Construction process of bridge downward turning method swivel bearing system

A construction technology and swivel technology, which is applied in the construction technology field of the swivel load-bearing system of the down-rotation method, can solve the problems of complex technology, difficulty in guaranteeing the construction quality of caps, and many construction procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

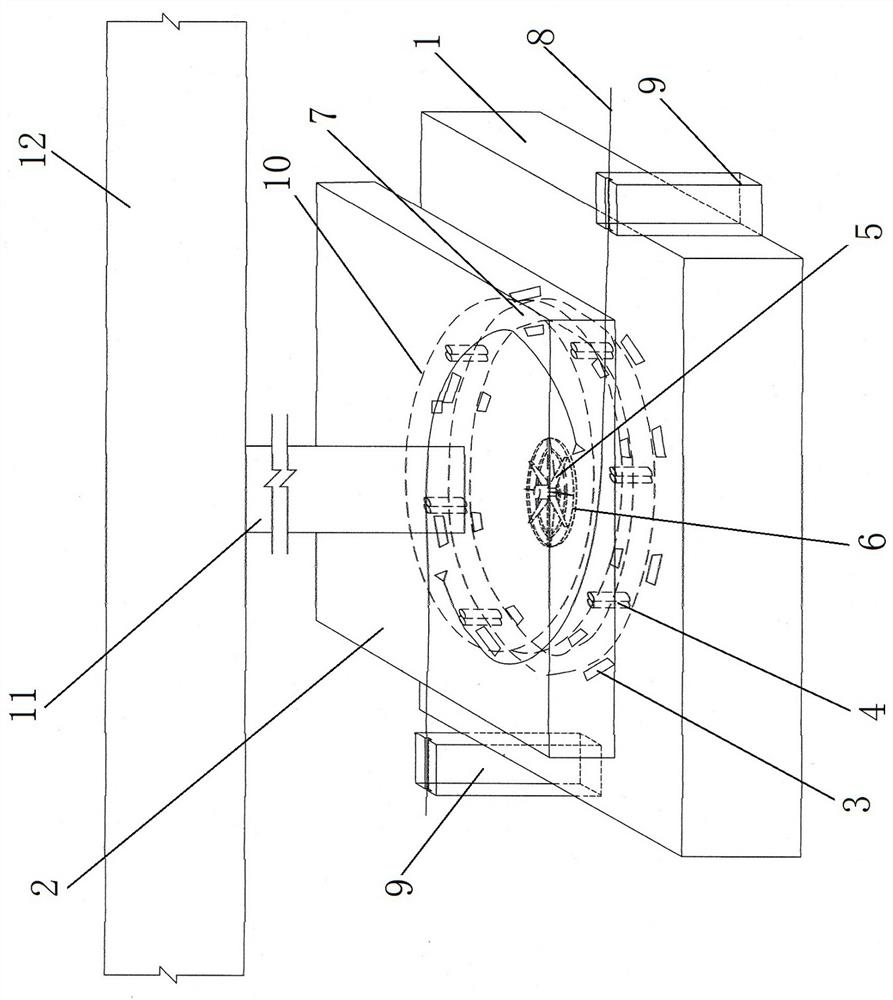

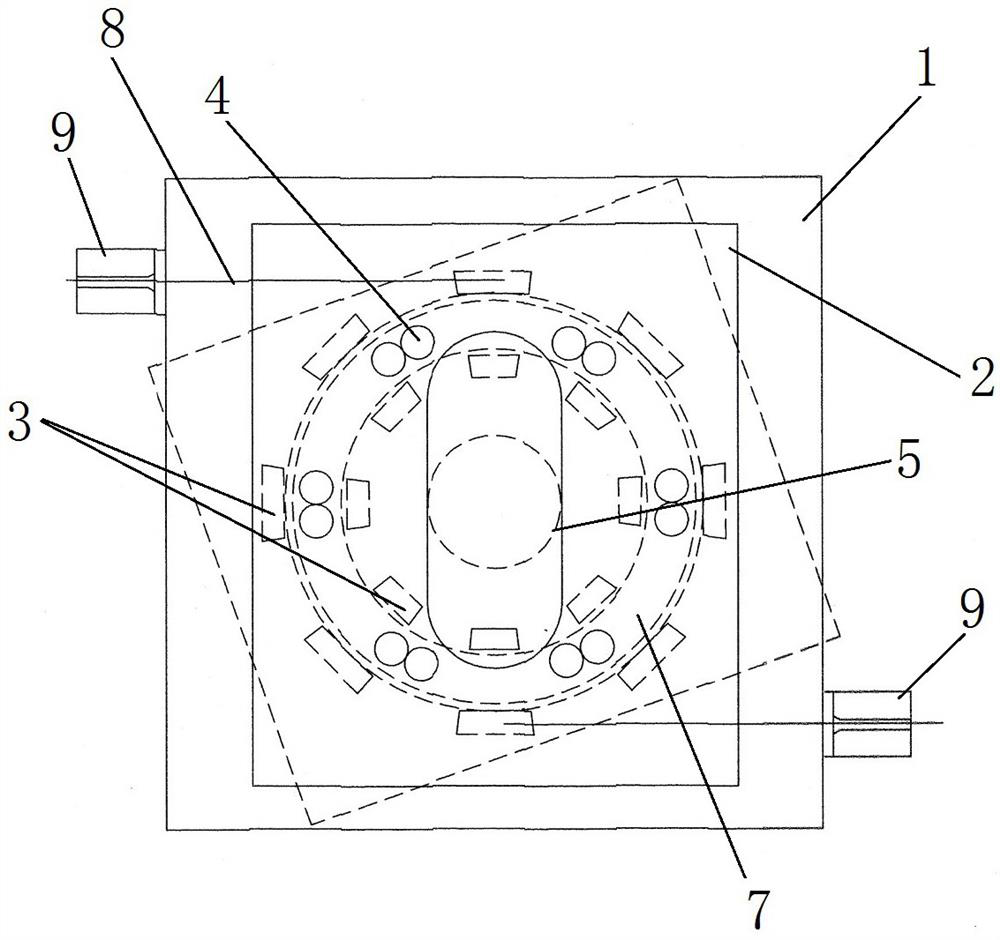

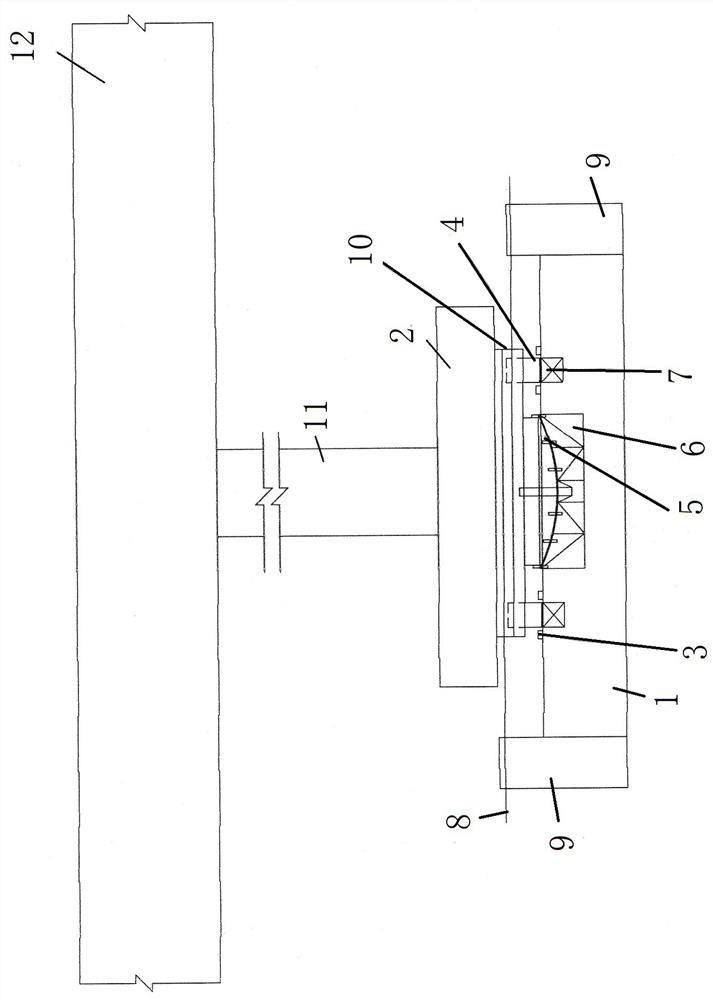

[0089] Combine below Figure 1-4 The present invention is further described;

[0090] 1. Clean the base of the platform, measure and stake out;

[0091]Clean up the base within the cap range, pour a concrete cushion, and measure the center and edge of the cap on the cushion.

[0092] 2. Binding the steel bars of the lower cap (lower turntable) and the steel bars of the traction reaction seat;

[0093] Install the reinforcement according to the requirements, install all the vertical reinforcement, only install the reinforcement of the first pouring concrete part of the horizontal reinforcement and distribution reinforcement, and install the traction reaction seat reinforcement at the same time.

[0094] 3. Install the lower cap (lower turntable) template and traction reaction seat template;

[0095] The formwork adopts bamboo glue formwork, and the formwork of the traction reaction seat and the formwork of the lower platform are installed together, and are fixed and supporte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com