Patents

Literature

174results about "Binding ends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

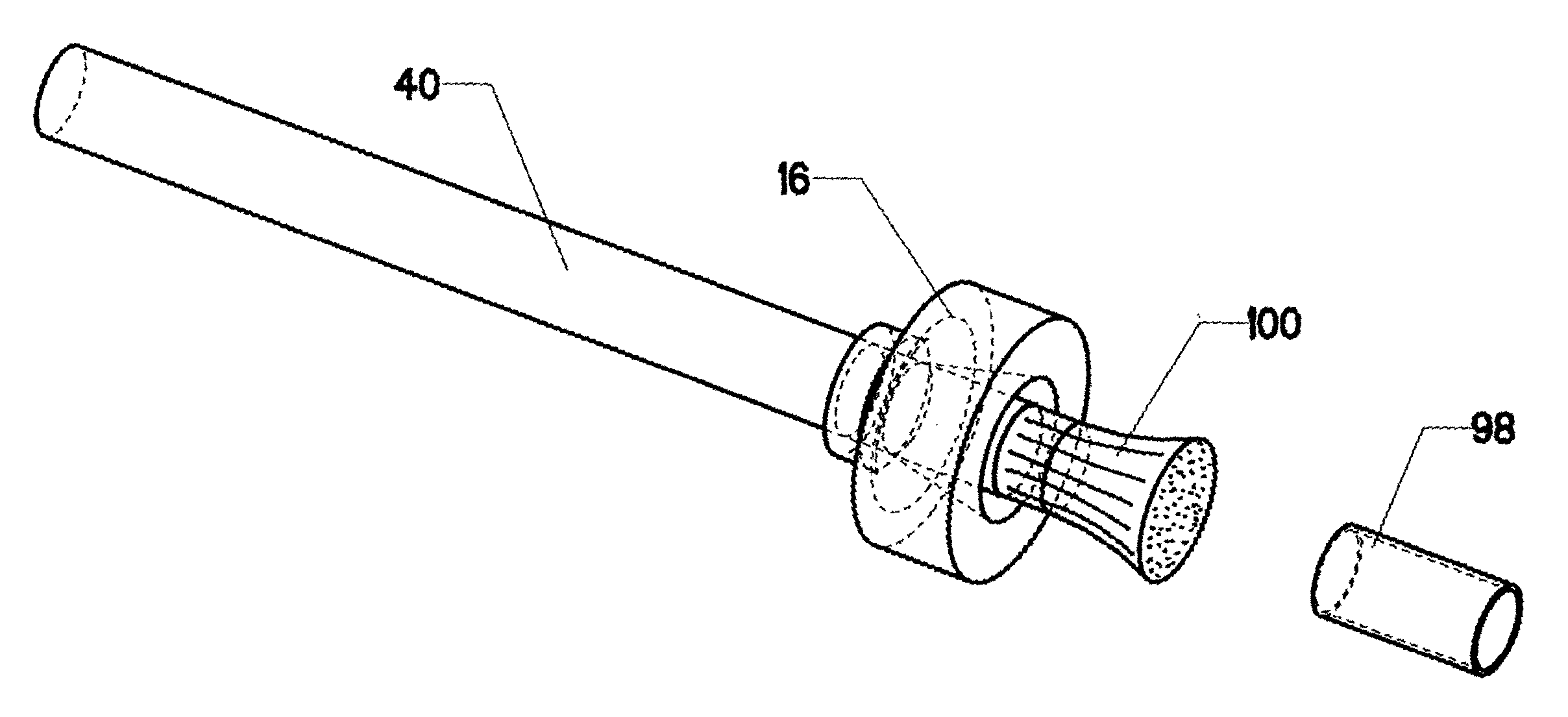

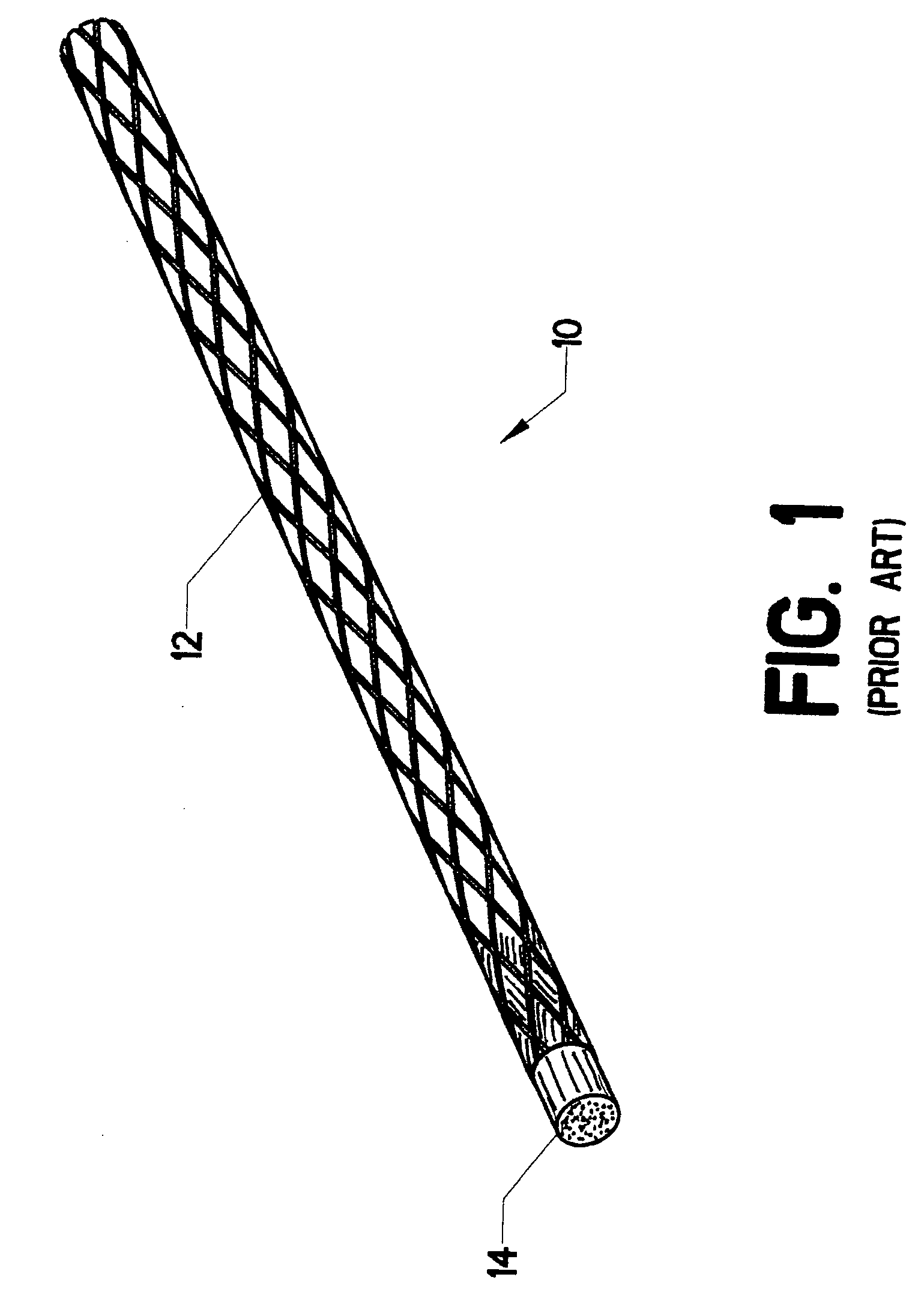

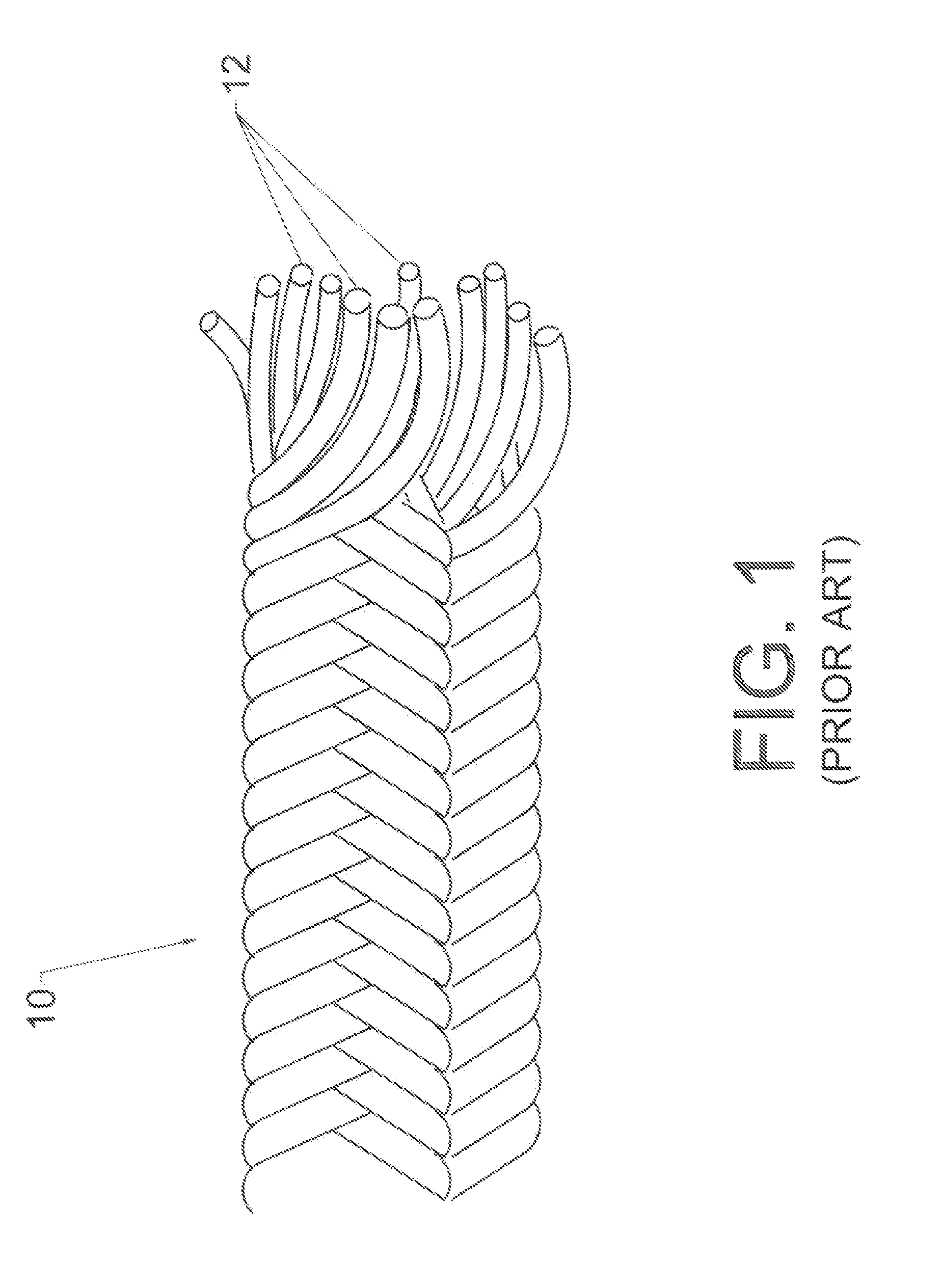

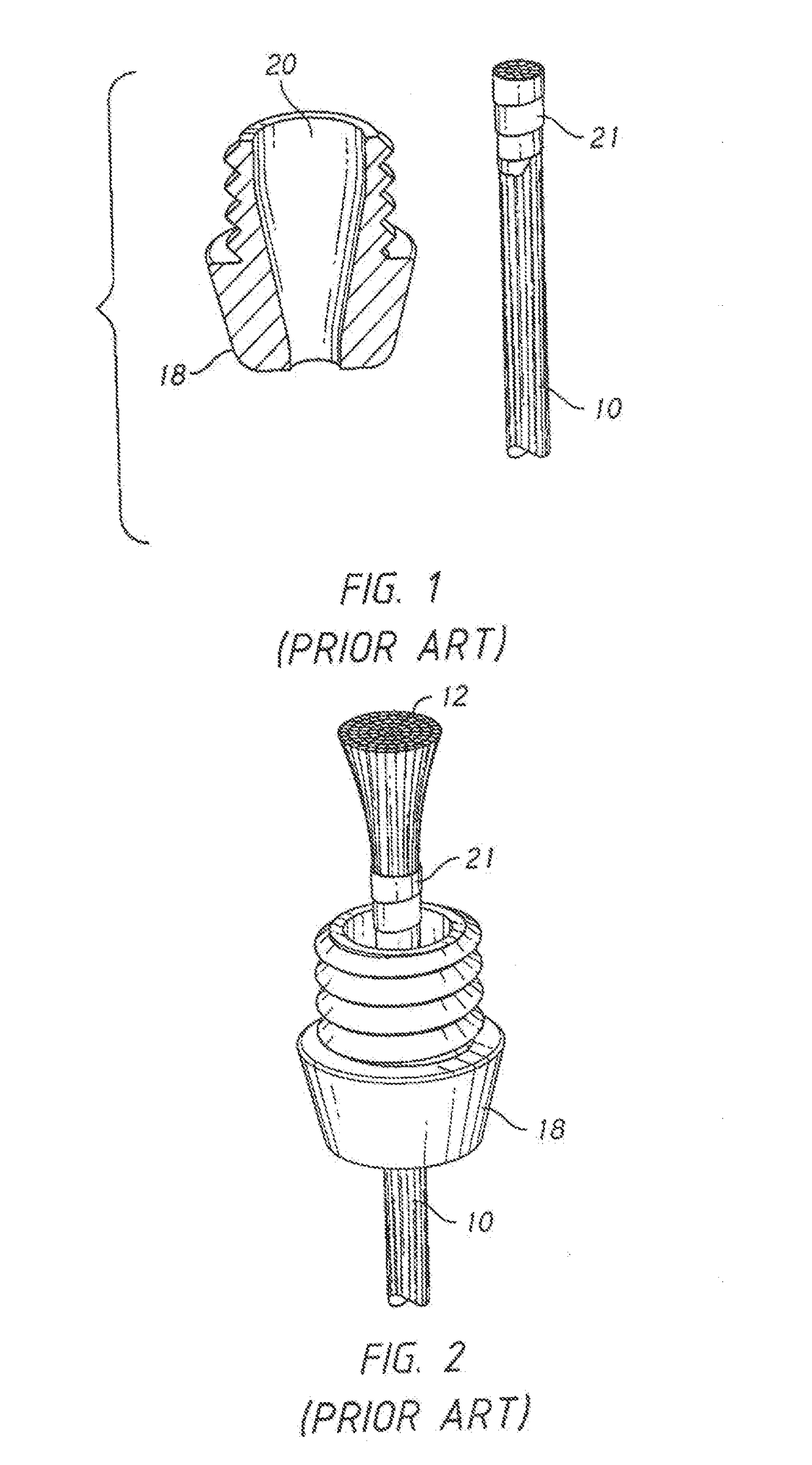

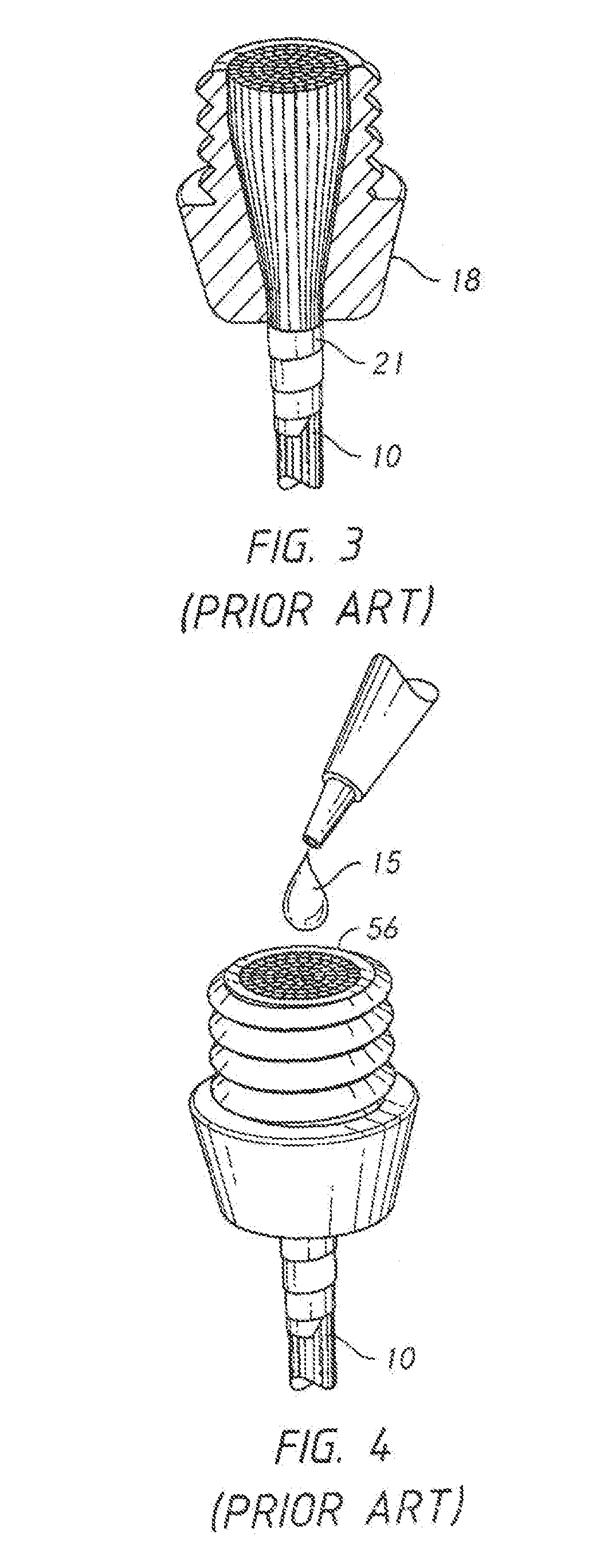

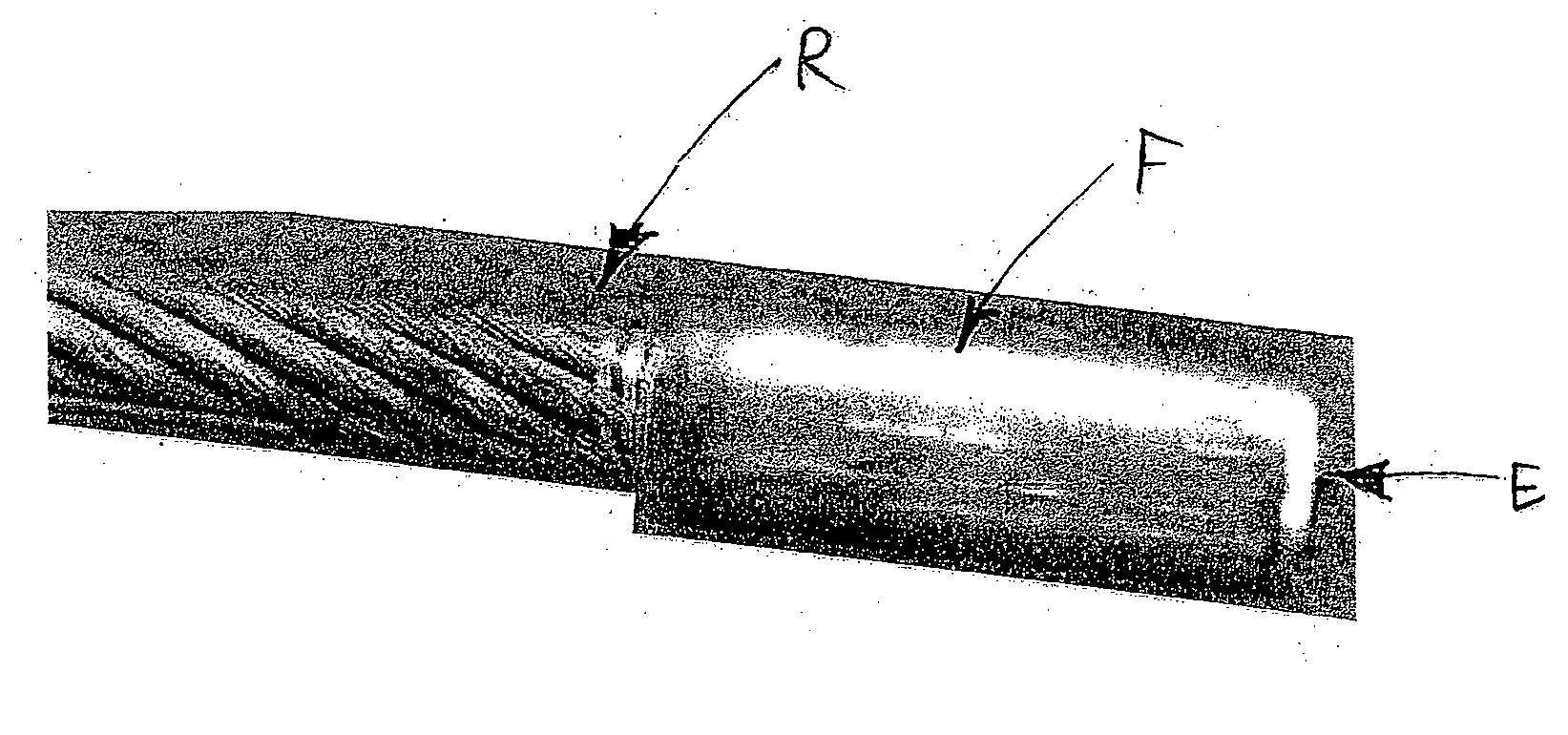

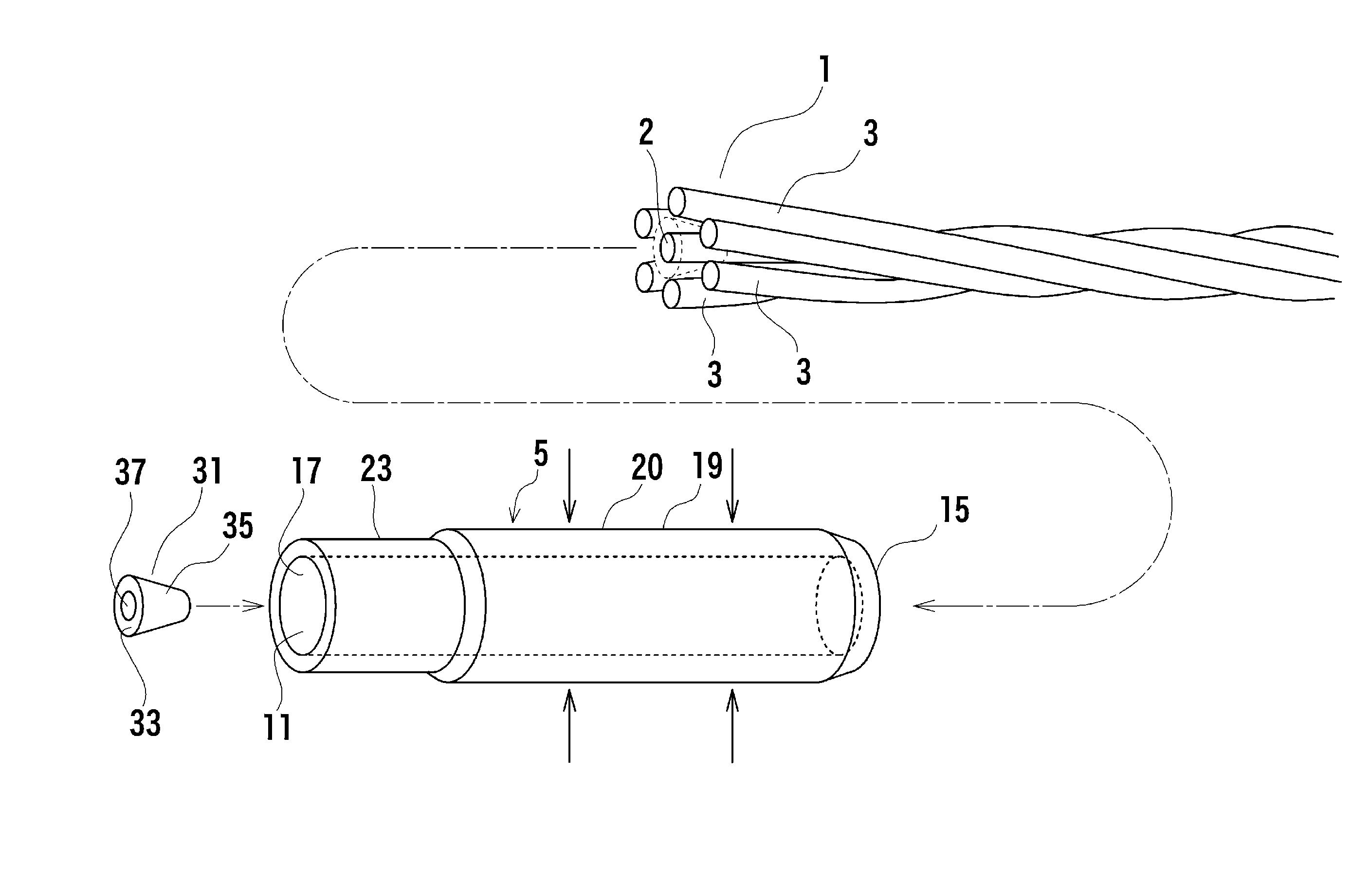

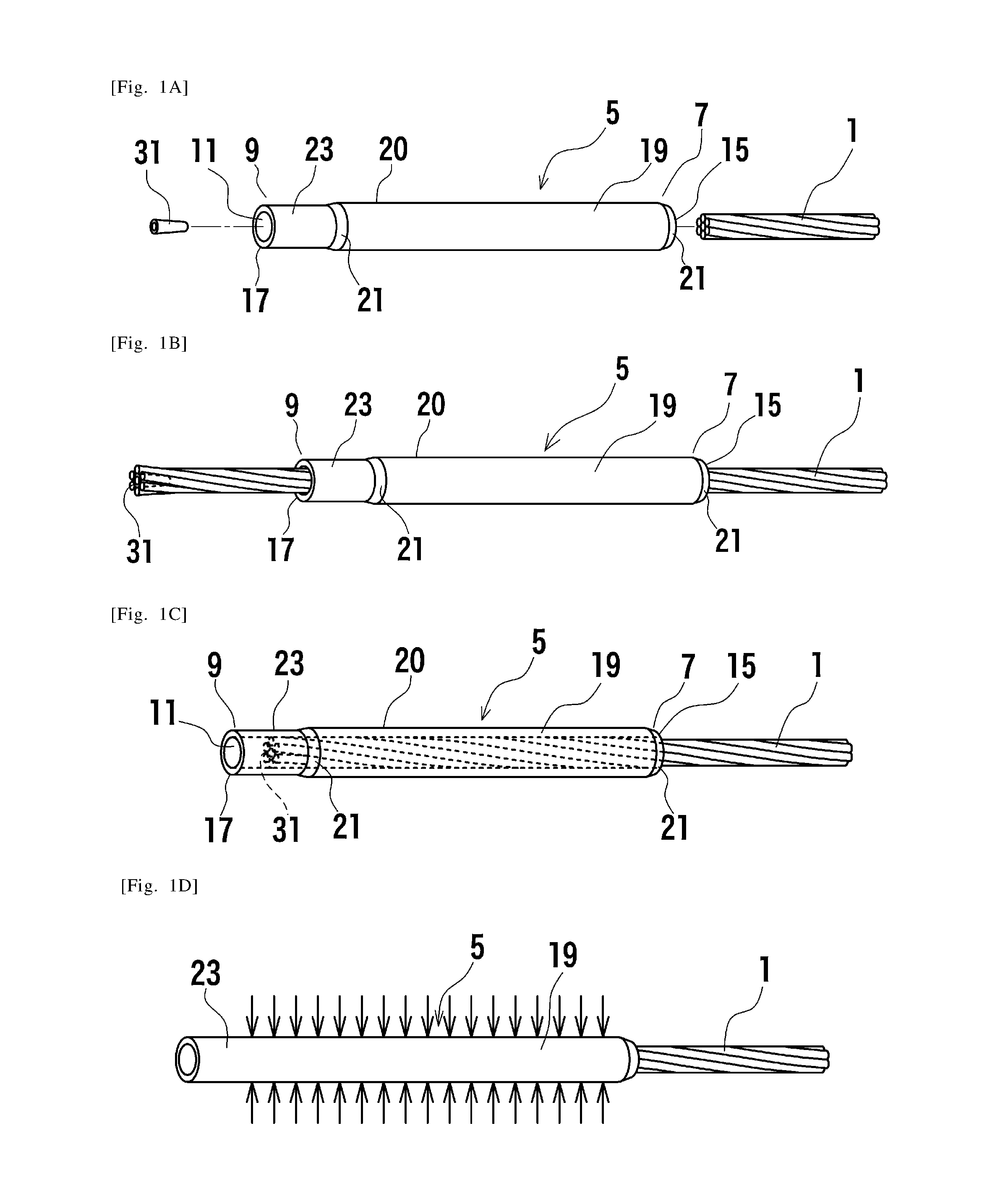

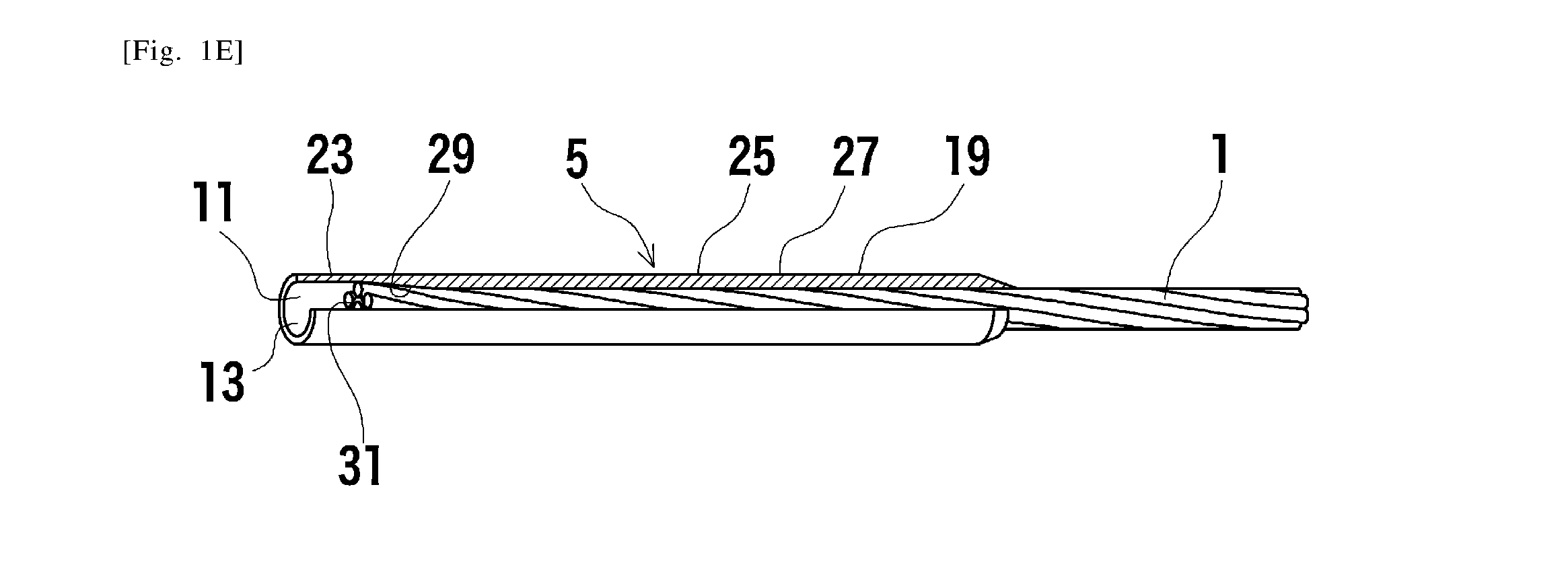

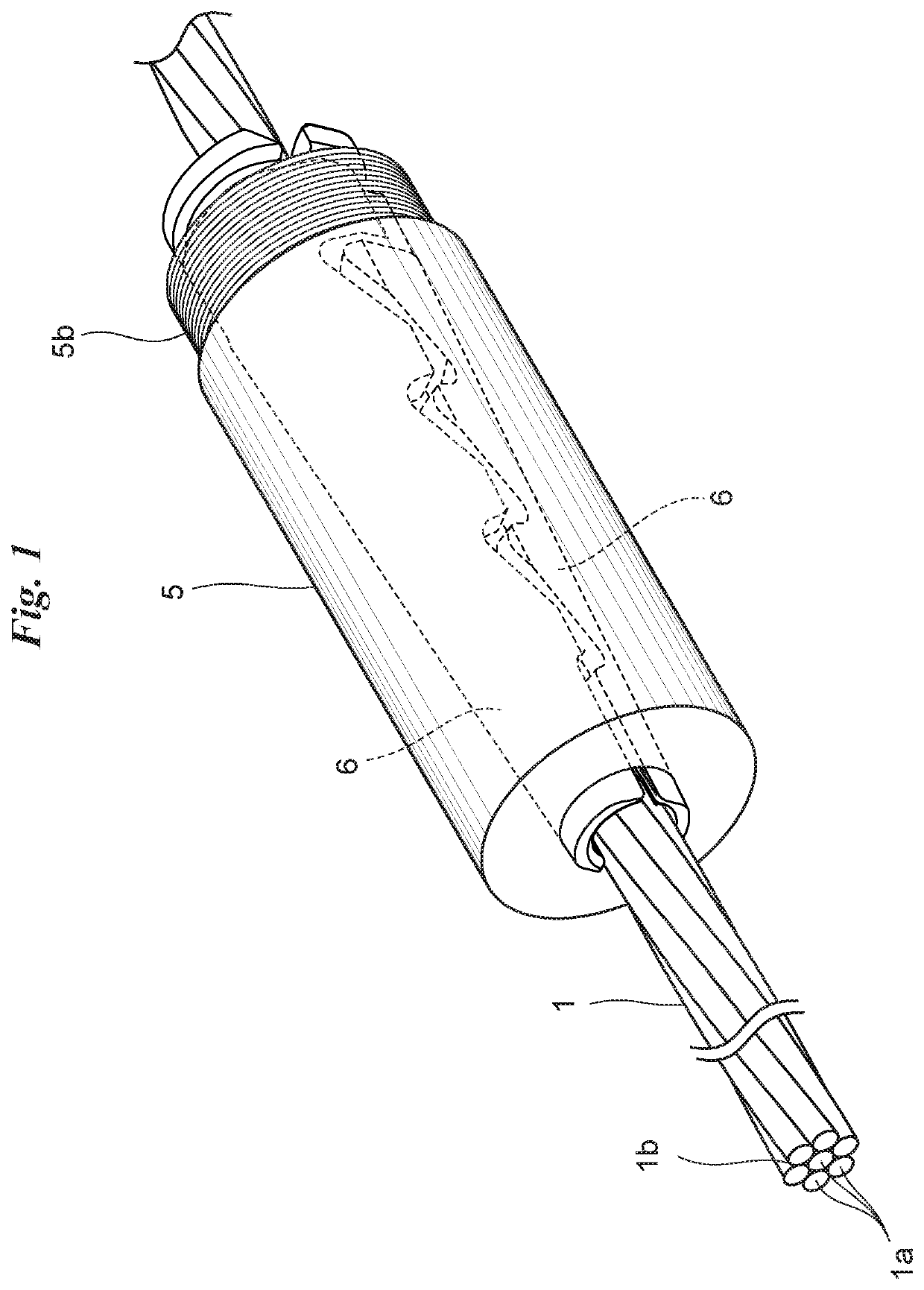

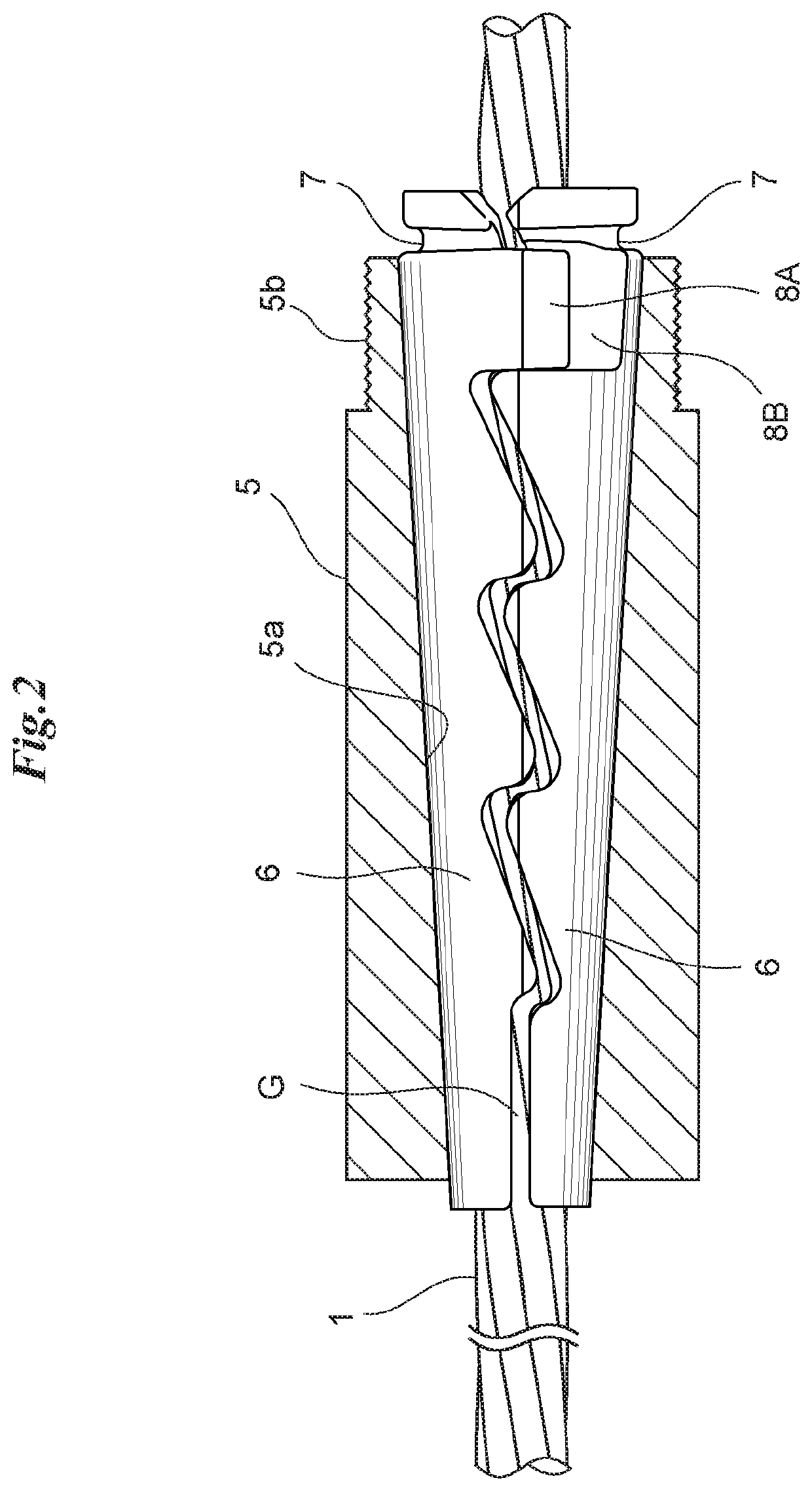

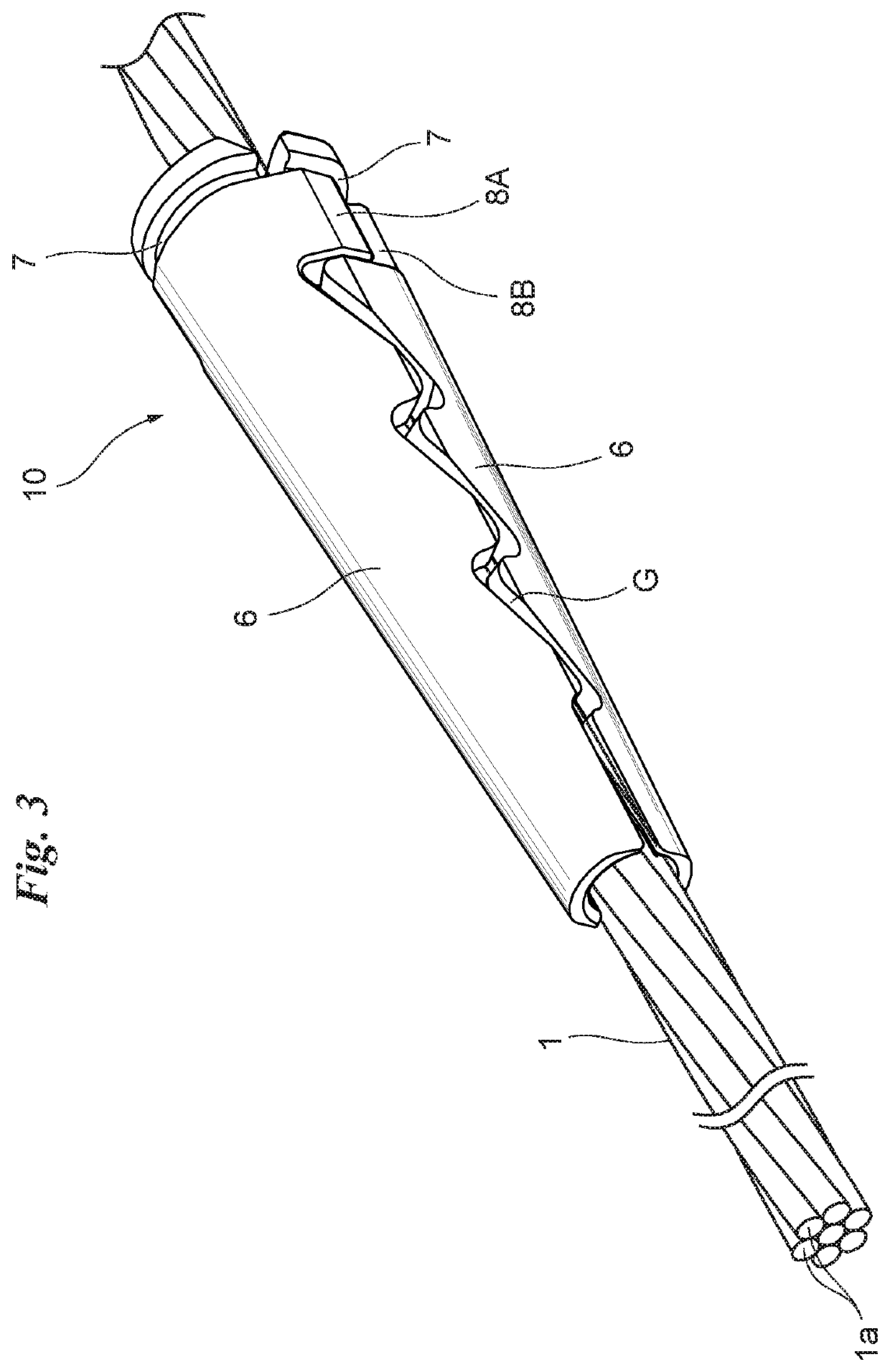

Cable manufacturing method

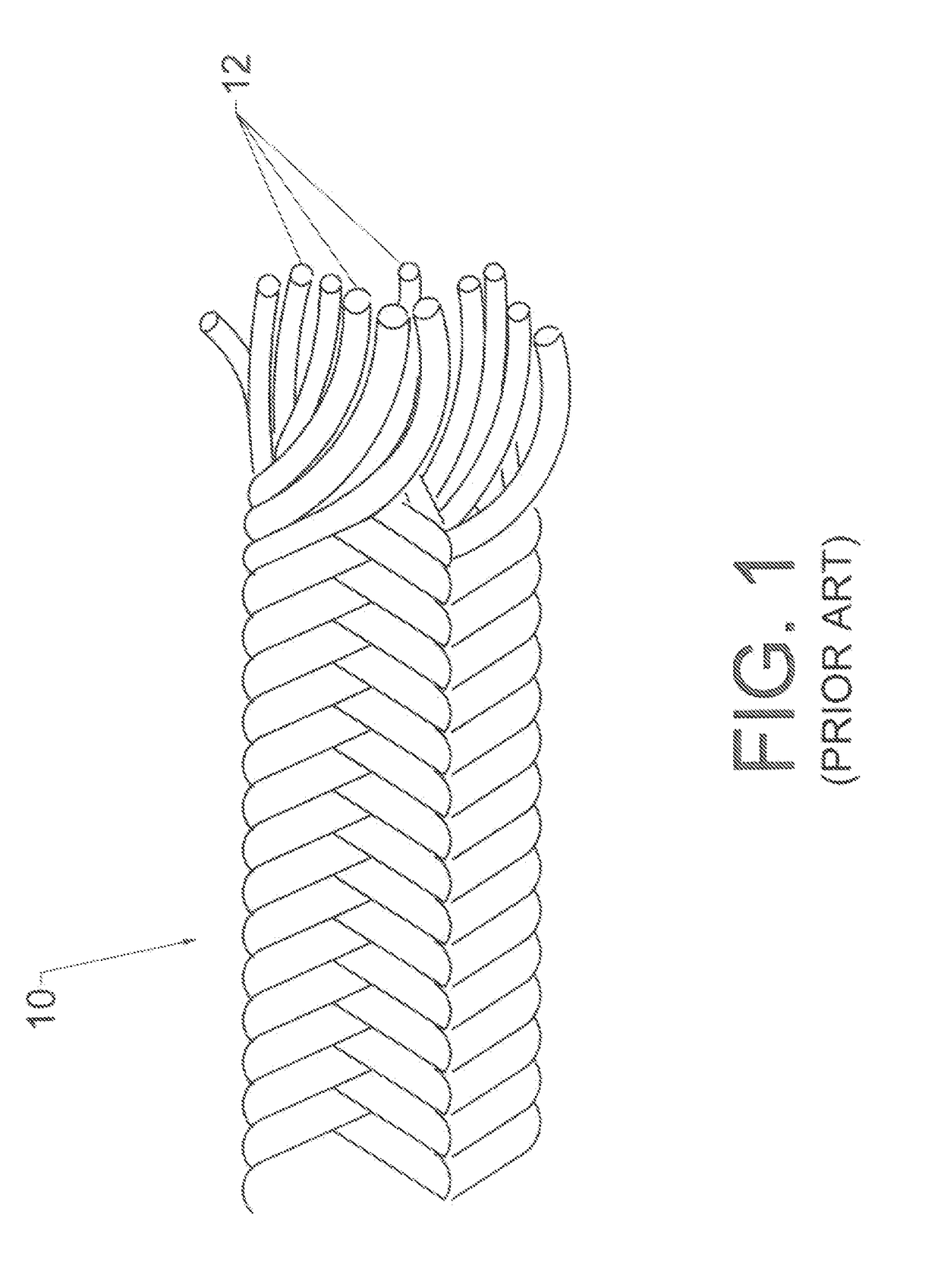

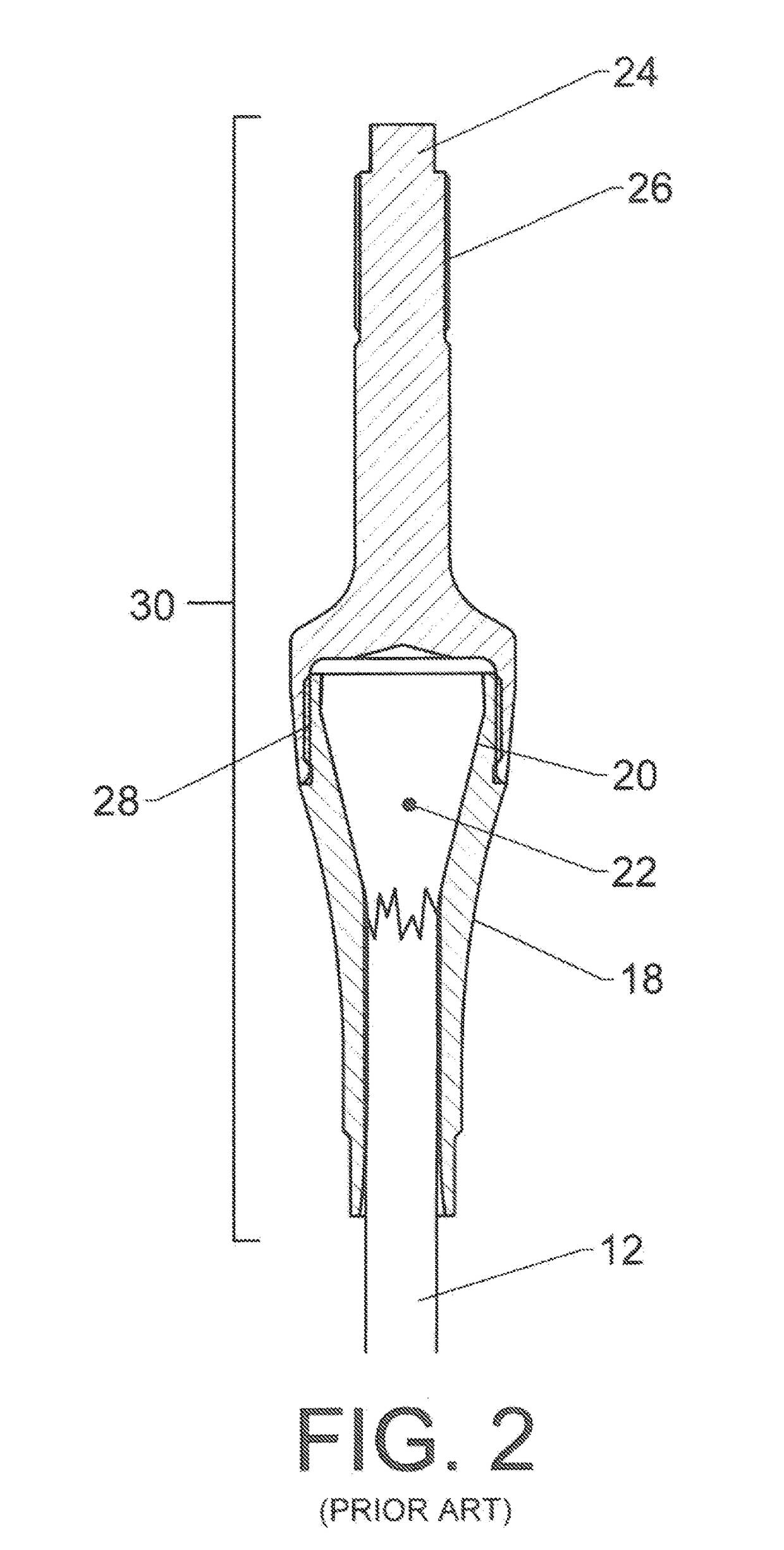

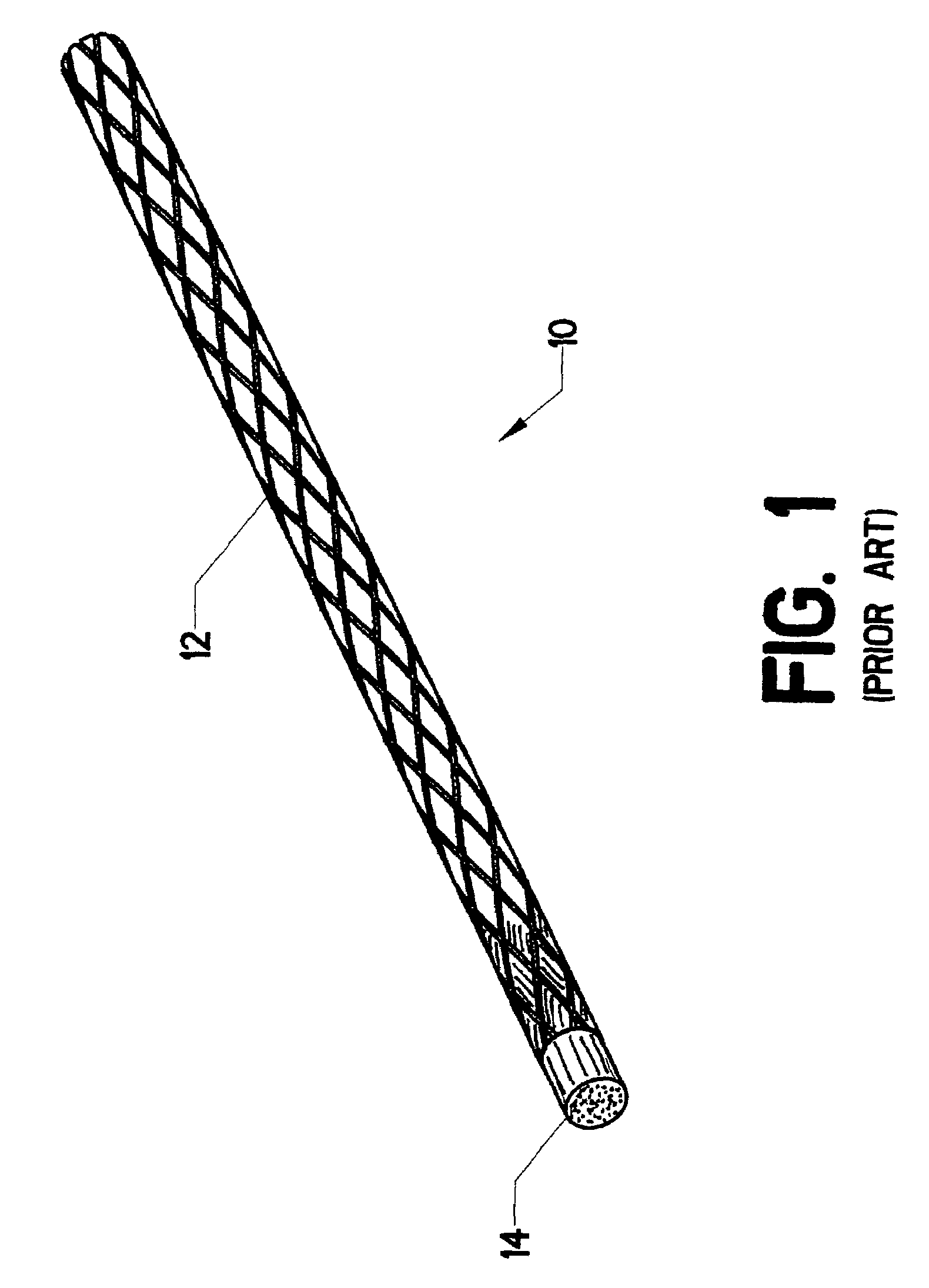

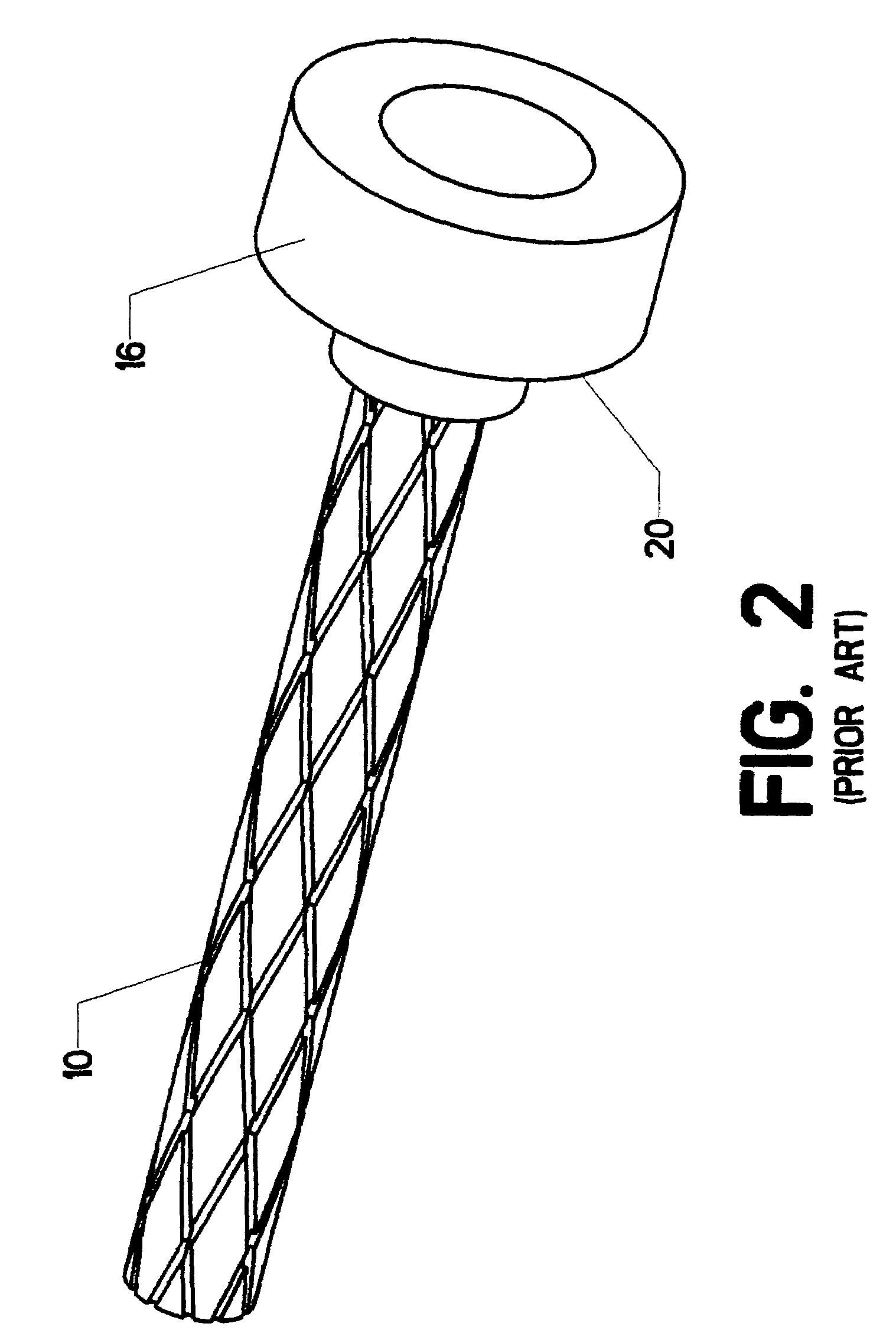

A method of manufacturing a cable assembly using stranded cable material. A manufacturing jacket is placed over the cable to hold the strands in a desired state. A length of jacketed cable is then cut to a desired length. Appropriate terminations are slipped over the manufacturing jacket on the cable's first end, its second end, or at some intermediate point. For a typical type of termination, a short portion of the manufacturing jacket is stripped away at the point of termination to expose the strands. After the terminations are placed in the appropriate position, potting compound or other mechanical means are typically applied to lock the terminations to the exposed lengths of strands. A completed cable assembly is thus created. However, the presence of the manufacturing jacket, while highly desirable for manufacturing, is often undesirable for end use. All of the manufacturing jacket, or in some instances a substantial portion thereof, is therefore removed, using a variety of disclosed methods, to form an unjacketed cable. A variety of techniques are disclosed for carrying out these steps, including the use of modified terminations and modified jackets. The finished product may have no jacket at all, a partial jacket, or a jacket which is different from the one used in the manufacturing process.

Owner:BRIGHT TECH CO LTD

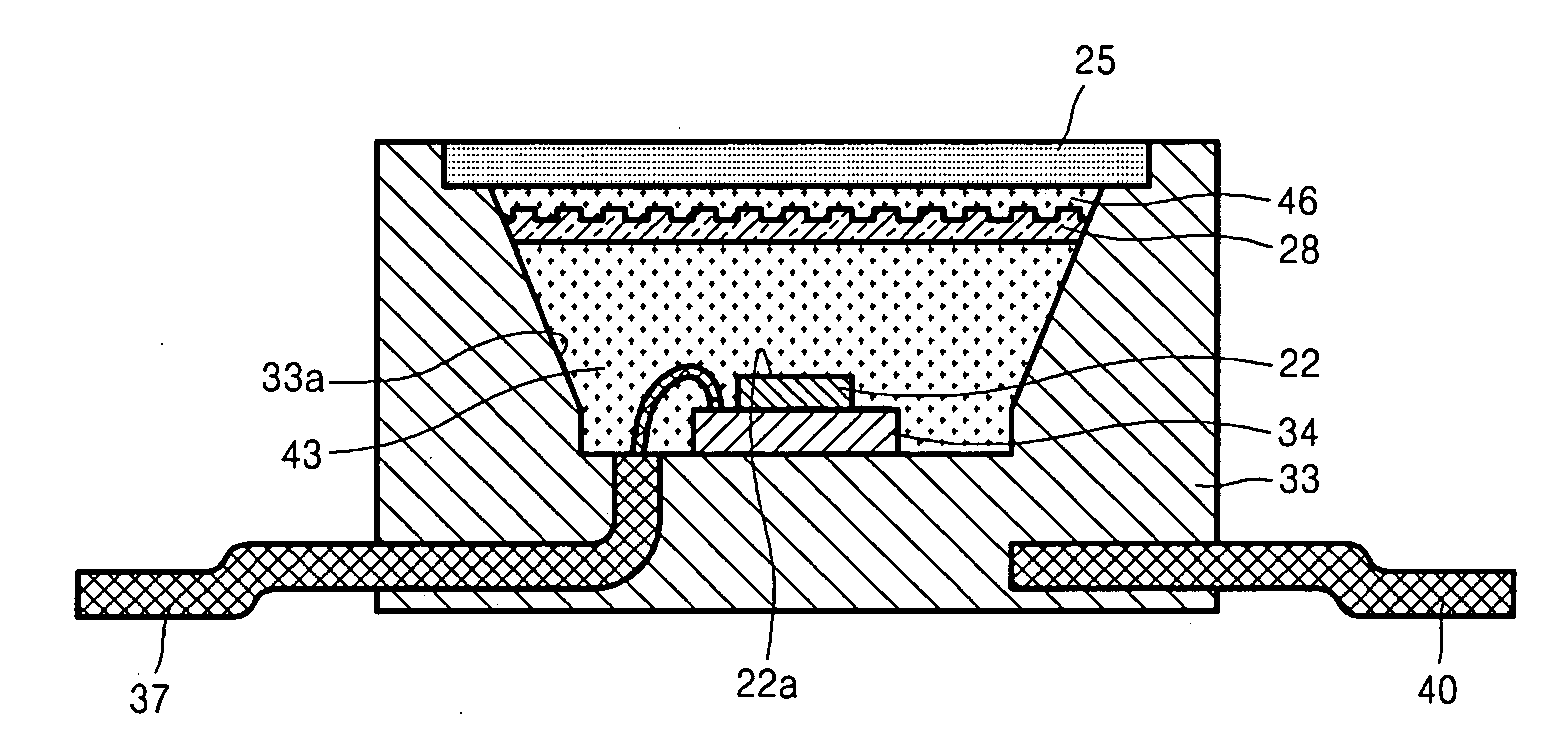

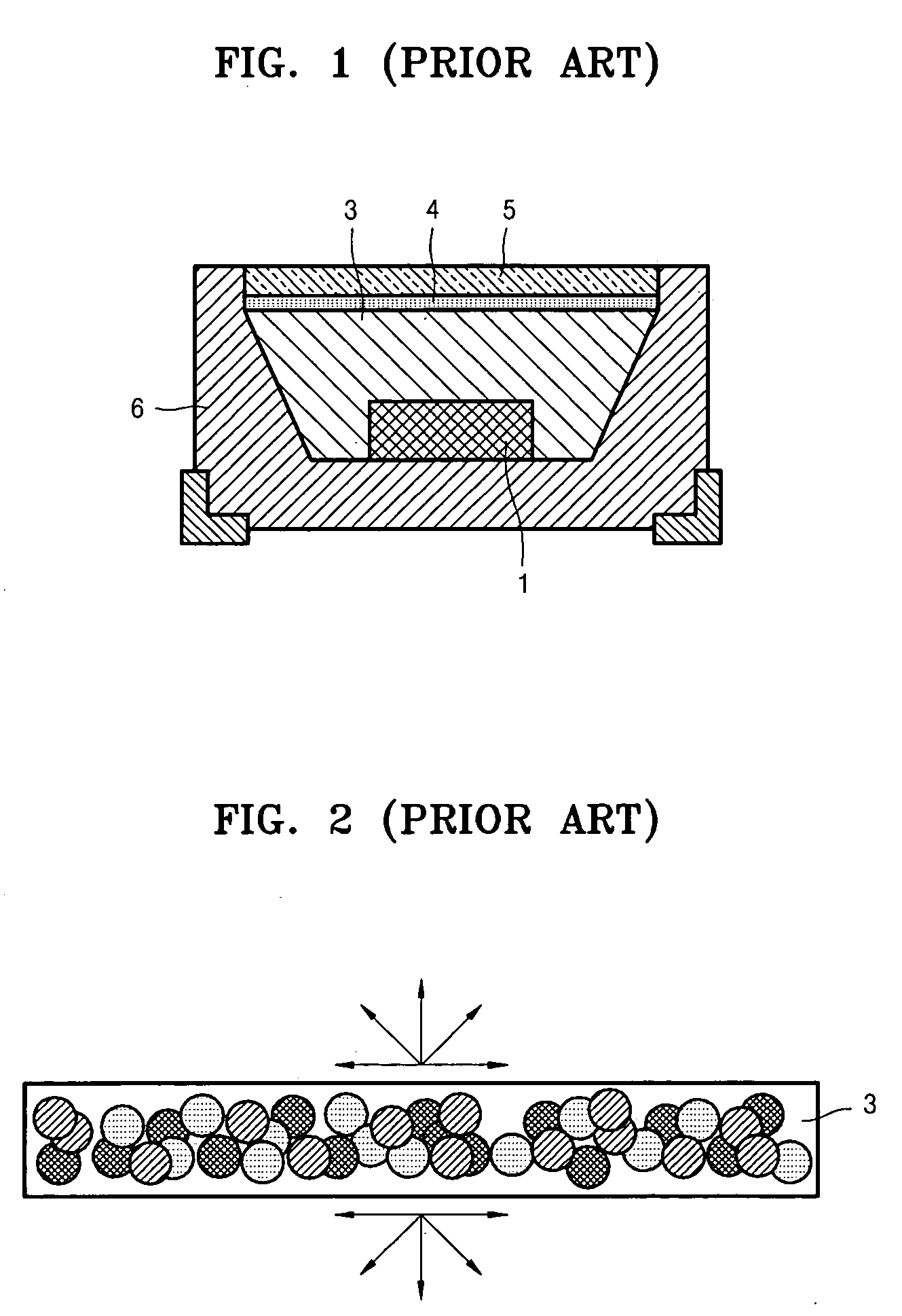

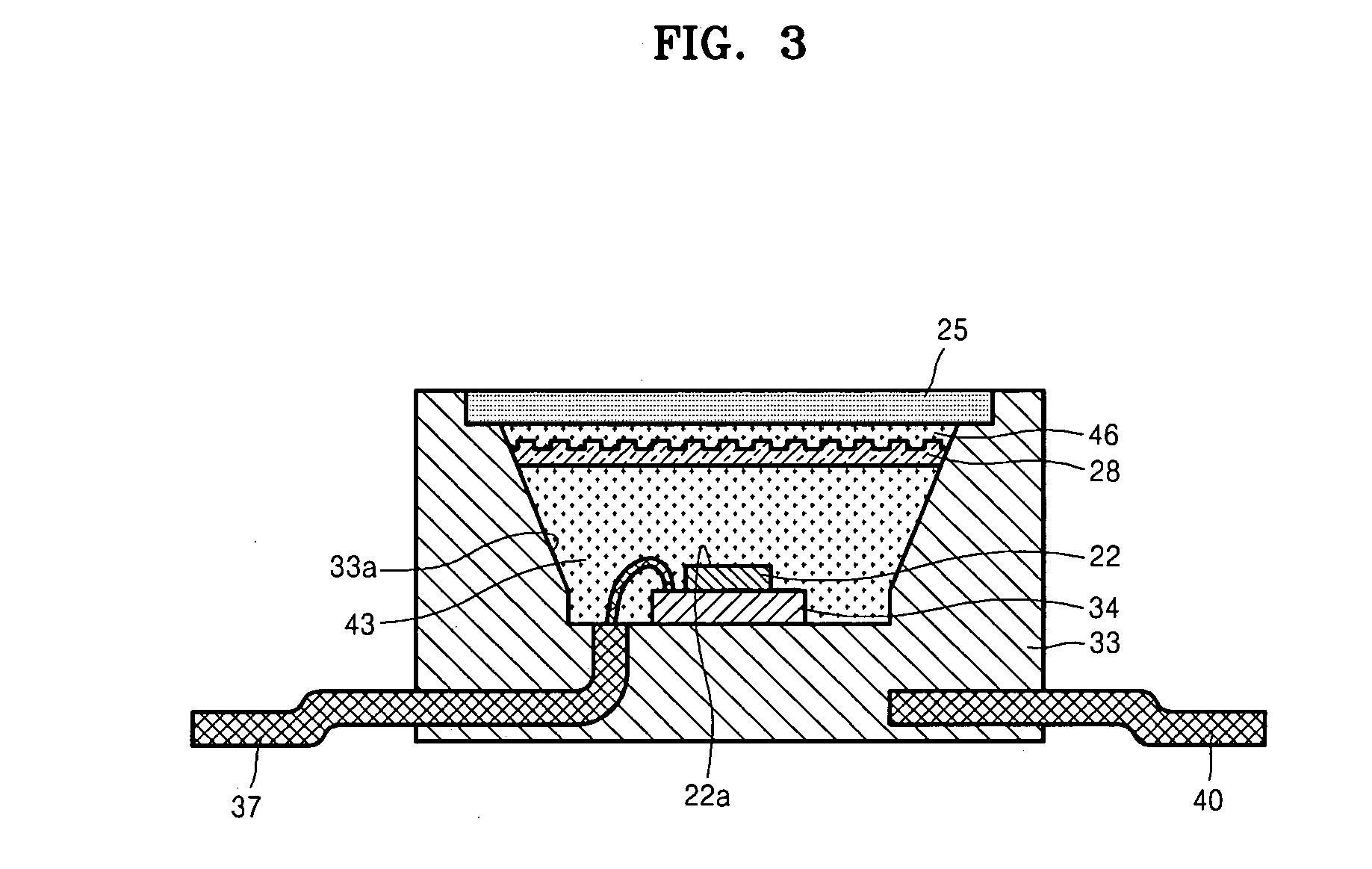

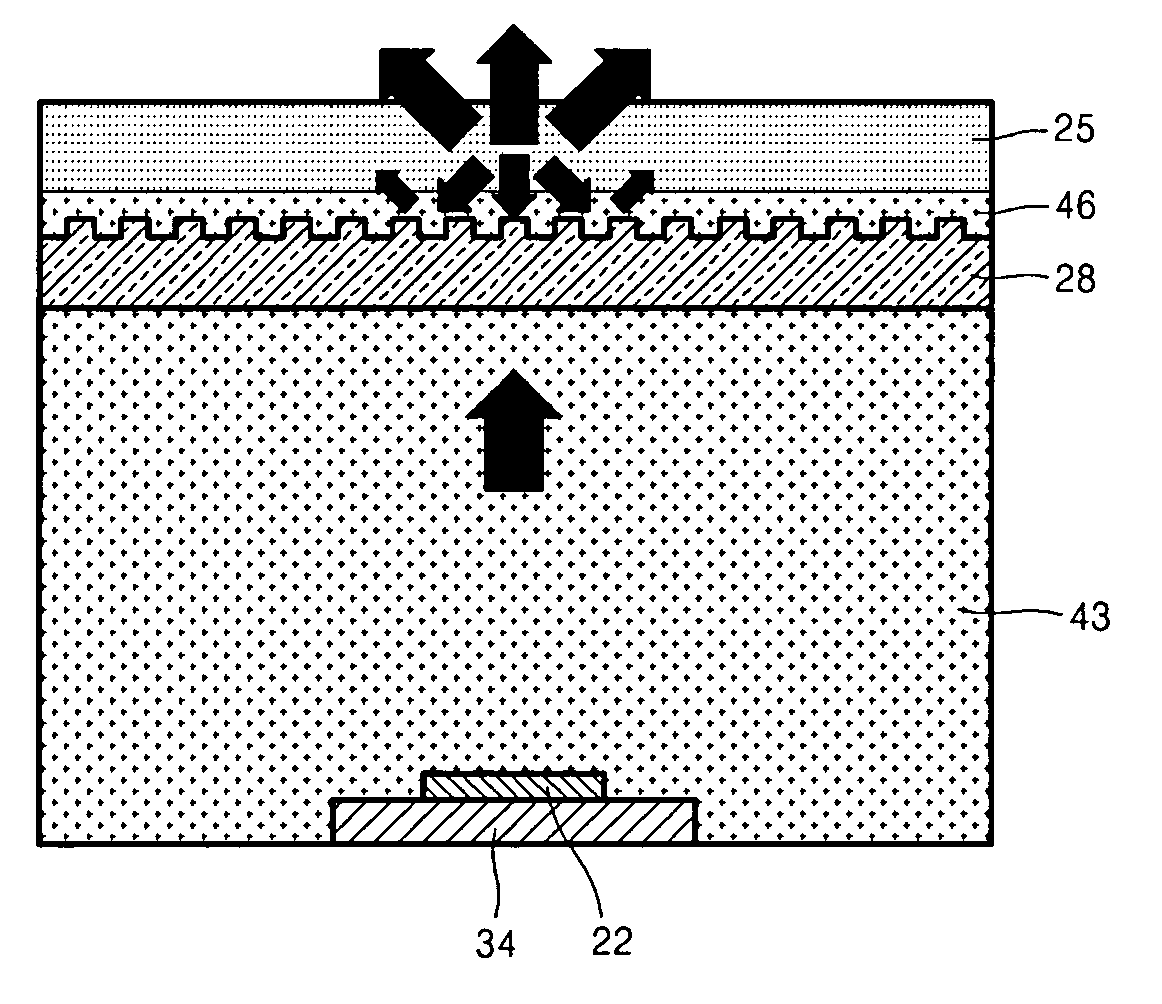

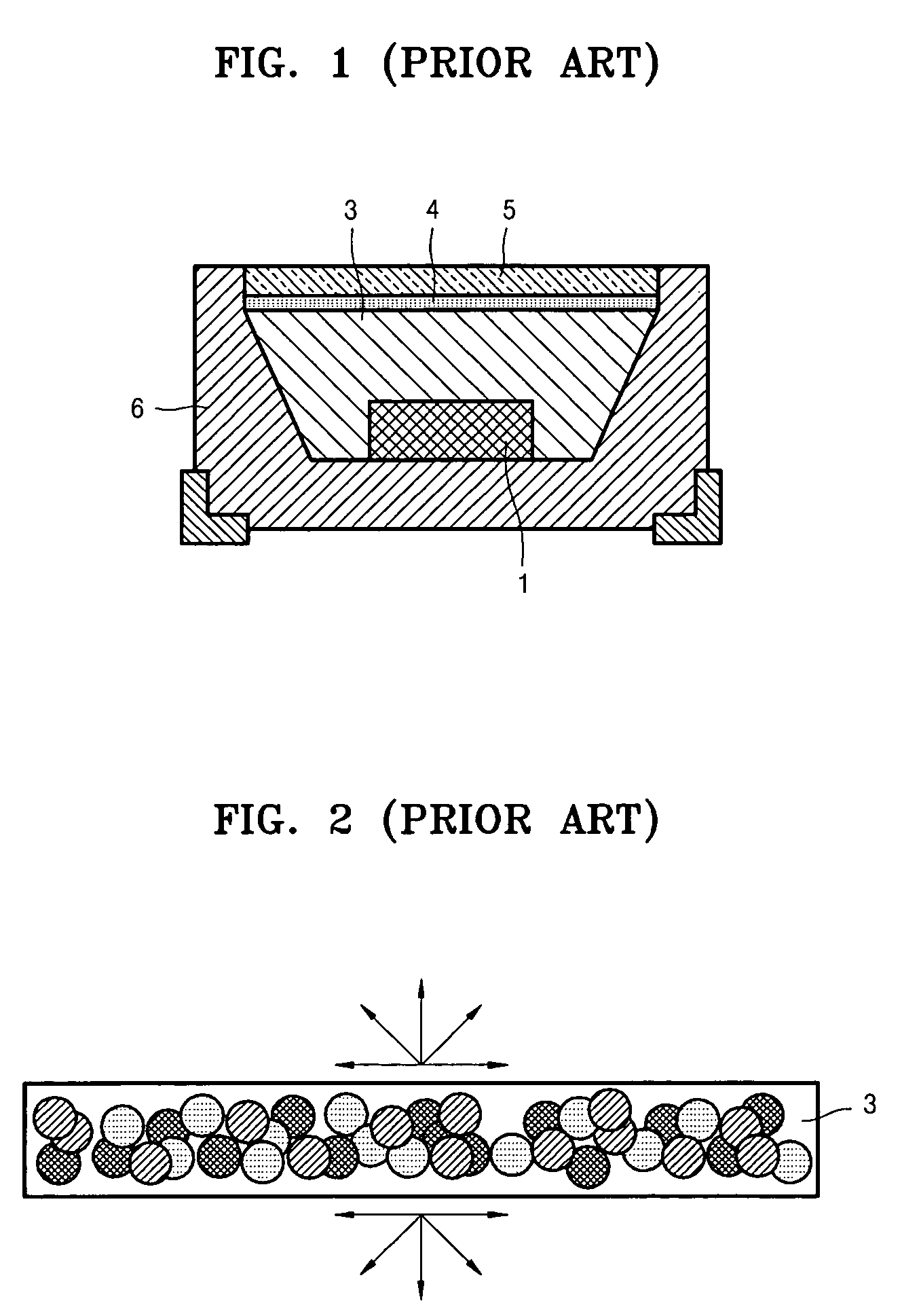

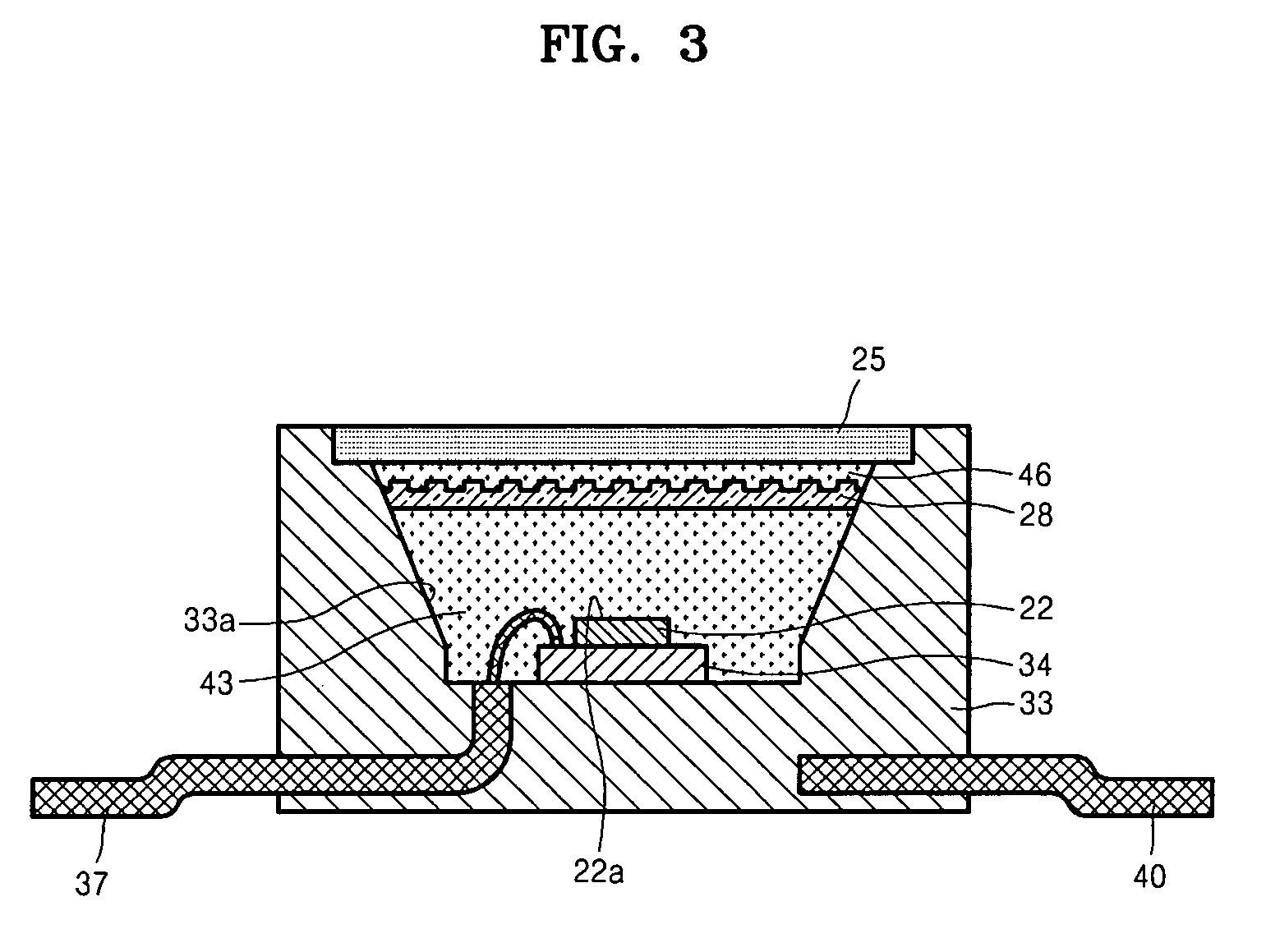

Light emitting diode module

ActiveUS20070176196A1High luminous efficiencyBinding endsOrnamental textile articlesPhosphorFluorescence

A light emitting diode module having improved luminous efficiency is provided. The light emitting diode module includes: a light emitting chip; a phosphor layer formed of phosphor materials emitting light having a wavelength longer than the light emitted from the light emitting chip using light emitted from the light emitting chip as an excitation source; and a reflection plate that is disposed between the light emitting chip and the phosphor layer and that reflects the light emitted by the phosphor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Technique for pouring hoisting cable anchorage head with alloy

The invention provides an anchoring technology of an alloy pouring steel wire rope, which belongs to steel wire ropes. The construction steps are as follows: preparing materials; clearing up a steel wire rope; washing surface grease on the steel wire rope; acid-washing; measuring the temperature of an alloy; plating a priming alloy; neutralizing; rinsing with hot water; fixing a sleeve body and the steel wire rope; treating the root of the sleeve body; pre-heating the sleeve body; melting the alloy and measuring the temperature; pouring the alloy; recharging the alloy; cooling; inspecting and treating; and coating grease lubricant. The anchoring technology has the advantages of convenient operation and reliable quality. In addition, the technology fills the blank of treating the ends of the steel wire rope in cableway construction, is not enslaved by people, and reduces the construction cost and increases the construction speed.

Owner:中国冶金科工股份有限公司

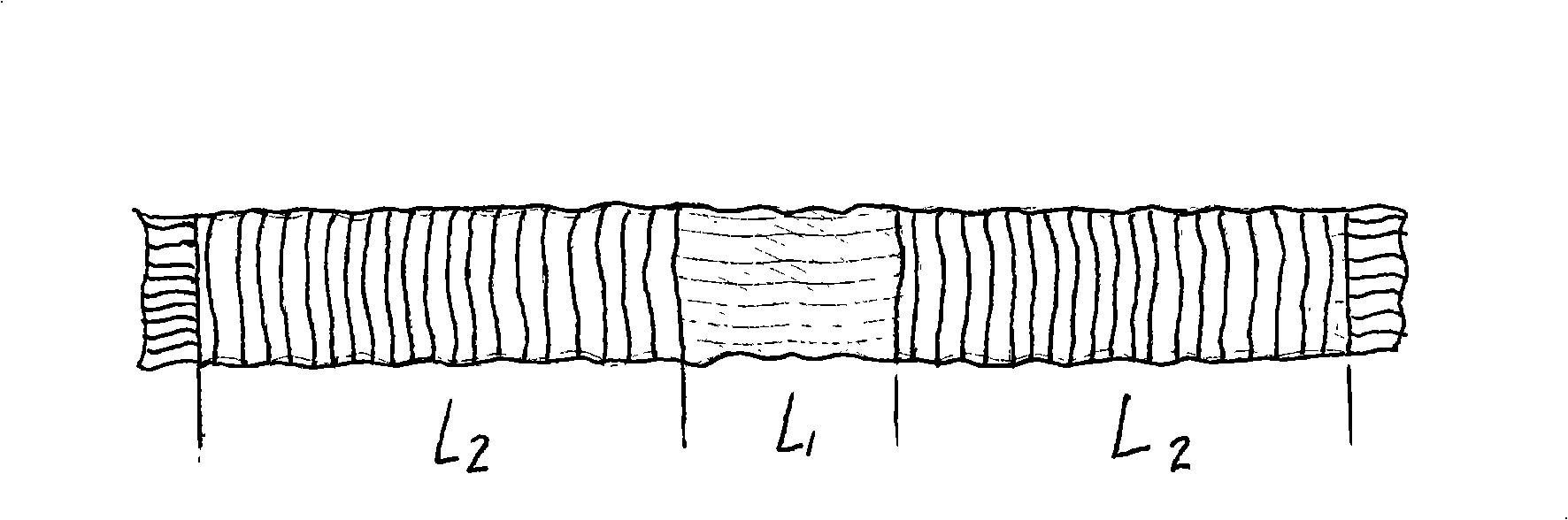

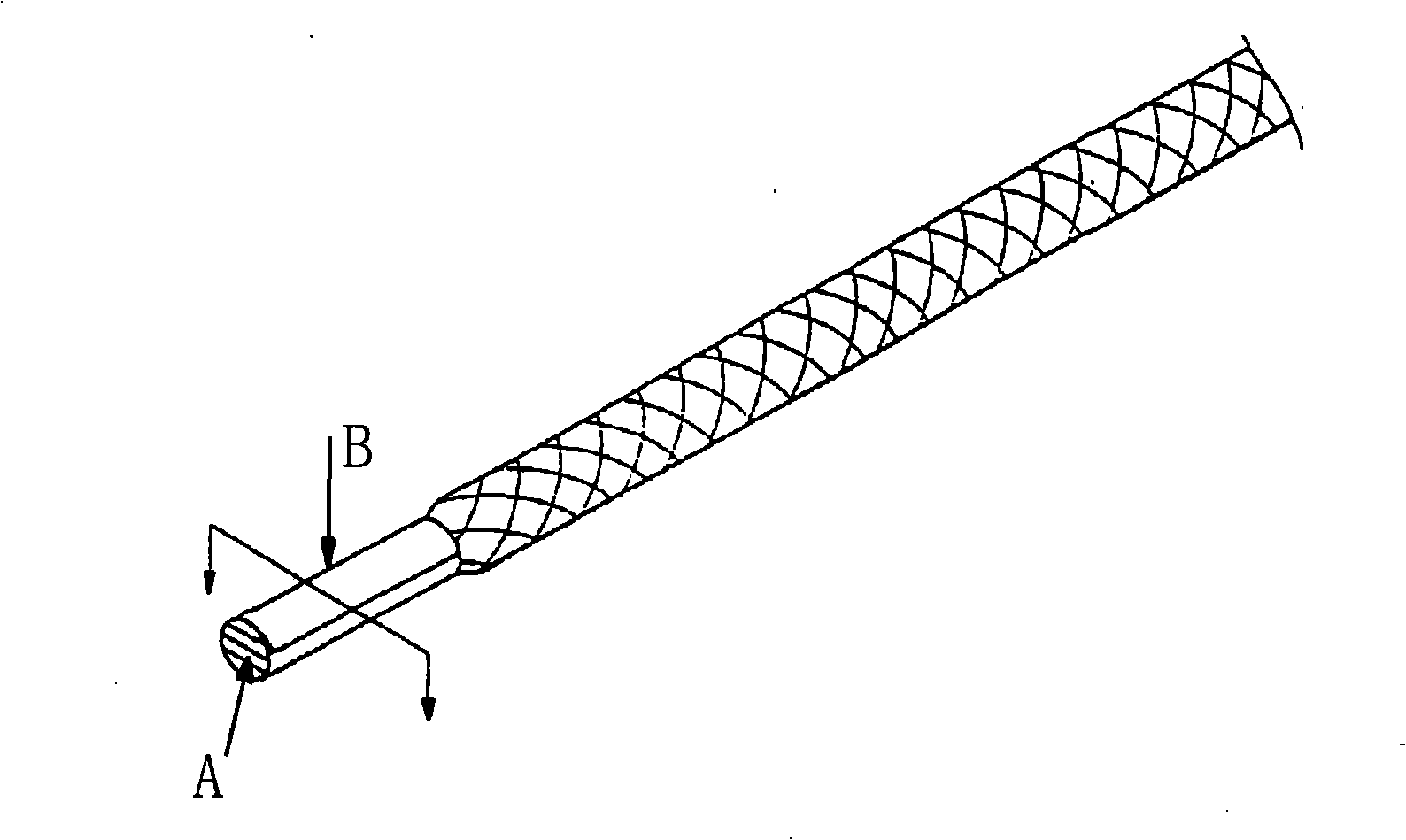

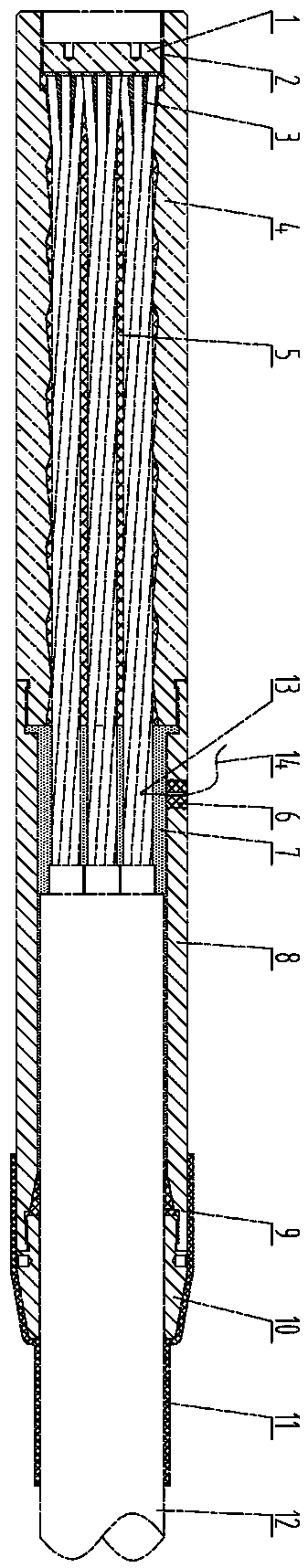

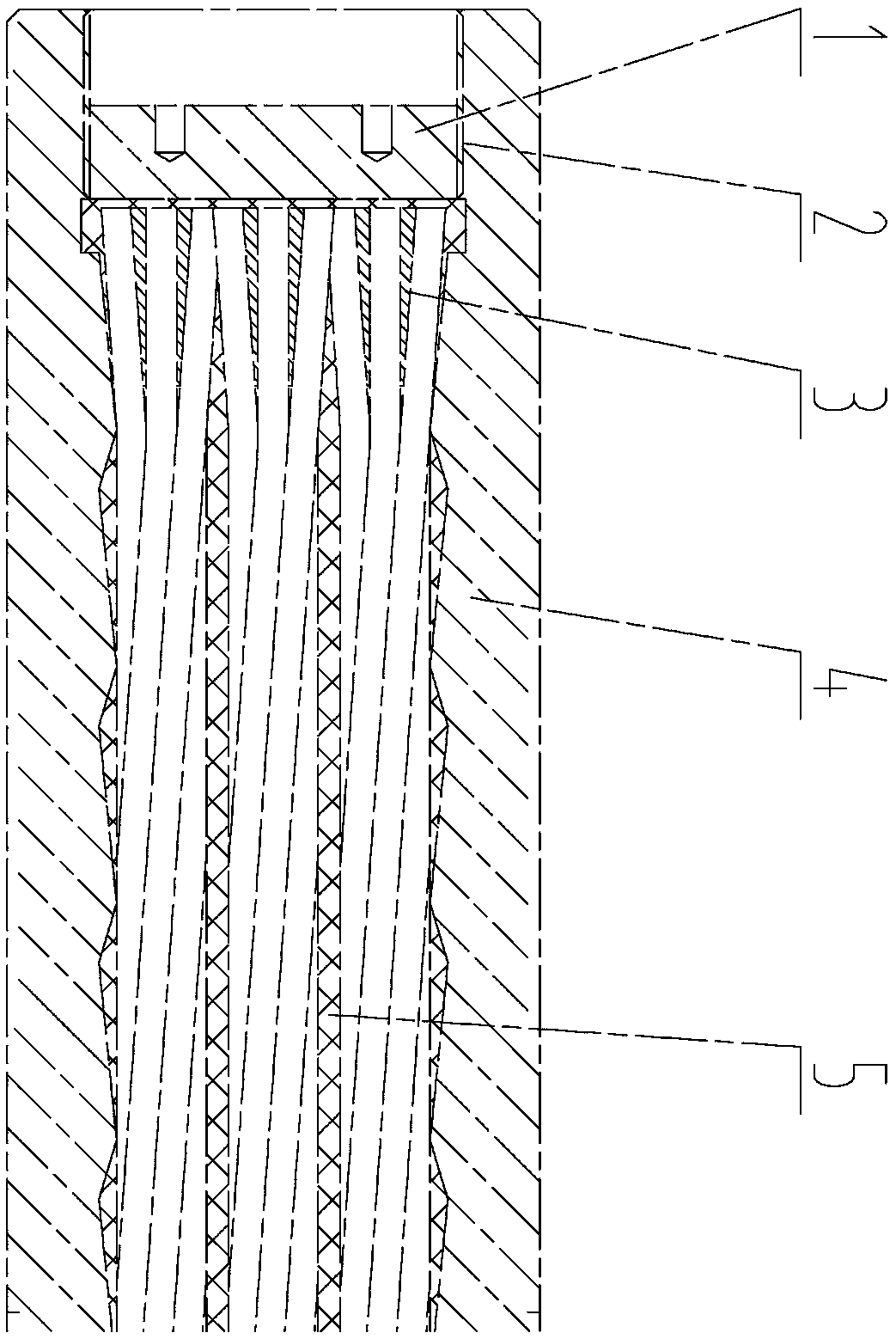

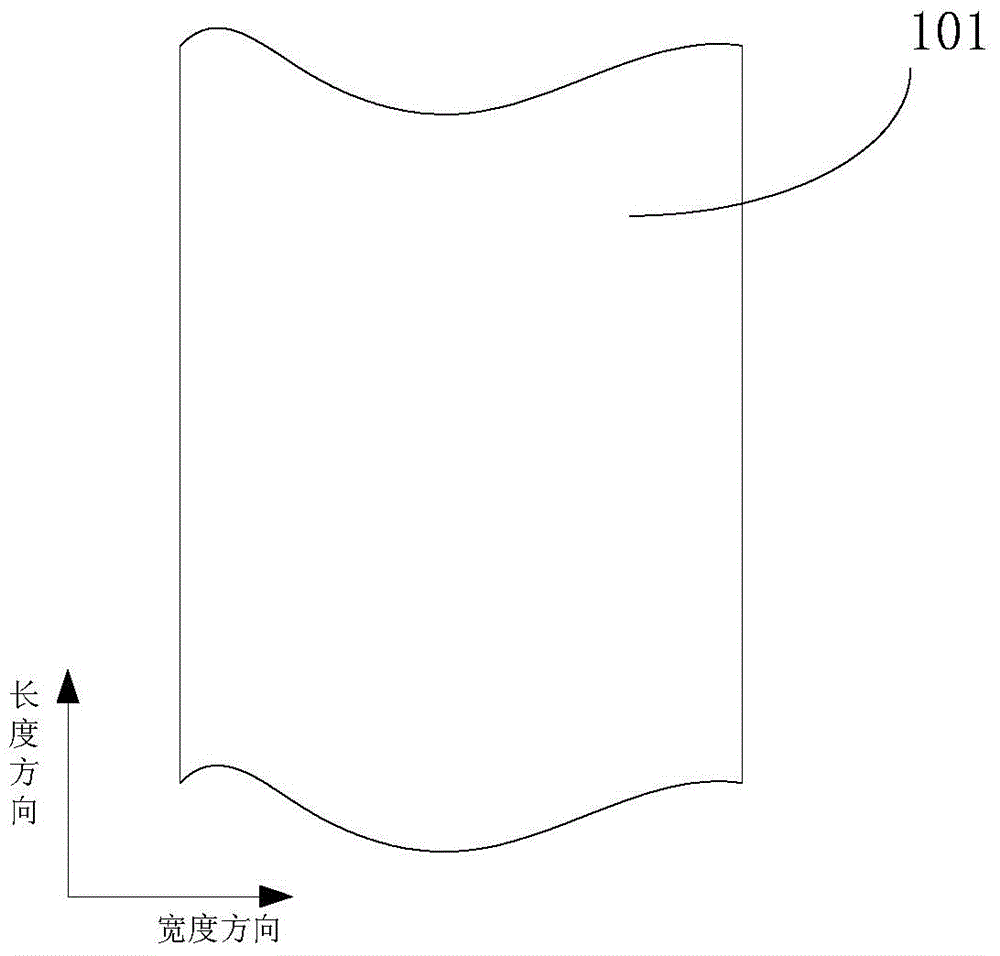

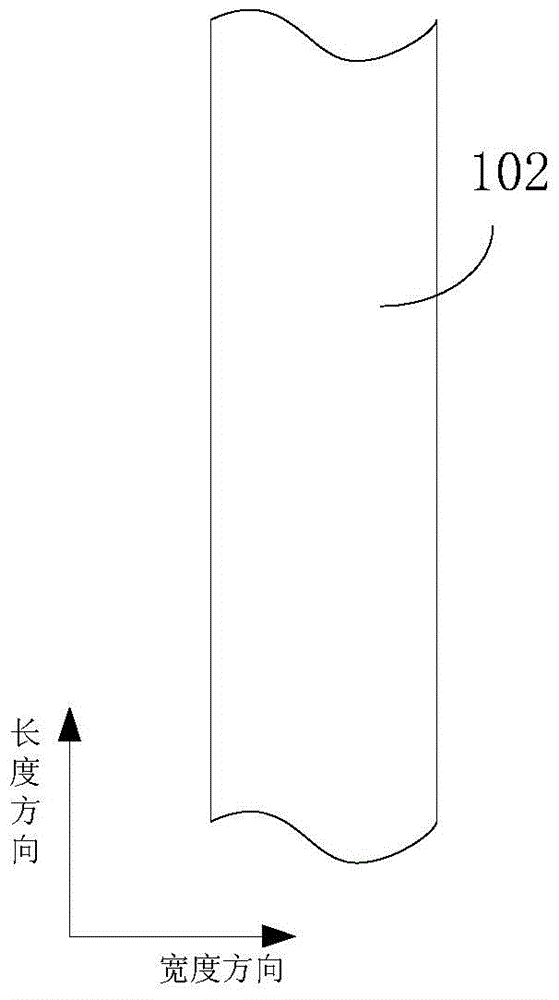

Manufacturing method of hot extrusion polyethylene zinc-aluminum alloy coating steel wire cable

ActiveCN105862592ASolving Corrosion ProblemsOvercome the fragile problemCable-stayed bridgeBinding endsPolyesterAlloy coating

The invention relates to a manufacturing method of a hot extrusion polyethylene zinc-aluminum alloy coating steel wire cable. In accordance with the arrangement rule of steel wires at the cross section of the cable, the length of the cable is controlled through the center standard wire, zinc-aluminum alloy coating steel wires are bundled through the twisting angle being 2-4 degrees, a high-strength polyester belt is wound on the outside of the steel wire bundle, a double-layer high-density polyethylene protection layer is hot-extruded through the double-cavity co-extrusion one-time forming process, wind-rain induced vibration prevention embossing is arranged on the outer layer of the polyethylene protection layer according to the wind-rain induced vibration design requirement of the cable, and coiling down and storage are performed after the two ends of the cable are anchored. Finally, the cables are transported to the erection scene according to the delivery request, and erected one by one. The manufacturing process of the cable is free from site limits of construction sites, small in climate factor influence, convenient to control due to factory production management, and capable of meeting the use requirements for long length, high accuracy and durability of stay cables in super-large long-span bridges at the marine environment.

Owner:JIANGSU FASTEN STEEL CABLE CO LTD

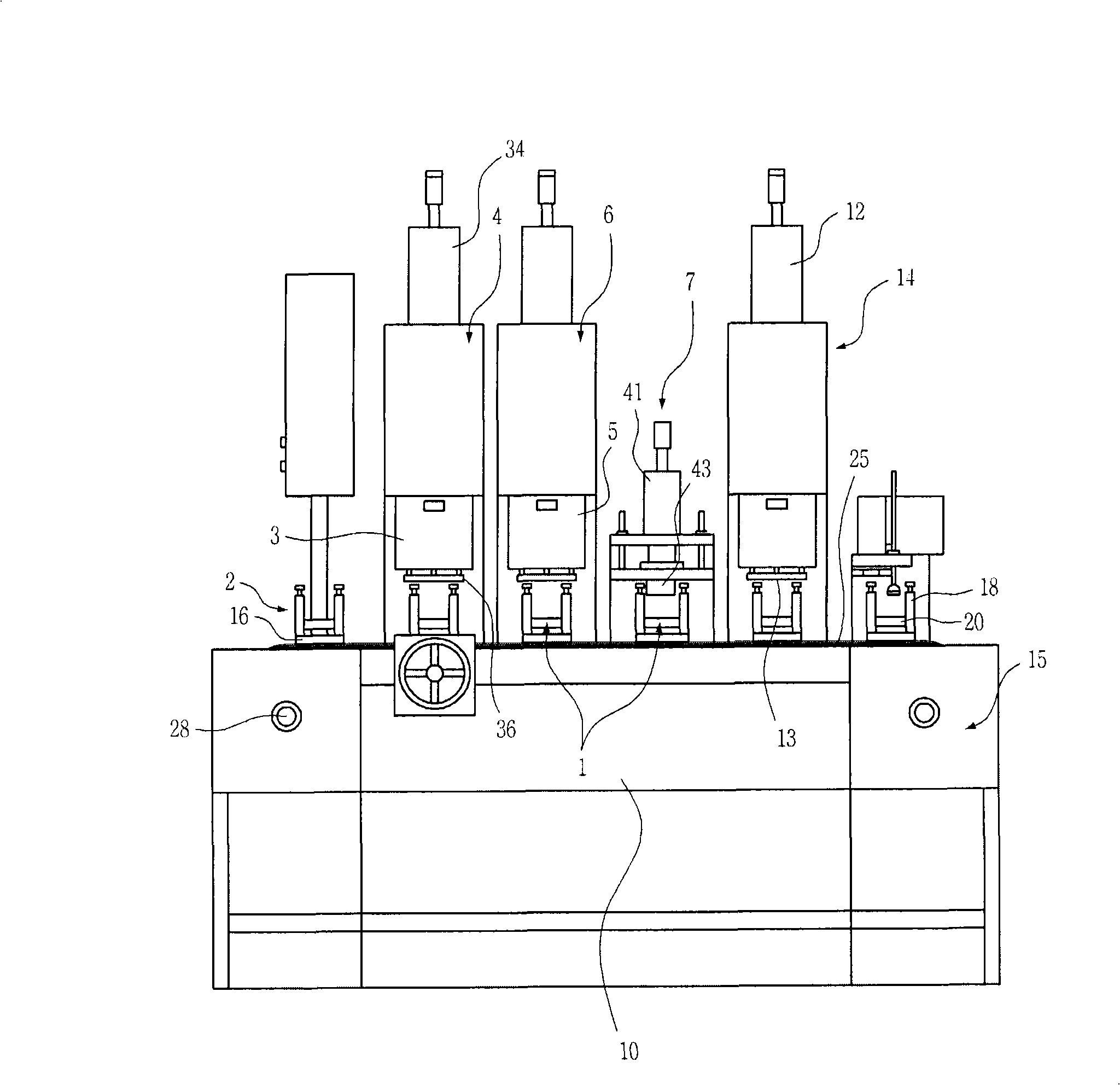

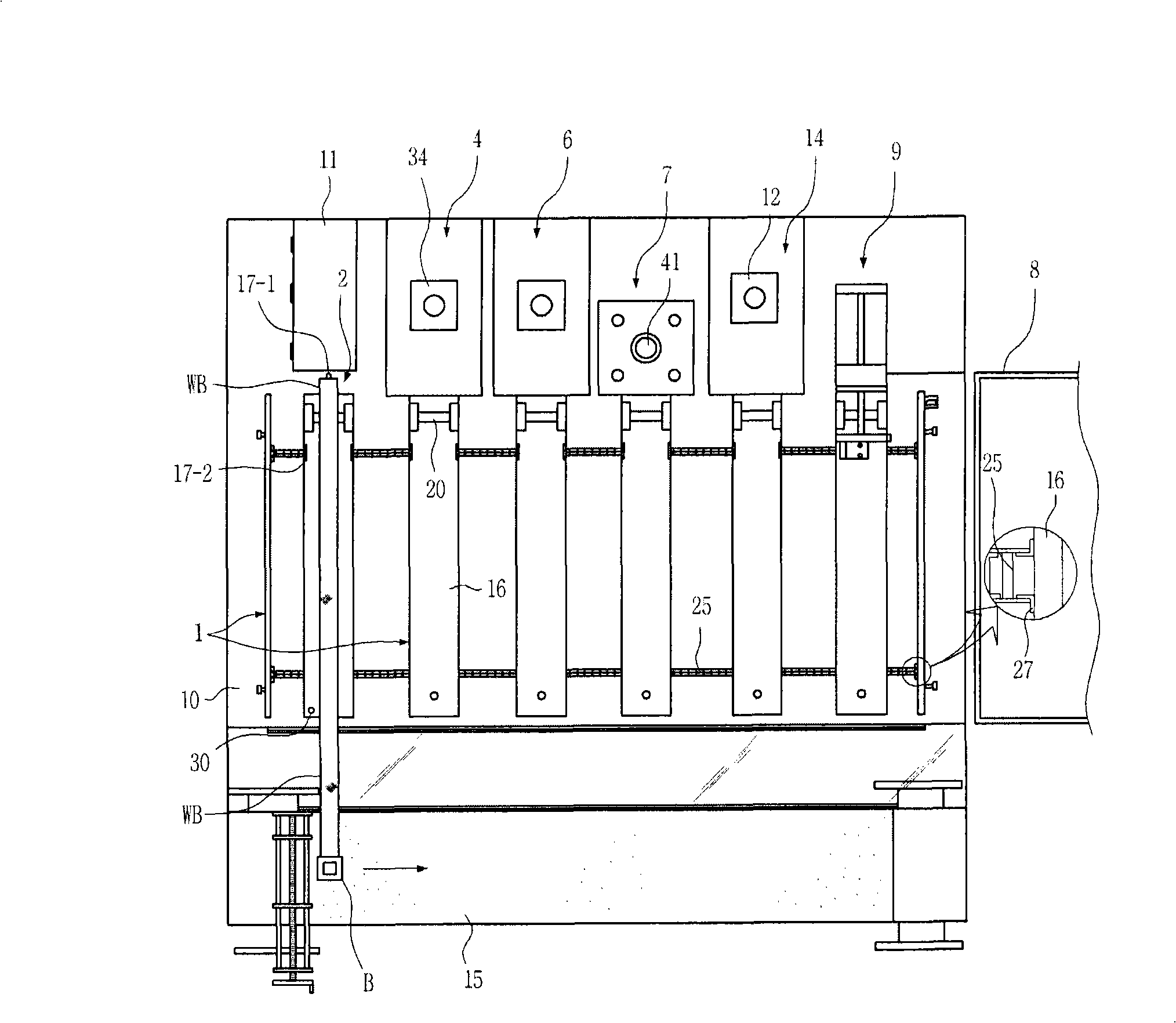

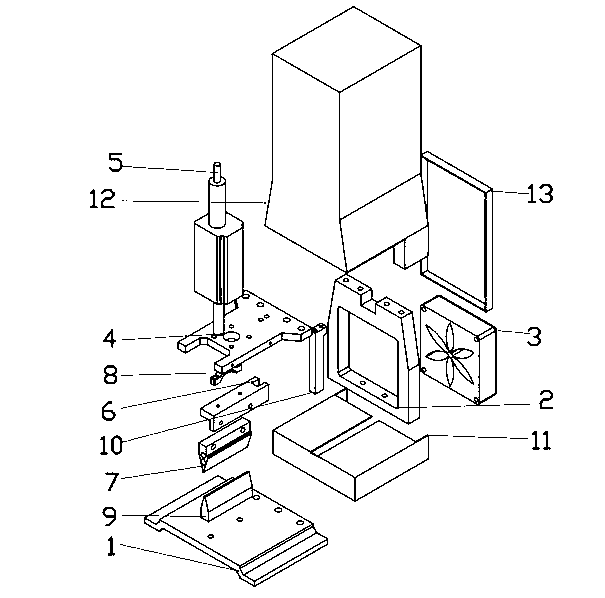

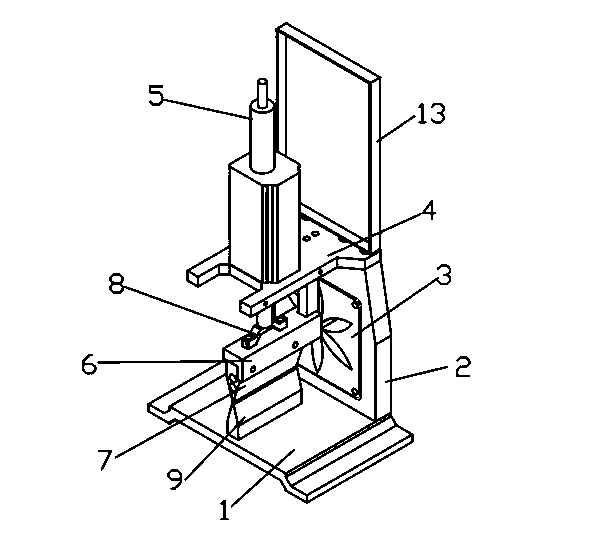

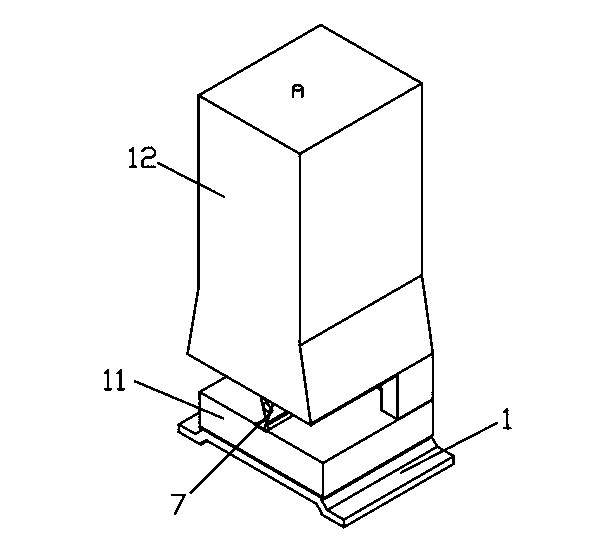

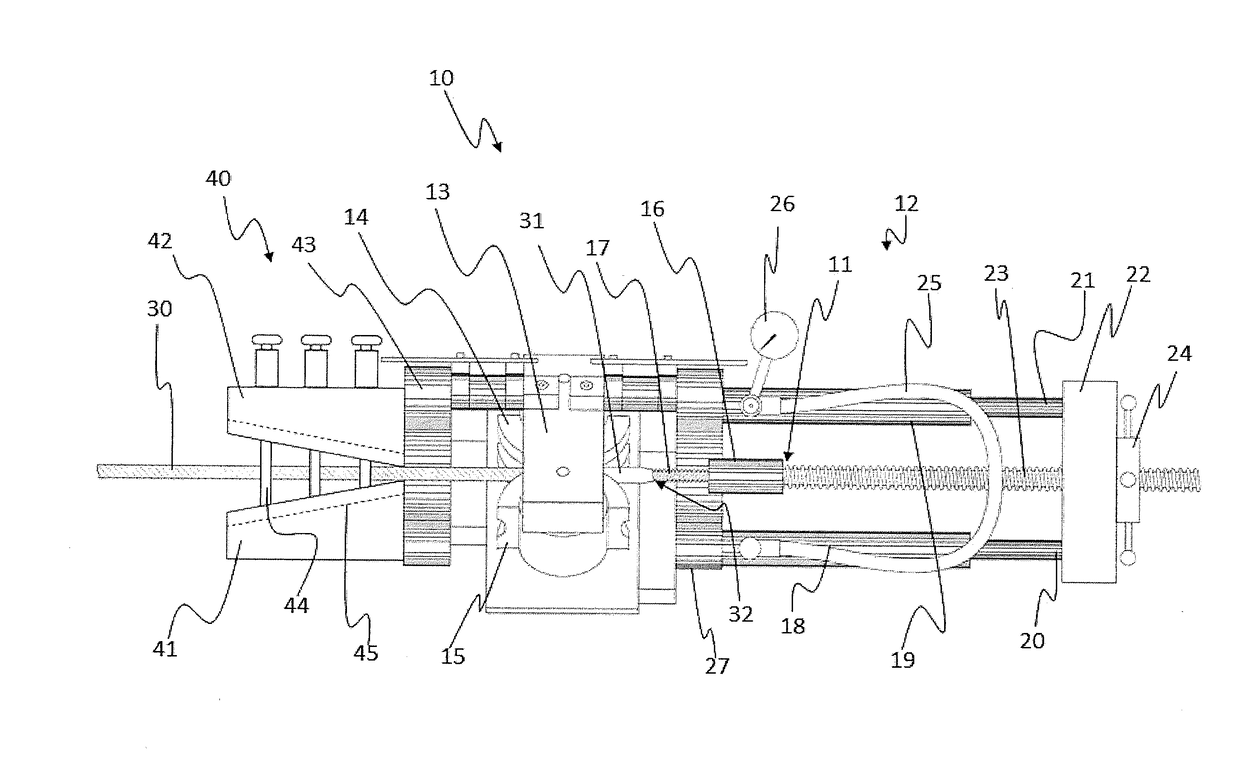

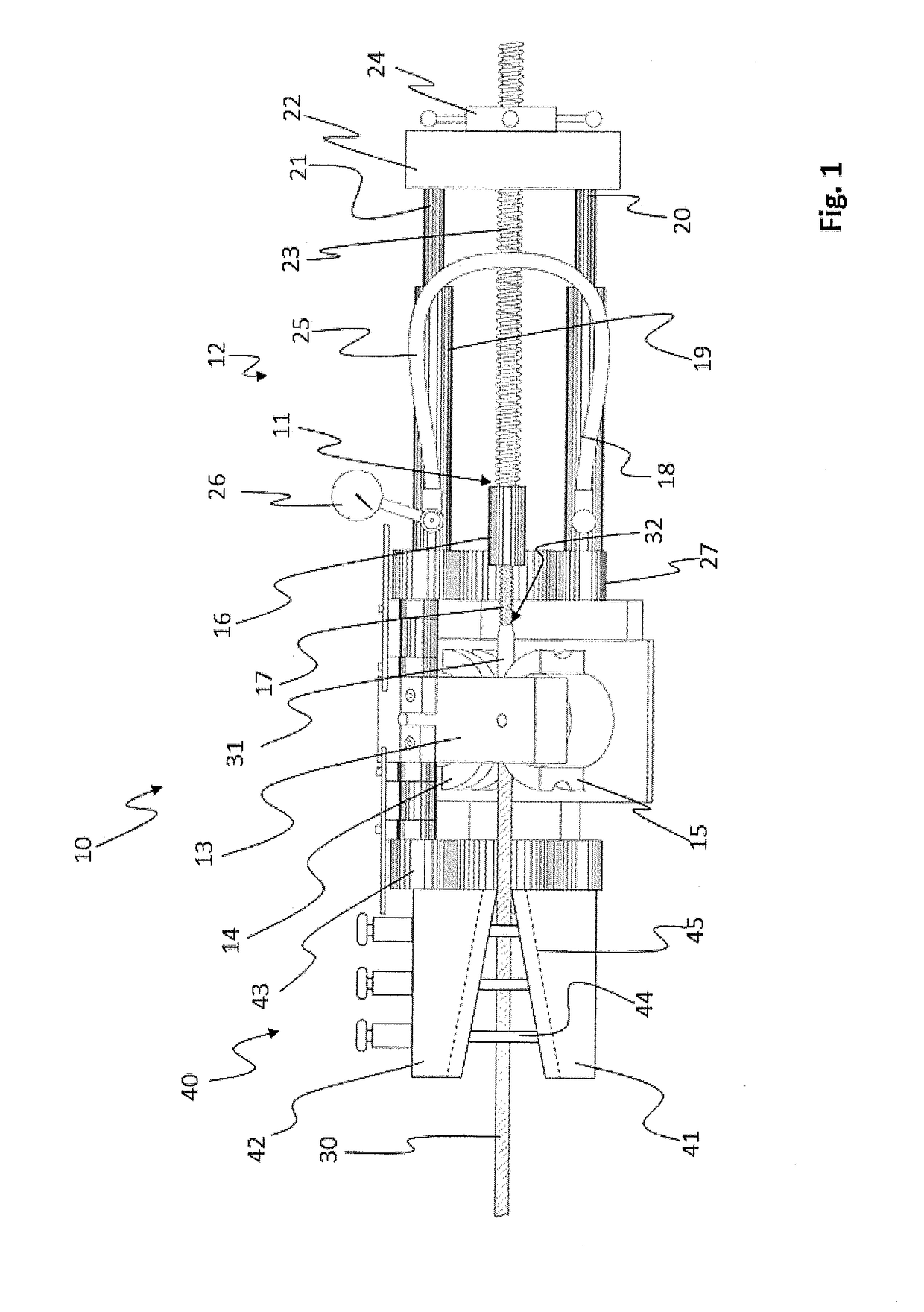

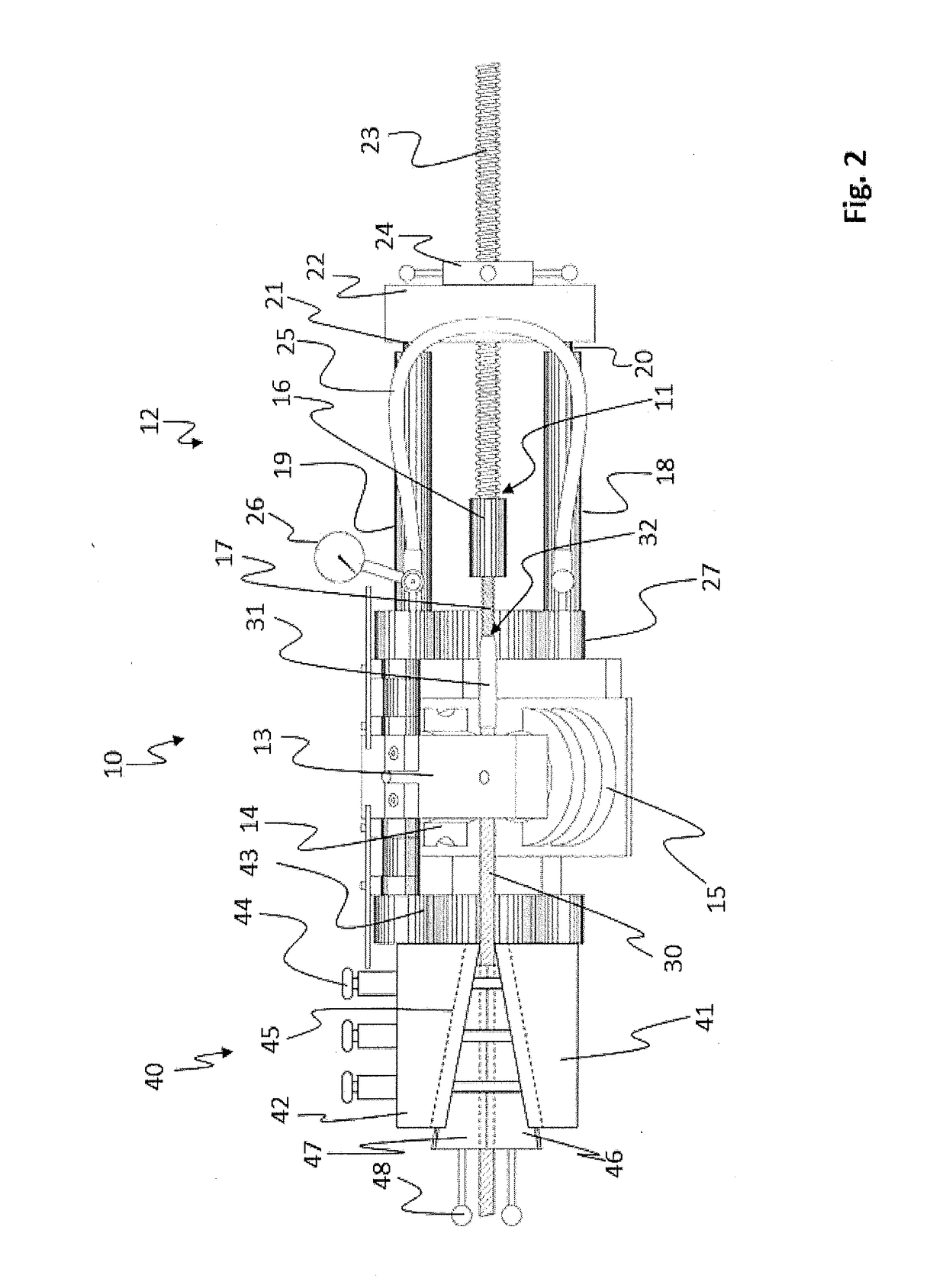

Waistband end processing device

ActiveCN101336756AImprove processing efficiencyBinding endsOther manufacturing equipments/toolsWelding

The present invention relates to equipment for processing an end of a waistband, wherein the equipment comprises the following components: a conveying part which conveys the waistband for at least one step width with a stepping mode; a cutting part which cuts the end of the waistband to a certain shape; and a soldering part which executes thermal welding to the cut end of the waistband that is conveyed with the stepping mode. Preferably, the cutting part is characterized in that the waistband is cut in a plurality of processes. The cutting part comprises the following components: a first ultrasonic cutting machine which cuts part thickness of the waistband part; and a second ultrasonic cutting machine which is apart from the first ultrasonic cutting machine for a distance equal with the conveying step width of the conveying part and totally cut the waistband.

Owner:WOOJIN PLASTIC

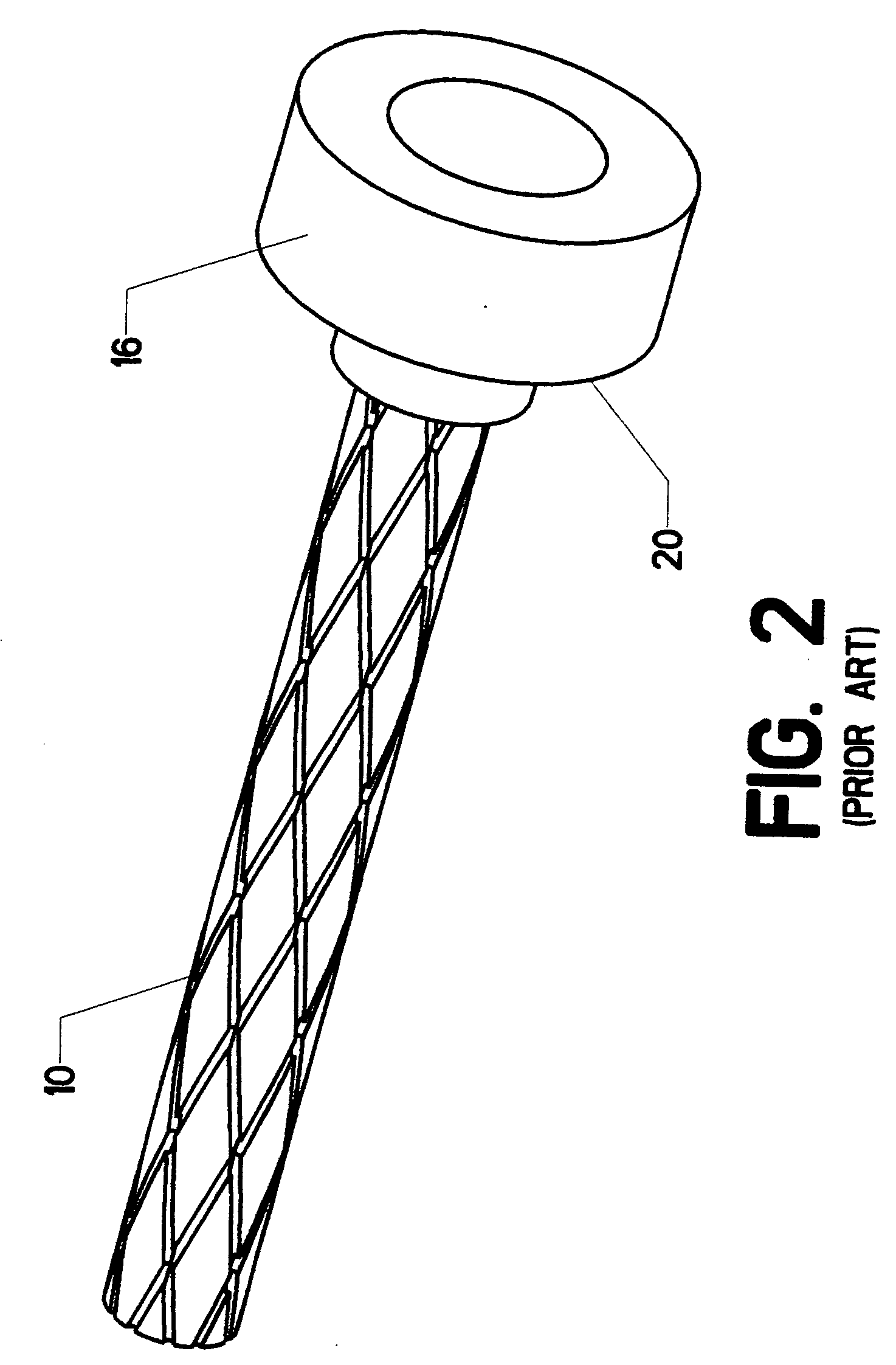

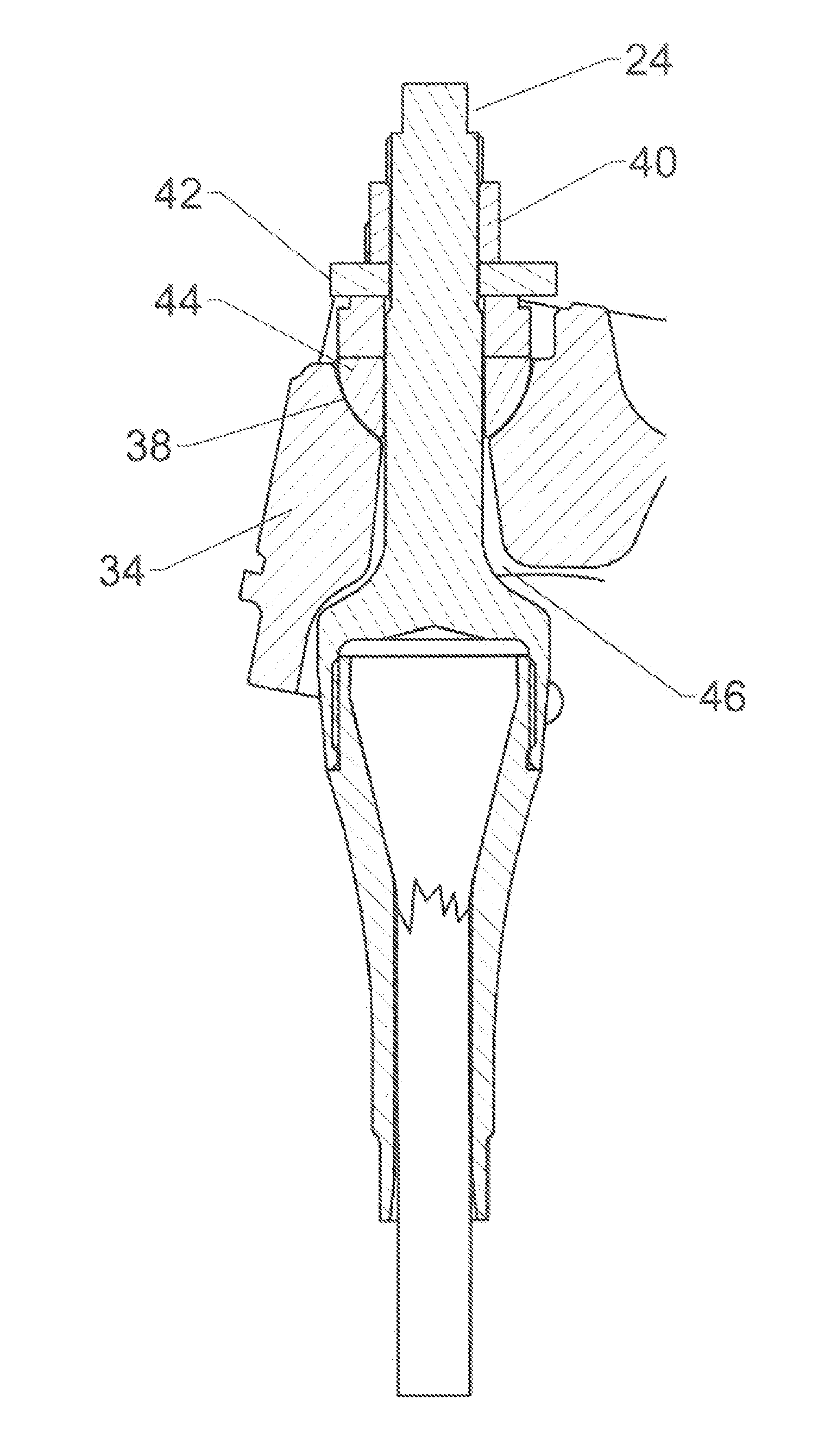

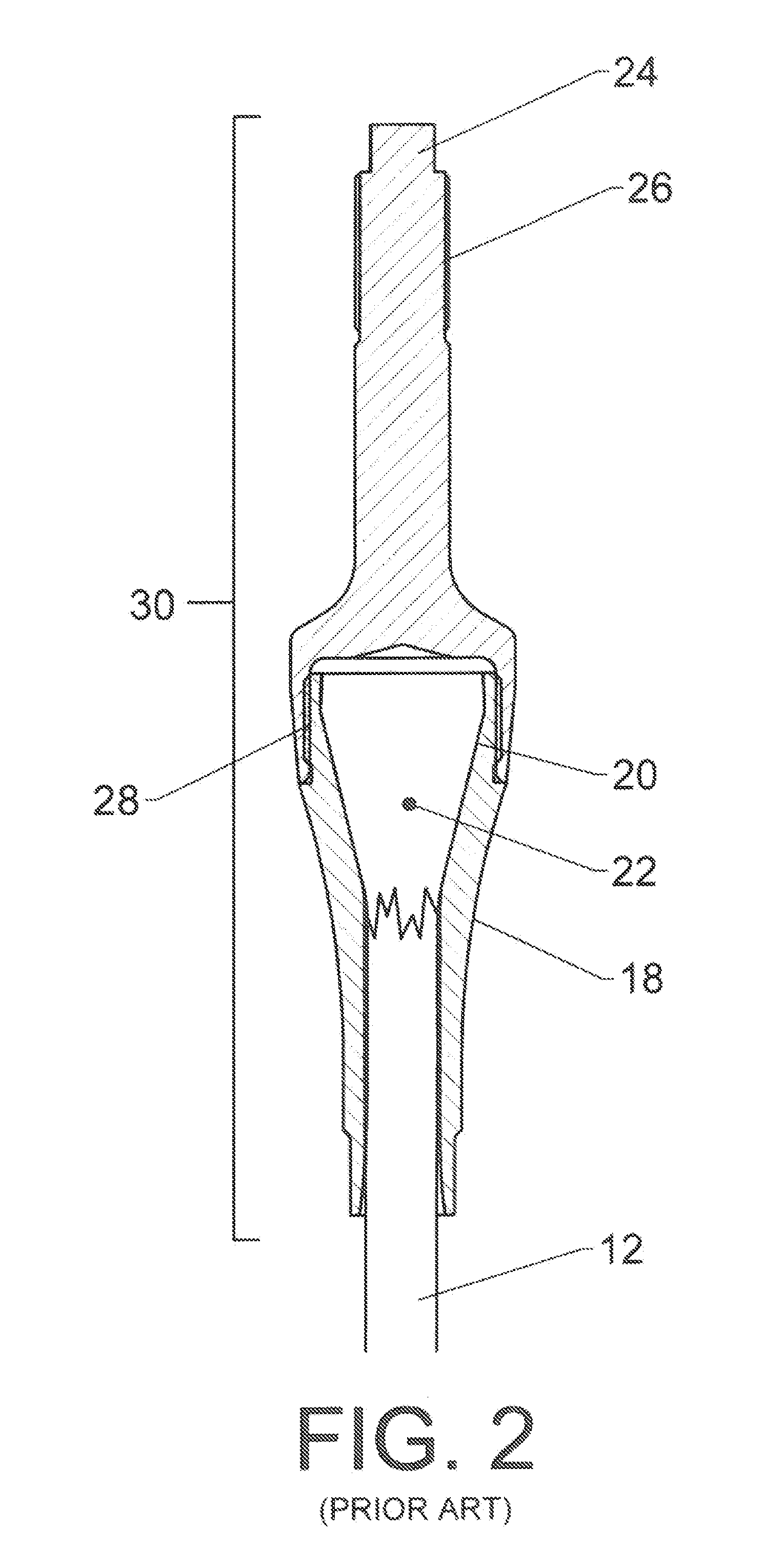

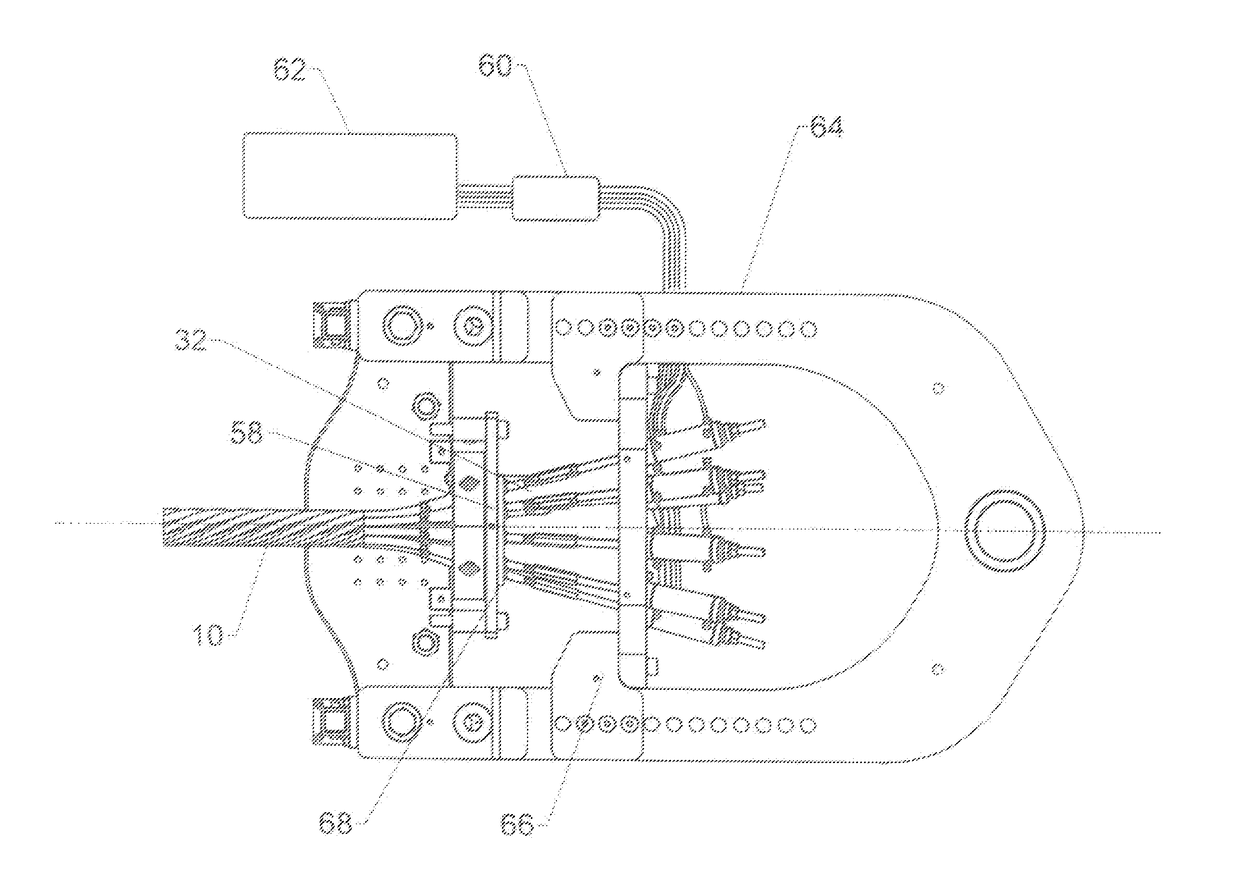

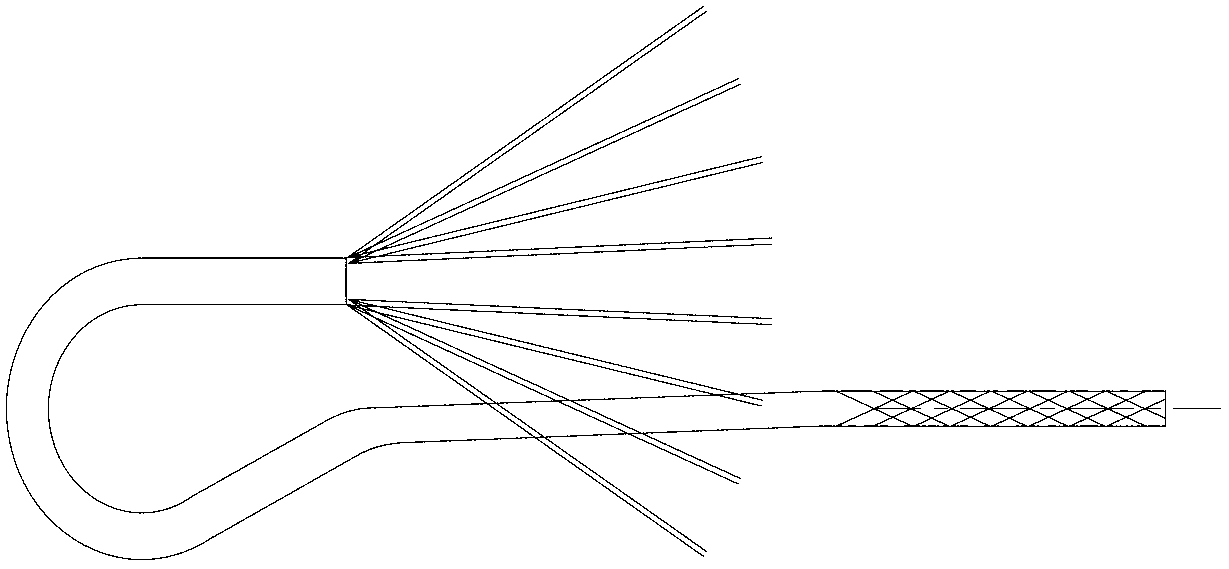

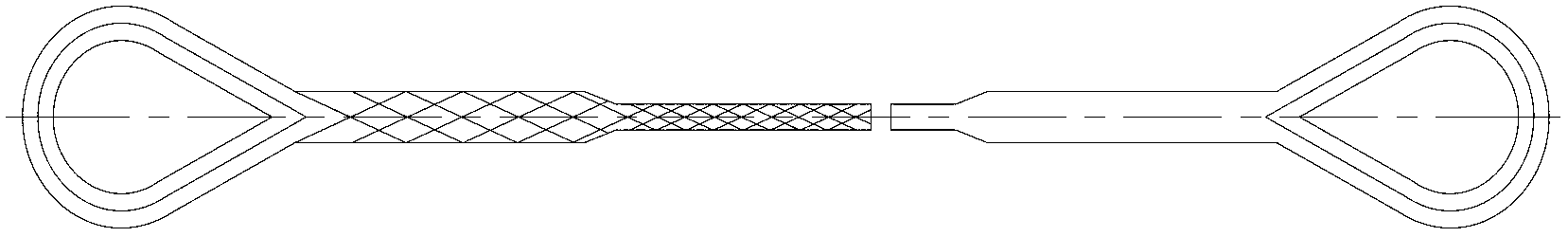

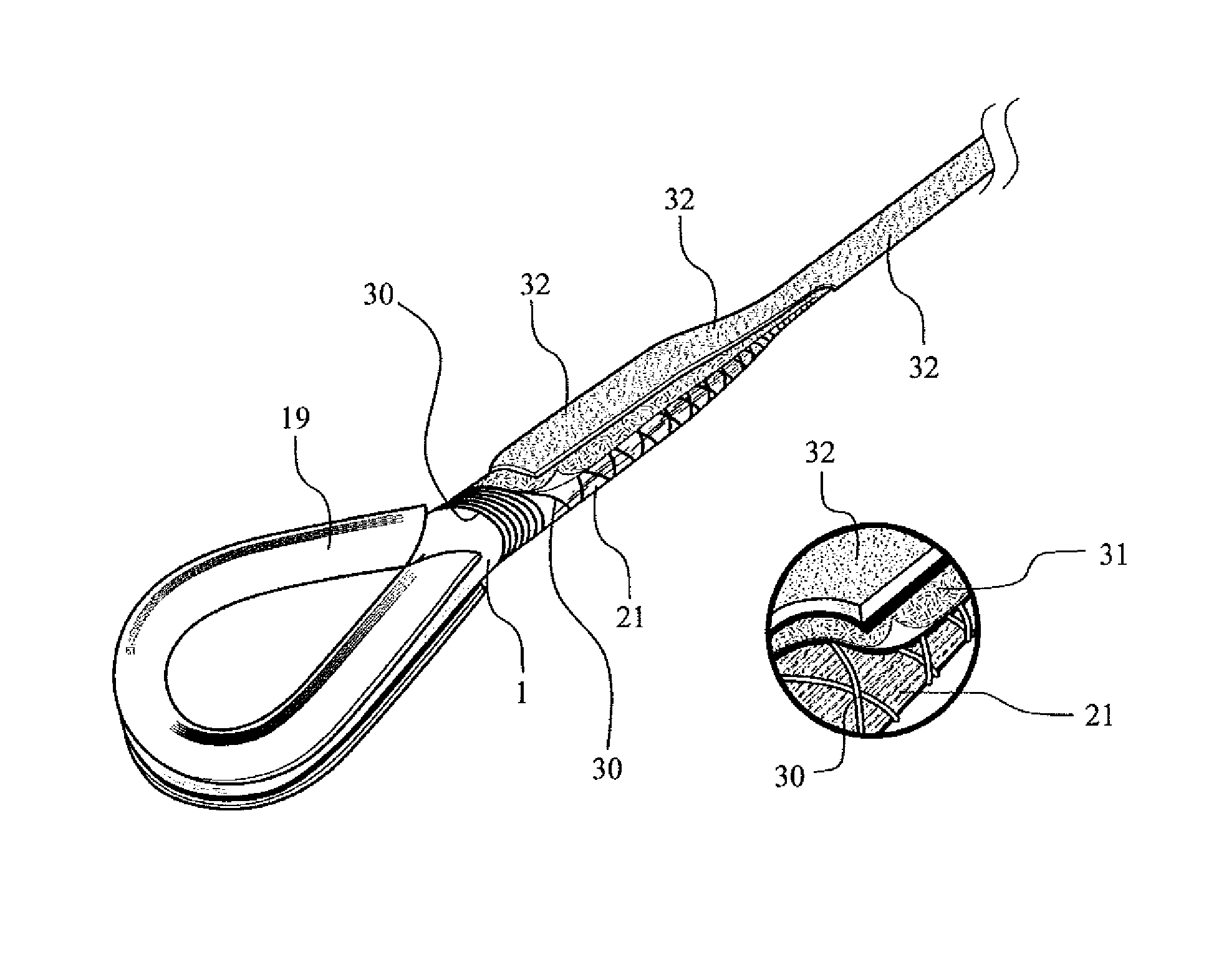

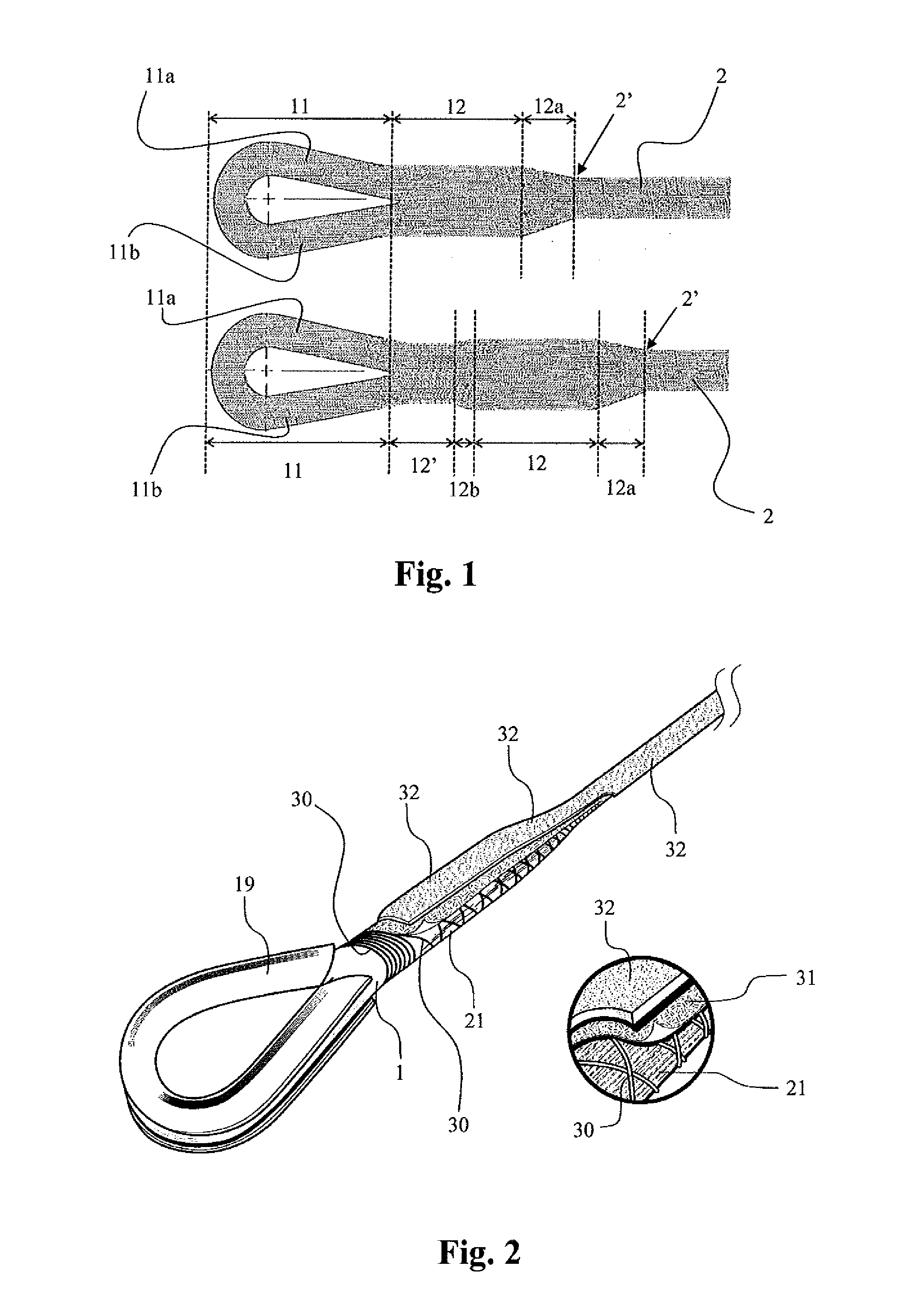

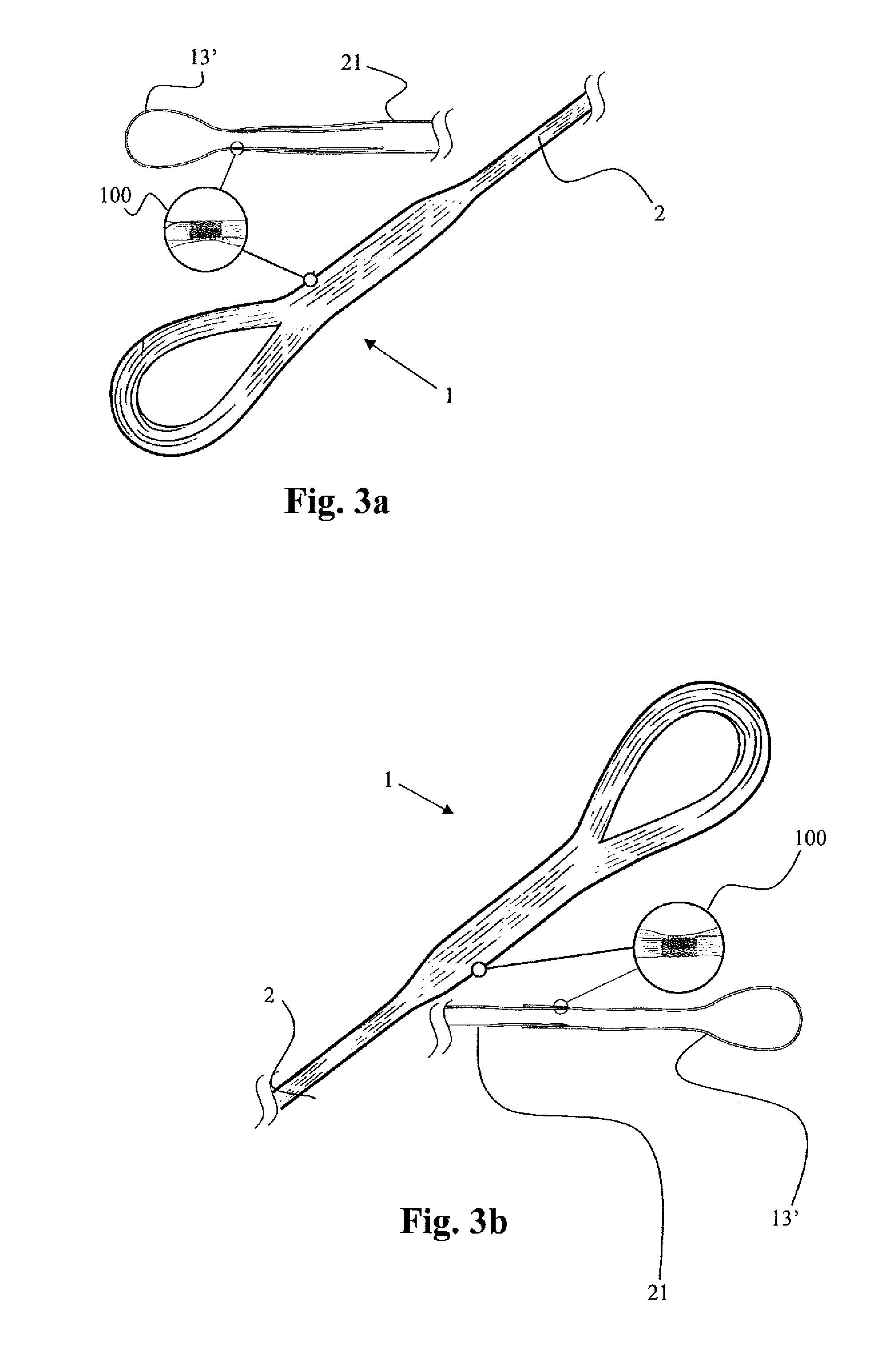

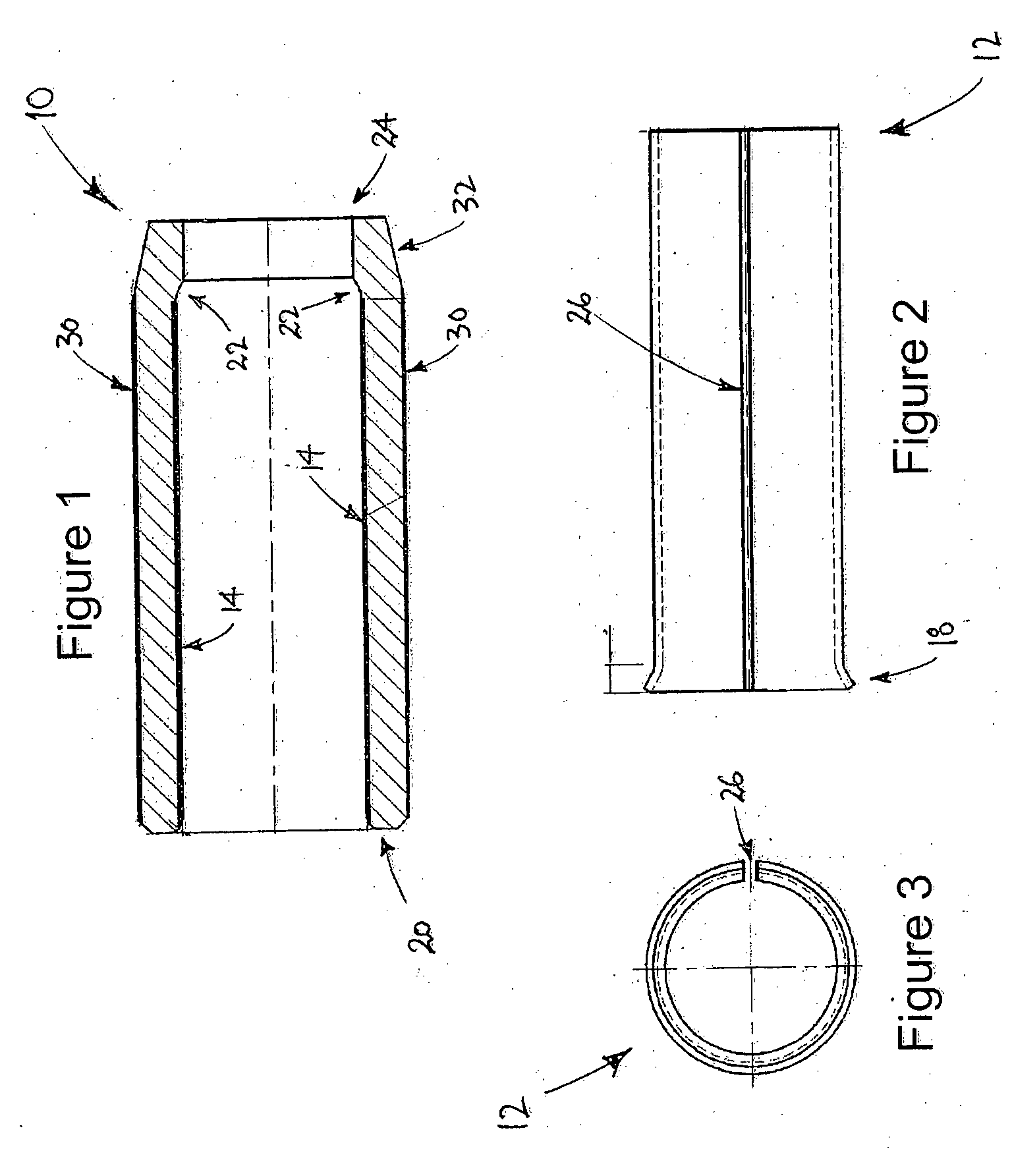

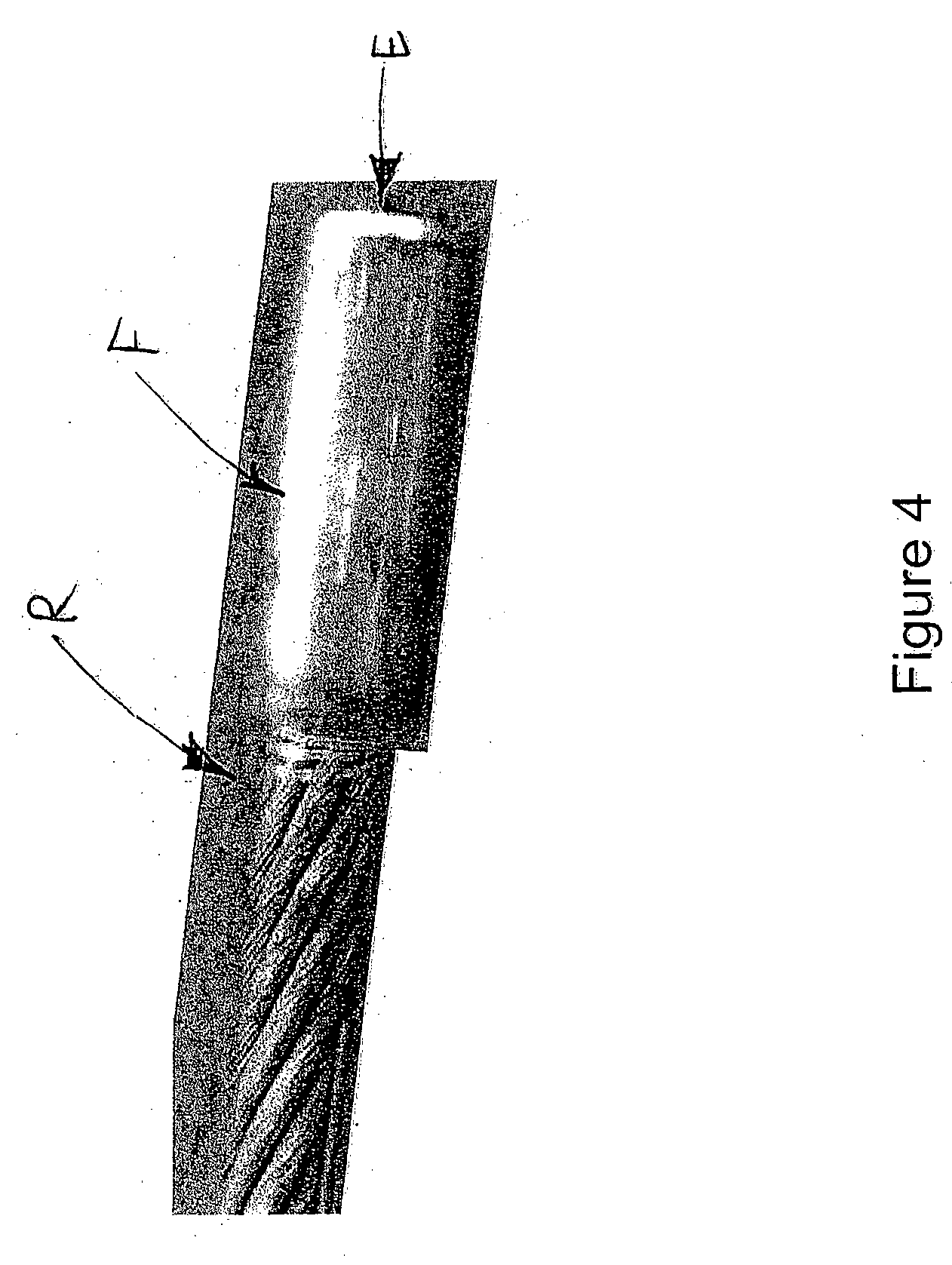

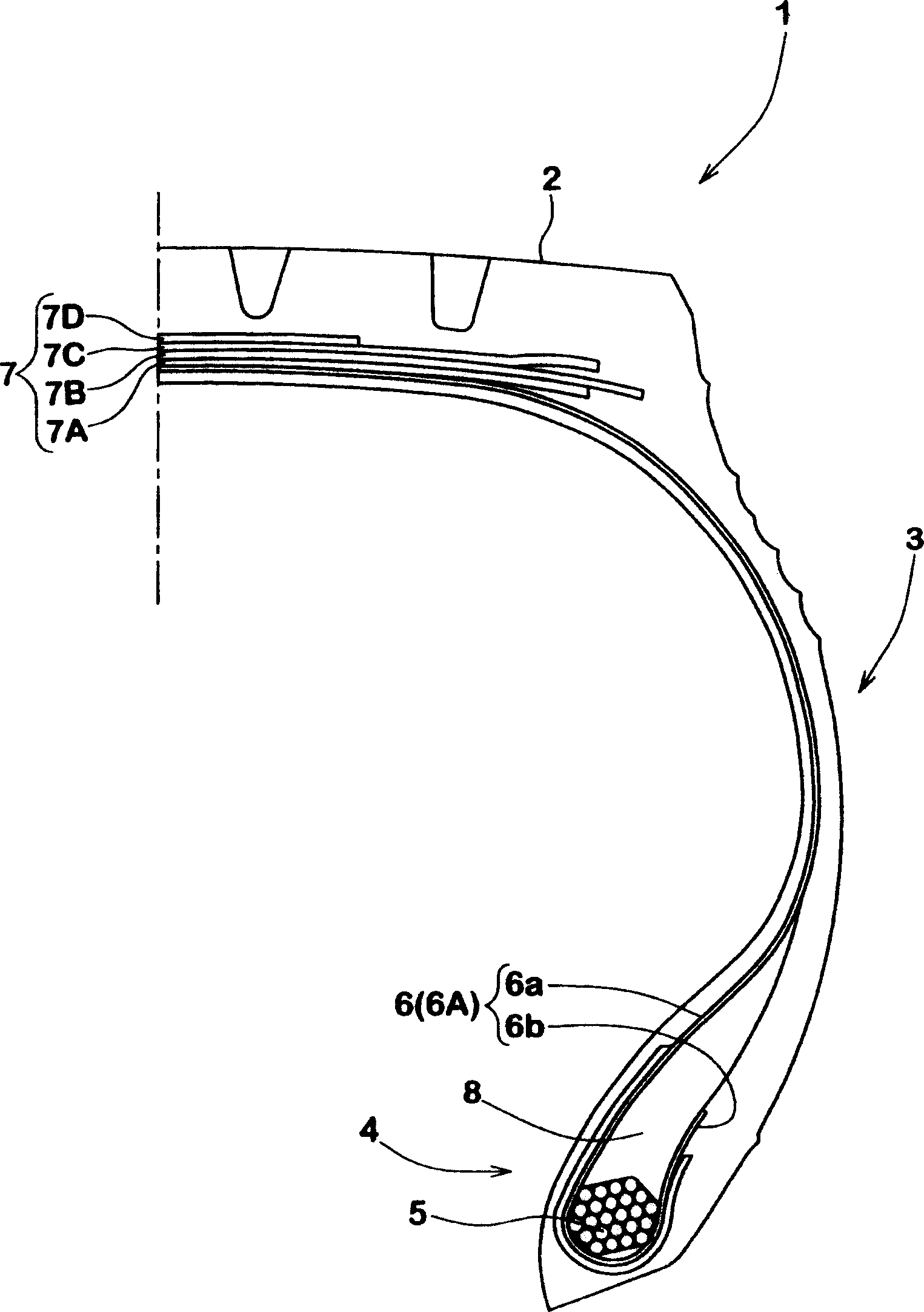

Advanced methods and designs for balancing a stranded termination assembly

Devices and methods for loading a cable in order to create a desired distribution of the load among the cable's constituent strands. Strand terminations are applied to many—and possibly all of—the cable's strands. The ultimate goal is to connect the strand terminations to a collector in order to create an overall cable termination. The relationship between each strand termination and the collector is allowed to “float” using the inventive process while the cable is tensioned and an appropriate spatial relationship between each strand tensioner and the collector is determined. One the appropriate relationship is found, it is configured to be repeatable (such as by locking the strand termination in place or by recording its position for later application to the same or similar collector).

Owner:BRIGHT TECH CO LTD

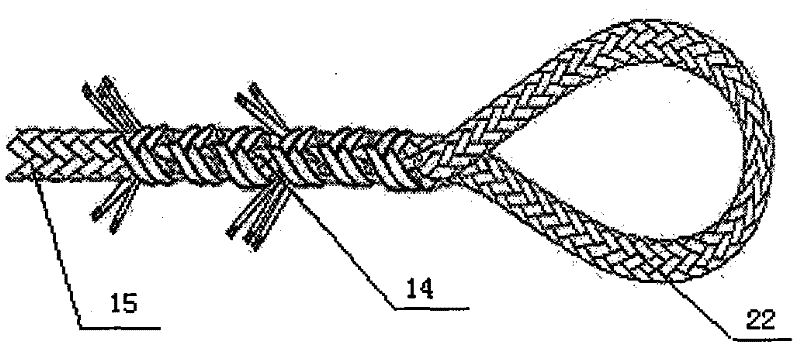

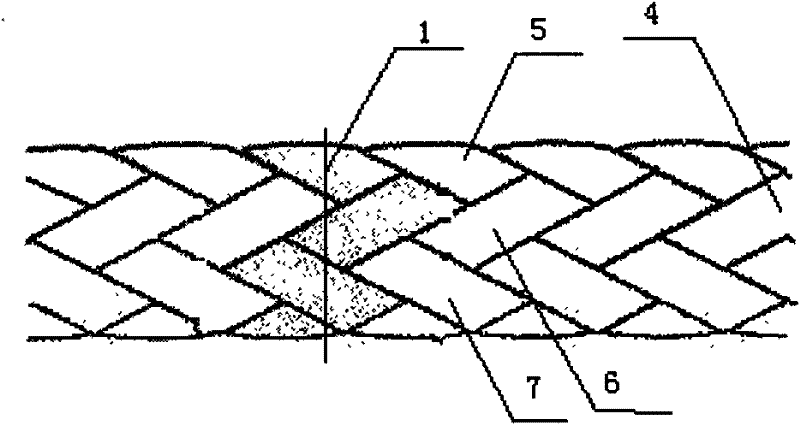

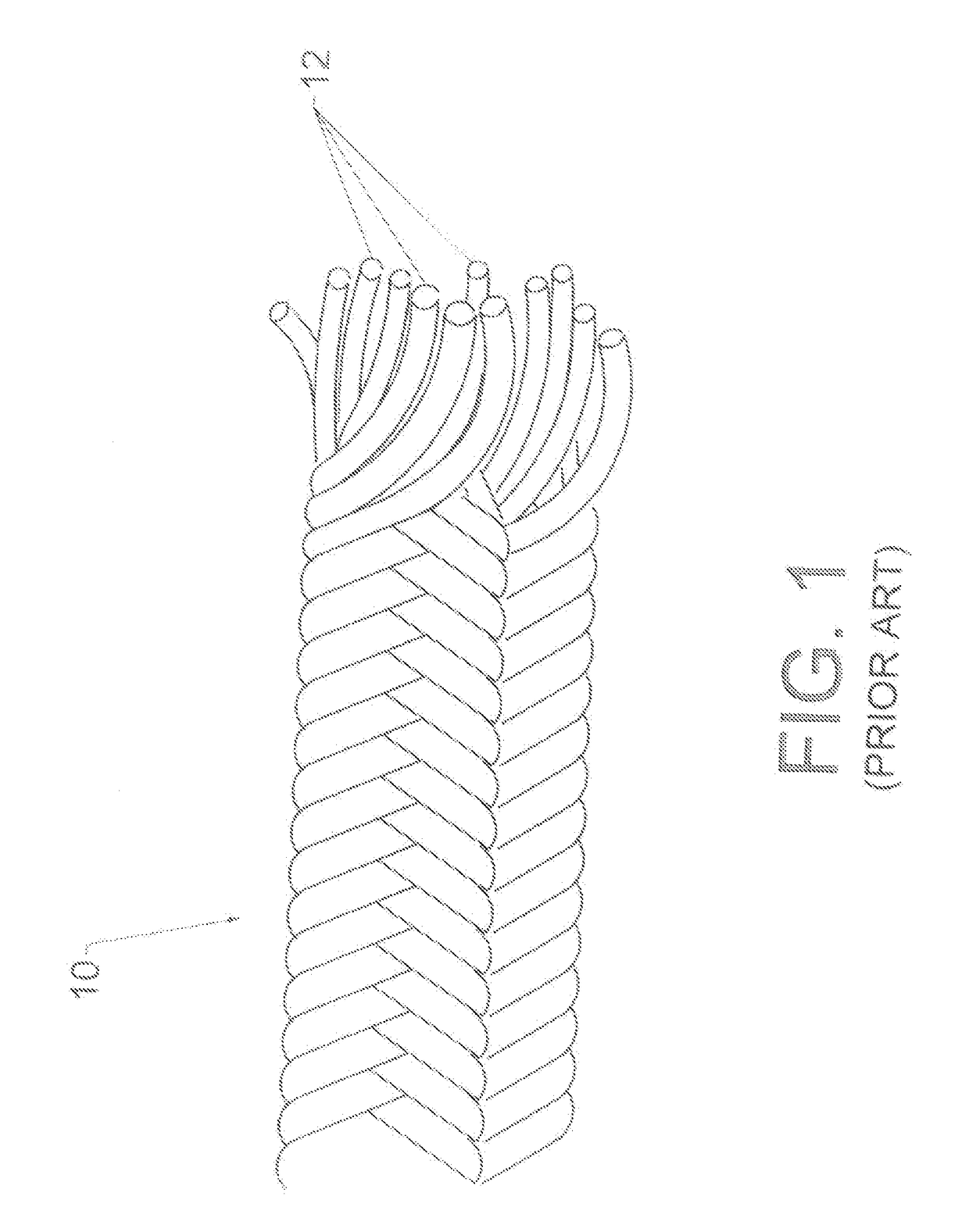

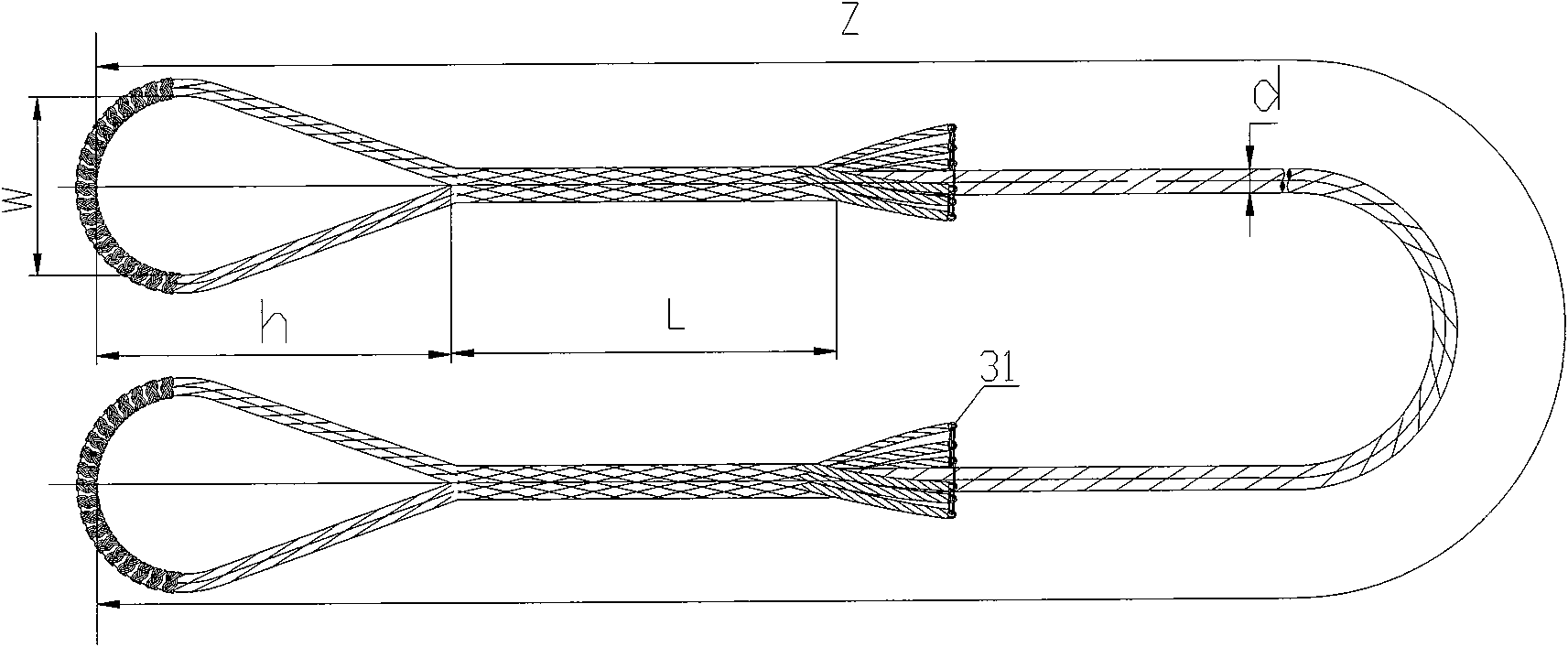

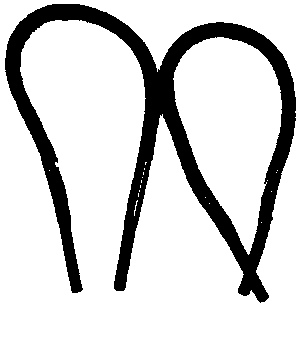

Twelve-strand rope sleeve and manufacturing method thereof

ActiveCN102191705ASimple structureImprove mechanical propertiesBinding endsProduction rateEngineering

The invention discloses a twelve-strand rope sleeve and a manufacturing method thereof. The twelve-strand rope sleeve comprises a sleeve ring, an inserting and weaving end and a main rope, wherein the main rope is connected with the sleeve ring through the inserting and weaving end; the manufacturing method of the sleeve ring and the inserting and weaving end comprises the following steps of: starting to measure from one end of the rope, making marks 1, 2 and 3 on the rope sequentially, extracting six rope strands as inserting and weaving rope strands towards the direction of the start-measuring end from the mark 1, burying the six residual rope strands into the rope from the mark 2 to the mark 3, transversely inserting three inserting and weaving rope strands through the mark 2, and starting to perform straight inserting and weaving on the rope by the six inserting and weaving rope strands from the mark 2 to the mark 3 so that the rope strands on the rope are staggered above and below the inserting and weaving rope strands. The twelve-strand rope sleeve manufactured by the method is long in service life, firm, reliable and secure, and durable and attractive; furthermore, the method is simple and easy in operation; and the production efficiency is improved.

Owner:JULI SLING

Advanced Methods and Designs for Balancing a Stranded Termination Assembly

Devices and methods for loading a cable in order to create a desired distribution of the load among the cable's constituent strands. Strand terminations are applied to many—and possibly all of—the cable's strands. The ultimate goal is to connect the strand terminations to a collector in order to create an overall cable termination. The relationship between each strand termination and the collector is allowed to “float” using the inventive process while the cable is tensioned and an appropriate spatial relationship between each strand tensioner and the collector is determined. One the appropriate relationship is found, it is configured to be repeatable (such as by locking the strand termination in place or by recording its position for later application to the same or similar collector).

Owner:BRIGHT TECH CO LTD

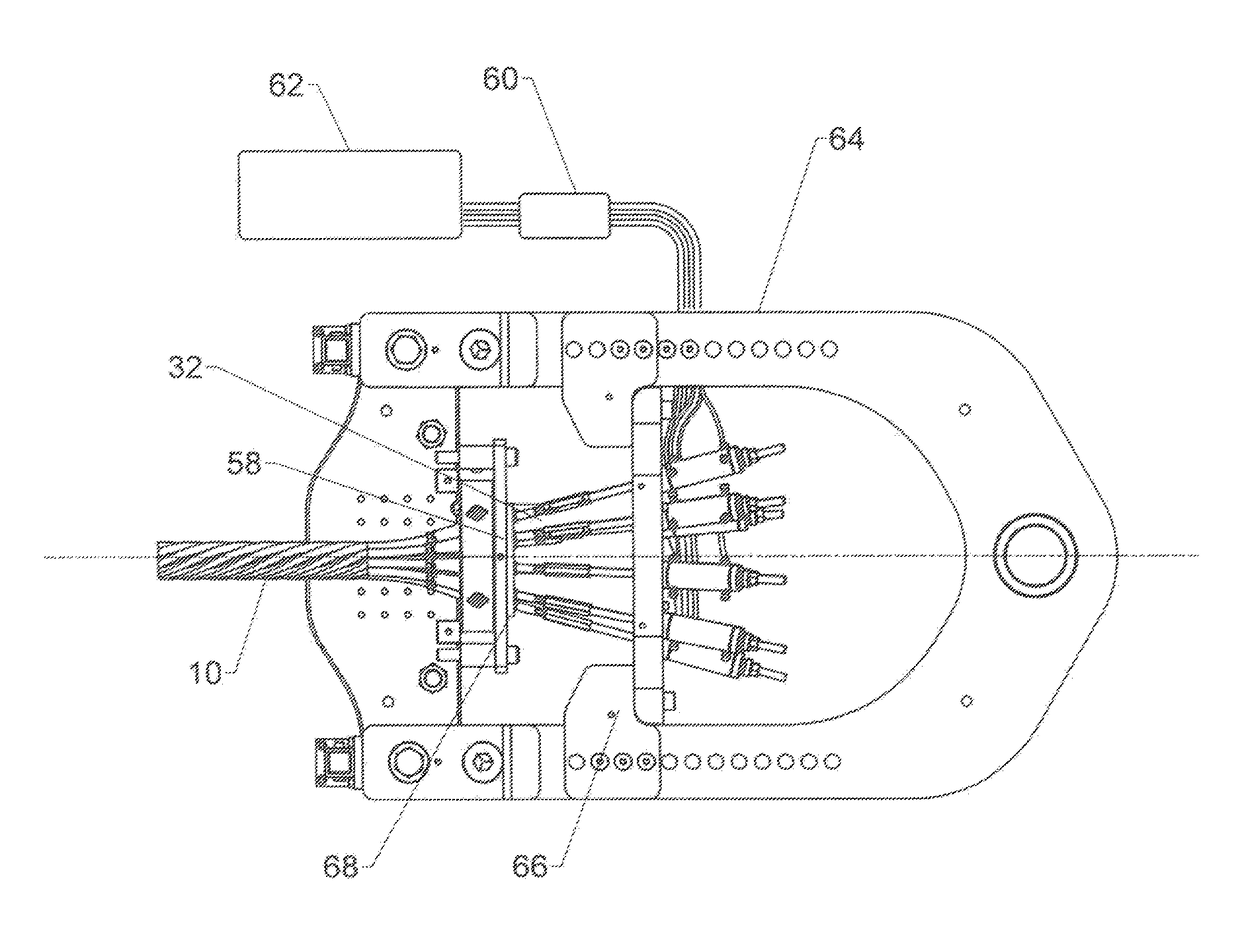

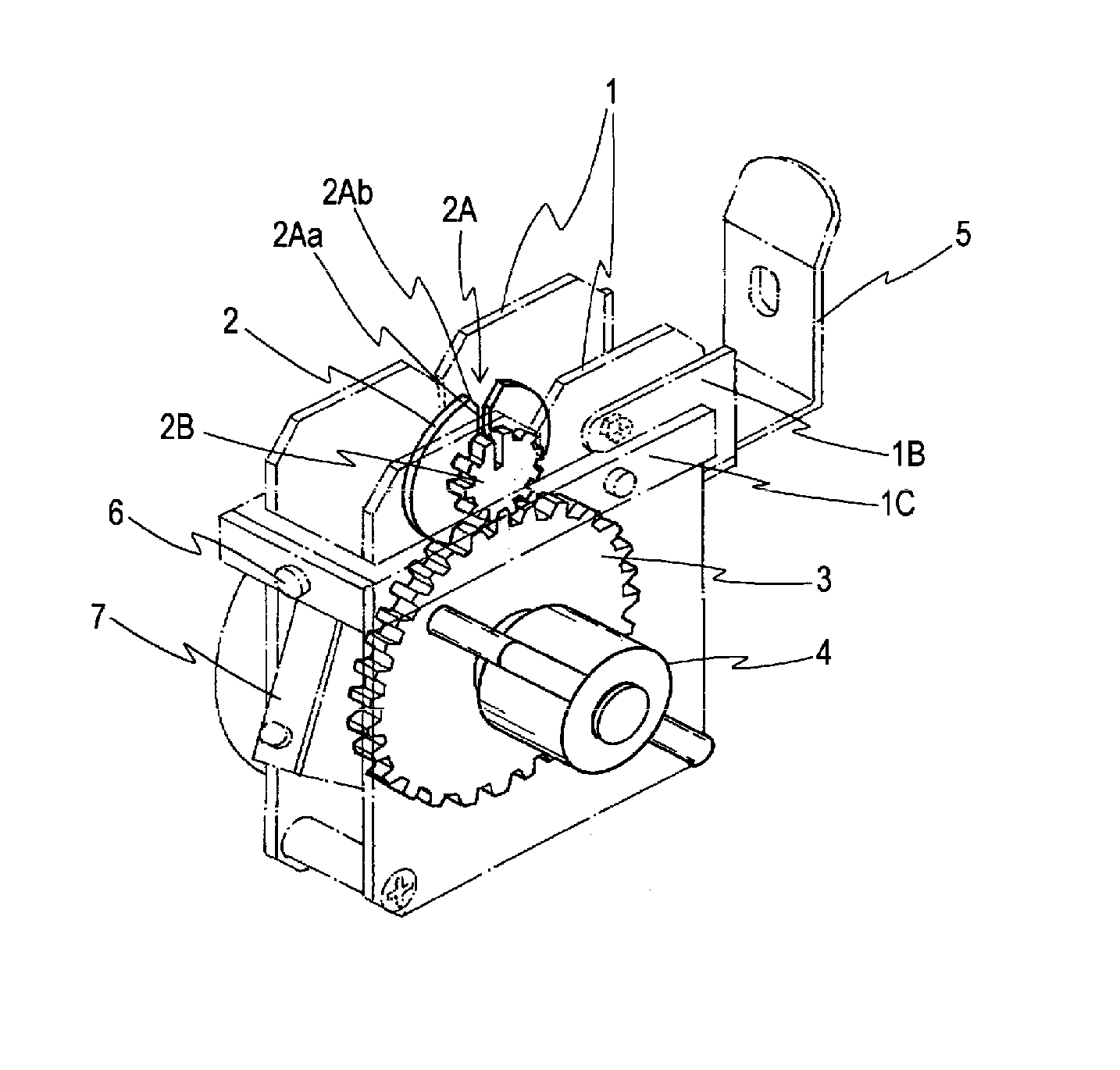

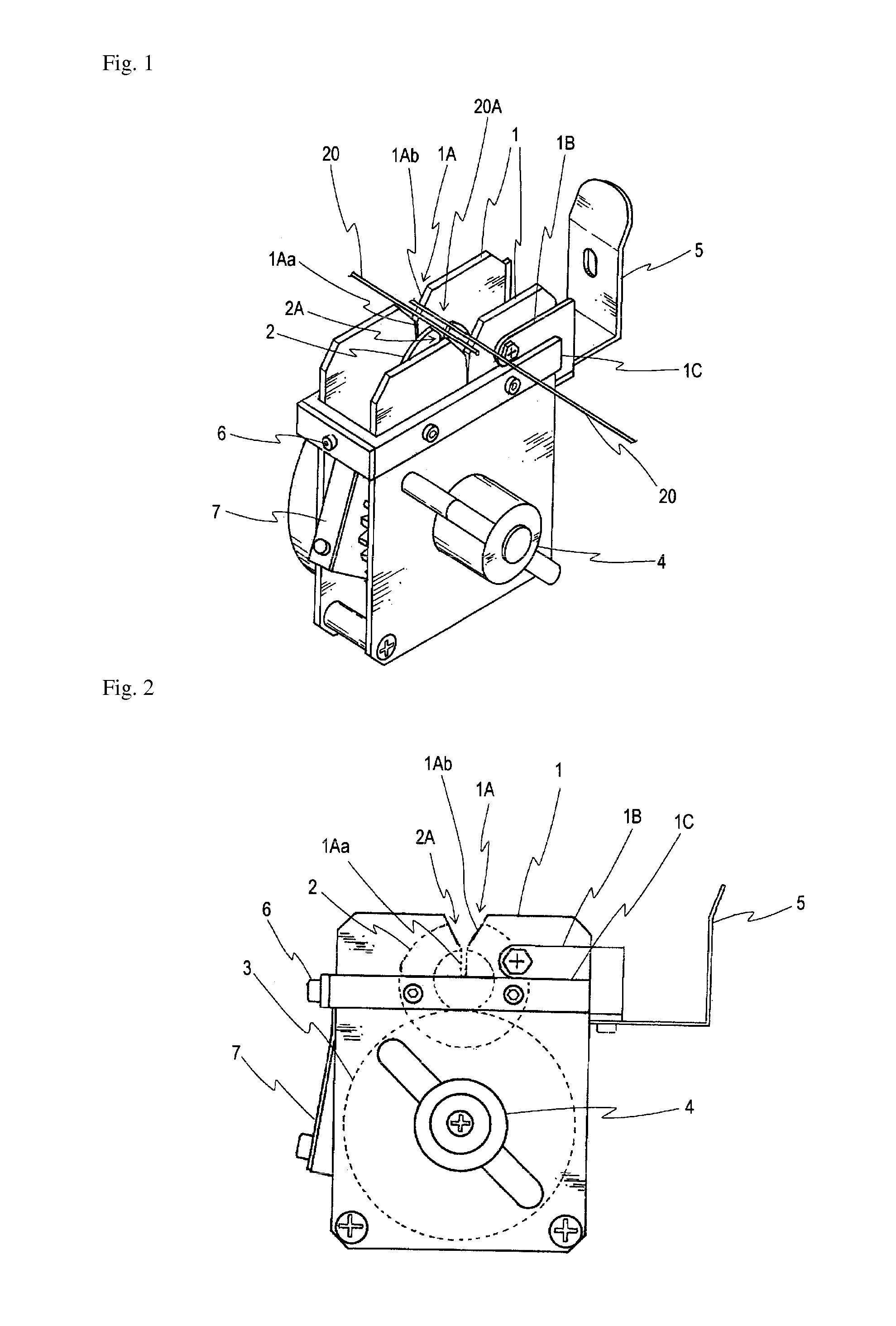

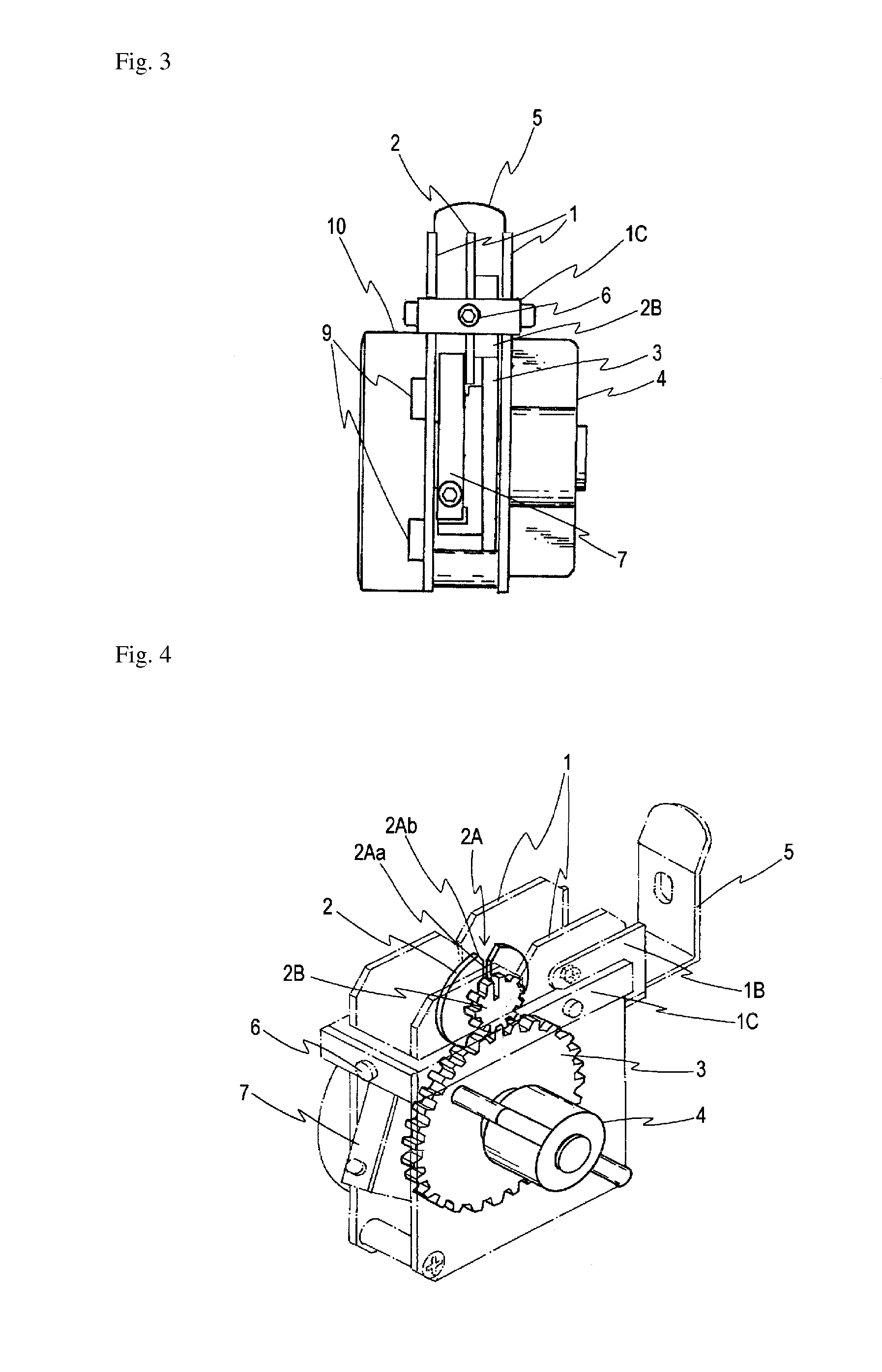

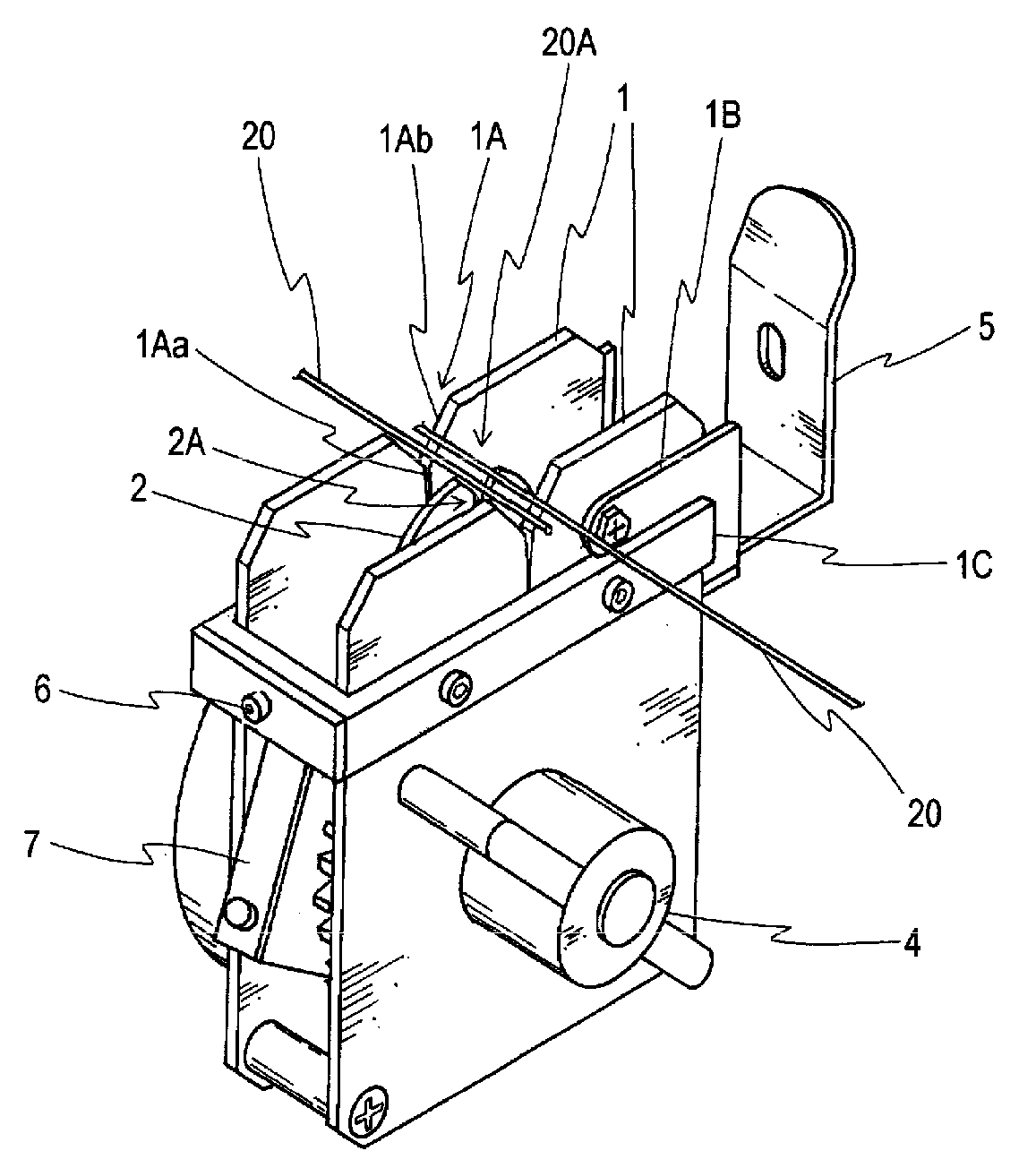

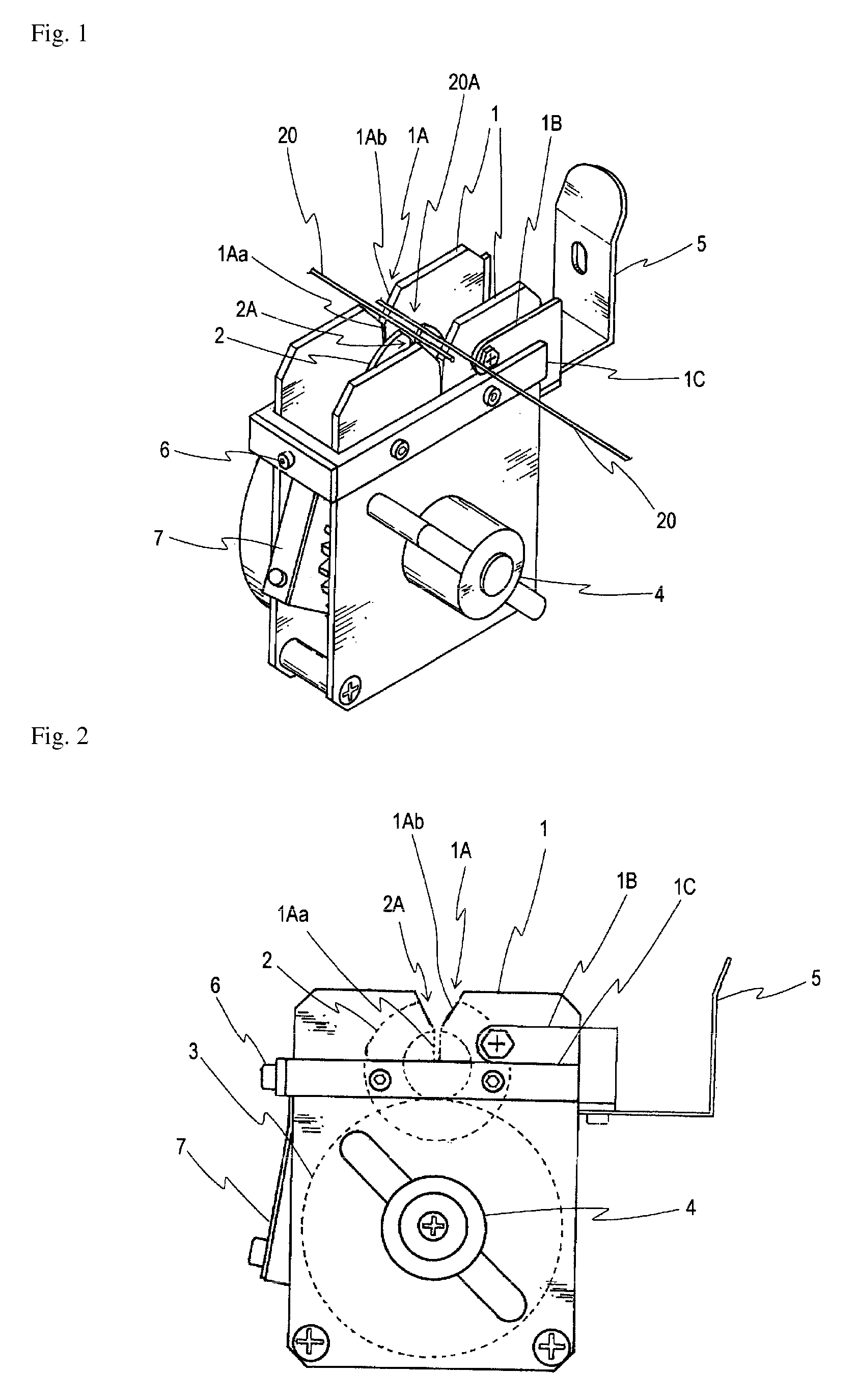

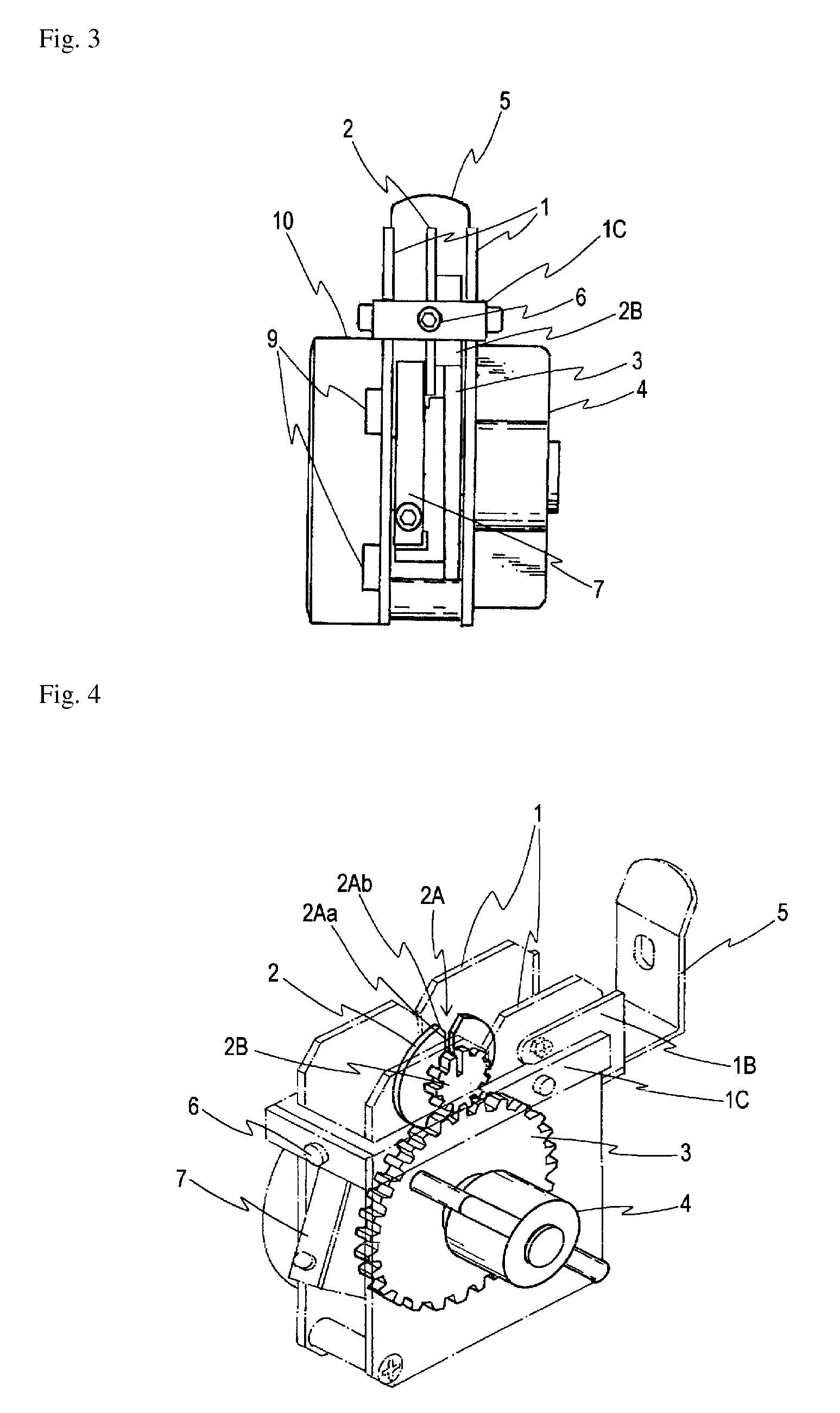

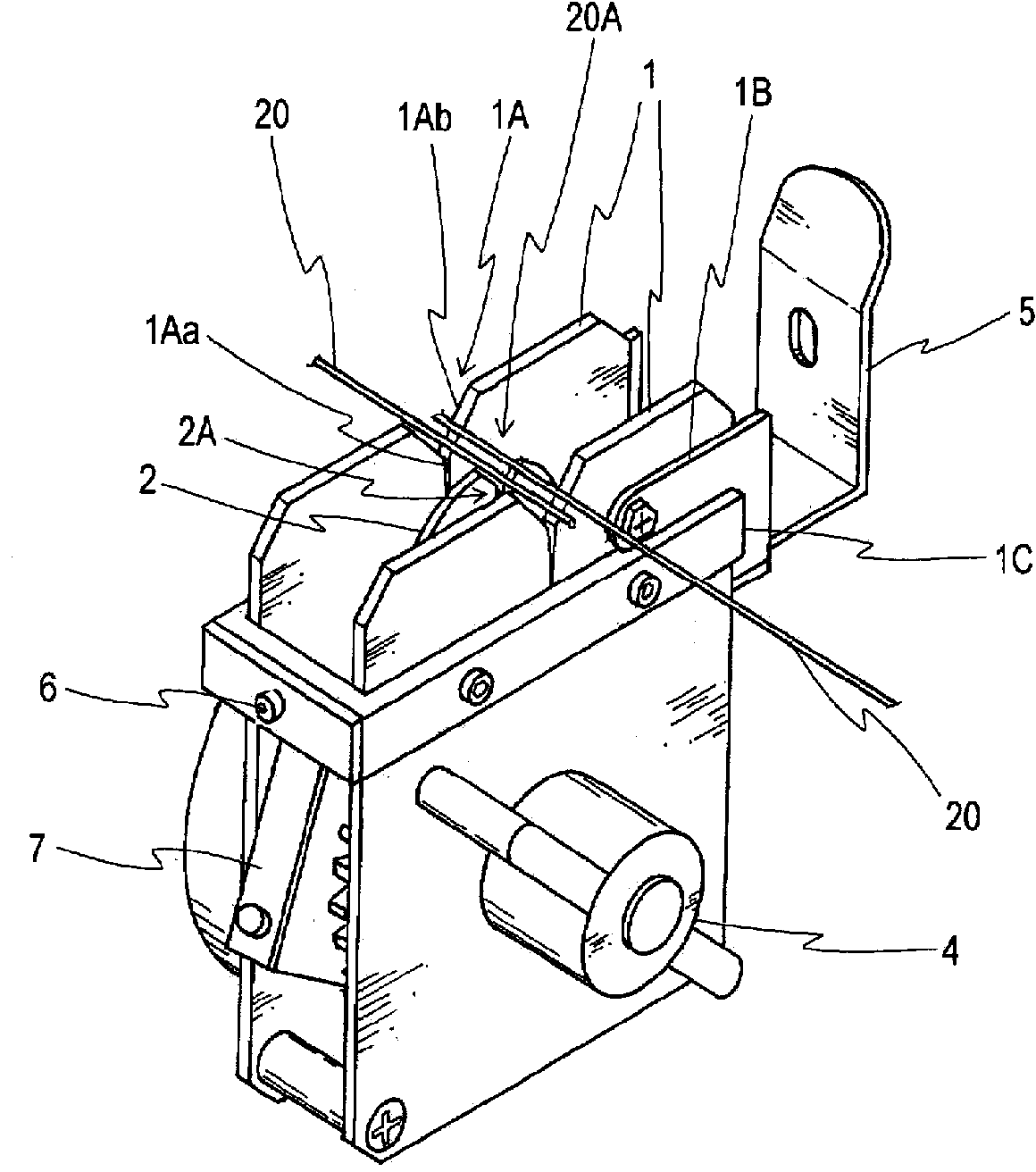

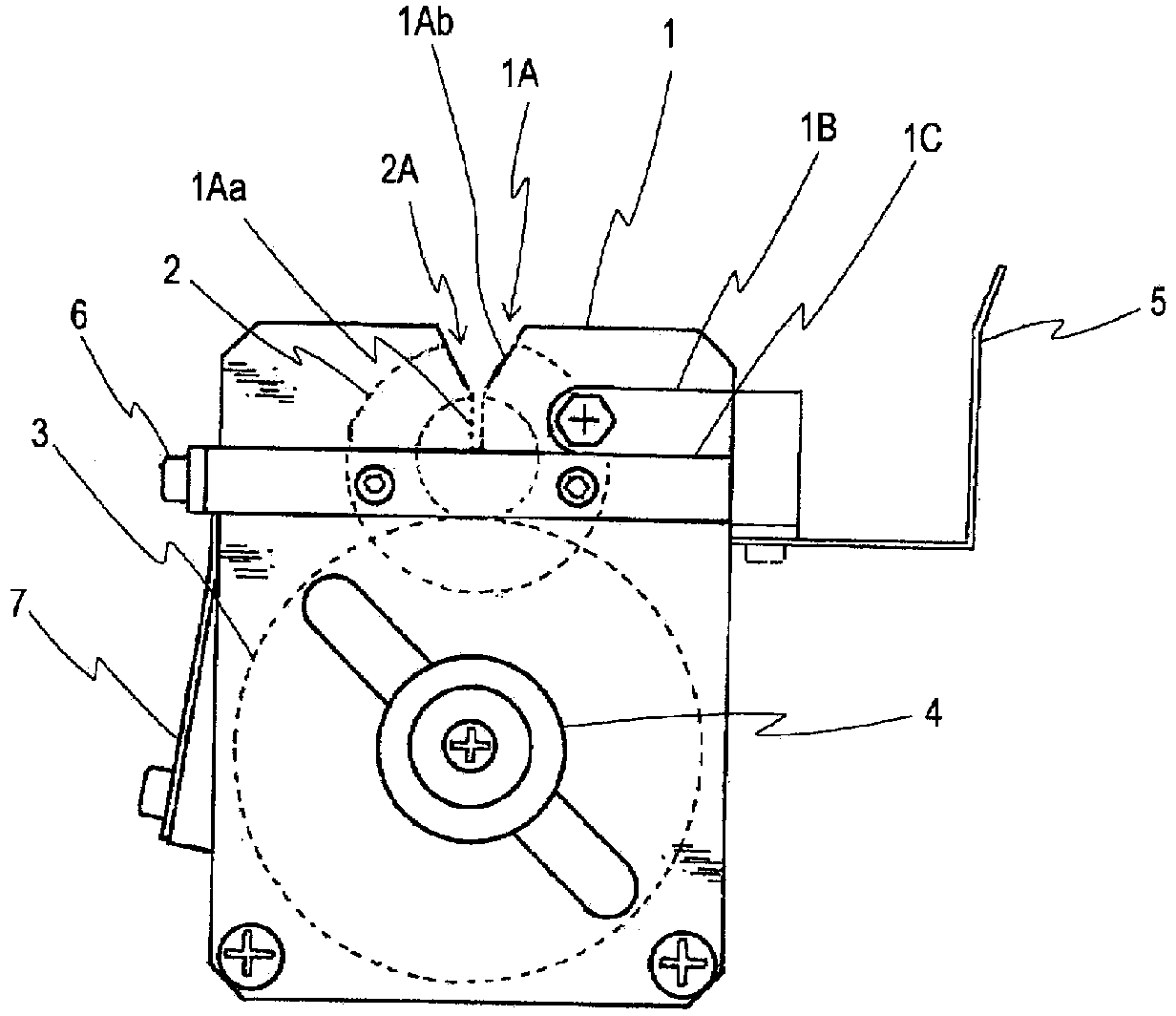

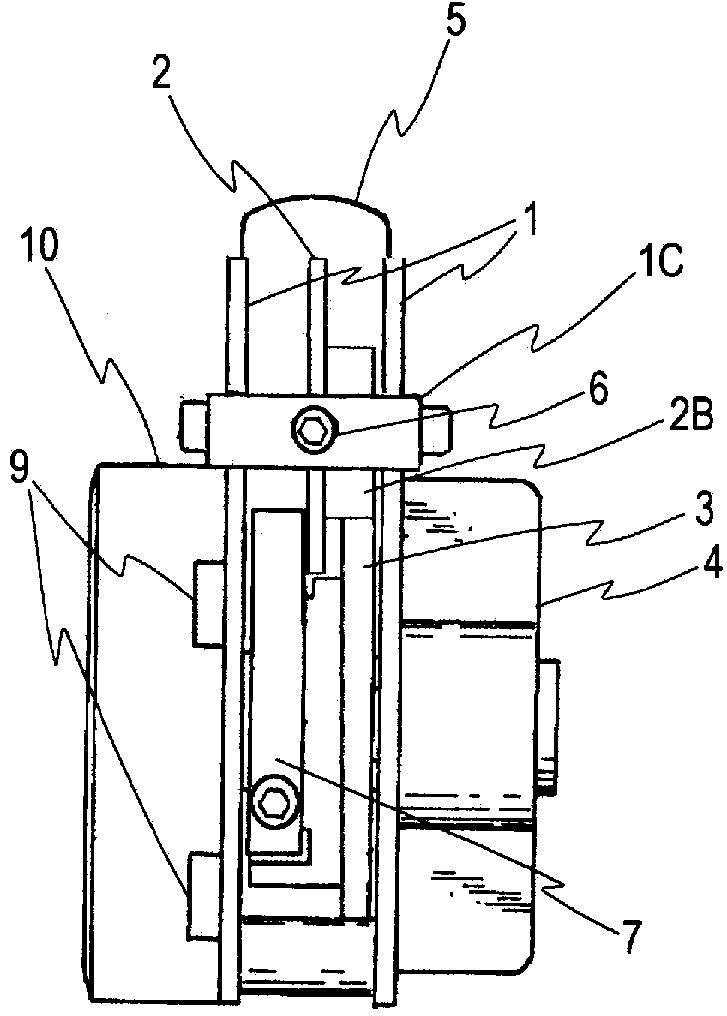

Metal filament body connecting method and connecting device

ActiveUS20140298770A1Improve portabilityFirmly connectedShaping toolsBinding endsMetal filamentEngineering

Provided is a metal filament body connecting method in which a connecting operation is easy and a metal filament body connecting device which is lightweight and has excellent portability.Provided is a metal filament body connecting method of connecting facing metal filament bodies 20. A pair of fixing members 1 fixing the facing metal filament bodies 20, and a rotating body 2 in which a cutout 2A is arranged between the pair of fixing members 1 are arranged; both end portions of a parallel portion 20A of a metal filament body formed by juxtaposing the facing metal filament bodies 20 are fixed by the pair of fixing members 1; an approximately central portion of the parallel portion 20A of the metal filament body is arranged in a cutout 2A of the rotating body 2; and then, the facing metal filament bodies 20 are twisted together by rotating the rotating body 2. The pair of fixing members 1 comprises a cutout 1A and a pressing member 1B; both end portions of parallel portion 20A of the facing metal filament bodies are arranged in cutouts 1A of the pair of fixing members 1; and the both end portions are fixed by pressing with the pressing member 1B.

Owner:BRIDGESTONE CORP

Methods and Designs for Balancing a Stranded Termination Assembly

ActiveUS20180245666A1Binding endsRopes and cables for vehicles/pulleyEngineeringSpatial relationship

Devices and methods for loading a cable in order to create a desired distribution of the load among the cable's constituent strands. Strand terminations are applied to many—and possibly all of—the cable's strands. The ultimate goal is to connect the strand terminations to a collector in order to create an overall cable termination. The relationship between each strand termination and the collector is allowed to “float” using the inventive process while the cable is tensioned and an appropriate spatial relationship between each strand tensioner and the collector is determined. Once the appropriate relationship is found, it is configured to be repeatable (such as by recording its position for later application to the same or similar collector).

Owner:BRIGHT TECH CO LTD

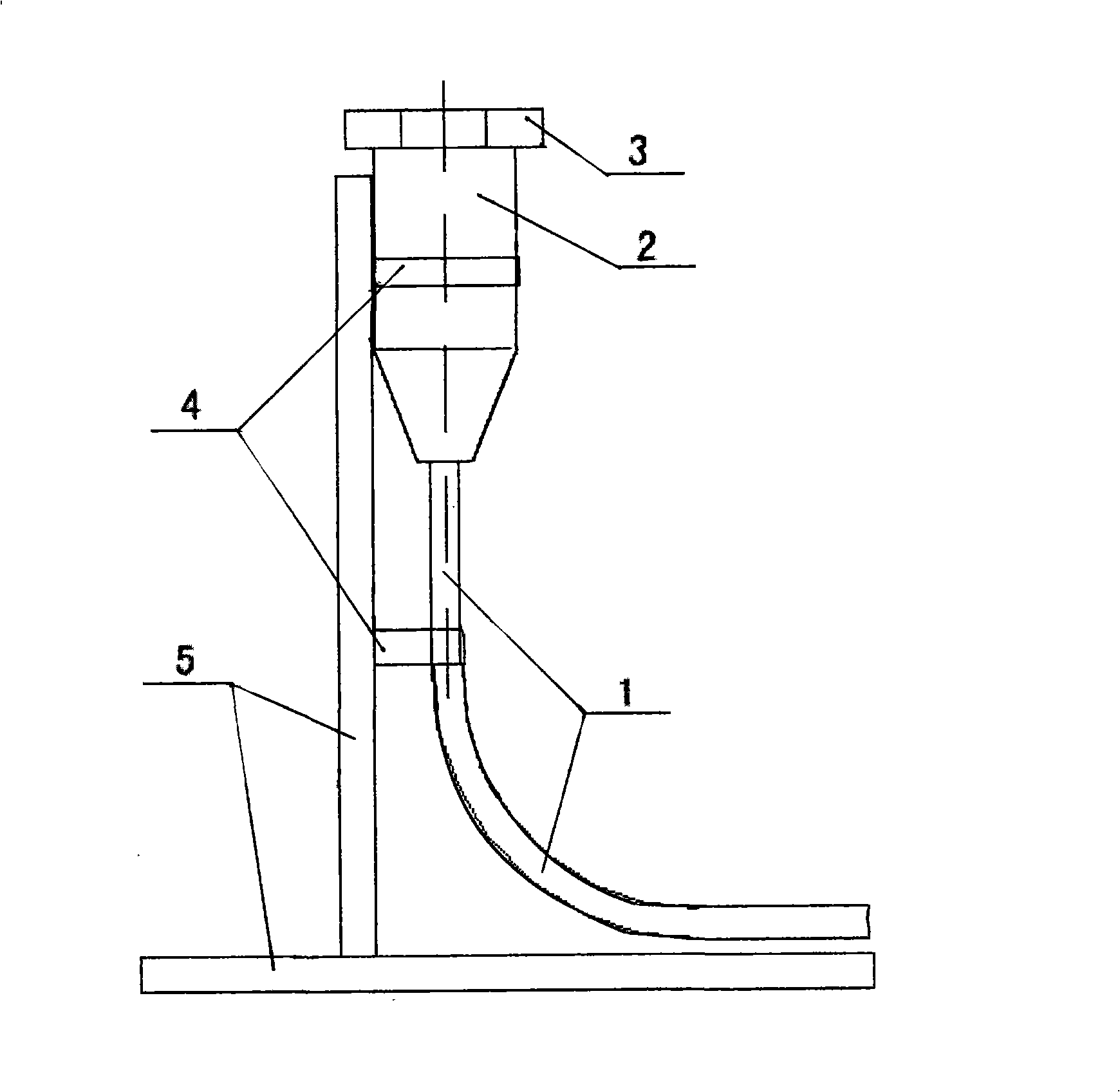

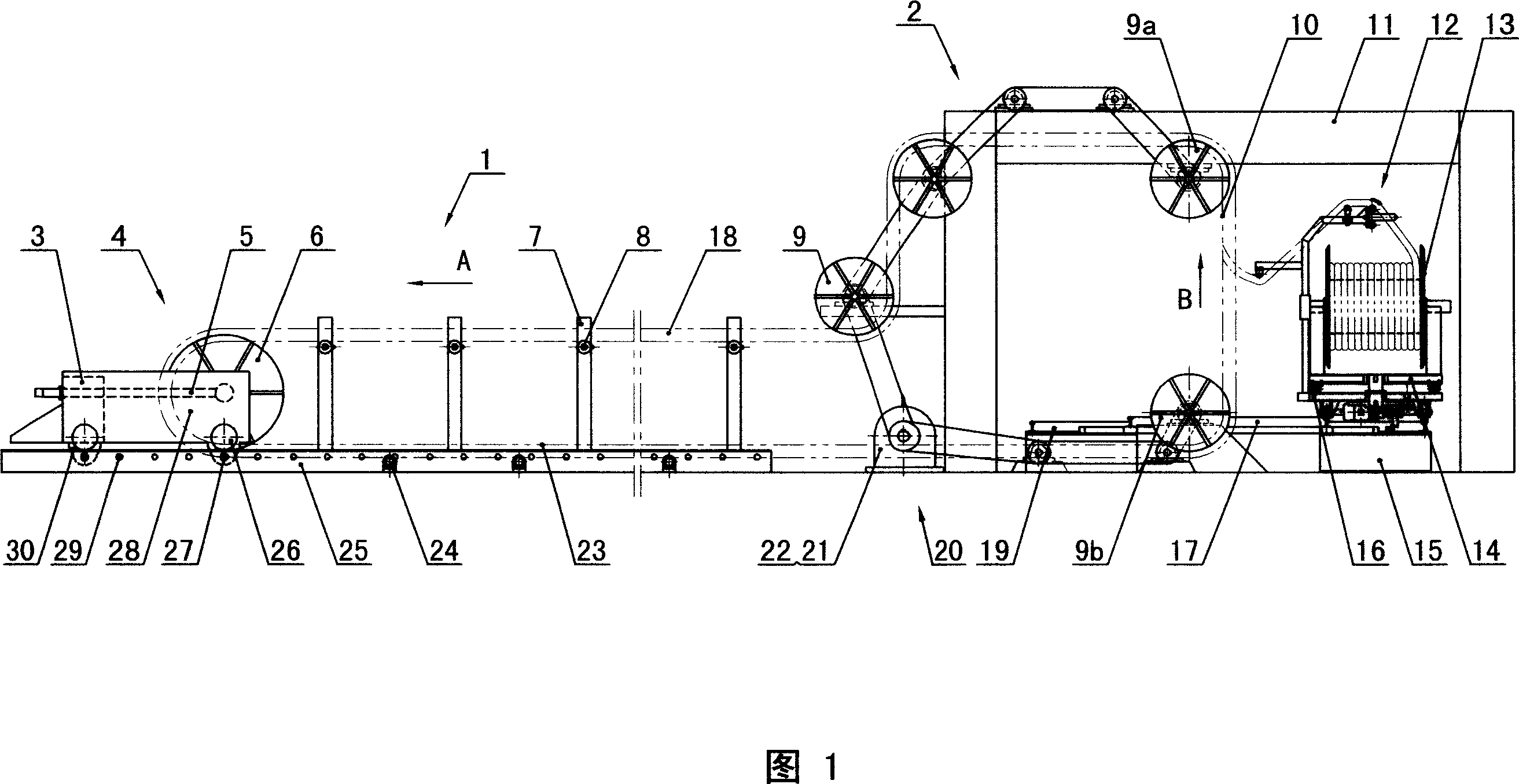

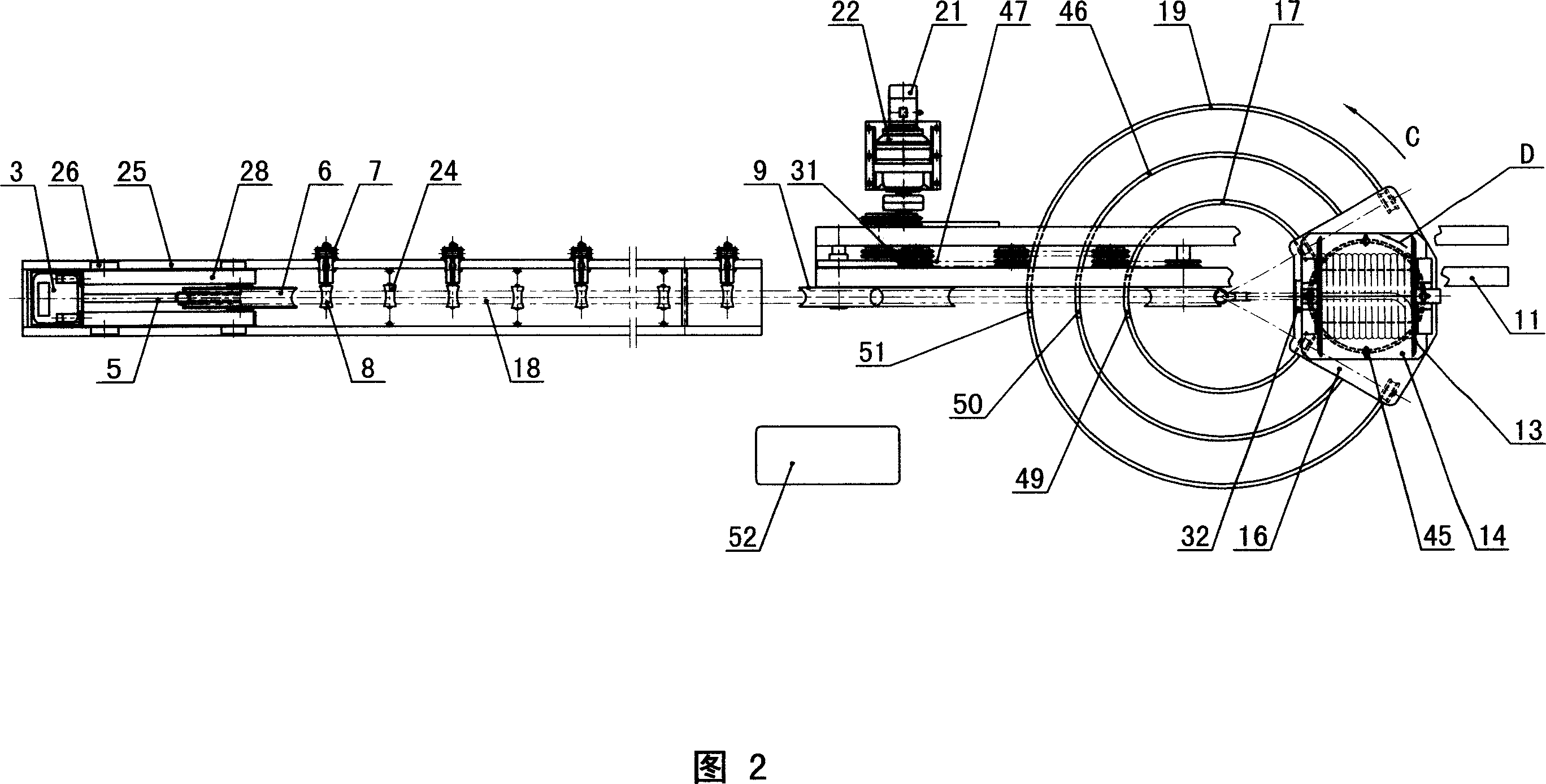

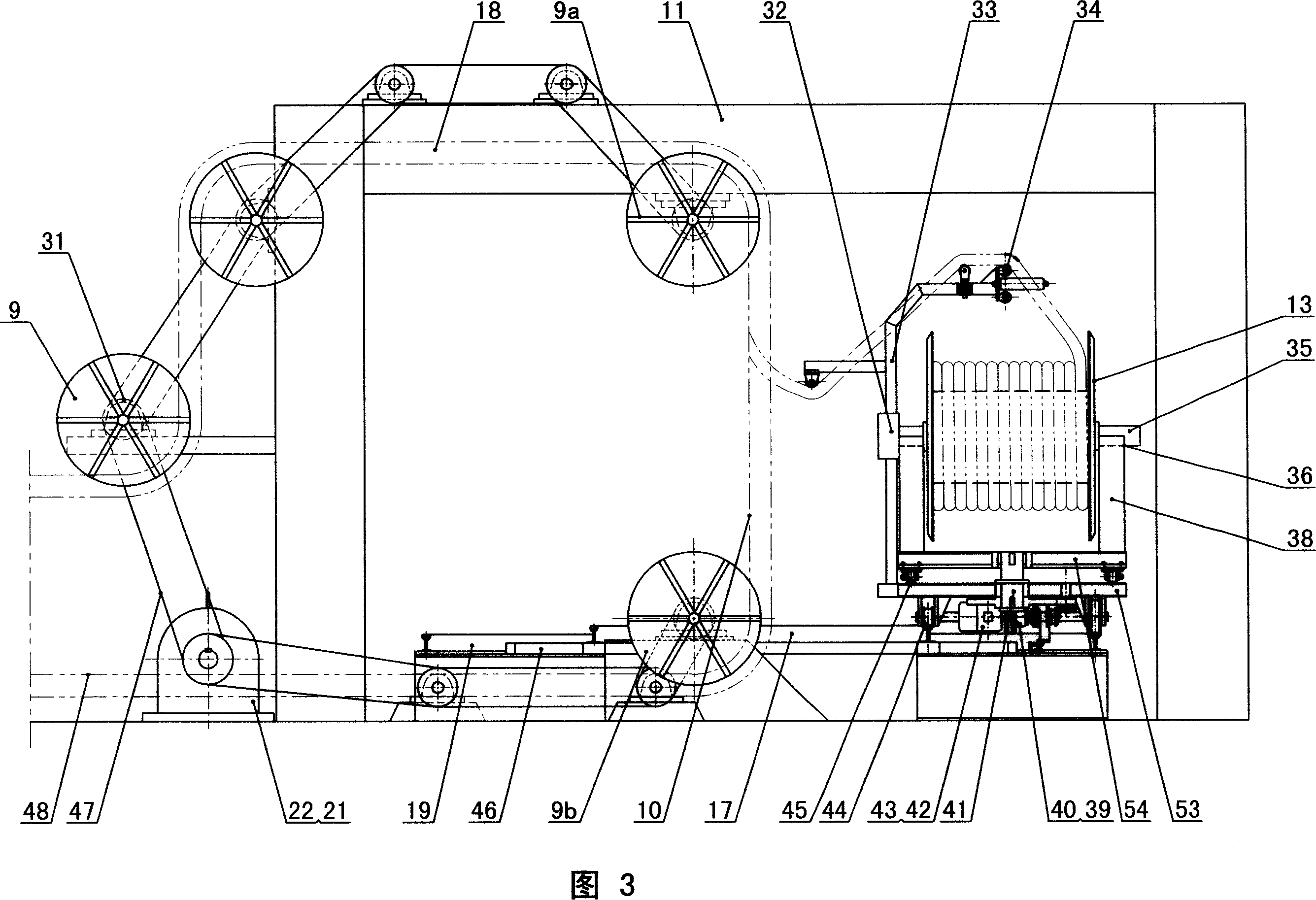

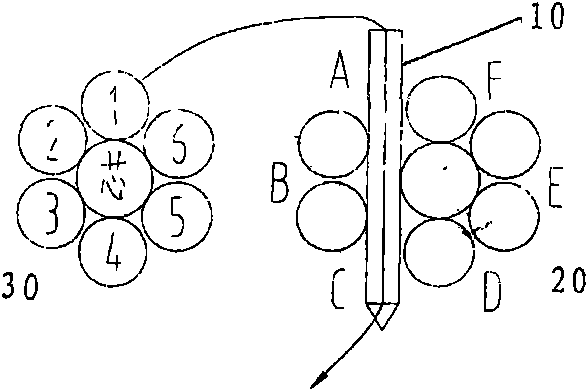

Device for producing jointless steel cable loop

ActiveCN1970883AIncrease productivityImprove product qualityBinding endsRopes and cables for vehicles/pulleyHorizonDrive wheel

The invention relates to a manufacturing equipment for bight of no-joint steel rope, comprising transmission system for core rope and winding system for child rope. The transmission system for core rope comprises stretching device and driving device. The stretching device comprises two linear guides and stretching wheel module set on two guides, which comprises a support for stretching wheel, a stretching wheel and a locating device for stretching wheel. The driving device comprises a support for driving wheel, several driving wheels and transmission system connected with each driving wheel. The winding system for child rope comprises a support fixed on the earth, two coaxial circular guides fixed on the support in horizon and with certain height to the earth and the winding rope device set on two circular guides, which comprises small vehicle, rotational bracket set on the small vehicle and spool set on the rotational bracket. The equipment in the invention is provided with automatically machining, producing efficiency and product quality improved greatly, and labor intensity lessened.

Owner:巨力索具(河南)有限公司

Metal filament body connecting method and connecting device

Provided is a connecting method for connecting facing metal filament bodies. A pair of fixing members fixing the facing metal filament bodies, and a rotating body in which a cutout is arranged-between the pair of fixing members. End portions of a parallel portion of a metal filament body formed by juxtaposing the facing metal filament bodies are fixed by the pair of fixing members and an approximately central portion of the parallel portion of the metal filament body is arranged in a cutout of the rotating body. Next, the facing metal filament bodies are twisted together by rotating the rotating body. The pair of fixing members comprises a cutout and a pressing member and both end portions of parallel portion of the facing metal filament bodies are arranged in cutouts 1A of the pair of fixing members and the end portions are fixed by pressing with the pressing member.

Owner:BRIDGESTONE CORP

Treating structure for sling rope weaving and inserting terminal

InactiveCN1637206AIncreased durabilityNo dispersalBinding endsLoad-engaging elementsEngineeringSynthetic resin

A processing structure for the braiding end of a sling, using a protective wire forming device composed of a loading part mounted on a rotary driving tool and a forming part for forming a protective wire, formed when the end of the wire rope is twisted and braided After inserting the above-mentioned protective wire from the end of the steel rope forming the collar, bend the part of the steel rope near the end, and weave its end into the twisted part of the steel rope, and insert the protective wire In this weaving part, both ends of the protective wire are processed, and at the same time, the protective wire is fixed with synthetic resin. The processing structure of the braided end of this sling can simply be loaded with a protective wire covered by the braided part exposed at the cut end on the sling collar, and can greatly improve the safety of the loaded protective wire. durability.

Owner:市川薰子 +1

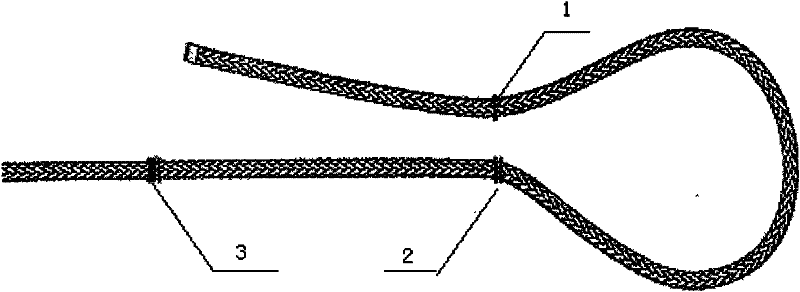

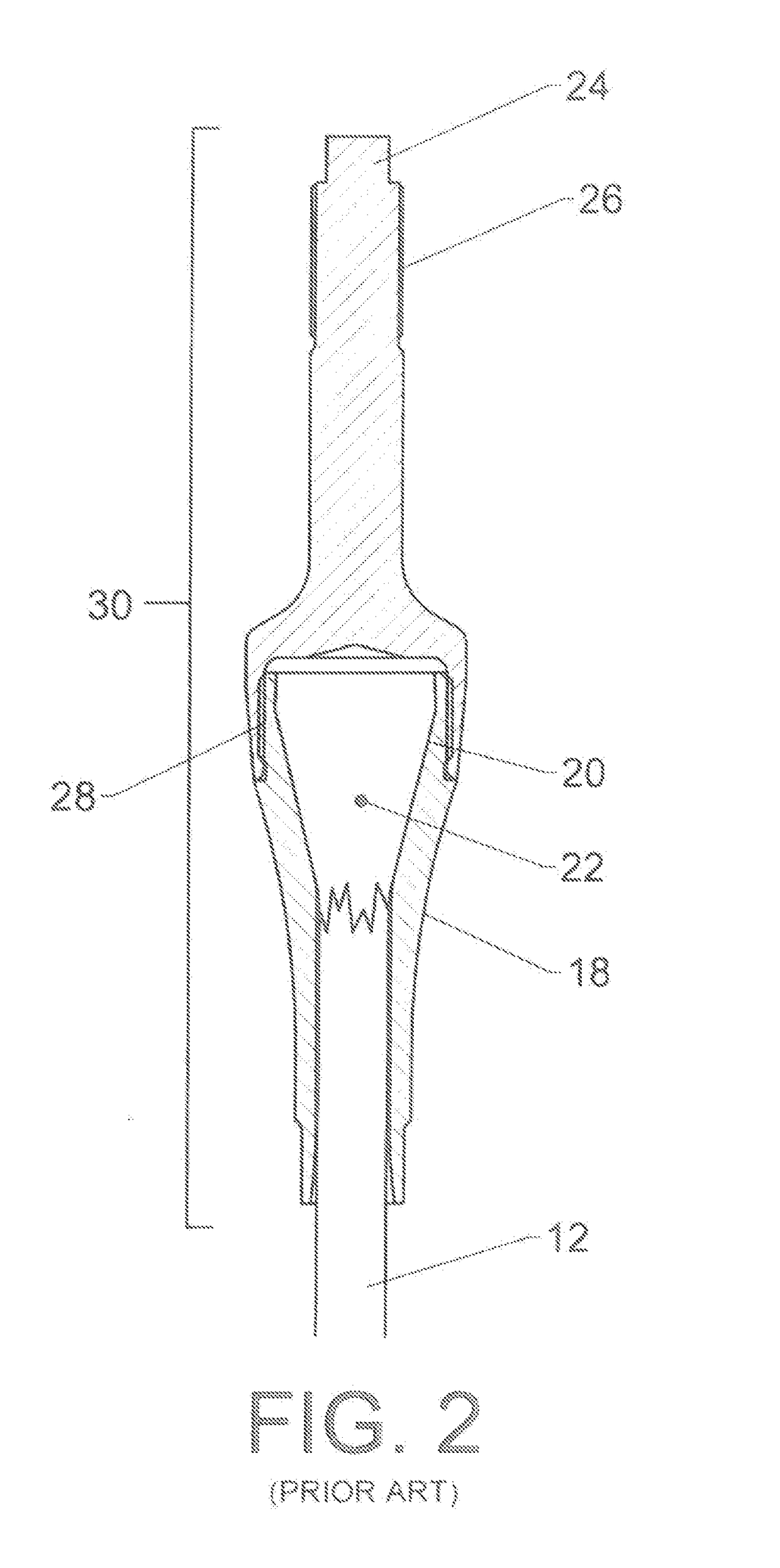

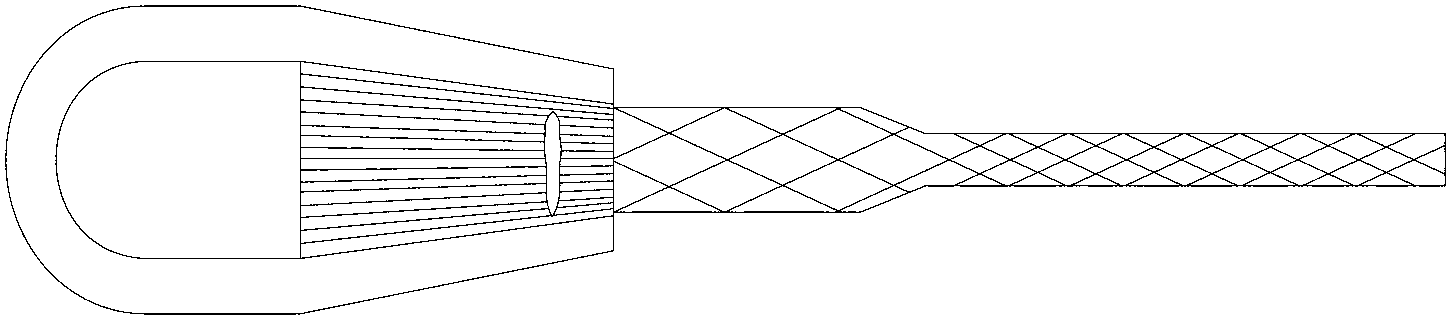

Method for casting and solidifying end portion of fiber rope

ActiveCN103255658AIncrease profitHigh consolidation strengthBinding endsFiberUltimate tensile strength

The invention discloses a method for casting and solidifying the end portion of a fiber rope. The method relates to the fiber rope and a joint. The method comprises the steps of scattering one end of the fiber rope, folding the end portion in half in an inserting and weaving mode, thickening the end portion of the fiber rope, inserting the partially thickened end portion of the fiber rope from the small-bore end of the joint, scattering fiber strands, inserted into the joint, of the fiber rope into a cone shape, allowing the fiber strands to be evenly distributed inside a casting cup, slowly pouring prepared resin into the casting cup, and allowing the end portion of the fiber rope and the joint to be solidified together. The joint and the thickening portion of the fiber rope are pre-tensioned, and fibers of the thickening portion are evenly stressed so that whole breaking force is improved. The method is used for solidification of the end portion, connected with the resin, of the fiber rope. According to the method for casting and solidifying the end portion of the fiber rope, the proper resin, the proper joint with an inverted-cone-shaped hole and a proper solidification part are selected for partial thickening and casting, solidification strength of the rope is improved so that the aim of equal strength casting of the fiber rope can be achieved, and therefore a fiber use ratio is improved.

Owner:JULI SLING

Cable and method for manufacturing a synthetic cable

Owner:BRASKEM SA

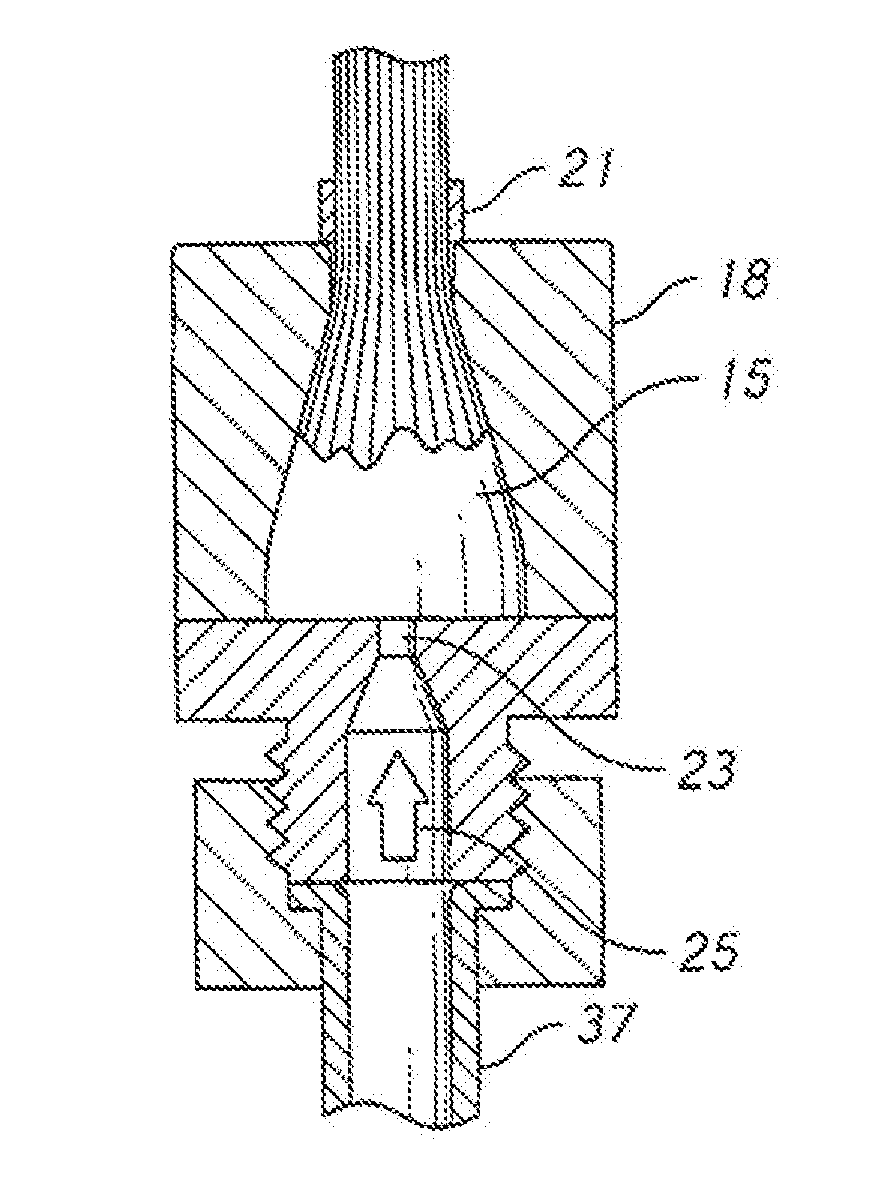

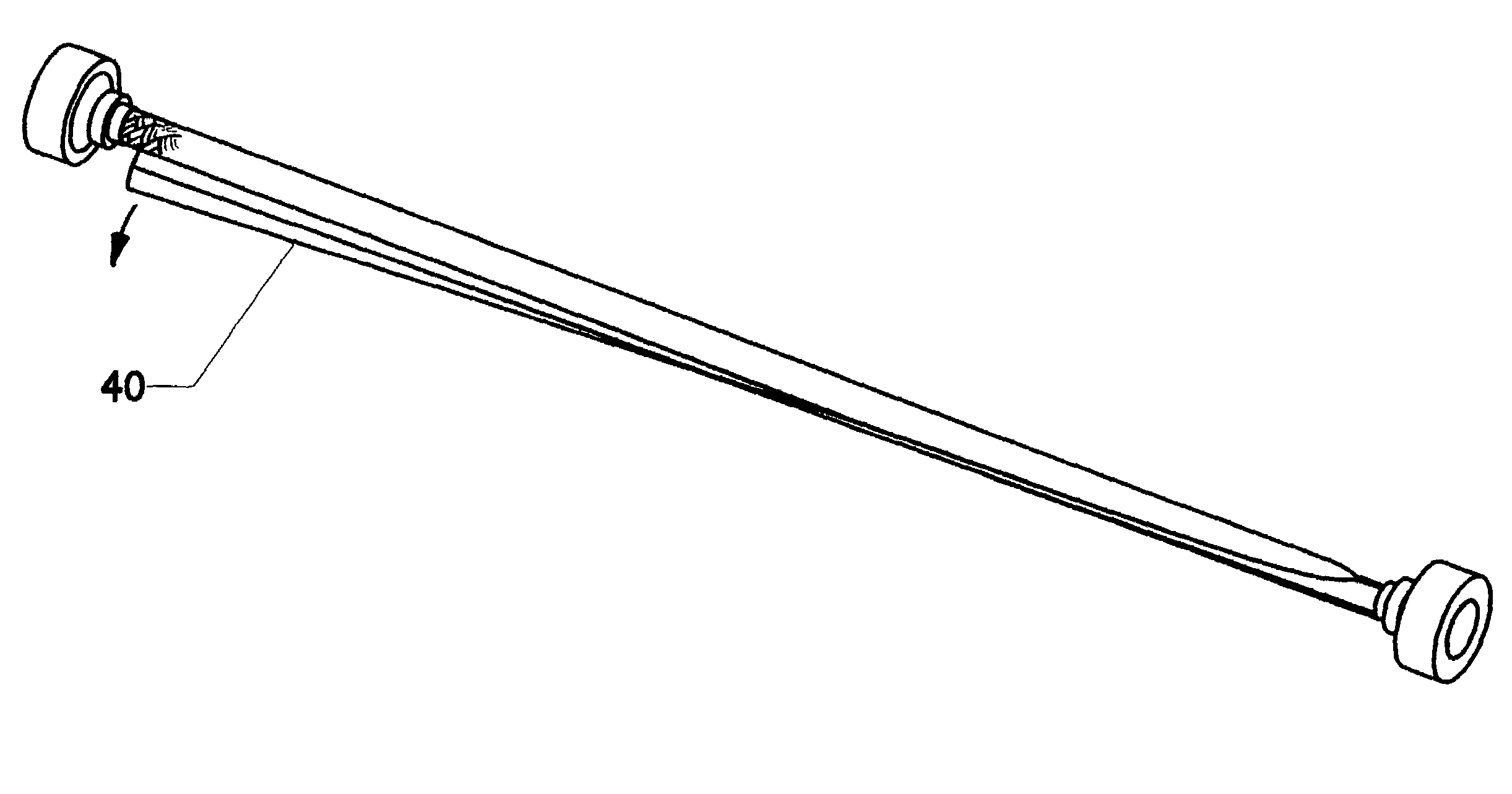

Inverted Injection Method of Affixing a Termination to a Tensile Member

ActiveUS20180320756A1Improves strand alignmentImprove load distributionBinding endsRopes and cables for vehicles/pulleyBiomedical engineeringInjections methods

A method for attaching an anchor to an end of a tensile member by inverting the assembly of anchor and tensile member and injecting pressurized potting compound. A length of filaments of the tensile member are placed within a cavity through the anchor. The anchor and filaments are placed in an inverted position, with the distal end of the anchor facing downward and the cable extending upward out of the anchor. If the anchor has an open distal end this is sealed. Liquid potting compound is injected into the anchor cavity and allowed to solidify. During the solidification process, a controlled translation (pulling) of the cable is preferably introduced.

Owner:BRIGHT TECH CO LTD

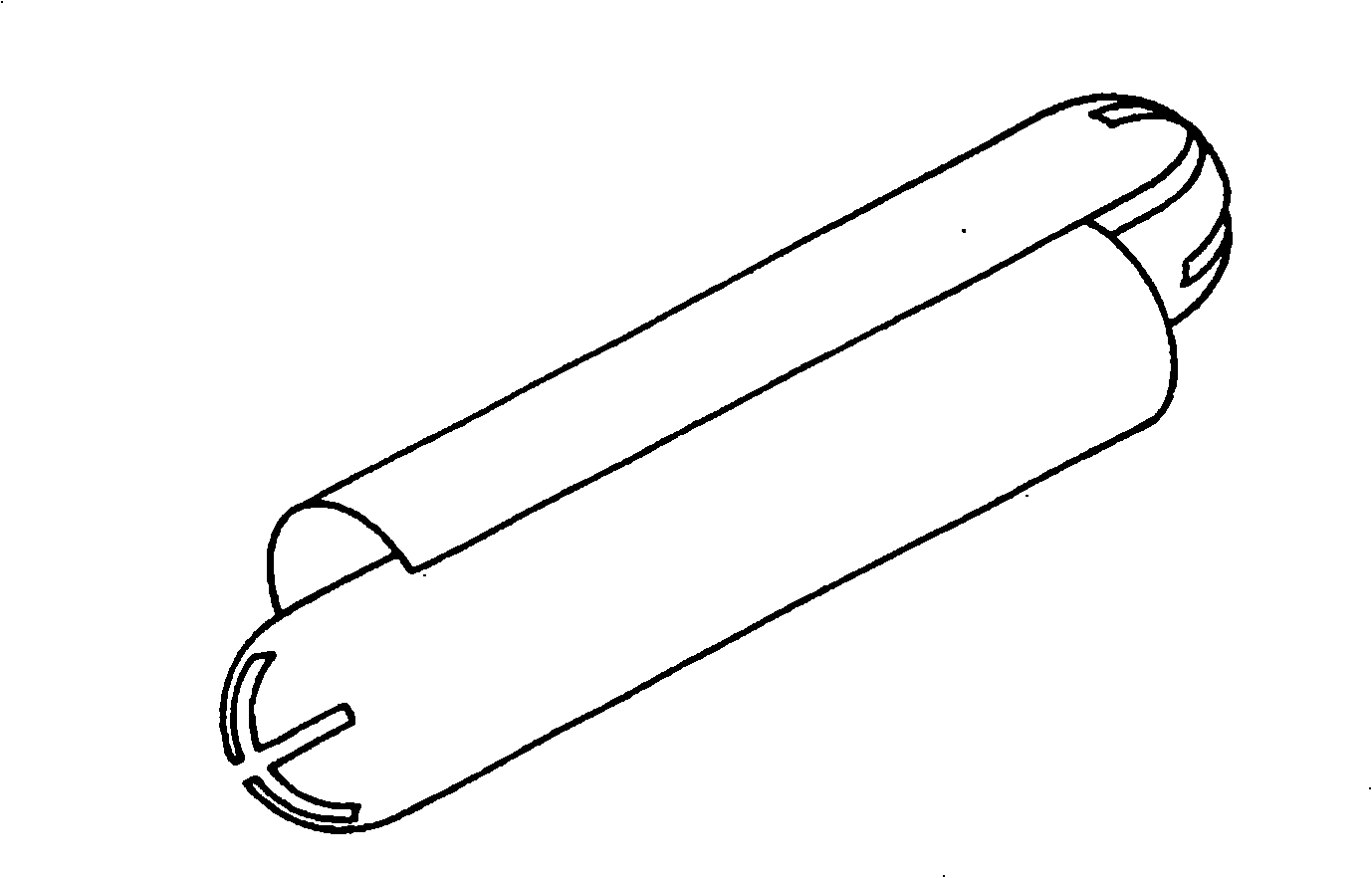

Dragline rope ferrule

ActiveUS20130047572A1High strengthEasy to buckleBinding endsMechanical machines/dredgersEngineeringFerrule

A method is disclosed for attaching a ferrule to a dragline rope. The method comprises locating the dragline rope in a die of a die-press, locating over the dragline rope a ferrule that is lined internally with a deformable material, and forcing the ferrule longitudinally through the die. The ferrule is caused to be internally expanded and be extruded back over the dragline rope, causing the lining to deform directly against the dragline rope and fastening the ferrule to the dragline rope.

Owner:BEKAERT WIRE ROPES

Cable manufacturing method

A method of manufacturing a cable assembly using stranded cable material. A manufacturing jacket is placed over the cable to hold the strands in a desired state. A length of jacketed cable is then cut to a desired length. Appropriate terminations are slipped over the manufacturing jacket on the cable's first end, its second end, or at some intermediate point. For a typical type of termination, a short portion of the manufacturing jacket is stripped away at the point of termination to expose the strands. After the terminations are placed in the appropriate position, potting compound or other mechanical means are typically applied to lock the terminations to the exposed lengths of strands. A completed cable assembly is thus created. However, the presence of the manufacturing jacket, while highly desirable for manufacturing, is often undesirable for end use. All of the manufacturing jacket, or in some instances a substantial portion thereof, is therefore removed, using a variety of disclosed methods, to form an unjacketed cable. A variety of techniques are disclosed for carrying out these steps, including the use of modified terminations and modified jackets. The finished product may have no jacket at all, a partial jacket, or a jacket which is different from the one used in the manufacturing process.

Owner:BRIGHT TECH CO LTD

Hot cutting machine for cutting automobile wire harness braided wire

InactiveCN103122572AReduce scrap rateReduce investmentBinding endsSevering textilesStructural engineeringMechanical engineering

The invention discloses a hot cutting machine for cutting an automobile wire harness braided wire in a mechanical cutting equipment field. The hot cutting machine for cutting the automobile wire harness braided wire comprises a baseplate which is arranged horizontally and a vertical plate vertically arranged on one lateral side of the baseplate, a fixed lower cutter with an upward cutter point is fixedly arranged on the surface of the baseplate, a cylinder fixed plate is horizontally fixed at the top end of the vertical plate, an adjustable cylinder is vertically arranged above the cylinder fixed plate, and the adjustable cylinder penetrates through the cylinder fixed plate. A piston rod at the front end of the adjustable cylinder is fixedly connected with a fixed support, a cutter seat is fixedly connected at the lower end of the fixed support, and a flexible upper cutter with a downward cutter point is arranged inside the cutter seat. A sharp cutting mouth is formed by matching the flexible upper cutter with the fixed lower cutter, the hot cutting machine is used for cutting the automobile wire harness braided wire, the braided wire can be melted in the process of heating and cutting, scattered phenomenon of a textile wire does not occur, and meanwhile the cutting mouth is intact and smooth after cutting. The hot cutting machine for cutting the automobile wire harness braided wire is capable of improving working efficiency, reducing rejection rate of wire harness, and is convenient to popularize greatly.

Owner:DONGGUAN HENGXIN PRECISION MACHINERY

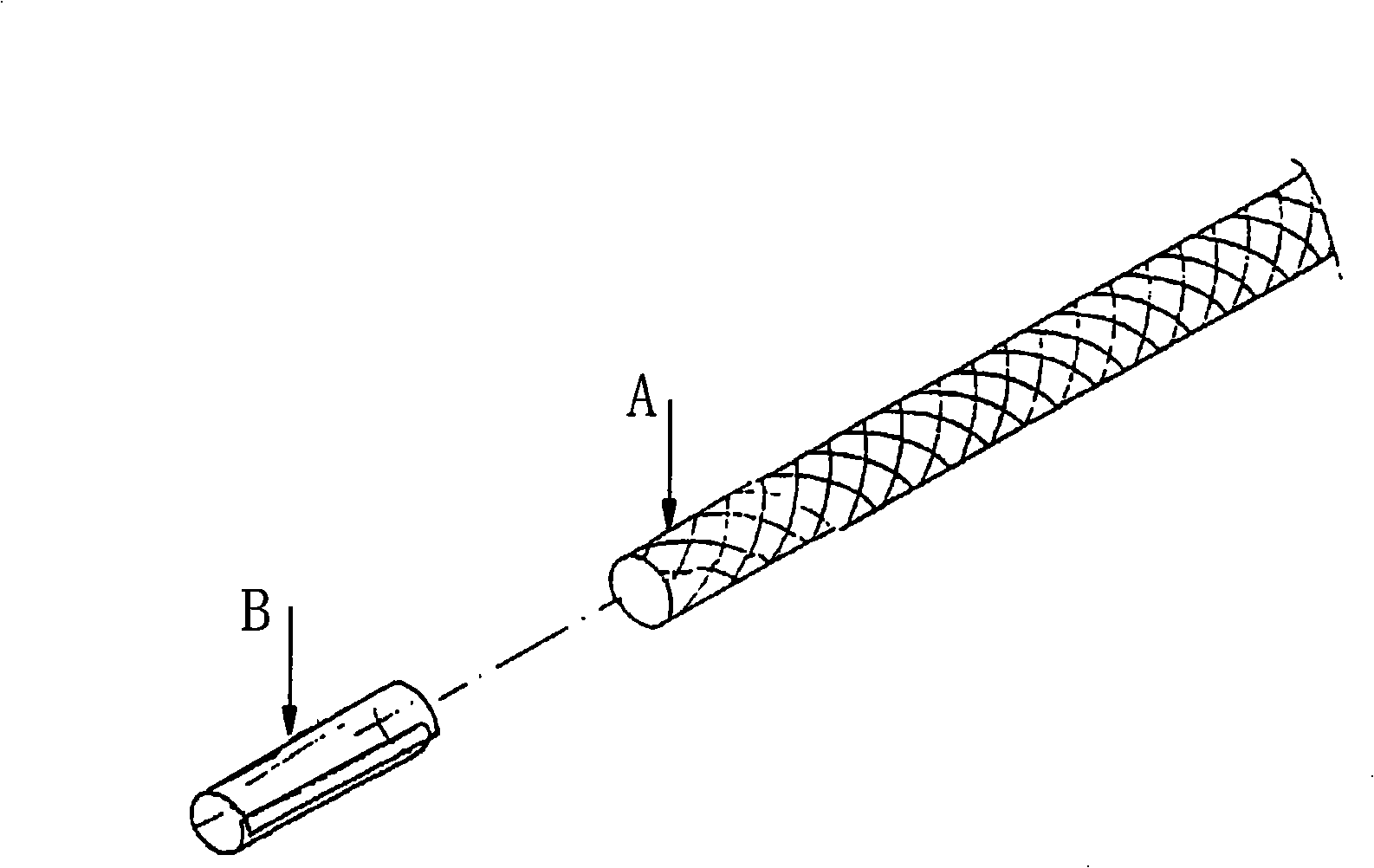

Metal filament body connecting method and connecting device

InactiveCN103917310AFirmly connectedReduce weightBinding endsFilament handlingMetal filamentMechanical engineering

Provided is a metal filament body connecting method that achieves easy connection work and a metal filament body connecting device that is lightweight and has excellent portability. A metal filament body connecting device is used for connecting opposite metal filament bodies (20) to each other. A pair of securing parts (1) for securing the opposite metal filament bodies (20), and a rotation body (2) provided with a notch (2A) between the pair of securing parts (1) at an appropriate distance therefrom are provided, both ends of metal filament body parallel parts (20A) formed by disposing the opposite metal filament bodies (20) side by side are secured by the pair of securing parts (1), approximately central sections of the metal filament body parallel parts (20A) are disposed in the notch (2A) of the rotation body (2), and thereafter the opposite metal filament bodies (20); are twisted by rotating the rotation body (2). The pair of securing parts (1) are respectively provided with notches (1A) and pressing members (1B), both the ends of the metal filament body parallel parts (20A) are disposed in the notches (1A), respectively, and secured by pressing both the ends by the pressing members (1B).

Owner:BRIDGESTONE CORP

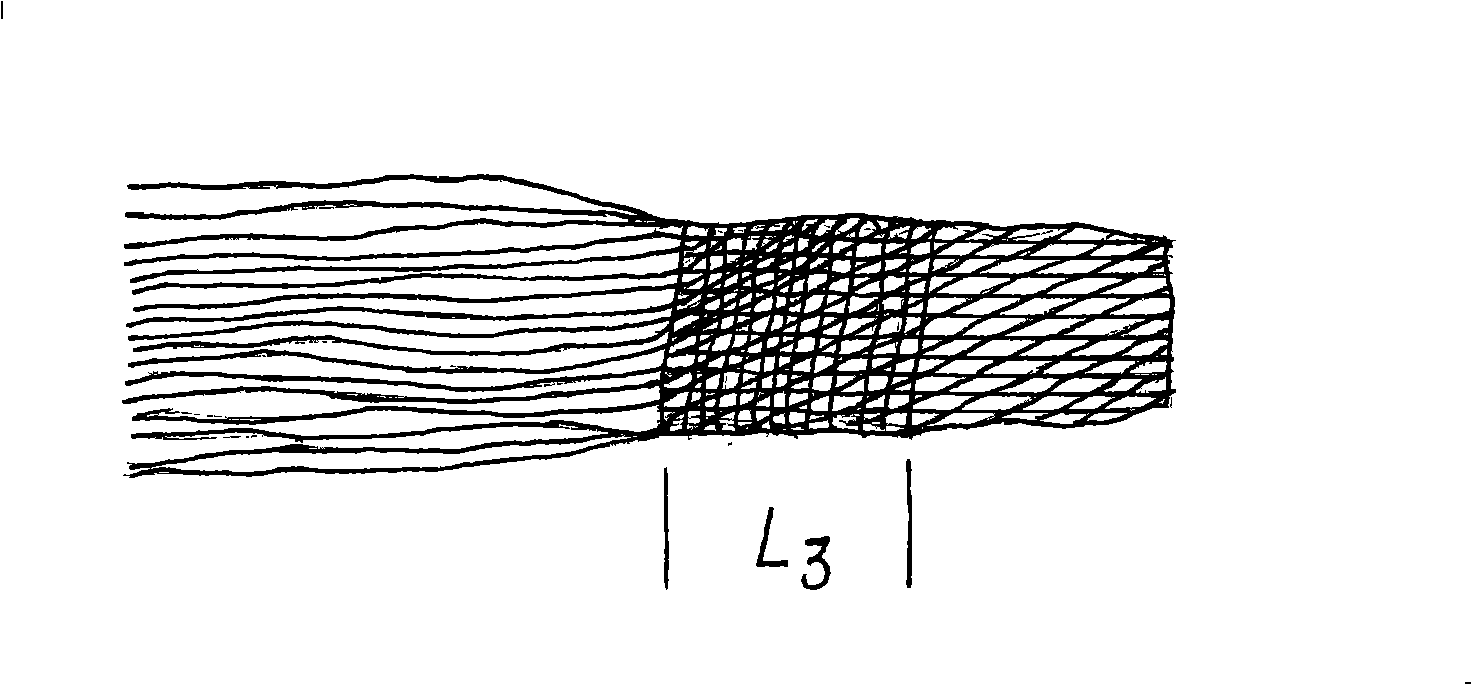

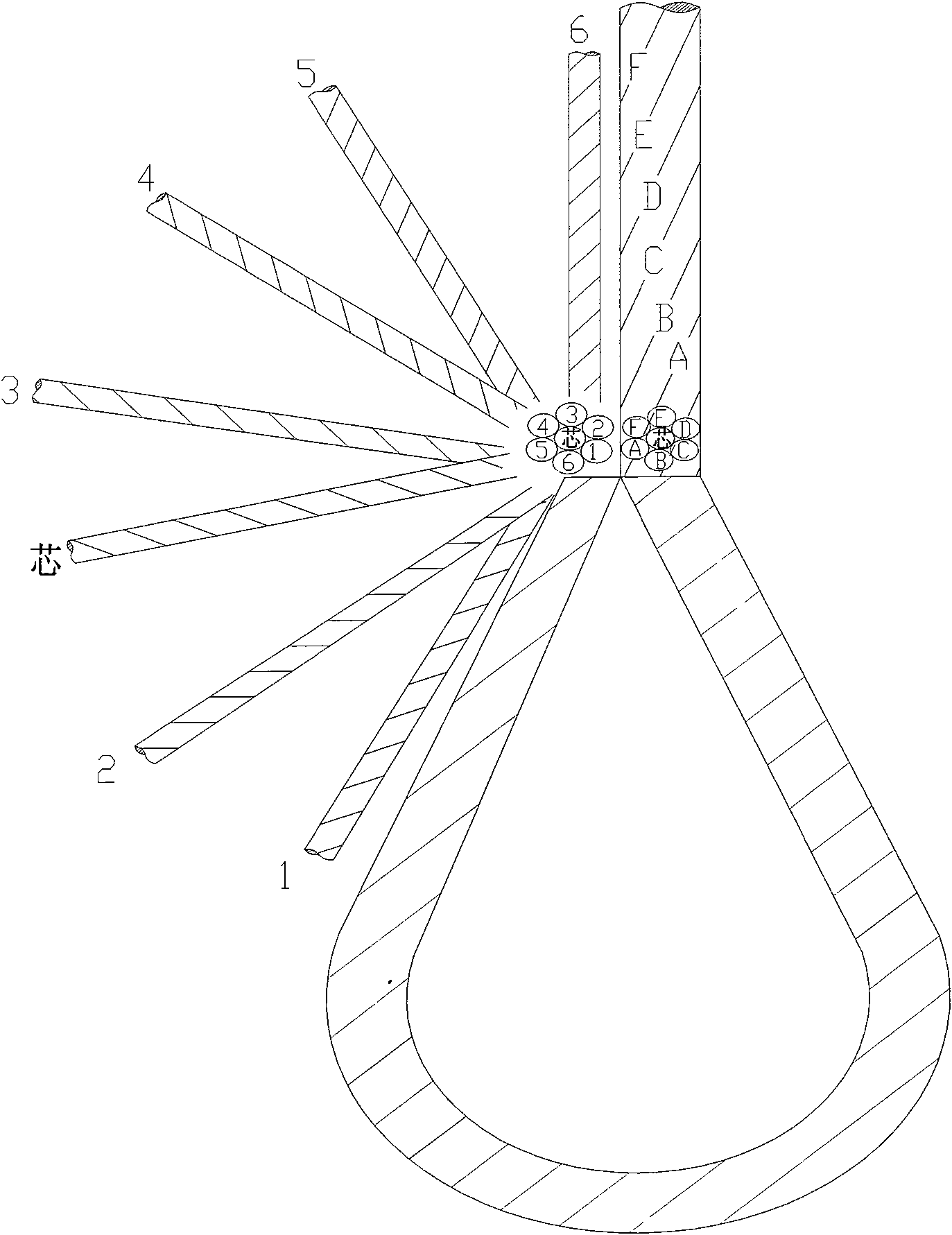

Method for splicing high-bearing-capacity steel cable

InactiveCN101565905AEasy to masterInsert method is simpleBinding endsLoad-engaging elementsMaterials scienceSteel rope

The invention provides a method for splicing a high-bearing-capacity steel cable and relates to the field of hoisting equipment. The prior splicing method can only splice small-diameter steel ropes, thereby limiting the diameter and bearing capacity of the steel ropes and failing to meet the requirements for splicing big-diameter and high-bearing-capacity steel cables. To overcome the drawback, the invention provides a method for splicing a cored big-diameter and high-bearing-capacity steel cable formed by six strands of steel ropes. The method comprises the following steps: firstly, numbering the gaps between the strands of steel ropes; secondly, splicing according to the splicing sequence for the first group in a table 1; and finally, splicing a second group and the following groups according to a table 2 till the splicing needles are met. The method has the advantages of suitability for splicing cored big-diameter steel cable, simplicity, and easy control by workers.

Owner:JULI SLING

Metal rope helmet machining process and matching die

The invention discloses a metal rope with a headgear processing technique, comprising the following steps that: 1. a cylindrical metal headgear is processed by the conventional technique, one end of the metal headgear is semiglobular, the other end has a circular opening, the semiglobular position is provided with a plurality of joint marks, a lateral edge is provided with a lateral joint mark which is connected and communicated with the two ends of the metal headgear; 2. a film type rope belt head is machined on a rope belt by adopting the conventional technique; 3. the film type rope belt head on the rope belt is inserted into the circular opening at one end of the metal headgear, the film type rope belt head and the metal headgear are inserted into a jointed synthesized matched die, a press machine is started, a plurality of punching thorns arranged on the die are stung into the metal headgear and the film type rope belt head at the same time to form reversed thorns to ensure that the metal headgear and the film type rope belt head as well as the rope belt are combined firmly; 4. the die is reset, the film type rope belt head and the metal headgear are taken out. The invention also discloses a die matched with the processing technique. The processing technique is safe and efficiency and has low defect rate.

Owner:LONGJIN FUSHI SHANGHAI

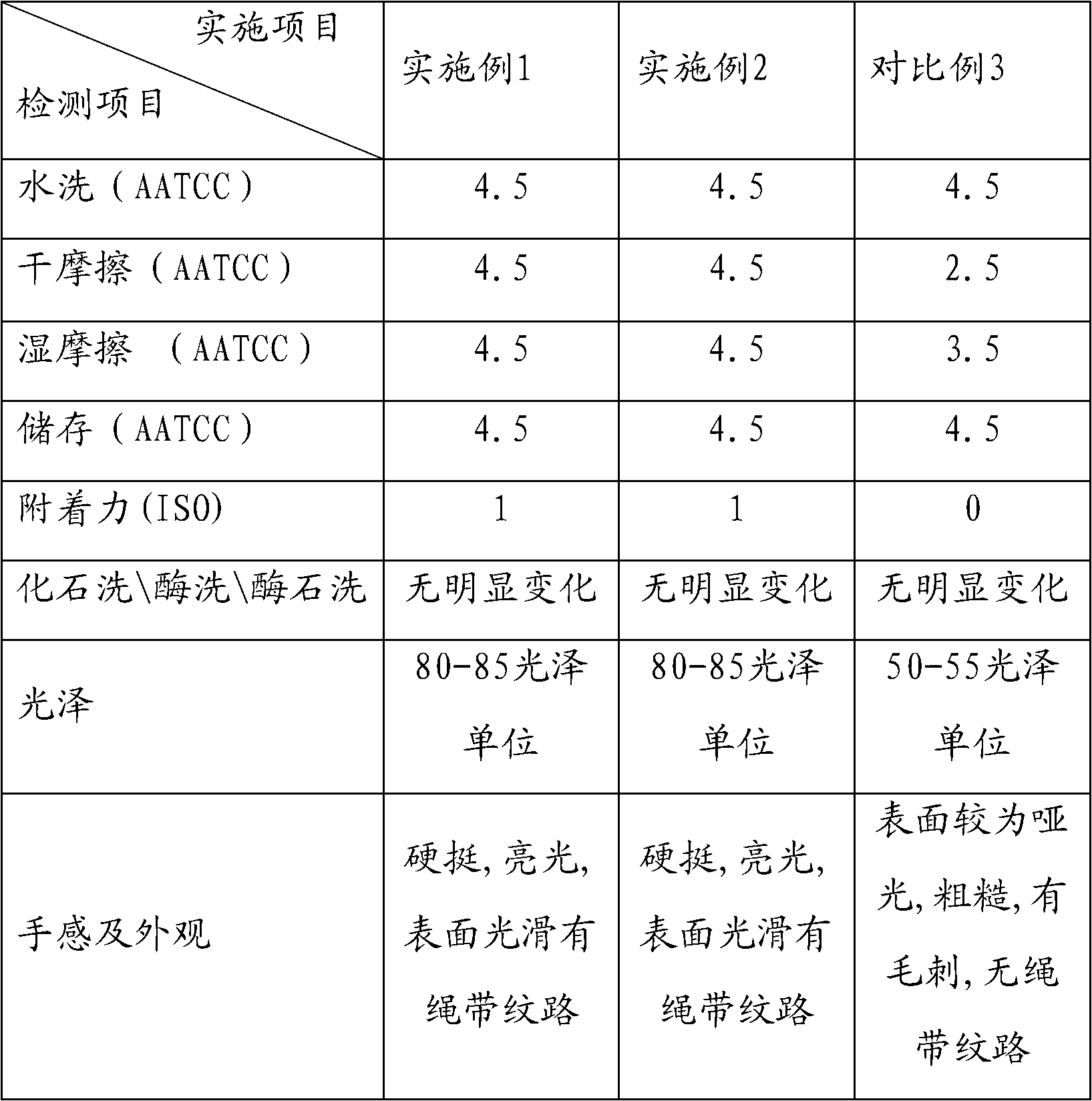

Bright hard wear-resistant inked rope tip and production process thereof

ActiveCN102851986ASimple operation processSimple production process implementationBinding endsFibre treatmentWear resistantEngineering

The invention discloses a bright hard wear-resistant inked rope tip. The inked rope tip is produced by the following method: a rope tip is soaked in setting size and solidified; the rope tip is soaked in ink, solidified and colored; finally, the rope tip is soaked in glossy varnish and solidified, and thereby the bright hard wear-resistant inked rope tip is obtained. The bright hard wear-resistant inked rope tip produced by the invention not only is as neat as ordinary rope tips made of plastic and metal, but also has the advantages that: the bright hard wear-resistant inked rope tip is highly glossy, the lines of a rope can be shown, and colors can be optionally matched.

Owner:广东康派环创科技有限公司

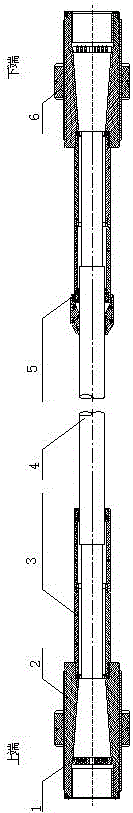

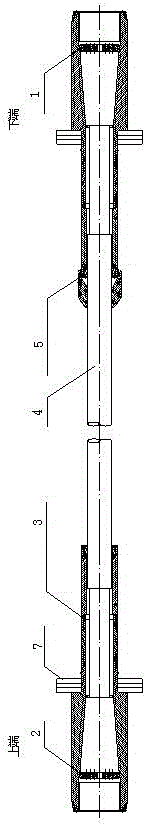

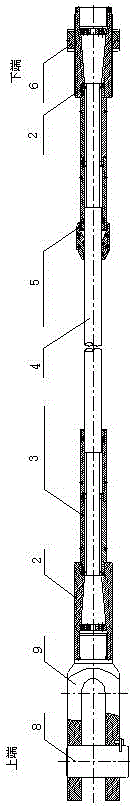

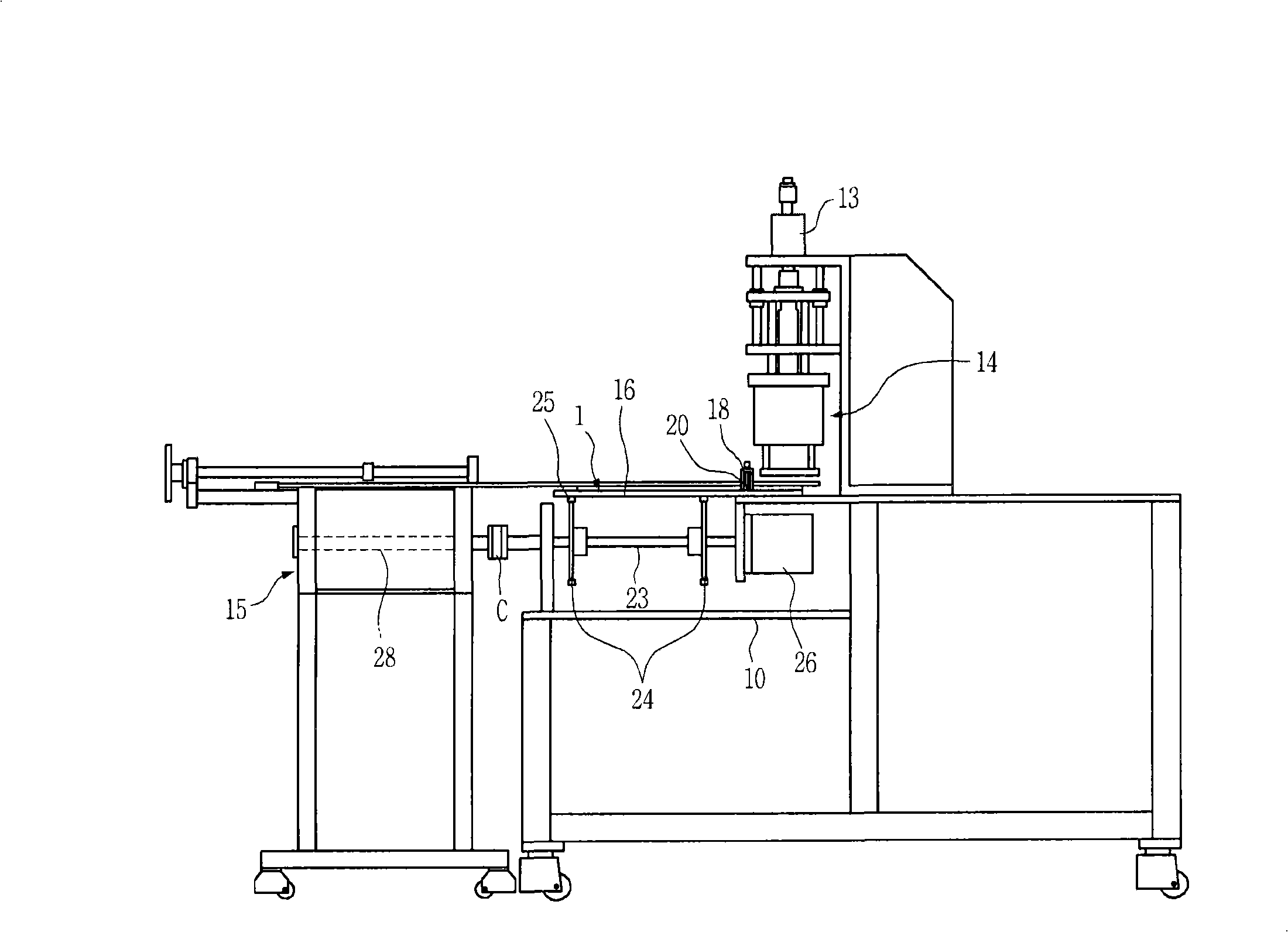

Apparatus and method for attaching a sleeve to a wire end

ActiveUS20170307492A1Easy to testManageable sizeBinding endsRopes and cables for vehicles/pulleyCouplingEngineering

Apparatus for attaching a sleeve comprising a coupling end to a steel wire. The apparatus comprises a pulling end arranged to connect to a sleeve to be attached to a steel wire, a pulling arrangement connected to the pulling end and being configured to pull a sleeve connected to the pulling end, a swaging arrangement comprising two opposed swaging rolls adapted to crimp the sleeve to a close press fit around a loose end of a steel wire. The apparatus further comprises a testing arrangement for testing the strain capacity of the attachment of a sleeve to a steel wire, the testing arrangement including a holding unit configured to effectively hold a portion of the steel wire fixed and allowing the pulling arrangement to pull the sleeve attached to a wire held fixed in the holding unit in order to verify the attachment.

Owner:WIRETEKNIK AB

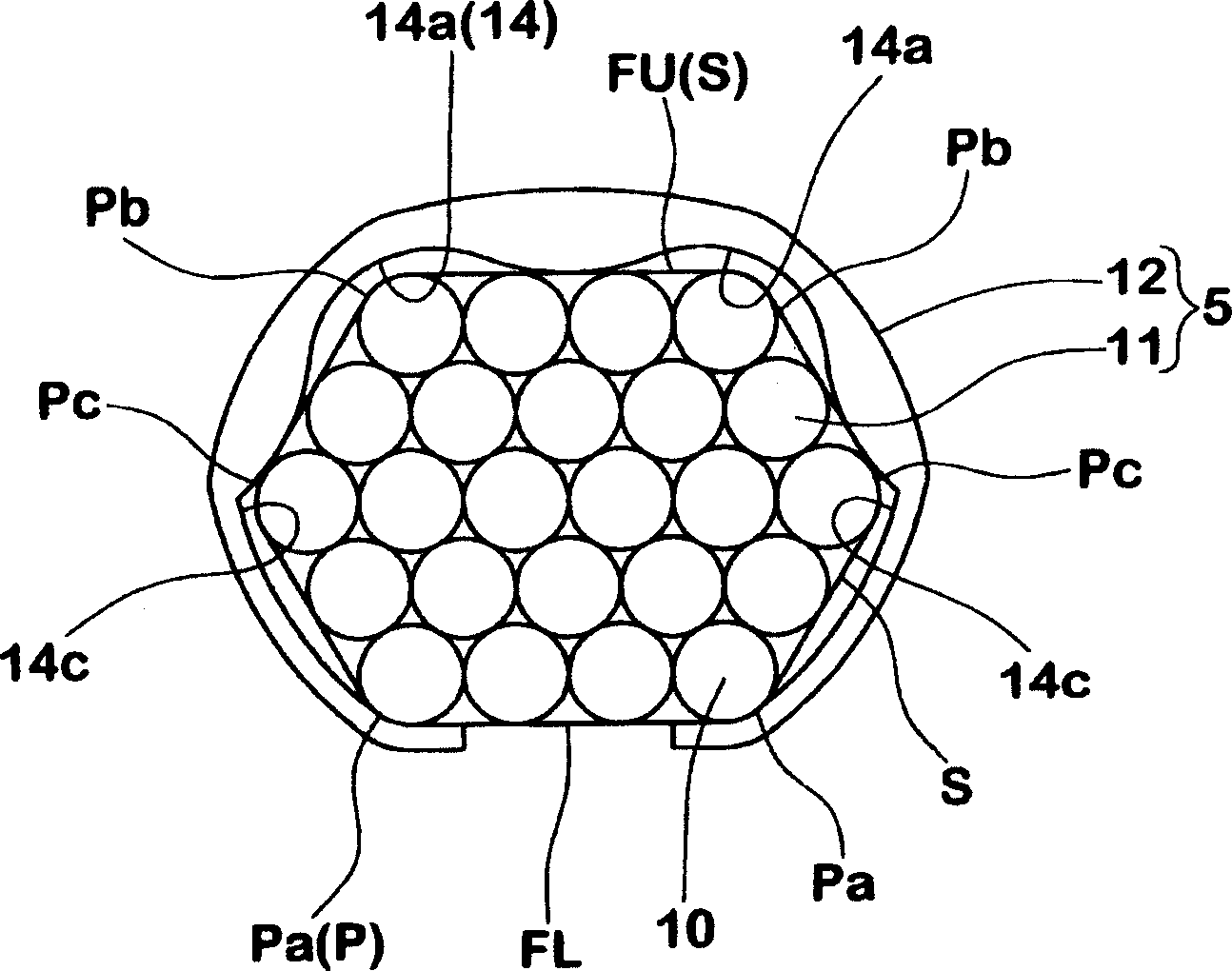

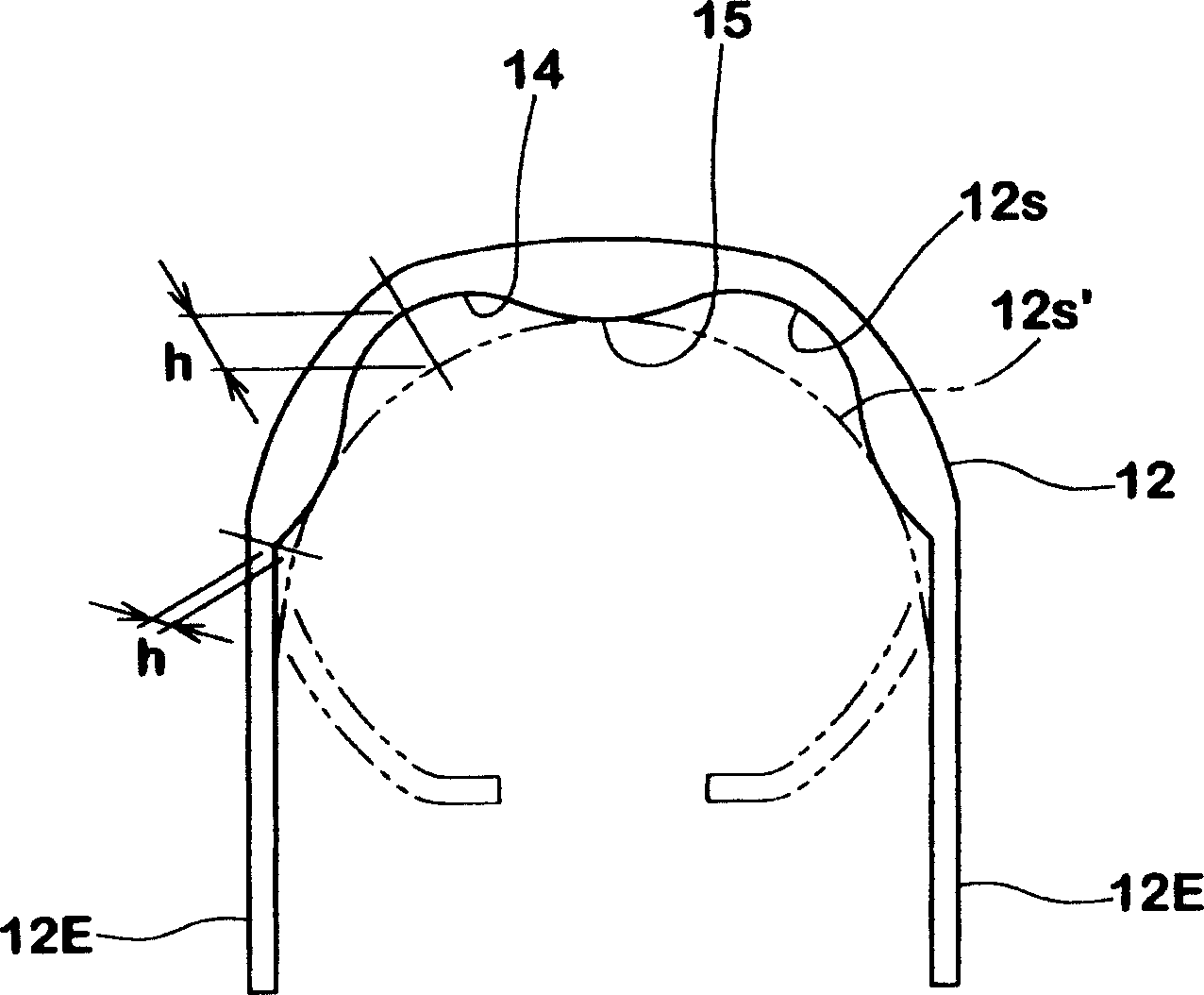

Bead core of pneumatic tire

PROBLEM TO BE SOLVED: To suppress positional displacement around a bead core of a staple metal fitting, and effectively suppressing damage on an inner liner rubber caused by this positional displacement.

Owner:SUMITOMO RUBBER IND LTD

Intelligent extruding stay rope based on filled type epoxy coating steel strand and manufacturing method

ActiveCN107740297ASolve the defect of insufficient sealingImprove sealingControlBinding endsEpoxyGrating

Provided is an intelligent extruding stay rope based on a filled type epoxy coating steel strand. One of side wires of the epoxy steel strand is a side wire with a groove, and optical fiber and an optical fiber grating sensor are implanted in the groove; the Bragg grating wavelength change of the intelligent side wire of the implanted epoxy steel strand is demodulated and analyzed by using an optical fiber grating demodulation device, and thus the stay rope force is measured; due to the fact that transmission of optical signals is not influenced by the environment, the optical fiber and the optical fiber grating sensor can stably and correctly monitor the stay rope force for a long time. An anchoring sleeve is of a single-inner-hole multi-inner-cone structure, the anchoring force is strengthened, on one hand, the epoxy layer of the filled type epoxy coating steel strand is not needed to be peeled, and on the other hand, the outer diameter of a whole anchor head is reduced. Inclinationis formed on the outer side surface of a sealing ring in a sealing cylinder, and the inclination is 10 degrees larger than the inner inclination of the sealing cylinder. The defects of multiple innerholes (the number of the holes is identical to that of the anchoring steel strands) and large machining difficulty of the anchoring sleeve of an existing extruding type stay rope are overcome, and thesingle-hole multi-inner-cone anchoring sleeve for the extruding stay rope based on the filled type epoxy coating steel strand is provided and is convenient to machine.

Owner:浙锚科技股份有限公司

Rigging and preparation method thereof

The invention relates to a rigging and a preparation method thereof, wherein the rigging comprises a rigging body. The rigging body comprises a carrier core and a sheath sleeved on the periphery of the carrier core. The carrier core comprises a plurality of single yarns disposed integrally, and each single yarn is made by packing or packing and twisting an ultrahigh molecular weight polyethylene film or strip. The technical solution provided by the invention replaces traditional UHMWPE fibers with the single yarns for the preparation of the rigging, and the rigging is high in strength utility ratio of UHMWPE film or strips, easy to process, low in cost and environmentally friendly without glue.

Owner:ZHENGZHOU ZHONGYUAN DEFENSE MATERIAL

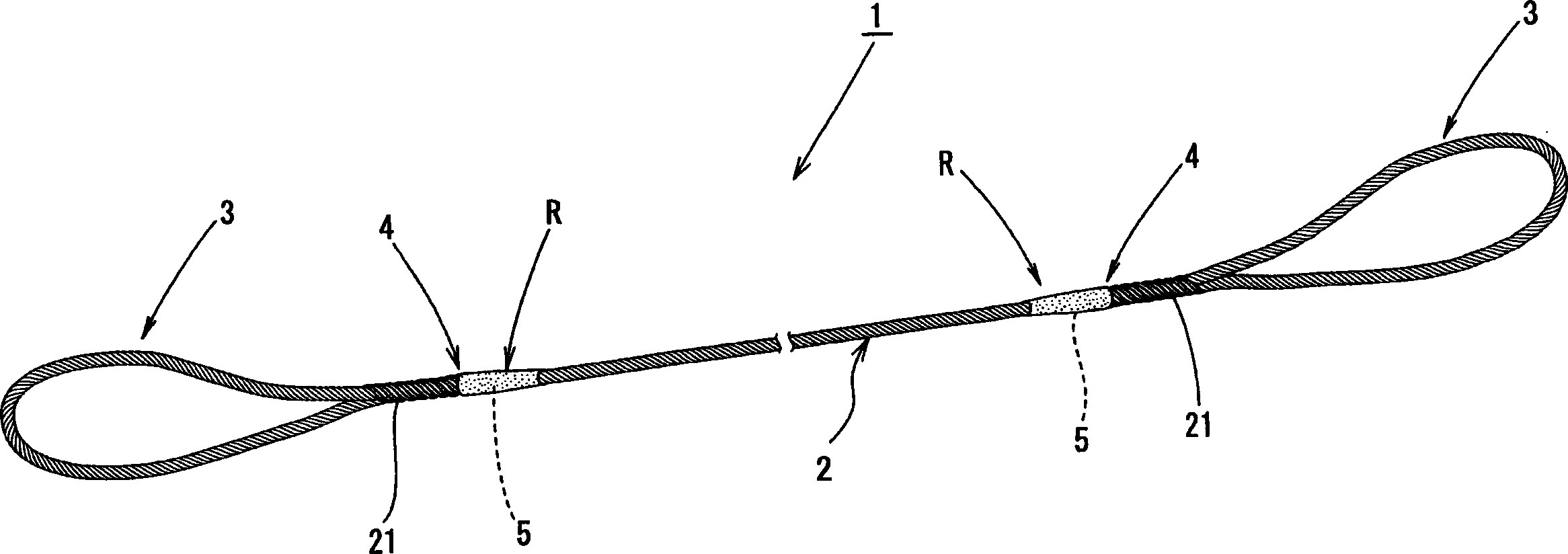

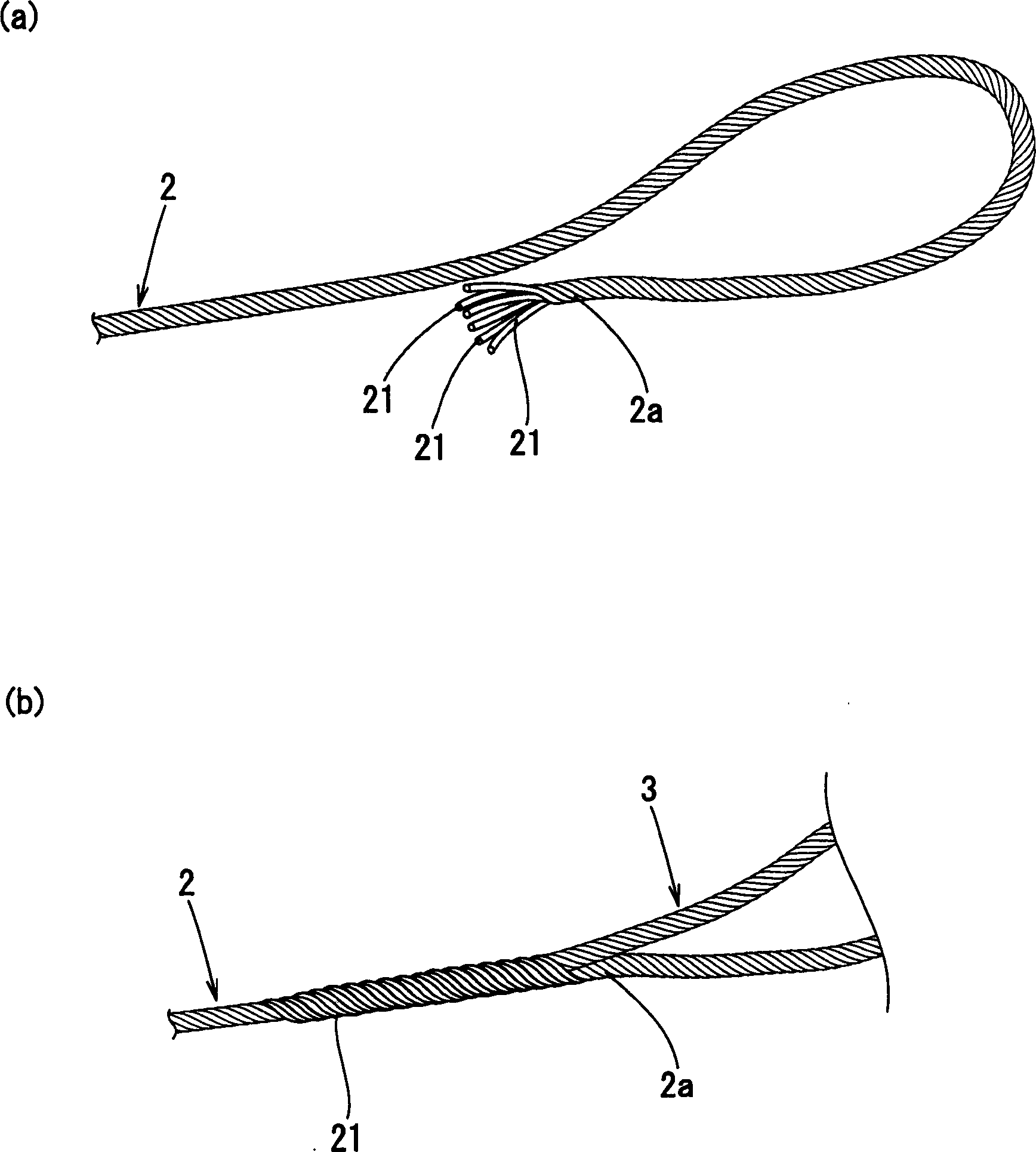

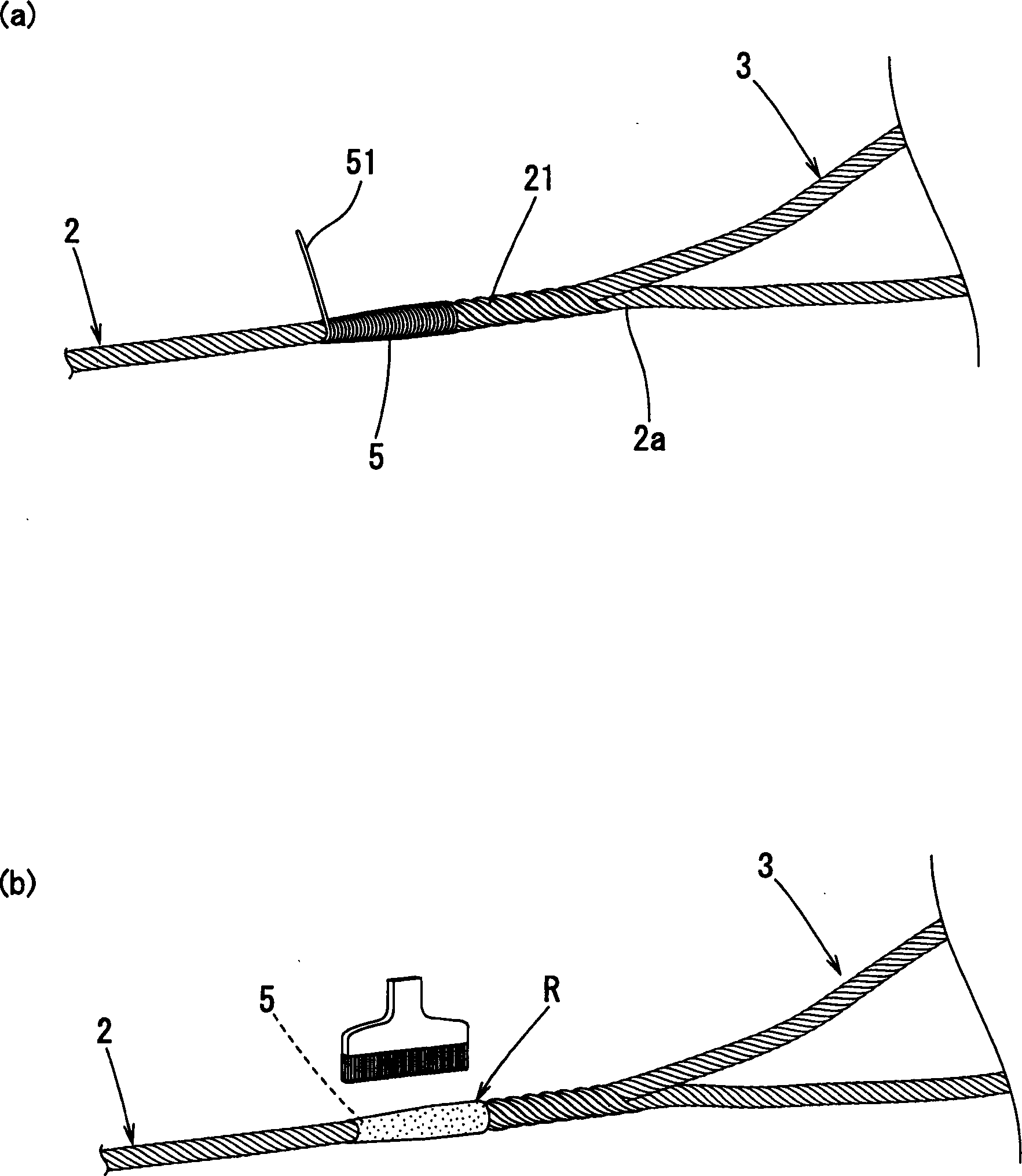

Rope End-Fastening Method, Rope with End Fastener, and End Fitting for Use in Rope End-Fastening Method

ActiveUS20170022661A1Reduce the overall diameterAvoid stress concentrationBinding endsRopes and cables for vehicles/pulleyEngineeringFastener

A rope terminal fixing method is provided, which may be used easily at a construction site, causes less shearing load, and may reliably prevent the falling-off of the rope.The rope terminal fixing method comprises the following steps. A tubular terminal metal fitting which comprises a proximal opening, a distal opening, and a through hole communicating the proximal and distal openings is prepared. A terminal of a rope is inserted through the proximal opening into the through hole, a portion of the terminal of the rope extended from the distal opening is loosened, and a diameter-enlarging member is fixed to a core wire of the rope. Then, the terminal of the rope is brought back into the through hole. A fixed width portion extending in an axial direction of the terminal metal fitting is pressed from the outside in a circumferential direction by swaging, such that a protrusion constraining the rope so as to reduce its diameter is formed in the through hole. The diameter-enlarging member cooperates with an end of the protrusion located on the distal opening side to constrain surrounding wires other than the core wire in a sandwiching manner. A rope with terminal fixing tools, which comprises the terminal fixing tools attached thereto by this method, is also provided.

Owner:TOKYO ROPE MFG +1

Light emitting diode module

ActiveUS8093615B2High luminous efficiencyBinding endsOrnamental textile articlesPhosphorFluorescence

A light emitting diode module having improved luminous efficiency is provided. The light emitting diode module includes: a light emitting chip; a phosphor layer formed of phosphor materials emitting light having a wavelength longer than the light emitted from the light emitting chip using light emitted from the light emitting chip as an excitation source; and a reflection plate that is disposed between the light emitting chip and the phosphor layer and that reflects the light emitted by the phosphor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Stranded cable wedge

InactiveUS20200002947A1Avoid damageBinding endsRopes and cables for vehicles/pulleyStructural engineeringElectric cables

A split wedge body, which has a curved inner surface, is formed gradually thicker from a tip portion to a terminal end portion thereof, and is made to cover the outer peripheral surface of a CFRP cable to thereby enclose the outer peripheral surface of the CFRP cable over a prescribed length thereof. A gap extending in the longitudinal direction is assured between end faces that oppose each other when a plurality of the split wedge bodies are arranged on the outer peripheral surface of the CFRP cable. The gap has an inclined portion that runs along a valley of the CFRP cable enclosed by the split wedge bodies.

Owner:TOKYO ROPE MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com