Manufacturing method of high-strength ultrahigh molecular weight polyethylene fiber rope

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of fiber ropes, can solve the problems of rough control of tension, unusable single-braided ropes, and inability to control the tension uniformly, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

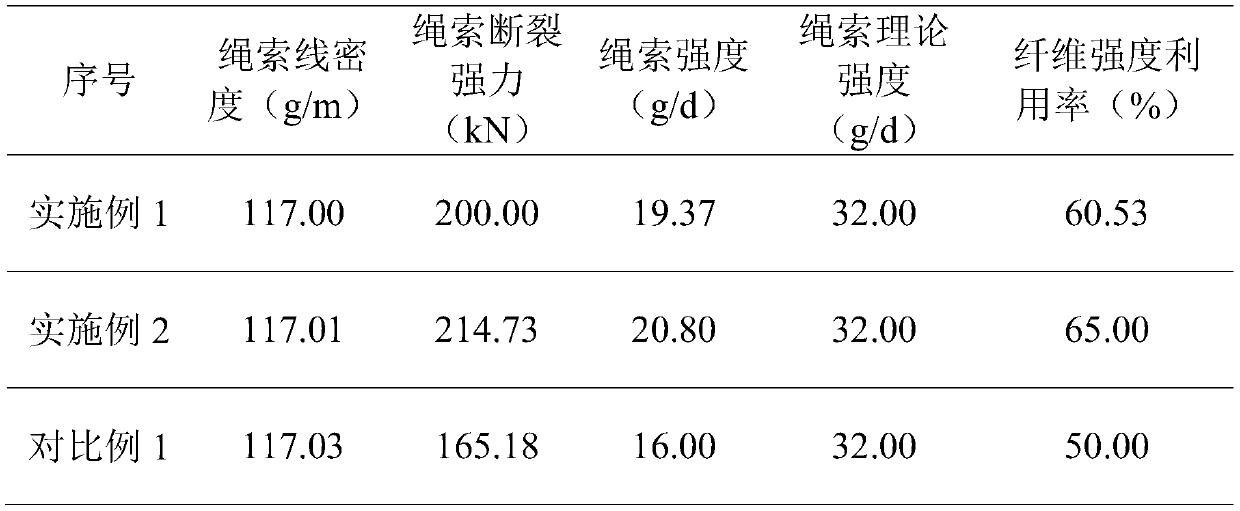

Embodiment 1

[0039] The manufacturing method of the high-strength ultra-high molecular weight polyethylene fiber rope disclosed in embodiment 1 includes:

[0040] Select a number of ultra-high molecular weight polyethylene fibers with a specification of 1600D and a strength of 32g / d for initial twisting, and perform 9 ring twists on a 250-type ring twister to form a rope yarn, and apply 0.054g to each ultra-high molecular weight polyethylene fiber / tex tension;

[0041] The ultra-high molecular weight polyethylene rope yarn is re-twisted, and 5 strands are re-twisted on a 722-type ring twister to form a rope strand, and each ultra-high molecular weight polyethylene rope yarn is applied with a tension of 0.170g / tex;

[0042] The ultra-high molecular weight polyethylene double-twist strands are braided into a rope, and the model is 320-12 single-knitting machine for braiding to make twelve strands of ultra-high molecular weight polyethylene single-braided rope. A tension of 0.310g / tex is ap...

Embodiment 2

[0045] The manufacturing method of the high-strength ultra-high molecular weight polyethylene fiber rope disclosed in embodiment 2 includes:

[0046] Select a number of ultra-high molecular weight polyethylene fibers with a specification of 1600D and a strength of 32g / d for initial twisting, and perform 9 ring twists on a 250-type ring twister to form a rope yarn, and apply 0.054g to each ultra-high molecular weight polyethylene fiber / tex tension, and heat setting treatment at 60°C;

[0047] The ultra-high molecular weight polyethylene rope yarn is re-twisted, and 5 strands are re-twisted on a 722 type ring twister to make a rope strand, and each ultra-high molecular weight polyethylene rope yarn is applied with a tension force of 0.170g / tex, and Heat setting treatment at 60°C;

[0048] The ultra-high molecular weight polyethylene double-twist strands are braided into a rope, and the model is 320-12 single-knitting machine for braiding to make twelve strands of ultra-high mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com