Waterproof anti-permeable agent and waterproof anti-permeable concrete prepared by utilizing same

A waterproof and impermeable and concrete technology, applied in the field of waterproof and impermeable materials and waterproof and impermeable concrete, can solve the problems of complex construction process, poor anti-seepage performance and high cost, and achieve simple construction process, strong cohesion and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1, a waterproof and anti-seepage agent, which is composed of the following weight ratios: cement (PC32.5): coagulant: expansion agent: fly ash: polypropylene fiber=1:0.0054:0.0876:0.0150:0.0045.

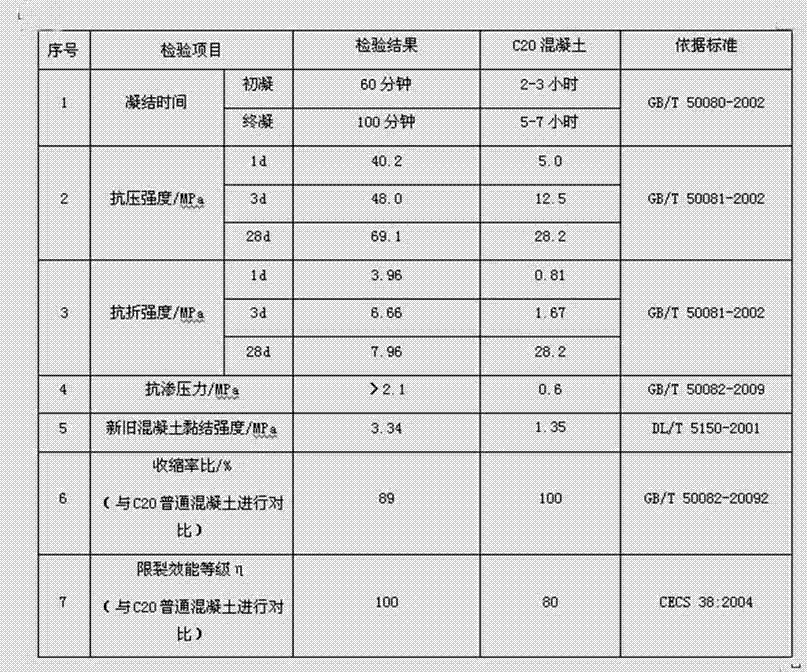

[0016] The above-mentioned waterproof and anti-seepage agent is compared with the commonly used C20 concrete for experimental analysis. C20 concrete is proportioned with the commonly used weight ratio, cement (P.O42.5): water: medium sand: crushed stone (5mm-20mm) = 1 :0.83:3.10:4.96. Take the above waterproof and anti-seepage agent according to the following weight ratio for performance test, waterproof and anti-seepage agent: stone (5mm-10mm): water = 1: 1.2: 0.214, the test results are as follows:

[0017]

Embodiment 2

[0018] Example 2, a waterproof and anti-seepage agent, which is composed of the following weight ratios: cement (PC32.5): coagulant: expansion agent: fly ash: polypropylene fiber=1:0.006:0.097:0.025:0.0055.

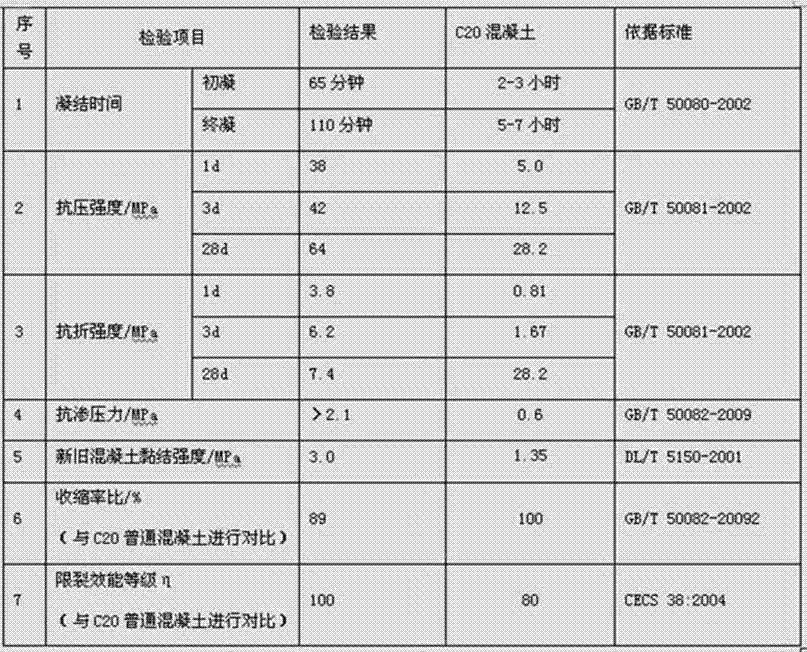

[0019] The above-mentioned waterproof and anti-seepage agent is compared with the commonly used C20 concrete for experimental analysis. C20 concrete is proportioned with the commonly used weight ratio, cement (P.O42.5): water: medium sand: crushed stone (5mm-20mm) = 1 :0.83:3.10:4.96. Take the above waterproof and anti-seepage agent according to the following weight ratio for performance test, waterproof and anti-seepage agent: stone (5mm-10mm): water = 1: 1.2: 0.214, the test results are as follows:

[0020]

Embodiment 3

[0021] Example 3, a waterproof and anti-seepage agent, which is composed of the following weight ratios: cement (PC32.5): coagulant: expansion agent: fly ash: polypropylene fiber=1:0.004:0.07:0.01:0.0035.

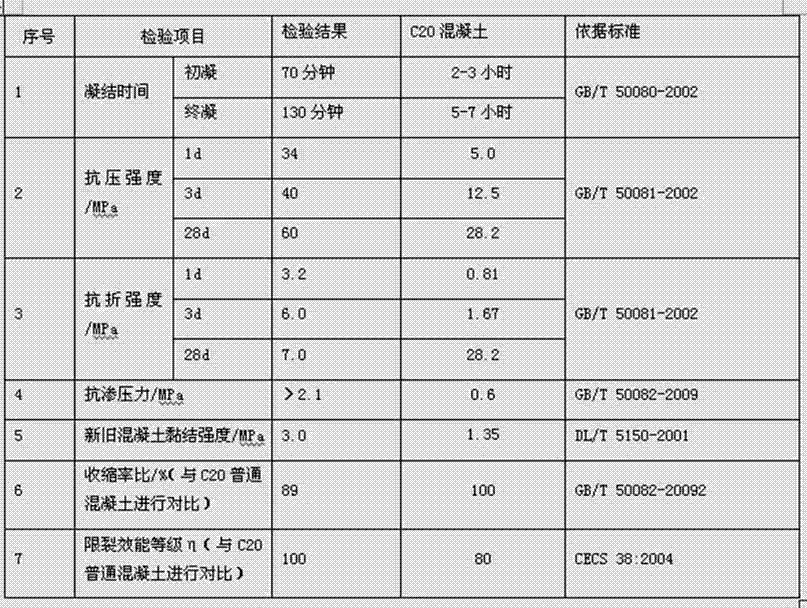

[0022] The above-mentioned waterproof and anti-seepage agent is compared with the commonly used C20 concrete for experimental analysis. C20 concrete is proportioned with the commonly used weight ratio, cement (P.O42.5): water: medium sand: crushed stone (5mm-20mm) = 1 :0.83:3.10:4.96. Take the above waterproof and anti-seepage agent according to the following weight ratio for performance test, waterproof and anti-seepage agent: stone (5mm-10mm): water = 1: 1.2: 0.214, the test results are as follows:

[0023]

[0024] The coagulant is a common coagulant, and its main component is sodium fluorosilicate.

[0025] A waterproof and anti-seepage concrete made of the above-mentioned waterproof and anti-seepage agent, which is composed of gravel, water, and waterproof and anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com