Cast-in-place X-shaped tapered pile with threaded end and construction method of tapered pile

A construction method, the technology of conical piles, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of reducing bearing capacity, large settlement, etc., and achieve the effect of eliminating impact, reducing impact, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

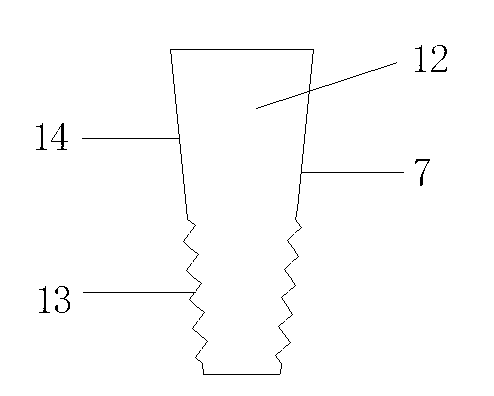

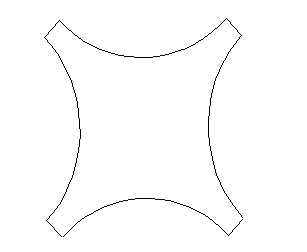

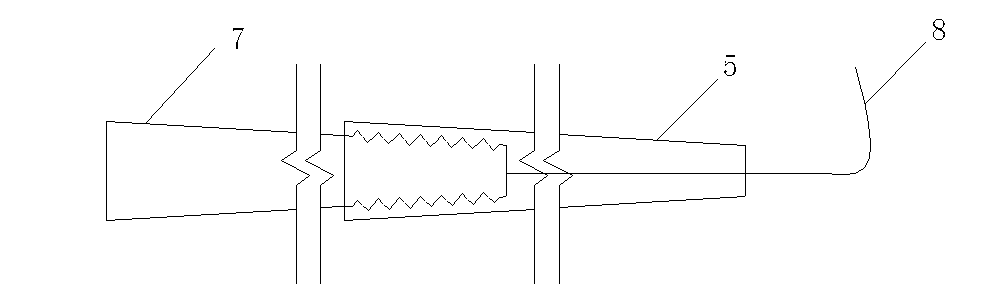

[0033] Such as figure 1 with figure 2 As shown, it is a cast-in-place X-shaped end threaded conical pile provided in Embodiment 1 of the present invention, which includes a plastic sleeve 7 and a pile body 12 filled in the cavity of the plastic sleeve 7 . The cross section of the pile body 12 is X-shaped. The cross-sectional area of the pile body 12 decreases gradually from top to bottom, and the pile body is vertically inverted tapered. The lower end of the pipe wall of the plastic sleeve 7 is a threaded pipe wall 13, and the rest of the pipe wall of the plastic sleeve 7 is a smooth pipe wall 14, so the pile body 12 also has a corresponding thread structure. The boundary position of the threaded pipe wall 13 and the smooth pipe wall 14 is mainly determined according to the boundary position of the negative friction resistance and the positive friction resistance of the pile body.

[0034] Such as Figure 3 to Figure 7 As shown, the embodiment of the present invention a...

Embodiment 2

[0044] Such as Figure 8 As shown, this embodiment is roughly the same as the cast-in-place X-shaped end threaded conical pile in Embodiment 1, the difference is that the lower end of the pipe wall of the plastic casing in this embodiment is a threaded pipe wall 15, The upper end is also a threaded pipe wall 16, and the middle is a smooth pipe wall 17. Preferably, the threaded pipe wall 15, the threaded pipe wall 16 and the smooth pipe wall 17 each account for one-third of the height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com