Deck type open shoulder arch bridge and constructing method thereof

A technology of arch bridge and design method, which is applied in the field of bridge structure, can solve the problems of inconvenient construction and poor durability, and achieve the effects of simplified construction, excellent seismic performance and less construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

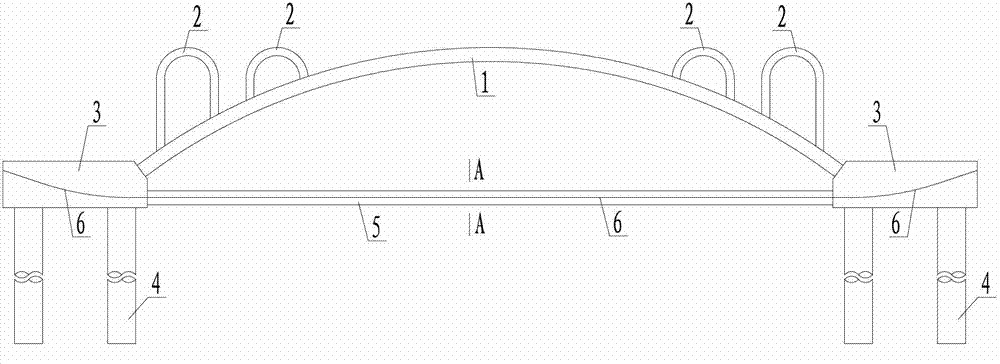

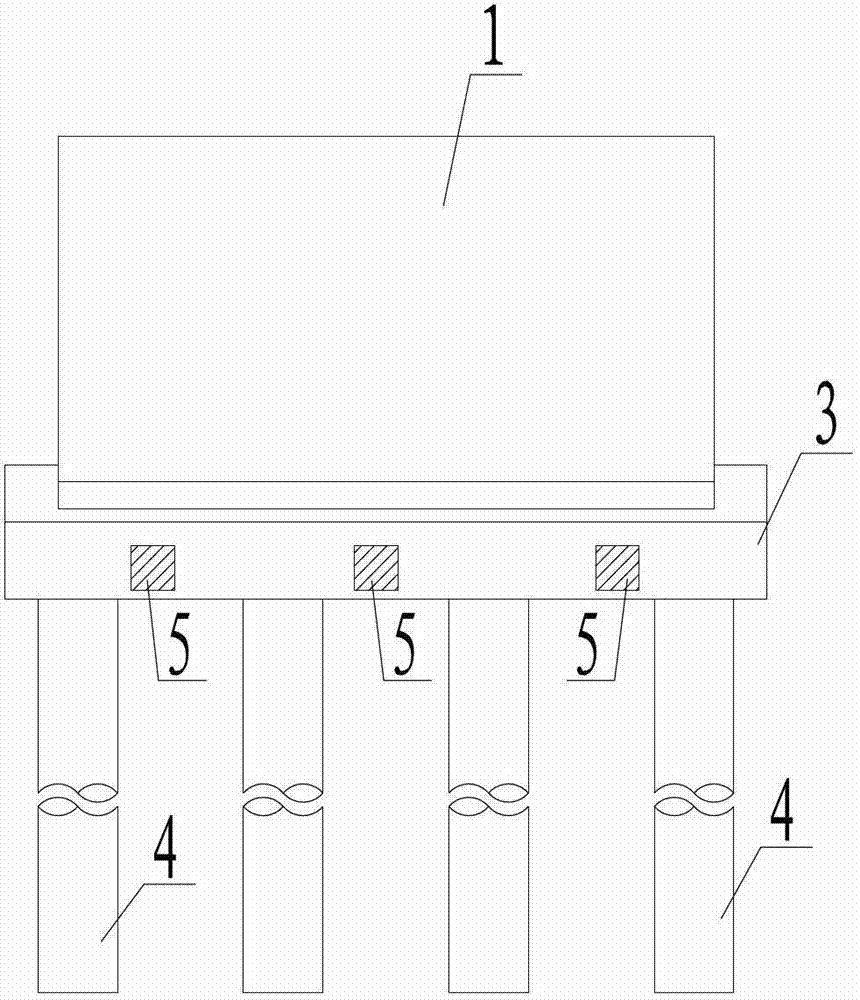

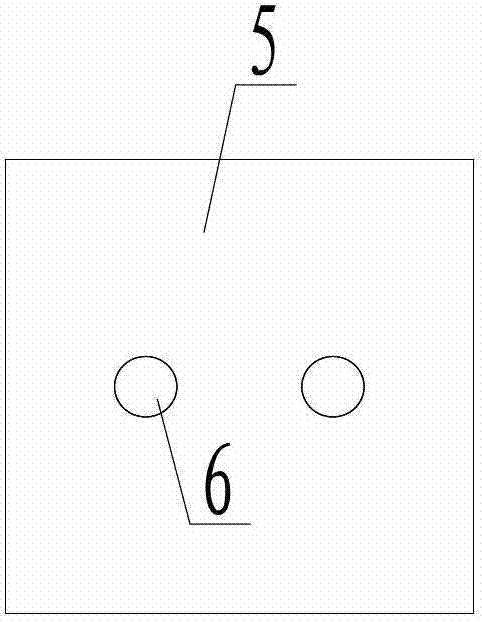

[0025] see Figures 1 to 3 , the present invention is an open-shouldered arch bridge structure with prestressed concrete tension and compression rods arranged between the arch foot caps, including the main arch ring 1, the arch upper belly arch 2, the cap 3, the pile foundation 4 and the prefabricated Stressed concrete tension and compression rods 5 and the upper belly arch 2 are arranged on both sides of the main arch ring 1 . In this structure, the pile foundation 4 and the prestressed concrete tension and compression rods 5 jointly resist the horizontal thrust at the arch foot of the main arch ring 1, wherein the prestressed concrete tension and compression rods 5 share most of the share.

[0026] The structural design of the present invention can be carried out according to the following process: (1) Preliminary estimation: take the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com