Patents

Literature

433results about How to "Improve structural integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

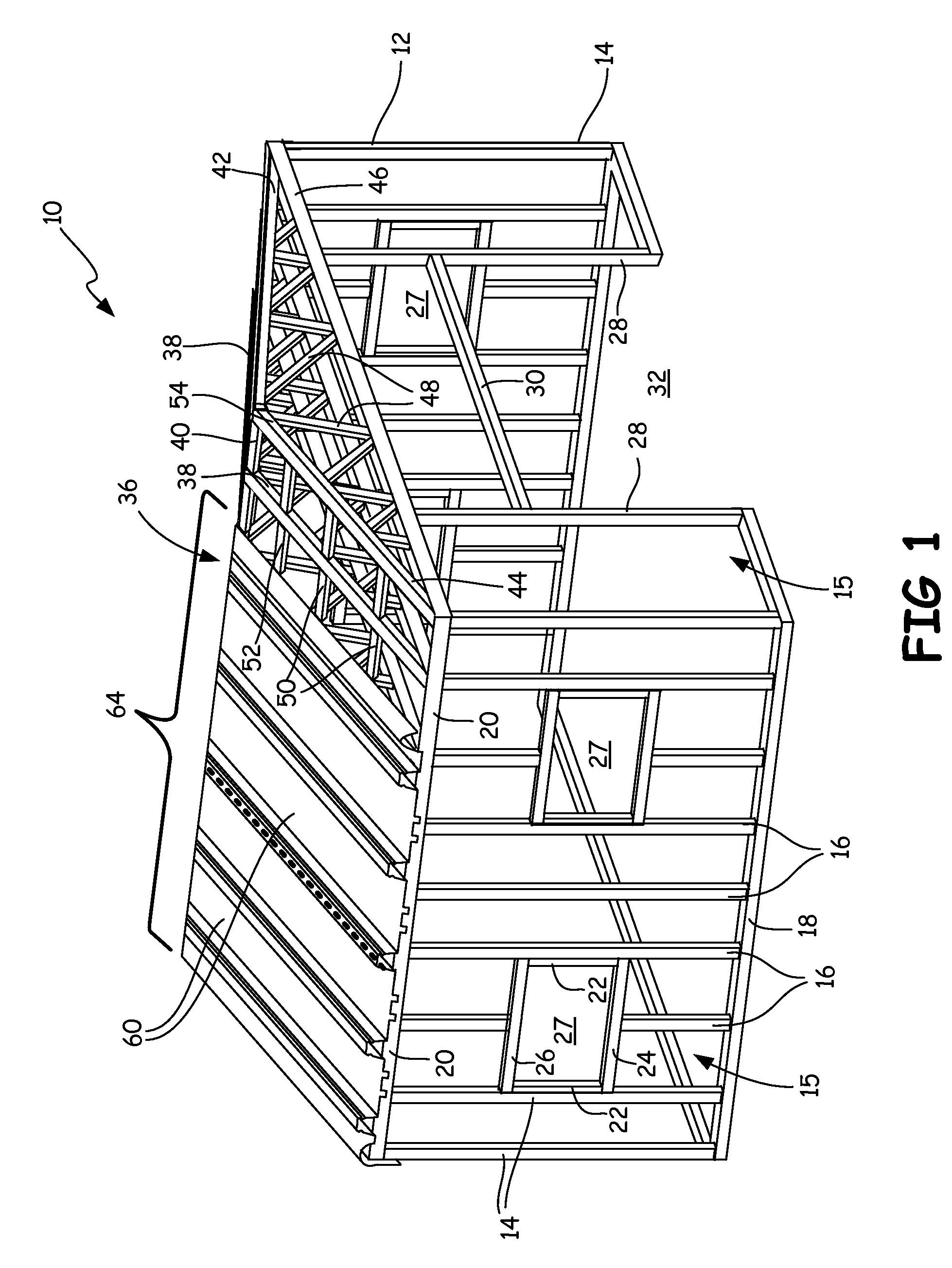

Lightweight plastic furniture

InactiveUS6058854AImprove structural propertiesEasy to carryFoldable tablesStowable tablesEngineeringHigh intensity

A lightweight, high-strength support platform for use in furniture construction, which has superior structural integrity and can be used, by way of example, in portable folding tables, in work tables and in modular furniture of the character typically used in modern office complexes. The support platform embodies a novel structural reinforcement core, and exhibits superior strength characteristics. In one form of the invention, the support platform is used in the construction of a lightweight, readily portable folding table which includes two pair of legs that are pivotally connected to the platform for pivotal movement between an extended operational position and a retracted storage and transport position.

Owner:VIRCO MFG

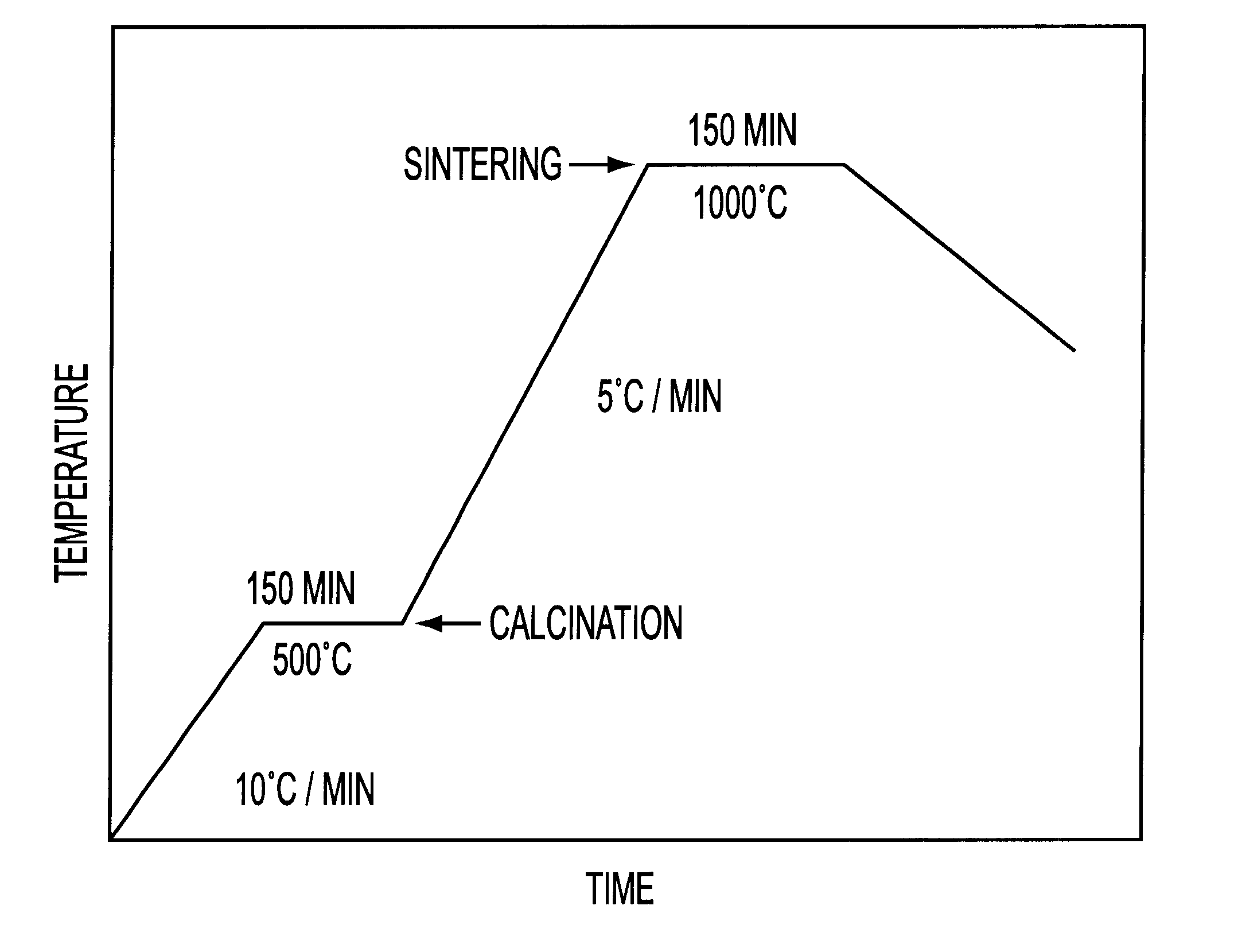

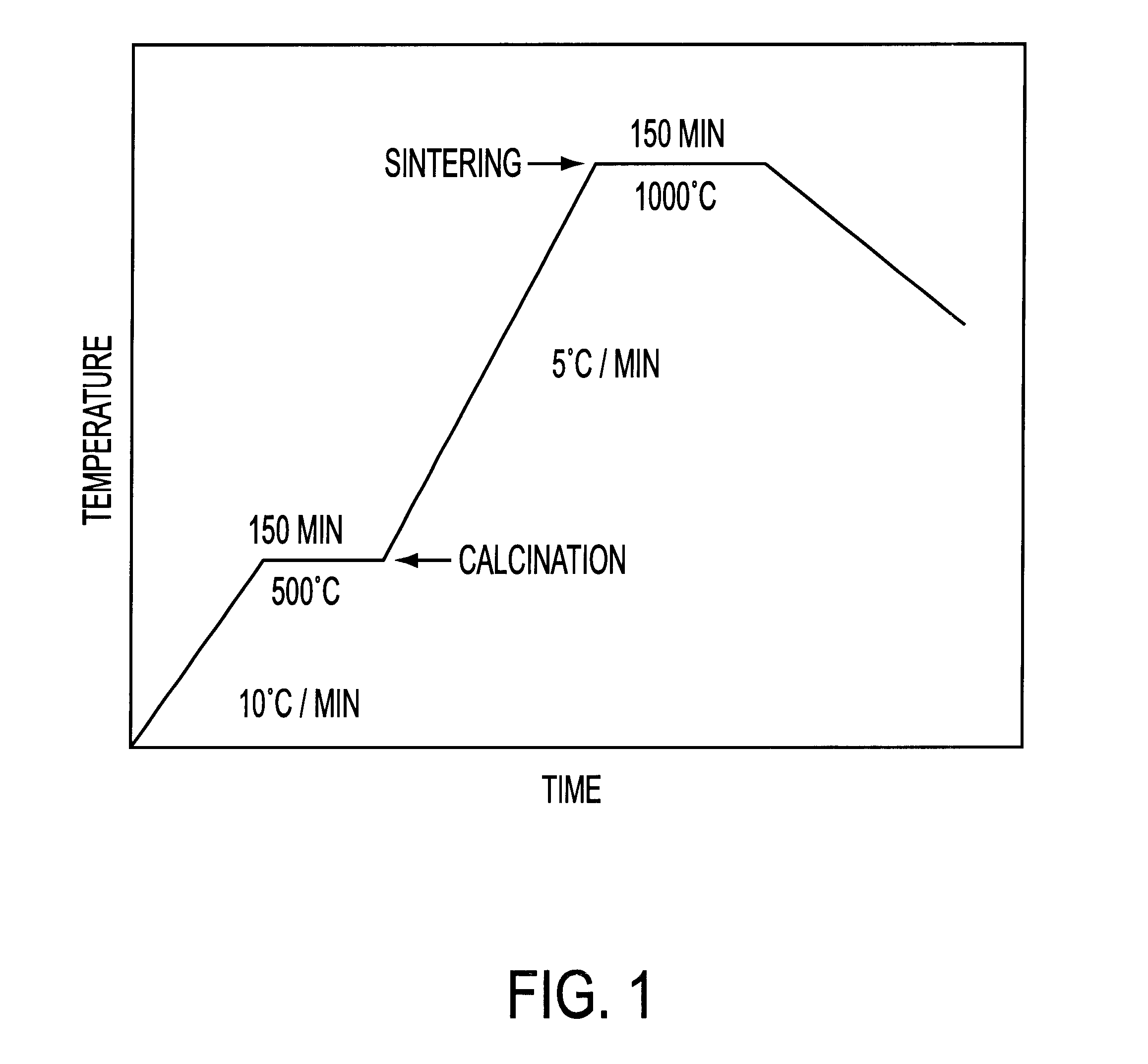

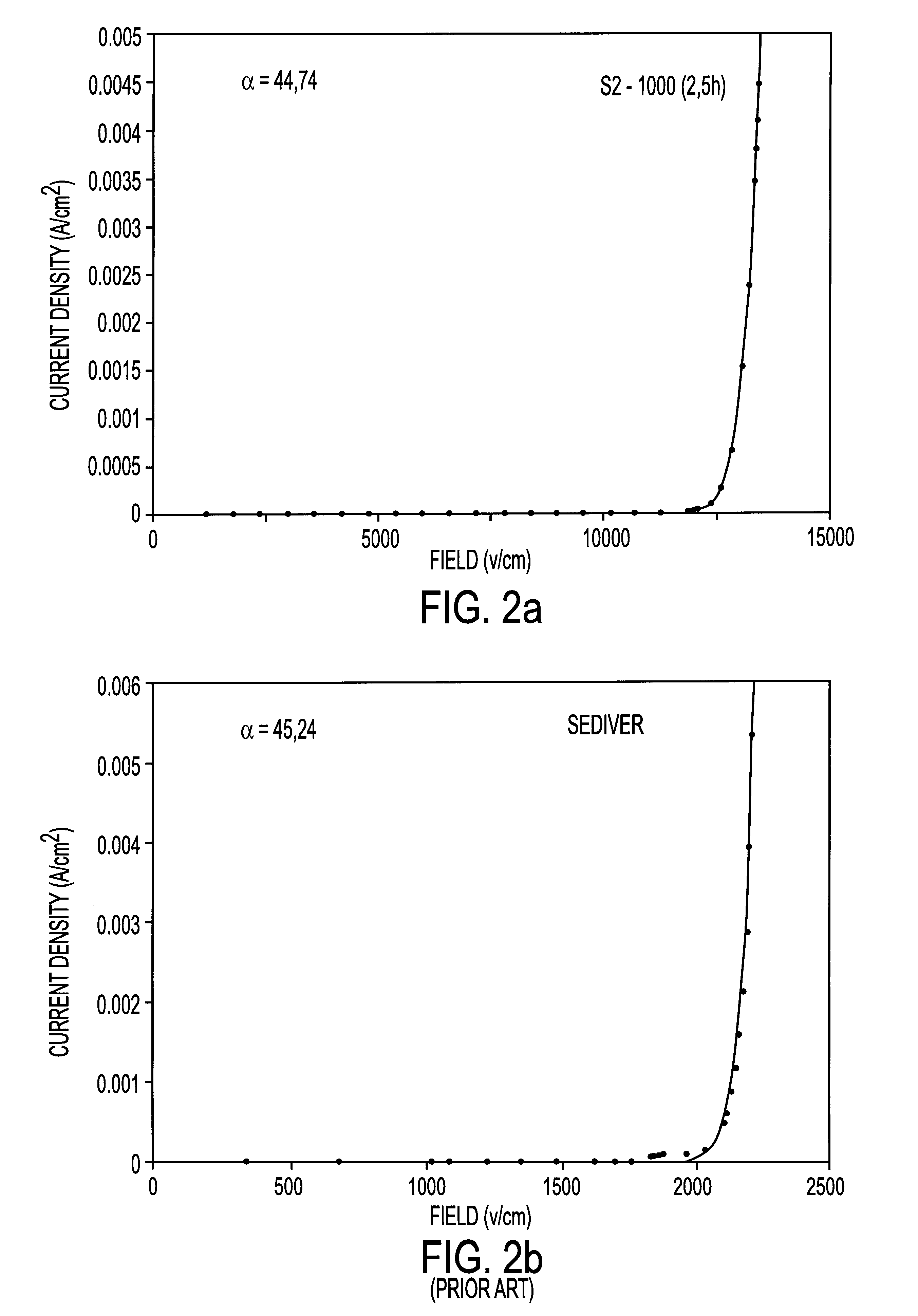

Varistors based on nanocrystalline powders produced by mechanical grinding

InactiveUS6620346B1Lower breakdown voltageImprove breakdown voltageMaterial nanotechnologyConductive materialGrain boundaryBreakdown voltage

The invention concerns novel varistors based on zinc oxide and a method for making same, which consists in using as base products nanocrystalline powders obtained by high-intensity mechanical grinding and in subjecting the mixture resulting from said nanocrystalline powders a consolidating treatment such as sintering, in suitably selected temperature and time conditions so as to retain the smallest possible grain size of ZnO. The resulting varistors have a very fine homogeneous microstructure and an average grain size characteristically not more than 3pm, i.e. five times smaller than standard materials. Said novel varistors have a larger number of grain boundaries per unit length unit and therefore a much higher breakdown voltage. Said voltage is characteristically higher than 10 kV / cm and can reach 17 kV / cm which is almost one order of magnitude above the breakdown voltage of standard varistors. The non-linearity coefficient of the current-voltage curve is also improved, and is greater than 20 and can reach values as high as 60. Moreover, the leakage currents below the breakdown voltage of said varistors, are much lower.

Owner:HYDRO QUEBEC CORP

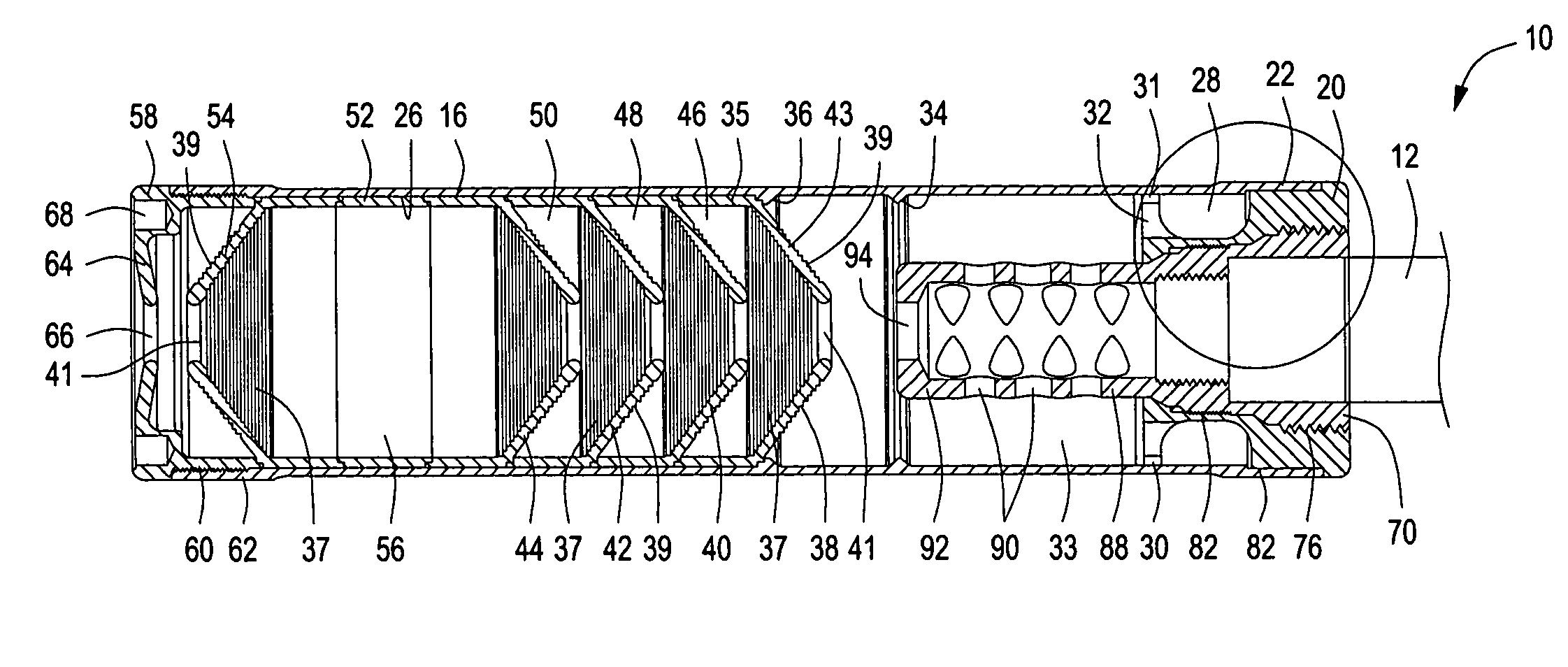

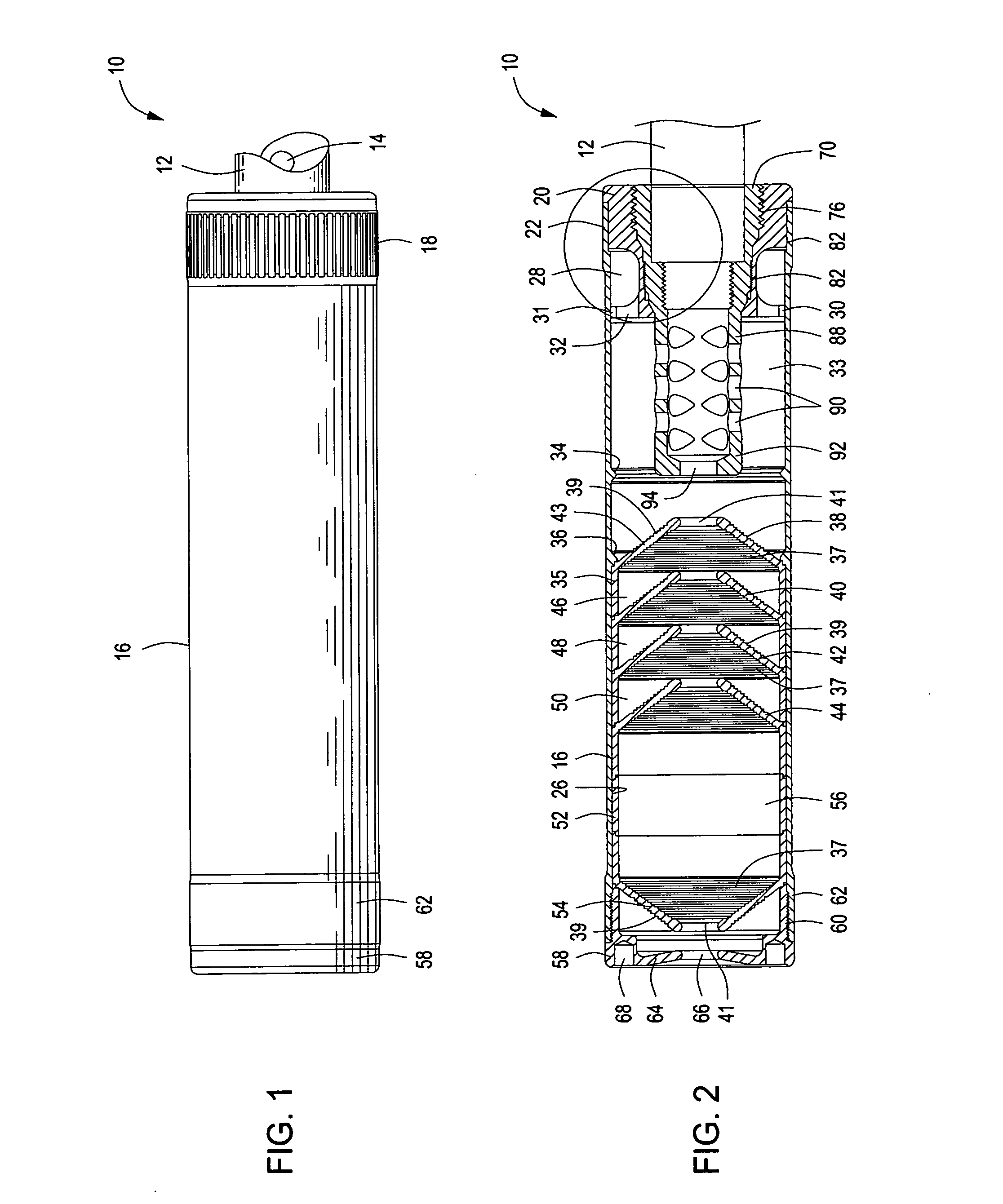

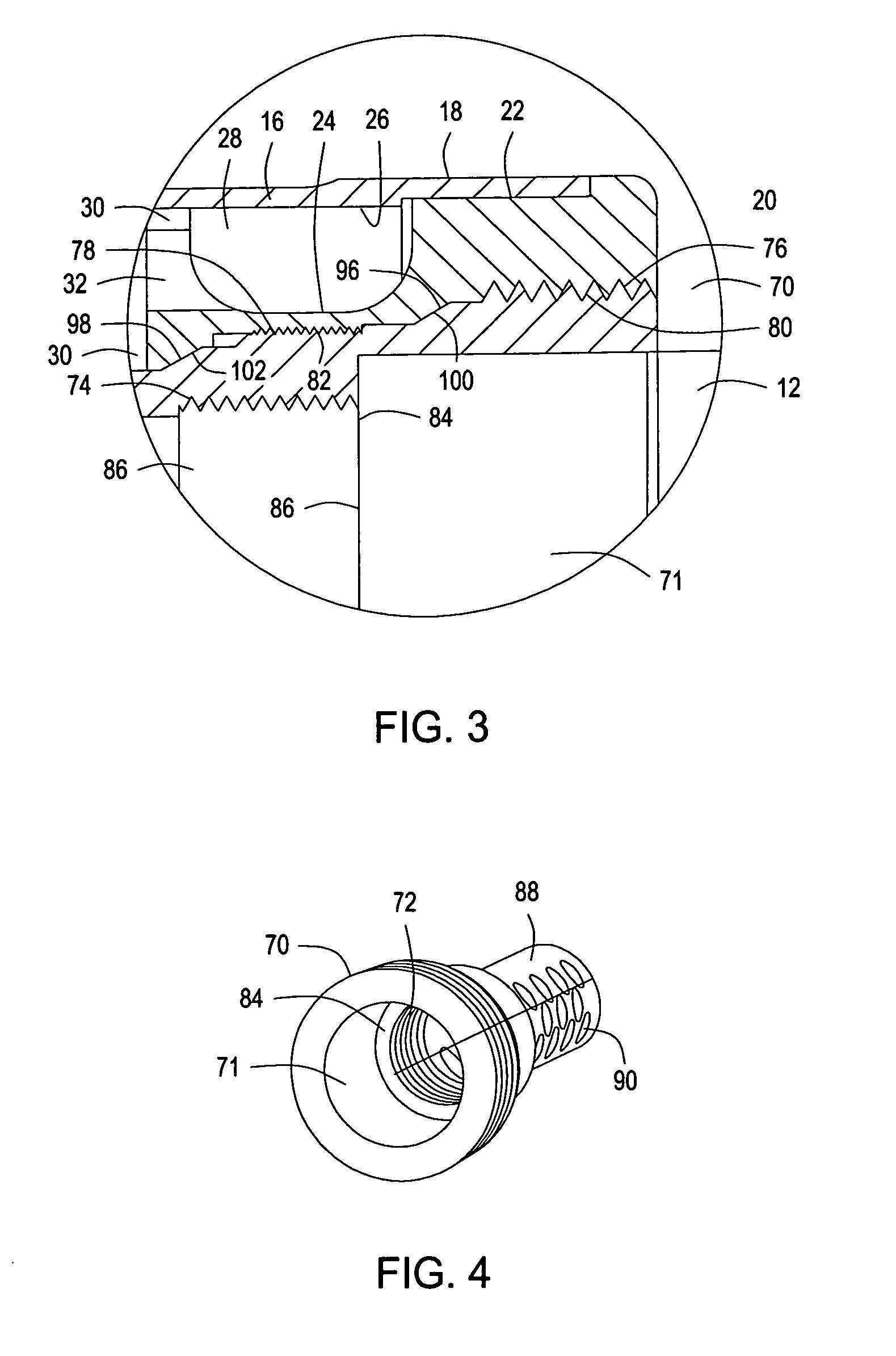

Suppressor for attachment to firearm barrel

InactiveUS20120152649A1Easy to assemble and disassembleImprove structural integrityMuzzle attachmentSuppressorEngineering

A suppressor mechanism has an elongate tubular housing containing baffles and into which is assembled a suppressor mount body having spaced thread sections and spaced tapered gas seal surfaces. An adapter / muzzle brake member defines an internally threaded section that establishes threaded connection with the reduced diameter externally threaded section of a typical firearm barrel that is prepared for attachment of a suppressor thereto. The suppressor mount body and the muzzle brake / adapter member each define spaced threaded sections that establish threaded connection and promote enhanced structural integrity. The spaced internal tapered surfaces of the suppressor mount body and the spaced external tapered surfaces of the muzzle brake / adapter member establish spaced internal cartridge gas seals that prevent high pressure hot cartridge gas and gunpowder residue from coming into contact with and potentially fouling the thread connections of the suppressor mount body and the muzzle brake / adapter member.

Owner:LARUE MARK C

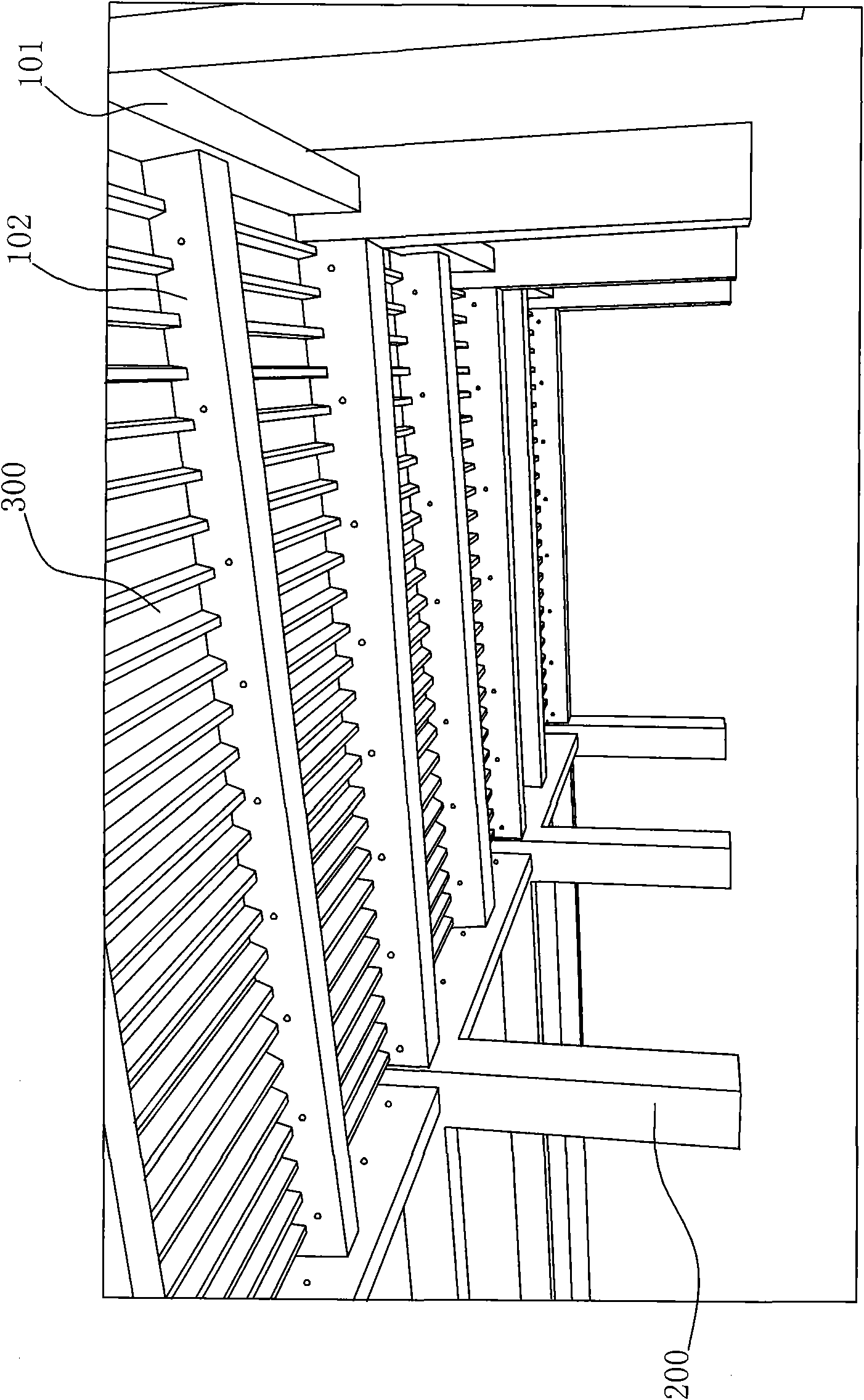

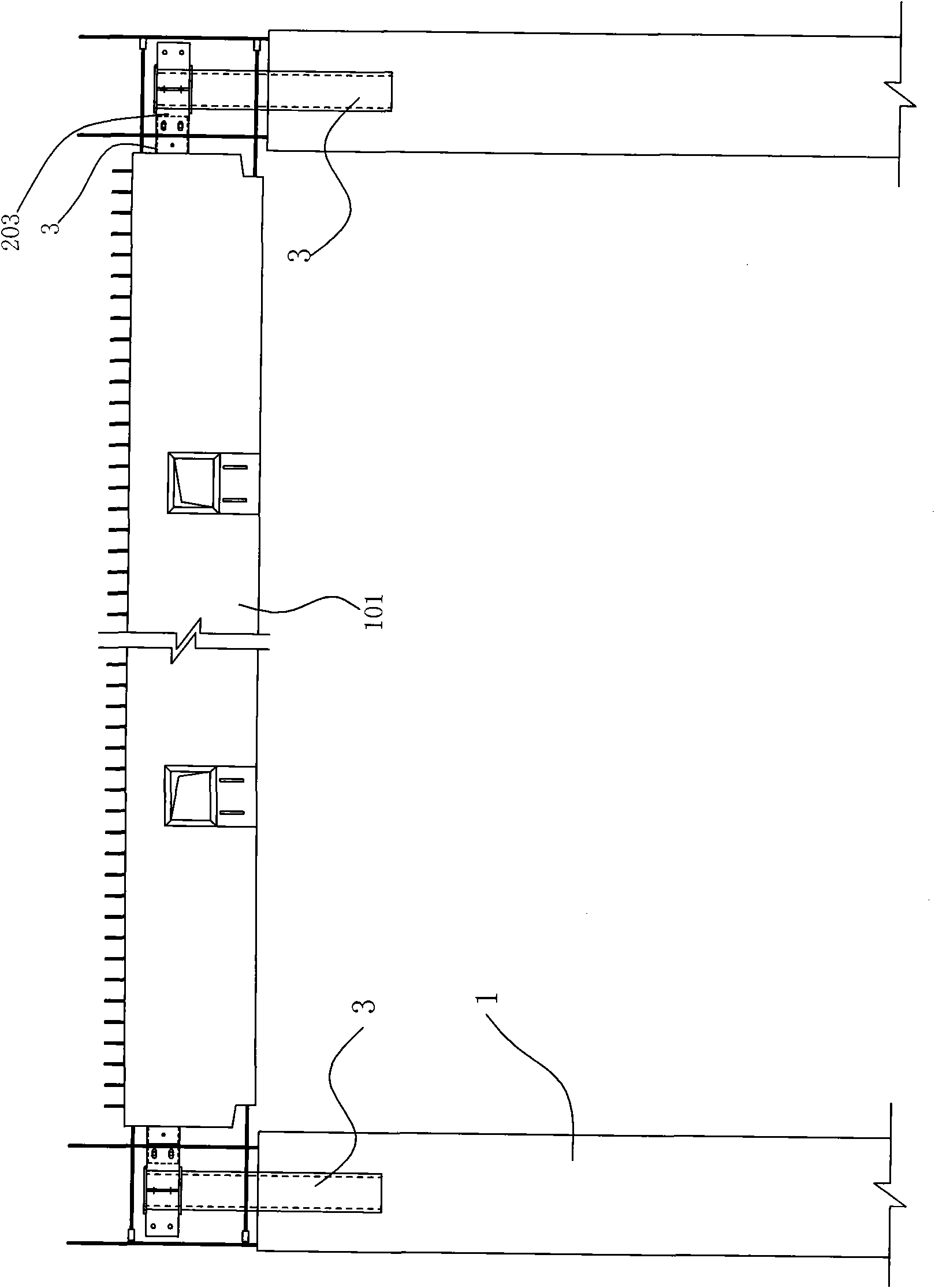

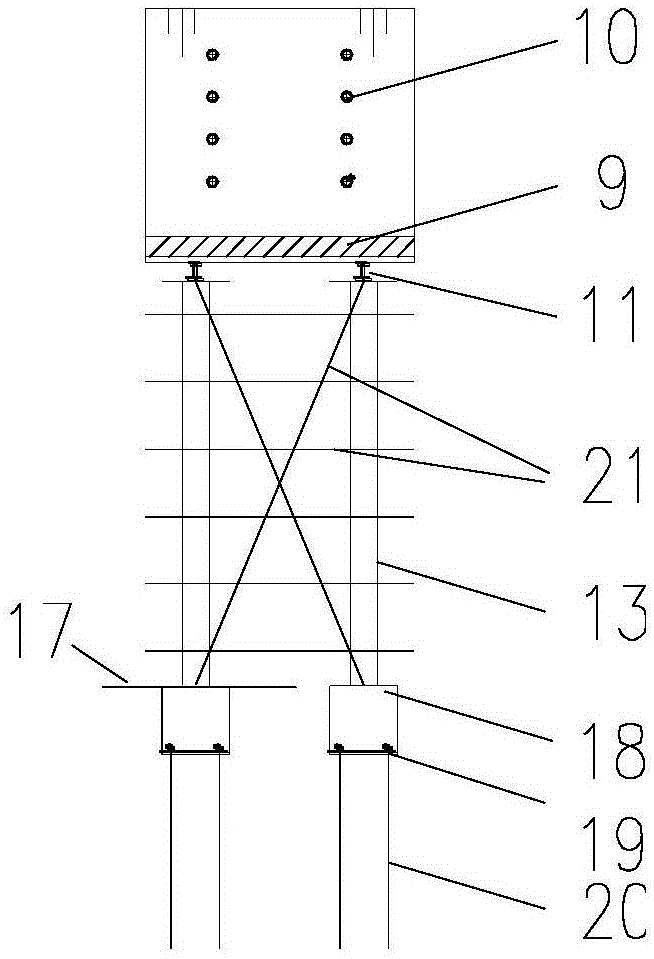

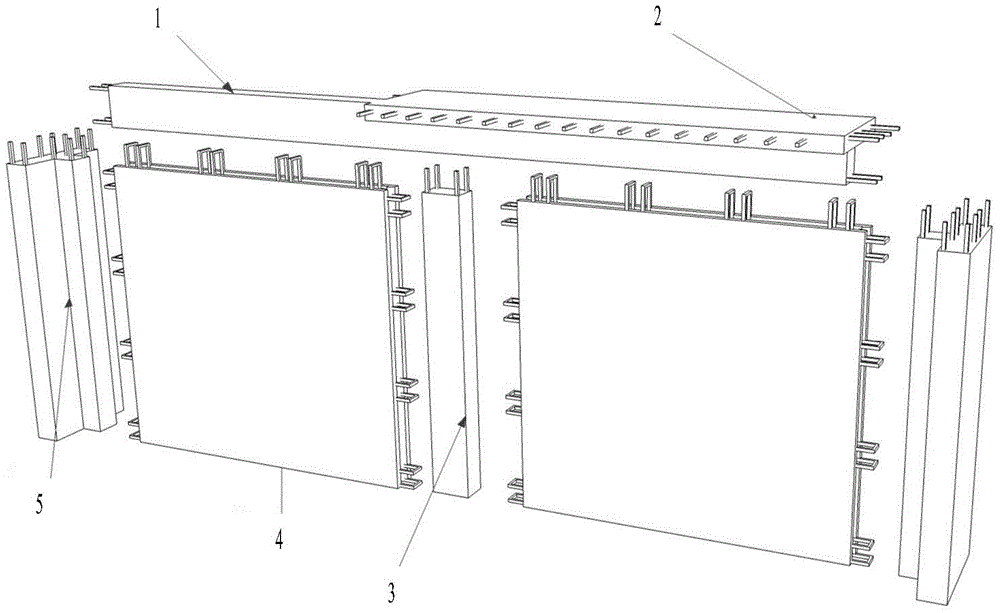

Mounting method of prefabricated building

ActiveCN106013811AImprove air tightnessImprove water tightnessFoundation engineeringBuilding material handlingEarthquake resistanceSewage

The invention discloses a mounting method of a prefabricated building, comprising the following steps: base level treatment, binding of basic steel bars, mounting of first level vertical members, pouring of basic concrete, mounting of first level top horizontal members, pouring of concrete, mounting of second level vertical members, pouring of concrete, mounting of second level horizontal members, pouring of concrete and sequential cyclic operation according to the mounting operation flow. The method disclosed by the invention has the advantages of good integrity of structural connection, good safety and earthquake resistance, good environmental friendliness and energy-saving performance, reliable quality and convenience of quality inspection; the prefabrication rate reaches over 95%; secondary large area pouring, leveling blanket, masonry and other field operation procedures are saved; labor and materials are saved; by virtue of continuous mounting, the efficiency is improved, and the construction period is shortened; precise mounting and one-step positioning can be realized; the safety risk is reduced, and the quality is upgraded; waste water, waste materials, garbage, dust and noise generated by site construction and pollution of transportation to the air environment are reduced; and the prefabricated building is safe, durable, energy-saving, efficient, green, environment-friendly, economical and applicable.

Owner:李藏柱

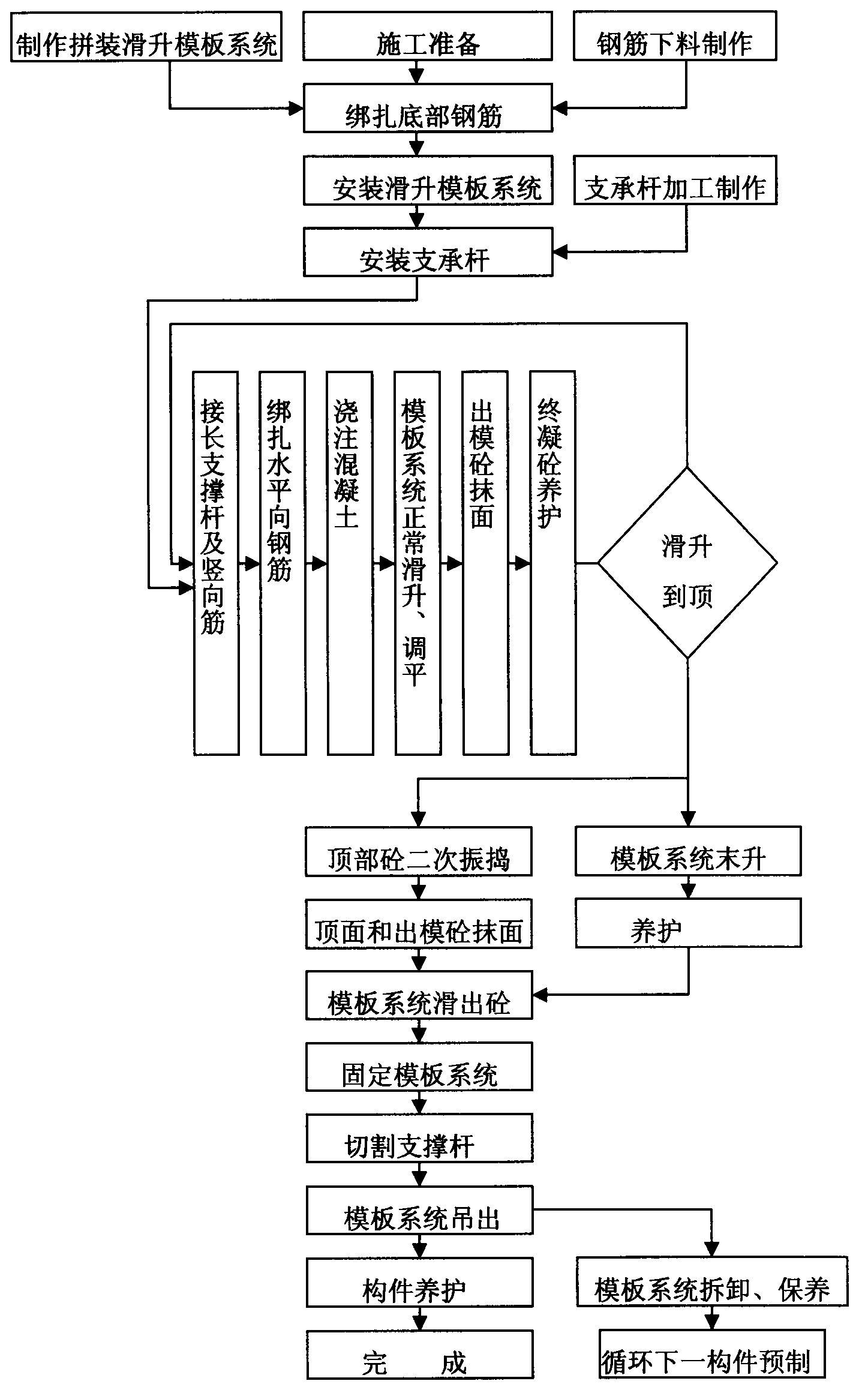

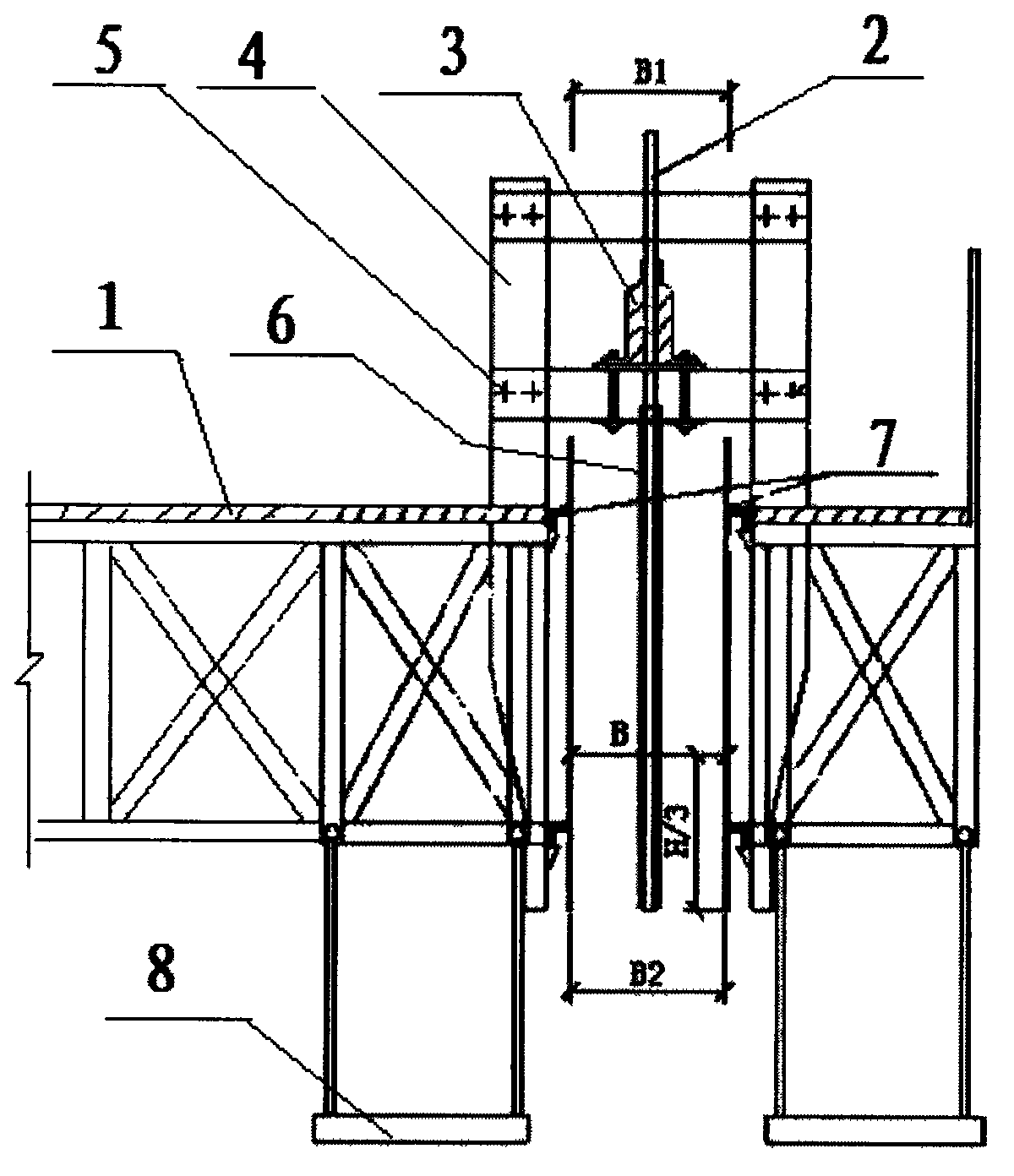

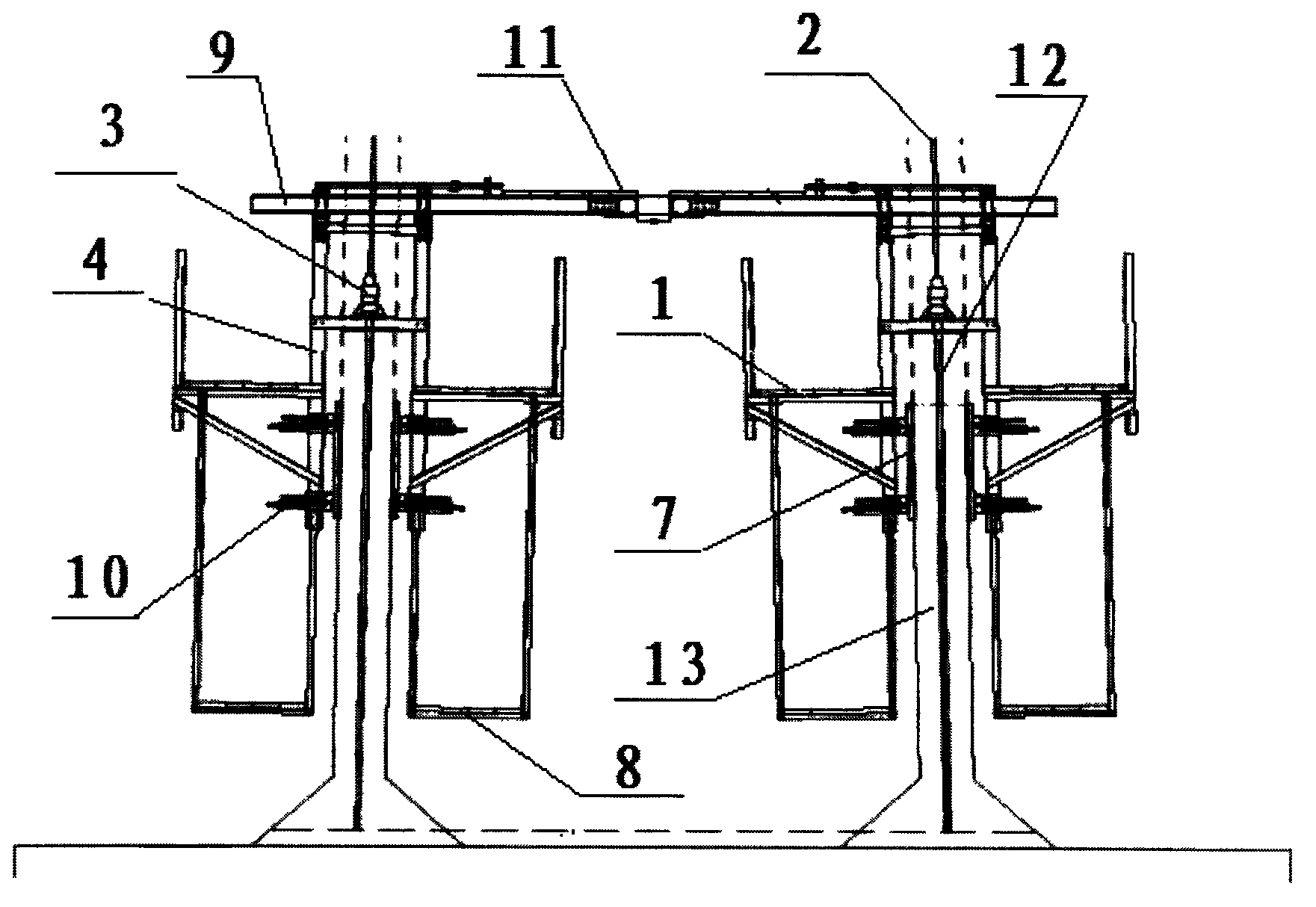

Road bridge variable section hollow high pier slip-form construction method

InactiveCN103161126AImprove construction progressEasy constructionBridge structural detailsBridge erection/assemblyRebarStructural integrity

The invention discloses a road bridge variable section hollow high pier slip-form construction method. A conventional fixed formwork is changed to a slip type movable steel mould, steel ribs are used for binding, concrete pouring is carried out, a slip form slips up and works horizontally and continuously, a hydraulic jack is used for climbing up along a support rod, the formwork carries out continuous slip-up construction from the bottom of a pier to the top of the pier, a whole slip-form device is driven to carry out pouring and forming in a one-time continuous mode at the same time to complete whole pier body construction quickly, and above all, the geometric dimension of a variable section can be changed by the fact that an adjusting support ceaselessly contracts and expands in a slip process of the formwork in construction. Construction is convenient and flexible, a support is of no need in slip-form construction, cycle disassembling and cycle assembling are of no need for the same section, materials are saved, labor consumption is low, construction progress is fast, structural integrity is good, and safety and reliability are achieved.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP

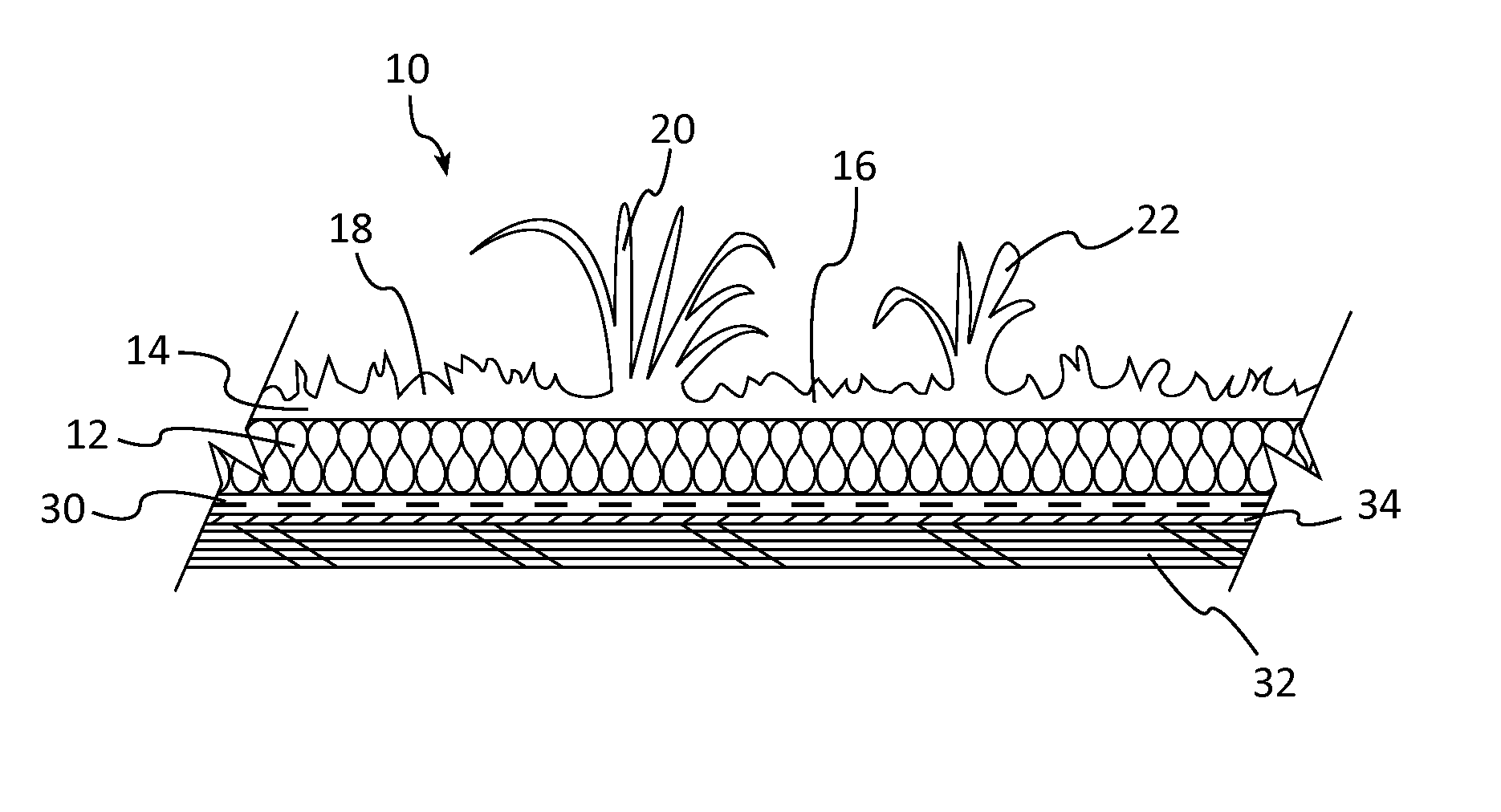

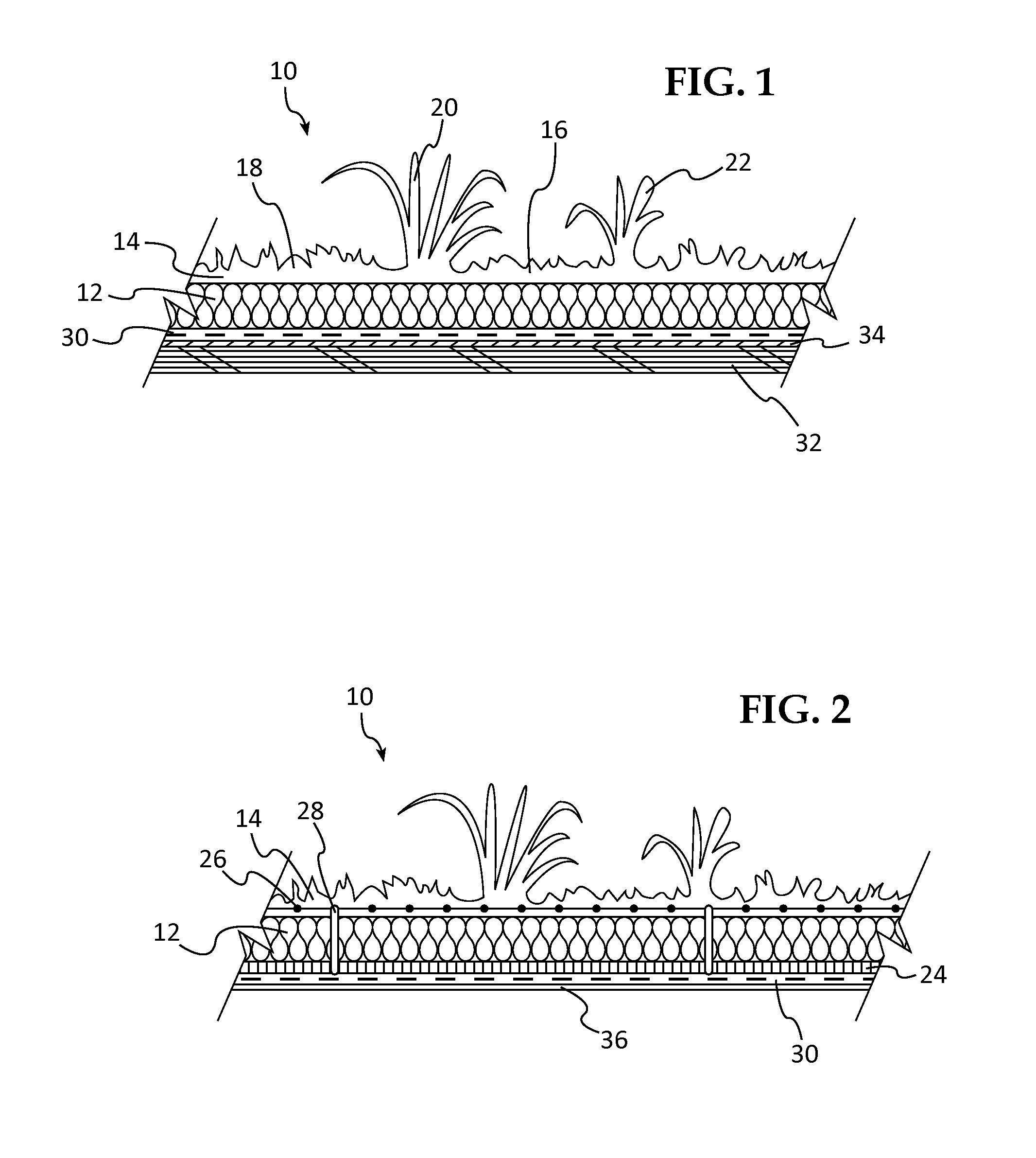

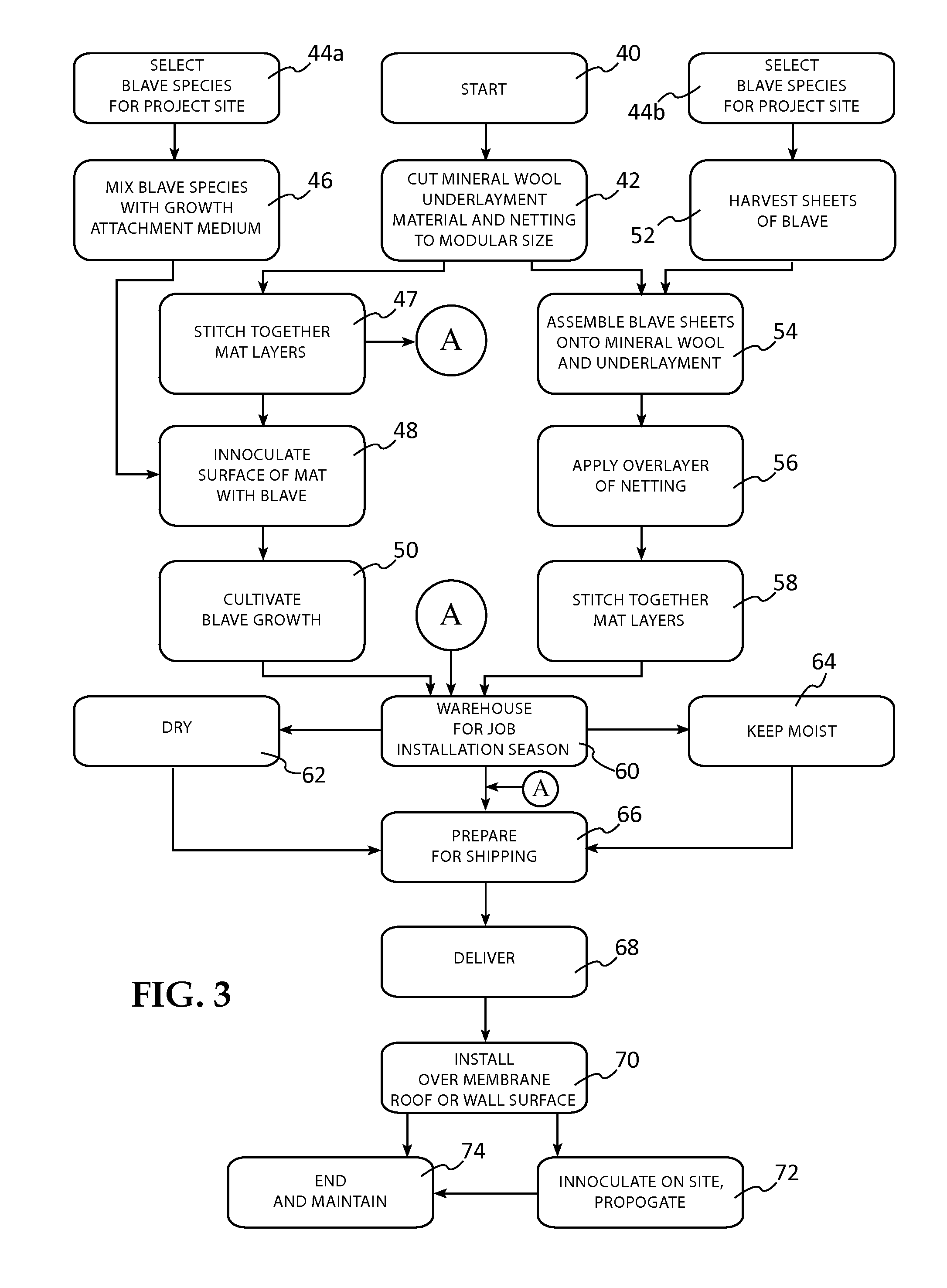

Living Roof and Wall Systems Using Cultivated Mineral Wool Mats to Support BLAVEs, Methods of Cultivation and InnoculantsTherefor

ActiveUS20110197504A1Improve integrityImproves Structural IntegrityRoof improvementHops/wine cultivationAdhesiveCell culture media

Soil-free living roof and wall systems comprising a living layer of Bryophytes, Lichen, And Vascular Epiphytes (BLAVE) on the surface of a thin, light-weight, flexible, fire-resistant mat of mineral wool having a density in the range of about 6-12 lbs / cu ft and thickness in the range of about ⅜″ to about ¾″. Mats are provided in modular units on the order of 2′×4′; no irrigation or growth medium is used. The mats are adhered to a roof or wall with adhesive or mastic, or may be secured with fasteners. In the preferred embodiment, modular units include flexible mineral wool mats over a base sheet of non-woven plastic fibers, on the order of from 2-4 mm thick, and a wide-mesh plastic netting over the BLAVE layer, sewn through to the base layer. Methods of mat module manufacture, innoculant mix production, installation and cultivation / propagation of BLAVE are disclosed.

Owner:ARCHIPHYTE

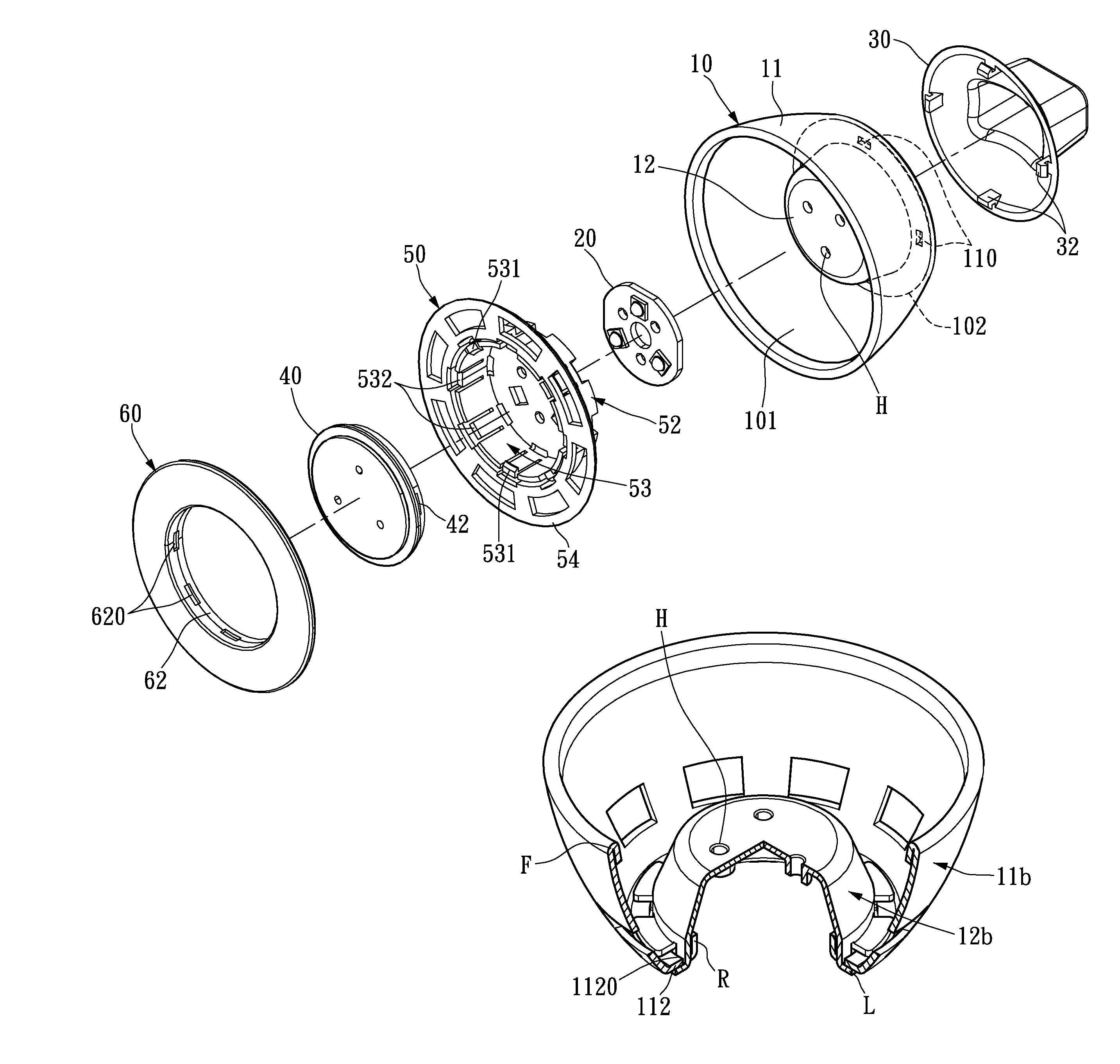

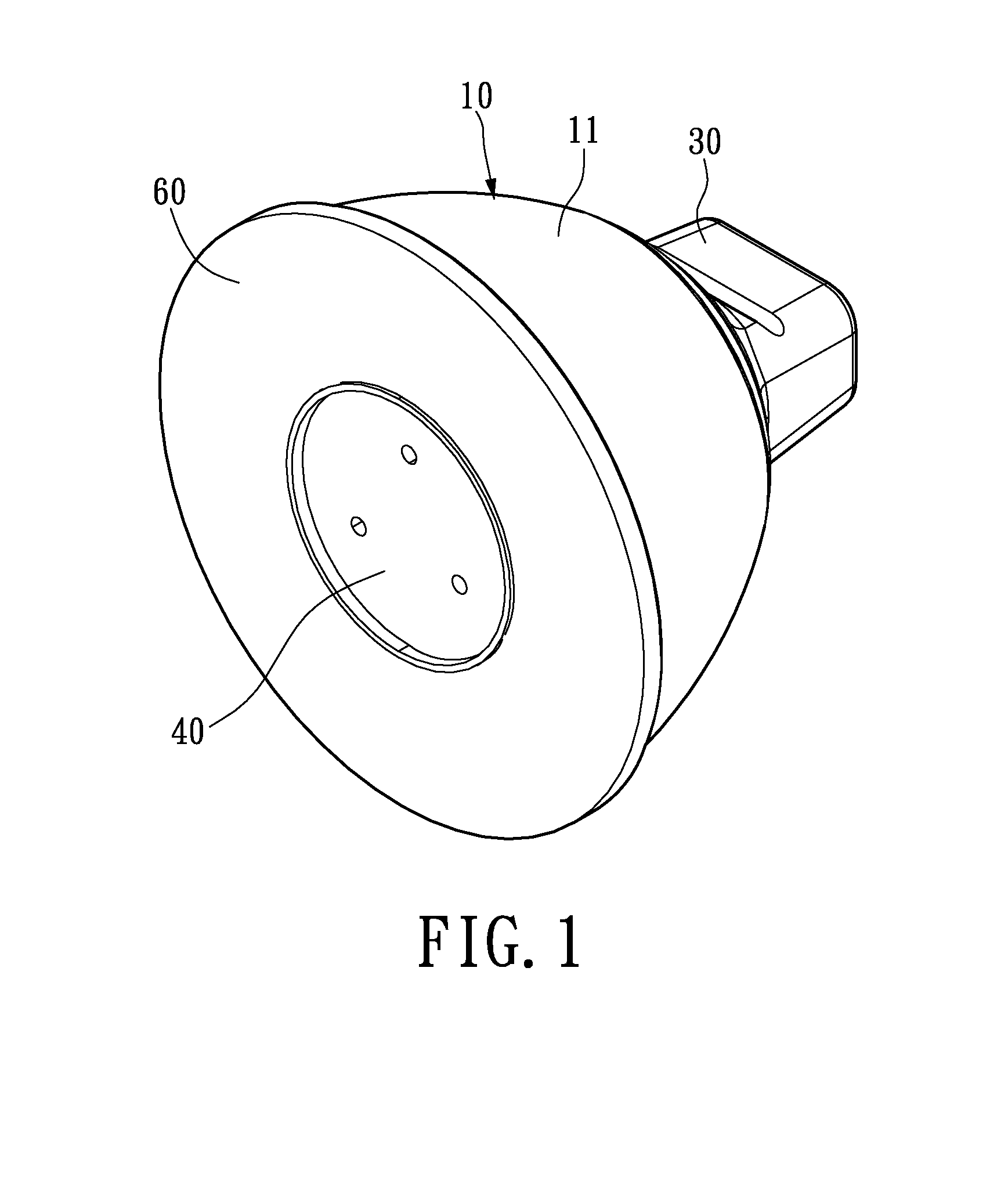

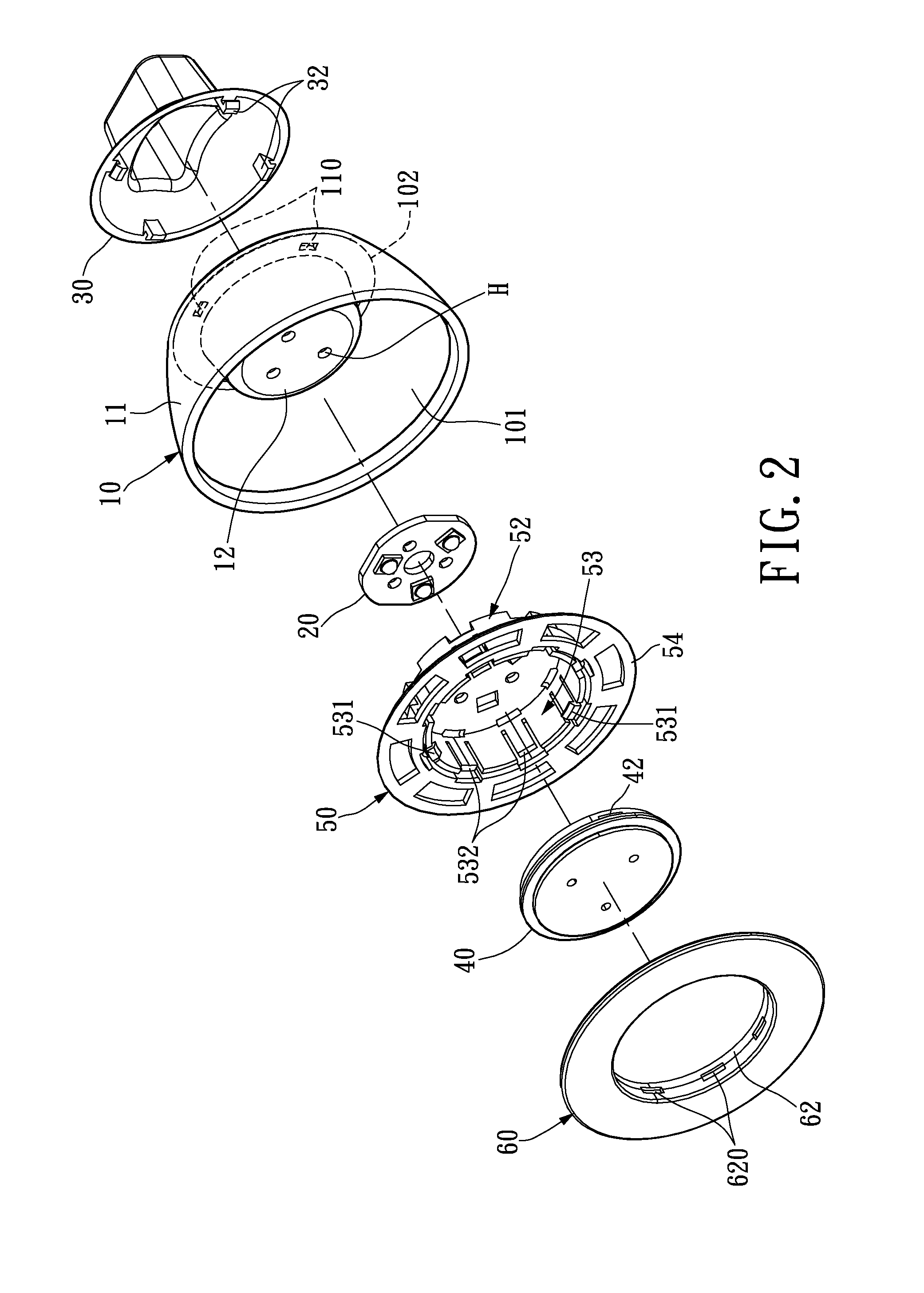

LED lamp

InactiveUS8388197B1Improve efficiencyLight weightPoint-like light sourceLighting heating/cooling arrangementsEngineeringLamp shell

The instant disclosure relates to a lamp having a heat dissipating lamp shell particularly suitable for housing solid state light sources. The lamp comprises a lamp shell of stamping construction and a light source unit. The lamp shell comprises an outer pot portion and an inner tray portion substantially concentrically coupled to the outer pot portion. Externally, the lamp shell forms a substantial portion of the lamp. The light source unit comprises a light module disposed on the inner tray portion of the lamp shell, a controller placed at the rear portion of the lamp shell, and an electrical connecter arranged exposedly from the rear of the lamp. The lamp shell of stamping construction is beneficially characterized by the light weight and strong structural integrity, which attribute to the work hardening property of the stamping process.

Owner:COOLER MASTER DEVELOPMENT CORP

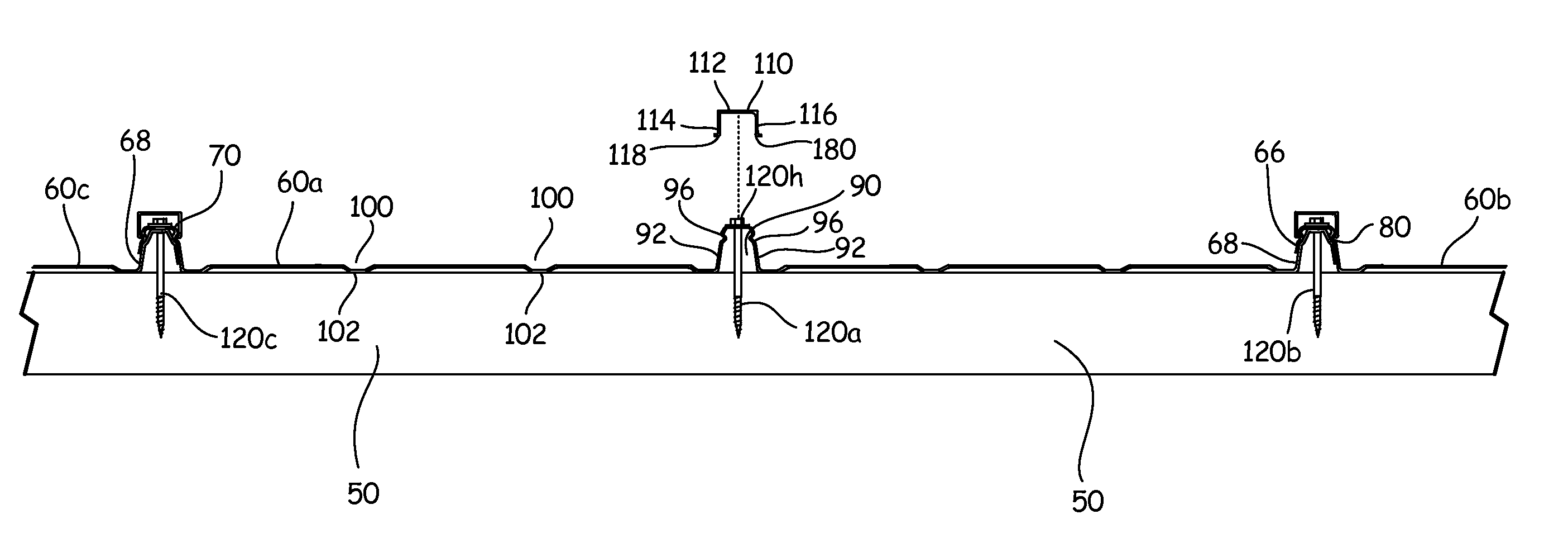

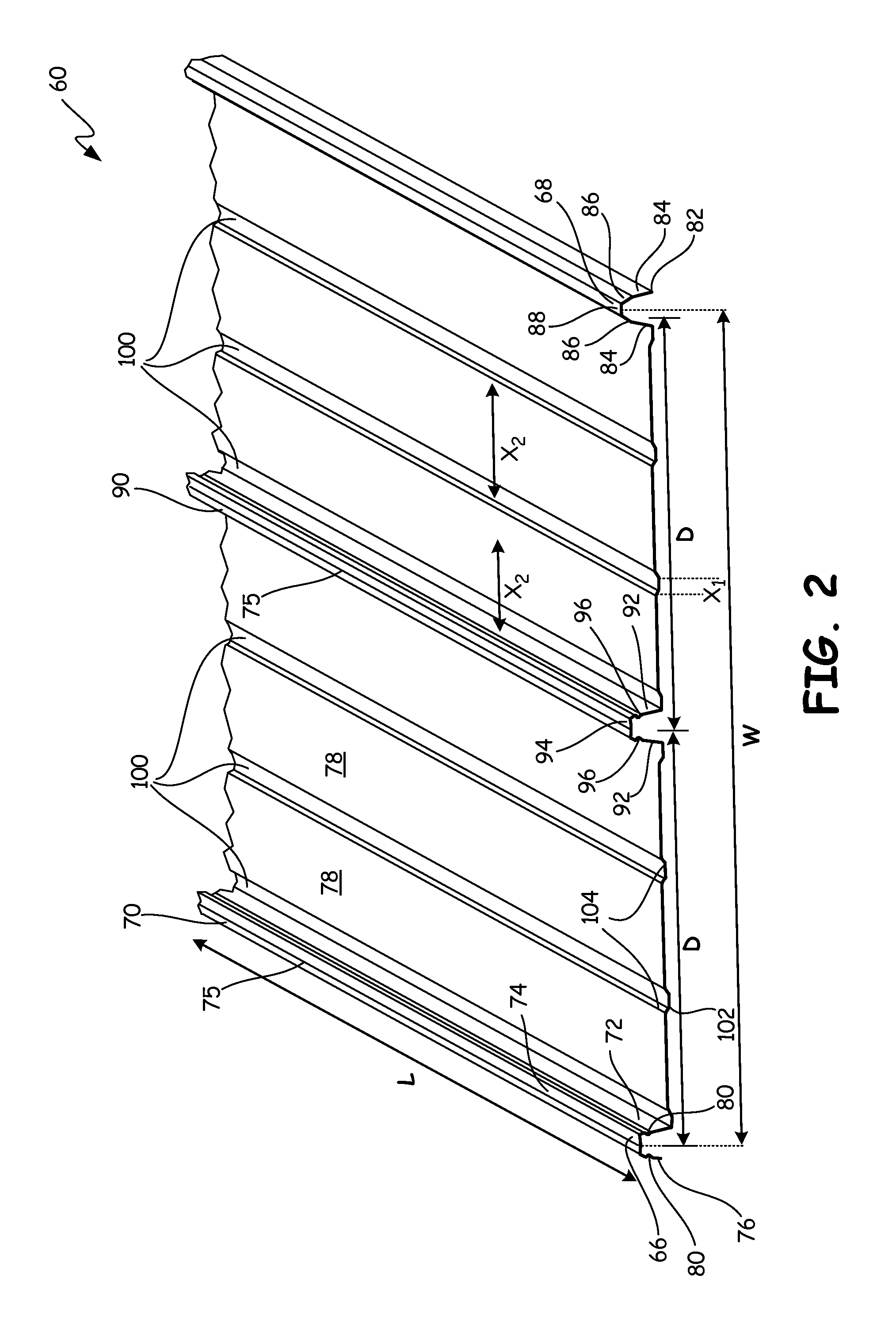

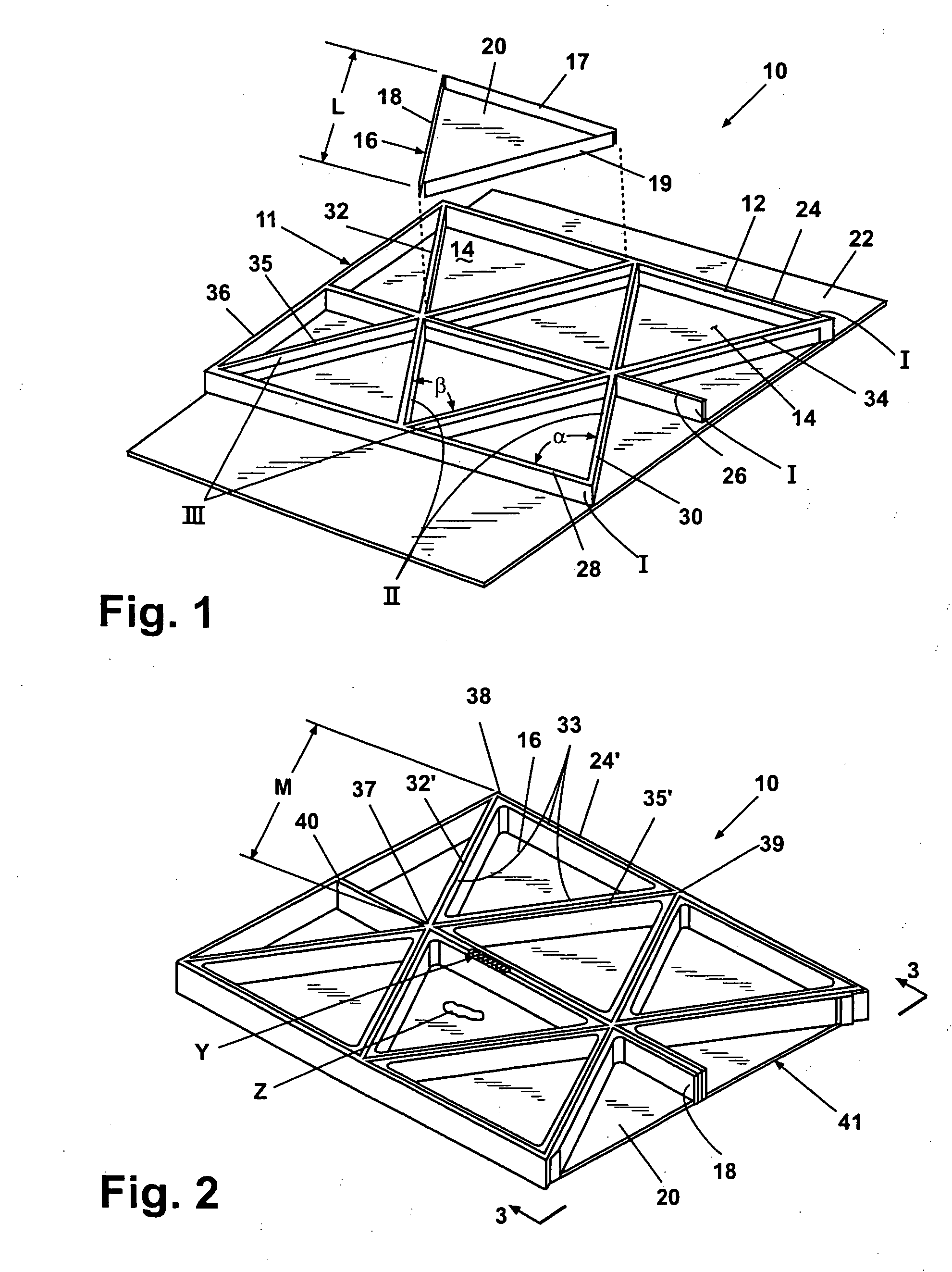

Concealed-fastener exterior cladding panels for building construction

ActiveUS9127451B1Improves Structural IntegrityLow costRoof covering using slabs/sheetsConstruction materialEngineeringInverted u

An exterior cladding panel assembly for covering an outside surface of a framed building is provided by the invention. A unique rib and batten system with overlapping raised female and male edge ribs on the adjacent installed panels, and raised interior ribs allow through fastening of the panels on the order of 32 inches or wider to the building's underlying framing structure with complete concealment of the fasteners, and without the need for special fastener clips. The ribs have an inverted U-shaped end profile that creates an open cavity between the rib top wall and the underlying framing member. The fastener can be driven through the rib top walls into the framing member without the need for a solid filler cleating strip.

Owner:LESTER BUILDING SYST

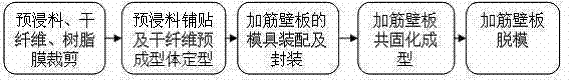

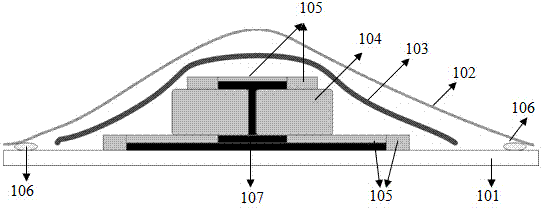

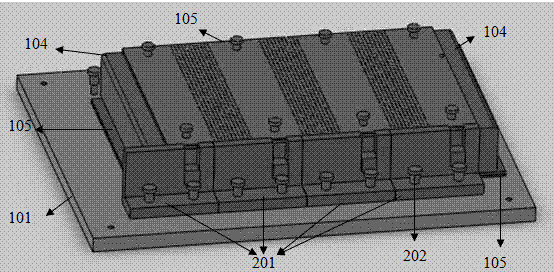

Prepreg/resin film infiltration co-curing forming method for composite stiffened wallboards

The invention discloses a prepreg / resin film infiltration co-curing forming method for composite stiffened wallboards. The method comprises the following steps: 1, tailoring prepregs, dry fibers and resin films; 2, spreading the prepregs and sizing dry fiber preforms; 3, assembling and packaging a mould for the stiffened wallboards; 4, co-curing and forming the stiffened wallboards; and 5, demolding the stiffened wallboards. According to the method, a skin is prepared by adopting prepreg spreading, ribs are prepared by the dry fiber preforms and the resin films, and in combination with the characteristics of a prepreg autoclave process and a resin film melting process, the ribs, the skin and the adhesive interface of the ribs and the skin are cured in an autoclave at the same time, thus realizing the co-curing forming of the stiffened wallboards with different rib forms and different material systems. The method can significantly improve the forming efficiency of the stiffened wallboard structure, reduce the manufacture cost, improve the quality of products and improve the flexibility and designability of the manufacturing process and is of great significance to the efficient low-cost manufacture of the composite material stiffened wallboard structure.

Owner:SHANGHAI AIRCRAFT MFG +1

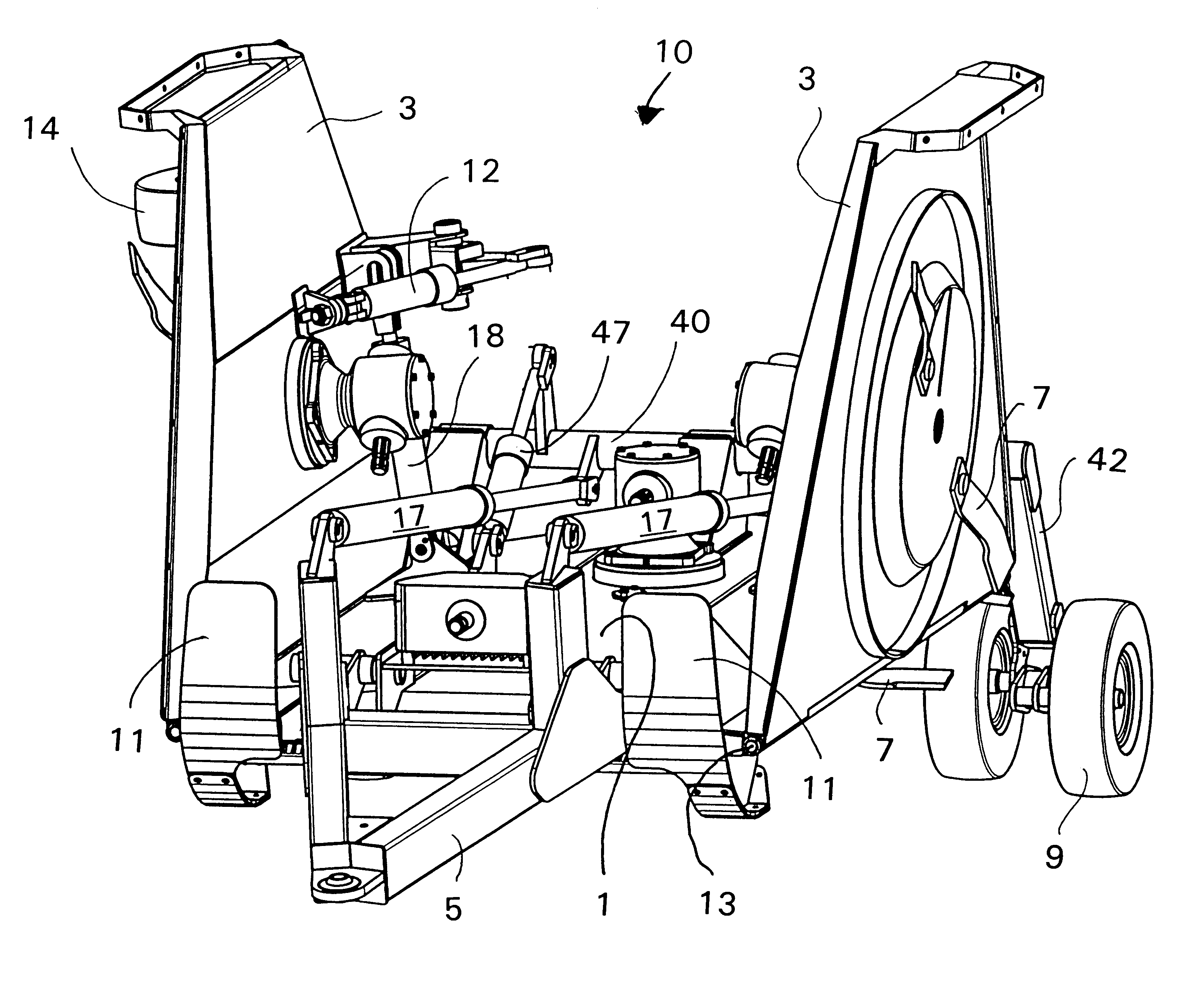

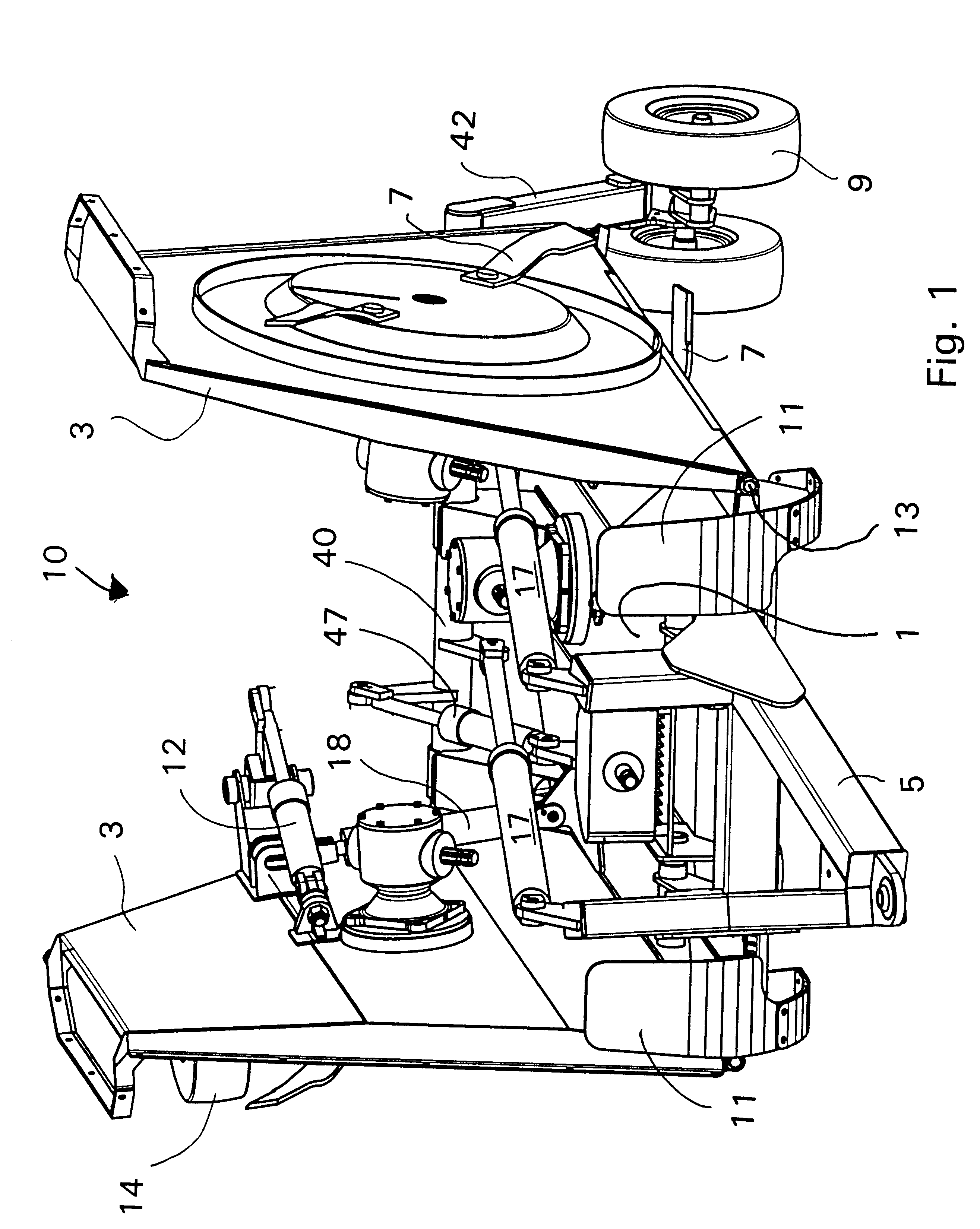

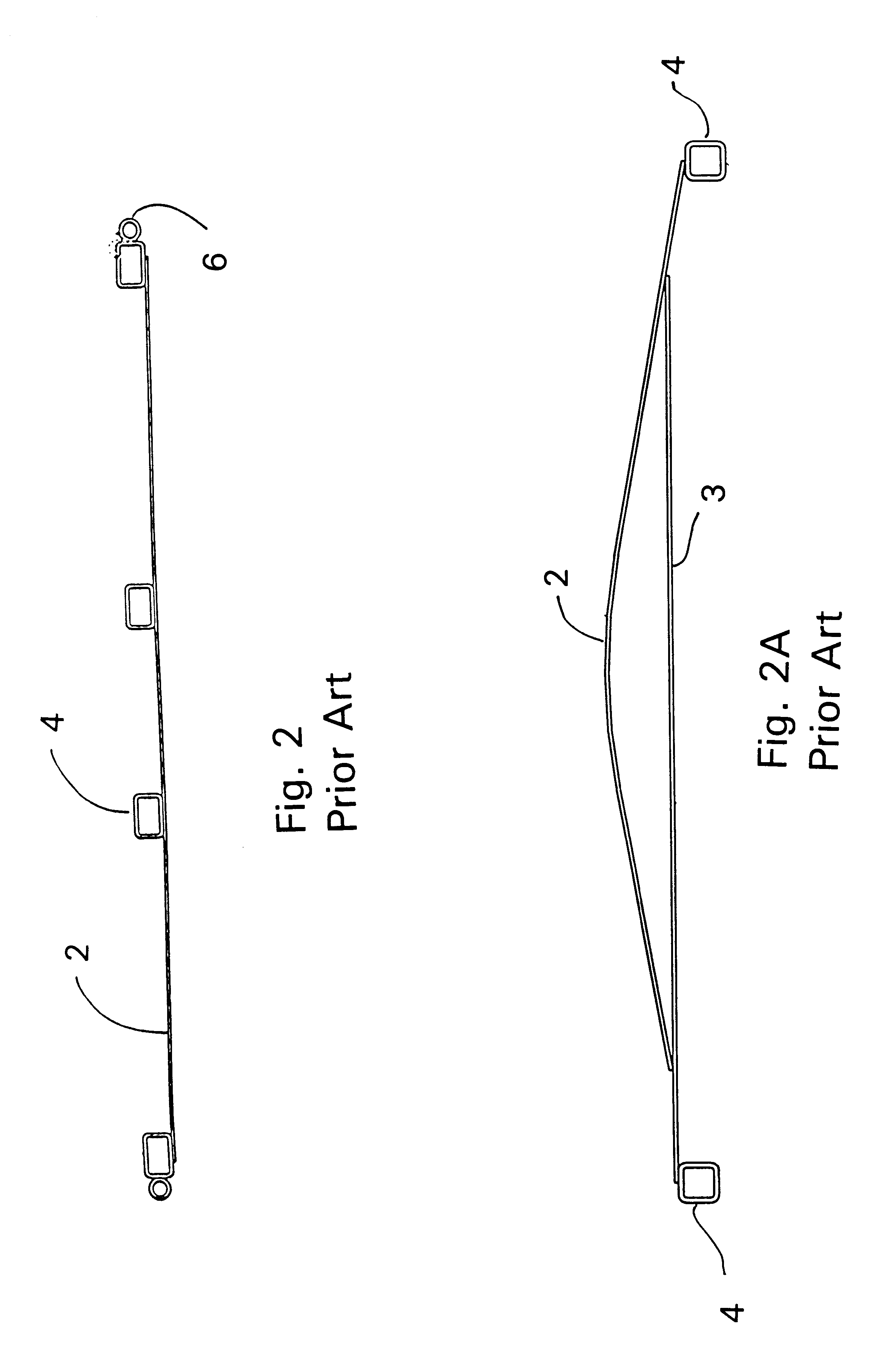

Double deck rotary mower body

A rotary mower for cutting vegetation including grass, brush and the like, and more particularly to a rotary ditch mower having a main body and extension wings or side sections supporting a number of cutting blades. The main body and extension wings are supported by contour following ground wheels and the main body also foldably supports the extension wings which may be inclined relative to the main body. The mower is also provided with a hitch pole for pull behind connection with a tractor and an articulation mechanism of the main body and extension wings for adjustment of cutting height over varying terrain during cutting operations as well as for raising the extension wings to a transport position and for raising the mower to a substantially vertical position, i.e., the main body and extension wings raised perpendicular with respect to the ground to facilitate servicing and maintenance of the mower.

Owner:DEGELMAN IND LP

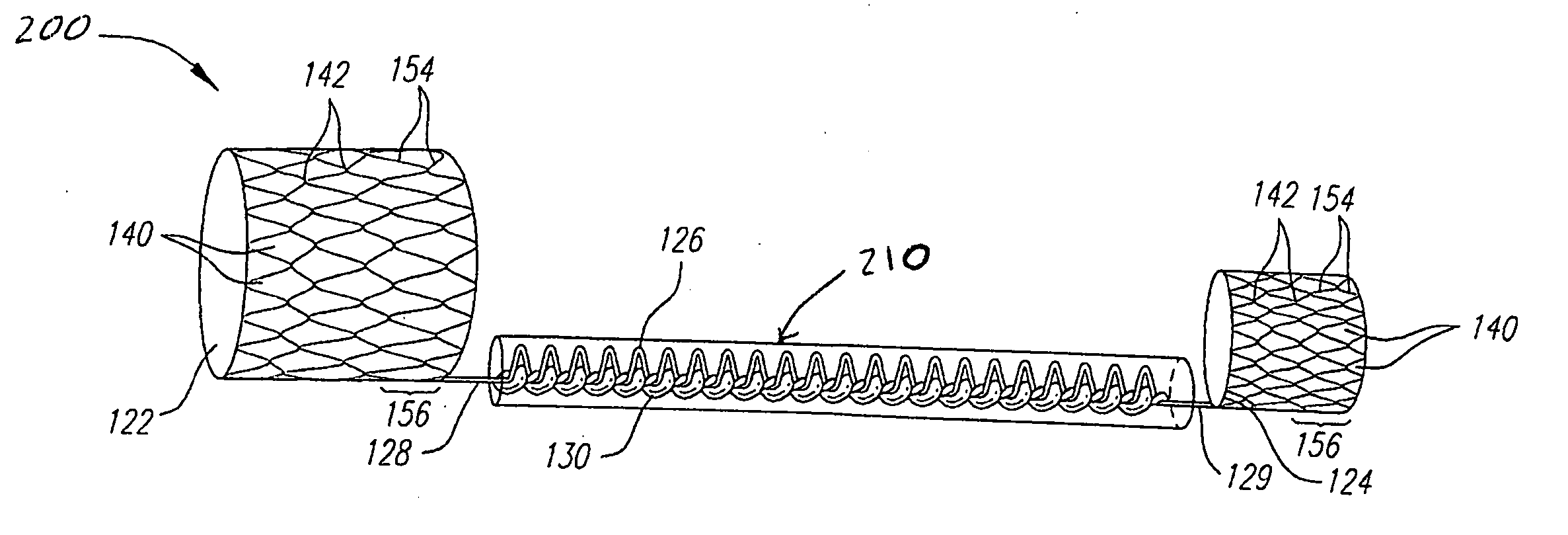

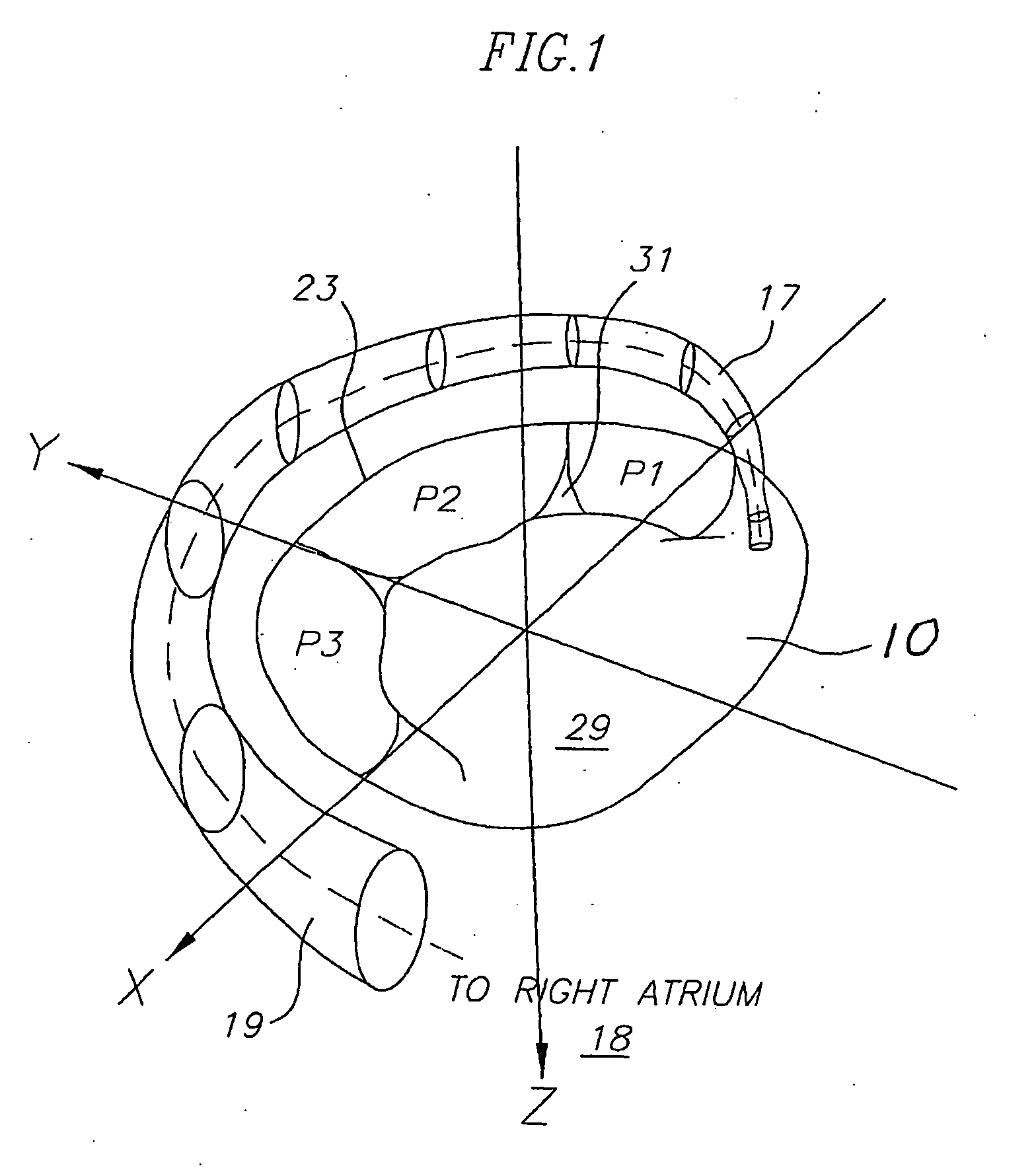

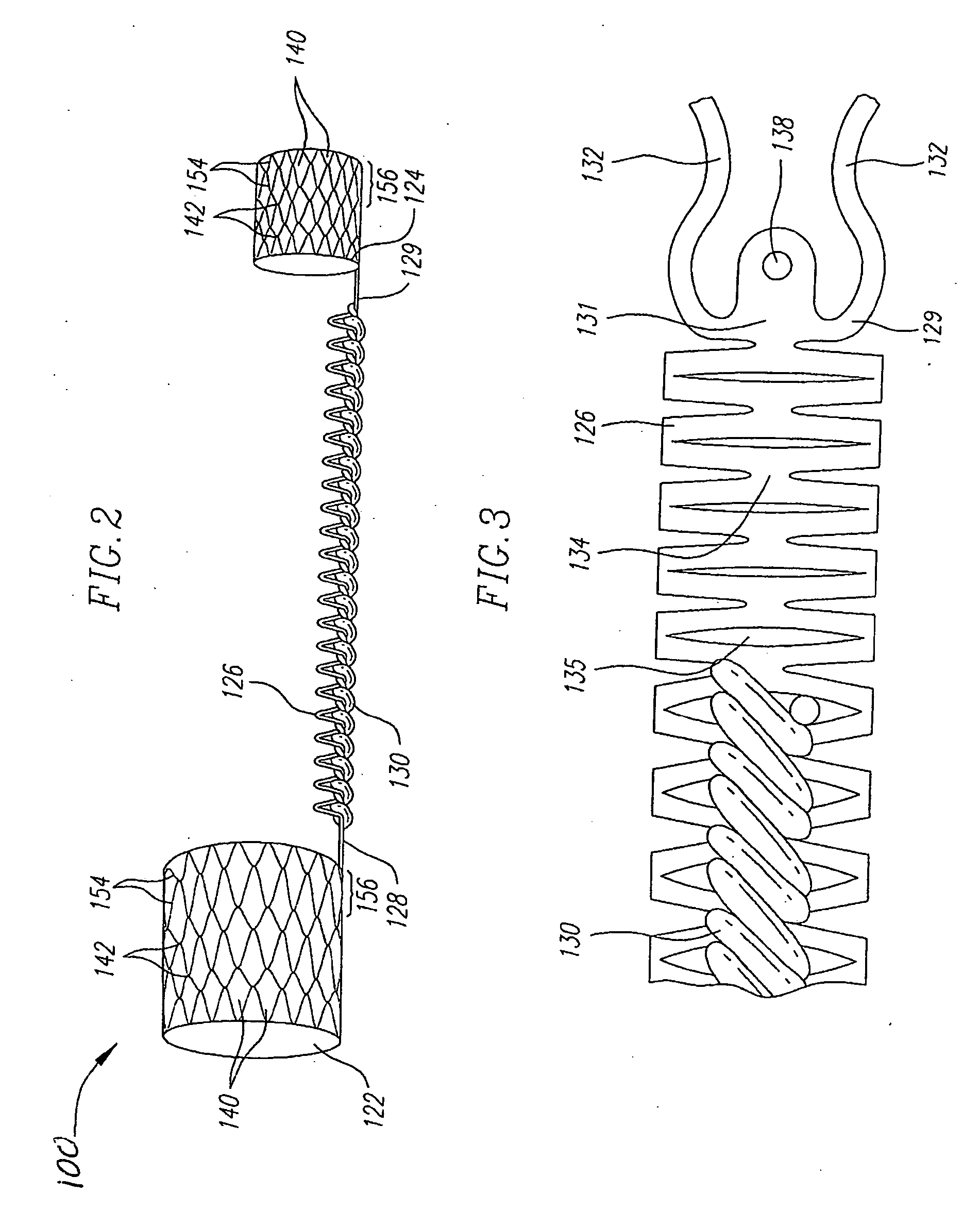

Medical implant with reinforcement mechanism

InactiveUS20070038297A1Improve structural integrityReducing and eliminating undesirable stress and strainHeart valvesWound clampsBiomedical engineeringMitral regurgitations

An improved medical implant for treating mitral regurgitation is provided. The medical implant comprises proximal and distal anchors connected by a bridge. The medical implant is configured to be delivered into a coronary sinus using a minimally invasive procedure. The bridge is preferably made of a shape memory material which is biased to contract after the implant is delivered. The medical implant further comprises a reinforcement mechanism configured to limit stresses and strains along the length of the bridge. In a preferred embodiment, the reinforcement mechanism is fixed to a plurality of attachment points along the bridge, thereby preventing excessive elongation between any two attachment points. A resorbable material is preferably disposed within gaps along the length of the bridge to temporarily maintain the bridge in an elongated condition. After the proximal and distal anchors are secured in the coronary sinus, the resorbable material gradually resorbs, thereby creating tension in the bridge which applies a force along the mitral valve annulus. The reinforcement mechanism ensures that stresses and strains and distributed evenly while the bridge is in tension.

Owner:EDWARDS LIFESCIENCES CORP

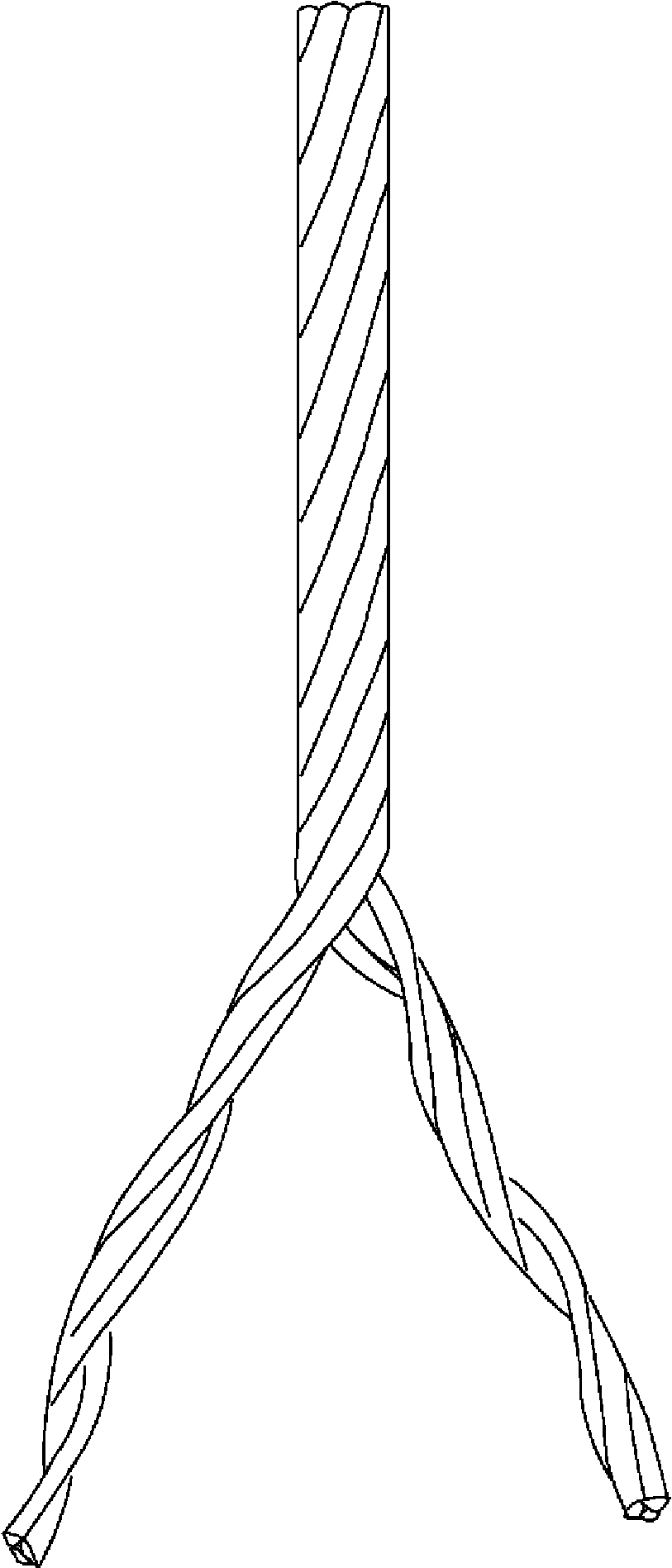

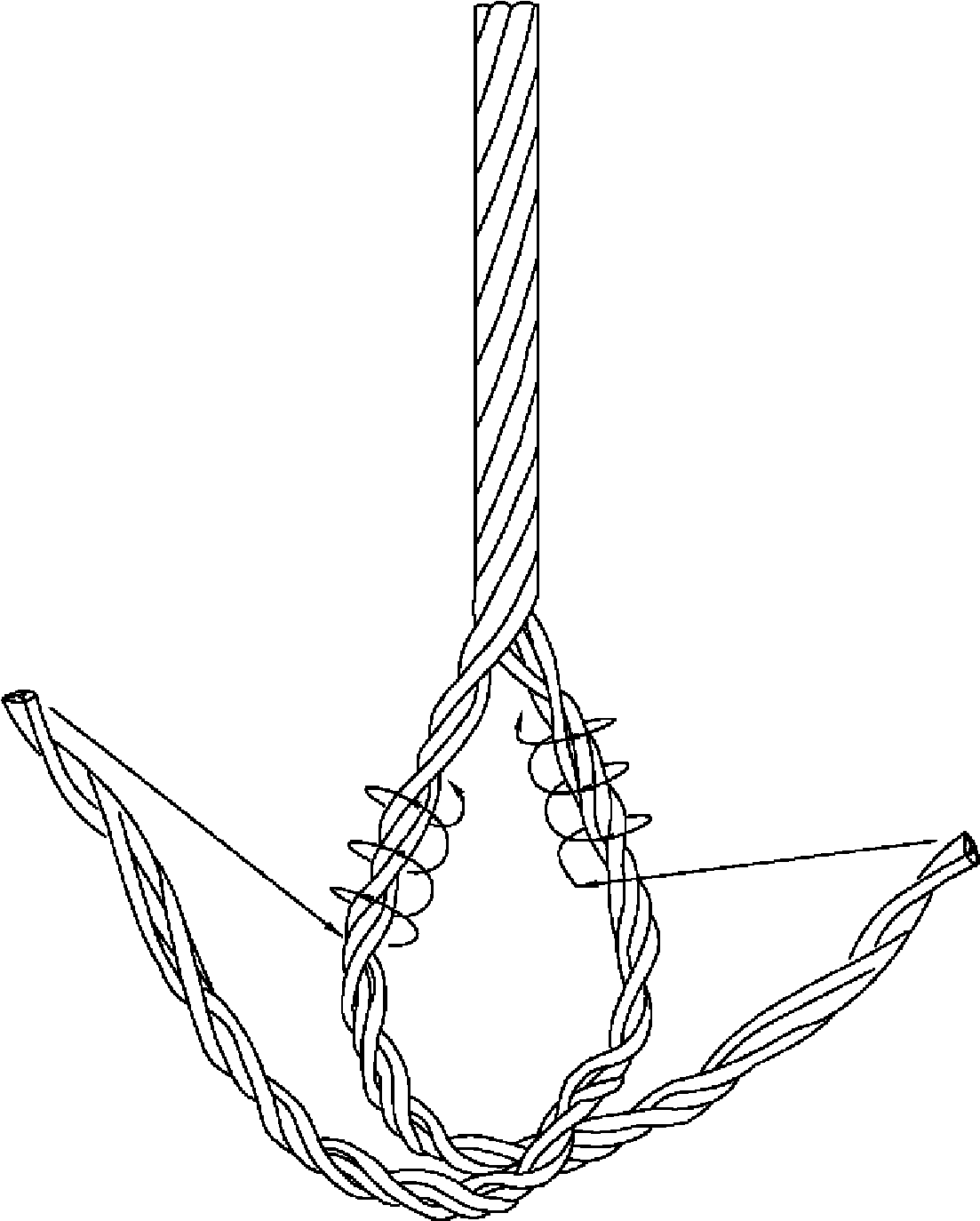

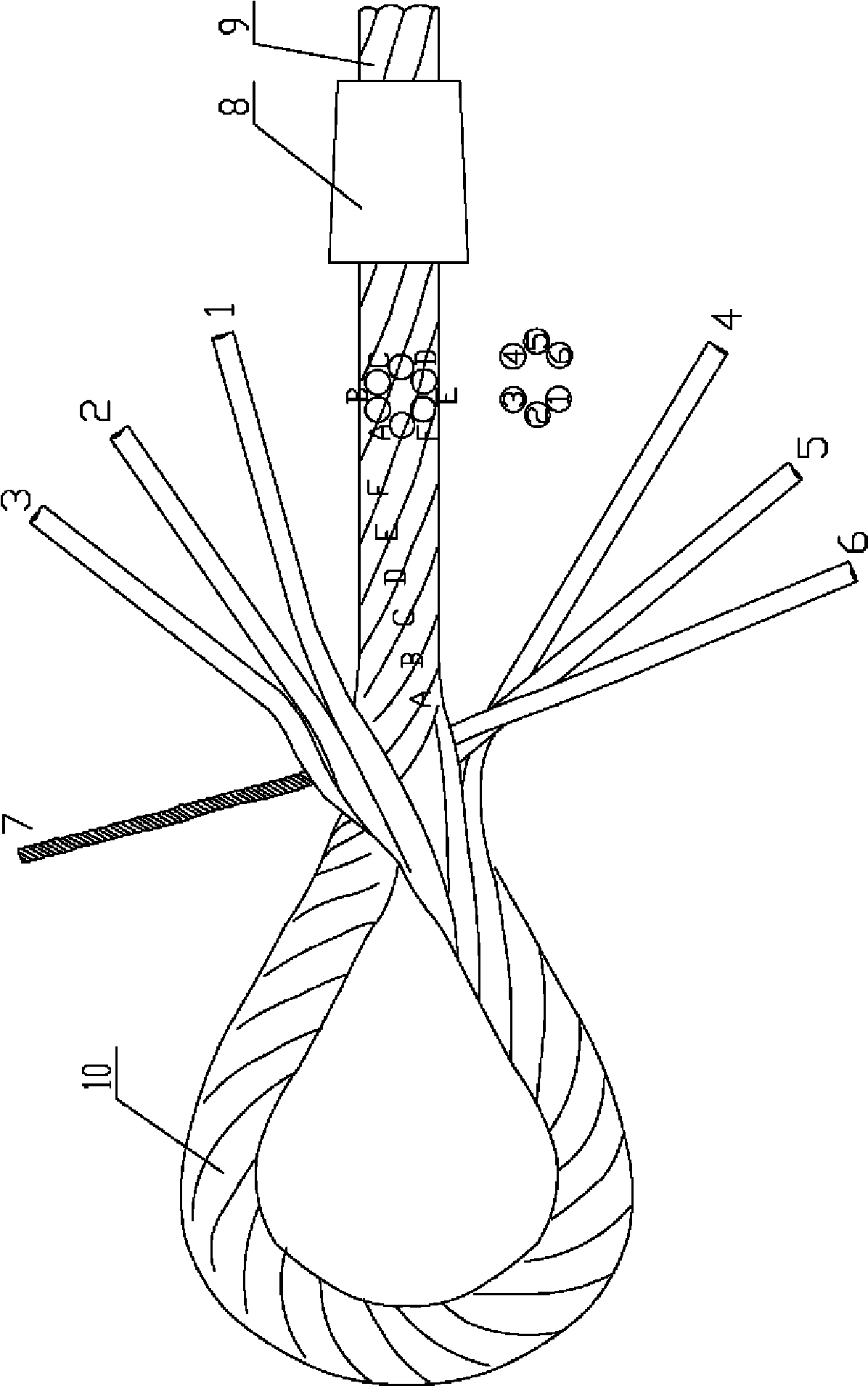

Steel wire rope insertion plaited rope sling and manufacturing method thereof

InactiveCN101487194AImprove structural integrityImprove mechanical propertiesBinding endsEngineeringWire rope

The invention relates to the technical field of wire rope suspended cables, in particular to a wire rope splicing sling and a preparation method thereof. The wire rope splicing sling comprises six mutually twisted wire ropes, and is obtained by the following steps: step 1: the ends of the six mutually twisted wire ropes are divided into two branches; step 2: the two divided branches are ringed to form a rope sling; step 3: the tails of all single-strand wire rope are sequentially spliced in the main body of the wire rope; and step 4: the residual ends of all single-strand wire ropes are cut off, thus obtaining the wire rope splicing sling. The wire rope splicing sling can obviously improve the structural integrity and mechanical performance of the wire rope suspended cable, and leads each-strand of wire rope at the connection of the sling joint to bear more uniform force, thus improving the maximum bearing load and prolonging the service life; and the wire rope splicing sling has the advantages of firmness, reliability, safety, durability, cleanness, beautiful appearance and good bearing performance, and the method is simple and convenient for operation.

Owner:王建新

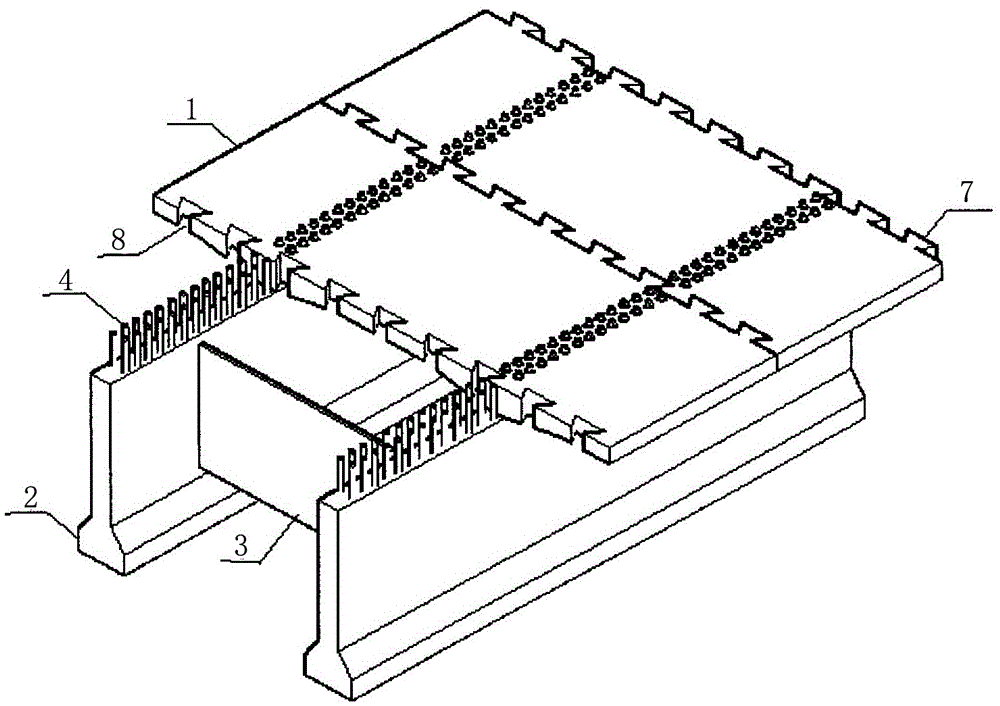

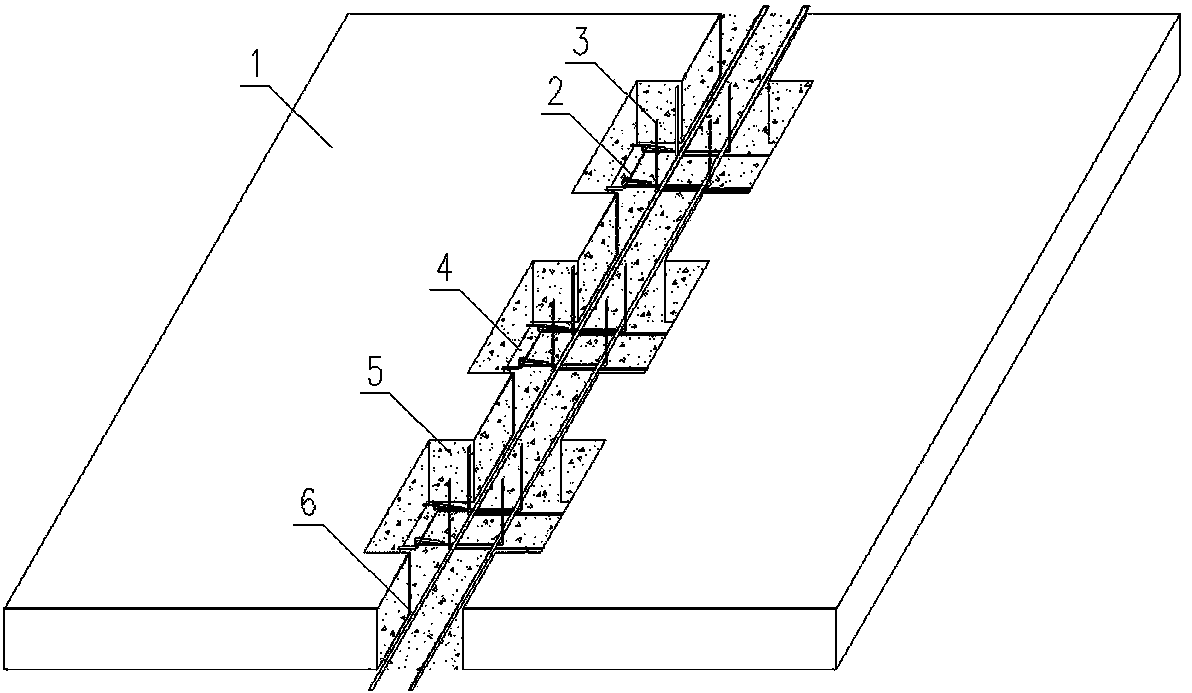

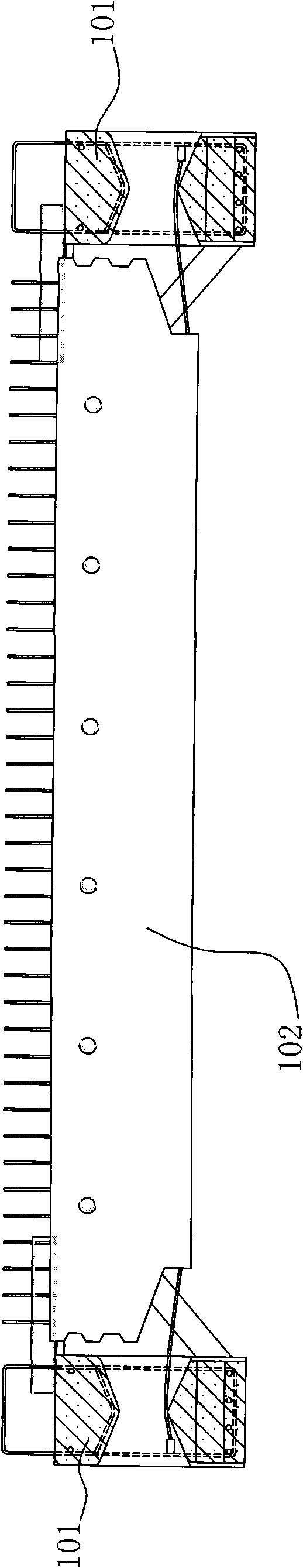

Prefabricated T beam and construction method

The invention discloses a prefabricated T beam and a construction method. The prefabricated T beam comprises bridge panels, a longitudinal beam and a steel transverse partition plate. The bridge panels and the longitudinal beam are prefabricated parts. The adjacent bridge panels are connected in an embedded mode. The portions, at the upper end of the longitudinal beam, of the bridge panels are evenly provided with preformed holes. Pre-buried deformed steel bars are arranged inside a bridge beam of the longitudinal beam. A pre-buried steel plate is arranged on the side face of the longitudinal beam. The pre-buried deformed steel bars need to stretch out of the upper edges of the spliced bridge panels on the basis of the length. The steel transverse partition plate is fixedly connected with the pre-buried steel plate on the longitudinal beam. The construction method comprises the steps of prefabricating the bridge panels and the longitudinal beam; connecting the steel transverse partition plate with the longitudinal beam after the longitudinal beam is suspended to a bridge pier and abutment; placing the bridge panels on the longitudinal beam, and connecting the adjacent bridge panels in the embedded mode; pouring epoxy mortar concrete into the preformed holes. The bridge panels and the longitudinal beam of the T beam are partially prefabricated separately, and therefore the wet joint problem existing in concrete T beam splicing is effectively solved.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Combined steel pile cofferdam provided with water swellable waterproof rubber fore shaft

InactiveCN102900089AFast constructionGood waterproof performanceBulkheads/pilesStructural rigidityWater resistance

The invention discloses a combined steel pile cofferdam provided with a water swellable waterproof rubber fore shaft, which comprises cofferdam pegs and cofferdam long piles used for connecting two adjacent cofferdam pegs. Each cofferdam peg comprises a U-shaped steel sheet pile and a fore shaft sub-part, and the left and right ends of each U-shaped steel sheet pile are respectively and fixedly connected with one fore shaft sub-part. Each cofferdam long pile comprises a steel pipe pile, a fore shaft parent part arranged at the outer side of the steel pipe pile, and a water swellable rubber liner arranged in the fore shaft parent part; a tubular inner cylinder matched with each fore shaft sub-part and a notch connecting the interior of each tubular inner cylinder with the exterior of each tubular inner cylinder are arranged on the fore shaft parent part; each water swellable rubber liner is fixedly arranged on the inner wall of the corresponding tubular inner cylinder; each fore shaft sub-part is sleeved into the corresponding tubular inner cylinder; and bentonite compound filler is filled in a gap between each fore shaft sub-part and each water swellable rubber liner. By taking the combination of a rigid steel pile and a flexible steel pile to have complementary advantages, the combined steel pile cofferdam has good water resistance; the fore shaft is reliable in connection; the material of the combined steel pile cofferdam is easy to obtain; and the combined steel pile cofferdam is strong in integral structural rigidity and low in cost and is quick to construct.

Owner:SOUTHEAST UNIV

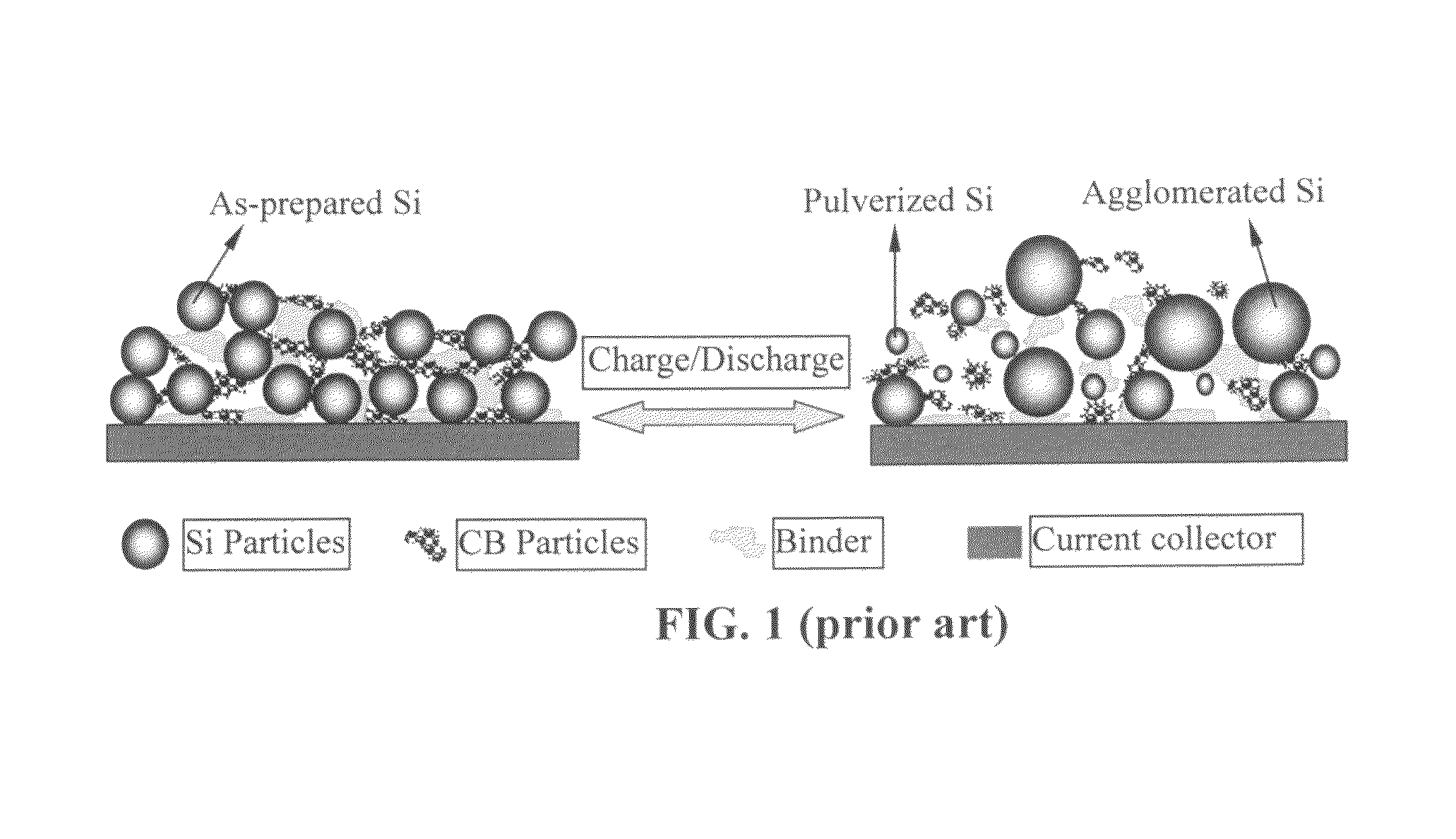

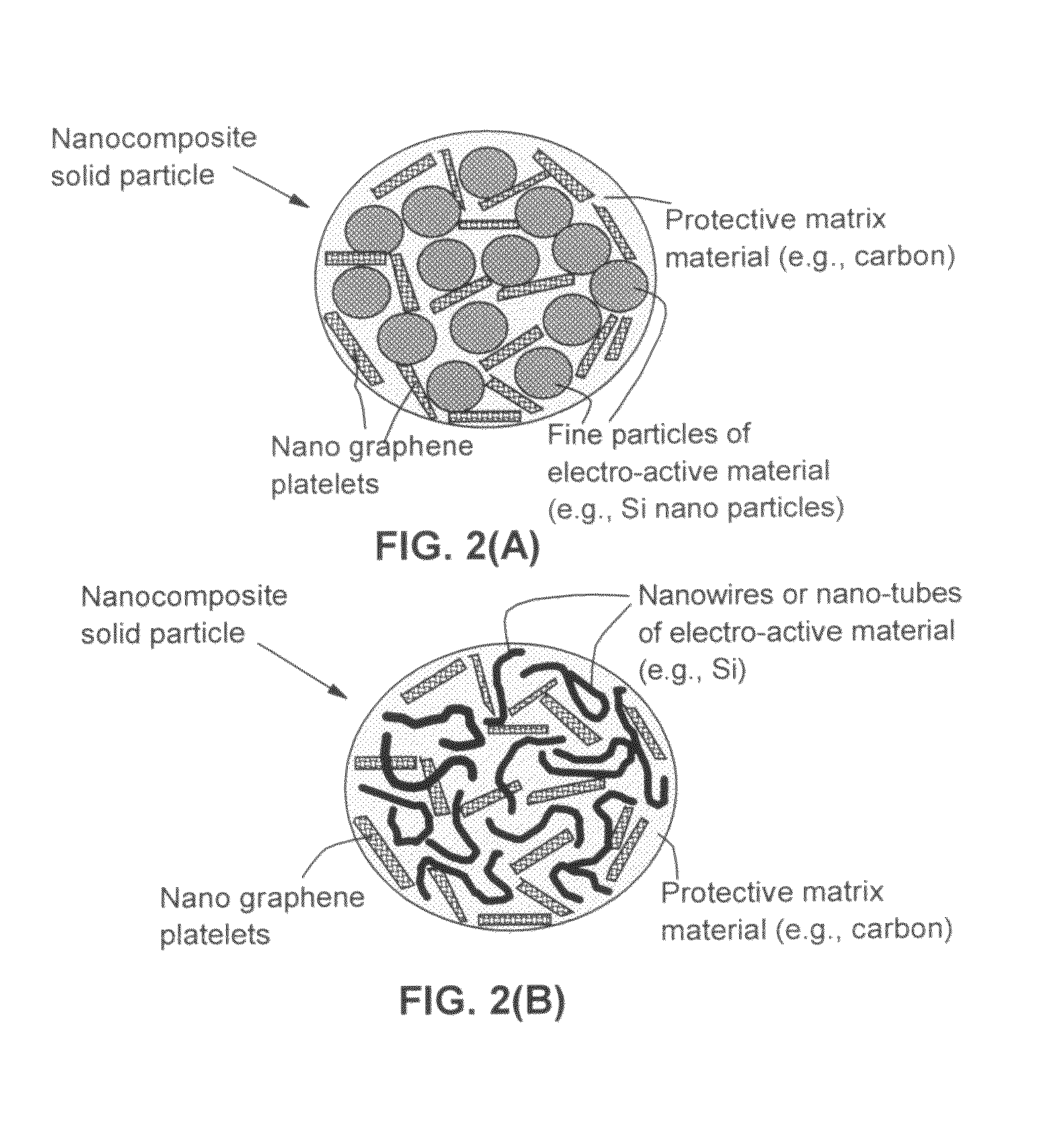

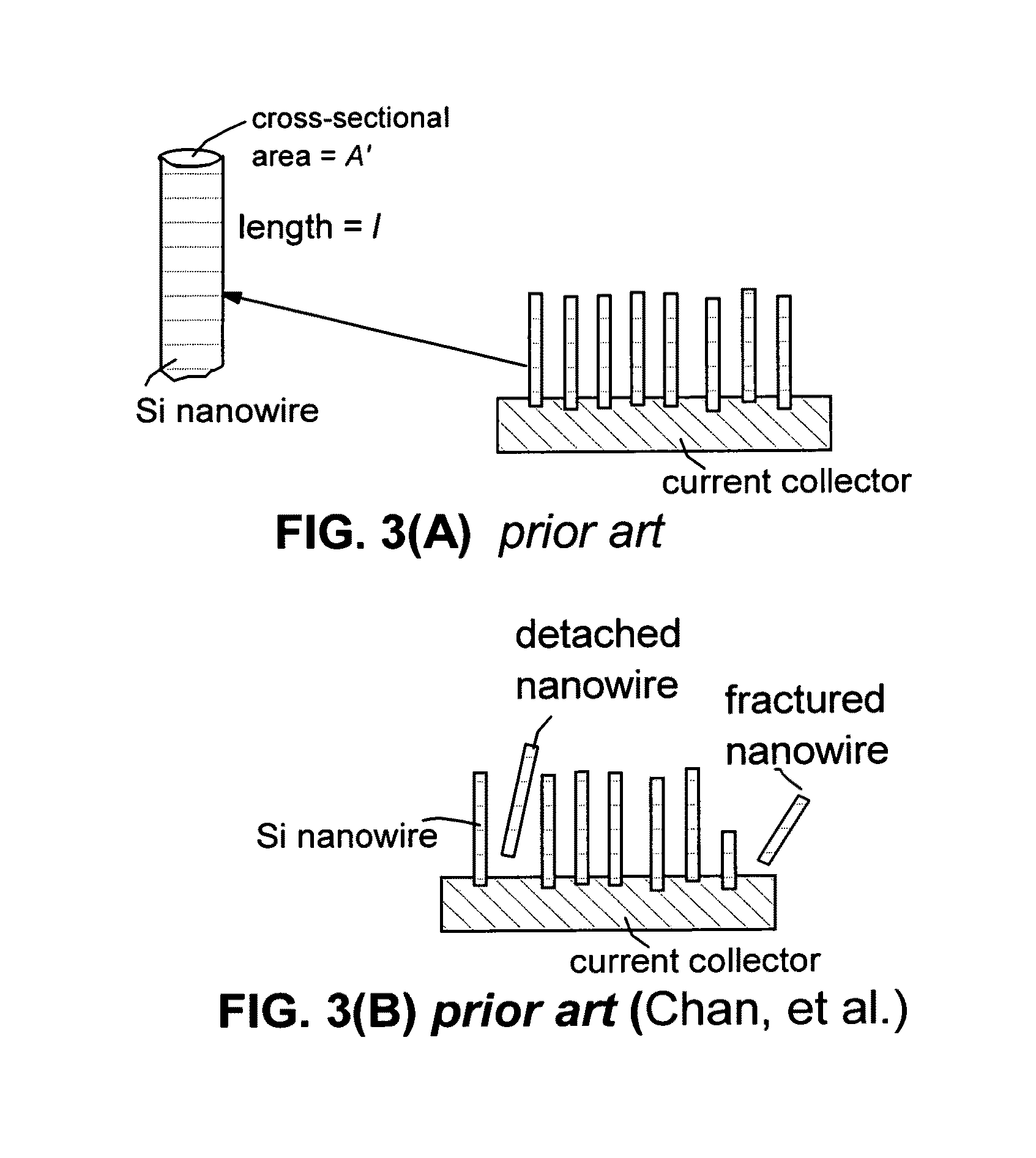

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS9093693B2Increase stiffnessHigh strengthActive material electrodesLi-accumulatorsLithium metalMaterials science

A process for producing solid nanocomposite particles for lithium metal or lithium ion battery electrode applications is provided. In one preferred embodiment, the process comprises: (A) Preparing an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) Preparing separated or isolated nano graphene platelets with a thickness less than 50 nm; (C) Dispersing the nano graphene platelets and the electrode active material in a precursor fluid medium to form a suspension wherein the fluid medium contains a precursor matrix material dispersed or dissolved therein; and (D) Converting the suspension to the solid nanocomposite particles, wherein the precursor matrix material is converted into a protective matrix material reinforced by the nano graphene platelets and the electrode active material is substantially dispersed in the protective matrix material. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such solid nanocomposite particles provide a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

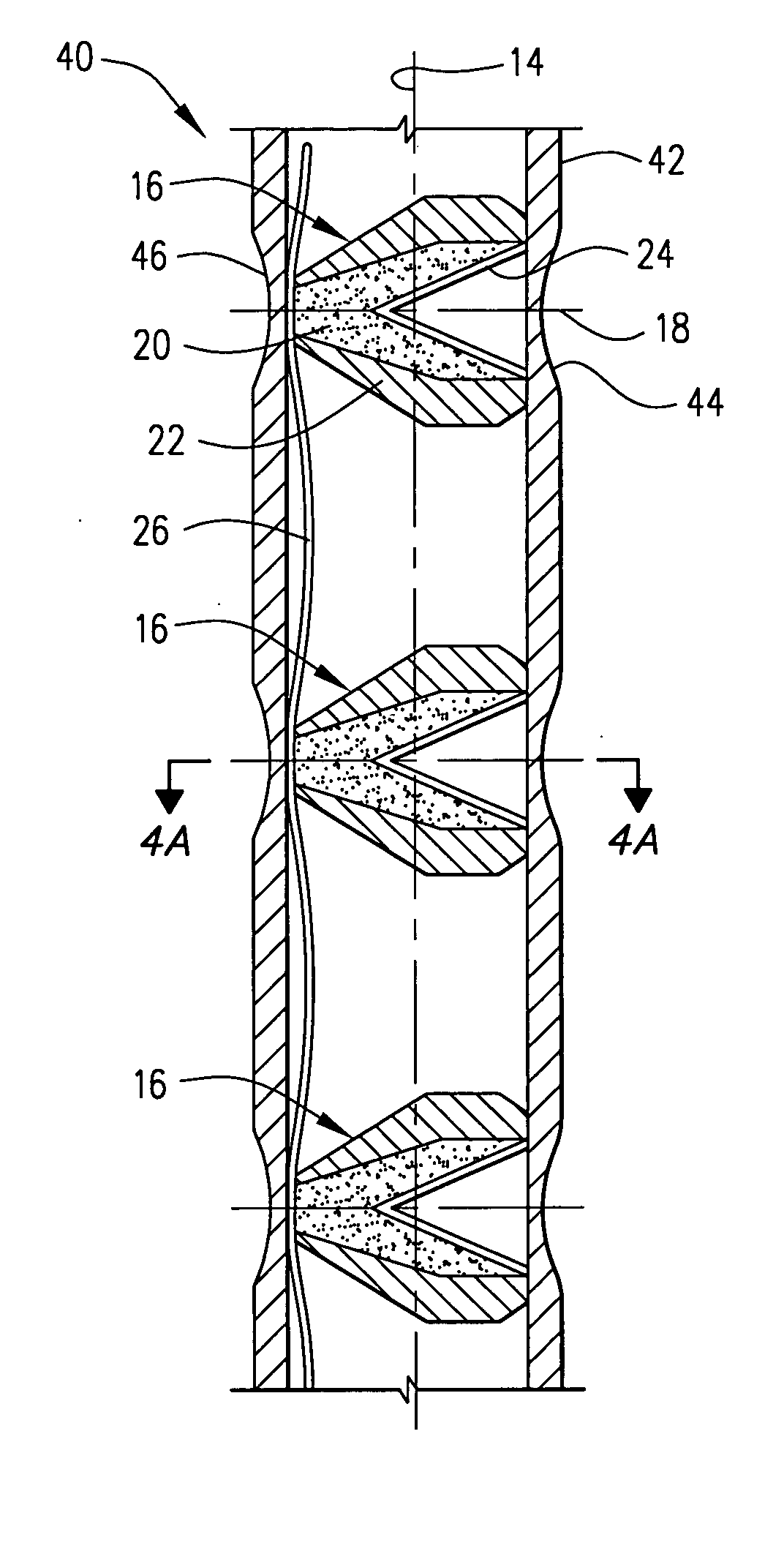

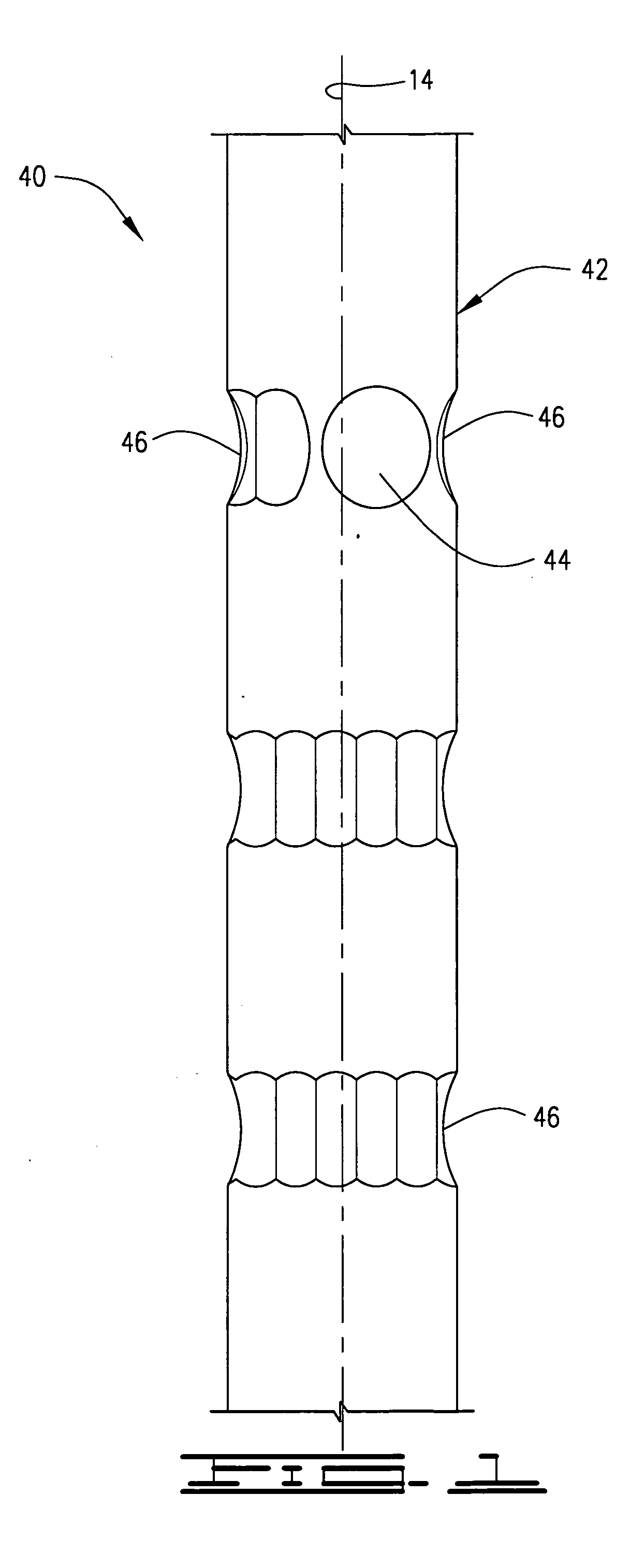

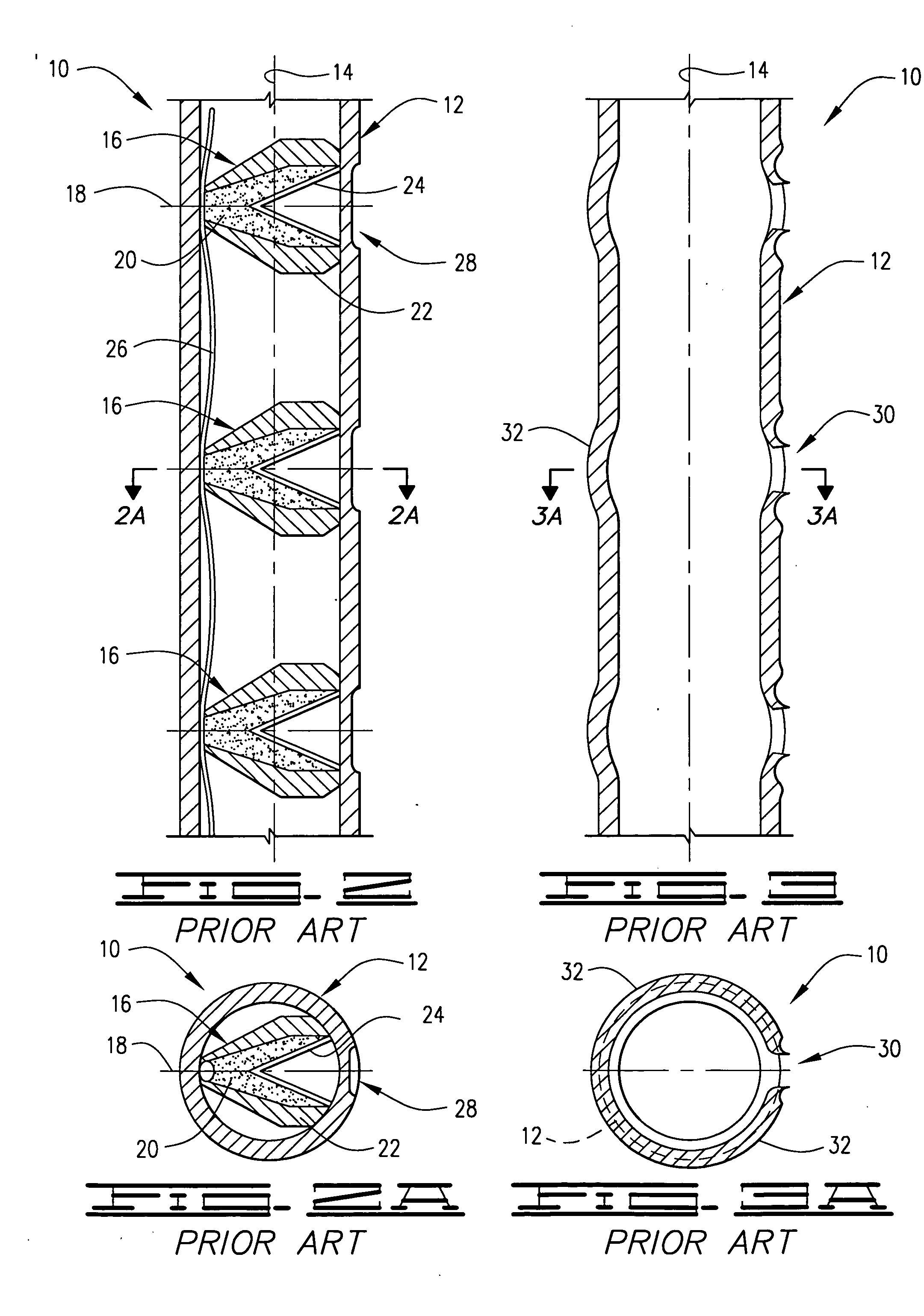

Faceted expansion relief perforating device

InactiveUS20050115441A1Less steelImprove structural integrityExplosive chargesBlasting cartridgesEngineeringMechanical engineering

The present invention is an improvement in the design of a perforating gun to perforate the casing in oil and gas wells. Perforating guns have a cylindrical body member with explosive charges at specified intervals designed to shoot outwardly through the body member, the well casing, cement sheath, and into the rock formation. Continuous faceted cuts in the vessel covering the greater part of the circumference, at the level of the charge, serve to reduce the outward distortion of the body member beyond the original diameter of the body member. Reducing the distortion serves to insure that the perforating gun can be removed from the well after the explosive charges have fired.

Owner:MAULDIN SIDNEY WAYNE

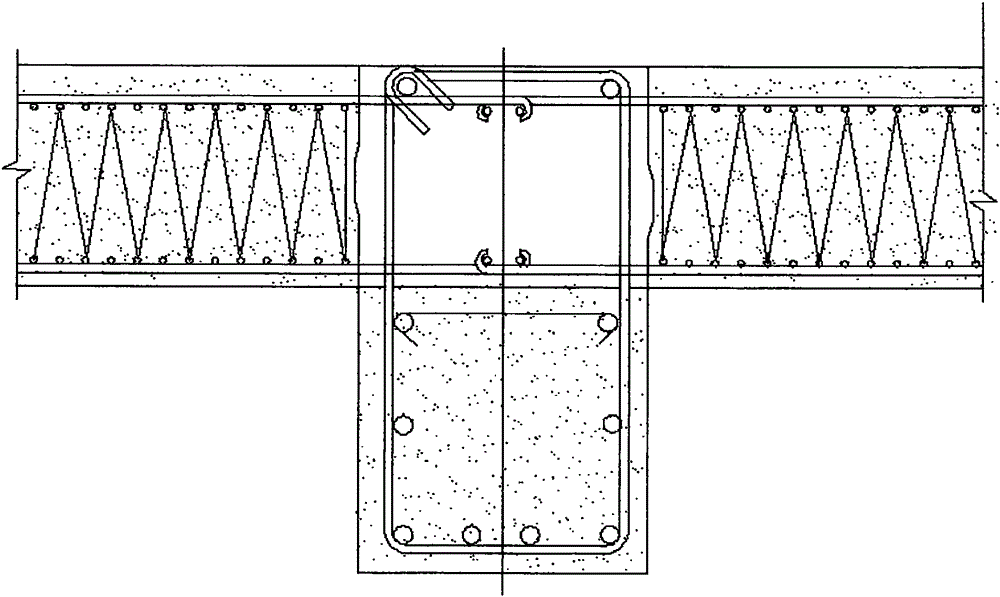

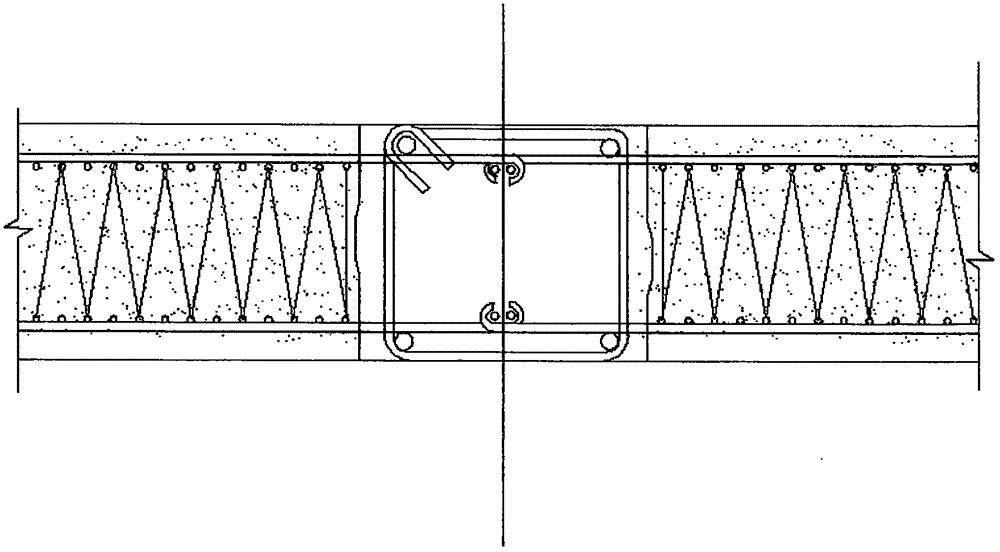

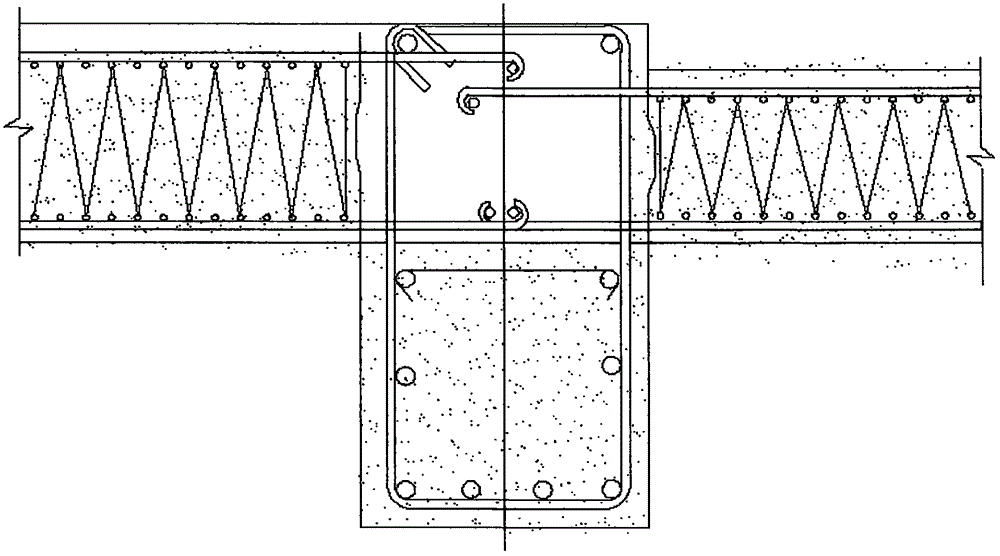

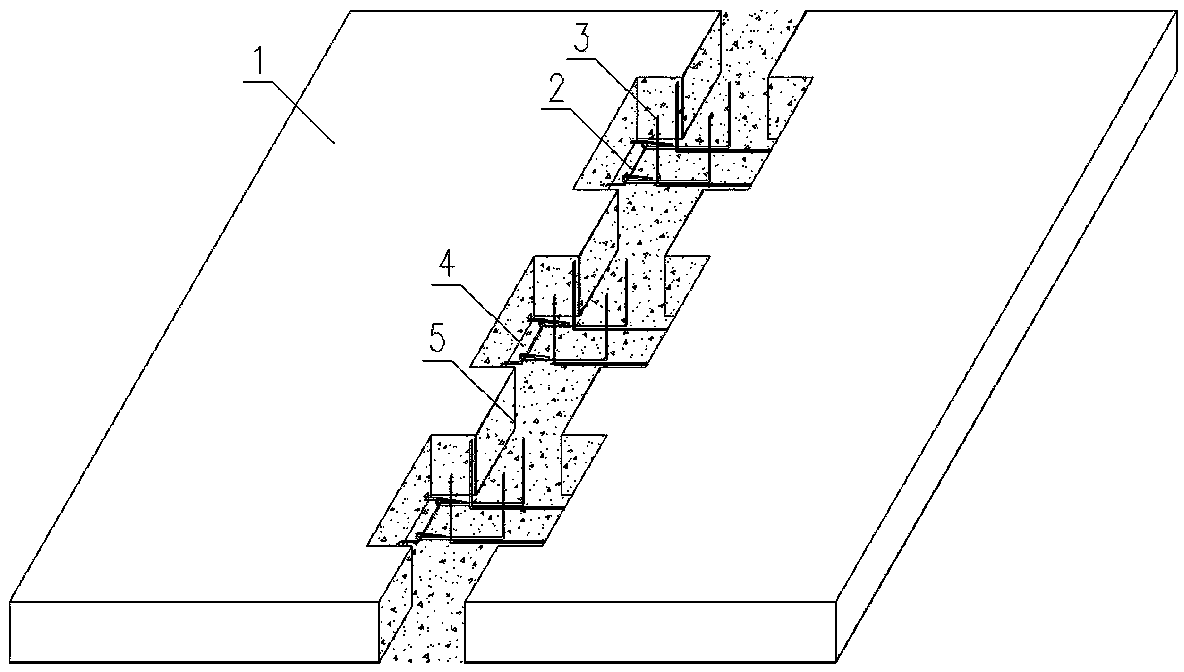

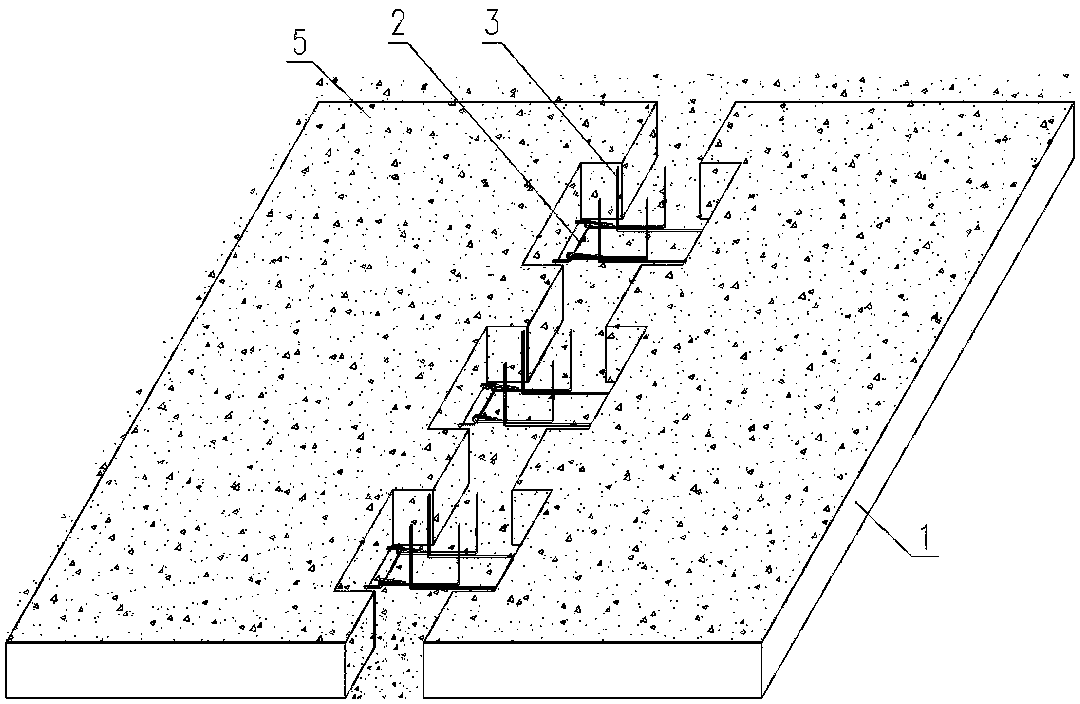

Connection method of precast reinforced concrete slabs

The invention discloses a connection method of precast reinforced concrete slabs, and belongs to the technical field of building structures. The connection method is characterized in that reinforcing steel bars which are fully anchored and of which exposed parts are in a shape of a half ring are embedded on lateral sides of the precast reinforced concrete slabs, transverse reinforcing steel bars are hung on the reinforcing steel bars in the shape of the half ring, and lapped in a reserved gap among the precast reinforced concrete slabs; a template is arranged at the lower part of the reserved gap, the precast reinforced concrete slabs are connected as a whole by pouring concrete in the reserved gap; or the template is arranged at the lower part of the reserved gap, and the concrete is poured in the reserved gap and at the upper parts of the precast reinforced concrete slabs to form a precast concrete composite slab. The connection method disclosed by the invention can improve the integrity of an assembled monolithic concrete structure and promote the development of building industrialization.

Owner:初明进

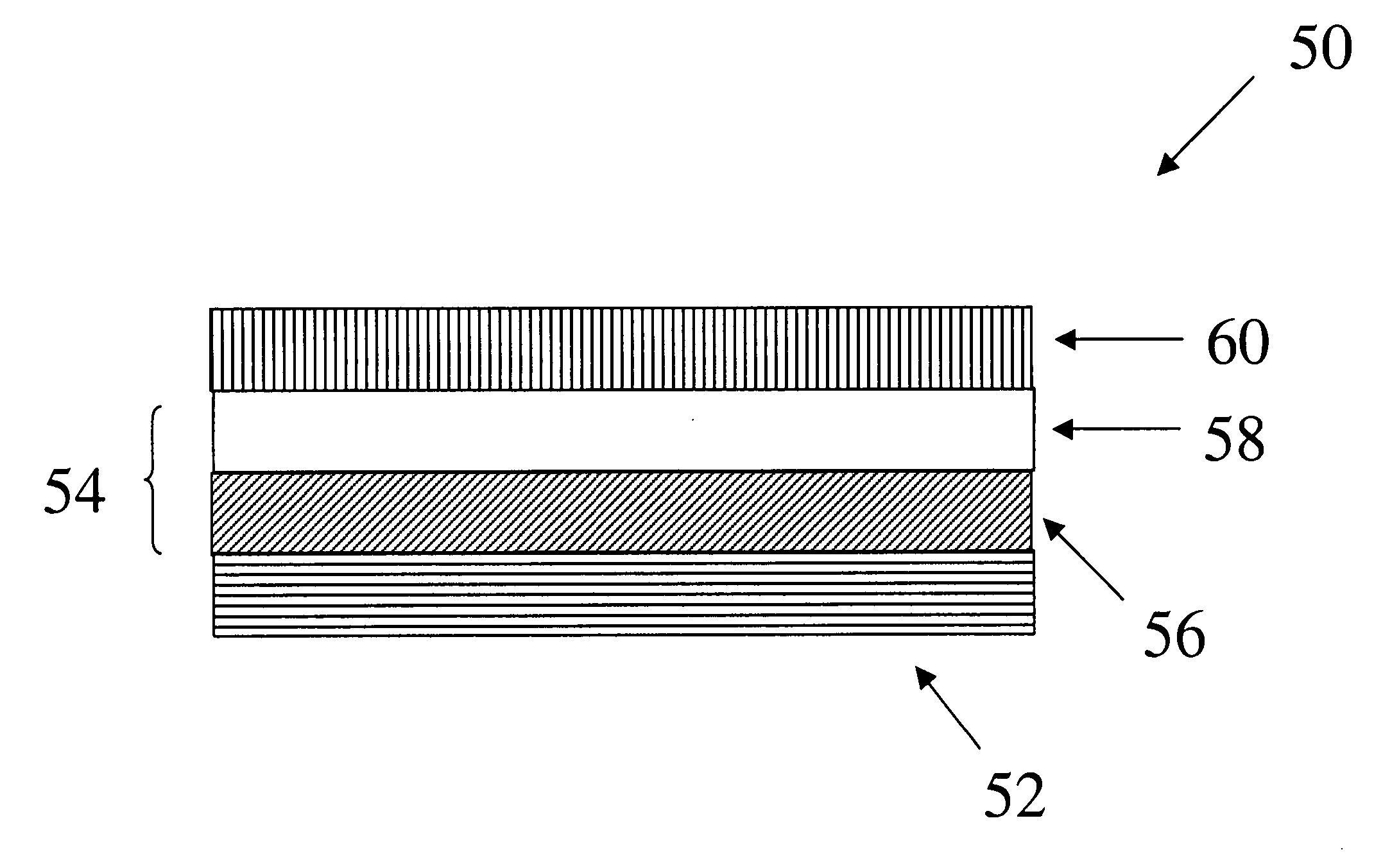

Method of making organic light emitting devices

InactiveUS20070176167A1Improves Structural IntegrityImprove structural integritySolid-state devicesSemiconductor/solid-state device manufacturingCross-linkOrganic light emitting device

The invention includes embodiments that relate to a method of making an organic light-emitting device comprising at least one bilayer structure. The method comprises providing at least one first layer comprising at least one cross-linkable organic material and at least one photo acid generator; exposing the first layer to a radiation source to afford a cross-linked first layer; and disposing at least one second layer on the cross-linked first layer. The method affords a bilayer structure having an enhanced structural integrity relative to the corresponding bilayer structure in which the first layer is not cross-linked. The invention also includes embodiments that relate to an organic light emitting device.

Owner:GENERAL ELECTRIC CO

Novel reinforced concrete prefabricated integrally-cast building structure system and construction method thereof

ActiveCN102418386AReduce steel consumptionReduce the overall heightFloorsBuilding material handlingReinforced concreteFloor slab

The invention relates to a novel reinforced concrete prefabricated integrally-cast building structure system, which comprises a floor slab, superposed beams and columns and / or shearing walls. Each superposed beam comprises a primary beam and a secondary beam and consists of a prestressed prefabricated beam and a cast-in-situ part. The prestressed prefabricated beam comprises a beam body and prestressed steel stranded wires. Section steel is arranged at the end parts of the beam body. One part of the section steel is buried in the beam body and the other part of the section steel is exposed at the end part of the beam body. The prefabricated beam in the primary beam is connected with the columns and / or the shearing walls through the section steel. The prefabricated beam in the secondary beam is placed on the primary beam through the section steels. A plurality of template supporting holes are longitudinally arranged on the beam body of the prefabricated beam of the secondary beam and the beam body of the prefabricated beam of the primary beam in parallel with the secondary beam. By adopting the prefabricated beams to be integrally cast with the cast-in-situ beams and the cast-in-situ floor slab to form a structure system, the prefabricated beams are fabricated by adopting a pre-tensioning prestressed technique and can be produced on a large scale in plants at one time and the production cost is reduced.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

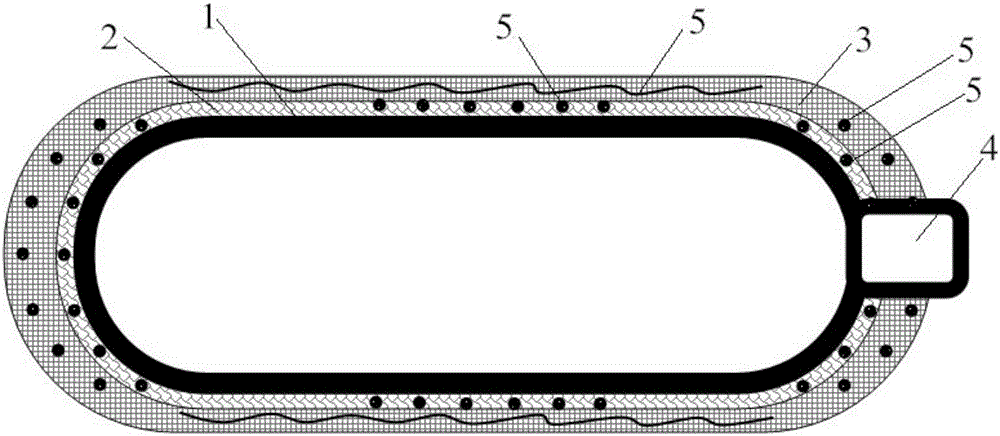

Intelligent-monitored three-dimensional composite material pressure resistant gas cylinder and preparation method thereof

PendingCN106696315AImprove integrityEliminate mechanical weak points between layersUsing optical meansElectrical/magnetic solid deformation measurementMedia accessMetal

The invention discloses an intelligent-monitored three-dimensional composite material pressure resistant gas cylinder and a preparation method thereof, and relates to the field of novel composite material pressure resistant containers. The intelligent-monitored three-dimensional composite material pressure resistant gas cylinder comprises a metal liner layer, a plastic interface layer, a surface three-dimensional woven composite material layer and a medium access port, wherein the metal liner layer is an overall seamless structure; the plastic interface layer is positioned between the metal liner layer and the surface three-dimensional woven composite material layer, and is provided with a strain induction device in the thickness middle position; and the surface three-dimensional woven composite material layer is positioned on the outermost surface of the pressure resistant gas cylinder, includes a cylinder body section and a seal section, and is also provided with a strain induction device in the thickness middle or surface position. The pressure resistant gas cylinder eliminates interlayer mechanical weak points of a two-dimensional composite material, can monitor tiny deformation of different parts of the pressure resistant gas cylinder in the use process in real time, predicts the service life, and gives an alarm when meeting dangers.

Owner:SHANDONG UNIV

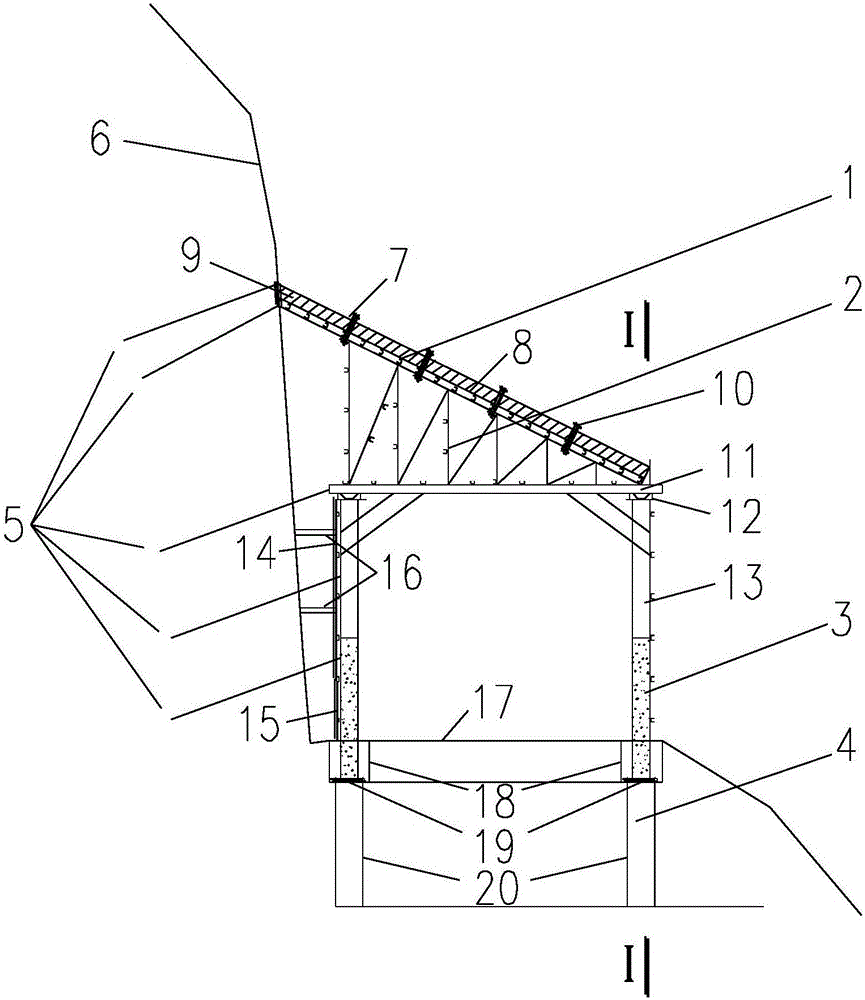

Combined energy dissipation shed frame structure for preventing rockfall of high and steep slope in earthquake region

InactiveCN106638340AImprove stabilityImprove seismic performanceProtective constructionSupporting systemPost disaster

The invention discloses a combined energy dissipation shed frame structure for preventing rock rolling-down hazards of a high and steep slope in highway construction, and belongs to the field of highway disaster prevention and control and post-disaster reconstruction engineering in an earthquake region. The combined energy dissipation shed frame structure is composed of a top surface anti-impact system tightly connected with an existing slope, a top surface supporting system composed of a three-dimensional steel frame system, a shed frame main structure composed of a cross beam and supporting steel tube stand columns on the two sides, a close-to-mountain side anchoring system for anchoring the top surface anti-impact system and the shed frame main structure, and a cast-in-place concrete bed formed by welding fixing pedestals to the bottoms of the steel tube stand columns and driving the fixing pedestals into a foundation through anchor rods. According to the combined energy dissipation shed frame structure, potential safety hazards caused by crag rockfall of a high and steep slope in an earthquake region to highway construction and vehicle driving are prevented, and the stability and seismic capacity of the shed frame structure are effectively improved. Compared with a traditional shed tunnel structure, the combined energy dissipation shed frame structure greatly shortens construction time and is beneficial to rapid traffic keeping and anti-disaster capacity improving.

Owner:DALIAN UNIV OF TECH

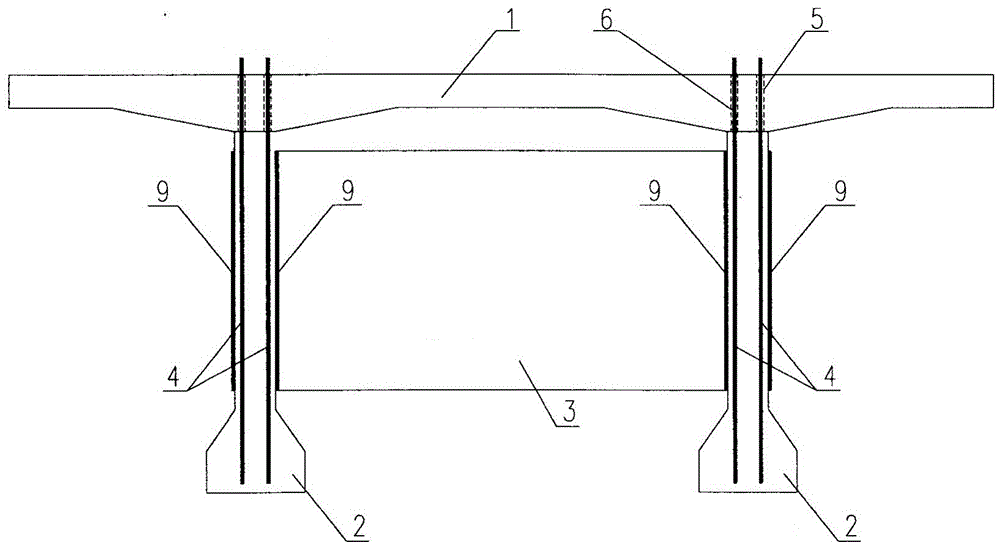

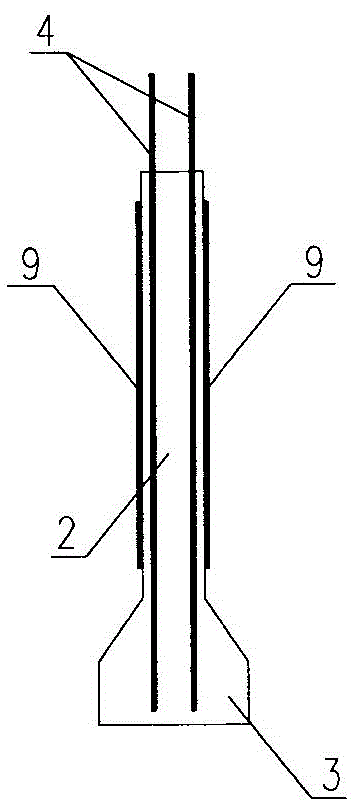

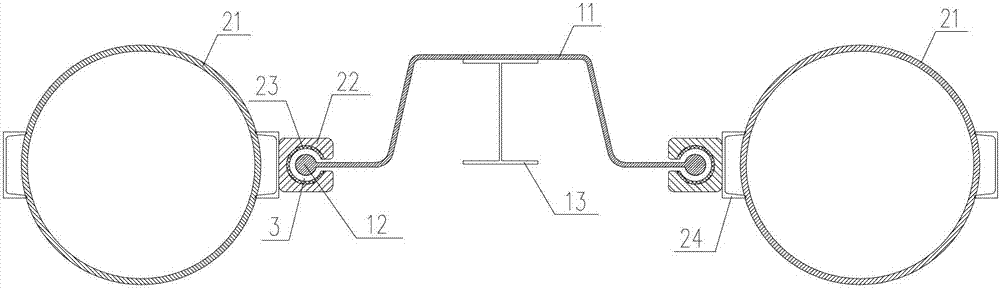

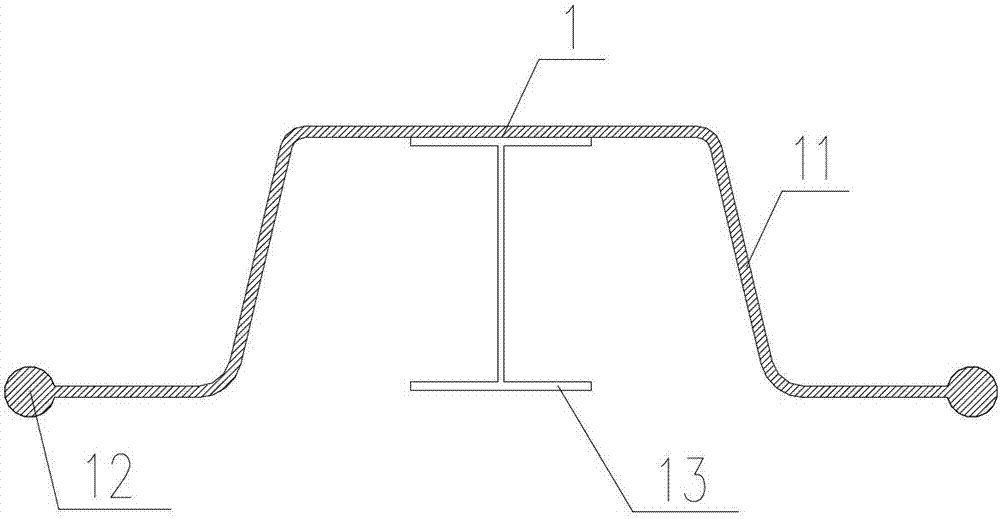

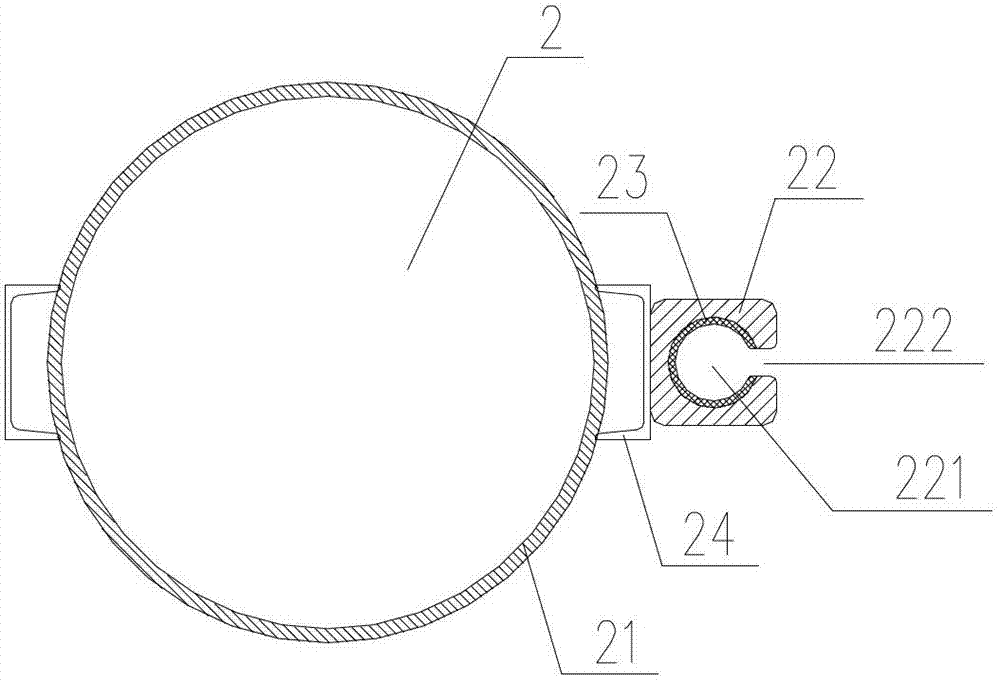

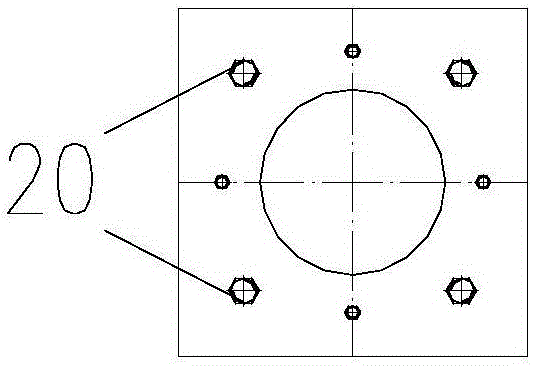

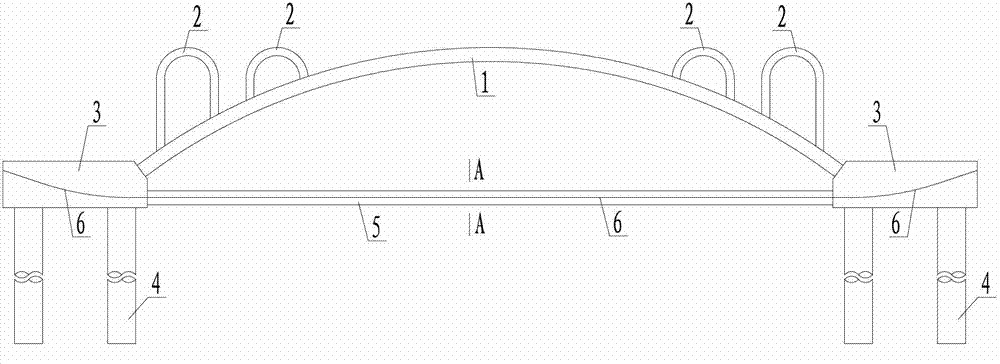

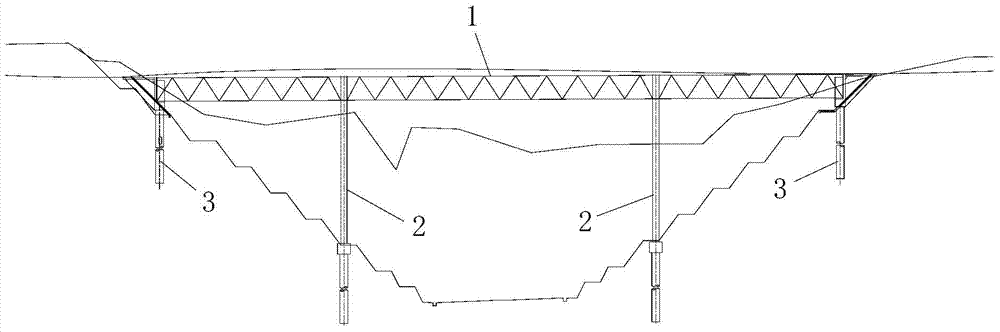

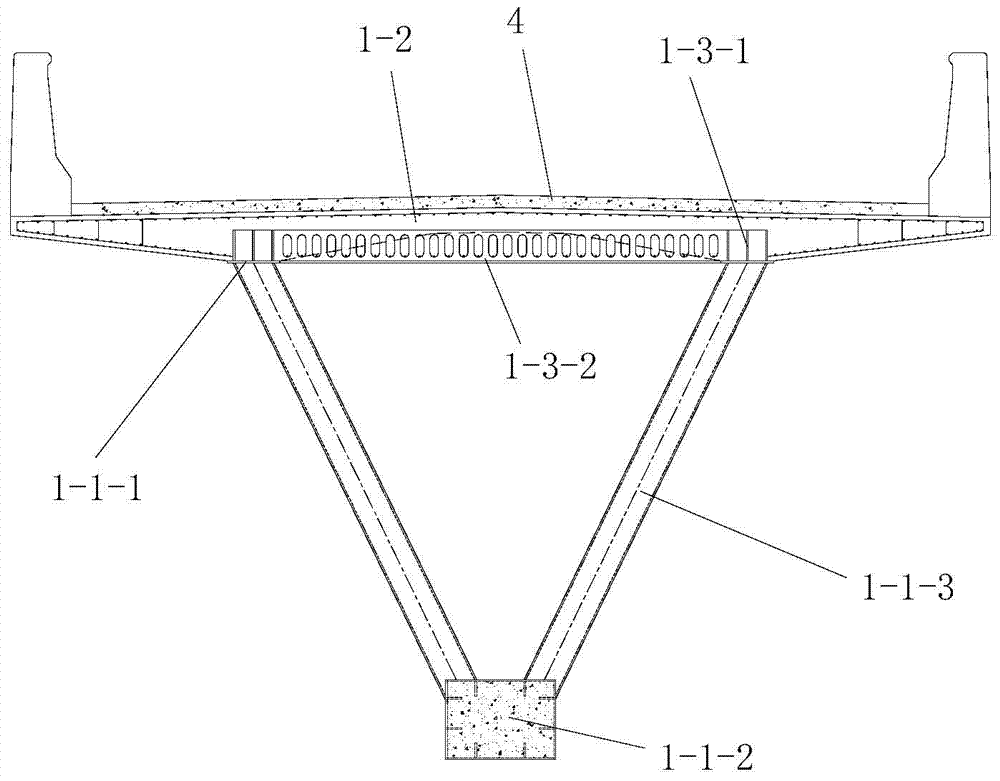

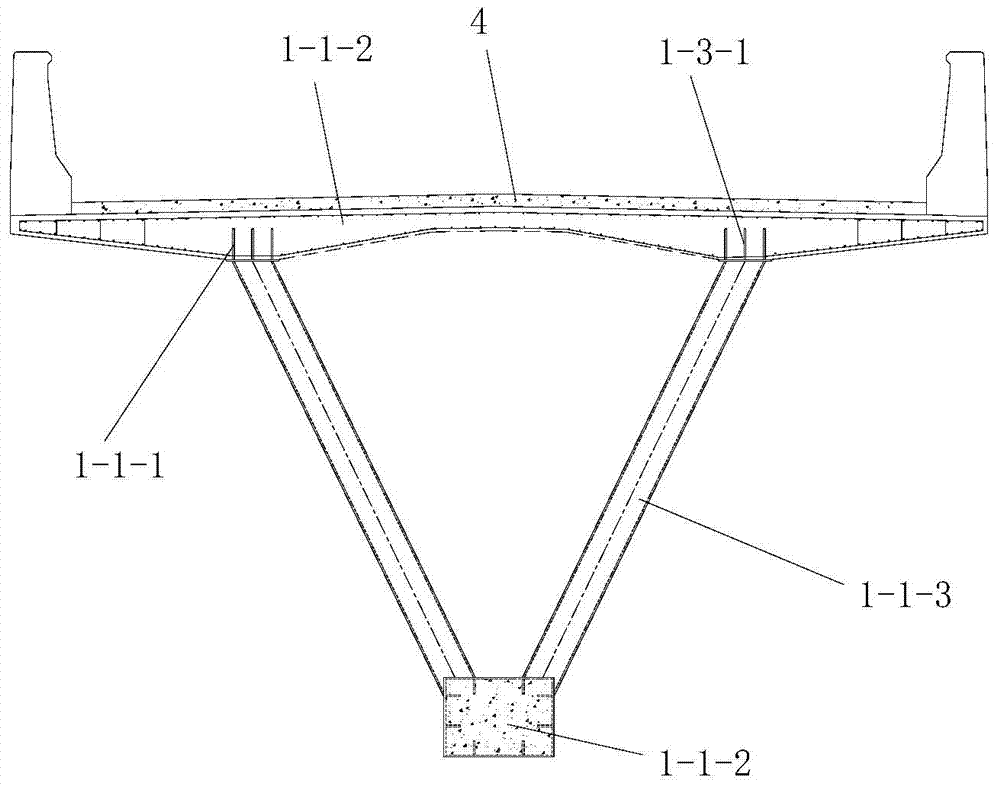

Deck type open shoulder arch bridge and constructing method thereof

InactiveCN103088749ASmall water blocking areaReduce weightBridge erection/assemblyArch-type bridgePrestressed concreteSpandrel

The invention belongs to the bridge technical field and relates to a deck type open shoulder arch bridge. The deck type open shoulder arch bridge comprises a main arch ring 1, upper spandrel arches 2, a bearing platform 3 and a pile foundation 4, wherein the upper spandrel arches 2 are arranged on both sides of the main arch ring 1, and arch feet of the main arch ring 1 are arranged in the bearing platform 3. The deck type open shoulder arch bridge further comprises a plurality of prestressed concrete pull-pressing rods 5. A prestressed wire 6 penetrates through each prestressed concrete pull-pressing rod 5, and two ends of the prestressed wire 6 are respectively anchored in the bearing platform 3 which is on the same side of the prestressed wire 6. The main arch ring 1, the pile foundation 4 and the prestressed concrete pull-pressing rods 5 are connected to form a whole through the bearing platform 3. Meanwhile, the invention provides a constructing method of the deck type open shoulder arch bridge. Prestressed steel beams in the prestressed concrete pull-pressing rods 5 can be once tensioned in place in constructing process, and no construction passageway is need to leave to conduct tension step-by-step.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

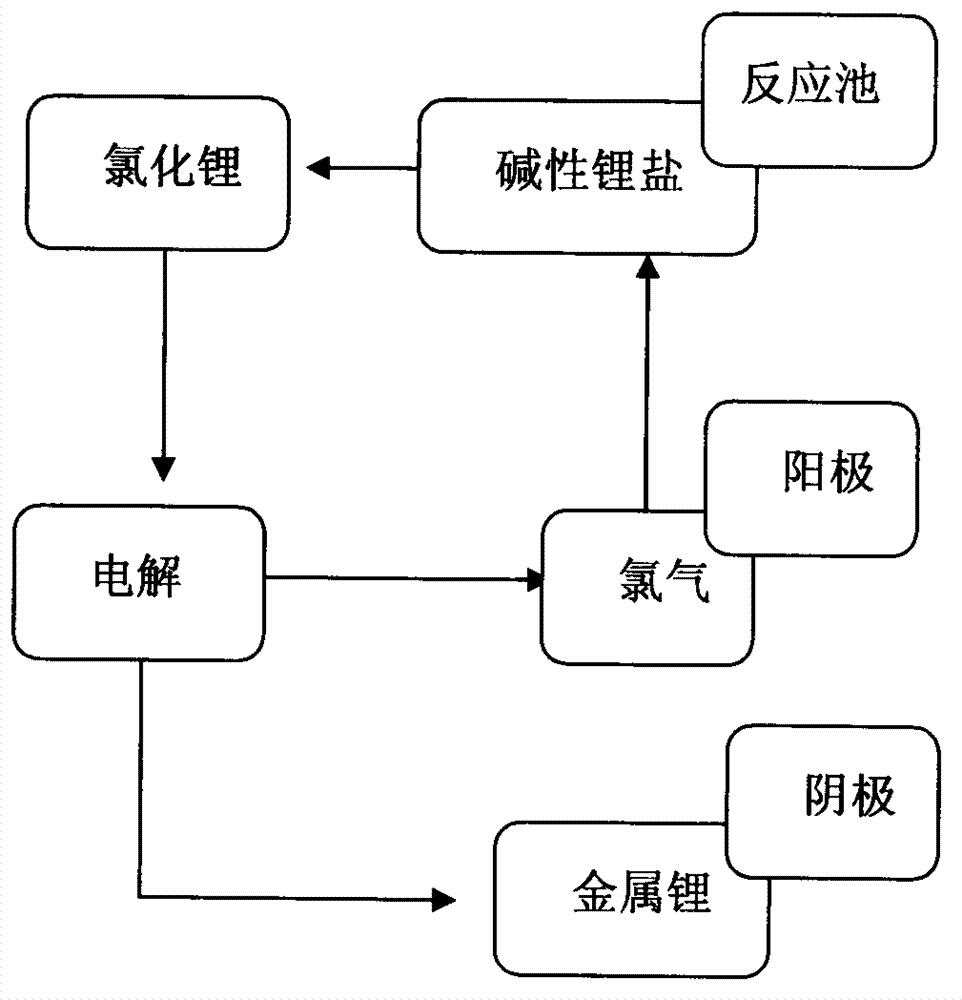

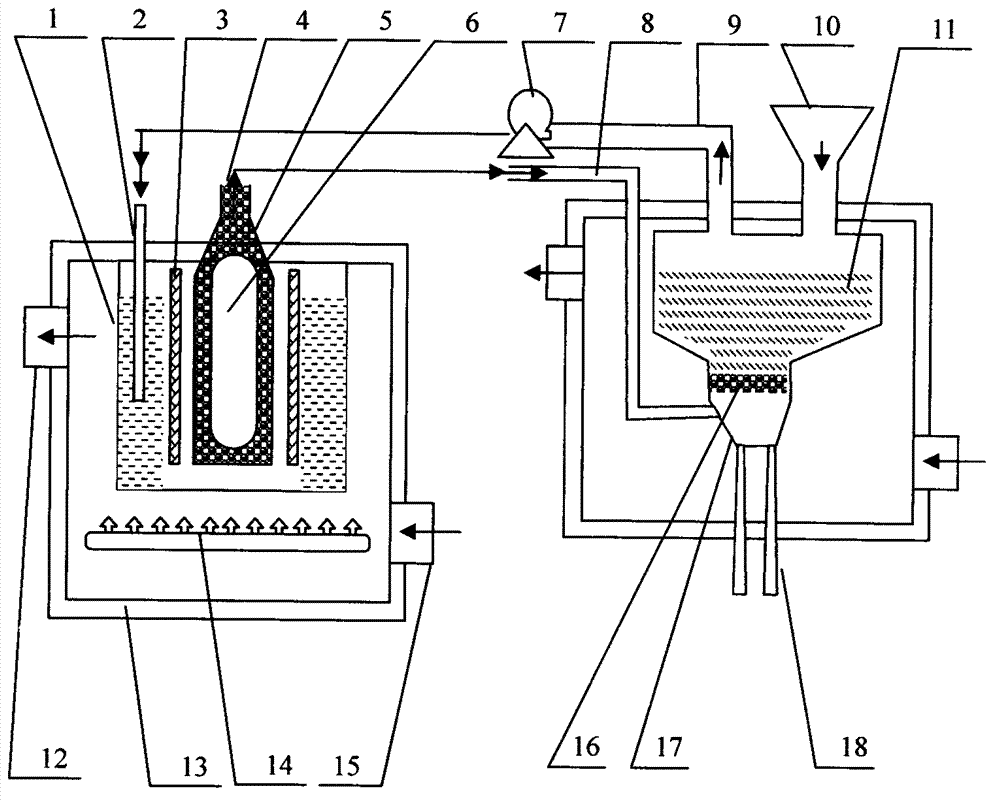

Method of preparing metallic lithium by one-step fusion electrolysis of lithium salt

The invention discloses a method of preparing metallic lithium by one-step fusion electrolysis of lithium salt. The method comprises the following steps that: chlorine gas generated by a graphite anode (6) in an electrolytic bath is pumped to a high-temperature fusion chamber (11) of a decomposition groove on a reaction tank (13) by a chlorine gas feedback pipe (8), passes through a porous-titanium sieve plate (16) from bottom to top, and reacts with the fused alkaline lithium salt to generate lithium chloride for further electrolysis, and due to rapid reaction, the metallic lithium is generated continuously from bottom to top. The method disclosed by the invention has the advantages that the chlorine gas becomes a carrier for carrying lithium ions actually, circulates between a decomposition chamber and the high-temperature fusion chamber (11) in the electrolytic bath in a back-and-forth manner without being exhausted outwards, so that not only are the production efficiency and the quality of the metallic lithium improved, but also auxiliary equipment required for exhausting the chlorine gas outwards and the influence are avoided; in addition, due to the reduced processes about concentrated crystallization, centrifugal separation, high-temperature drying, lithium ingot fusion and vacuum distillation and the like, the procedure is obviously saved, the cost for the equipment and production is reduced and large business opportunity is brought for application of downstream processes and products.

Owner:新疆骏强科技发展有限公司

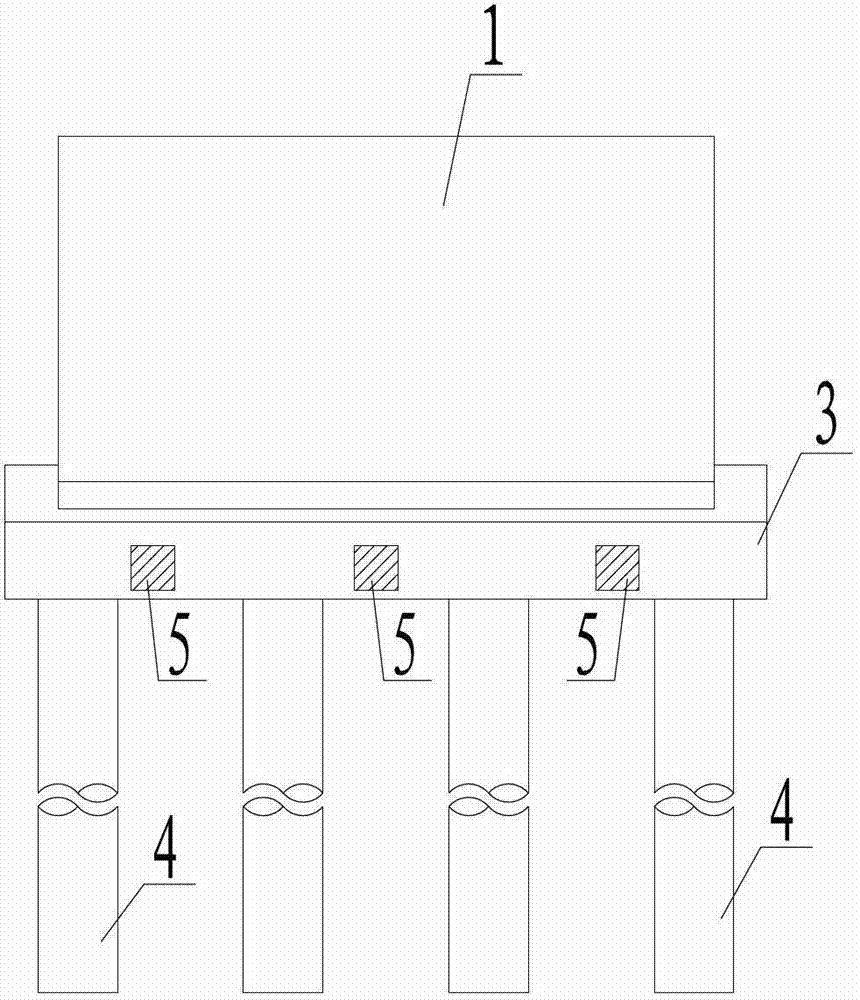

Continuous rigid frame bridge based on steel truss-concrete slab composite beam

InactiveCN103669194ALight weightImprove leaping abilityTruss-type bridgeBridge structural detailsSheet steelBridge deck

The invention discloses a continuous rigid frame bridge based on a steel truss-concrete slab composite beam. The continuous rigid frame bridge comprises a bridge substructure and the steel truss-concrete slab composite beam supported by the bridge substructure. The steel truss-concrete slab composite beam comprises a steel truss and a concrete bridge deck which is laid over the steel truss. The steel truss comprises one or more steel truss units; each steel truss unit is an inverted-triangle truss girder, wherein the inverted-triangle truss girder is composed of two upper chords, a lower chord, a left line of diagonal web members and a right line of diagonal web members, each upper chord comprises a first horizontal steel plate and a plurality of first vertical perforated steel plates evenly laid on the first horizontal steel plate, an upper chord transverse connecting system connected between the two upper chords comprises a plurality of upper chord transverse connecting pieces, and each upper chord transverse connecting piece comprises a second horizontal steel plate and a plurality of second vertical perforated steel plates evenly laid on the second horizontal steel plate. The continuous rigid frame bridge is simple in structure, reasonable in design, convenient to construct, good in stress performance, good in using effect and capable of effectively solving various problems existing in an existing continuous rigid frame bridge.

Owner:CHANGAN UNIV

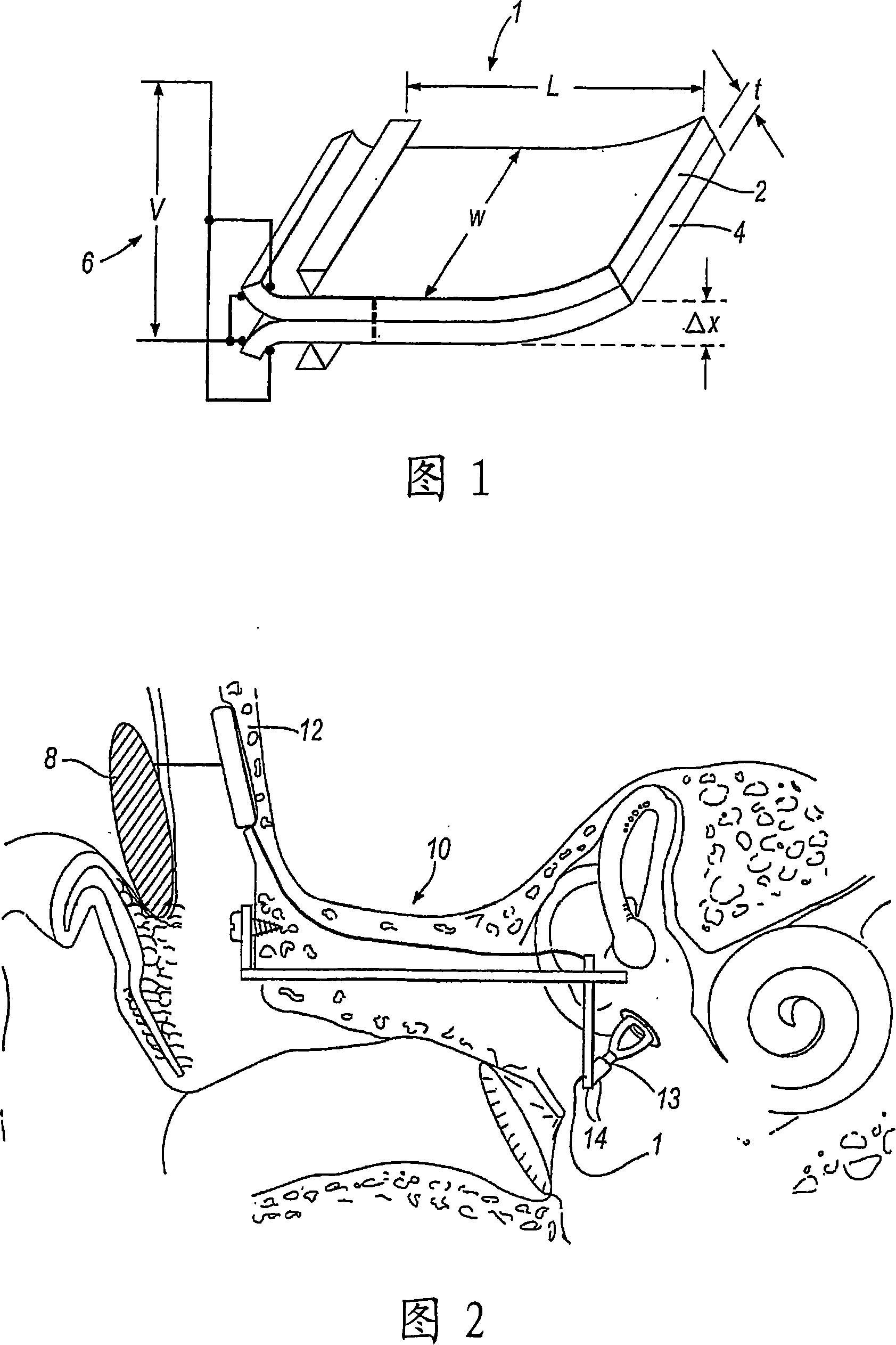

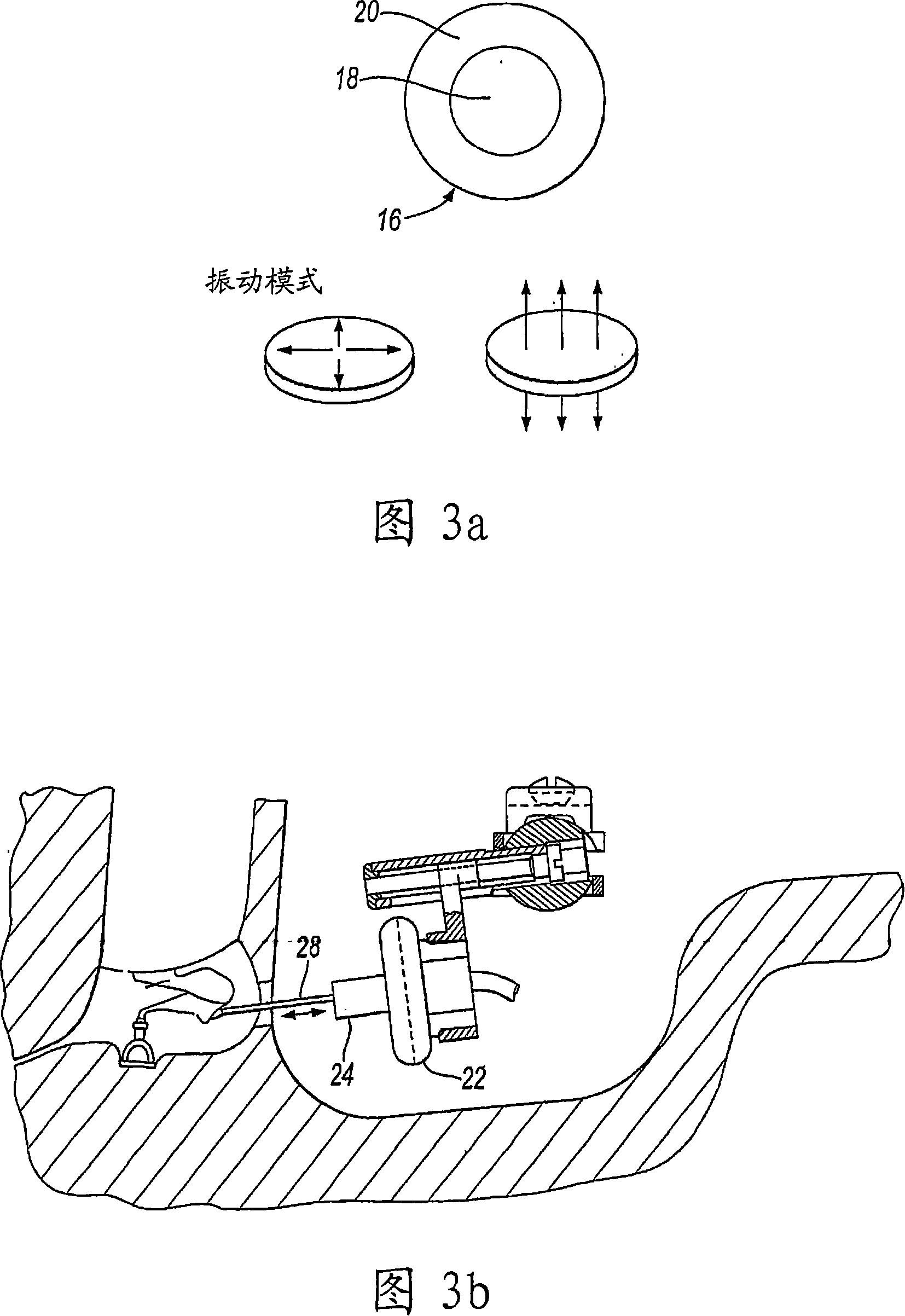

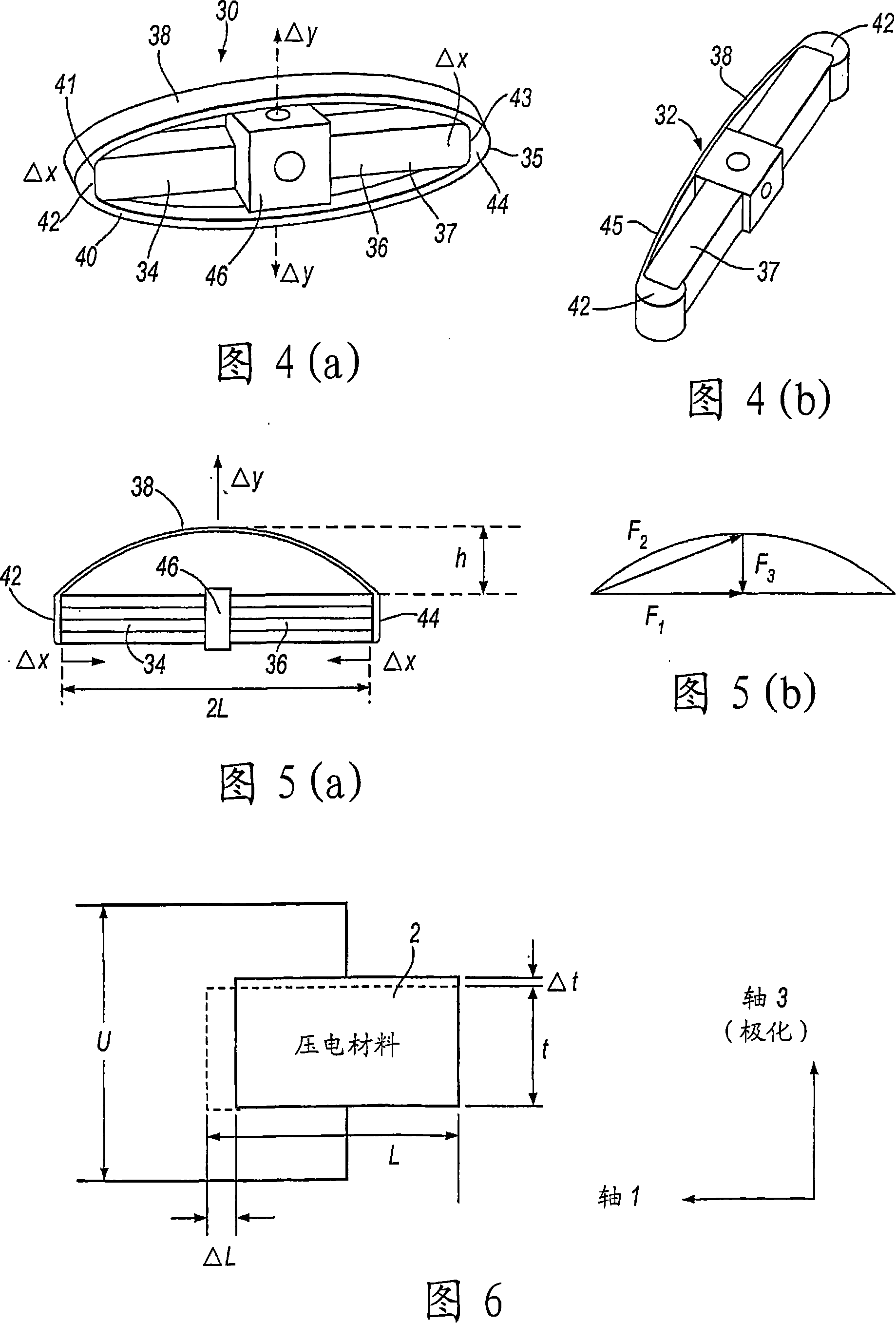

Hearing implant

ActiveCN101128172AImprove structural integrityAvoid destructionPiezoelectric/electrostrictive microphonesEar treatmentAudio power amplifierMiddle ear

The present invention concerns an actuator for an implantable hearing aid for implantation into the human middle ear. The actuator comprises a substantially elongate piezoelectric component (34, 36) having first and second operating end faces (41, 43), said end faces extending substantially at right angles to the longitudinal axis of the piezoelectric component. Also there is provided a frame component comprising at least one flextensional amplifier element (32), the flextensional amplifier element being integral with and connecting first and second frame end portions (42, 44), the first and second frame end portions also extending substantially at right angles to longitudinal axis of the piezoelectric component when fitted thereto, whereby the first and second end portions are in contact with the piezoelectric component end faces.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

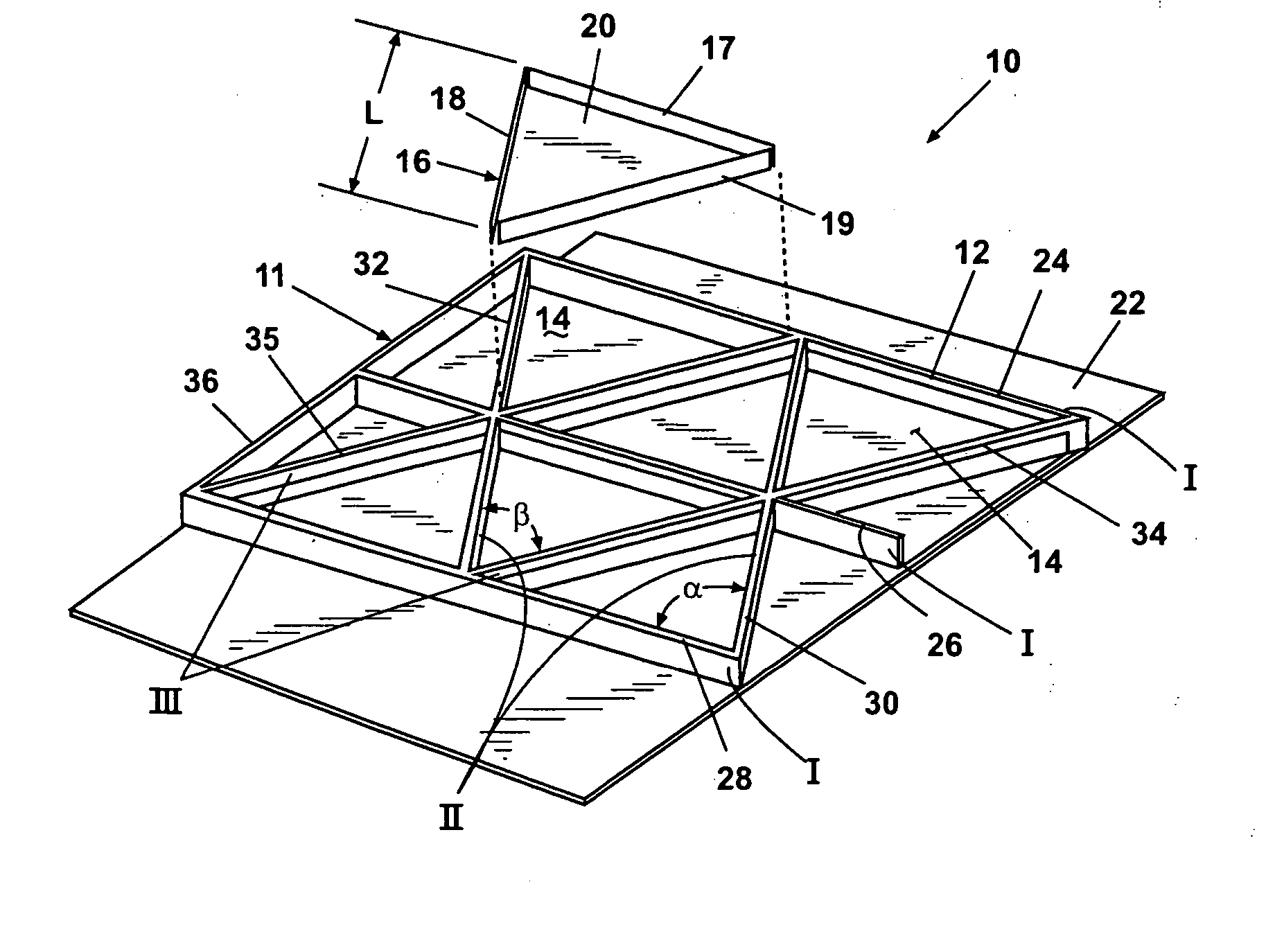

Cellular composite grid-stiffened structure

ActiveUS20060172121A1Improved composite structureImprove structural integrityAircraft stabilisationLayered productsComposite gridMesh grid

A cellular composite structure includes a grid having groups of angularly intersecting ribs. The ribs of each group are oriented substantially in the same direction to each other and angularly oriented from the other rib groups. An additional rib defines a composite structure outer perimeter wall and can be differently angularly oriented from the other ribs. A contiguous rib wall is created by segments of ribs defined by rib intersections. The contiguous rib wall bounds a cavity. A multilayer sheet cap member with extending walls to engage the contiguous rib wall is positioned within the cavity. The engagement walls extend from individual sheet perimeter portions angularly oriented to the sheet. The ribs and cap member have pre-impregnated resin. Heating the cap member and ribs activates the resin and co-cures the composite structure.

Owner:THE BOEING CO

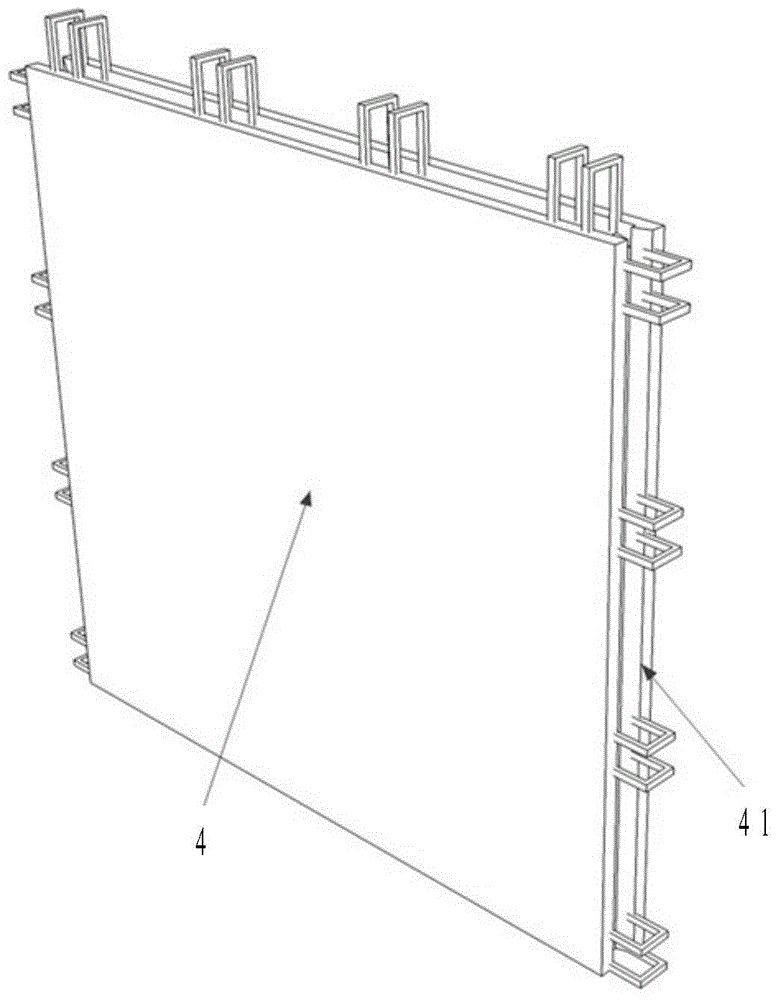

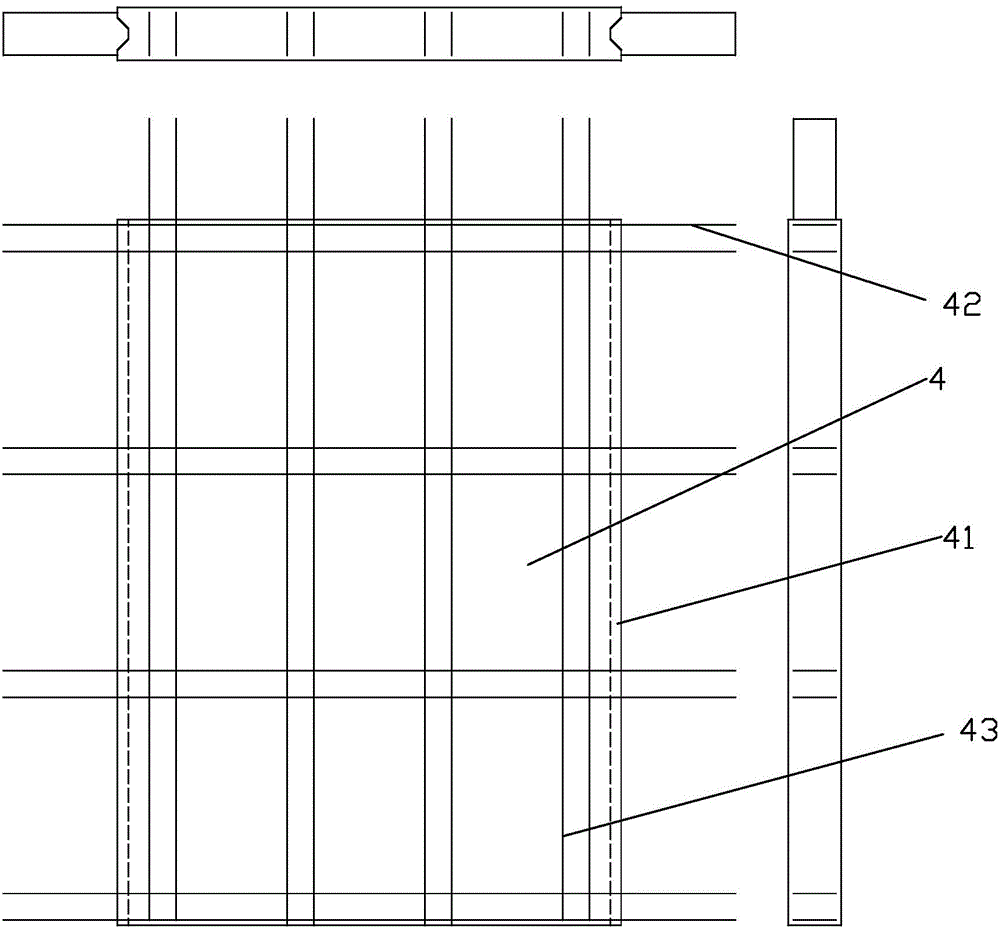

Prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection and construction method of prefabricated steel fiber sludge-made ceramisite concrete wall

A prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection comprises prefabricated wall plates, cast-in-place connection columns and cast-in-place vertical edge components, wherein the two lateral sides of each prefabricated wall plate are each of a T-shaped groove structure, horizontal and vertical reinforcing steel bars are arranged in the prefabricated wall plates, each cast-in-place column is embedded in the T-shaped groove structures of the corresponding adjacent prefabricated wall plates to connect the prefabricated wall plates, each cast-in-place vertical edge component is provided with a longitudinal protrusion structure matched with the corresponding T-shaped groove structure, the longitudinal protrusion structures are embedded in the T-shaped groove structures on the outer sides of the edge prefabricated wall plates, longitudinal ribs are arranged in the cast-in-place vertical edge components, and reliable anchoring is achieved when the longitudinal ribs and the horizontal reinforcing steel bars in the edge prefabricated wall plates are embedded and spot welding is conducted on the joints one by one. The invention further provides a construction method of the prefabricated steel fiber sludge-made ceramisite concrete wall, and by means of the innovation of materials, the connection mode and the rib matching mode, the wall structure can have the advantages of being capable of lowing energy consumption and reducing vibration, ecological, environmentally friendly, capable of being rapidly constructed, economical and practical.

Owner:西咸新区矩阵住宅工业有限公司

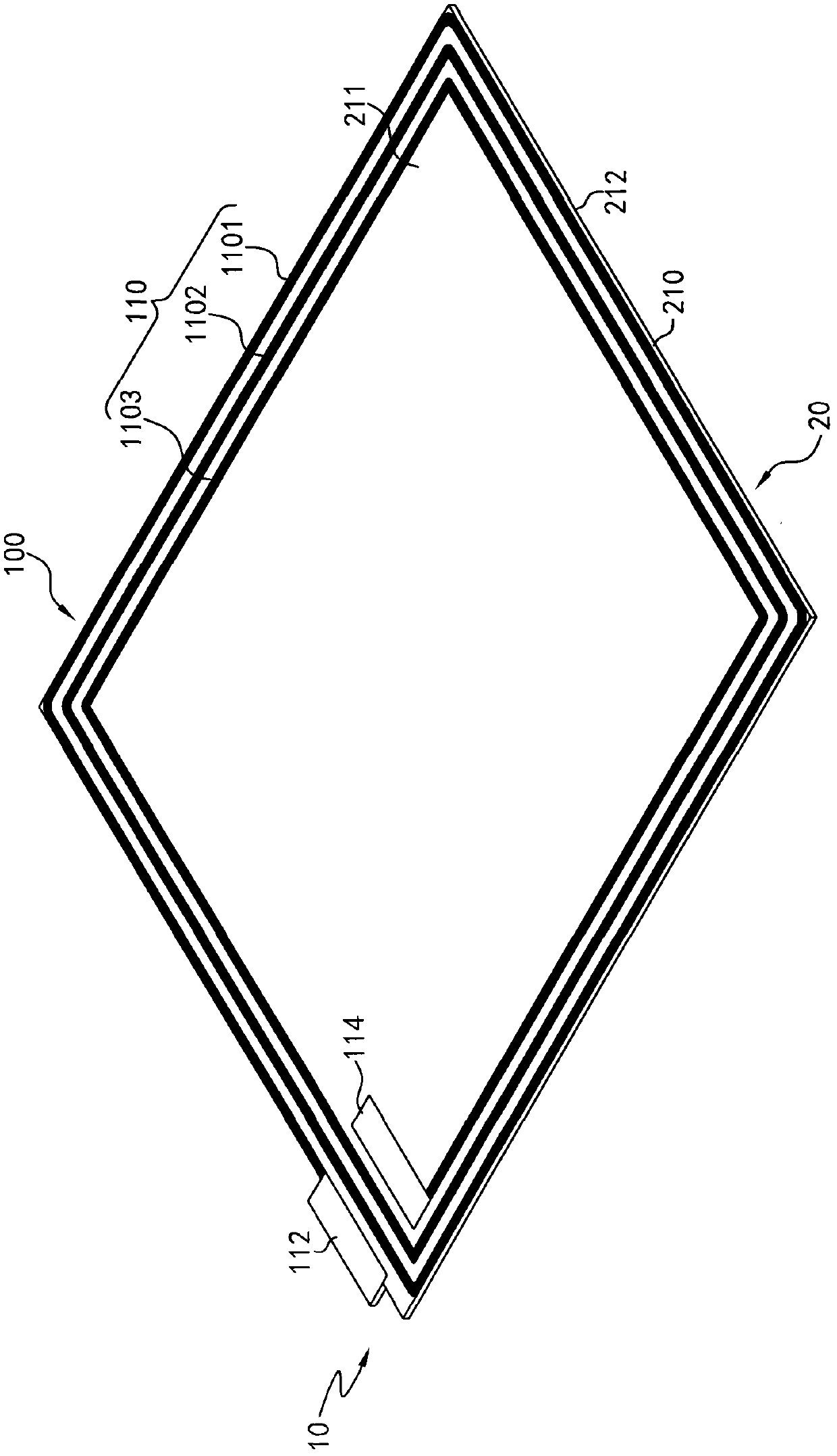

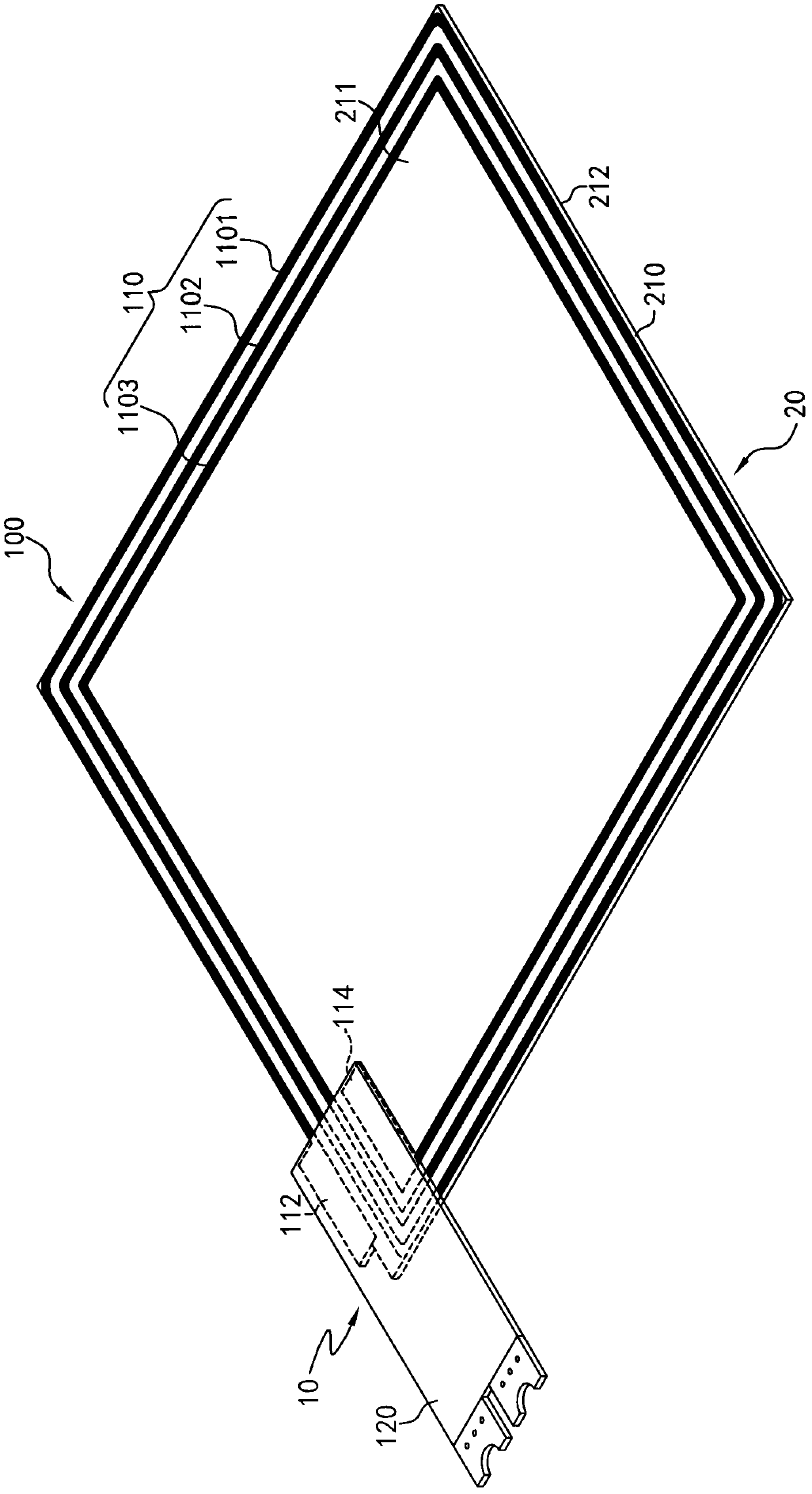

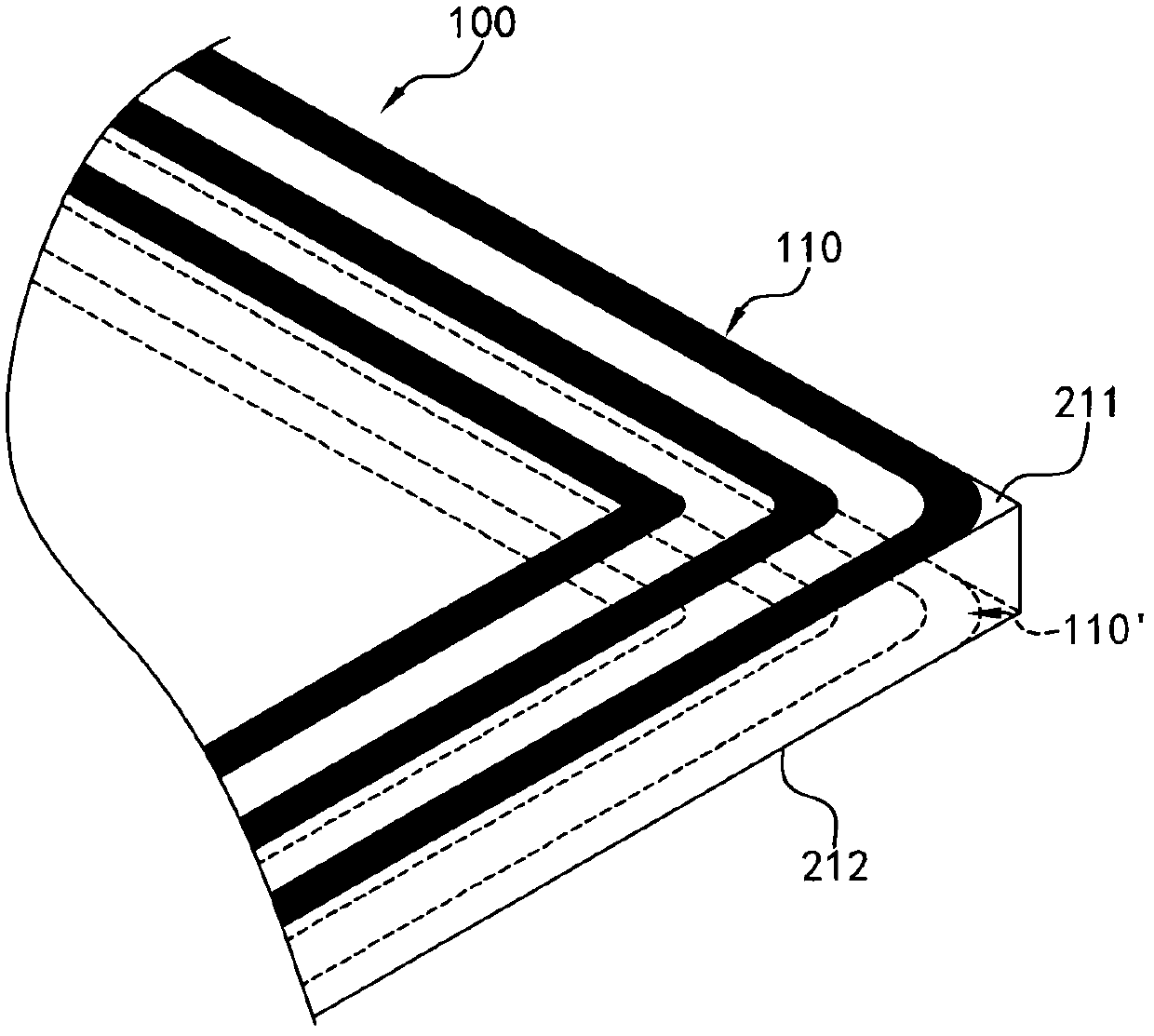

Antenna module as well as touch module and electronic device using same

InactiveCN102569987ASave volume and spaceGood structural integrityAntenna supports/mountingsRadiating elements structural formsAcousticsMaterials science

The invention discloses an antenna module, as well as a touch module and an electronic device using the same. The antenna module comprises a transparent substrate and an antenna line arranged on the transparent substrate. The antenna line comprises a pair of electrodes and a coil block connected with the electrodes. The electronic device comprises a motherboard, a display panel and the antenna module. The transparent substrate and the motherboard are folded on two opposite sides of the display panel, so that the circuit design space of the electronic device using the antenna module can be reduced.

Owner:SMART APPROACH

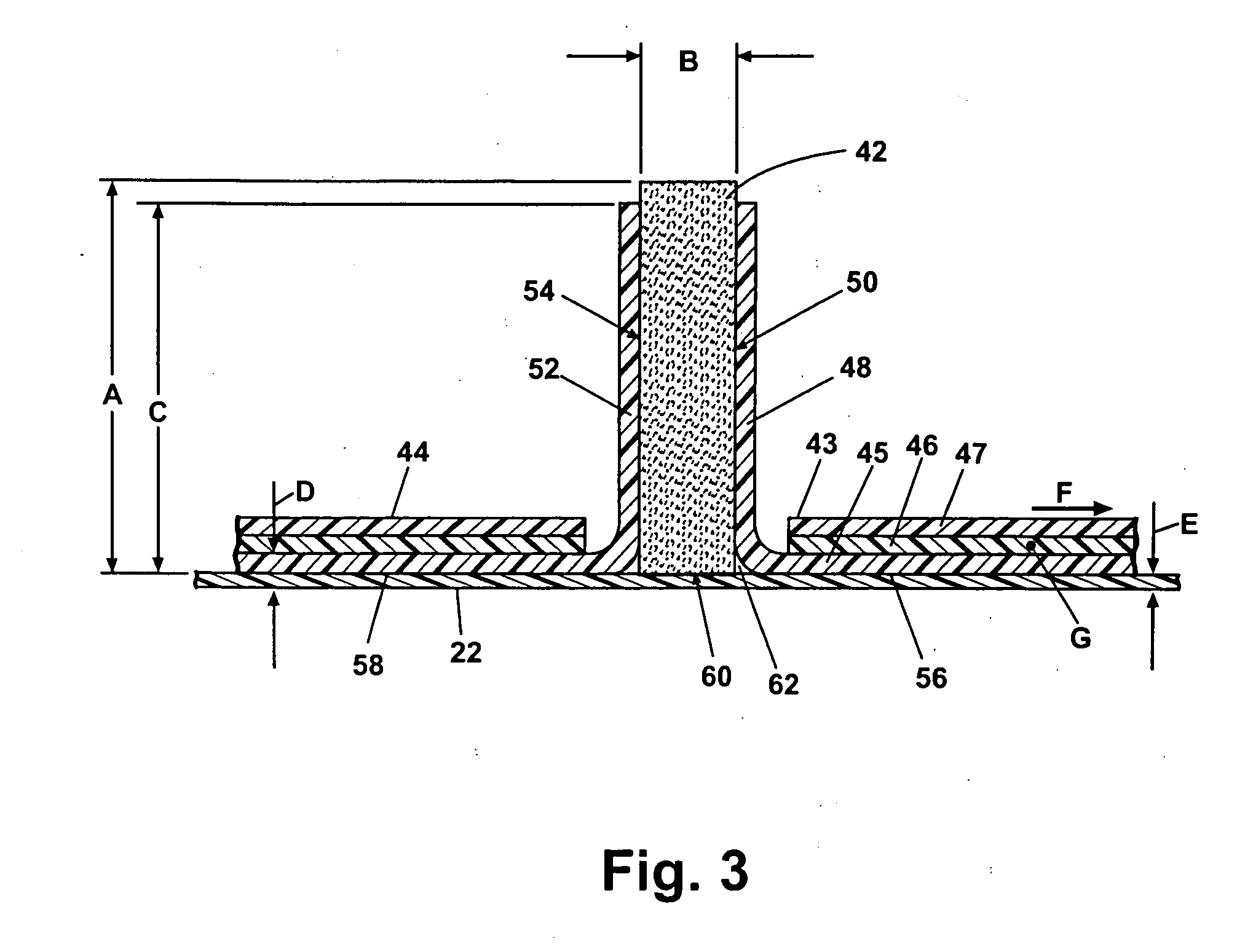

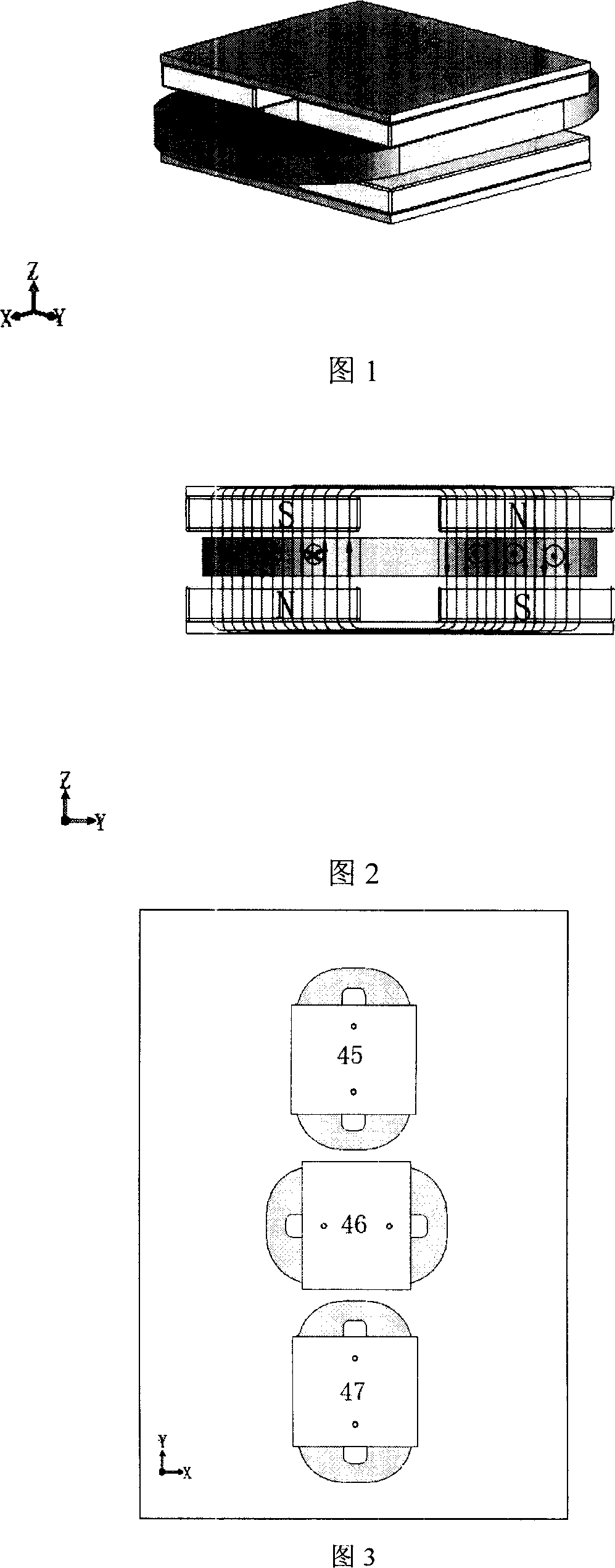

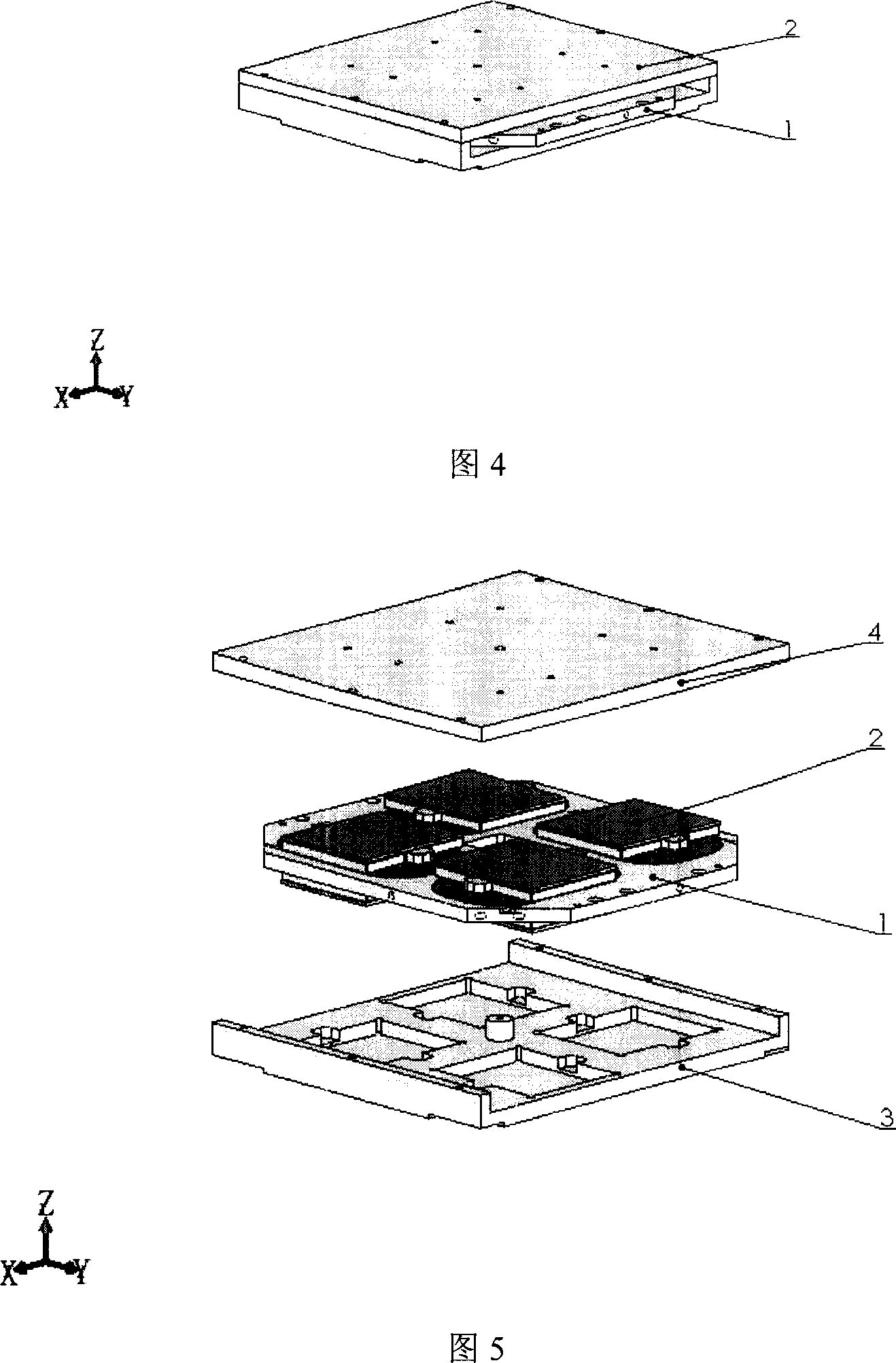

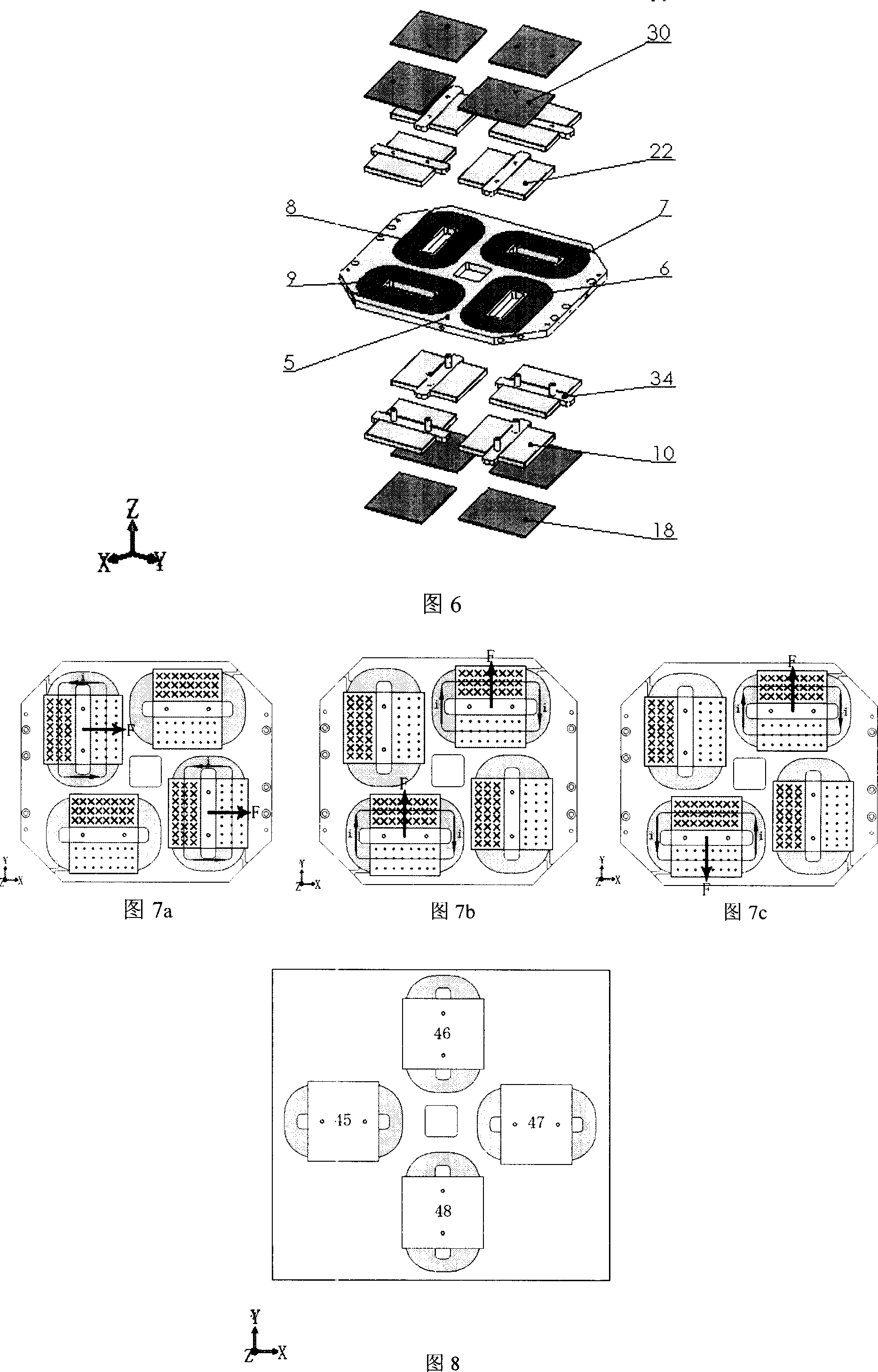

An ultra-thin 3-freedom degree plane motor

ActiveCN1996726ACompact structureImprove structural integrityPropulsion systemsEngineeringDegrees of freedom

Ths invention discloses one super thin three freedom plane motor to provide one micro work bench execution parts with high accuracy, which comprises coil parts ad permanent magnetic parts composed of three sets of drive units to realize the three freedom in plane, wherein, the two sets of drive units axis lines are parallel without overlapped; the third set of drive unit axis line is cross with front two sets with each composed of one or more coil with same drive direction unit.

Owner:TSINGHUA UNIV +1

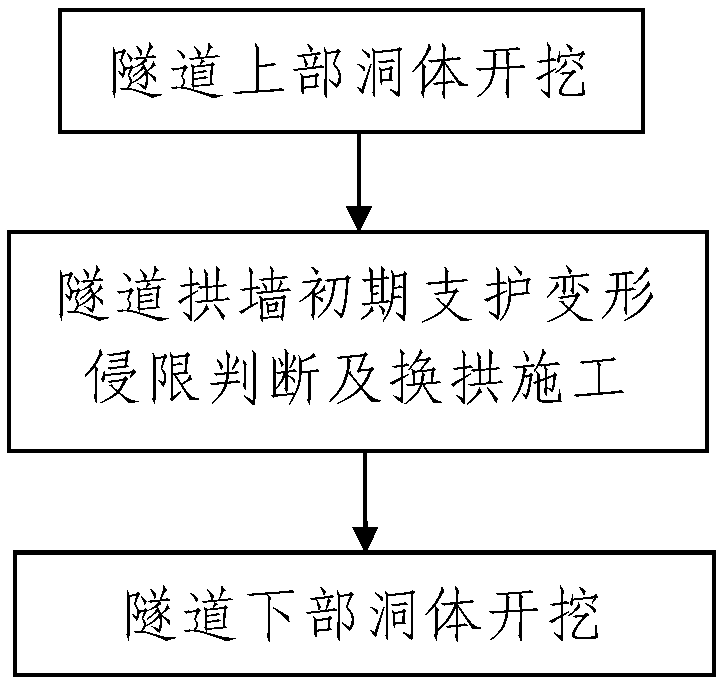

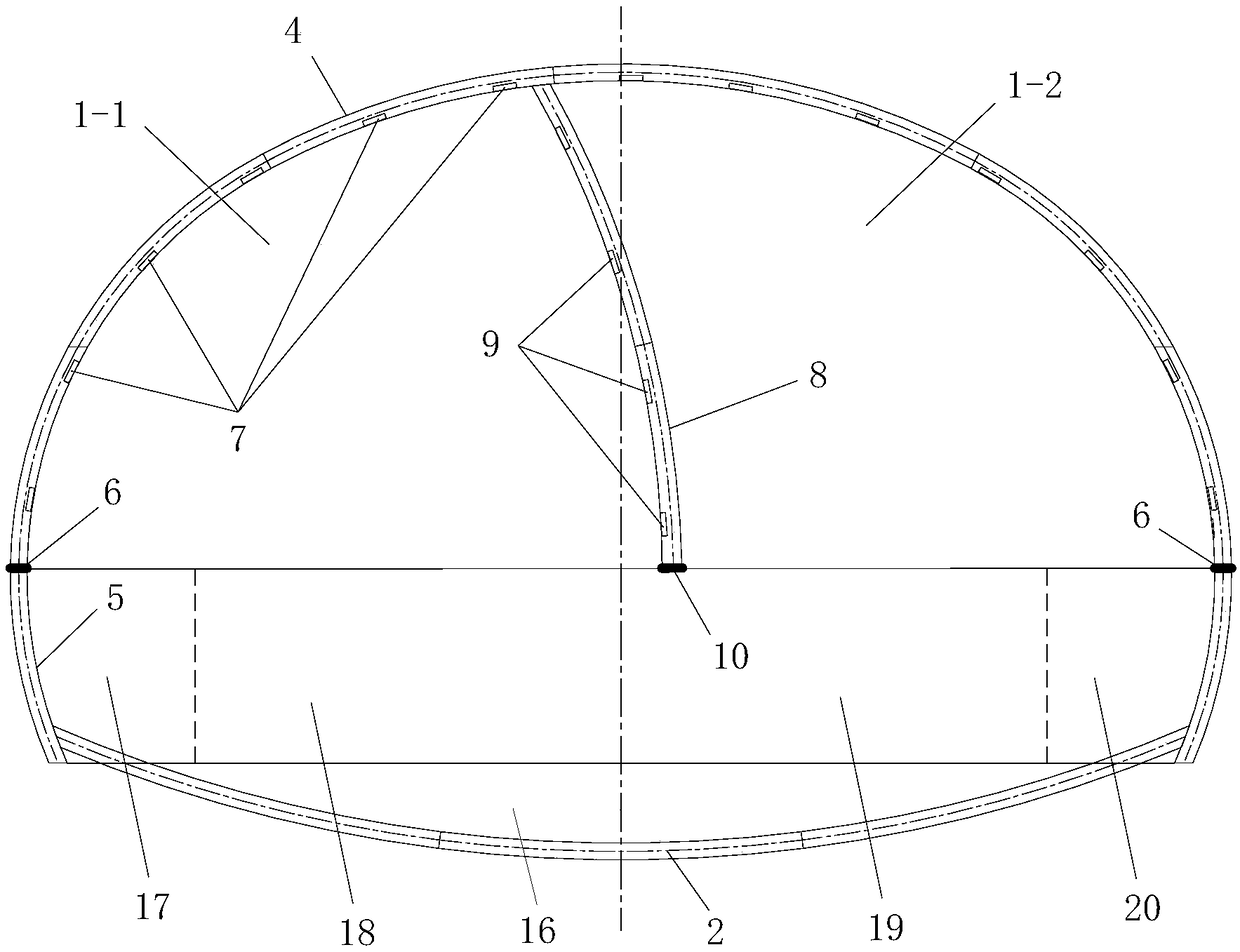

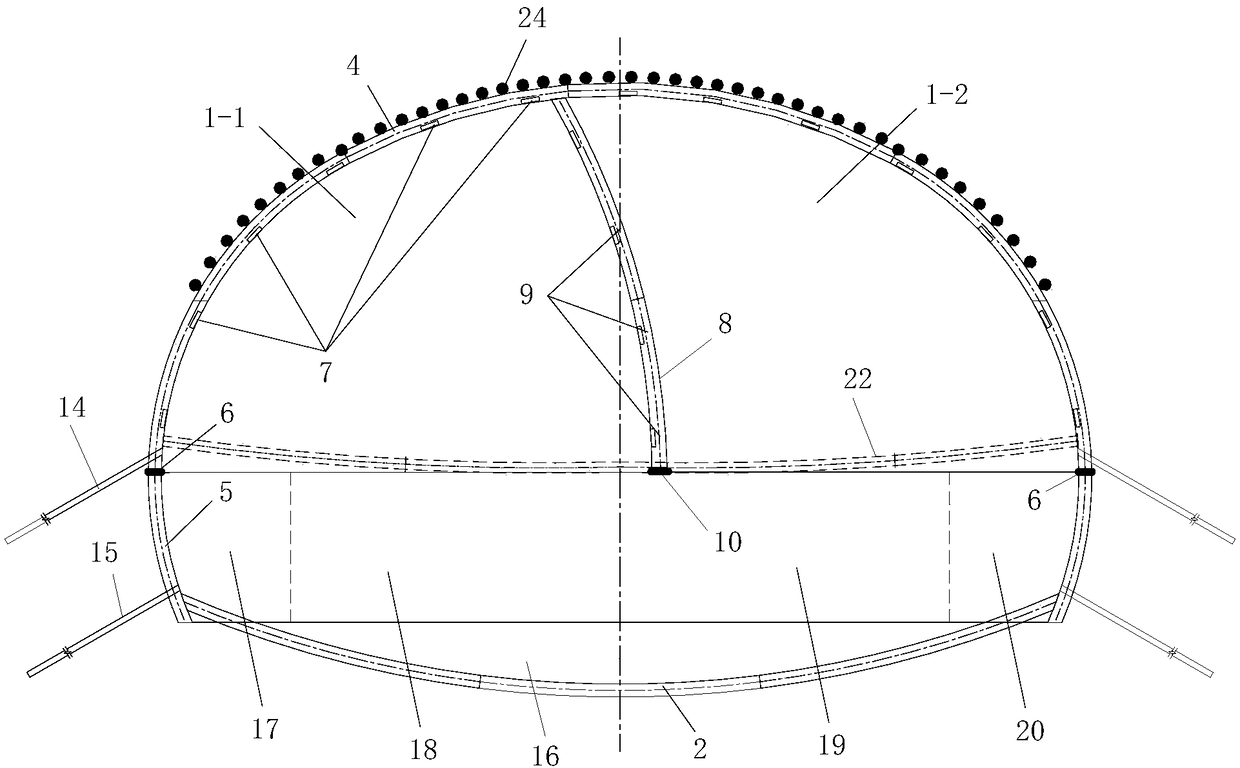

Excavation and support method of large cross-section tunnel through fault fracture zone

ActiveCN108843332AThe method steps are simpleReasonable designUnderground chambersTunnel liningSupporting systemFracture zone

The invention discloses an excavation and support method of large cross-section tunnel through fault fracture zone. The initial support structure of tunnel comprises a whole cross-section support system and the lattice girder and shotcrete support structure of the tunnel. A temporary support structure of middle-partition wall is arranged between a left pilot tunnel and a right pilot tunnel. The actual construction includes the steps: 1, excavation of the upper tunnel body; 2, the judgment of the initial support deformation of the tunnel arch wall and the construction of the replacement arch; 3, excavation of the lower tunnel body. The excavation and support method of large cross-section tunnel through the fault fracture zone has reasonable design, simple construction, and good use effect.Only the upper half section of the tunnel is excavated by the center diaphragm method, and the excavation cross-section is reduced so that the stability of the arch roof is ensured. The whole cross-section support system and the temporary support structure of middle-partition wall are supported by the underpass beam and joined together to form a stable monolithic support system, which can avoid the sinking of the supporting arch and ensure the stability of the initial support effectively. Besides, the construction of replacement arch is conducted on only half cross-section of the tunnel and the cost can be saved, and the construction safety can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com