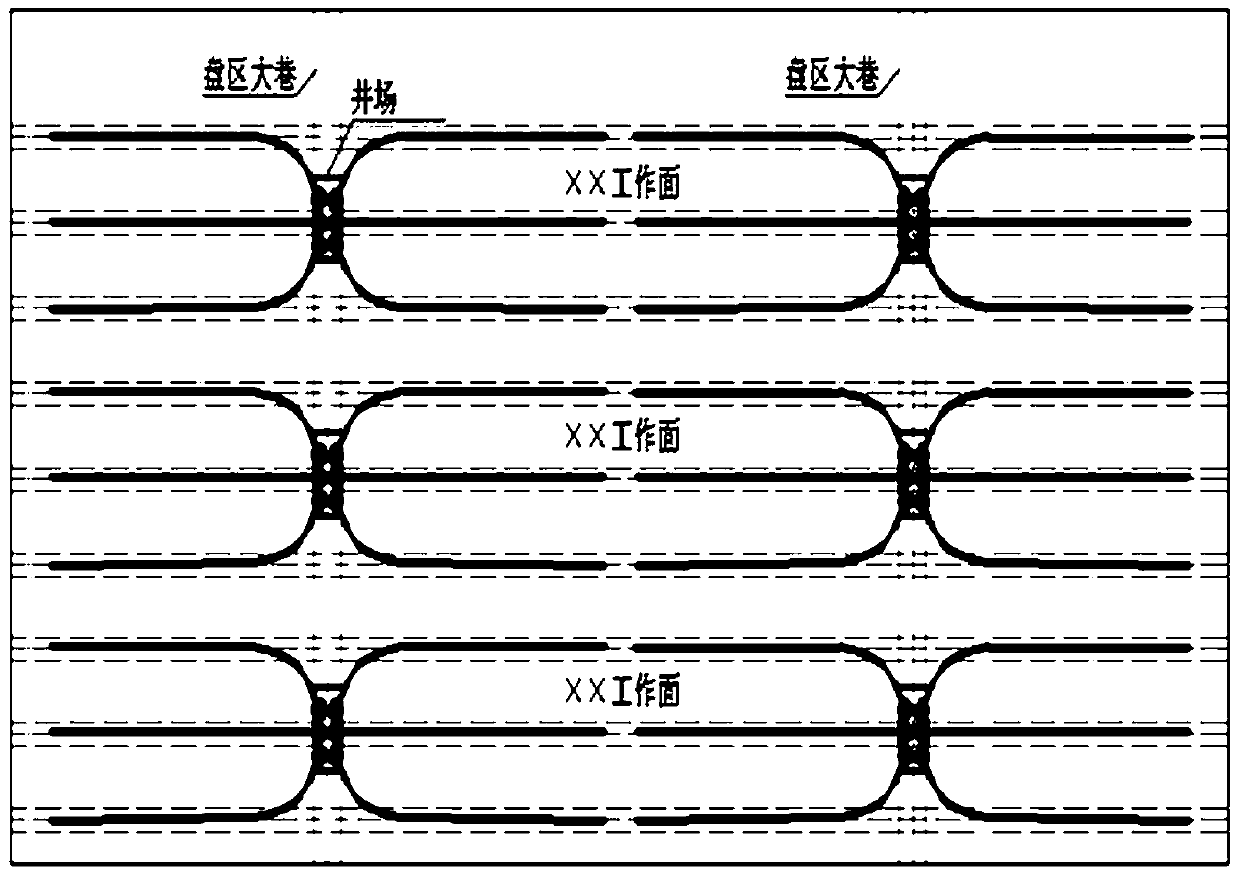

Industrialized development method for coal district coal-bed gas wells

InactiveCN107558984ASmall amount of workReduce construction linksFluid removalDirectional drillingDrill siteHorizontal wells

The invention belongs to the field of coal-bed gas development geology and engineering and non-conventional gas development engineering and geological engineering, and provides an industrialized development method for coal district coal-bed gas wells so as to enable singular and dispersive drilling, fracturing, discharging and mining and gathering and transportation operation modes for coal district coal-bed gas development to be developed to modular layout-centralized operation for the coal district coal-bed gas wells. The method includes the steps that coal-bed gas well pattern design is carried out on a to-be-mined coal district, well pattern drill sites are arranged along panel main roadways, L-shaped wells are adopted, and drilling along working face coal pillars is conducted for horizontal wells; the coal-bed gas wells are arranged in a modularized mode, horizontal wells are arranged along the left and right sides of stope face coal pillars in each drill site, and for multiple coal beds, horizontal wells are drilled along coal-bed coal pillars of the working face, so that the modular layout purpose of the coal-bed gas wells is achieved; and a plurality of coal-bed gas wells are constructed at the same time in a centralized mode by adopting the operation mode that multiple technical processes including drilling, fracturing, discharge and mining and gathering and transportation are integrated. Accordingly, the industrialized development purpose of the coal district coal-bed gas is achieved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD +2

Connecting piece and construction method for mounting building decorative stone panel

ActiveCN103321382AEasy to operateReduce fastening linksCovering/liningsWallsArchitectural engineeringSurface plate

Owner:齐河智谷产业发展有限公司

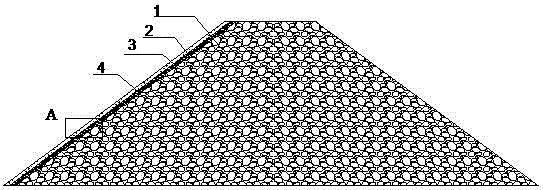

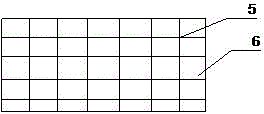

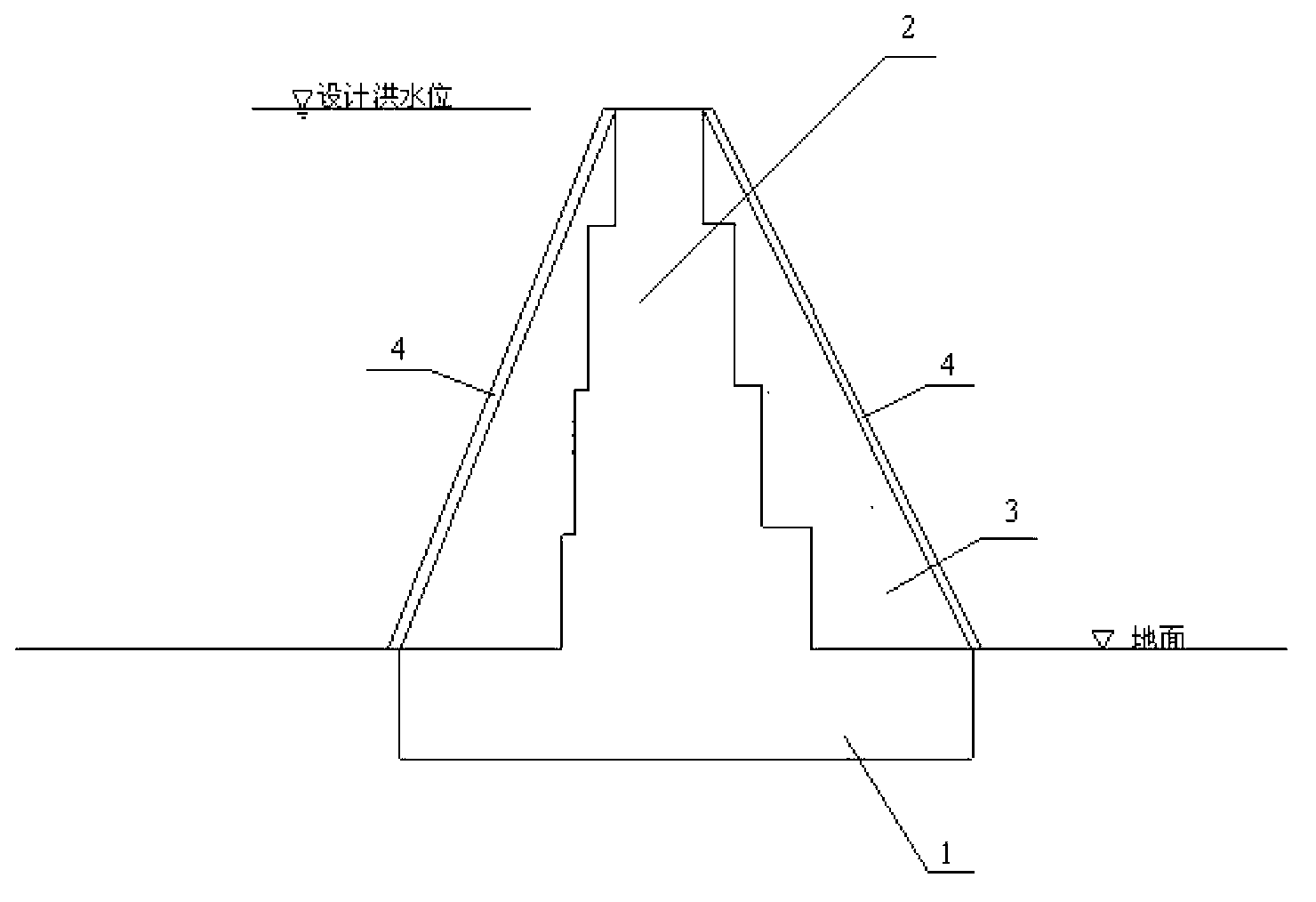

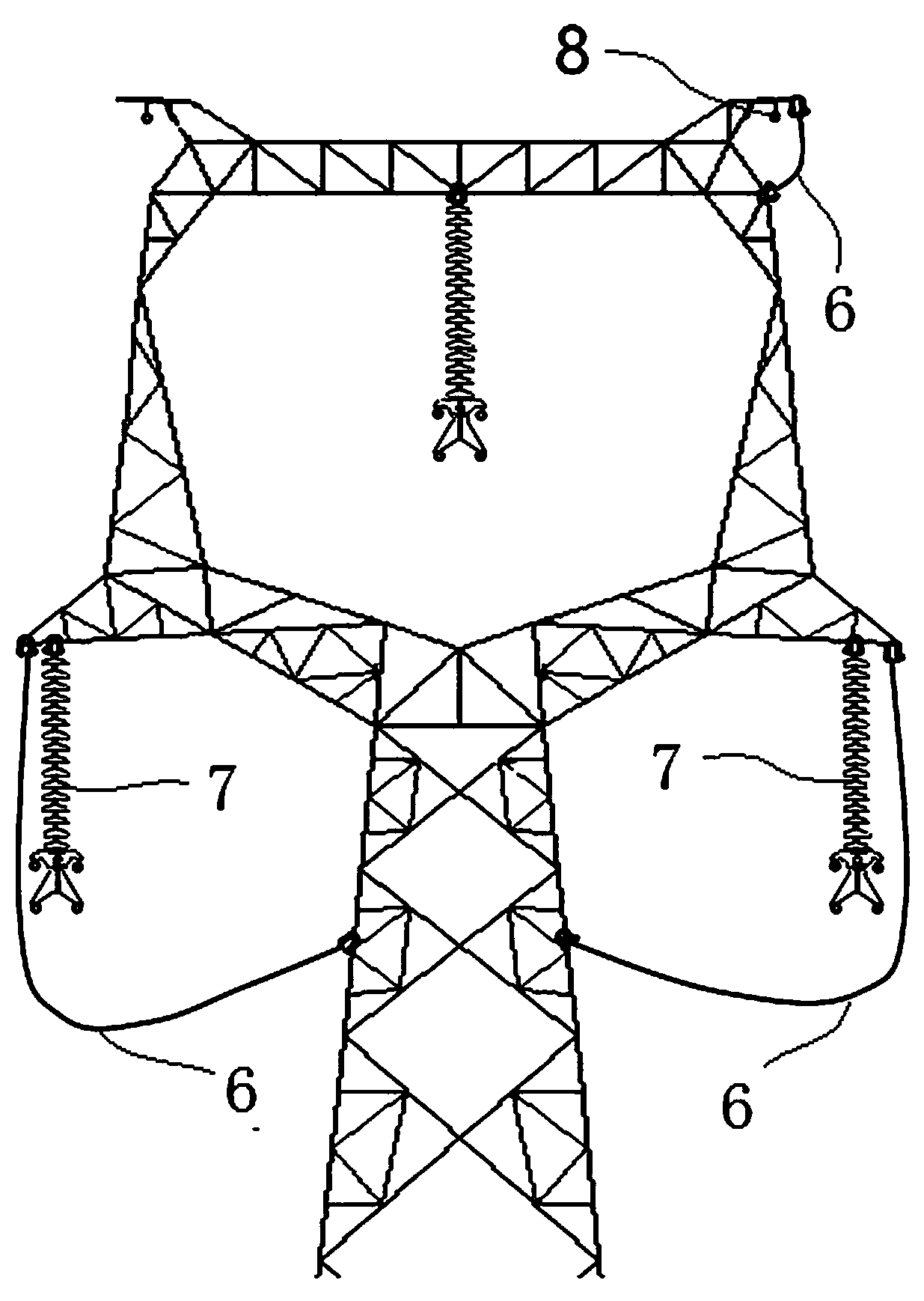

Double-deck concrete faced rock-fill dam and construction method thereof

ActiveCN104594297AReduce heat of hydrationImprove anti-seepage performanceEarth-fill damsRock-fill damsGeomembraneTransition layer

The invention discloses a double-deck concrete faced rock-fill dam. The double-deck concrete faced rock-fill dam comprises a rock-fill accumulation body, a concrete face, geo-membrane and a super-polymer compound concrete face, the upper side of the rock-fill accumulation body is laterally covered with the super-polymer compound concrete face, the super-polymer compound concrete face is covered with the geo-membrane, and the geo-membrane is covered with the concrete face. The invention also discloses the double-deck concrete faced rock-fill dam construction method. According to the double-deck concrete faced rock-fill dam and the construction method thereof, the filling requirement to the accumulation body of a dam body is relatively lower, and it is avoided that a normal concrete faced rock-fill dam requires a higher degree of filling density and a loaded filter with impermeability in the process of filling; concrete hydration heat is effectively reduced, and construction links are few; the impermeability ability of the dam body is enhanced, and the loaded filter and a transition layer are not needed to be constructed on the back of concrete faces; the geo-membrane is arranged between double-deck concrete faces, and self compact concrete can be effectively protected from flowing into the accumulation body; the double-deck concrete faced rock-fill dam construction method has the advantages of being fast in construction speed, simple in process, suitable to popularize and apply and good in practicability.

Owner:YUSHUN ECOLOGICAL CONSTR +1

Ecological embankment

The utility model discloses an ecological embankment. The ecological embankment comprises a foundation, an embankment and a protective slope, wherein the foundation and the embankment are made of rock-fill concrete, the protective slope is soil body, and two slopes of the embankment are in the shape of stages. The rock-fill concrete used in the ecological embankment takes the large-particle-size rock-fill as aggregates, thereby reducing cement usages, saving costs, speeding up construction speed, and effectively reducing the hydration heat of concrete. Therefore, the ecological embankment has the advantages of simple manufacturing processes, less construction links, small floor spaces, and enabling to be used under multi-foundation conditions. Because the protective slope is soil body, plants such as grass and low shrubs can be planted on the soil body and the plants are adaptable to the soil body, thereby strengthening the effect of beautification.

Owner:TSINGHUA UNIV

Green paint for wardrobe surface

The present invention discloses a green paint for wardrobe surface. The paint is compose of the following materials by weight: 41-45 parts of E-44 epoxy resin, 5-8 parts of 200 polyamide resin, 5-7 parts of methyl methacrylate, 50-60 parts of weak acidic water, 4.8-5.2 parts of butanol, 1.2-1.8 parts of a natural pigment, 6-8 parts of calcined clay, 4.5-5.5 parts of a non-leafing aluminum slurry, 2-4 parts of organic soil, 0.3-0.7 part of a thickener, 3.5-5 parts of a complex defoamer, and 0.6-1.5 parts of a curing agent. The present invention not only reduces environmental pollution, improves the coating efficiency, reduces the construction link, and saves construction costs.

Owner:ANHUI BAIYI FURNITURE

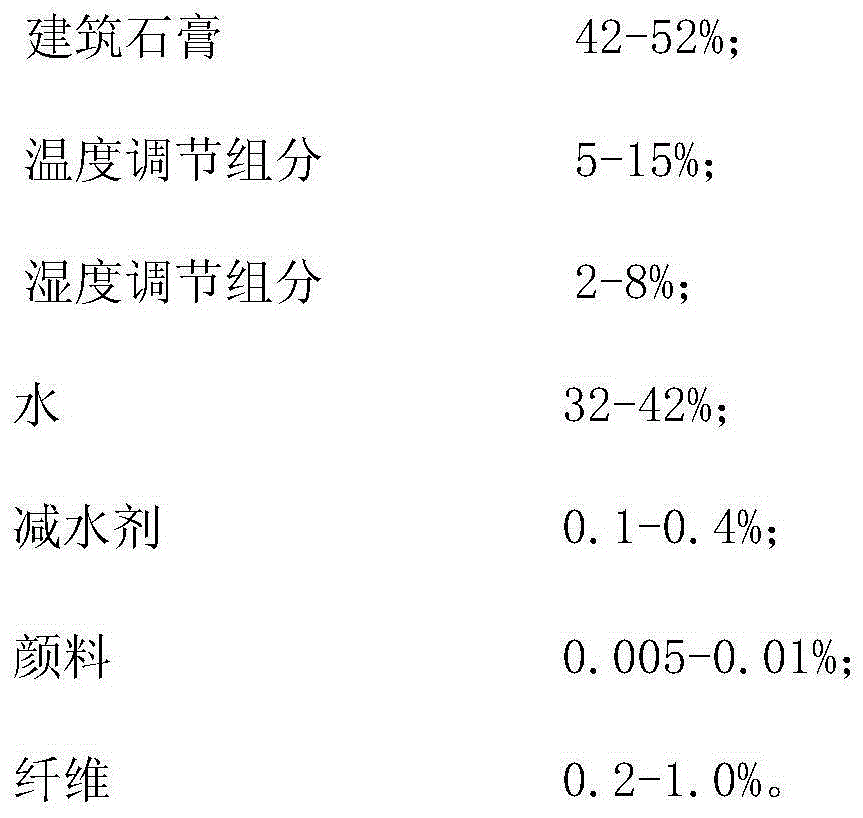

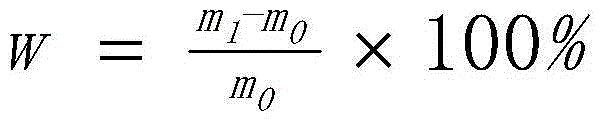

Wall material capable of adjusting indoor environmental temperature and humidity and preparation method of wall material

InactiveCN105218056ASimple preparation processImprove thermophysical propertiesFiberThermal insulation

The invention discloses a wall material capable of adjusting indoor environmental temperature and humidity and a preparation method of the wall material. The wall material is prepared from components in percentage by weight as follows: 42%-52% of building plaster, 5%-15% of temperature adjustment components, 2%-8% of humidity control components, 32%-42% of water, 0.1%-0.4% of water reducing agents, 0.005%-0.01% of pigments and 0.2%-1.0% of fiber. According to the wall material, the preparation process of a functional wall material is optimized, fluctuation of indoor environmental temperature and humidity is reduced, the durability, the anti-permeability, the anti-cracking performance and the fireproof performance of a wall body are improved, and energy consumption is reduced during construction; with the adoption of the temperature adjustment components and the humidity control components, the wall material has the function of indoor environmental temperature and humidity adjustment, the homogeneity of the wall material is guaranteed, and a product has high strength and seldom contracts; the thermal physical performance of the wall material is excellent, the wall body does not require a thermal-insulation layer, and construction procedures are reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

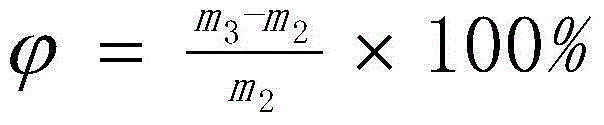

System for material control and management in construction process of ultra-high voltage direct current transmission

InactiveCN107180300AReduce construction linksImprove organization and entryResourcesInformation technology support systemQuality controlTransmission line

The invention discloses a system for material control and management in the construction process of ultra-high voltage direct current transmission, and belongs to the field of ultra-high voltage transmission line information management. The invention aims to solve a technical problem that confused management, long dispatching time and nonuniform quality control occur easily because a lot of materials, constructors and construction links are required in the construction process of ultra-high voltage direct current transmission lines. The adopted technical scheme is that the system structurally comprises a remote server, a group server, a switch, a client and a construction process management module, the construction process management module is connected with the client through the Internet, the client and the construction process management module are connected with the group server through the switch, and the group server is connected with the remote server through the Internet, wherein the remote server is used for storing various types of data and completing calling of various types of information, and the goup server is used for collecting data of different work division departments and updating the collected data to the remote server.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

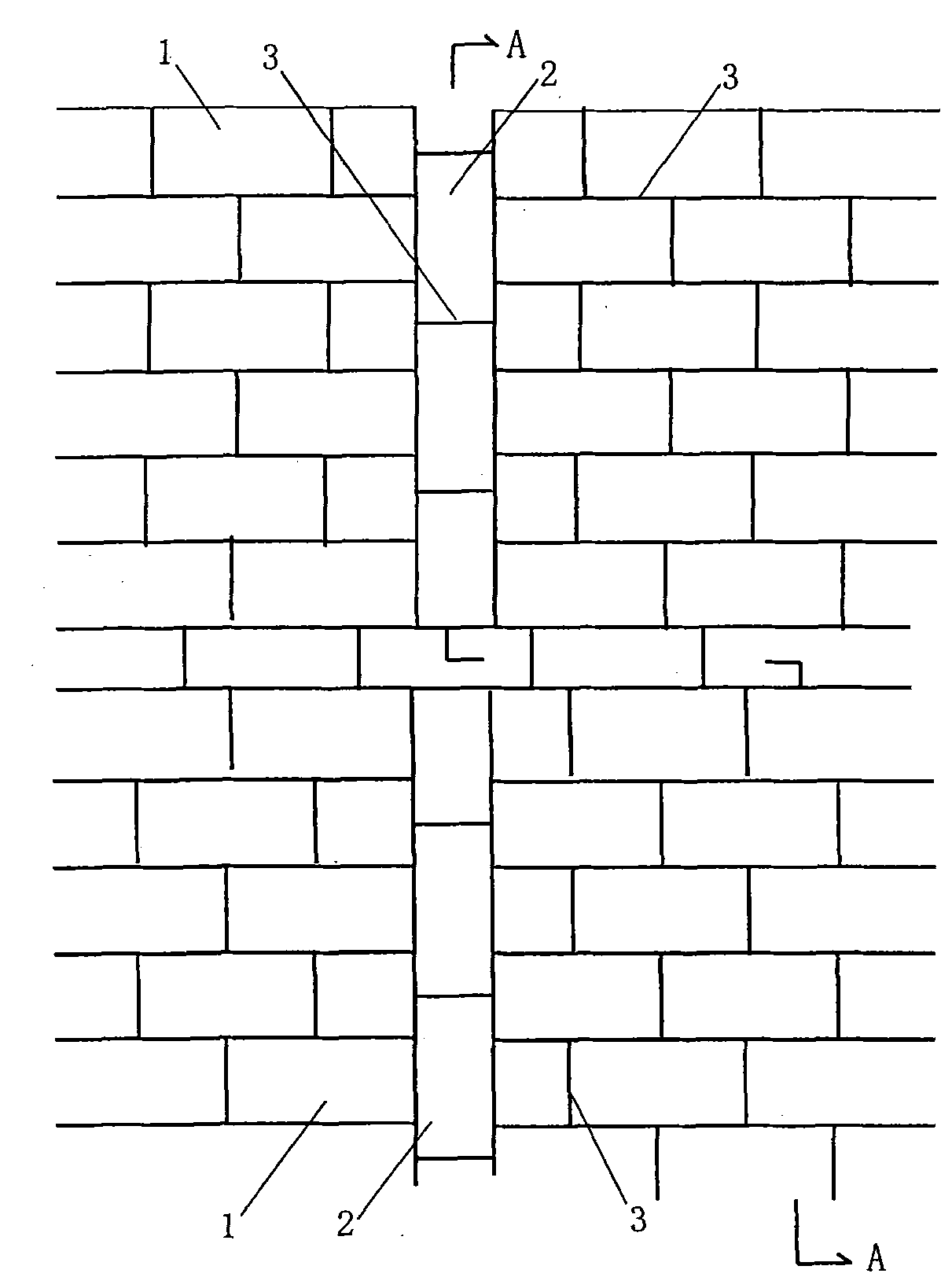

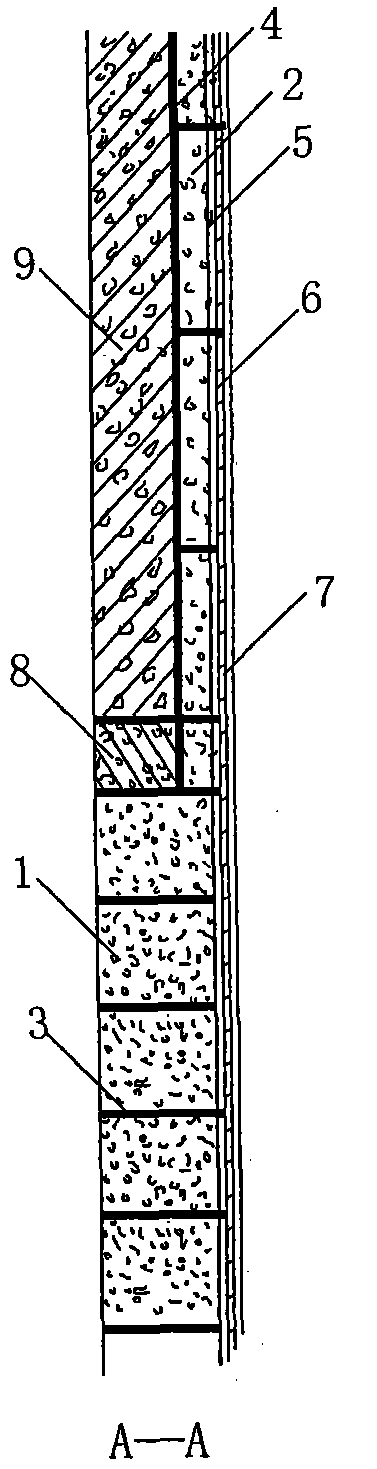

Manufacturing and building method of heat preservation block (building plate) for inorganic self thermal insulation wall body

InactiveCN103883064AExtended service lifeImprove insulation effectWallsHeat proofingFoam concreteThermal insulation

The invention discloses a manufacturing and building method of a heat preservation block (building plate) for an inorganic self heat preservation wall body. The heat preservation block (building plate) is prepared from materials of heat preservation blocks, heat preservation building plates, heat preservation mortar, adhesive mortar, alkali-resistant mesh cloth and surface mortar, wherein each heat preservation block is a cuboid foamed concrete product, each heat preservation plate is a cuboid platy foamed concrete product with the certain thickness, and each foamed concrete product is prepared from a cement material by virtue of a chemical or physical foaming technology as a scientific formula; the self heat preservation wall body is filled and built by adopting the heat preservation blocks among beams and upright columns with a framed building structure and selecting the heat preservation mortar to carry out staggering seam mashing; the outer wall surface built by the heat preservation blocks is protruded out of the outer side surfaces of the beams and the upright columns by a certain size and has the same thickness with each high heat preservation plate adhered to the outer side surfaces of the beams and the upright columns. The novel energy-saving self heat preservation building structure has the advantages of high-intensity, heat preservation, fire proof, sound insulation, convenience in construction due to integration of anti-seismic external wall heat preservation and main body construction, low cost and high efficiency.

Owner:顾世章

Construction method for semi-rigid anti-cracking road surface in alpine region

InactiveCN110306401AExtended service lifeReduce internal stressIn situ pavingsPaving detailsSurface layerFilling materials

The invention belongs to the technical field of road surface construction, and solves the technical problem that a semi-rigid base road surface in the prior art severely cracks in the alpine region. The invention discloses a construction method for the semi-rigid anti-cracking road surface in the alpine region. The method comprises the following steps of a, paving a semi-rigid anti-cracking lowerbase; b, paving a permeable layer on the semi-rigid anti-cracking lower base, and using a basalt fiber belt as a reinforcing layer; c, paving a semi-rigid anti-cracking upper base on the permeable layer; d, using construction machinery to conduct crack pre-cutting on the semi-rigid anti-cracking upper base so as to obtain pre-cracks of the same spacing, then filling the pre-cracks with crack filling materials, and after the pre-cracks are filled, attaching crack pasting materials on the surfaces of the pre-cracks; e, paving a protective layer on the semi-rigid anti-cracking upper base, whereinthe protective layer comprises a sealing layer composed of a second permeable layer and slurry and a waterproof layer above the sealing layer; and f, paving a surface layer on the protective layer, wherein the surface layer is made of asphalt mixed materials and has an upper layer, a middle layer and a lower layer. According to the construction method, the phenomenon of cracking of the semi-rigidroad surface in the alpine region can be effectively prevented.

Owner:张贵霖

Dust prevention curing process for temporary construction load

ActiveCN107447617ATightly boundHave self-healing abilityIn situ pavingsRoads maintainenceRoad surfaceRoad construction

The invention discloses a dust prevention curing process for a temporary construction load. The dust prevention curing process comprises the following steps: step 1, curing construction of the road: A, laying and curing a lower layer road foundation; B, laying and curing an upper layer road foundation; C, sealing the upper layer road foundation and the lower layer road foundation after curing for more than 10 hours to obtain the cured road; and step 2, performing dust prevention curing construction on the cured road: spraying a dust depressor solution onto the surface of the cured road according to the proportion of 1.0-1.5 L / m[2]. According to the dust prevention curing process for the temporary construction load, the road construction period is shortened, the road damage rate is reduced, the road maintenance is facilitated, the maintenance cost is reduced, and regreening and recultivation after the road is abandoned in the later period are facilitated.

Owner:STATE GRID CORP OF CHINA +4

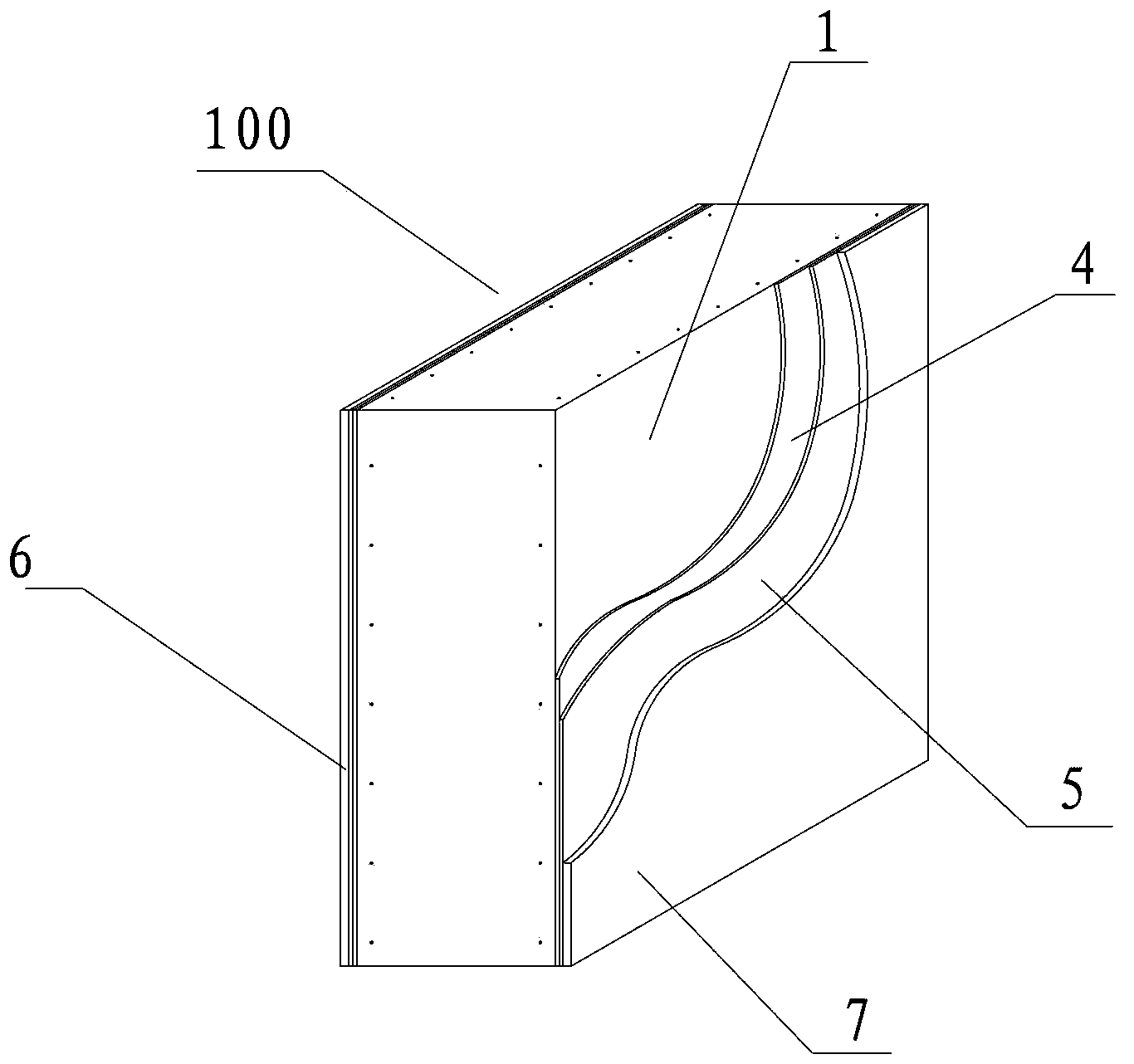

Composite foam glass self-heat-preservation veneer-free outer wall board

The invention provides a composite foam glass self-heat-preservation veneer-free outer wall board. The composite foam glass self-heat-preservation veneer-free outer wall board is characterized by comprising a plate blank, a glass fiber reinforced plastic protection layer, a carbon fiber reinforcing layer, an inner wall veneer layer, an outer wall veneer layer and a plate edge member mounted on the plate blank, wherein the plate blank comprises foam glass and steel wire nets attached to the two sides of the foam glass; the glass fiber reinforced plastic protection layer is mounted at the outer part of the plate blank; the carbon fiber reinforcing layer wraps the plate blank and the glass fiber reinforced plastic protection layer; the inner wall veneer layer and the outer wall veneer layer are mounted on the inner and outer sides of the composite foam glass self-heat-preservation veneer-free outer wall board. The composite foam glass self-heat-preservation veneer-free outer wall board disclosed by the invention has the advantageous effects that the foam glass in the composite foam glass self-heat-preservation veneer-free outer wall board has the characteristics of heat preservation, fire protection, environmental friendliness, durability, ageing resistance and the like. The wall board has enough strength and rigidity so as to meet the requirement of wind load and construction safety aspects; the composite foam glass self-heat-preservation veneer-free outer wall board can be reliably connected with a building main body, can meet the requirements of durability, water prevention and the like of a building, and reduces construction procedures of outer board construction, rendering and the like.

Owner:扬州智光环保科技发展有限公司

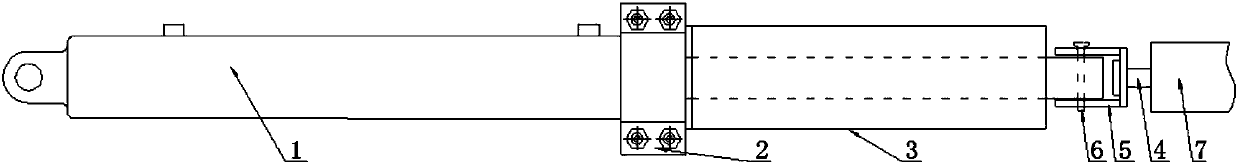

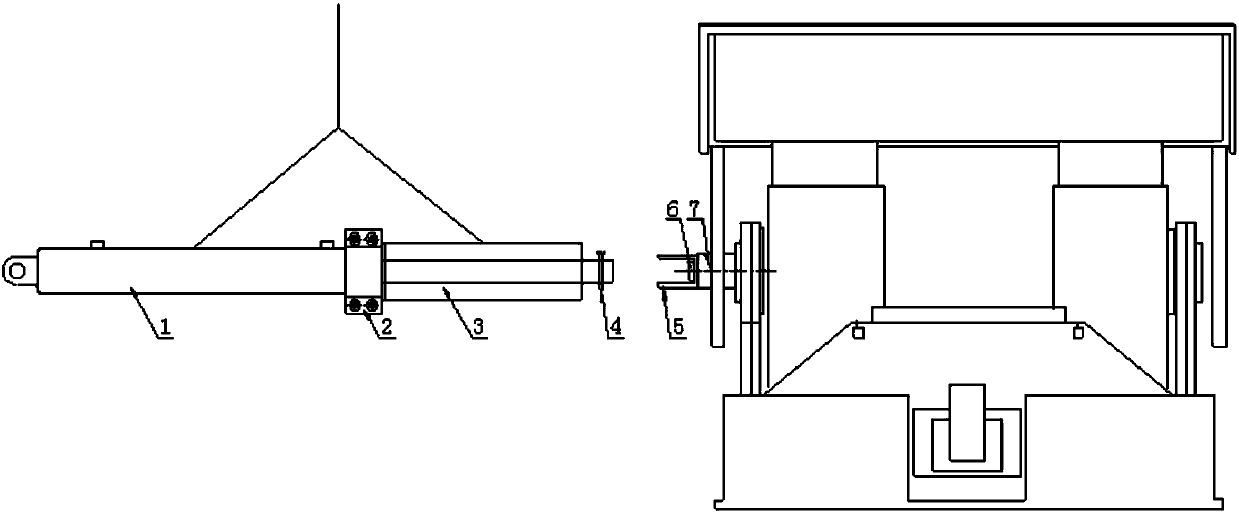

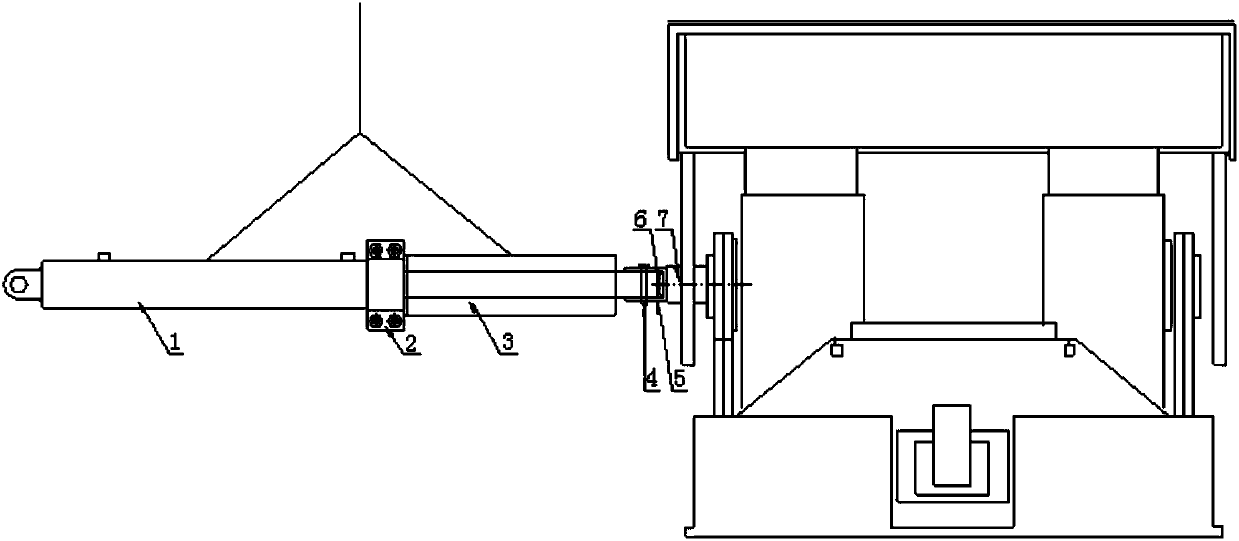

Hydraulic pin pulling device and pin pulling method adopting same

PendingCN107932419AImprove personnel safety factorReduce labor intensityMetal-working hand toolsHydraulic cylinderJackscrew

The invention discloses a hydraulic support pin shaft pull-out device. The hydraulic support pin shaft pull-out device comprises a jack, a hoop, a sleeve, a pin pulling bolt, a connecting head, a jackpin shaft and a hydraulic operating valve. The jack is connected with the sleeve through the hoop, and the jack is sleeved with the sleeve; the pin pulling bolt passes through a middle hole of the connection head, and then is fixed to a hydraulic support pin shaft; and the connection head is fixed to the front end of a hydraulic cylinder pushed out by the jack through the jack pin shaft. The hydraulic pin pulling device (the hydraulic support pin shaft pull-out device) is fixed to a top plate through a coir rope or a hoist chain; and by adjusting the chain length, the position and the heightof the hydraulic pin pulling device are determined. The invention discloses a method for adopting the hydraulic support pin shaft pull-out device for performing hydraulic support disassembling. The hydraulic support pin shaft pull-out device has the beneficial effects that due to the use of the hydraulic pin pulling device, the safety coefficient of personnel in the pin pulling process is increased, the construction links are reduced, the labor intensity of a worker is greatly reduced, and the pin pulling effect and the labor efficiency are improved.

Owner:HUAINAN MINING IND GRP

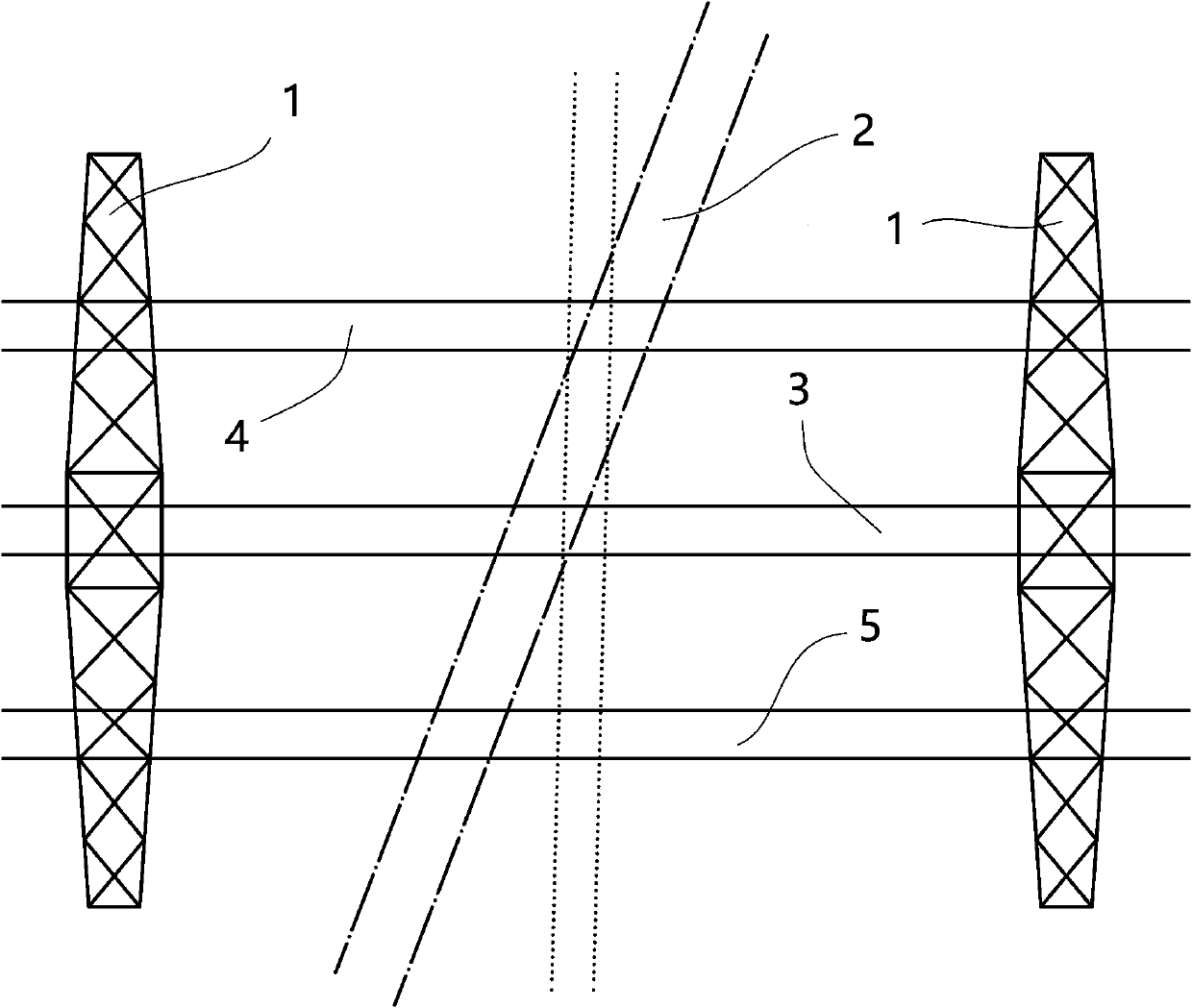

Method for replacing ground wire by crossing high-speed rail through old wire net sealing

ActiveCN111355187AThere is no hidden danger of damage to high-speed rail electrification equipmentImprove securityApparatus for overhead lines/cablesTowerWire rope

The invention discloses a method for replacing a ground wire by crossing a high-speed rail through old wire net sealing, and relates to the field of methods for replacing the ground wire of an overhead transmission line across the high-speed rail. The construction of replacing the ground wire across the high-speed rail generally adopts a method of erecting crossing frames on two sides of the high-speed rail for net sealing, and the construction method is long in construction period and high in construction cost. According to the method, old towers are utilized, a stretching all-in-one machineis adopted to drive tension, and an old ground wire is utilized to draw and unfold a new wire one by one, one phase comprises four sub-wires, the operations of net sealing and net dismounting are respectively carried out twice, a capping net is arranged below each sub-wire of each phase for protection when the wire is replaced, the capping net arranged when the wire of the ground wire is replacedis used for protection, phase wires and the ground wire on two sides of the old towers on two sides of a crossing point are protected by binding steel wire sleeves, and the installation of accessoriesis also protected after the capping net is dismounted. According to the method, the erecting of a crossing frame, the arranging of traction steel wire ropes is not needed, guiding ropes and tractionsteel wire rope switching links are avoided, the construction period can be shortened, the construction cost is reduced, and the construction safety is improved.

Owner:浙江省送变电工程有限公司 +2

Construction process of bridge downward turning method swivel bearing system

PendingCN111676825AReduce construction proceduresConstruction quality is easy to guaranteeBridge erection/assemblyRebarJackscrew

The invention relates to a construction process of a bridge swivel bearing system, in particular to a construction process of bridge downward turning method swivel bearing system and mainly solves theproblem that the existing swivel construction quality is not easy to guarantee and the like. The construction process comprises the following steps: cleaning a bearing platform base; binding lower bearing platform reinforcing steel bars, and dragging counter-force seat reinforcing steel bars; mounting a lower bearing platform template and a traction counterforce seat template; pouring lower bearing platform concrete for the first time; identifying a spherical hinge mounting reference; fixing a slideway support, a lower spherical hinge support, a slideway plate and a lower spherical hinge; mounting a lower bearing platform upper half part reinforcing steel bar and a boosting counterforce seat reinforcing steel bar; pouring lower bearing platform concrete; installing a jack boosting counterforce seat template and pouring concrete; mounting a positioning shaft; lubricating grease is filled between the upper and lower spherical hinges; installing an upper spherical hinge and performing trial rotation; sealing a gap between the upper and lower spherical hinges; mounting supporting legs, temporary supports, an upper bearing platform, a rotary table bottom die, side dies, upper bearing platform reinforcing steel bars and anchoring rotary body traction bundles; pouring concrete on the upper bearing platform; swivel spherical hinge installation completion. By means of the constructionprocess, construction quality is easy to guarantee.

Owner:CHINA RAILWAY 19TH BUREAU GRP 1ST ENG +1

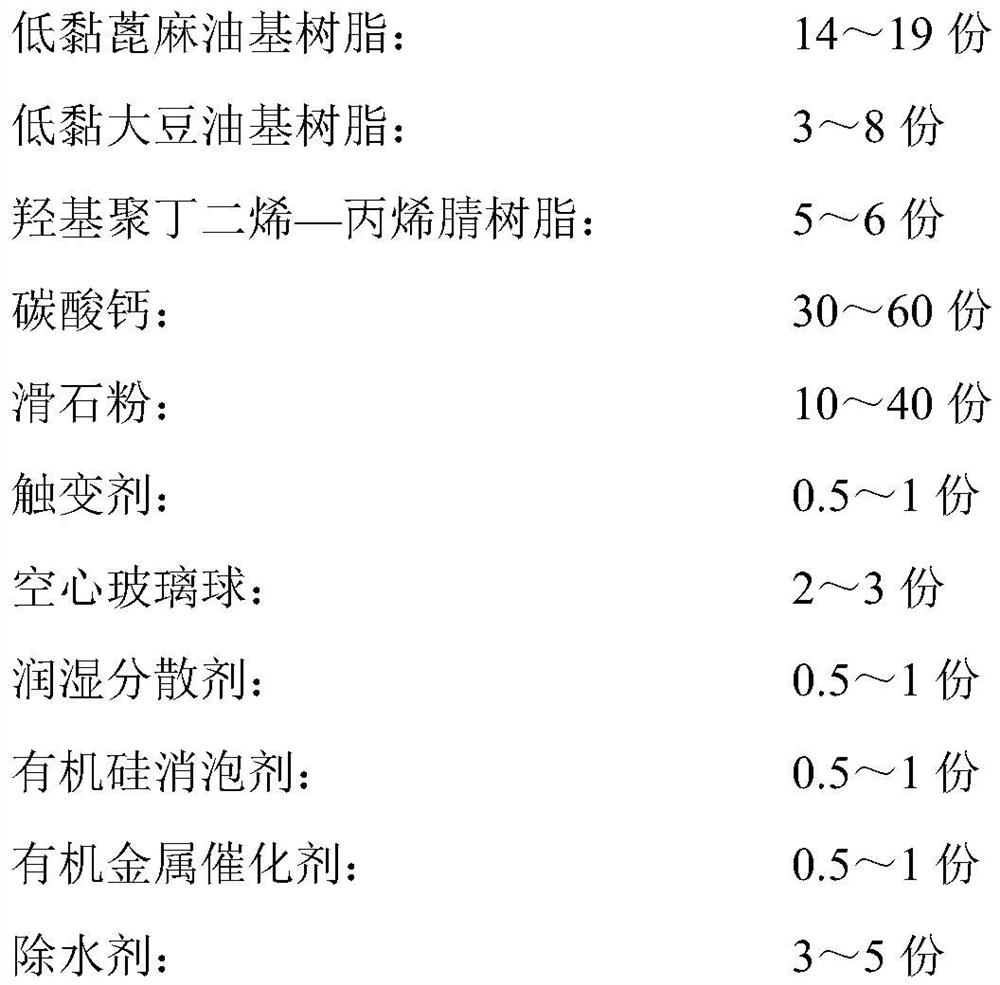

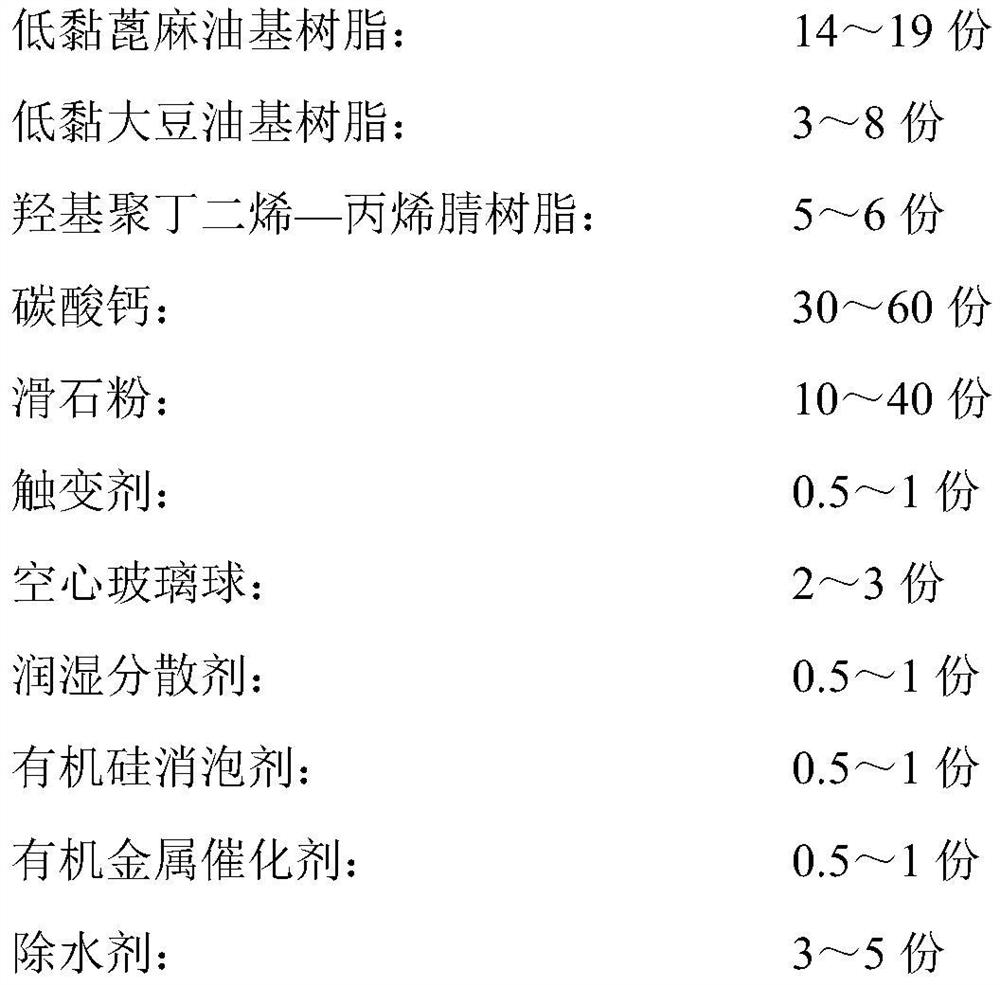

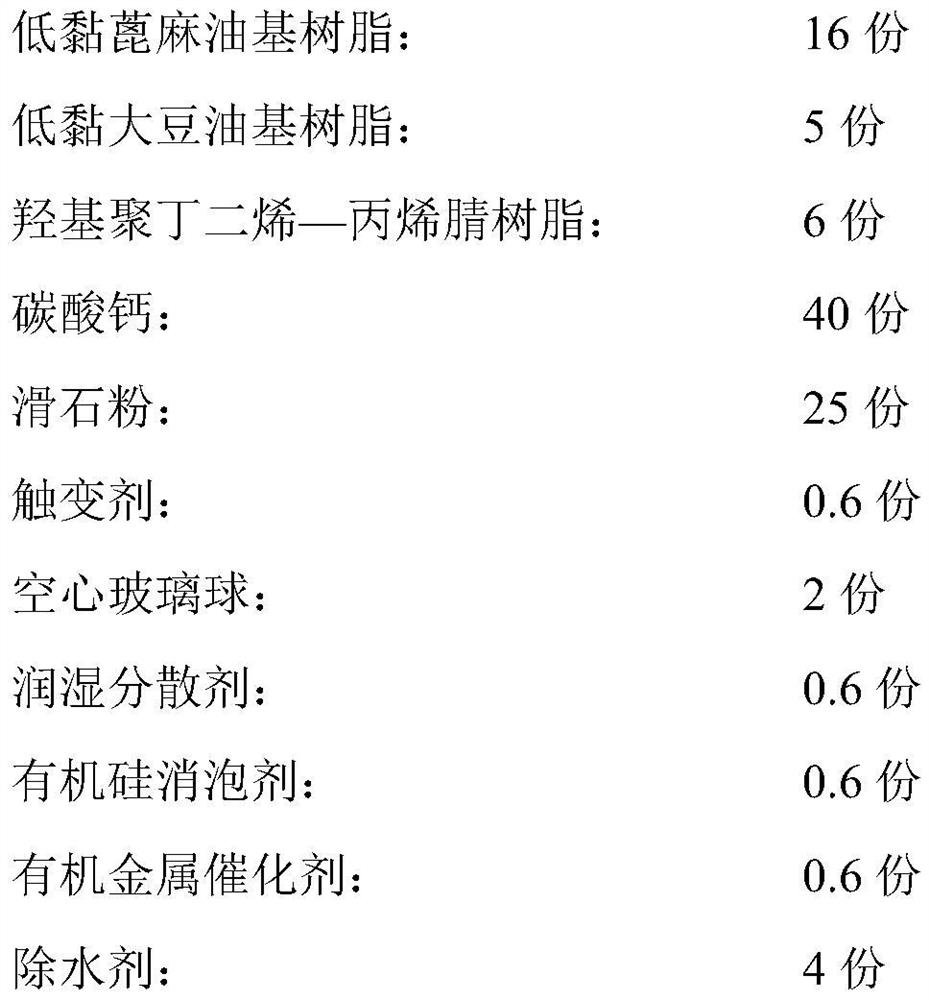

Sprayable solvent-free two-component polyurethane putty and preparation method and use method thereof

InactiveCN111621185ANo flammable and explosive hazardsRealize three effects in oneFilling pastesPolymer scienceAcrylonitrile

The invention provides sprayable solvent-free two-component polyurethane putty which comprises low-viscosity solvent-free bio-based resin and a low-viscosity polyisocyanate curing agent so that the viscosity of a whole coating mixing system is relatively low; in addition, hydroxyl-terminated polybutadiene-acrylonitrile resin is introduced into a formula system so that the wet adhesion and the flexibility of the system to a metal substrate are improved, and the corrosion resistance of the system is greatly improved. Resin used in the invention is solvent-free soybean oil-based and castor oil-based resin, no volatile component exists, other components are inorganic powder, and no low-boiling-point organic volatile matter exists in the whole formula system so that the product is more environment-friendly, and no flammable and combustible hidden danger exists; compared with an existing solution, three effects of priming paint, putty and floating coat are integrated, the construction linksare greatly reduced, the construction efficiency is improved, and the unit labor cost is reduced; the polyurethane material has better cold temperature performance, and the repair quality is greatly improved.

Owner:榕珍新材料科技发展(上海)有限公司

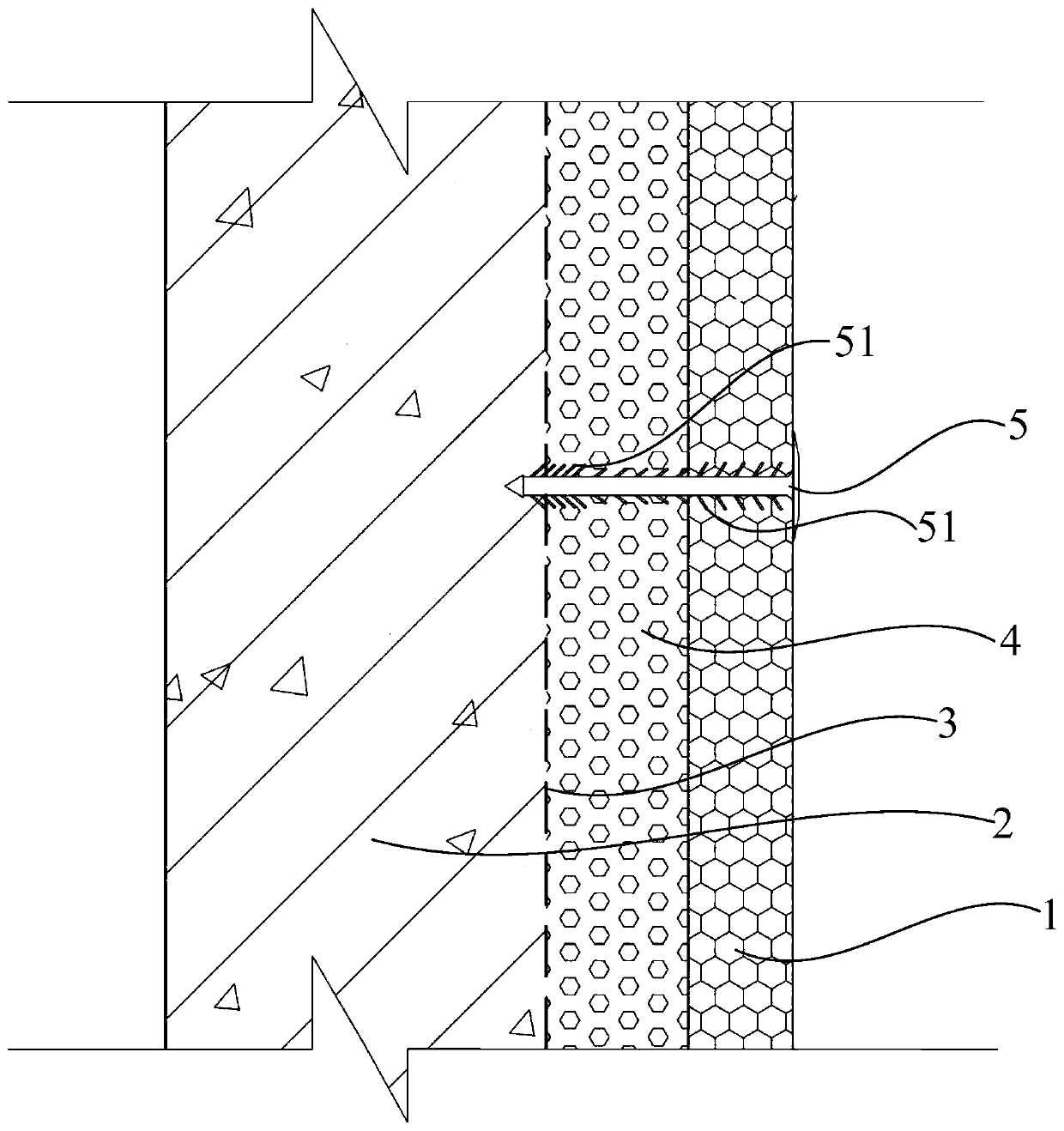

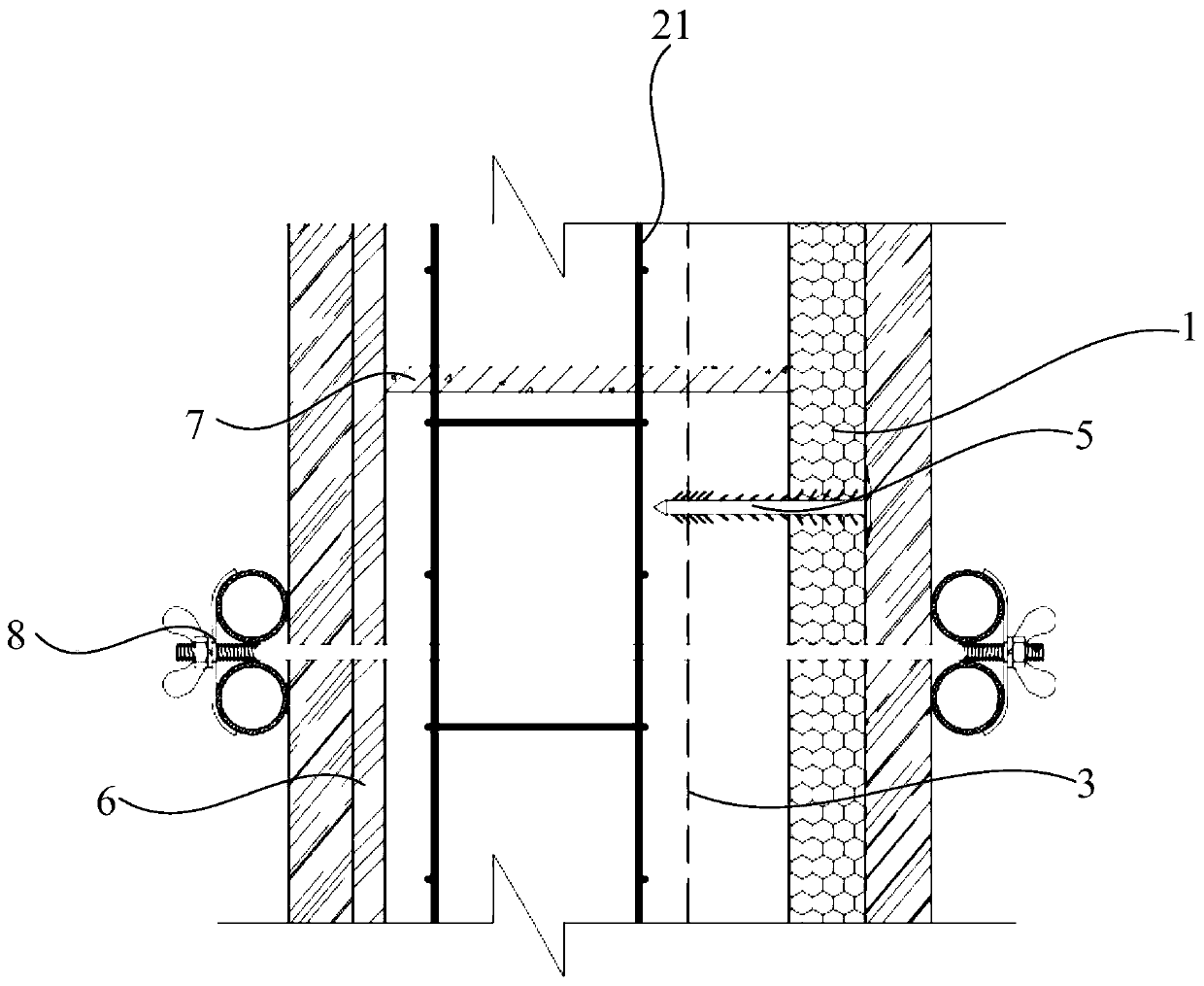

Low-energy-consumption building wall insulation structure and construction method thereof

PendingCN111424842AImprove smoothnessImprove securityWallsClimate change adaptationInsulation layerArchitectural engineering

The invention discloses a low-energy-consumption building wall insulation structure and a construction method thereof. The low-energy-consumption building wall insulation structure comprises a wall layer, a fast-ribbed formwork mesh, an A-level fireproof insulation layer, a polyurethane foam insulation material layer and a plurality of connectors. The wall layer and the A-level fireproof insulation layer are arranged at an interval, two ends of the connectors are connected with the wall layer and the A-level fireproof insulation layer respectively, the fast-ribbed formwork mesh is located between the wall layer and the A-level fireproof insulation layer and connected with the wall layer, the polyurethane foam insulation material layer is poured between the wall layer and the A-level fireproof insulation layer and connected with the wall layer, the fast-ribbed formwork mesh and the A-level fireproof insulation layer. The method comprises few construction links, greatly improves the construction efficiency and has low comprehensive cost; structural strength is high, detachment is effectively prevented, and firmness and safety of the low-energy-consumption building wall insulation structure are greatly improved.

Owner:SHANGHAI SHENGKUI PLASTIC IND

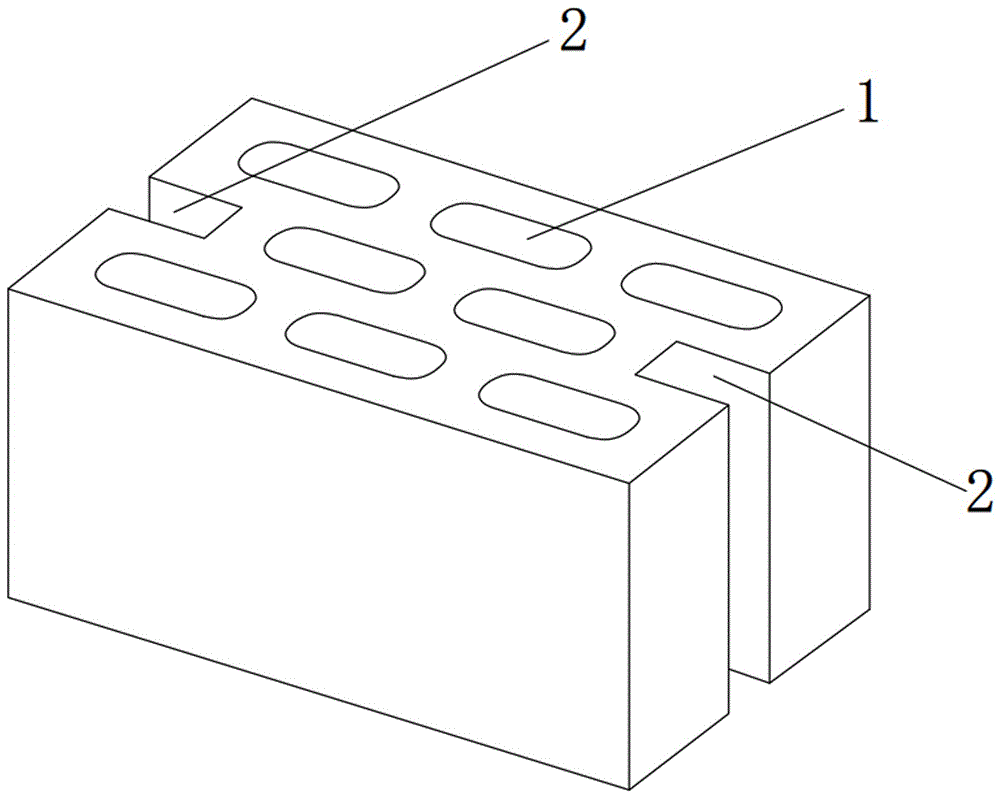

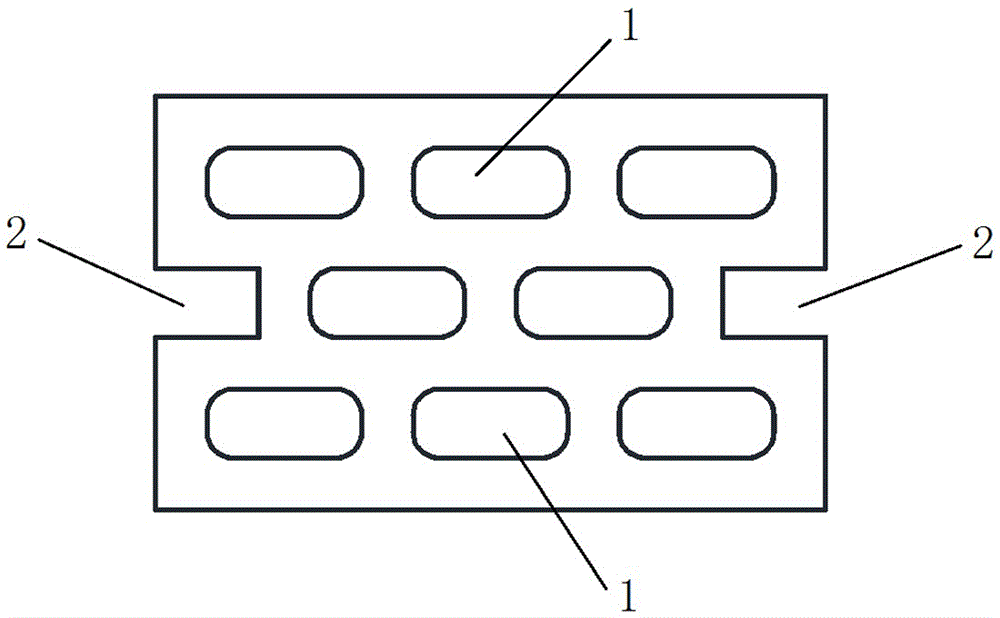

Environment-friendly heat-preserving hollow building block and preparation method thereof

ActiveCN105948600AHigh mechanical strengthImprove insulation effectSolid waste managementWallsEnvironmental resistanceBrick

The invention relates to the technical field of building materials, in particular to the technical field of hollow building bricks, and particularly discloses an environment-friendly heat-preserving hollow building block. The building block comprises the following raw material components in parts by weight: 1 part of cement, 0.35-0.428 part of fly ash, 1.326-1.685 parts of pumice stone coarse aggregates, 1.258-1.537 parts of ferrous mine tailing sand and pumice sand mixed fine aggregates, 0.003-0.006 part of additive and 0.35-0.45 part of water. The preparation method of the environment-friendly heat-insulating hollow building block comprises the following steps: uniformly mixing and stirring all the raw material components, entering a mold for vibration molding and curing. The building brick has the advantages of being higher in compressive strength, good in heat preservation and heat insulation properties, low in preparation cost and the like and can realize the effective utilization of pumice stone resources and ferrous mine tailing sand solid wastes; the preparation method of the environment-friendly heat-insulating hollow building block is simple and easy to implement and is particularly suitable for popularization and use in the northern area of China.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

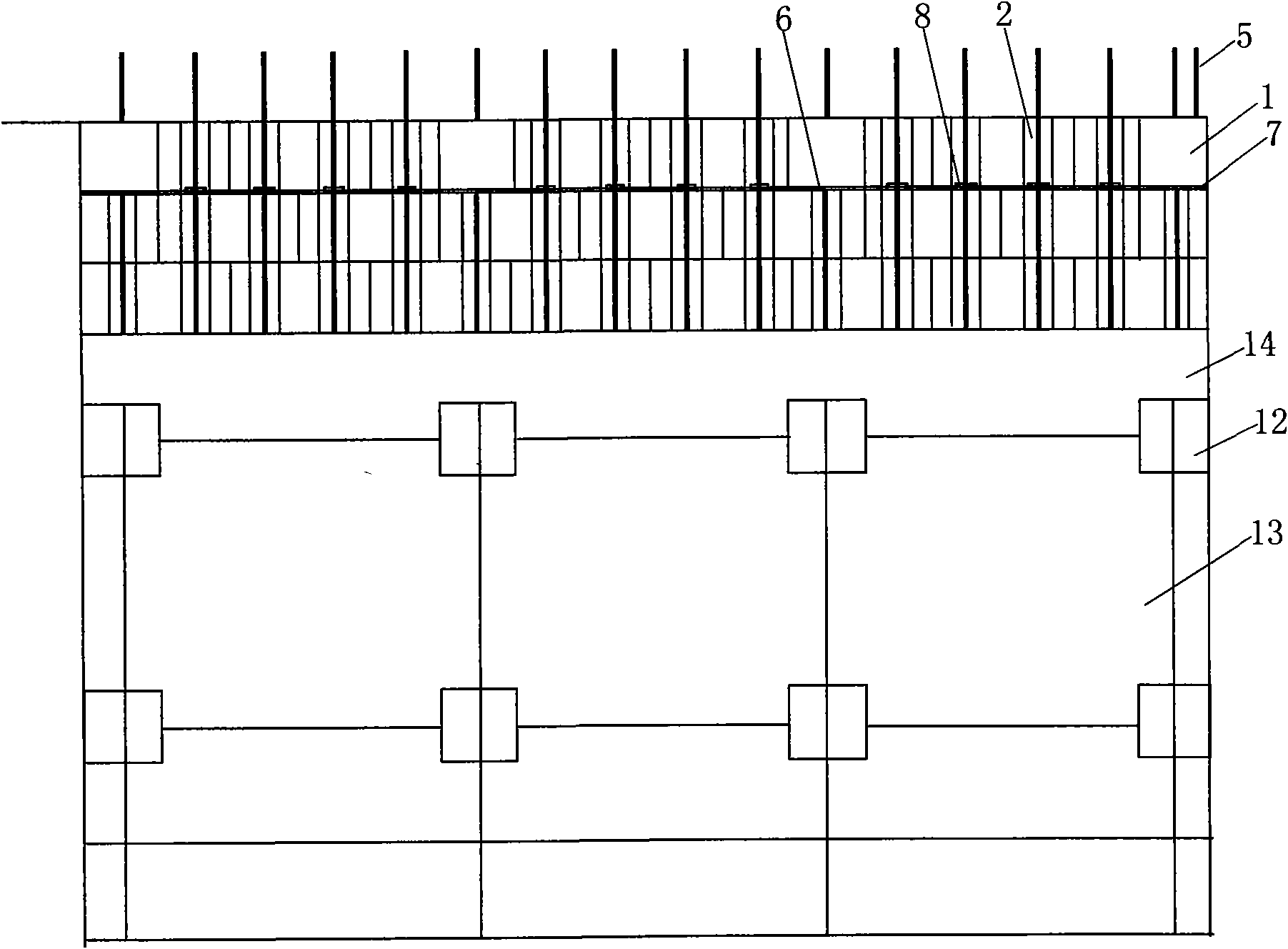

Thermal insulation aseismic wall

InactiveCN101769020AImprove insulation effectImprove seismic performanceWallsClimate change adaptationBrickSteel bar

The invention relates to a thermal insulation aseismic wall which comprises aseismic brick bodies, longitudinal steel bars, transverse bars, corner bars, a thermal insulation clamping board and a thermal insulation board. Grooves are formed on four sides of the aseismic brick bodies, slotted holes are formed on the brick bodies, and trenches are formed on the brick surfaces. The transverse bars and the corner bars are provided with annular elbows. The thermal insulation clamping board is provided with a sleeve, a vertical board and a cross board. The transverse bars and the corner bars are placed when the aseismic wall is built up to a certain storey height. The annular elbows of the bars are aligned with the grooves on two sides of the brick bodies. The longitudinal steel bars are sheathed in the sleeve of the thermal insulation clamping board, and inserted in the annular elbows of the transverse bars and the corner bars along the grooves of the brick bodies of an inner wall and an outer wall after completing the building up of each storey. Then the thermal insulation clamping board is used for positioning, an outer wall binding agent is coated, and an outer wall thermal insulation board is embedded. The thermal insulation aseismic wall is a building structure which integrates the masonry of a wall body, the thermal insulation of the outer wall and the aseismic property. The invention aims at providing the novel energy-saving environment-friendly aseismic wall which can improve the thermal insulation strength of the outer wall, the structural strength of a main body and the aseismic intensity, facilitate the construction and realize low cost and high efficiency.

Owner:顾世章

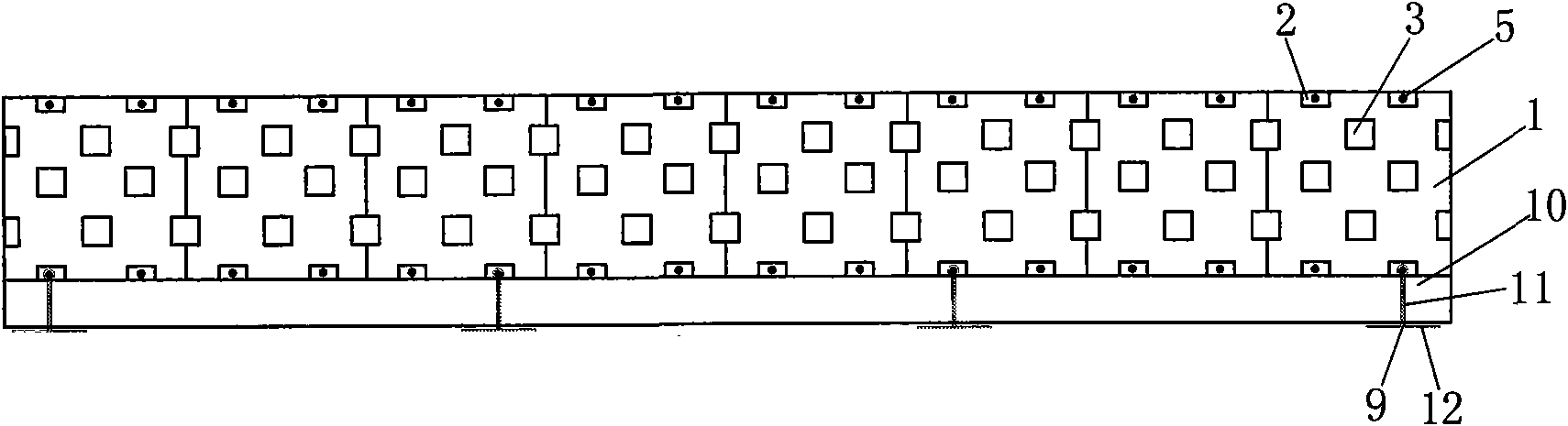

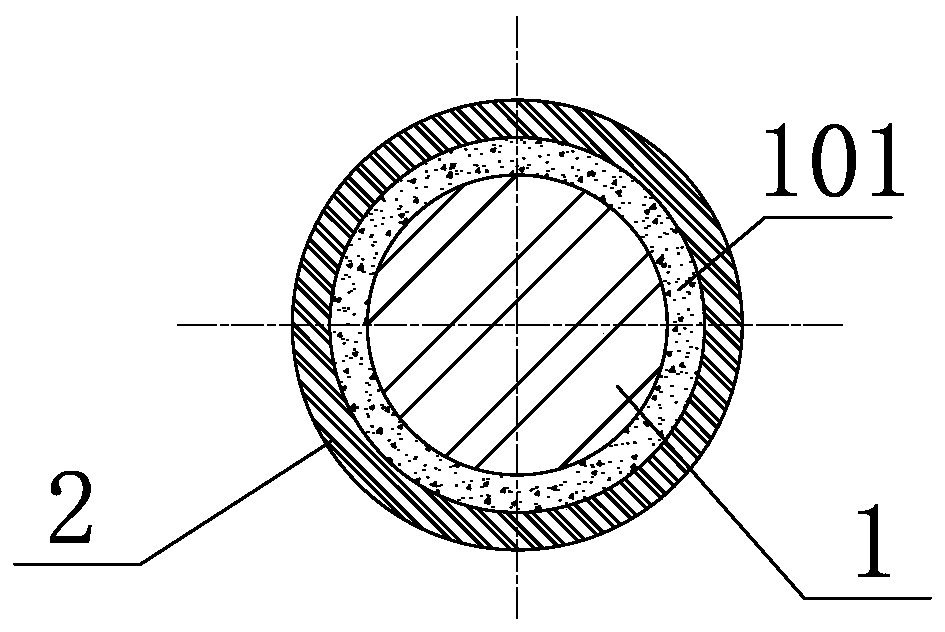

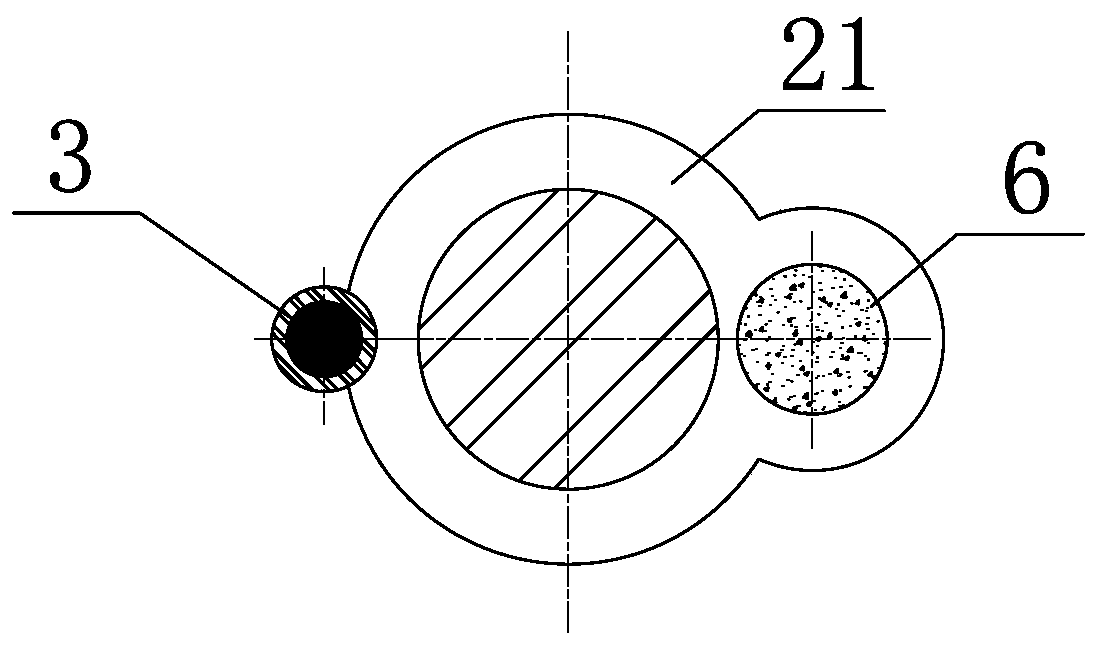

Precast perforated pipe pile and preparation method

InactiveCN101768962AImprove bearing capacityFlexible adjustment of bearing capacityBulkheads/pilesDistribution characteristicSteel tube

The invention provides a precast perforated pipe pile. A perforated pipe and concrete arranged in and out the perforated pipe form a pipe body, and the outer wall of the pipe body is provided with a self-tapping screw which is a spiral bump arranged on the outer wall of the pipe body. The bottom end of the pipe body is a flat head or a tip head, and the top end of the pipe body is a multi-face column and is externally sheathed with a side limited ring. The side limited ring is in a horn shape, and foundation soil is arranged between the pipe body and the side limited ring. The preparation method of the precast perforated pipe pile comprises the following steps: the perforated pipe is manufactured by steel pipes with different specifications, and the thickness is larger than 2 mm; the aperture of perforated holes in the perforated pipe is manufactured by a cutting mode and is determined according to the grain diameter of stone in the concrete, and the distribution of the perforated holes from the pile top to the pile end is determined according to the distribution characteristics of additional stress of the pile; the spiral bump of the outer pipe of the perforated pipe is determined according to the bearing capacity of single pile and the rotational torque; and a variety of parameters of the perforated pipe precast pile are determined according to shared building load, final foundation deformation, foundation soil conditions and conditions for affecting pile sinking.

Owner:吴保全

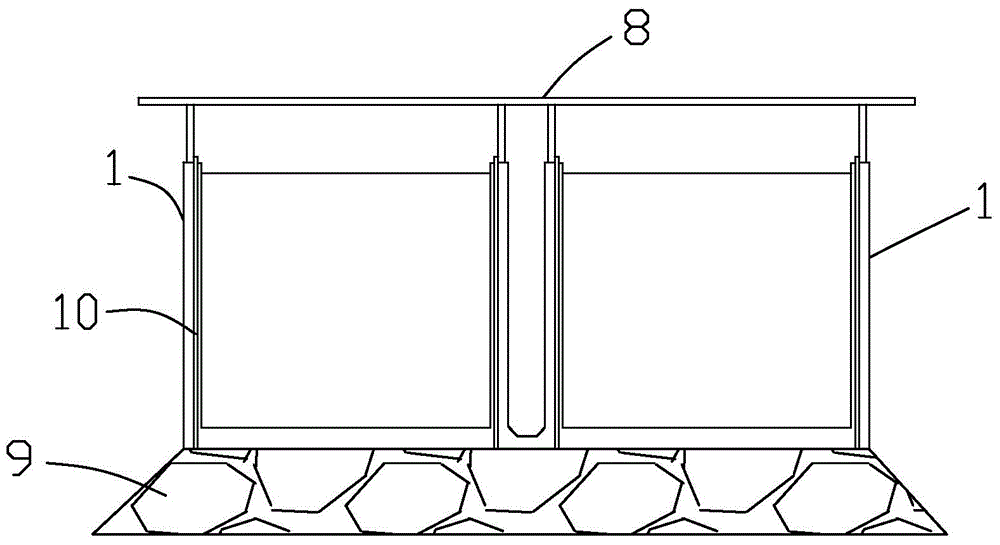

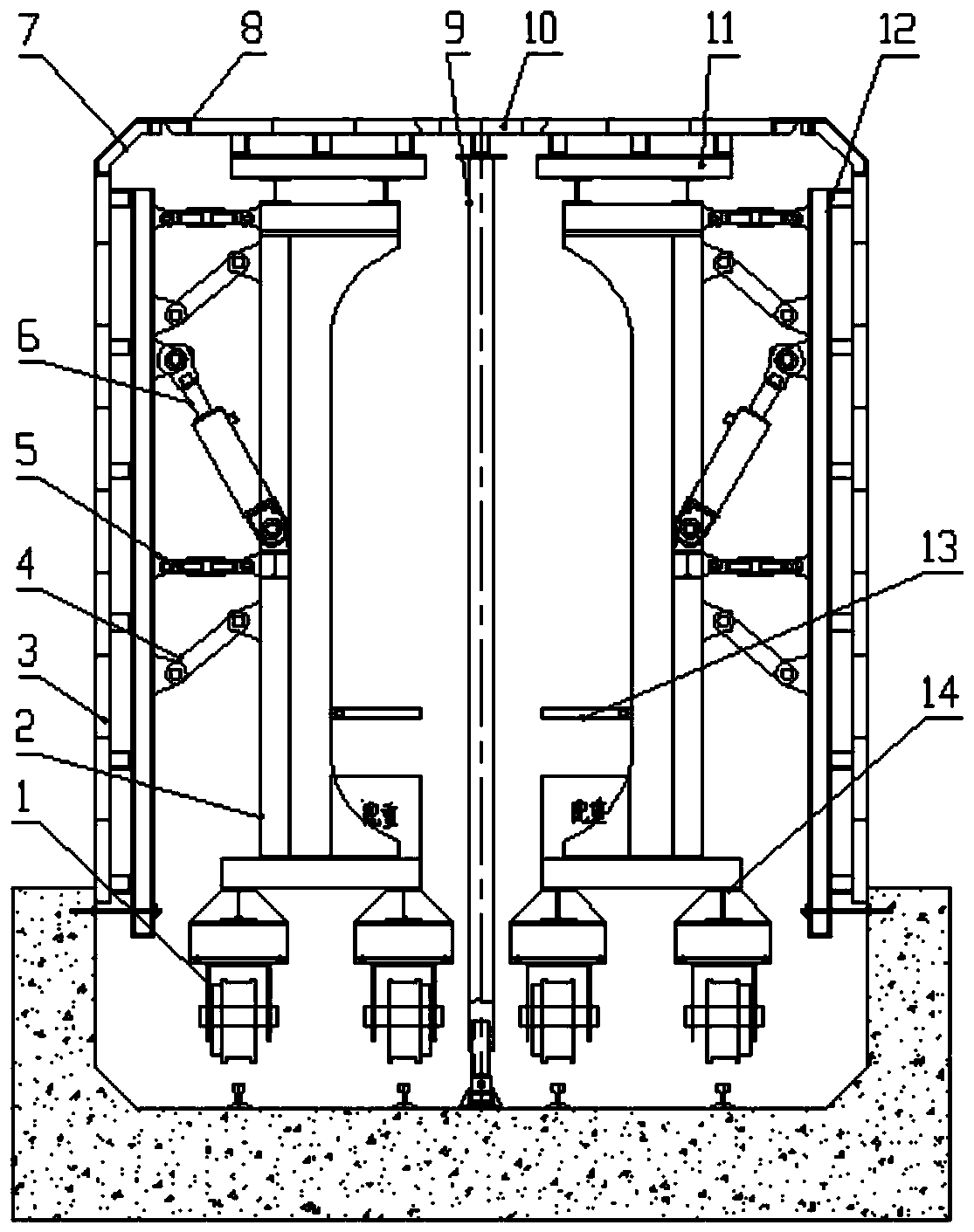

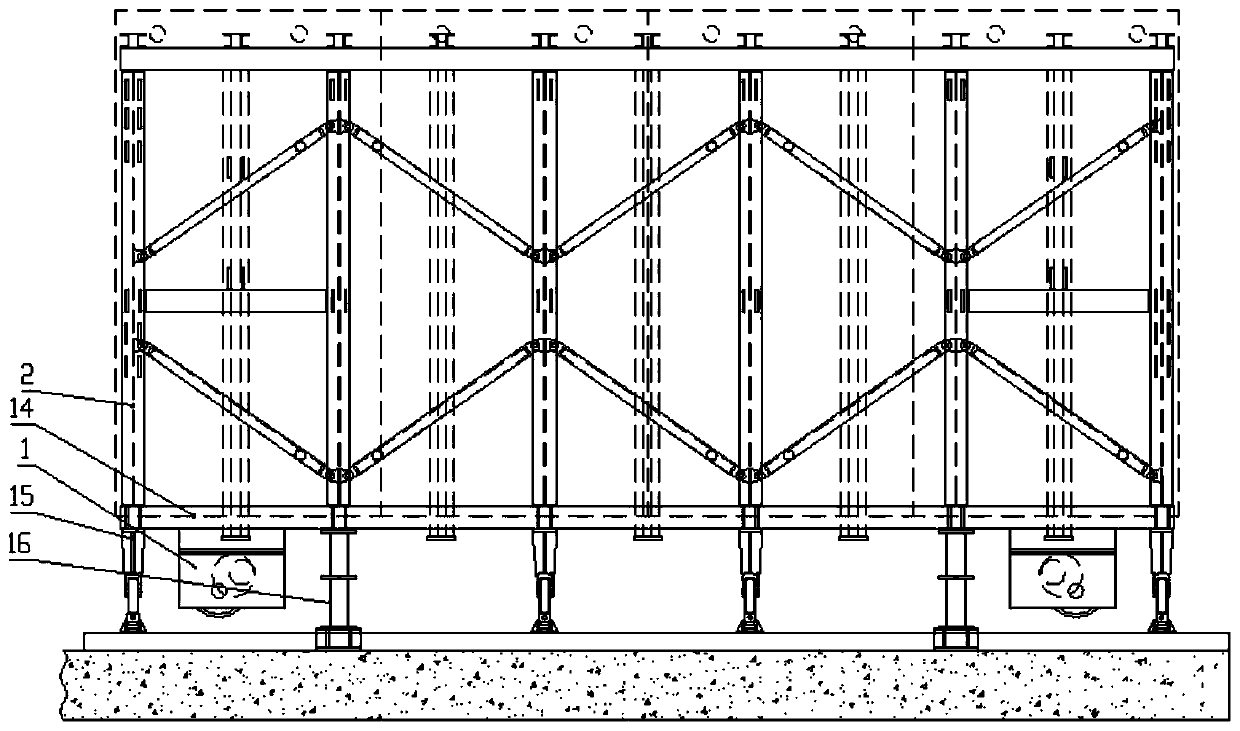

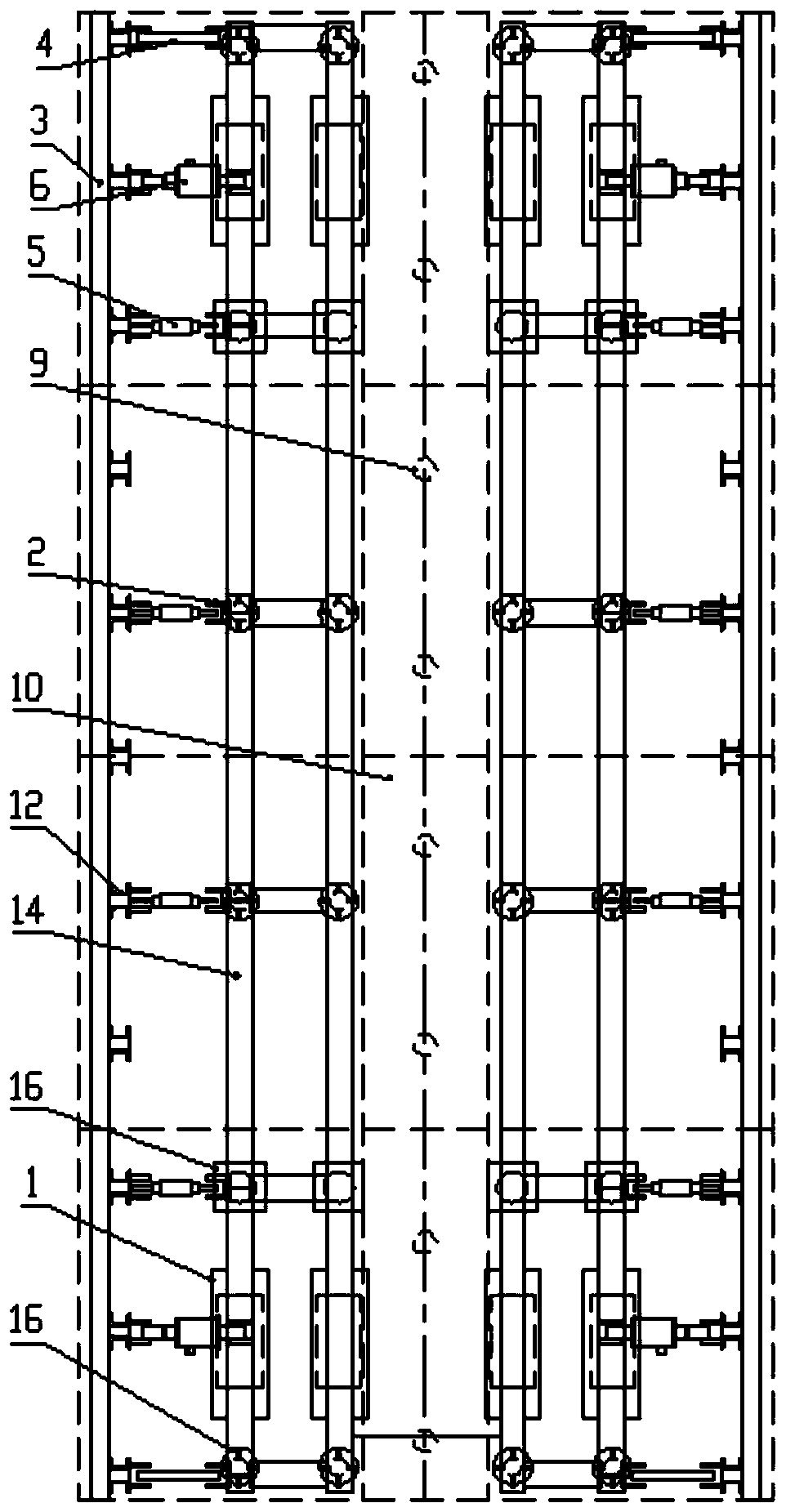

Quick support formwork for pipe gallery and construction method thereof

PendingCN110629793AReduce construction linksSimplify the construction processArtificial islandsUnderwater structuresPlinthUltimate tensile strength

The invention discloses a quick support formwork for a pipe gallery and a construction method thereof. The quick support formwork includes a traveling structure, a supporting structure located on theupper part of the traveling structure, an auxiliary structure used for assisting construction, a side wall formwork, a top corner formwork, a top side formwork, and a top middle formwork; the supporting structure includes a support base, a special-shaped vertical column, a positioning connector, a support screw, a demolding oil cylinder, a side wall formwork bracket, a top mold bracket, the special-shaped vertical column is mounted on the support base as the main body of the supporting structure, the positioning connector, the support screw, and the demolding oil cylinder are mounted on the outer side of the special-shaped vertical column and connected with the side wall formwork bracket; the auxiliary structure includes an integral jacking cylinder, an in-place fixing screw, a rotating platform, and a middle support rod used for supporting the top middle formwork. When side wall position concrete meets the demolding requirements specified in the construction specifications, the side wall formwork and the top side formwork can be demolded separately, and the top middle formwork is retained until the concrete strength of pipe gallery roof slabs fully meet the design requirements.

Owner:中铁隧道集团二处有限公司 +1

Roller compacted concrete punching and slurry adding integrated device and roller compacted concrete punching and slurry adding method

ActiveCN111319123AReduce investmentDoes not affect the production and transportation systemFeeding arrangmentsSurface layering apparatusRoller-compacted concretePunching

The invention provides a roller compacted concrete punching and slurry adding integrated device and a roller compacted concrete punching and slurry adding method. The device comprises a punching rod with a conical head, a grouting pipe opening protective sleeve and a lifting driving device thereof, a grouting hose, a slurry storage and slurry adding device and a punching power device. A sleeve part of the grouting pipe opening protective sleeve is arranged outside the punching rod in a sleeving manner, and a certain gap is formed between the inner wall of the sleeve part of the grouting pipe opening protective sleeve and the punching rod for grouting. The grouting pipe opening protective sleeve can abut against the lower portion of the punching rod and ascend relative the punching rod under the action of the lifting driving device to open and close the gap. The grouting pipe opening protective sleeve is connected with the grouting hose, and the grouting hose is connected with the slurry storage and slurry adding device. The integrated device has the advantages that a concrete production and transportation system is not affected, the structure is simple, quantitative slurry adding is achieved, manpower resource investments are low, construction links are less, and the construction quality is highly guaranteed.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com