Rigging and preparation method thereof

A technology of rigging and bearing core, which is applied in the direction of textile cables, textiles and papermaking, and binding of ends. It can solve the problems of low strength utilization rate, high cost, and easy to generate burrs, etc., and achieve high strength utilization rate and easy processing. , The effect of no glue environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Such as image 3 As shown, the present embodiment provides a method for preparing a rigging, which at least includes the following steps:

[0065] Step S301: The ultra-high molecular weight polyethylene film or strip is bundled or bundled and twisted to obtain a single yarn.

[0066] Step S302: arranging a plurality of single yarns integrally to obtain a bearing core.

[0067] Step S303: thread the load-bearing core into the hollow sheath to make the sling body of the rigging; or, feed the load-bearing core during the process of weaving the sheath with the material for the sheath, so that the sheath is woven around the load-bearing core to make a rigging body. rigging body

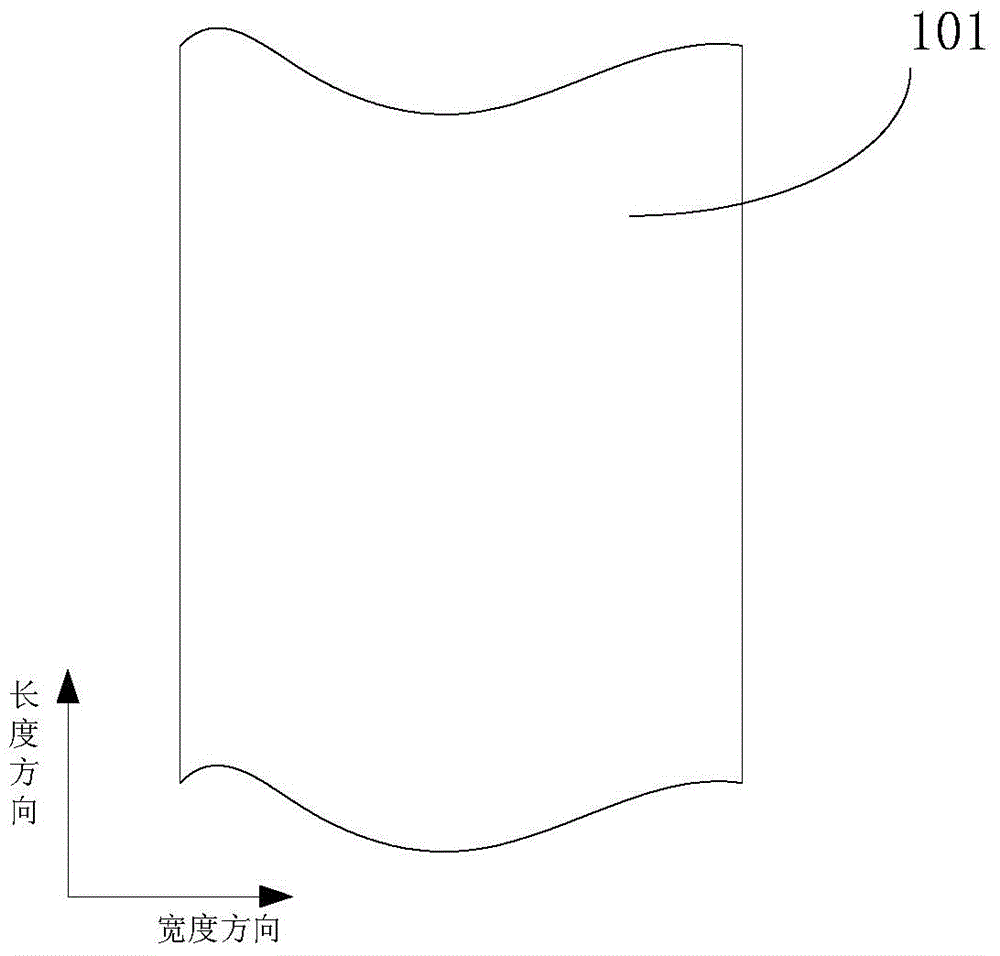

[0068] An optional structure of the single yarn in step S301 is shown as figure 2 As shown, the single yarn 201 can be made of UHMWPE film or tape. A better converging process of ultra-high molecular weight polyethylene film or strip For example: put the ultra-high molecular weight polyethylene...

Embodiment 2

[0114] Different from the first embodiment above, in the technical solution provided by this embodiment, a polyurethane resin layer is also formed on the outer surface of the bearing core, and the preferred process steps are as follows: Figure 5 shown, including:

[0115] Step S501: The ultra-high molecular weight polyethylene film or strip is bundled or bundled and twisted to obtain a single yarn.

[0116] Step S502: arranging a plurality of single yarns integrally to obtain a bearing core.

[0117] Step S503: Put the bearing core into the water-based polyurethane resin emulsion, so that the outer surface of the bearing core is soaked in the water-based polyurethane resin emulsion.

[0118] Step S504: drying and shaping the bearing core soaked with the water-based polyurethane resin emulsion, so as to form a polyurethane resin layer on the outer surface of the bearing core.

[0119] Step S505: thread the load-bearing core into the hollow sheath to make the rigging body of ...

Embodiment 3

[0122] This embodiment provides a rigging, the bearing core is 8 braided ropes, and the preparation method is as follows:

[0123] The ultra-high molecular weight polyethylene strips with a linear density of 300 denier, a width of 3 mm, a thickness of 0.02 mm, a breaking strength of 28 g / d, a tensile modulus of 1700 g / d, and an elongation at break of 1.9% are bundled to obtain a single yarn . 53 single yarns are bundled together to obtain a yarn strand. The 8 strands of yarn are braided by a braiding machine, wherein part of the axis of the braider rotates along the S direction to twist the 4 strands of yarn along the S direction (the twist is 15 per meter), and part of the axis of the braider rotates along the Z direction Twist the remaining 4 yarn strands along the Z direction (the twist is 15 pieces / meter), and the twisted yarn strands of each strand are interspersed with each other and interweaved as a whole, thus braiding and making the bearing core. The diameter of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com