Patents

Literature

88 results about "Hardpan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In soil science, agriculture and gardening, hardpan or soil pan is a dense layer of soil, usually found below the uppermost topsoil layer. There are different types of hardpan, all sharing the general characteristic of being a distinct soil layer that is largely impervious to water. Some hardpans are formed by deposits in the soil that fuse and bind the soil particles. These deposits can range from dissolved silica to matrices formed from iron oxides and calcium carbonate. Others are man-made, such as hardpan formed by compaction from repeated plowing, particularly with moldboard plows, or by heavy traffic or pollution.

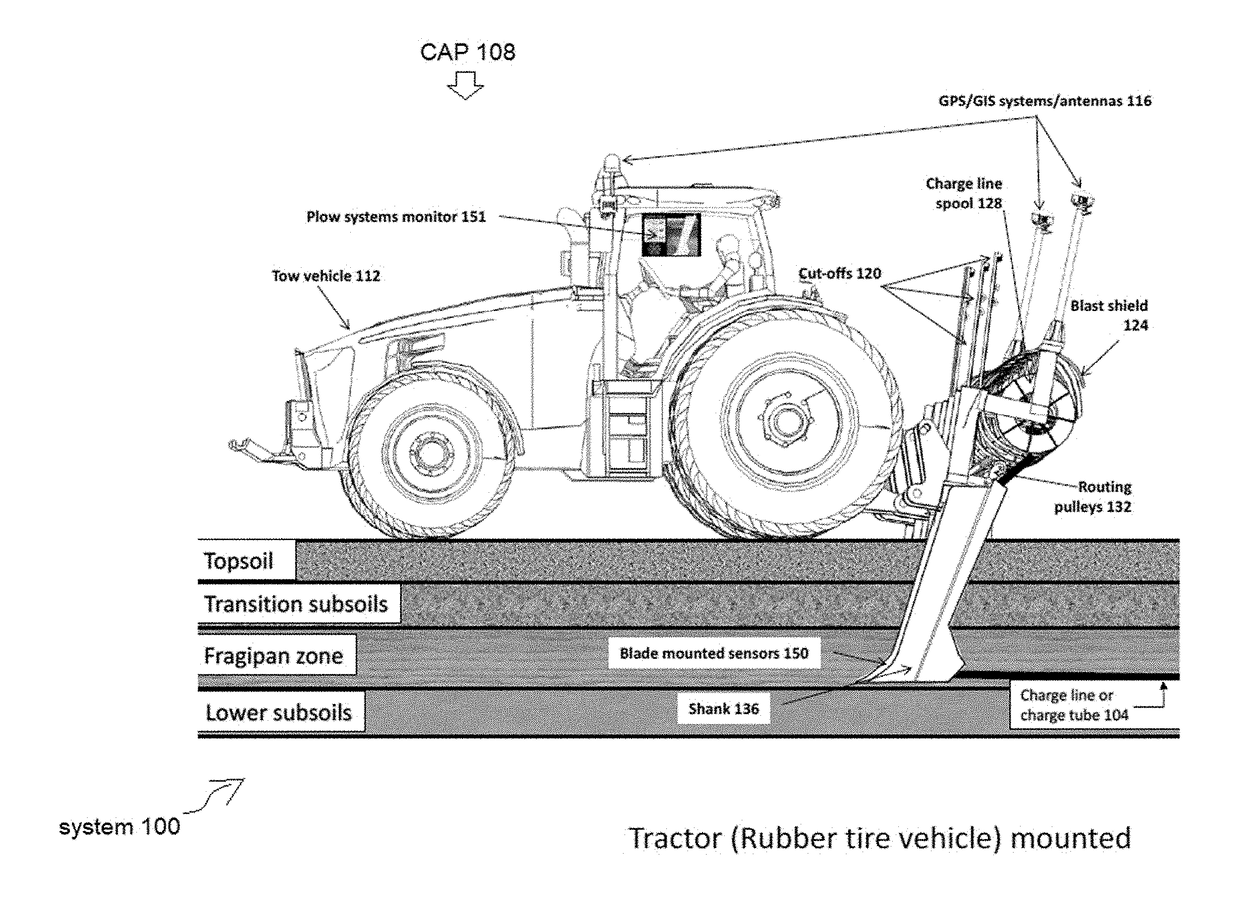

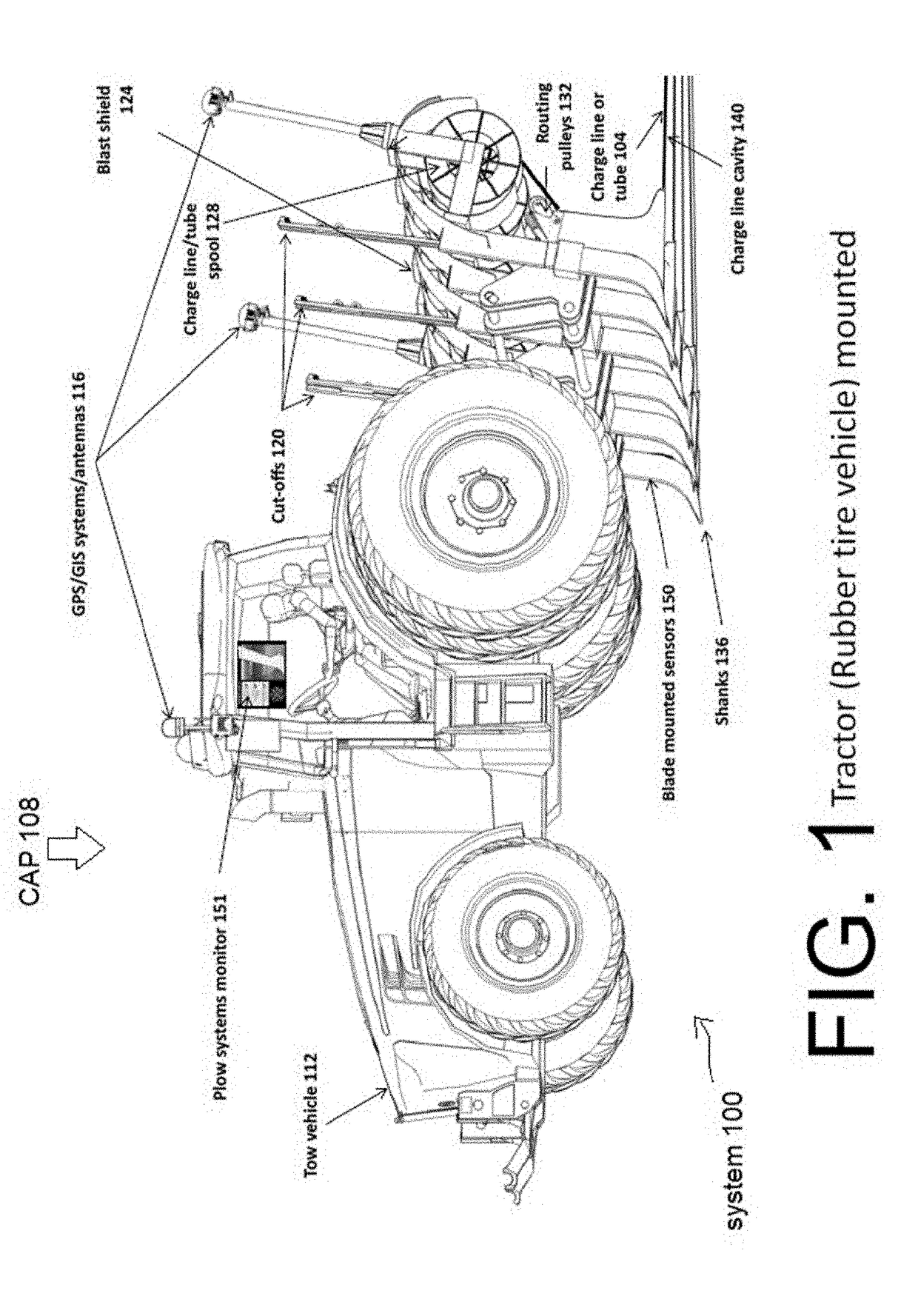

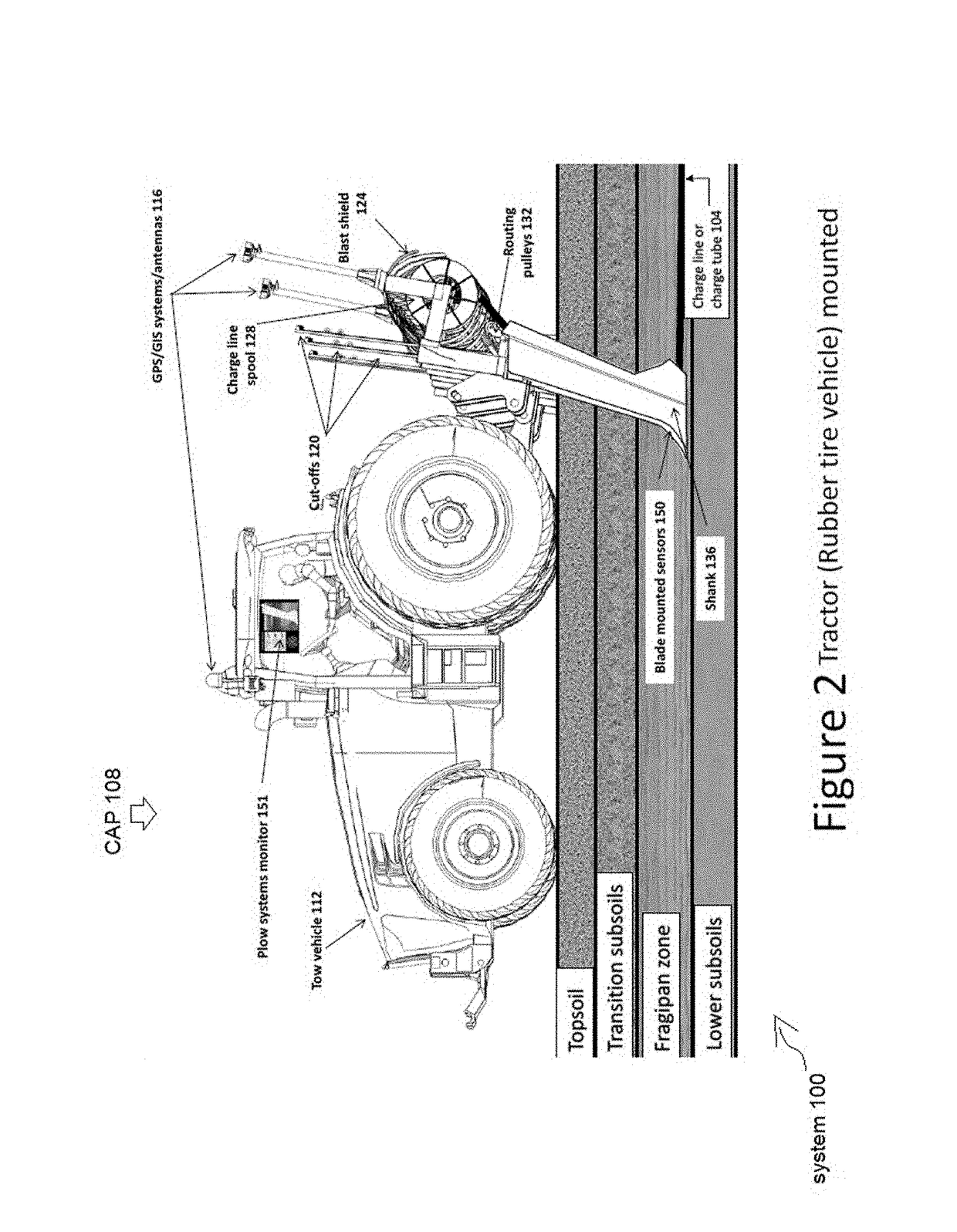

Agriculture System and Method

An agricultural enhancement method for removing or overcoming soil fragipan, hardpan, or other natural and / or artificial soil compaction barriers is disclosed. These barriers prevent root and / or water penetration, which inhibits agricultural development. Consequently, removing and overcoming these barriers is beneficial to the soil and to agricultural yields.

Owner:OLIVER TROY

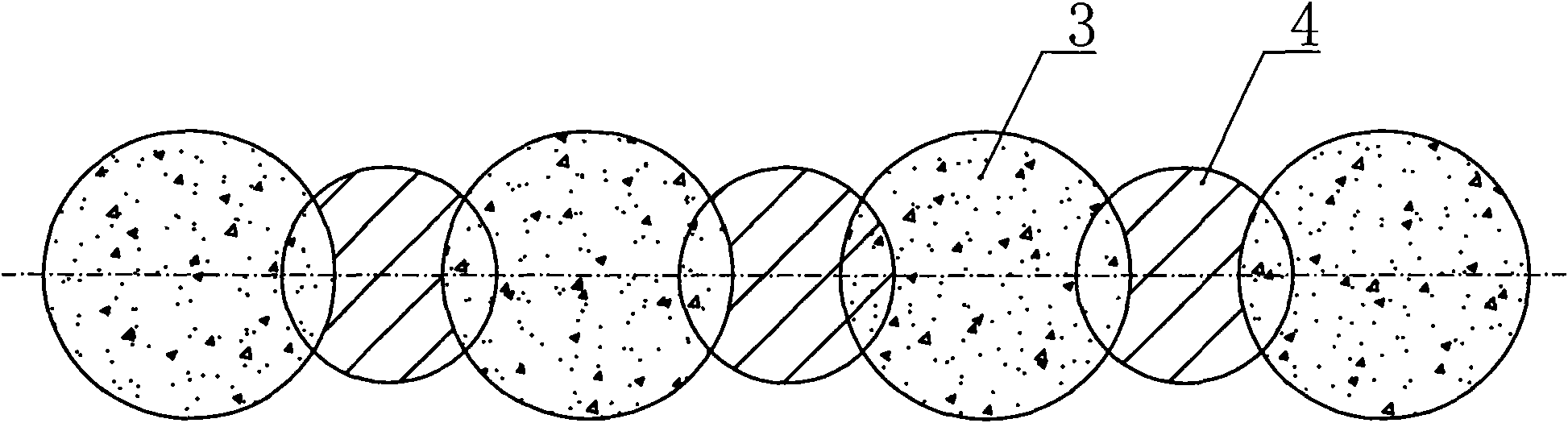

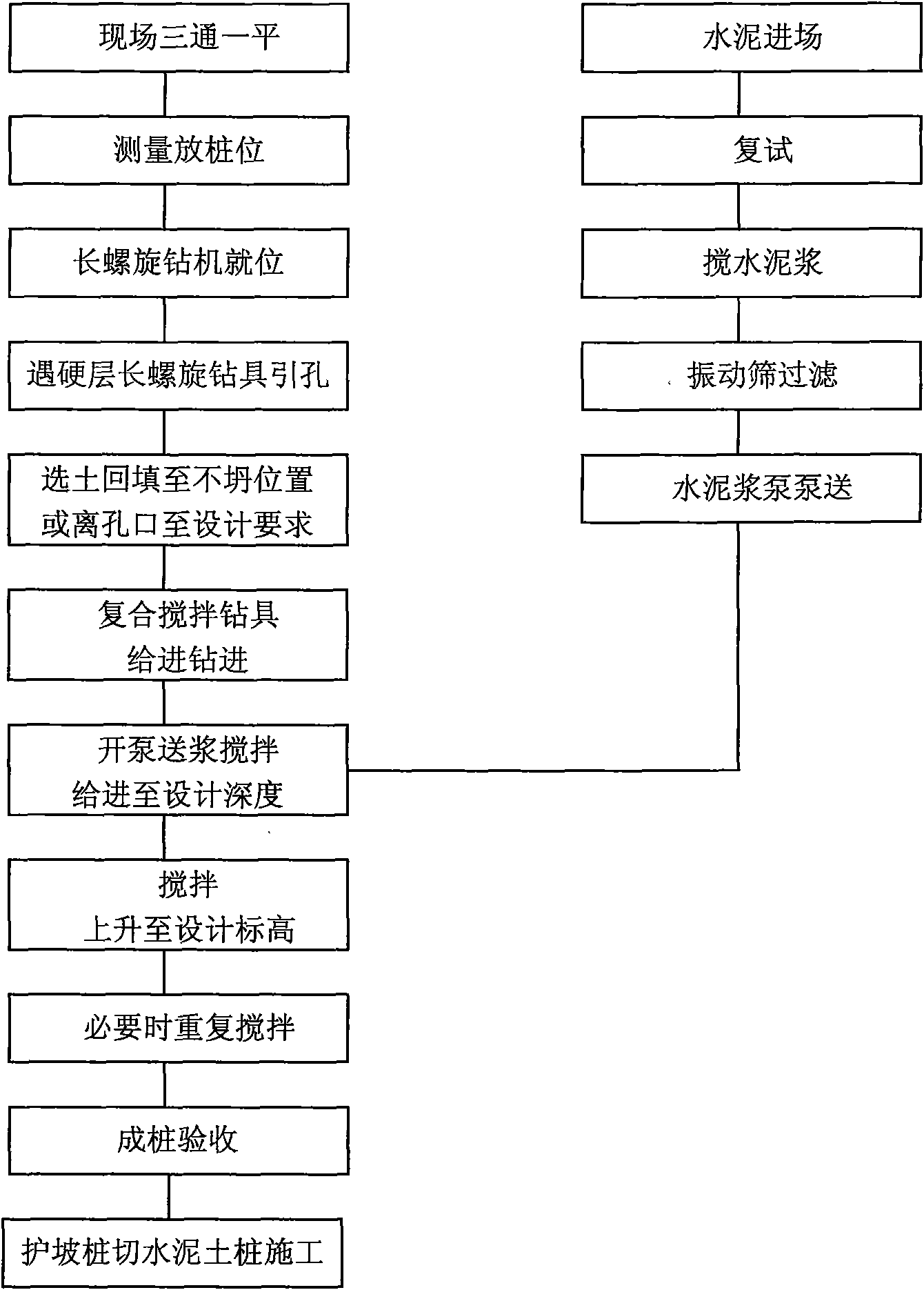

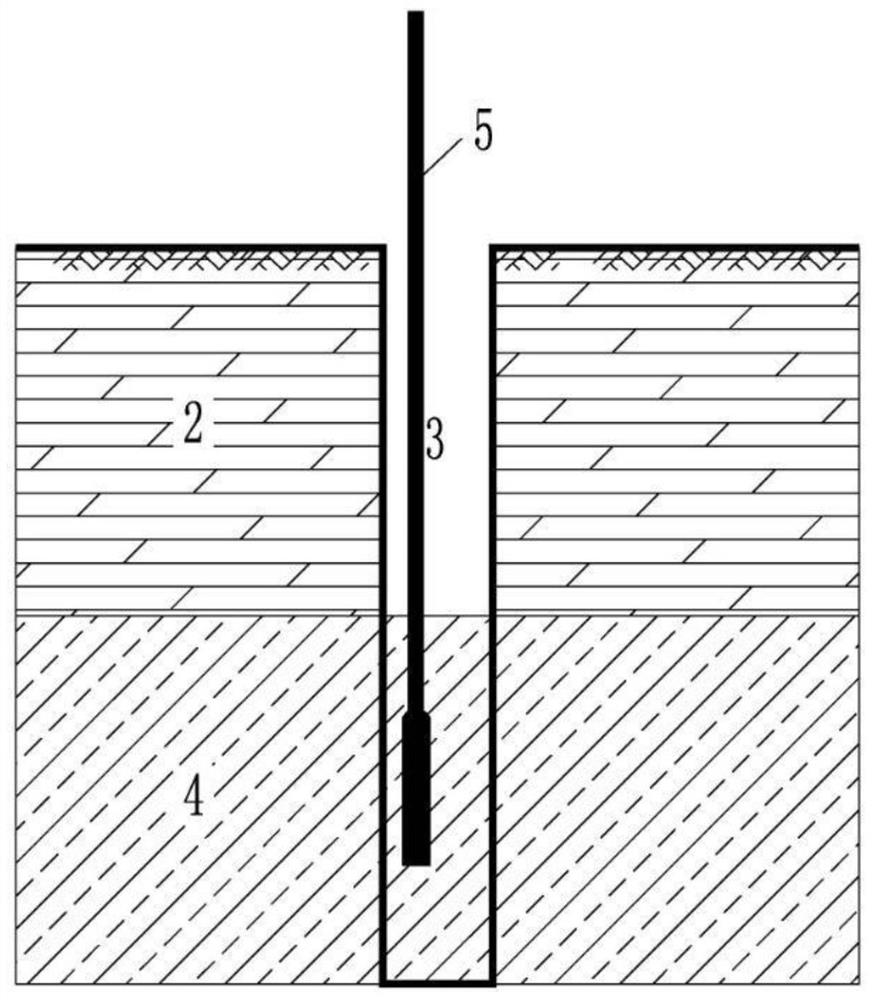

Occlusive pile of long spiral stirring water-stop curtain and construction process thereof

InactiveCN101603309AOvercome drillingPlay a supporting roleDrill bitsRotary drillingEngineeringHardpan

The invention relates to a novel pile-forming method of a cement-soil stirring pile. The method comprises the following steps: measuring and putting lines to determine pile position; putting a long spiral drill in place, and adopting the long spiral drill to drill a hole to determine the accurate position of a pile, loosen a hardpan and eliminate underground barrier; backfilling to the opening of the hole, or reversing and lifting the drill; drilling by a long spiral stirring pile drill while pumping and stirring serum to a designed hole bottom elevation; during returning upwards, guniting while stirring to the designed elevation, and then stirring repeatedly and guniting to form a pile; after finishing stirring pile construction, making use of the long spiral stirring pile drill to drill the stirring pile to form holes; and finally, inserting slope-protection piles used in steel reinforcement cage construction after concrete grouting to form an entire curtain. The novel pile-forming method has the advantages that a long spiral stirring pile is adopted to lay a foundation for the smooth construction of slope-protection piles; the renovated long spiral drill can drill in harder soil stratum, sand stratum and gravel stratum, thereby reaching the designed depth and diameter; and the integral curtain with occlusive slope-protection piles and cement-soil piles not only supports foundation pits, but also realizes effective water stopping.

Owner:深圳市南华岩土工程有限公司

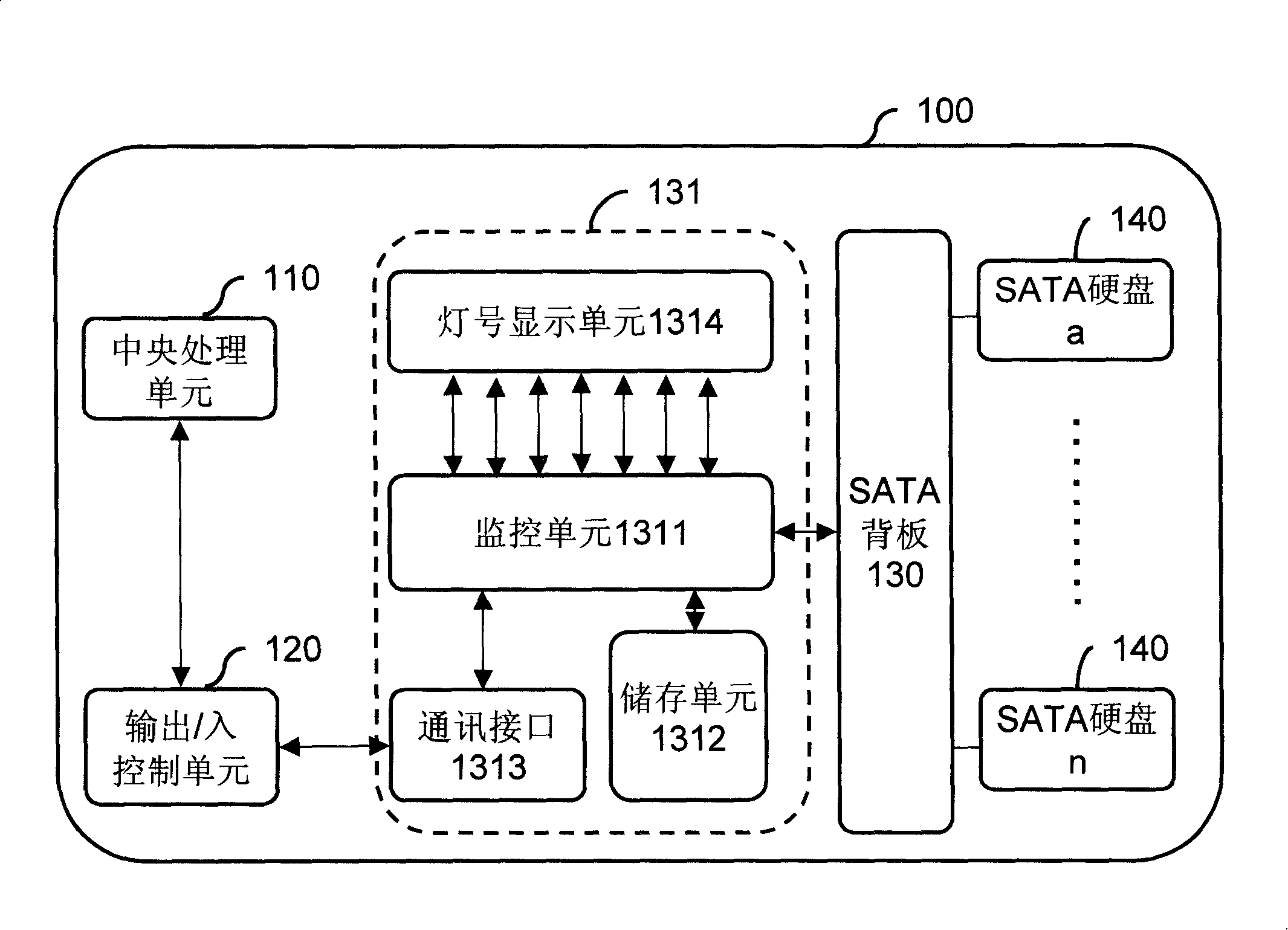

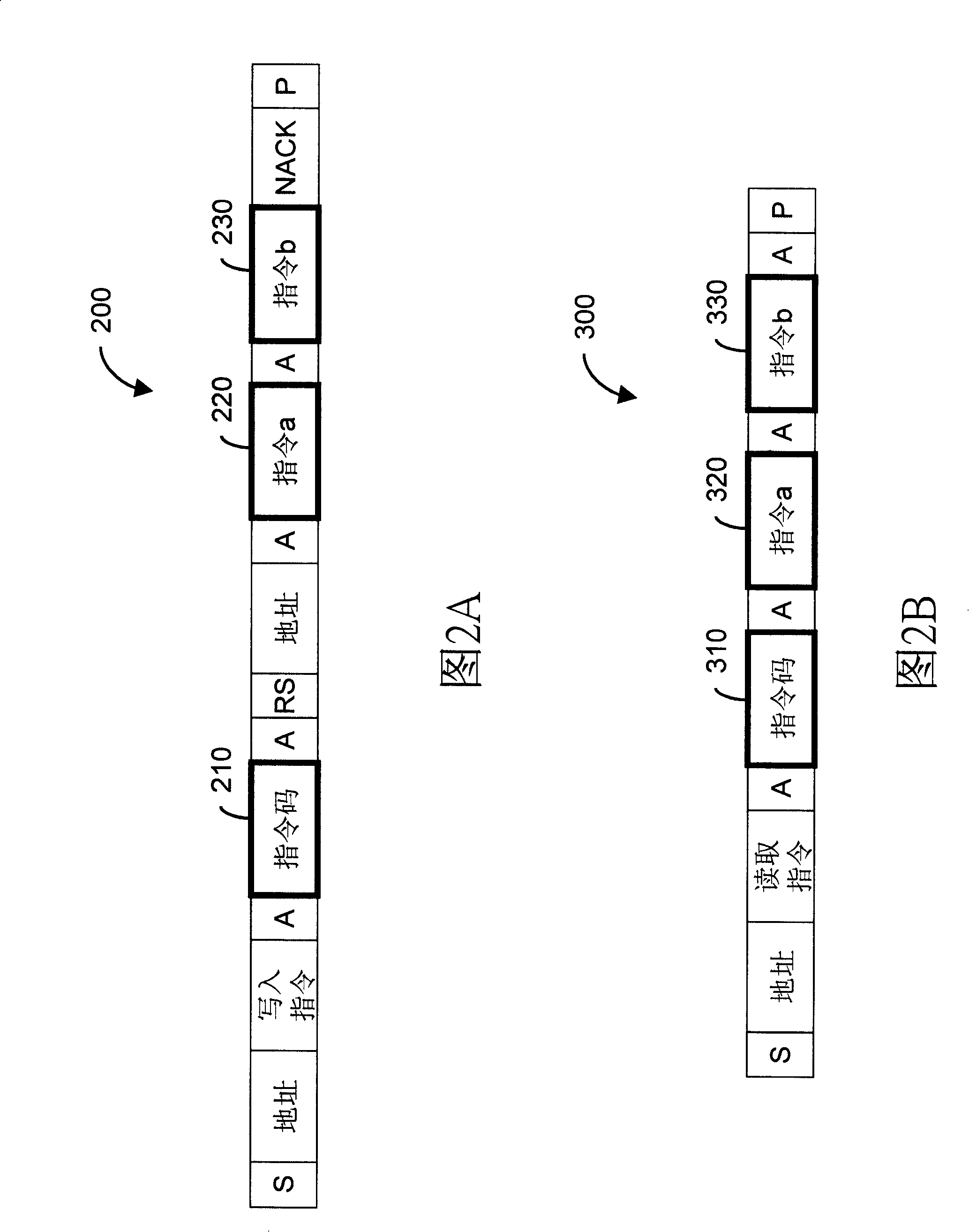

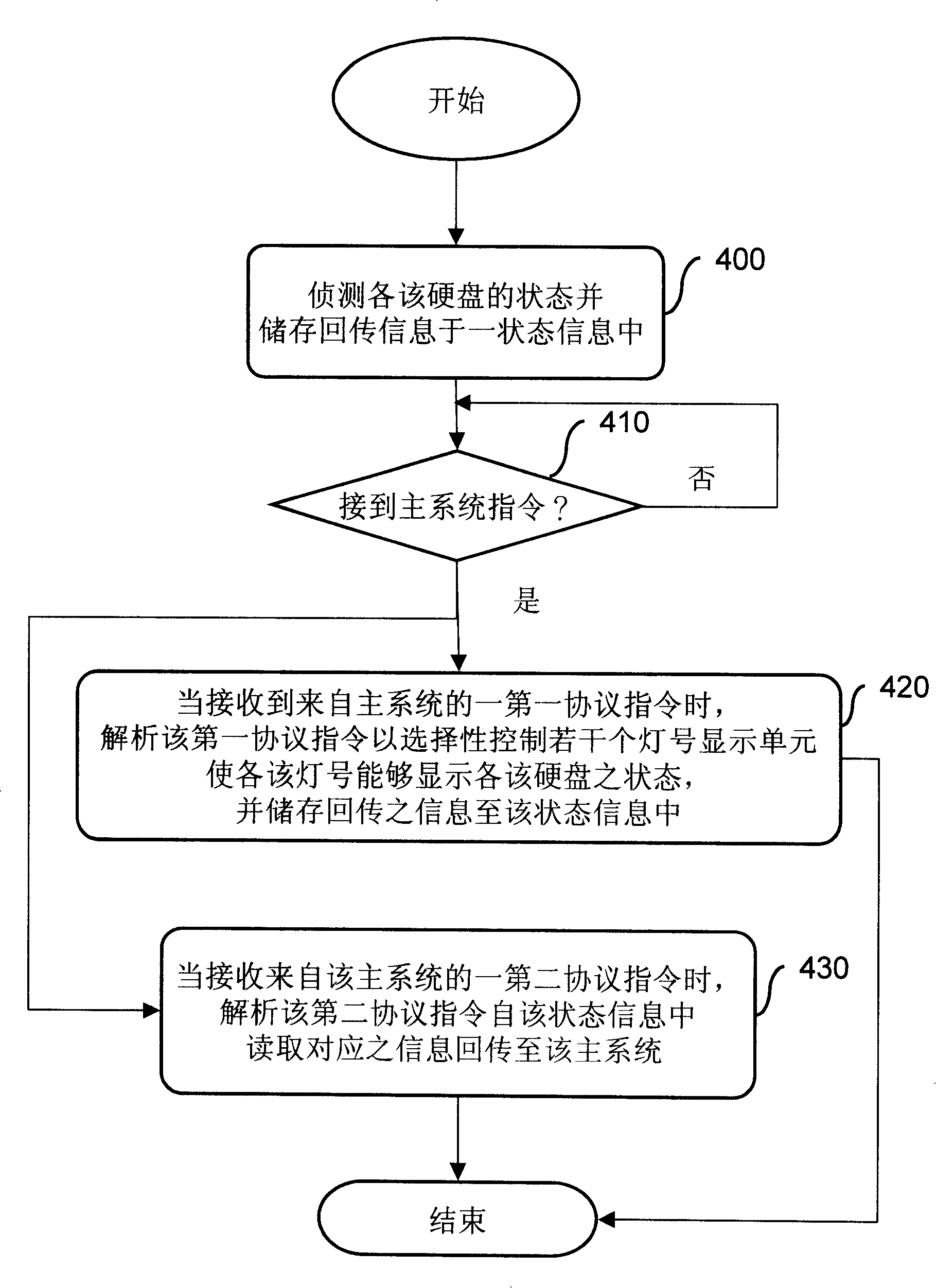

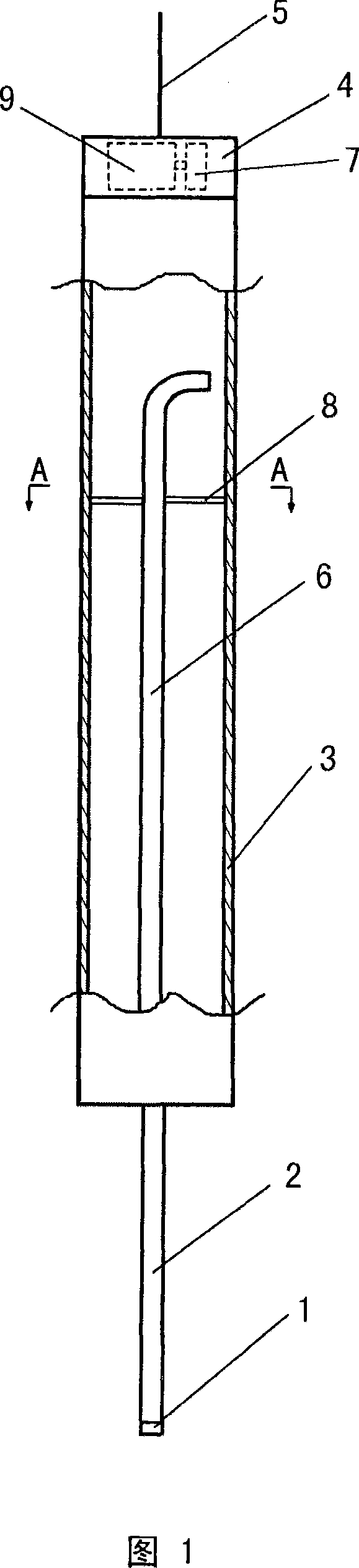

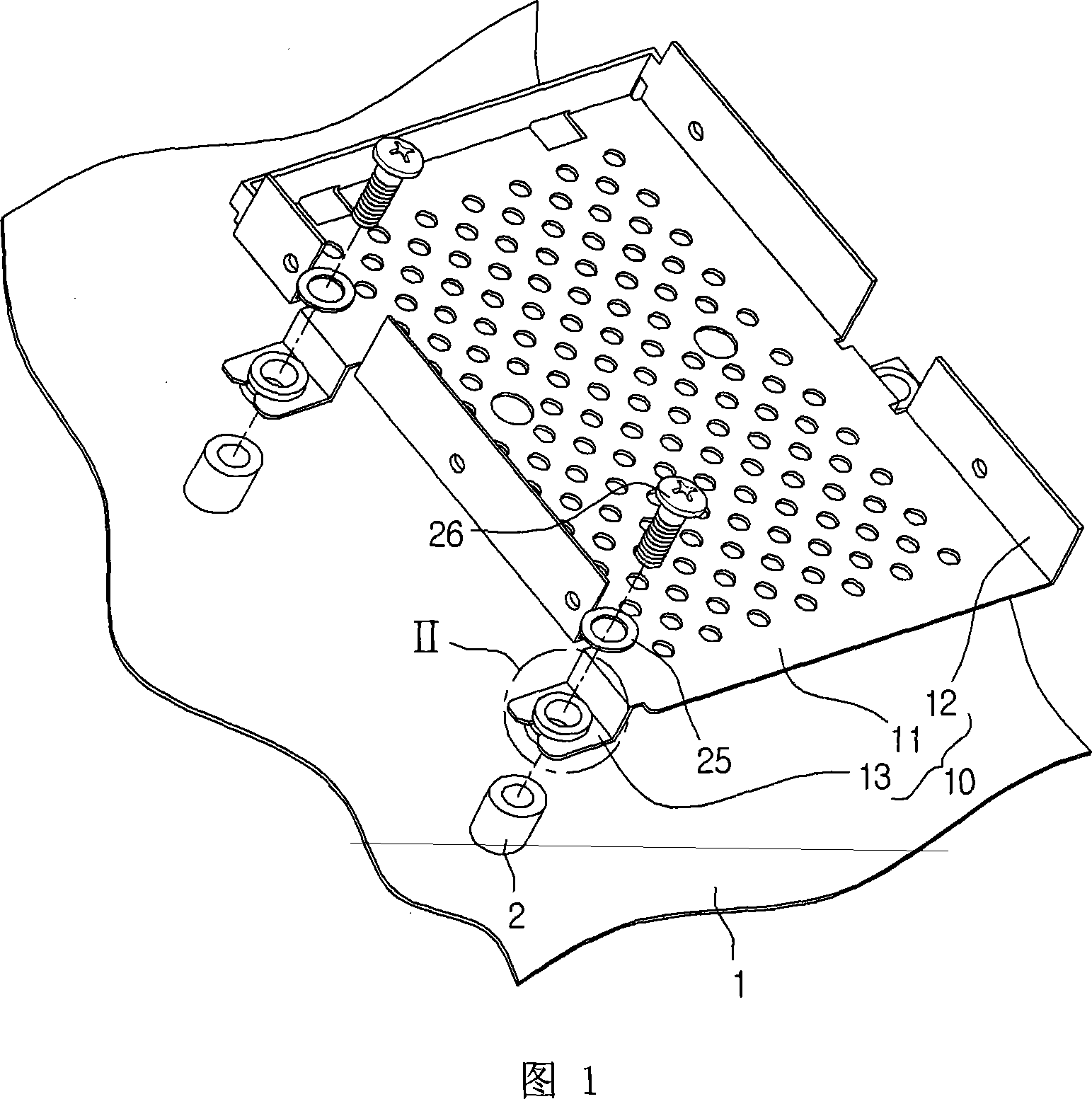

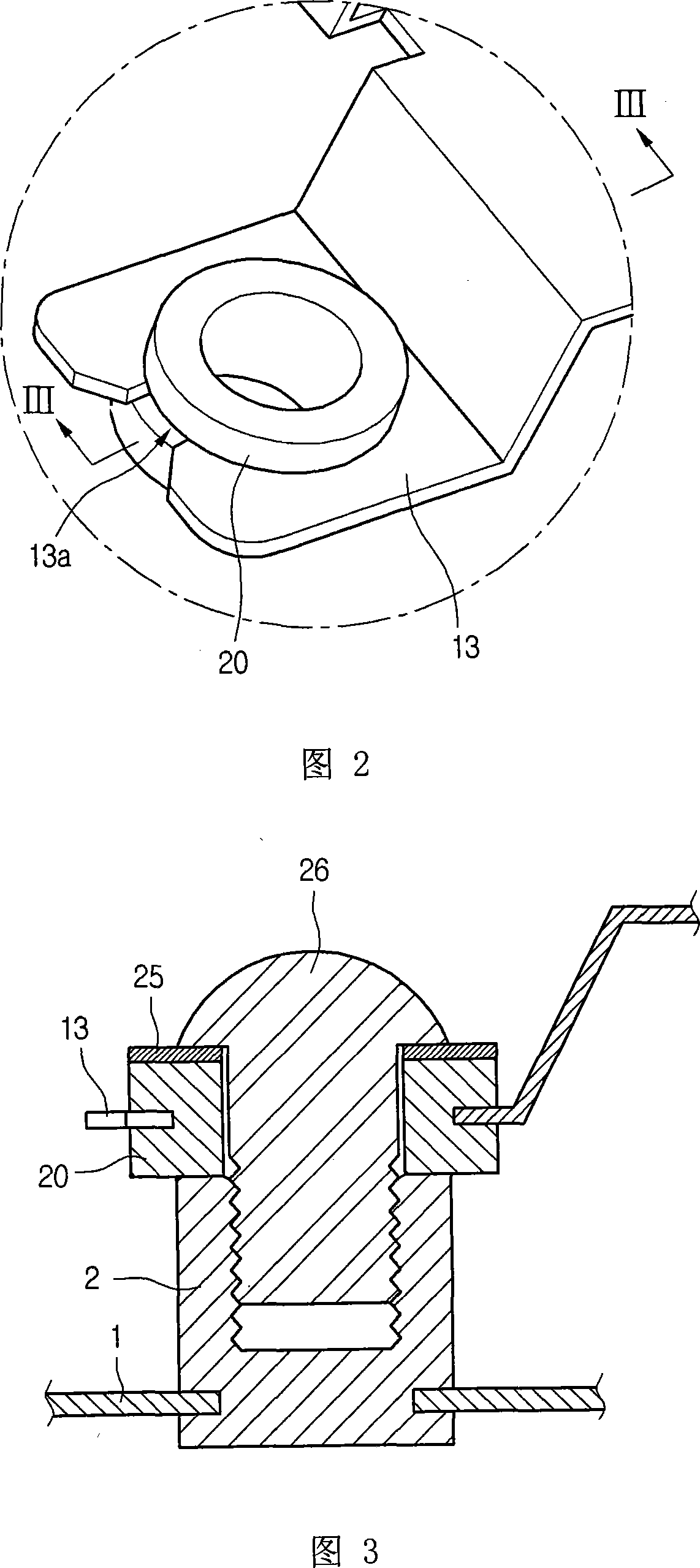

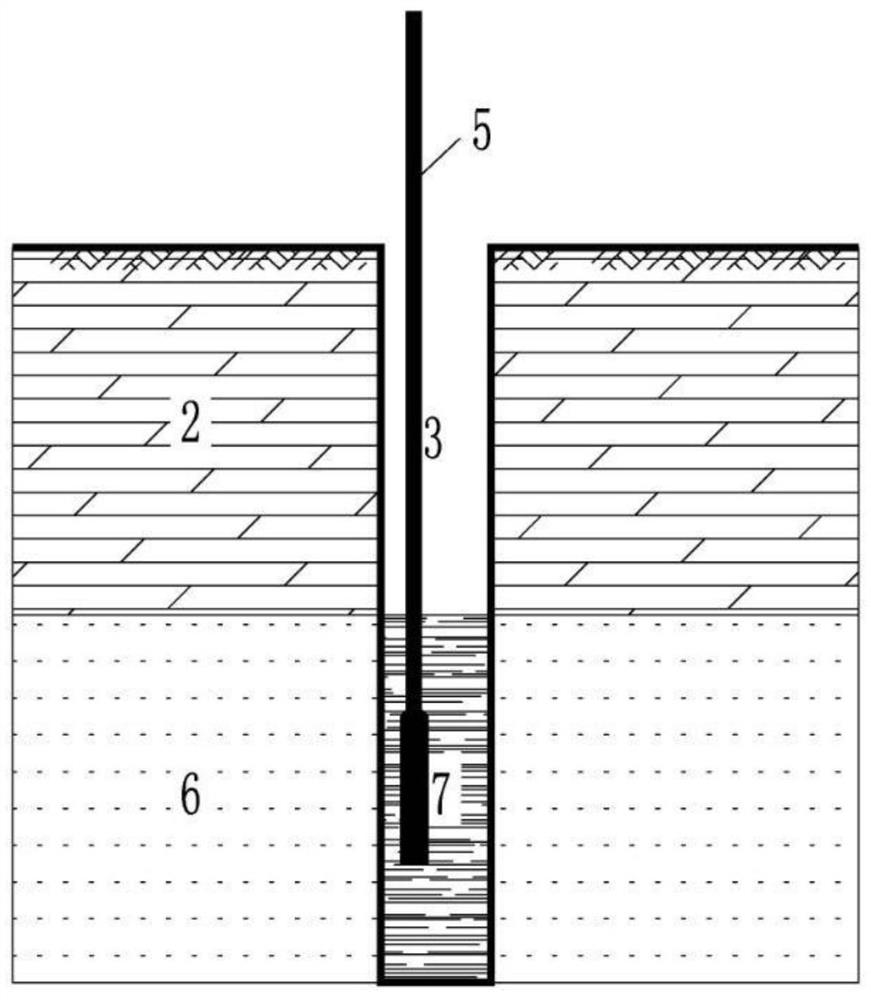

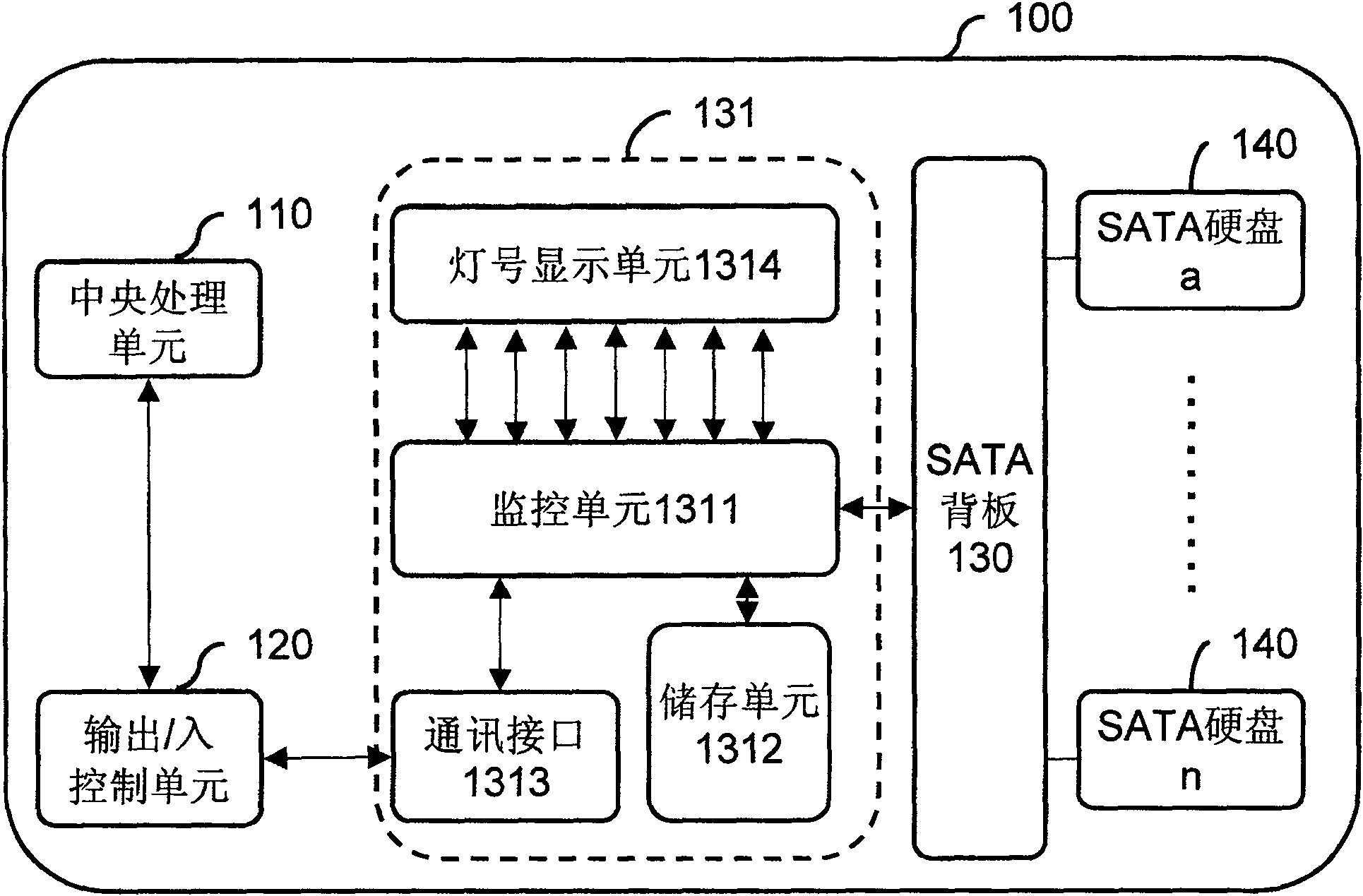

Apparatus and method for monitoring SATA hardpan

The invention provides a monitoring apparatus for a SATA hard disk and a monitoring method thereof. A plurality of hard disks which are connected on the backboard of the SATA hard disk are monitored through the monitoring apparatus arranged on the backboard of the SATA Serial ATA, the monitoring apparatus is independent of a main system, a cresset display is directly arranged on the monitoring device to display the state of each hard disk in a visualization way; and the main system can execute the operations such as the hard disk state detecting, the cresset display controlling and the state information reading through sending out the defined protocol instructions to the monitoring device.

Owner:MITAC COMP (SHUN DE) LTD +1

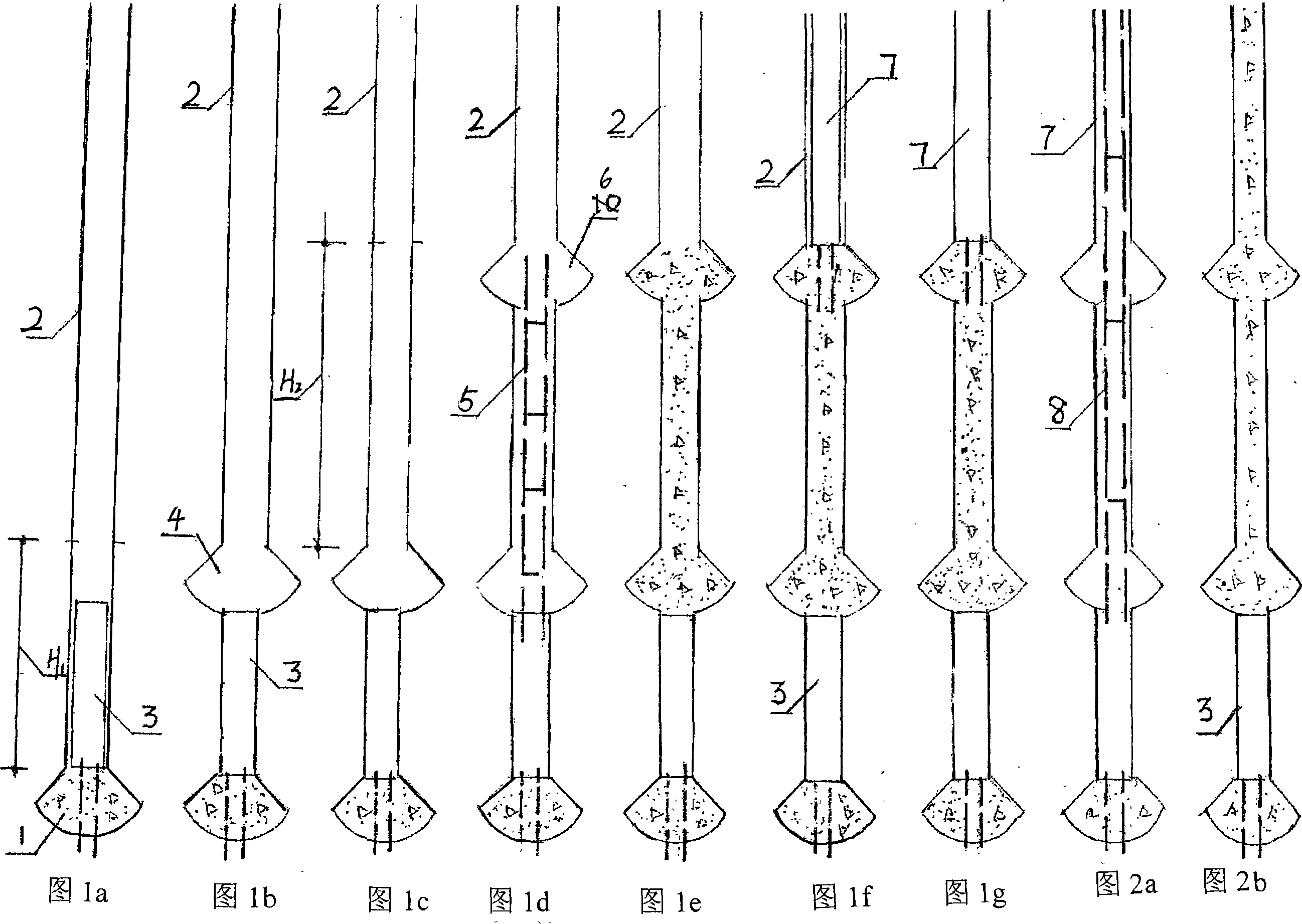

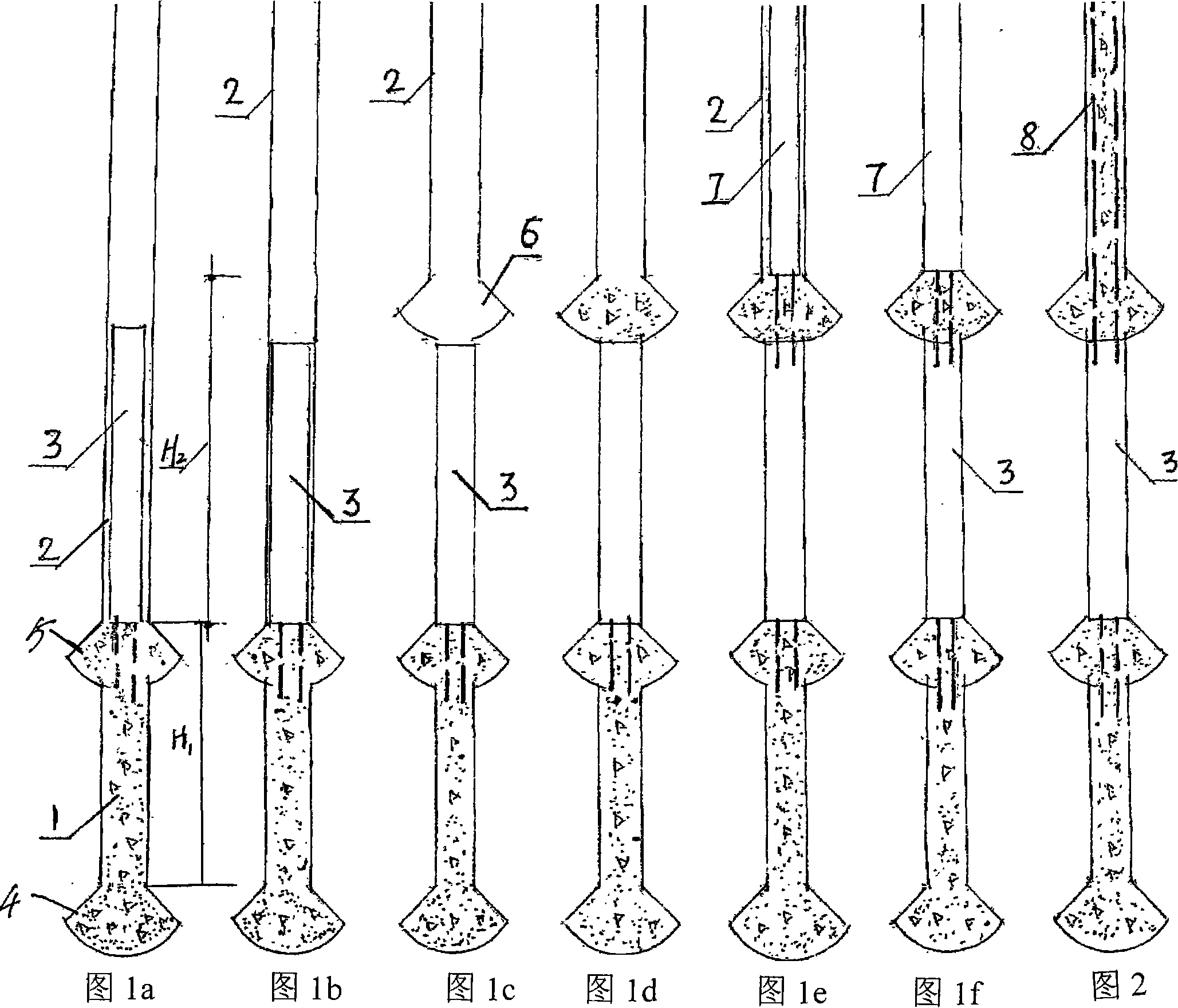

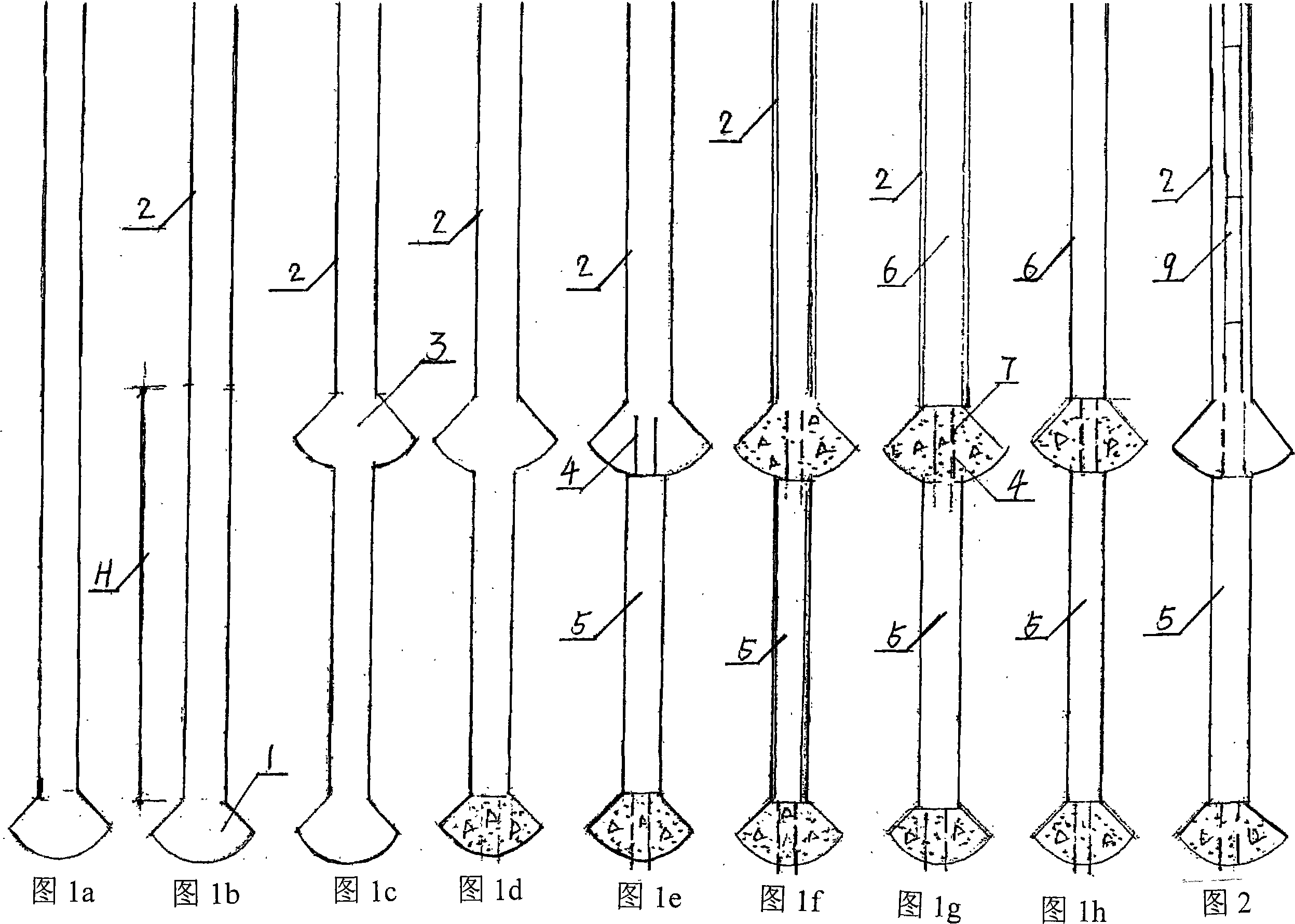

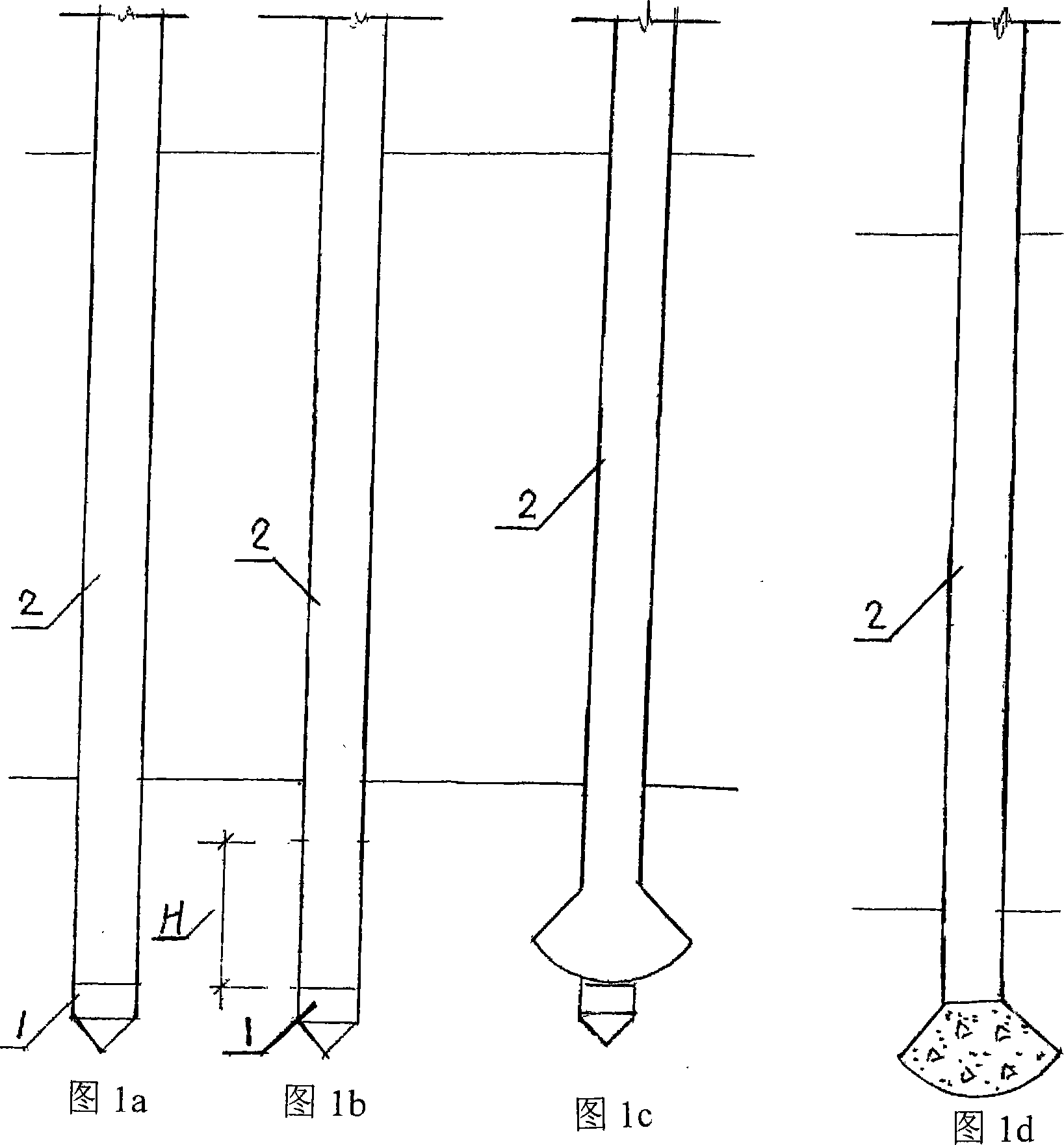

Blasting pile-forming method for three-stage bottom-enlarging prefabricated and cast-in-situ steel concrete combination pile body

InactiveCN101126237AHigh concentricityImprove carrying capacityBulkheads/pilesReinforced concreteCarrying capacity

The invention relates to a blast method to construct the pile which has a composite three-section pedestal pile body and a cast-in-situ reinforced concrete pile body. The invention comprises the technique procedures that: a. an immersed tube with a metal pile crown is sunk to the hardpan until the design elevation is reached; b. the metal pile crown is taken out; c. the lower pedestal space is processed and the soil is cleaned, the lower pedestal is cast with concrete and a prefabricated hollow pile body which has a steel dowel at the lower end is placed into the immersed tube, then the immersed tube is pulled to the designed distance H1; d. the middle pedestal space is processed and then the immersed tube is pulled to the designed distance H2, then the upper pedestal space is enlarged with an extrusion equipment, then the fabricated solid pile body is placed and the soil is cleaned, then a long steel bar is lowered from the immersed tube to pass through the upper and the lower section and slightly pass through the middle pedestal; e. the middle and the upper pedestals are cast with concrete and the middle and upper section with reinforced concrete is cast to form the pile body; f. the immersed tube is taken out to form the pile. The invention can distinctly improve the utilization ratio of the material strength and the reduction coefficient can reach 0.9-1.0; the diameter ratio of the pedestal diameter to the pile body can reach 3.5-5.0, which considerably improves the carrying capacity of the individual pile.

Owner:周亚萍

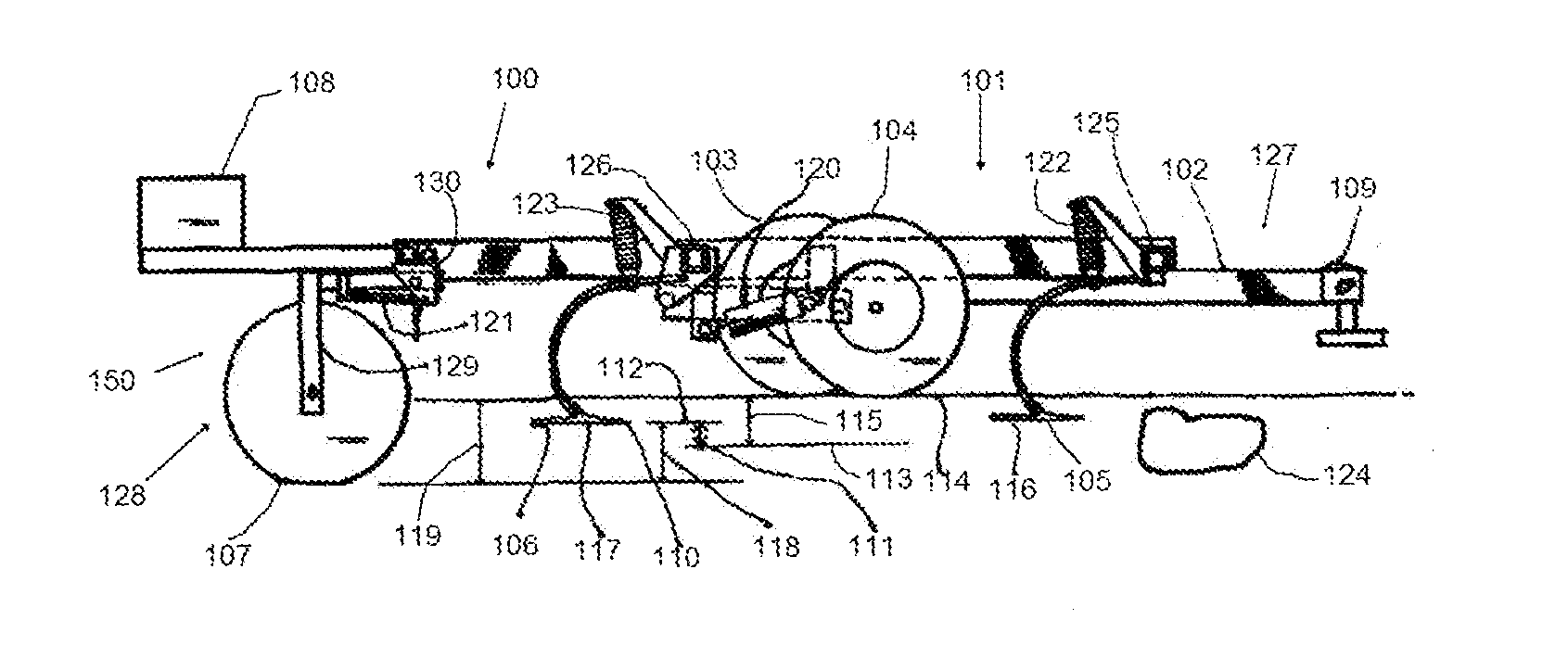

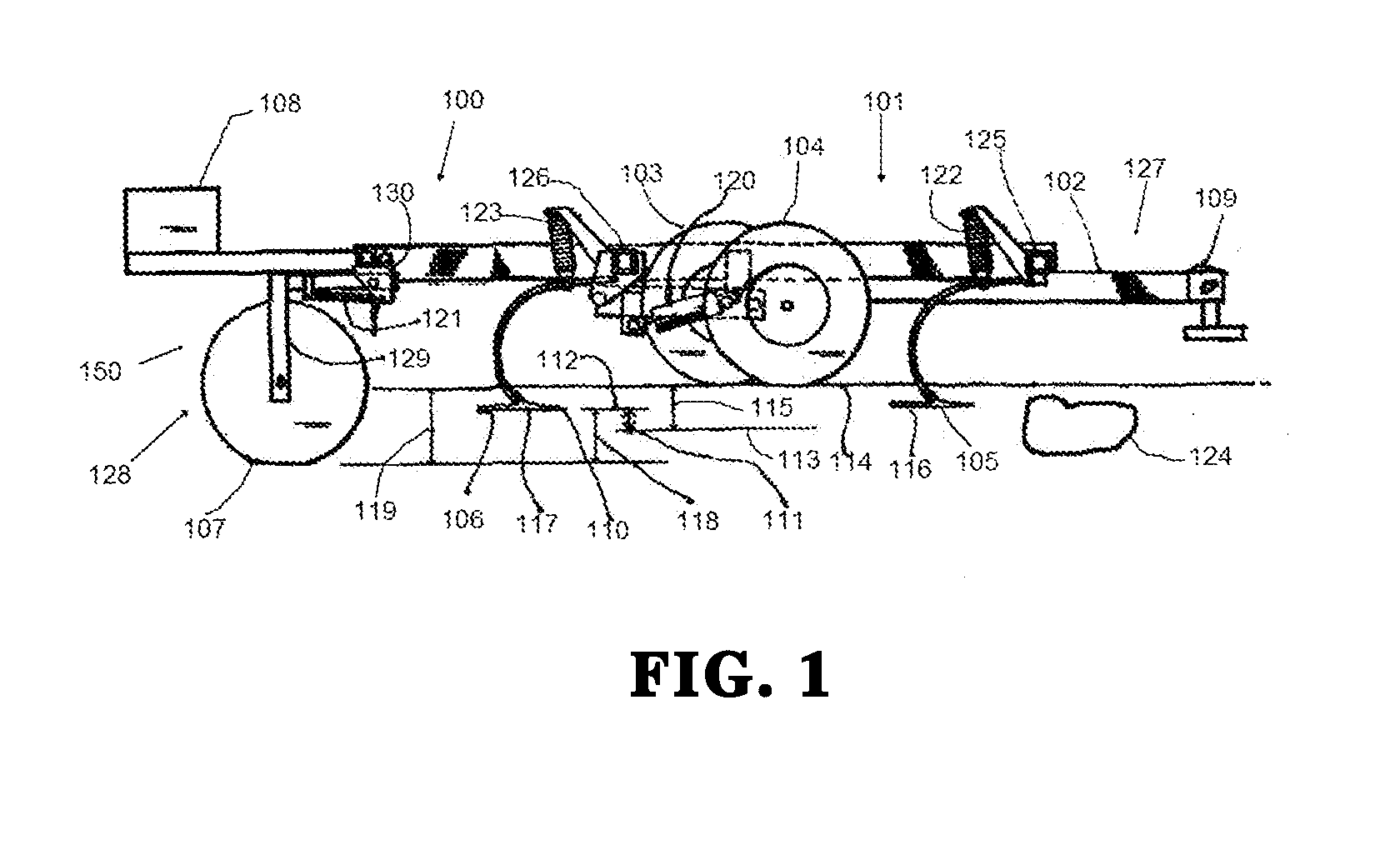

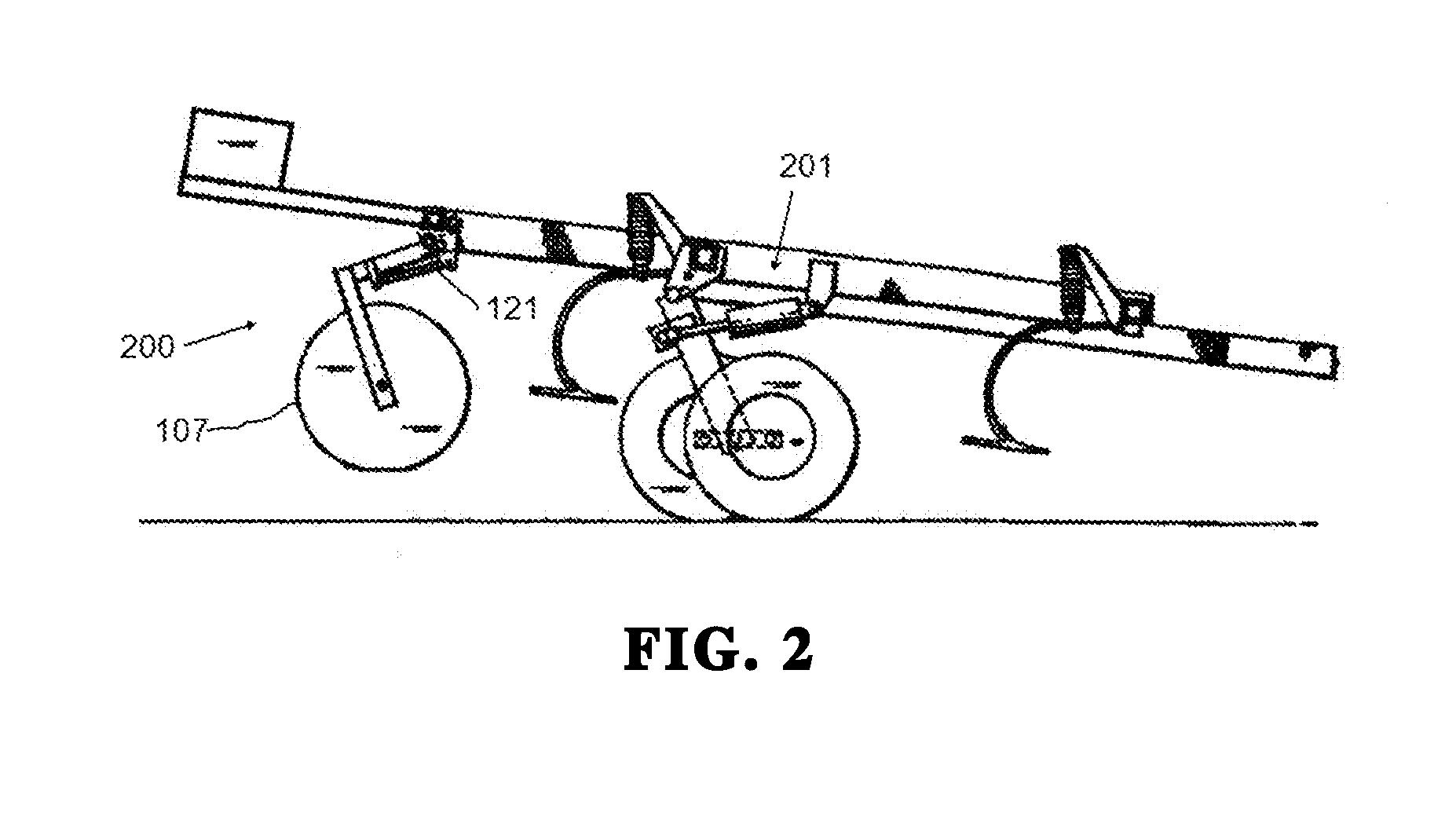

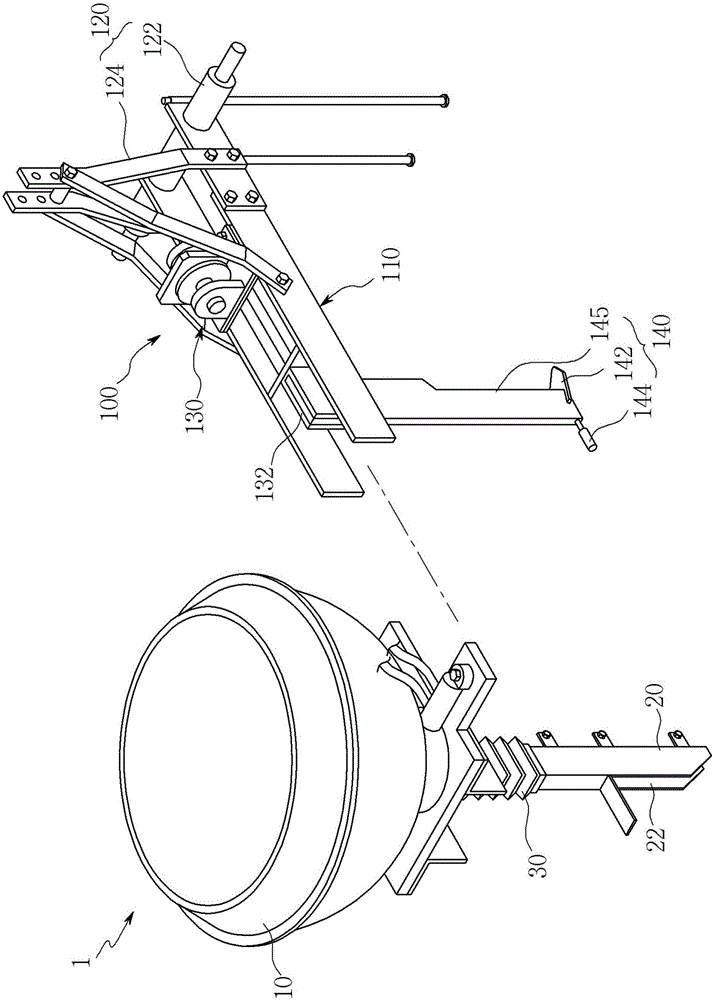

Combined vertical and horizontal tillage with hardpan penetration

An exemplary best mode embodiment and various alternative embodiments are shown for combining horizontal and vertical tillage to solve both weed control and penetration of compaction layer. In one exemplary embodiment a large colter or tine is disposed behind a plow, sweep, concave disc, or other horizontal tillage implement to slice the soil to penetrate any compaction created by the implement. In another exemplary embodiment, a colter with lateral blades penetrates a surface compaction layer, chops crop residue and hoes and levels the soil all in one pass with one implement. We have discovered that a deeper-penetrating tailing ground slicing implement behind a horizontal tillage device results in full root depth for a stronger crop and better yields with normally deep-rooted crops such as corn and the like.

Owner:SMITH TRAVIS R +1

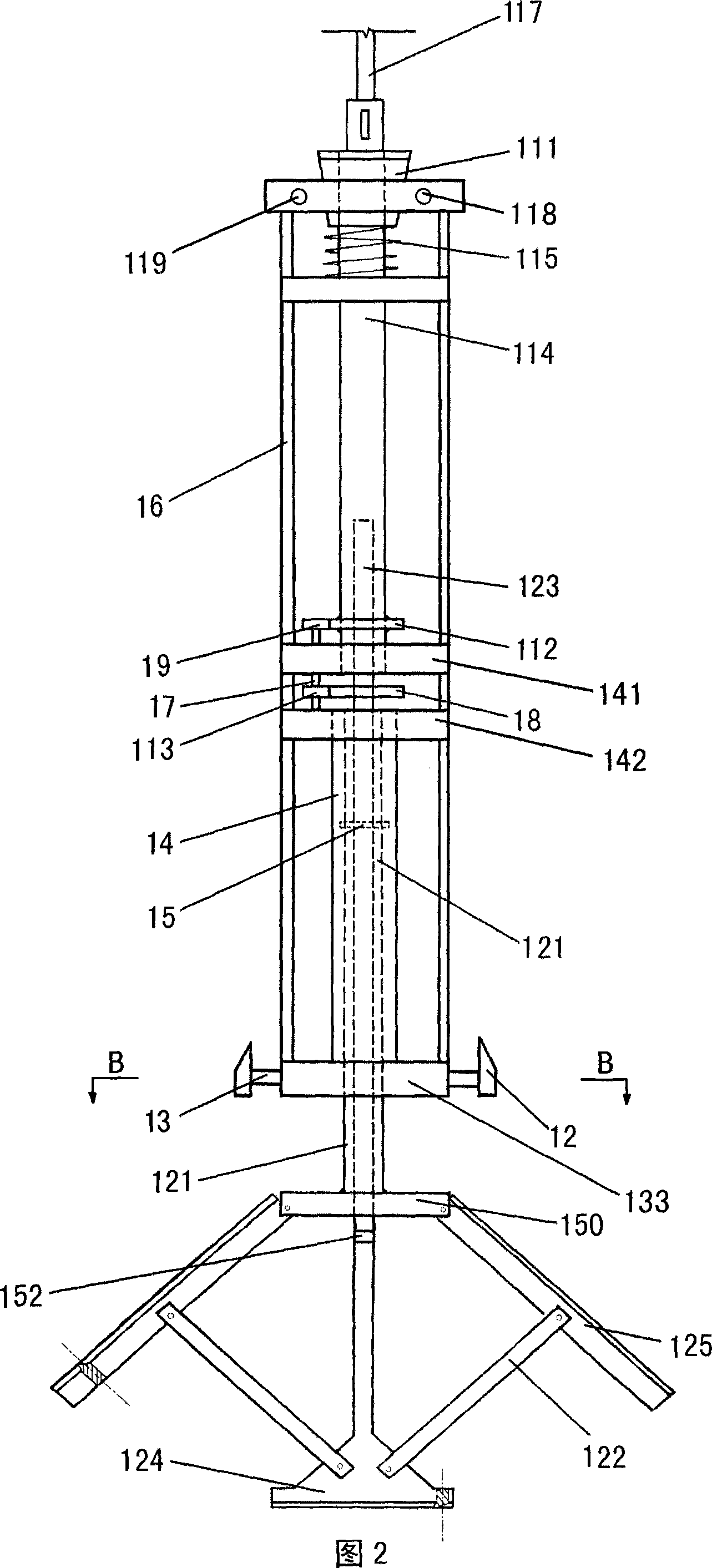

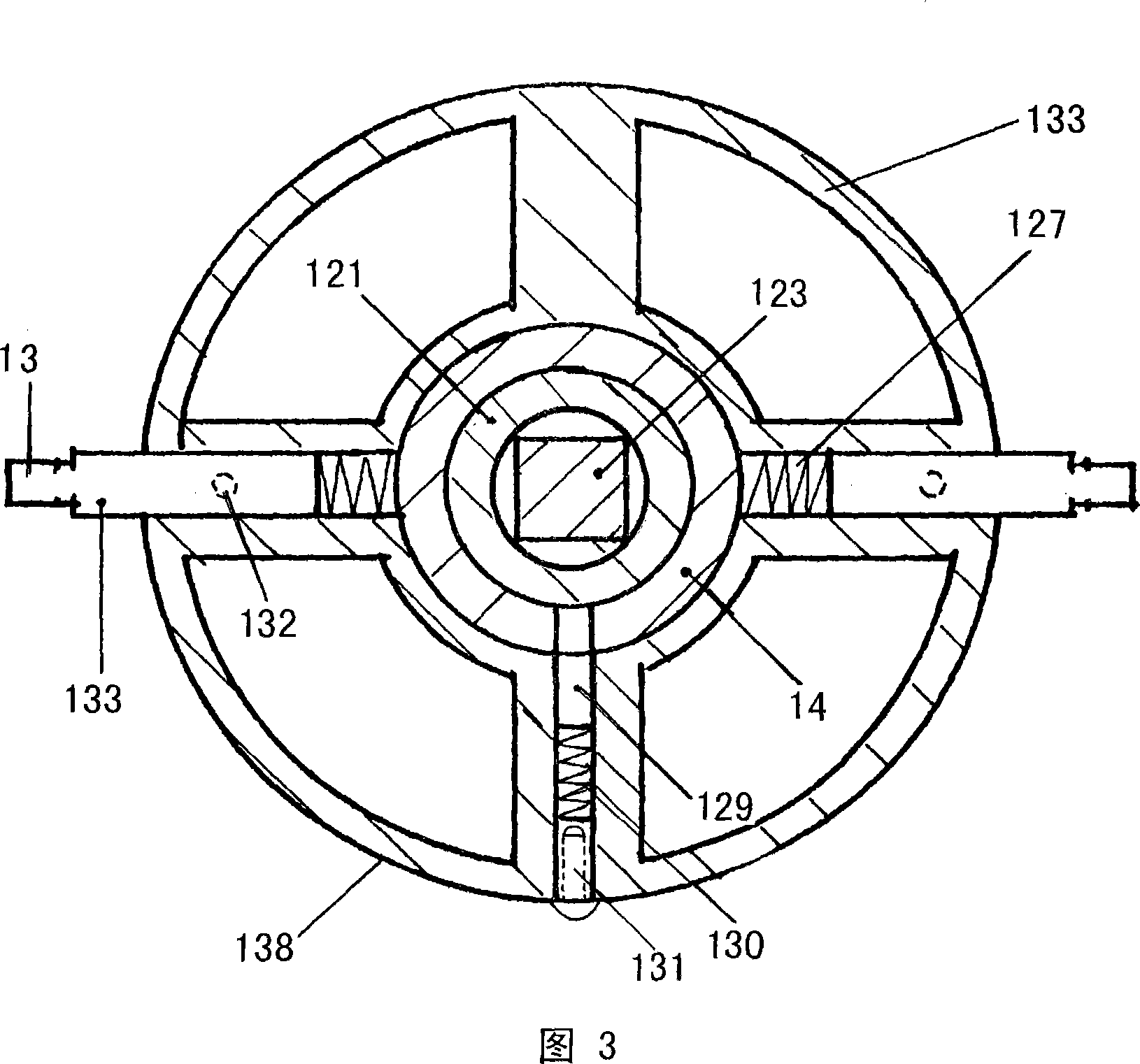

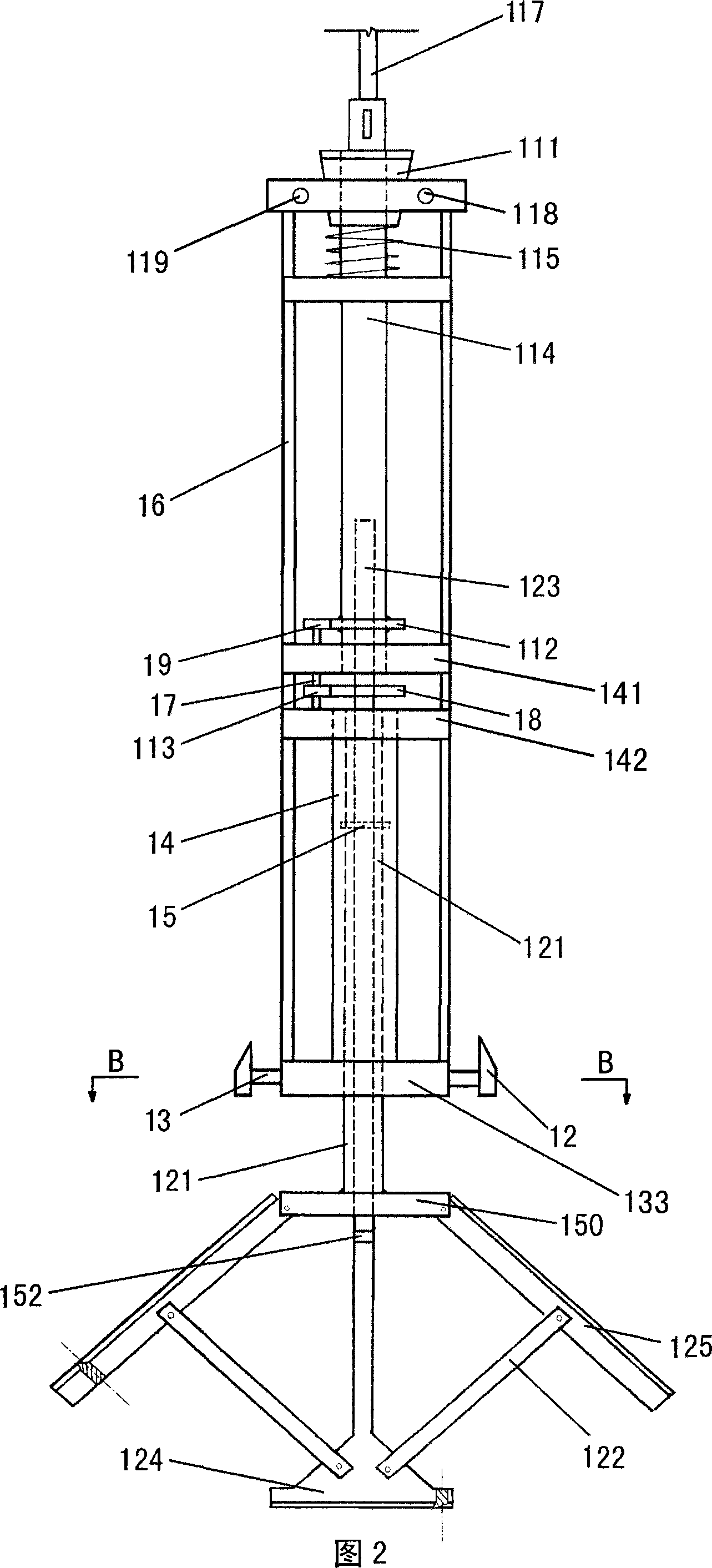

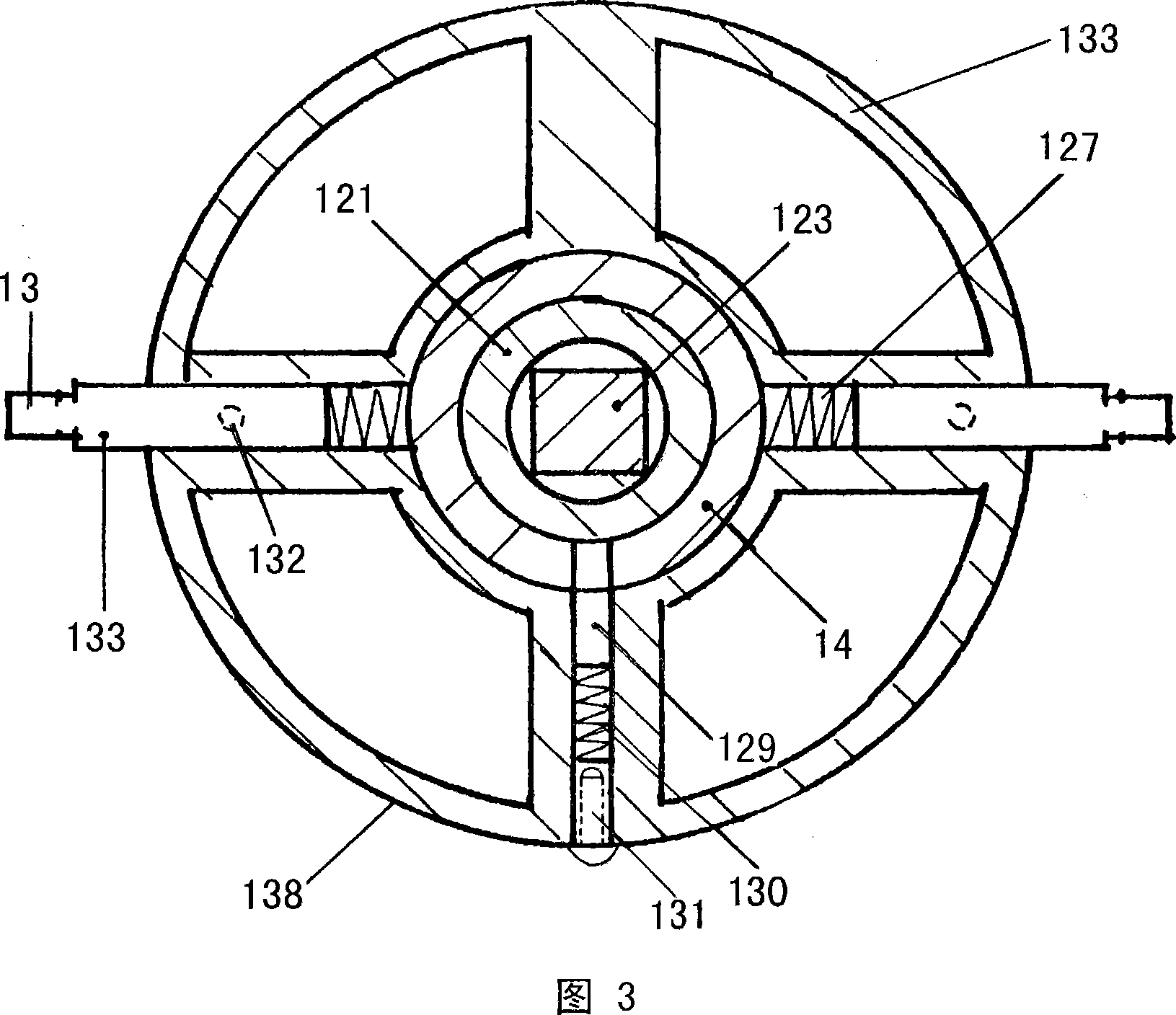

Submarine pipeline laying machine and hydraulic jetting combined rotating ditcher for 500-meter deep hardpan

The invention relates to a submarine pipeline laying machine and hydraulic jetting combined rotating ditcher for 500-meter deep hardpan, is applied to a submarine hardpan seabed of 500 meters and within 500 meters, and belongs to the technical field of marine engineering equipment. The ditcher comprises main parts such as an external bracket, an outer rotating cylinder, cutter teeth, an upper suspension cylinder, a lower support pillar, a plough share, nozzles, a high-pressure water pipe, an inner cylinder, baffle plates, a sealing rubber waterproof pad, a motor, an output transmission shaft, a shaft coupling, an upper-plane ordinary gear train, a lower-plane ordinary gear train, a top cover, a bottom cover and bearings, wherein the top cover, the bottom cover, the outer rotating cylinder and the cutter teeth are driven by the motor through the upper and lower-plane ordinary gear trains to rotate to realize a seabed groundbreaking function; the hardpan can be crushed by high-pressure water jetted by the high-pressure water pipe and the nozzles, so that the cutting resistance of the cutter teeth is reduced; liquefied soil is sucked out by a slurry pump suction pipe to realize a submarine ditching function. The ditcher has the advantages of being large and deep in ditching, high in working efficiency and environmental adaptability, remarkable in social and economic benefits, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

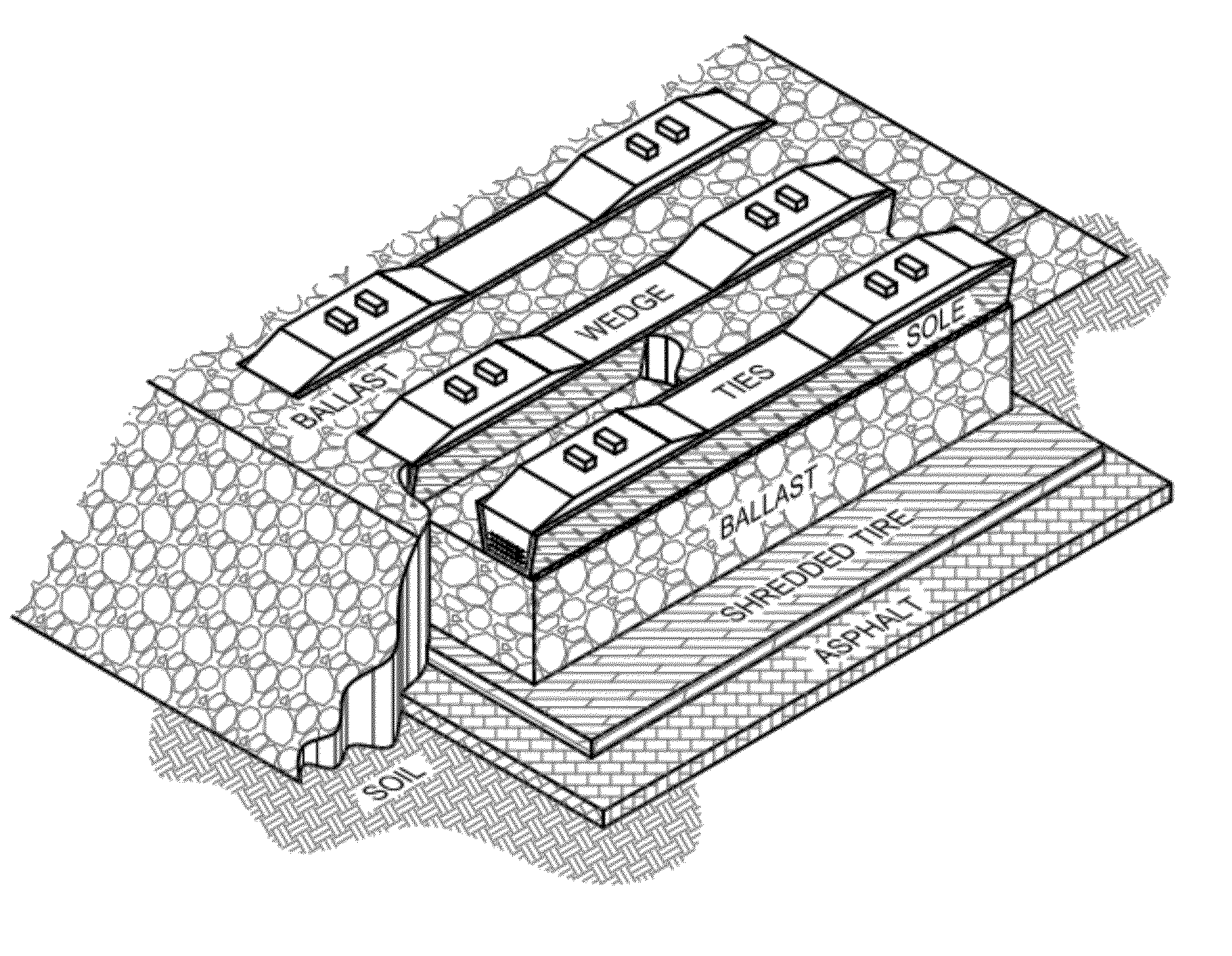

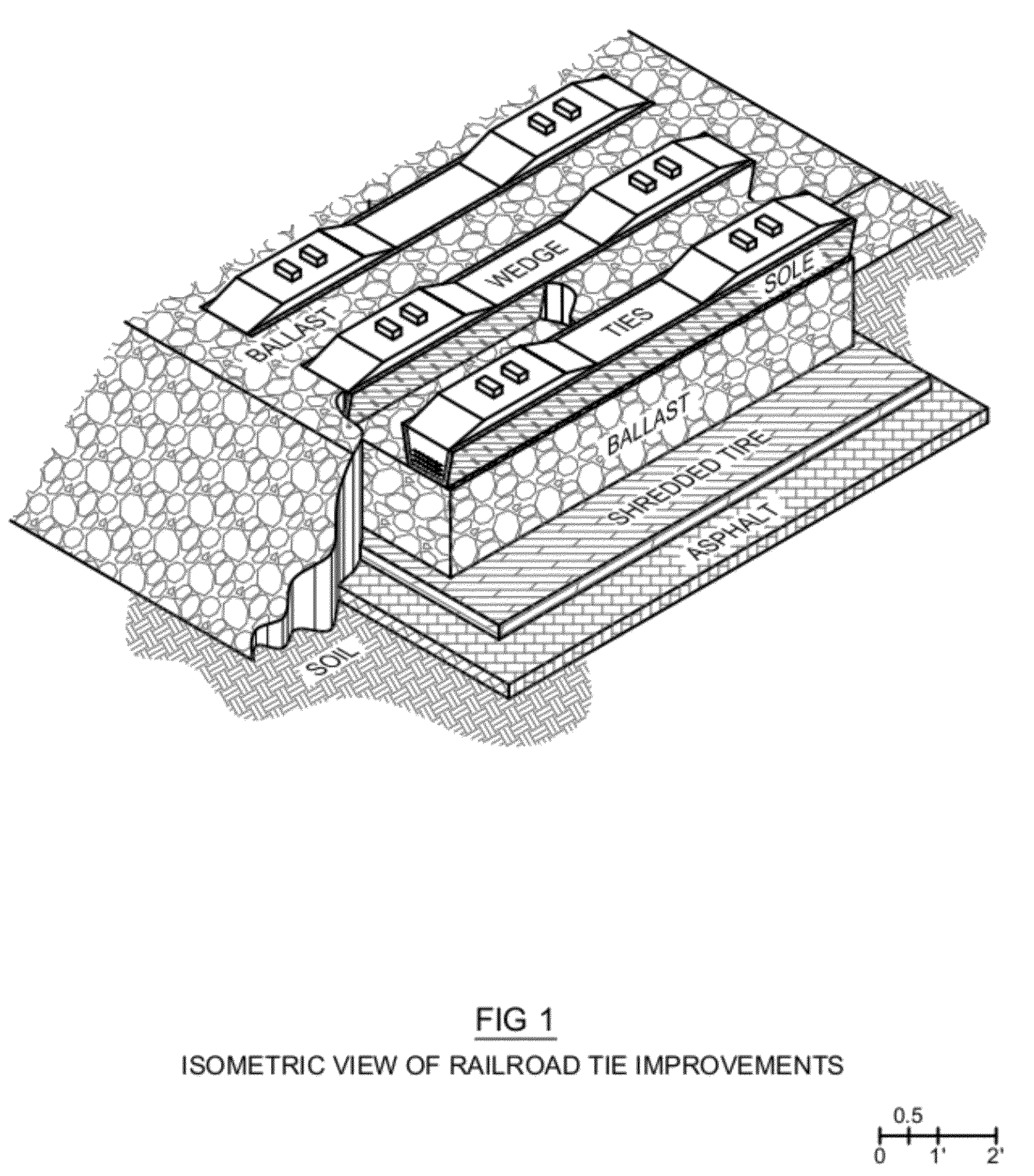

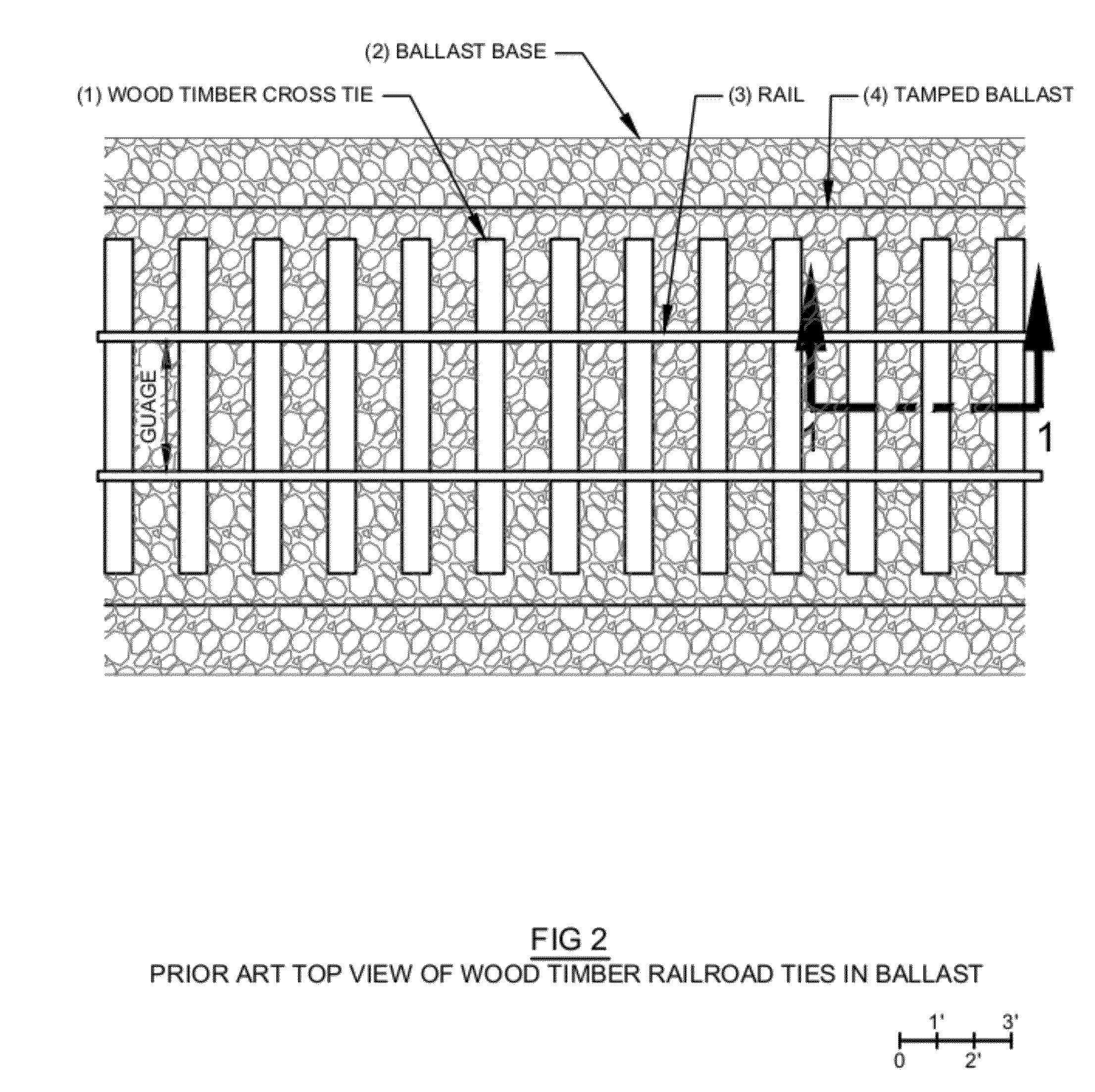

Wave Amplitude Attenuation and Wear Prevention Methods for Non-Wood-Timber Railroad Ties

InactiveUS20120305663A1Reduce wave amplitudeReduce frequencyBallastwayTemporary pavingsA wave amplitudeUltrasound attenuation

Non-wood-timber (NWT) railroad ties such as concrete remove cushion and pressure wave attenuation provided by wood timber railroad ties. I provide methods to reintroduce cushion and wave attenuation by means of adding an elastomeric sole. To further increase wave attenuation a layer of ground automobile tire is placed between the hardpan and ballast. Also, reclaimed asphalt is an inexpensive means to create hardpan that reduces railroad tie pumping.

Owner:AXTON KYLE DAVID

Process and composition for forming an earthen hardpan

ActiveUS7374371B2Small volume expansionDrilling compositionOrganic fertilisersSodium BentoniteHardpan

A brine sealant solution and both a one-step and two-step process for producing an earthen hardpan in a pond or slush pit is described. The process disperses clay in an aqueous solution using monovalent and divalent cations and bentonite clay. The dispersed clay is then used to fill the seepage capillaries. A second aqueous solution of monovalent and divalent cations and a wetting agent is applied and aggregates the clay and creates a hardpan.

Owner:CRILL DICK

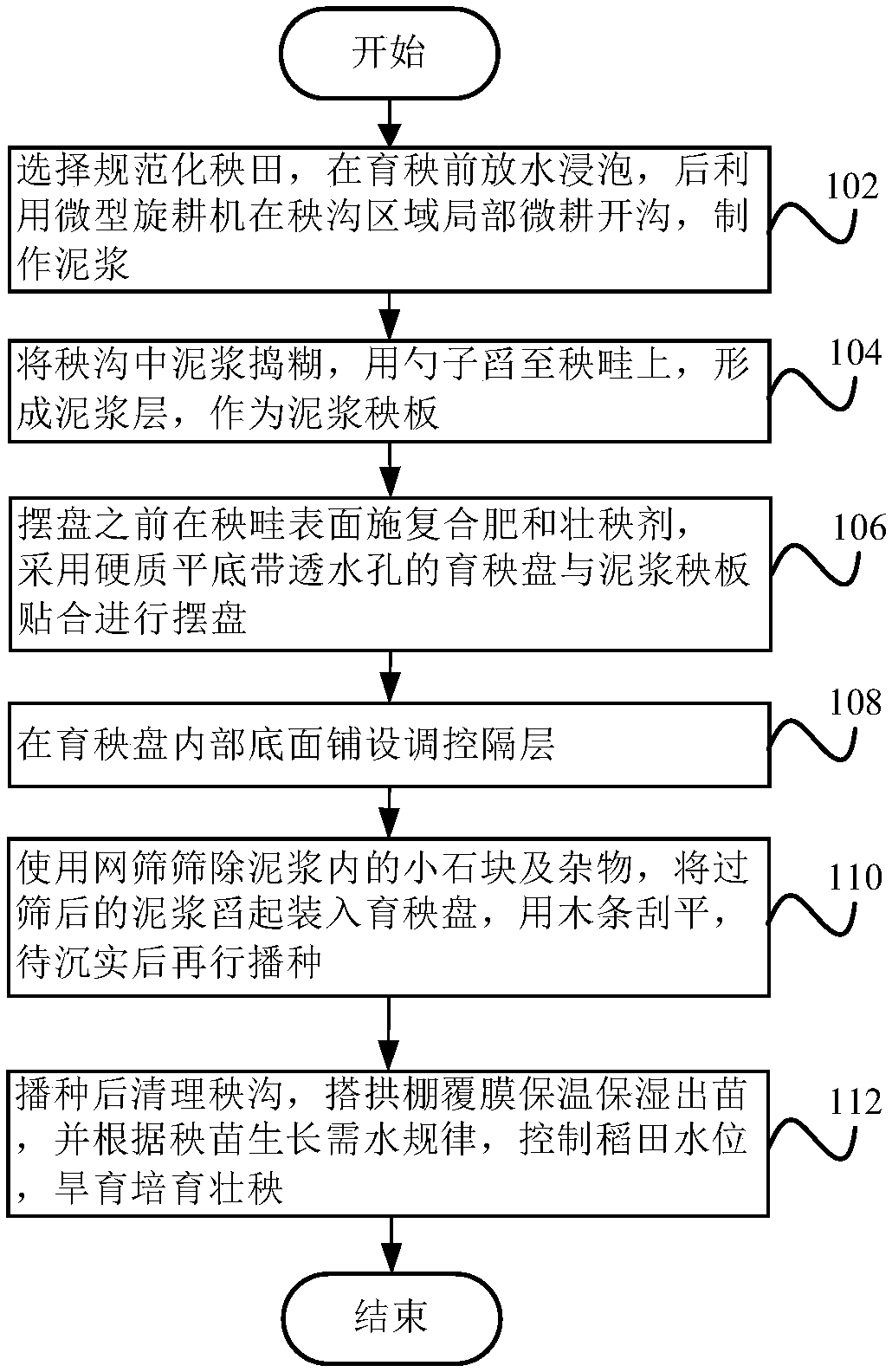

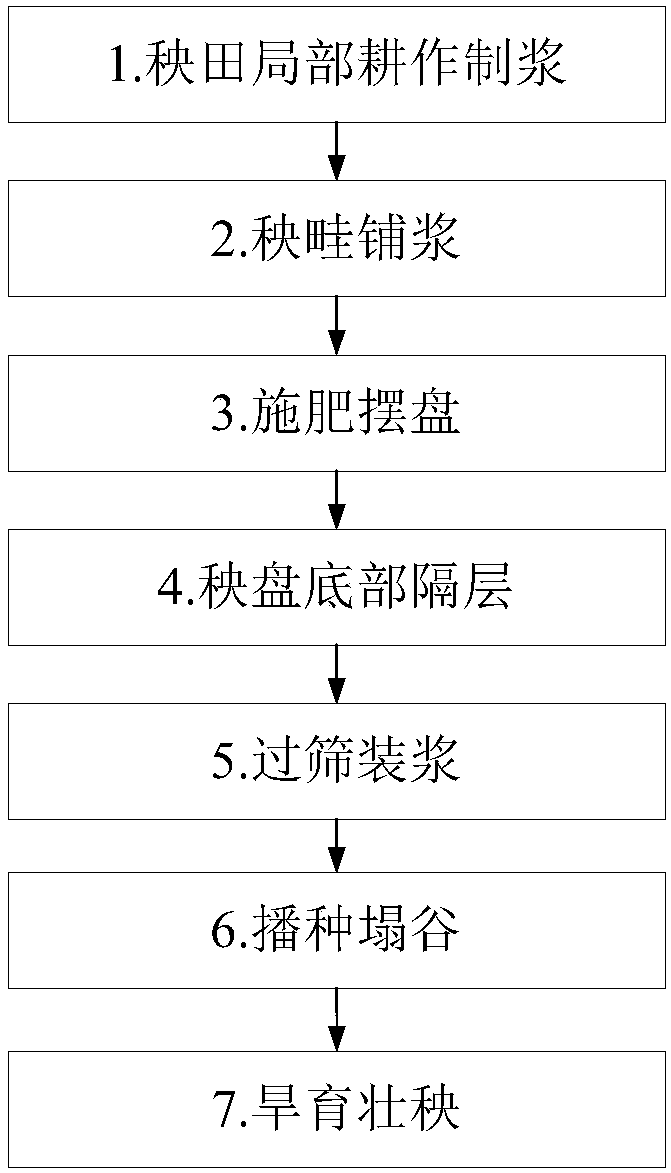

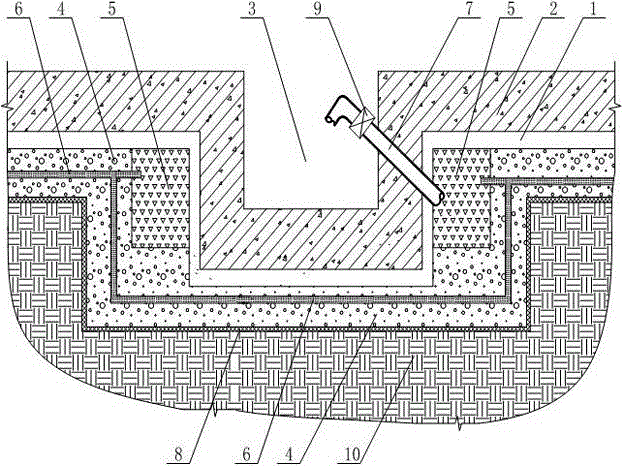

Method for raising seedlings in mud for mechanical transplanted rice fields

InactiveCN109418095AReduce churnGood regulationRice cultivationSoil-working methodsFiltrationRoot growth

The invention provides a method for raising seedlings in mud for mechanical transplanted rice fields, and belongs to the technical field of agricultural production. The method for raising seedlings inmud for mechanical transplanted rice fields comprises the steps of: cultivating a part of a rice field for preparing mud; laying mud in seedling beds; conducting fertilization and laying seedling-raising trays; conducting sieving and loading mud; conducting sowing and slightly pressing rice seeds; and conducting dry raising and strengthening seedlings. In the method, a mini-sized machine is usedto plough and prepare the land in a cultivation area in advance, the mud is prepared, then a layer of the mud is laid on a non-cultivation area to prepare a hard seedling plate with a compact lower part and a loose upper part before seedling raising, porous hard seedling-raising trays are laid on the surface of the seedling plate after fertilization, and a partition layer is laid at the bottom ofeach seedling-raising tray for facilitating root growth. Small stone and debris in the mud are removed by filtration of a steel mesh screen, and then the trays are loaded with seedlings for raising, thereby solving the problem of uneven emergence of seedlings caused by uneven mixing of mud and fertilizers and uneven spreading of seedling-strengthening agents, improving the mud structure in the seedling-raising trays, promoting root growth and facilitating regulation and control on seedlings and cultivation of strong seedlings.

Owner:江苏年豊现代农业科技有限公司

Pressure-releasing structure of basement anti-floating plate and construction method thereof

ActiveCN103147464BSolving Buoyancy ProblemsSolve the problem of water collectionProtective foundationBasementWater flow

The invention discloses a pressure-releasing structure of a basement anti-floating plate and a construction method thereof. The pressure-releasing structure comprises a cushion layer and a basement bottom plate on the cushion layer, wherein water-collecting pits are formed in the cushion layer and the basement bottom plate; a layer of hardpan is paved below the cushion layer; filtering layers are paved around the water-collecting pits; flow-guide pipes are paved in the hardpan and are gathered in the filtering layers; flow-leading pipes are arranged on the side walls of the water-collecting pits; and the water-collecting pits are communicated with the filtering layers through the flow-guide pipes. Water generating floatation outside a basement is led into the basement, so that the floatation is reduced. The hardpan is paved below the cushion layer, so that the problem that water outside foundation pits of the basement is gathered is solved, the underground water is collected through a flow-guide pipe arranged in the hardpan, the flow-leading pipes change the underground water into gravity water in the basement, and the problem of the floatation of the underground water is completely solved from the construction starting stage of a building.

Owner:四川省建研万瑞科技有限公司

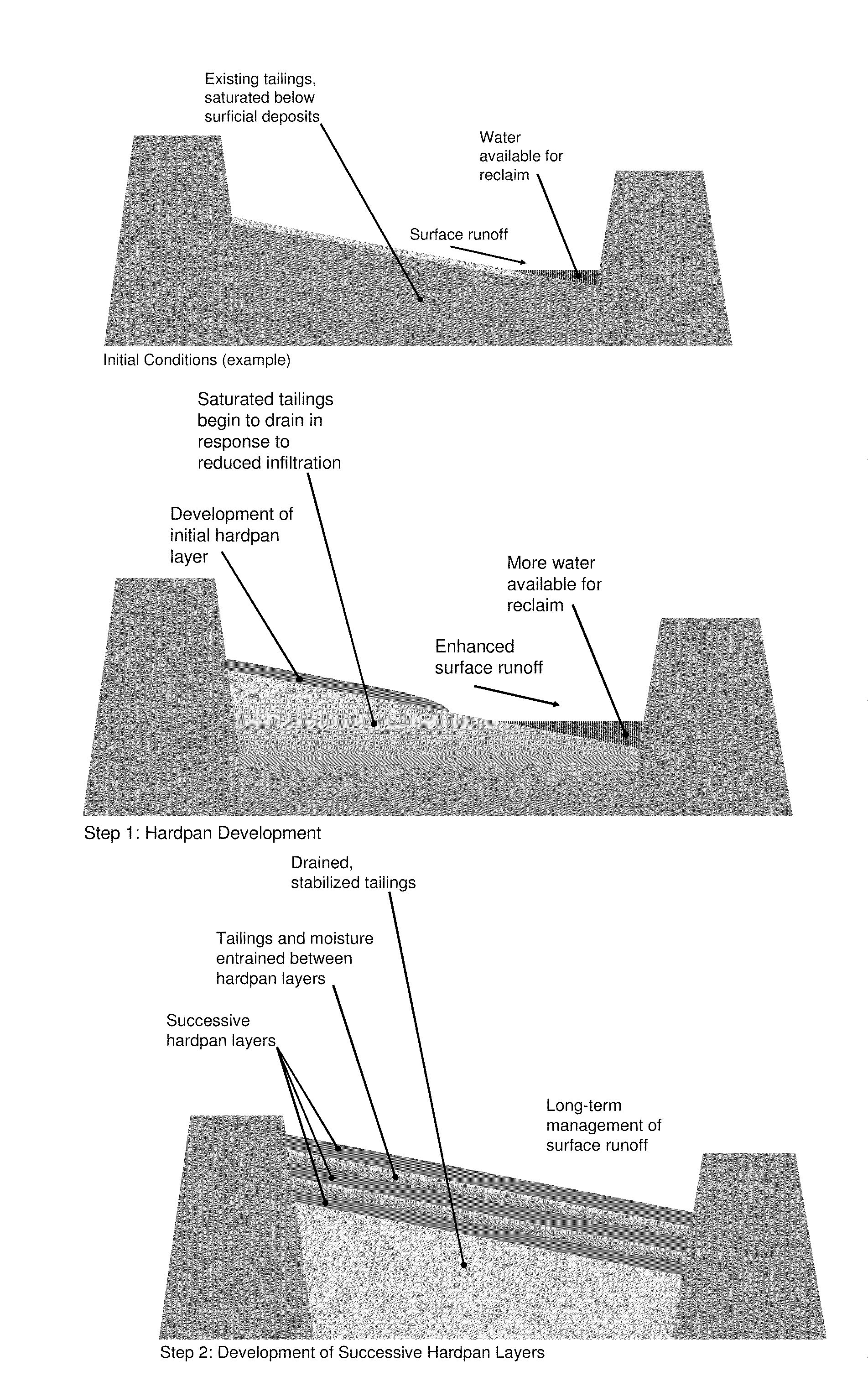

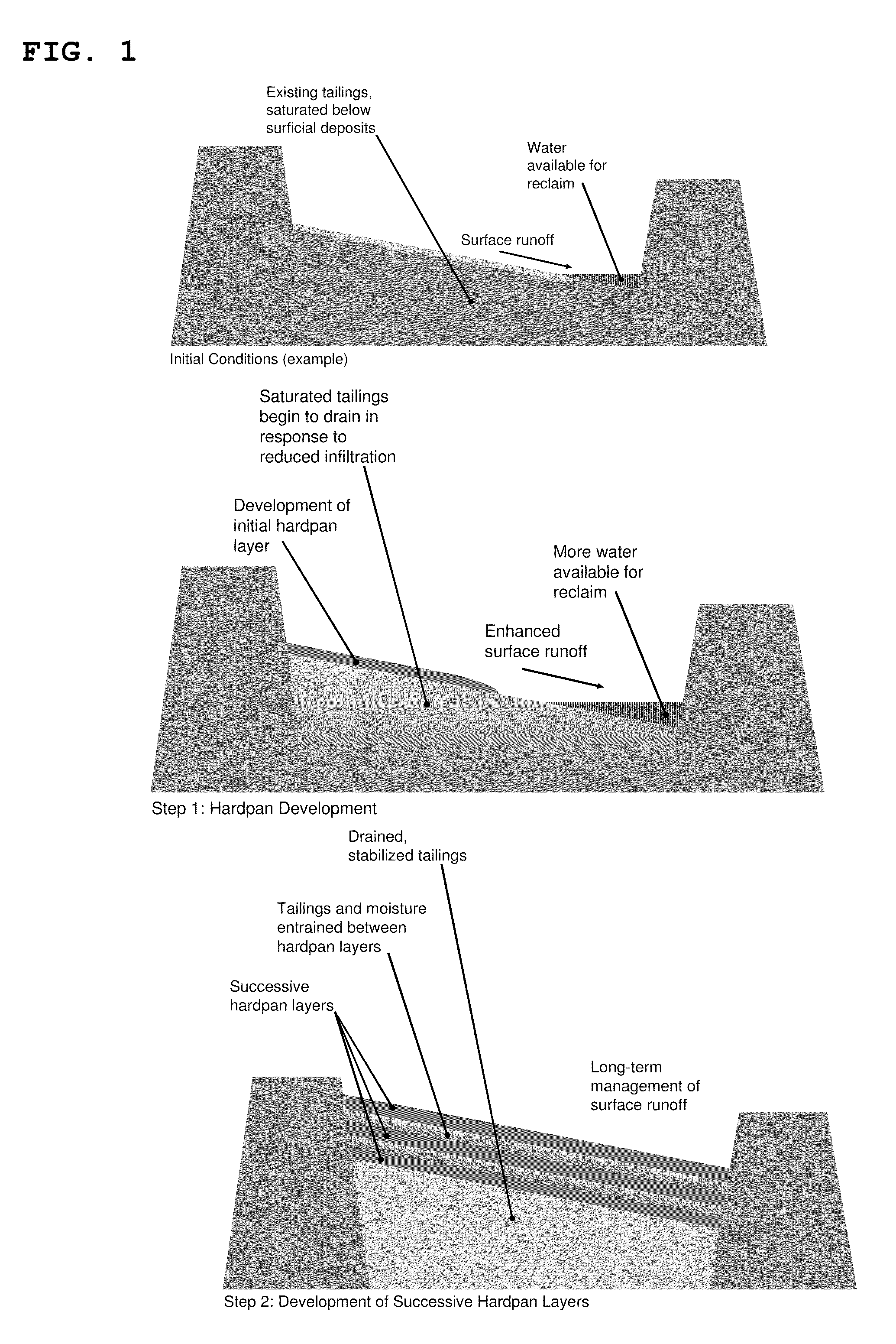

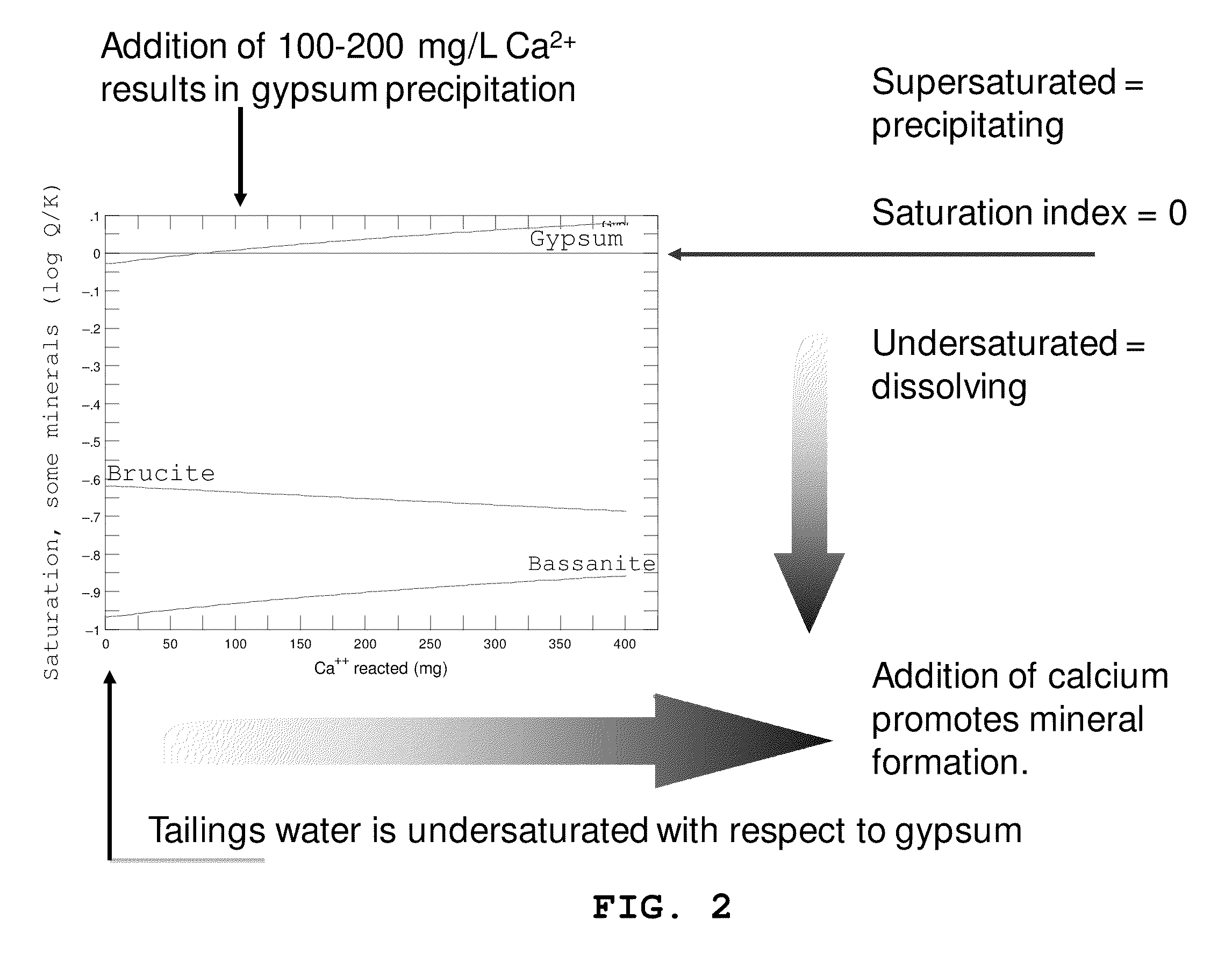

Mineral hardpan formation for stabilization of acid- and sulfate-generating tailings

InactiveUS20090311048A1Stabilizing mine tailingsReduce environmental pollutionWater contaminantsContaminated soil reclamationSulfateHardpan

The invention provides methods of stabilizing mine tailing through the formation of solid evaporate mineral surface hardpan thereby stabilizing mine tailings and decreasing environmental contamination surrounding a tailings impoundment.

Owner:HORST JOHN F +2

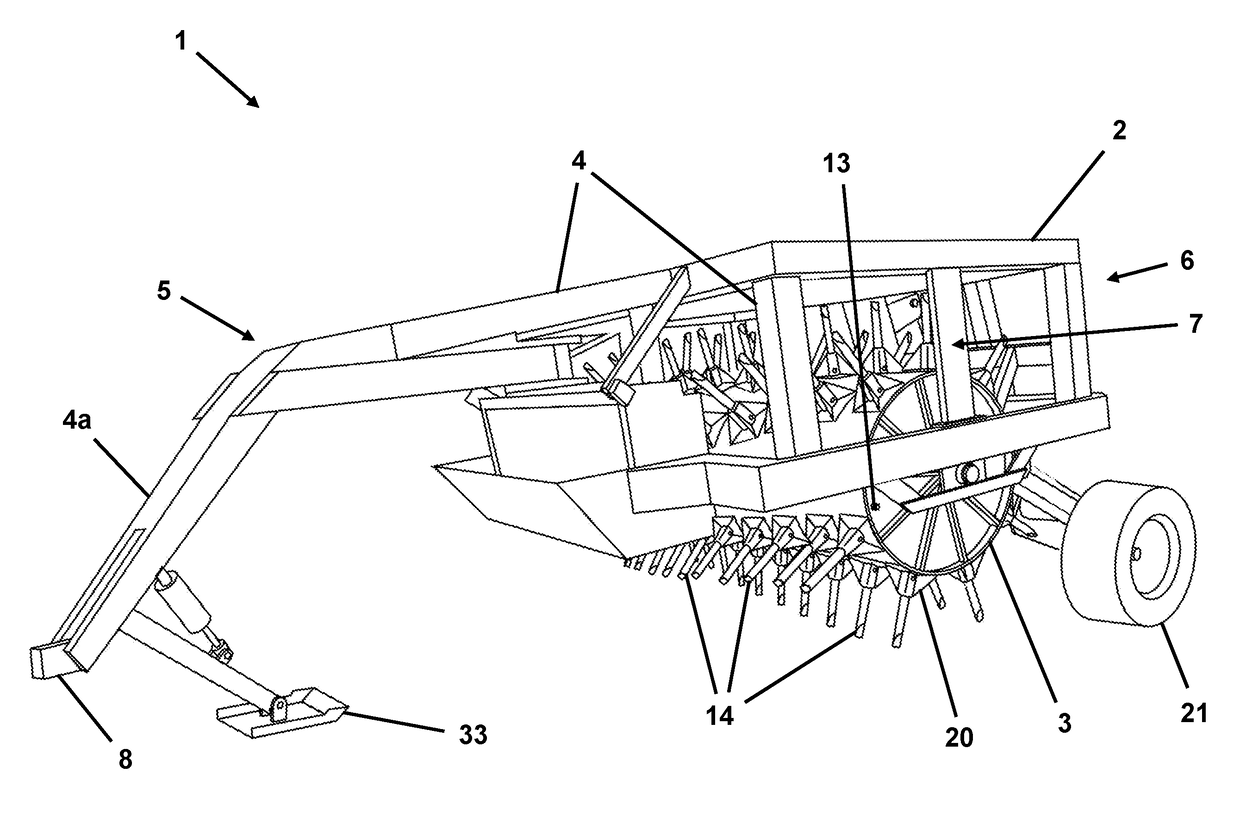

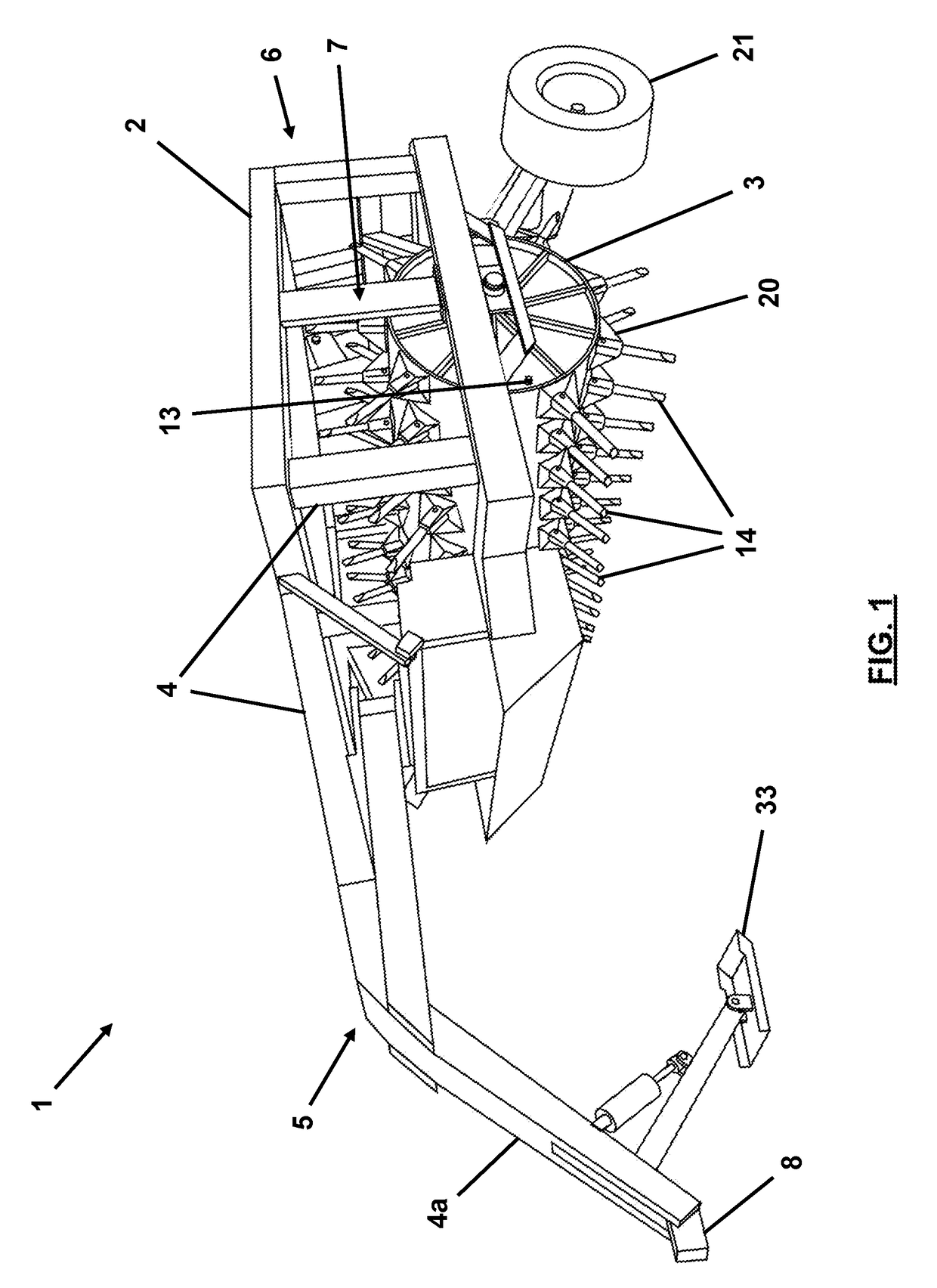

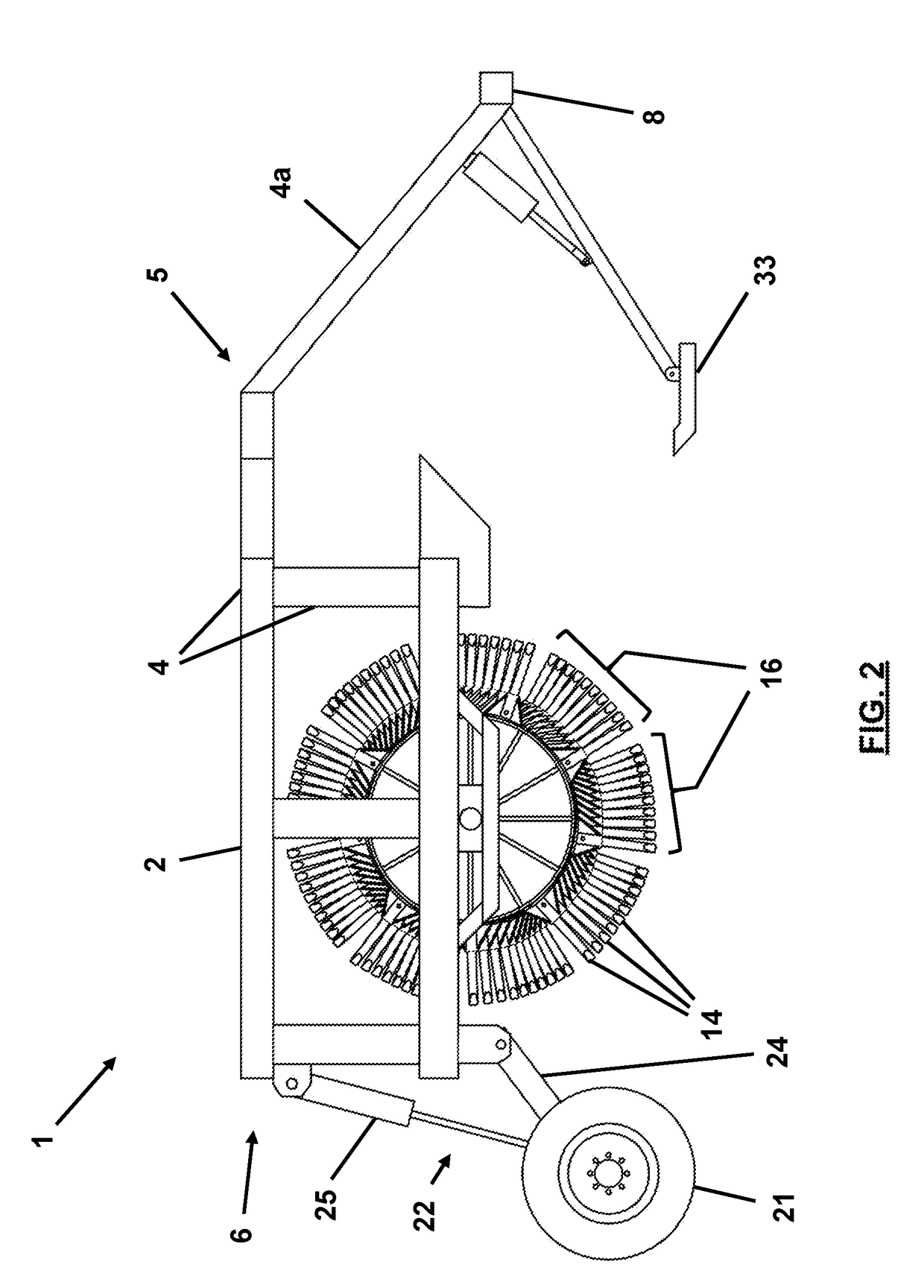

Hardpan Apparatus

An apparatus for breaking up the hardpan subsoil layer of agricultural land has a wheeled frame adapted to connect to a tractor. A roller is rotatably mounted within the frame. A plurality of spike members are attached to the circumferential face of the roller and extend outwardly therefrom beneath the frame for penetrating engagement with the hardpan subsoil layer, to thereby break up the hardpan.

Owner:JANZEN JACK +1

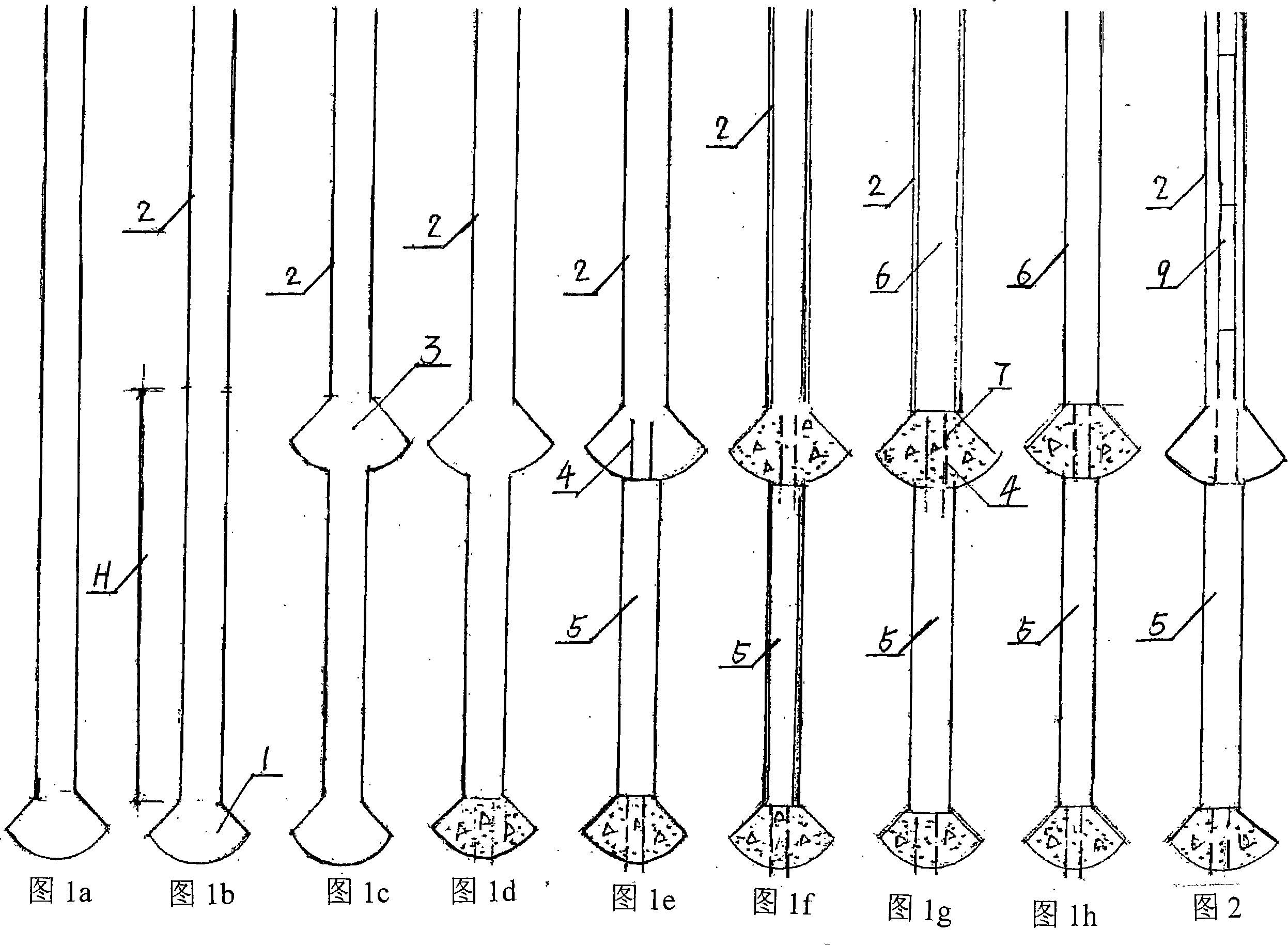

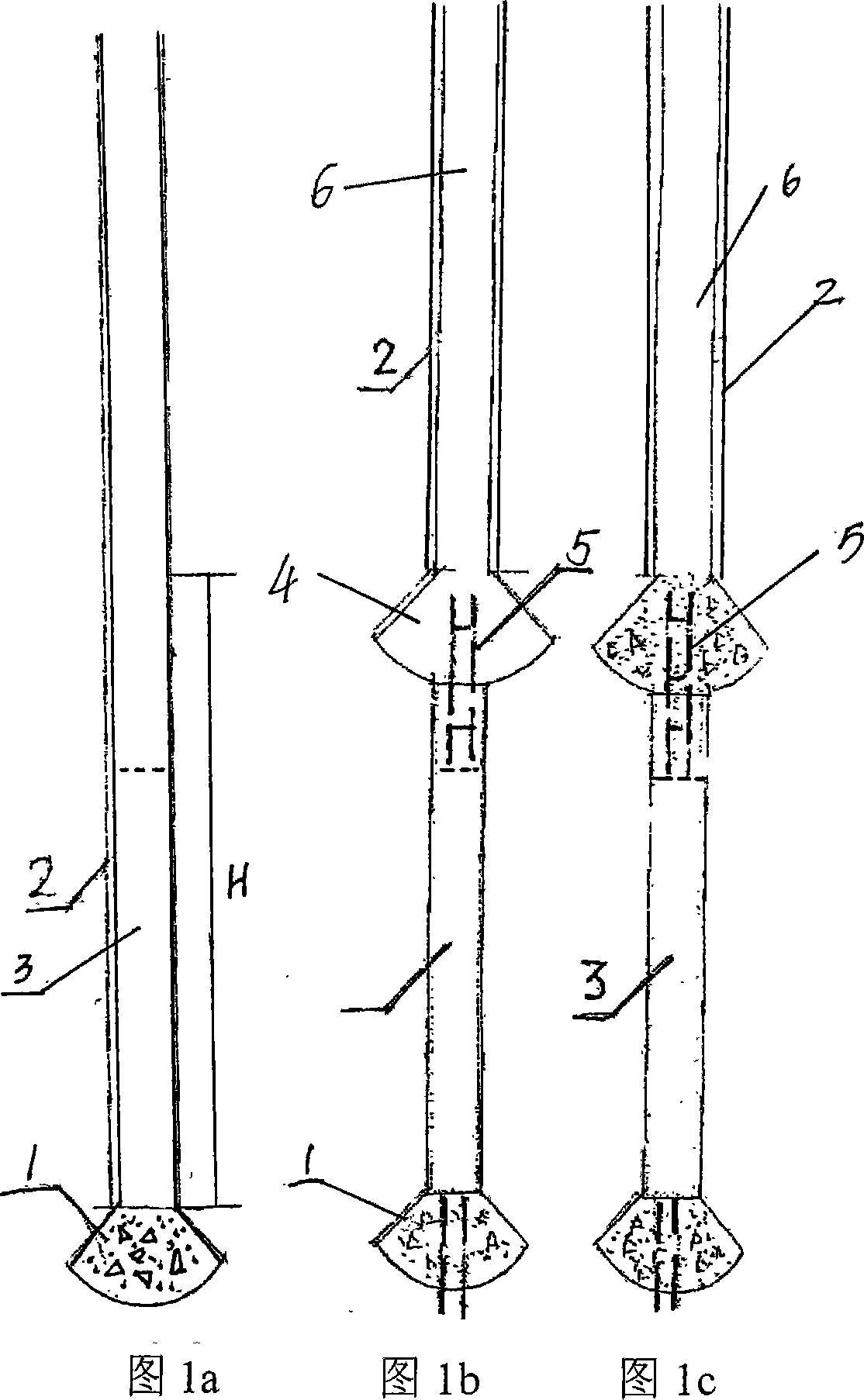

Blasting pile forming method for three-stage bottom expanding composite pile body

InactiveCN101135147AIncrease profitHigh precision of bottom expansion in constructionBulkheads/pilesThree stageHardpan

The blasting piling process of three-stage under-reamed combined pile stem includes the following steps: 1. immersing immersed tube with metal pile head into hardpan; 2. taking out the metal pile head; 3. forming the lower base space through blasting, drawing the immersed tube to the first designed distance, forming the middle base space through blasting, taking out soil, setting the prefabricated pile stem with steel dowels in the lower end into the immersed tube, pouring the lower base, the middle base and the lower pile stem with concrete; 4. drawing the immersed tube to the second designed distance, forming the upper base space through blasting, and pouring the upper base with concrete; 5. setting the upper prefabricated pile stem with steel dowels in the lower end into the immersed tube, and connecting the steel dowels to the upper base; and 6. withdrawing the immersed tube and pouring cement mortar into gap. The pile has high material strength utilizing rate and low construction cost.

Owner:周亚萍

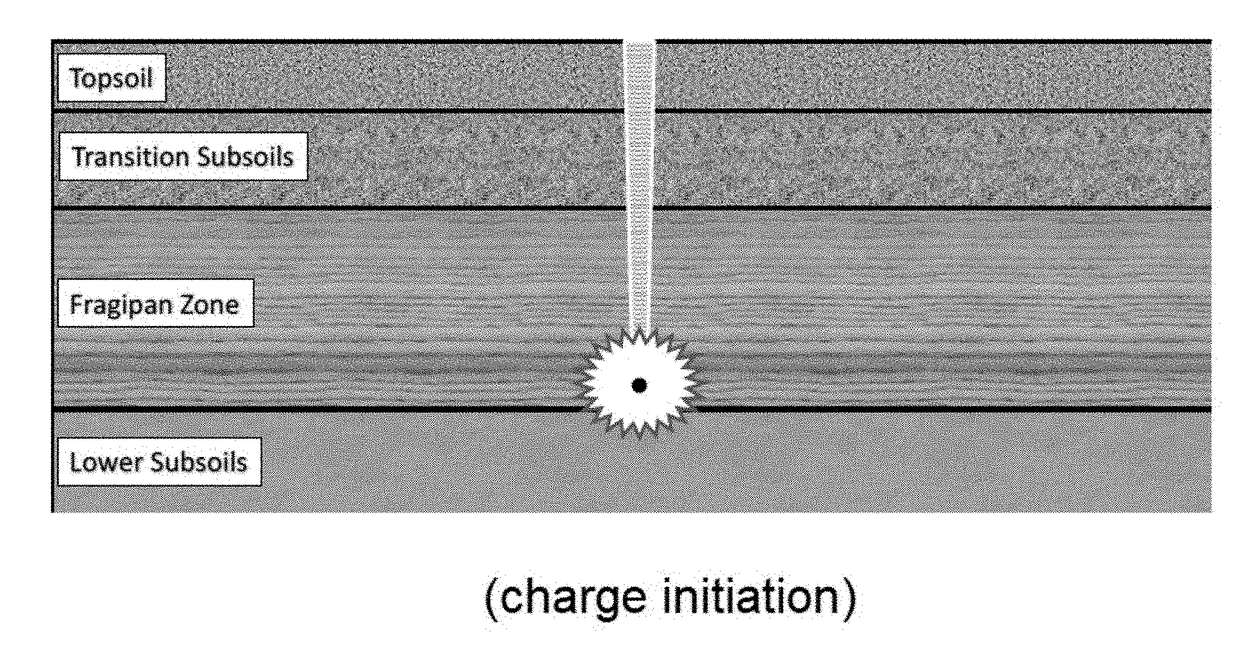

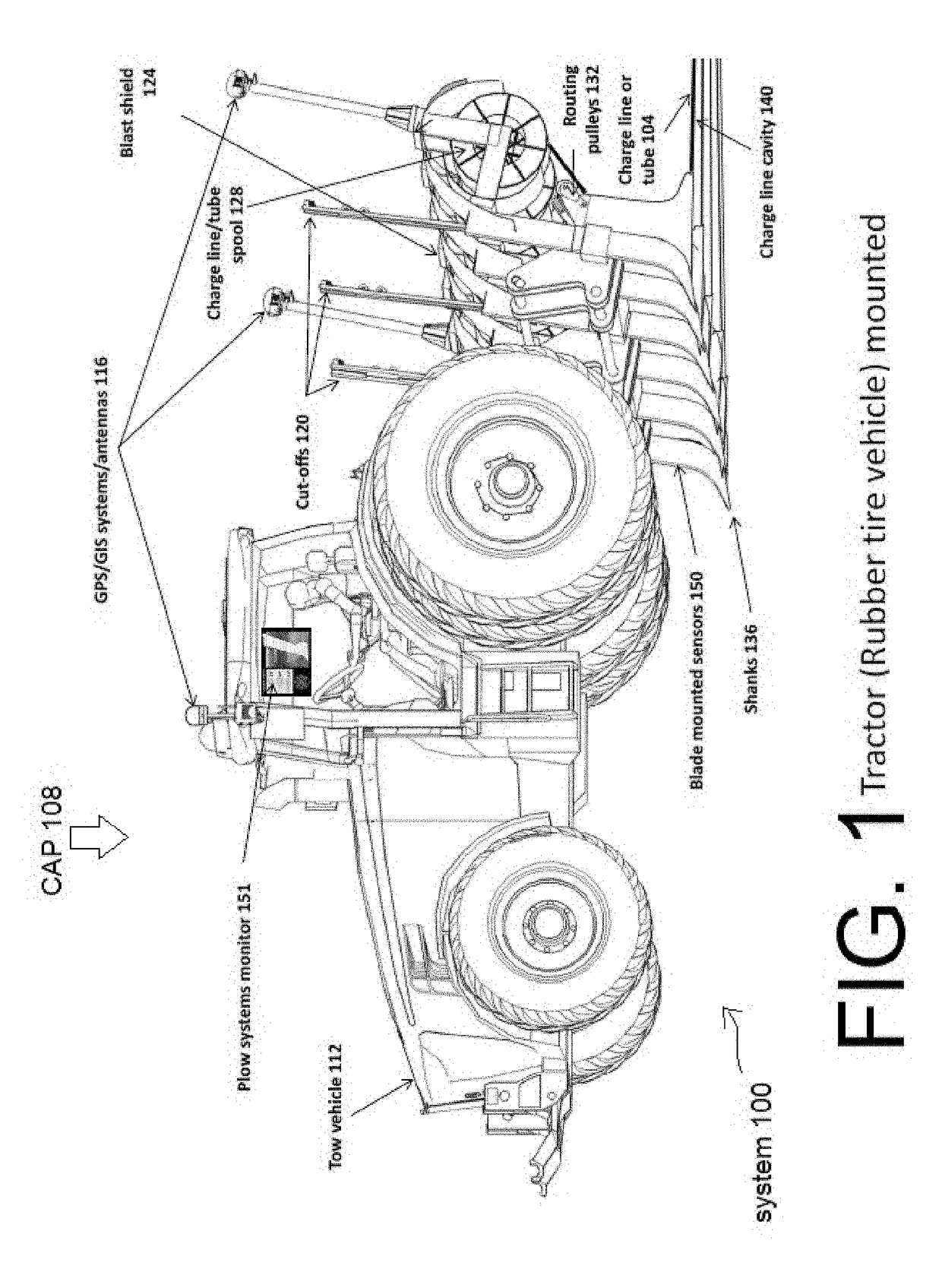

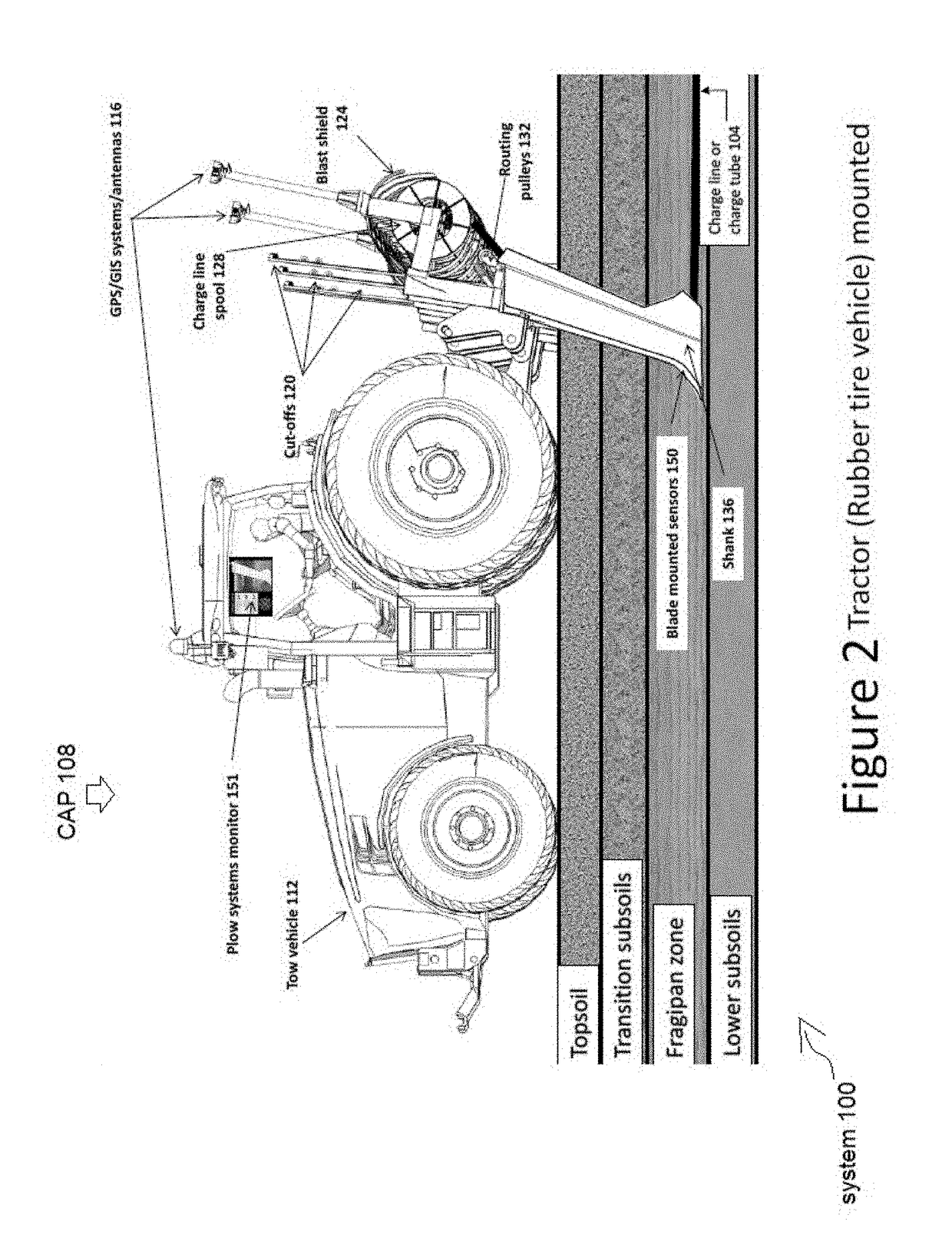

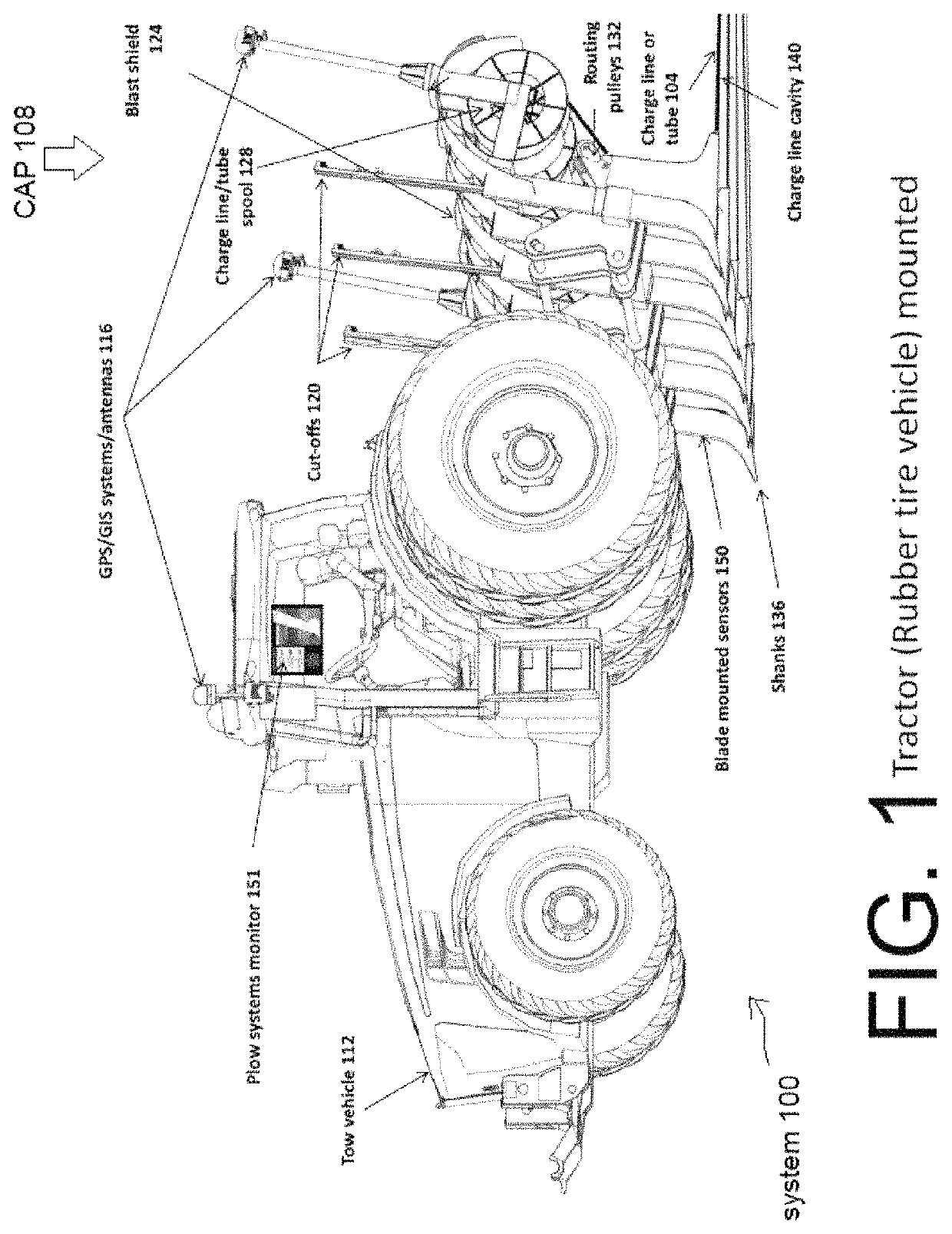

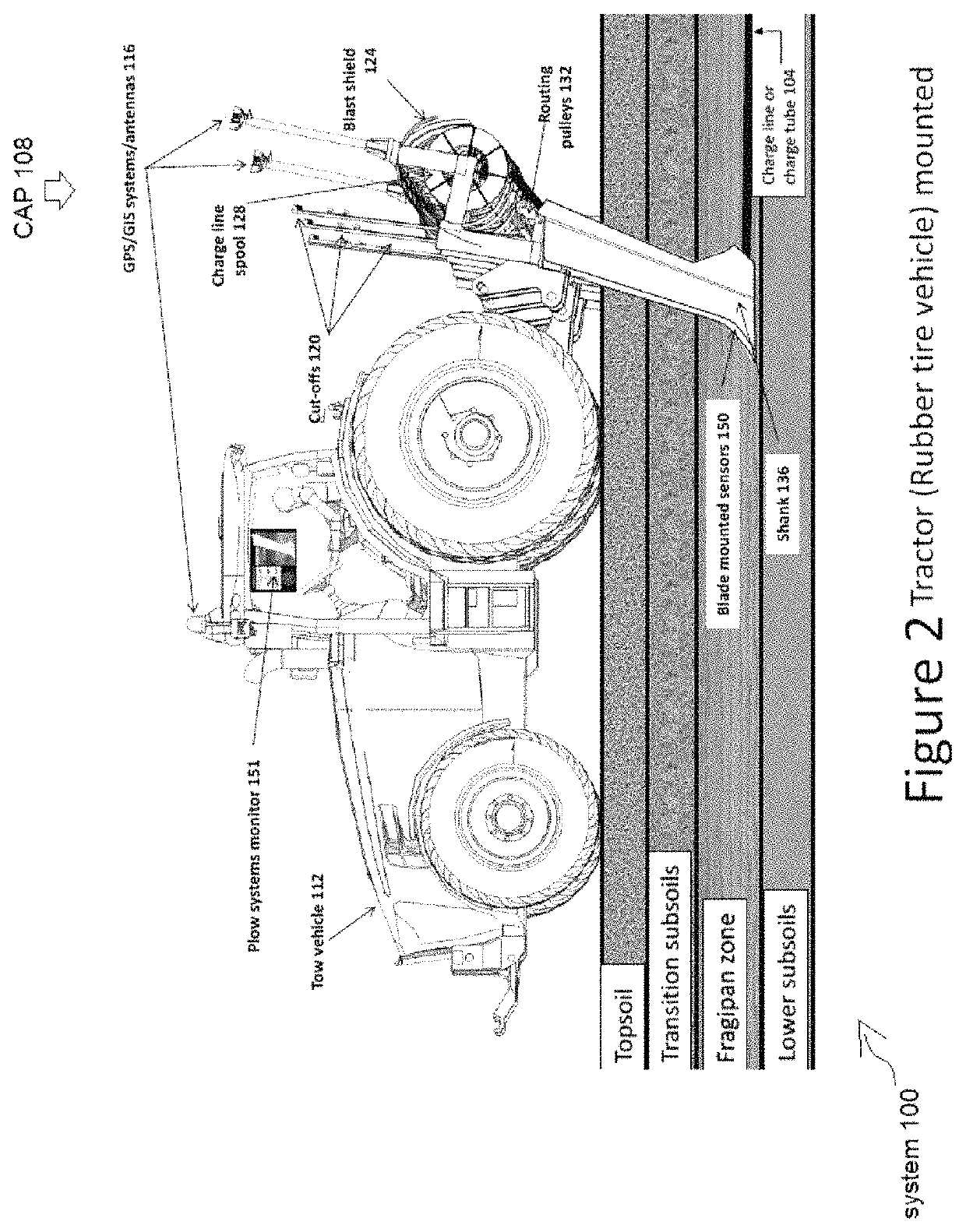

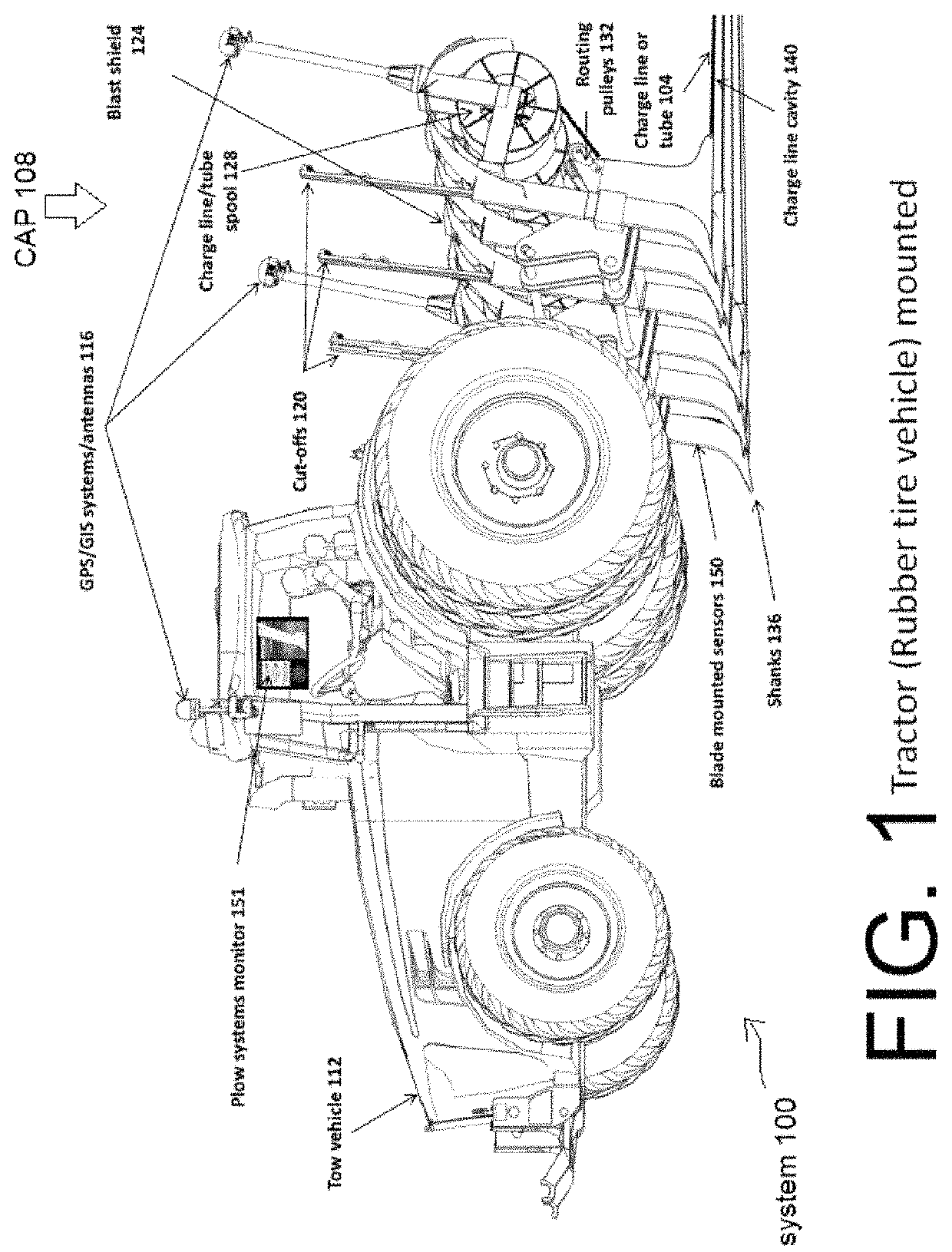

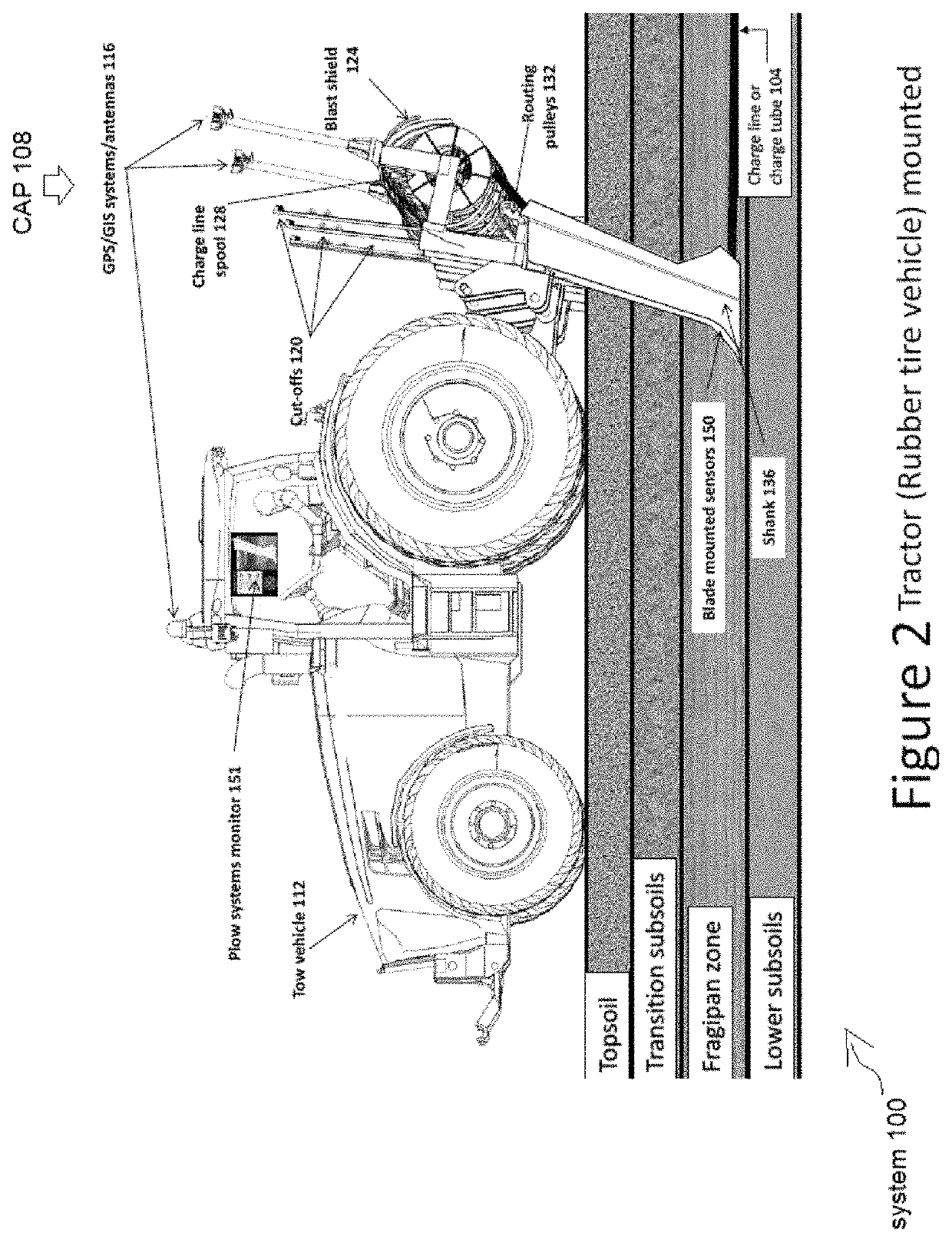

Agriculture System and Method

ActiveUS20180184575A1Beyond capacityReduce net vibrationDefence devicesSoil loosening devicesSoil scienceHardpan

An agricultural enhancement method for removing or overcoming soil fragipan, hardpan, or other natural and / or artificial soil compaction barriers is disclosed. These barriers prevent root and / or water penetration, which inhibits agricultural development. Consequently, removing and overcoming these barriers is beneficial to the soil and to agricultural yields.

Owner:OLIVER TROY

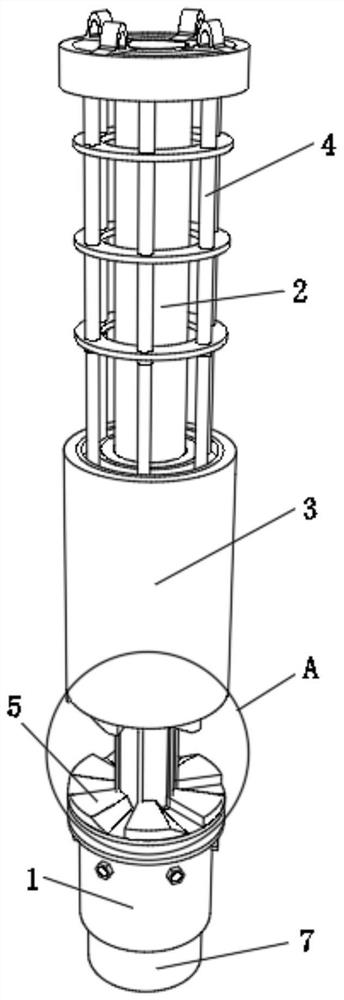

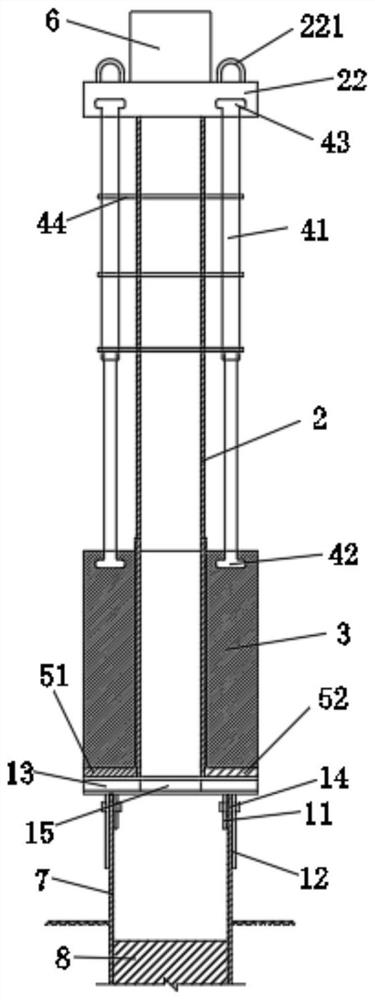

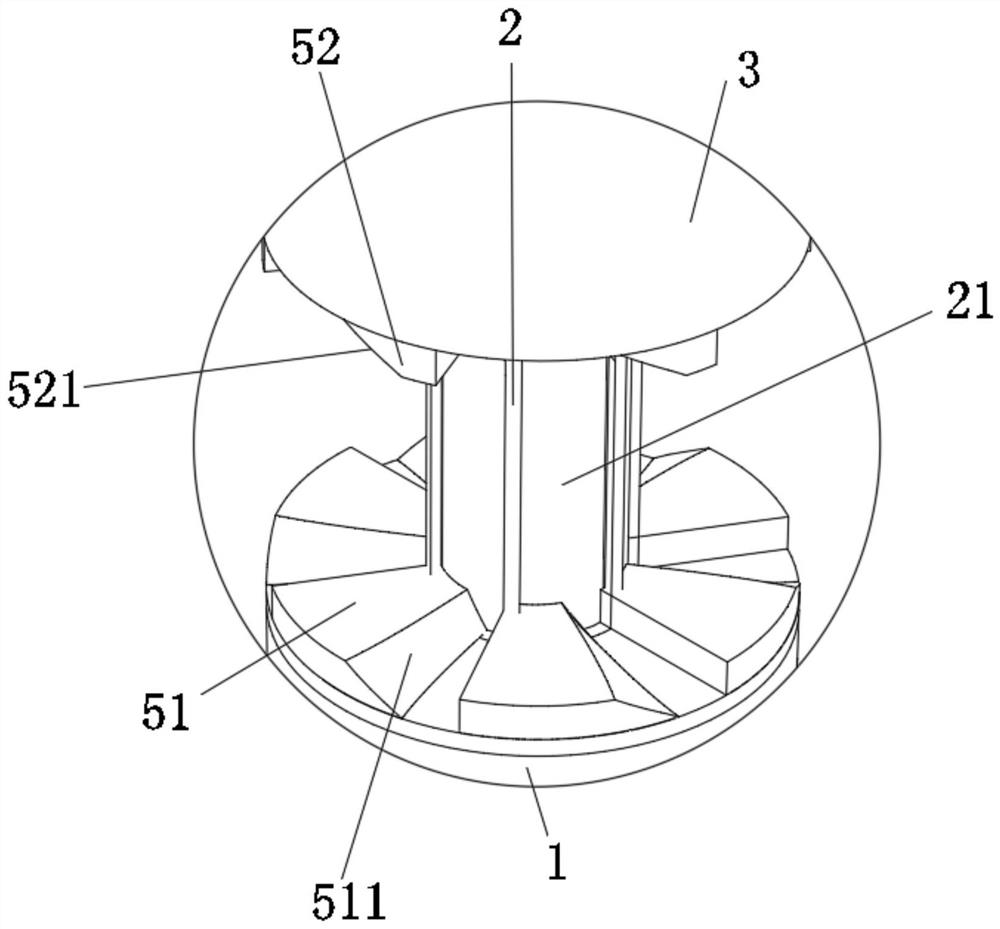

Steel pipe pile sinking device

PendingCN114277797AIncreased ability to traverse various soil layersExtended soil classBulkheads/pilesPile capHardpan

The invention provides a steel pipe pile sinking device. The steel pipe pile sinking device comprises a pile cap arranged at the top end of a steel pipe pile; the bottom end of the supporting cylinder is arranged on the pile cap; the pile hammer is arranged on the outer side of the supporting cylinder in a sleeving manner; the lifting mechanism is connected with the pile hammer and used for driving the pile hammer to move along the supporting cylinder; and the slewing mechanism is arranged on the pile hammer and the pile cap and used for enabling the pile hammer to impact the pile cap vertically and downwards or enabling the pile hammer to rotate relative to the pile cap and impact the pile cap. According to the method, the problem that the pile cannot be sunk to the designed depth due to the fact that a hammer is rejected in the pile sinking process due to soil plugs, hard strata and the like can be solved, the damage to soil layers around the pile and at the pile end is small, the bearing capacity loss of the pile is small, the equipment hoisting frequency is reduced, the application field of the steel pipe pile is greatly expanded, energy consumption is reduced, and the construction efficiency and safety are obviously improved.

Owner:CCCC FOURTH HARBOR ENG INST +2

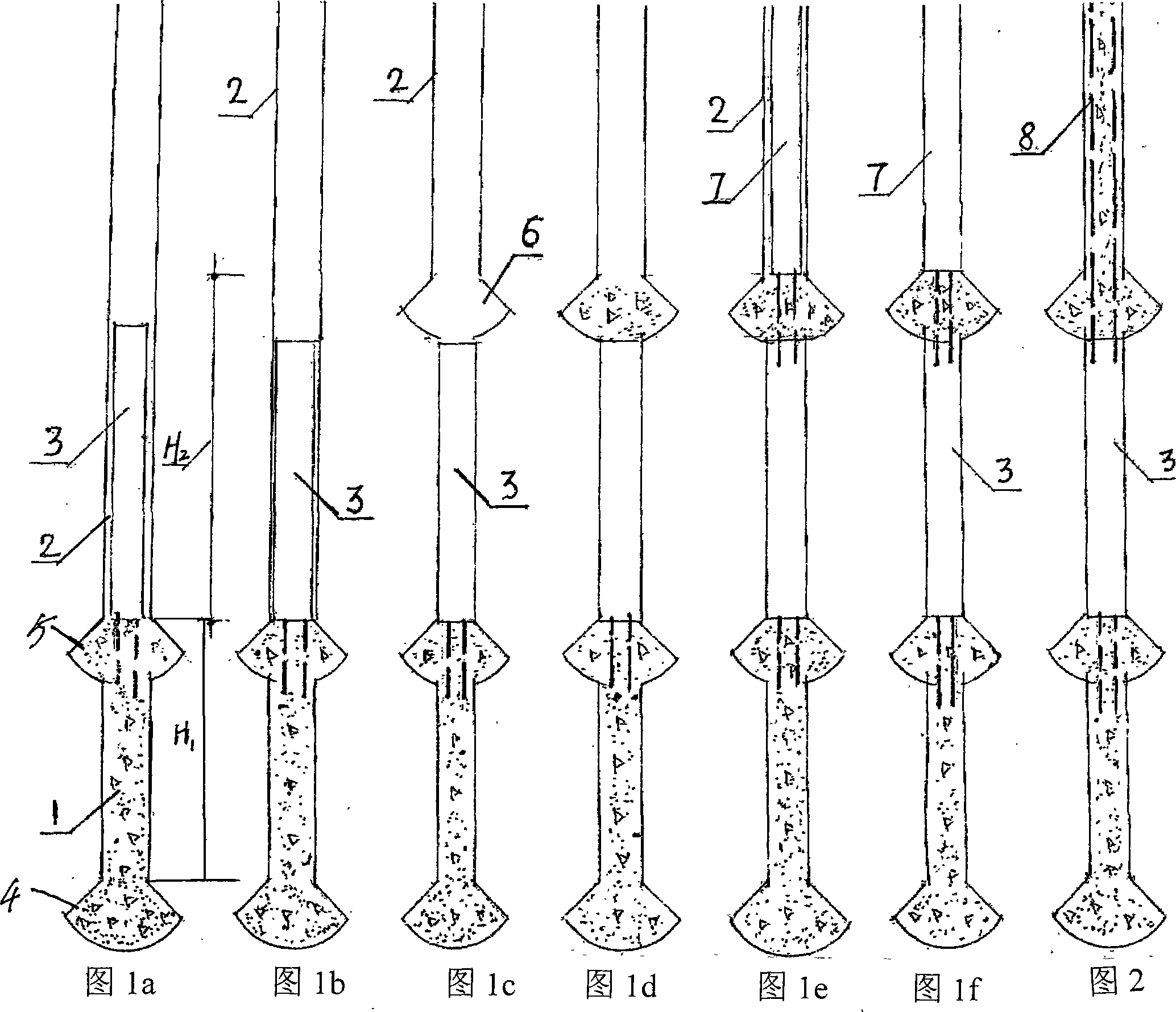

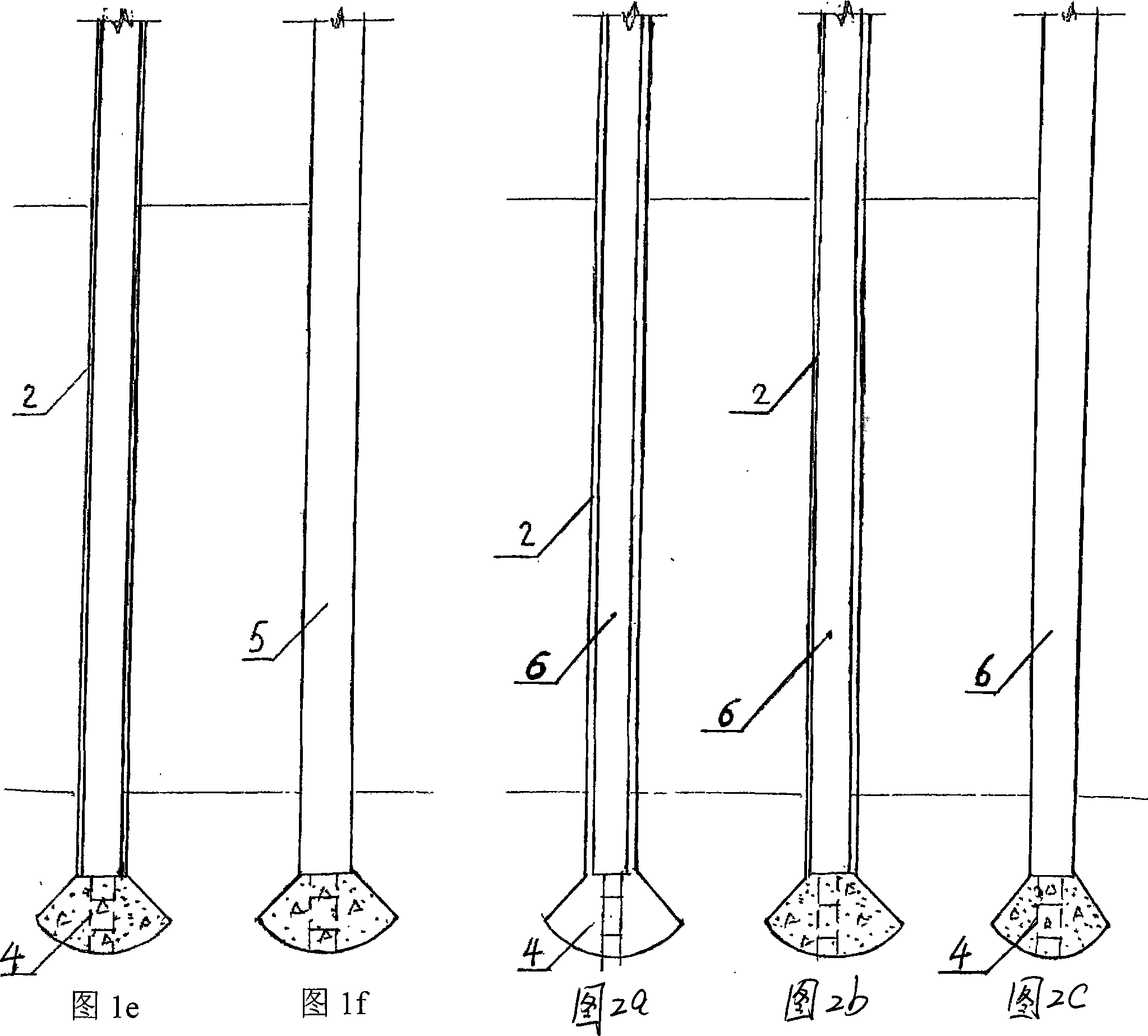

Mixed pile-forming method for multilevel expanding bottom pile with high bearing capacity

InactiveCN101130957AImprove carrying capacityImprove strength utilizationBulkheads/pilesHardpanImmersed tube

The present invention relates to construction of building pile foundation engineering, and is especially mixed piling process of multistage under-reamed pile with prefabricated pile foundation and great bearing capacity. The mixed piling process includes the following steps: immersing immersed tube with metal pile head into hardpan, taking out the metal pile head, forming the lower base space and taking out soil, drawing upwards the immersed tube to designed distance, forming the upper base space and taking out soil, pouring the lower base with concrete and inserting steel dowels, setting the prefabricated pile stem for the steel dowels to connect the lower prefabricated pile stem, the base and the upper prefabricated hollow pile stem integrally, withdrawing the immersed tube and injecting cement mortar to around the pile stem. The pile has small stem diameter, accurate location, high material strength utilizing rate and other advantages.

Owner:陈宁华

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

The invention discloses a building pile foundation project and a construction method, in particular to a bottom-expanding and pile-forming method for a sinking pipe precast steel concrete pedestal pile, comprising penetrating the sinking pipe through a soft soil layer and pressing the sinking pipe to a design height hardpan; taking out a metal pile head, descending the sinking pipe to expand the bottom, finishing the bottom expanding and soil digging, hauling the bottom expanding device out of the ground, taking soil with an air soil absorption device until the clearance of the soil; putting a radiation shaped steel bar into a pedestal cavity and nailing the steel bar into the hardpan, pouring a qualitative concrete produced on the ground through the sinking pipe to the pedestal cavity to form a concrete pedestal, descending the precast steel concrete pile body and integrating with an on-the-spot poured concrete pedestal docking anchor through a steal bar at the bottom as a whole; pulling out the sinking pipe to form a pile after pouring grout along an interior side of the sinking pipe. The invention selects clear soil without grain virtual soil, has high efficiency, enhances effectively single pile bearing capacity, reaches design requirements, guarantees pile pedestal project quality, reduces construction cost, increases material strength utilization ratio, and leads the pile to work under a most economic condition, and enhances construction security.

Owner:王国奋

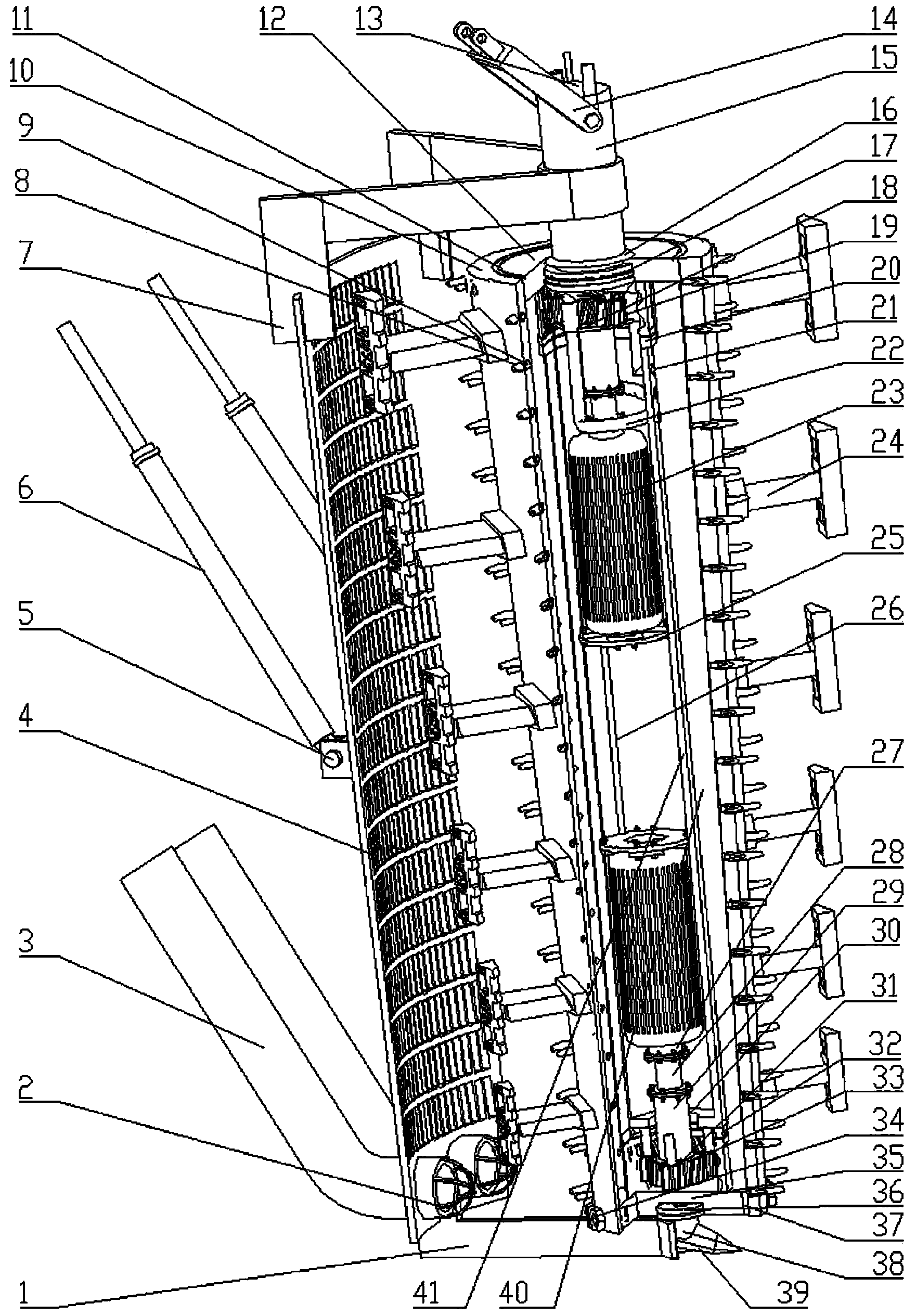

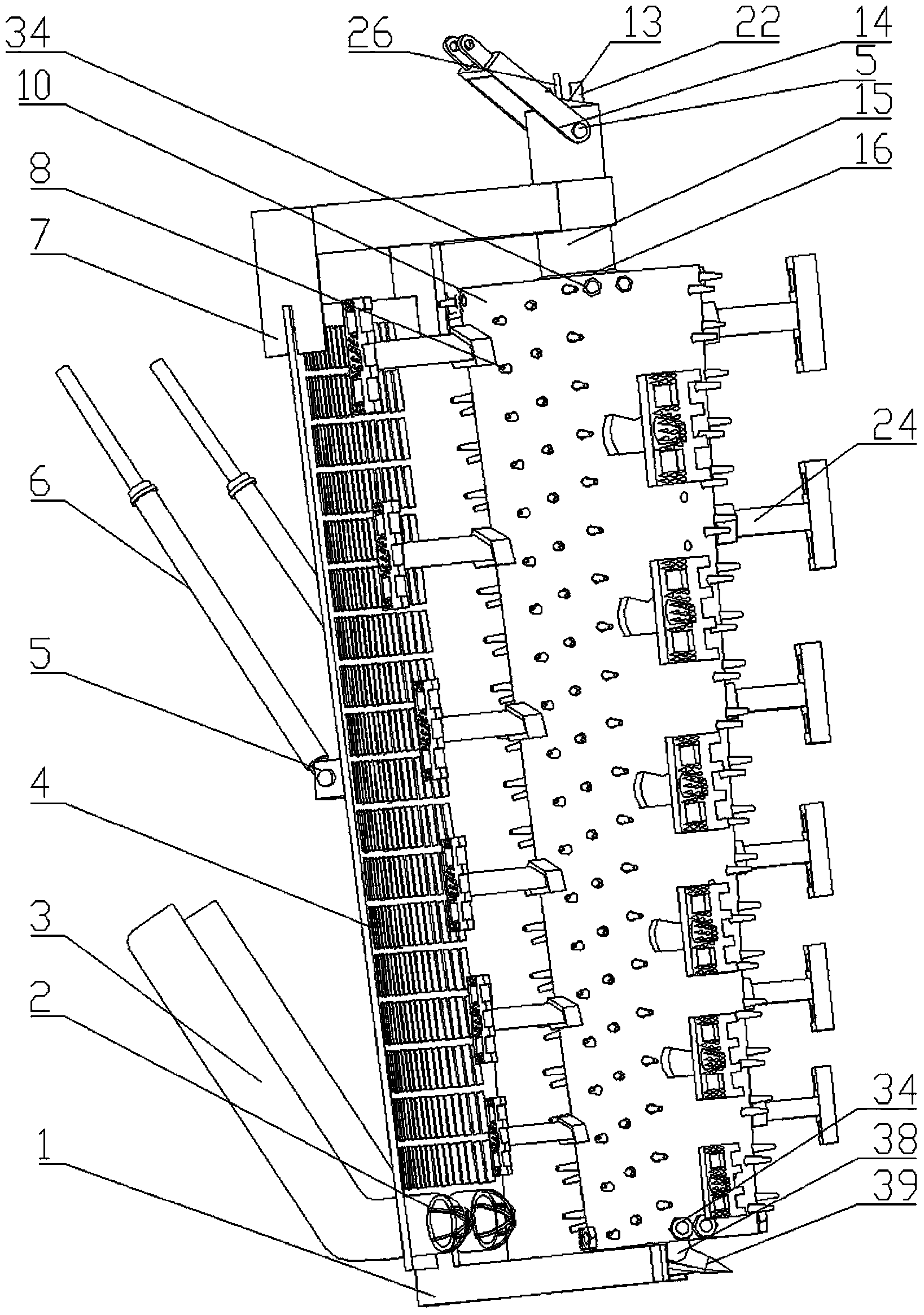

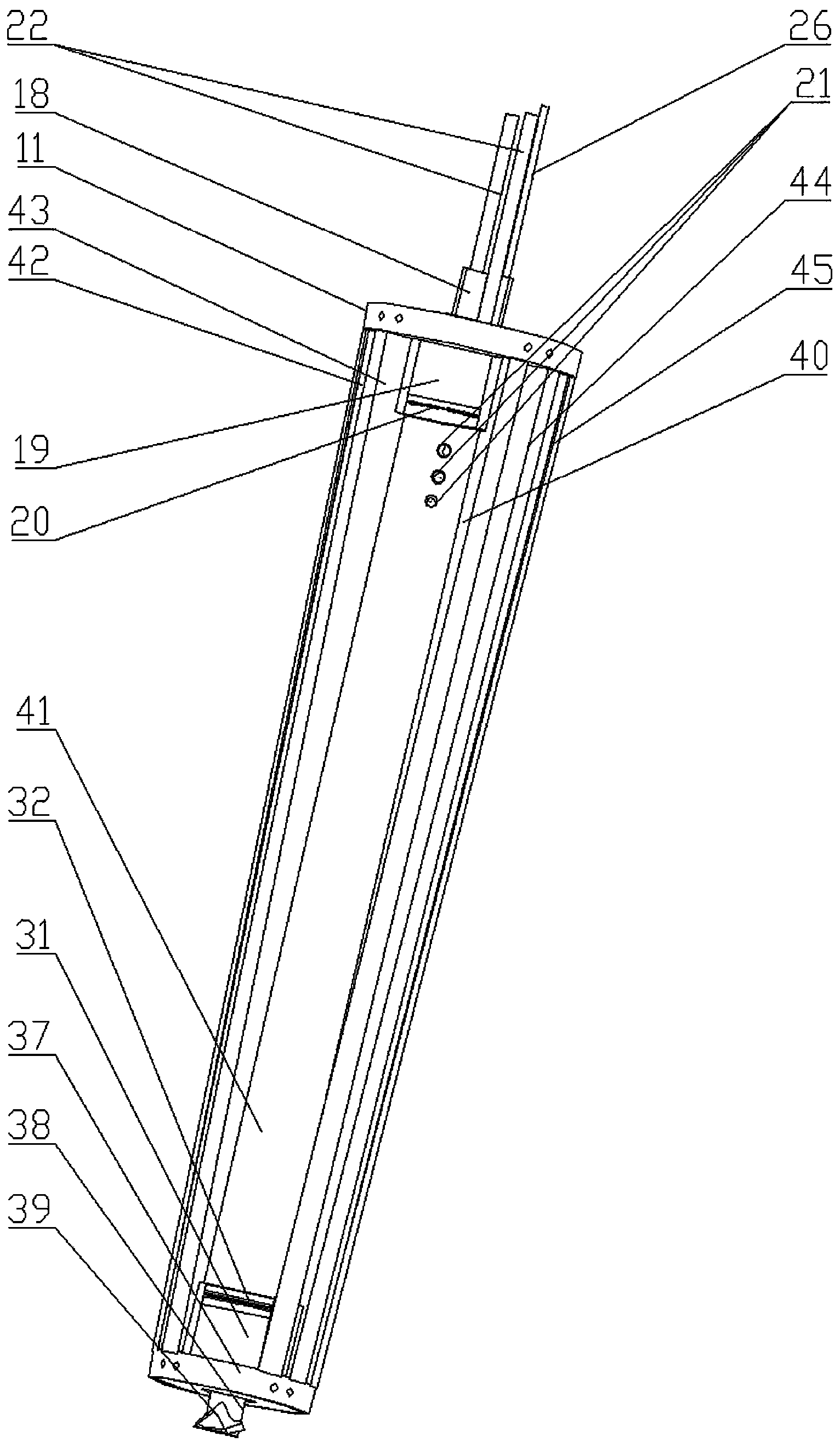

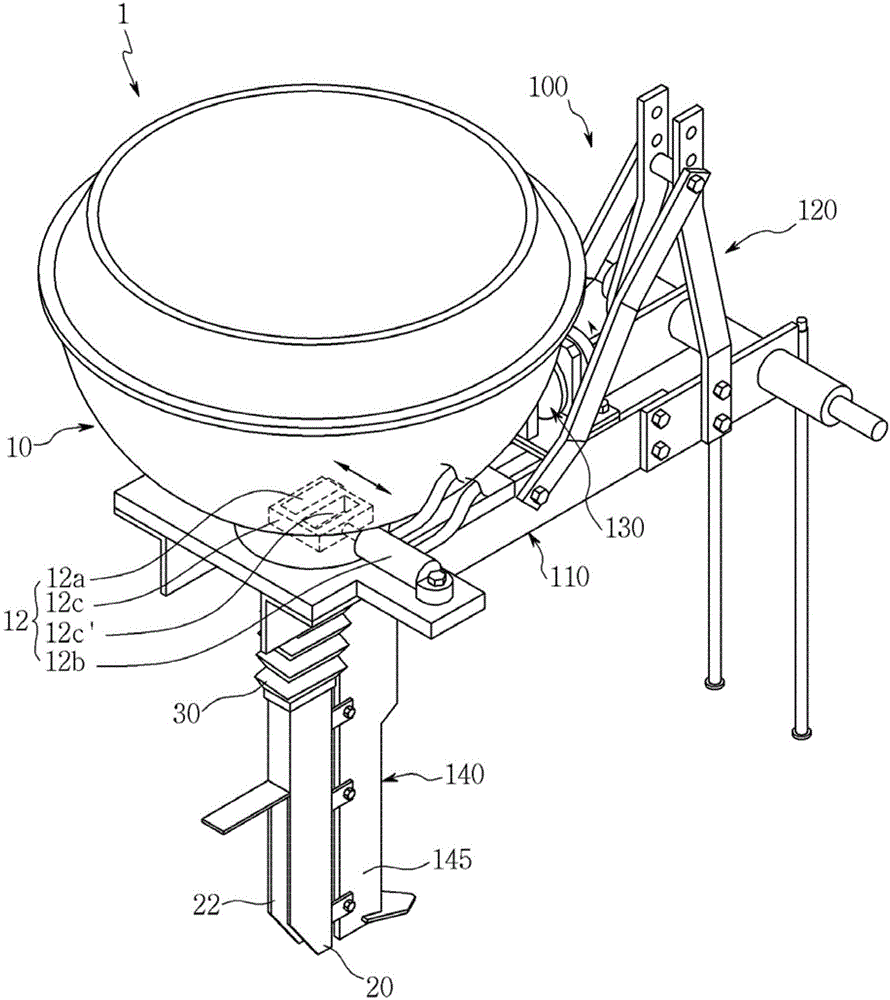

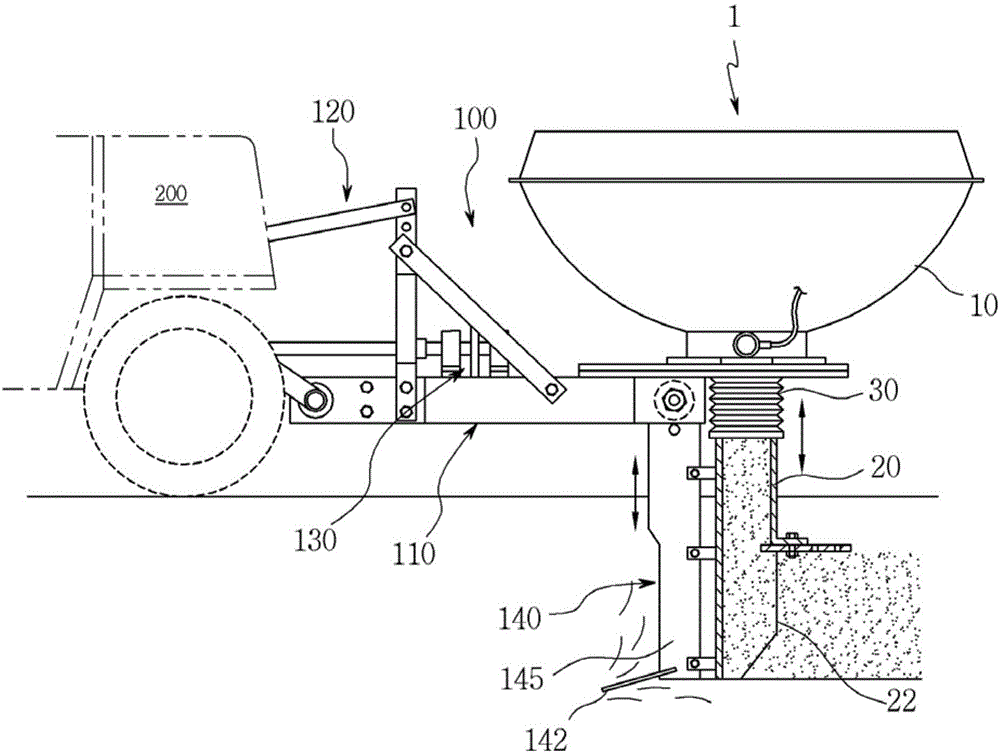

Input supply apparatus for pan-breaker

Provided is an input supply apparatus for a pan-breaker, comprising: a receiving hopper that drops an input received therein by using an opening / closing part, which is formed as a base on the upper rear side of a main body frame of the pan-breaker, in order to effectively supply the input required in a process of crushing a hardpan by the pan-breaker; a discharge pipe that is mounted on the rear side of a crushing blade support of the pan-breaker and has a rectangular discharge hole formed therein in which to discharge the input, falling from the receiving hopper, to the soil of the crushed hardpan; and a flexible connecting pipe connected between the opening / closing part and the discharge pipe to guide the input, falling from the receiving hopper, to the discharge pipe. Therefore, it is possible to effectively supply an input, which is suitable for a necessary application, to soil, thereby effectively inducing the growth of crops and preventing the crops from being easily turned over.

Owner:金庚镐

Mixed pile forming method for high-bearing prefabricated and cast-in-situs steel concrete composite pile body

InactiveCN101135150AHigh concentricityImprove carrying capacityBulkheads/pilesReinforced concreteEngineering

The present is prefabricating and in-situ reinforcing concrete casting process for constructing high bearing capacity combined pile stem. The process includes the following steps: 1. immersing immersed tube with metal pile head into hardpan to design elevation; 2. taking out the metal pile head; 3. forming the lower base space, taking out soil, casting lower concrete base, immersing one prefabricated hollow pile stem with steel dowels in the lower end into the immersed tube, and drawing upwards the immersed tube to one first designed distance; 4. forming the middle base space, drawing upwards the immersed tube to one second designed distance, forming the upper base space and penetrating reinforcing bars through the upper and the middle base spaces; 5. pouring concrete to form the upper base, the lower base and the middle pile stem; 6. setting the prefabricated pile stem with steel dowels into the immersed tube; and 7. withdrawing the immersed tube.

Owner:周亚萍

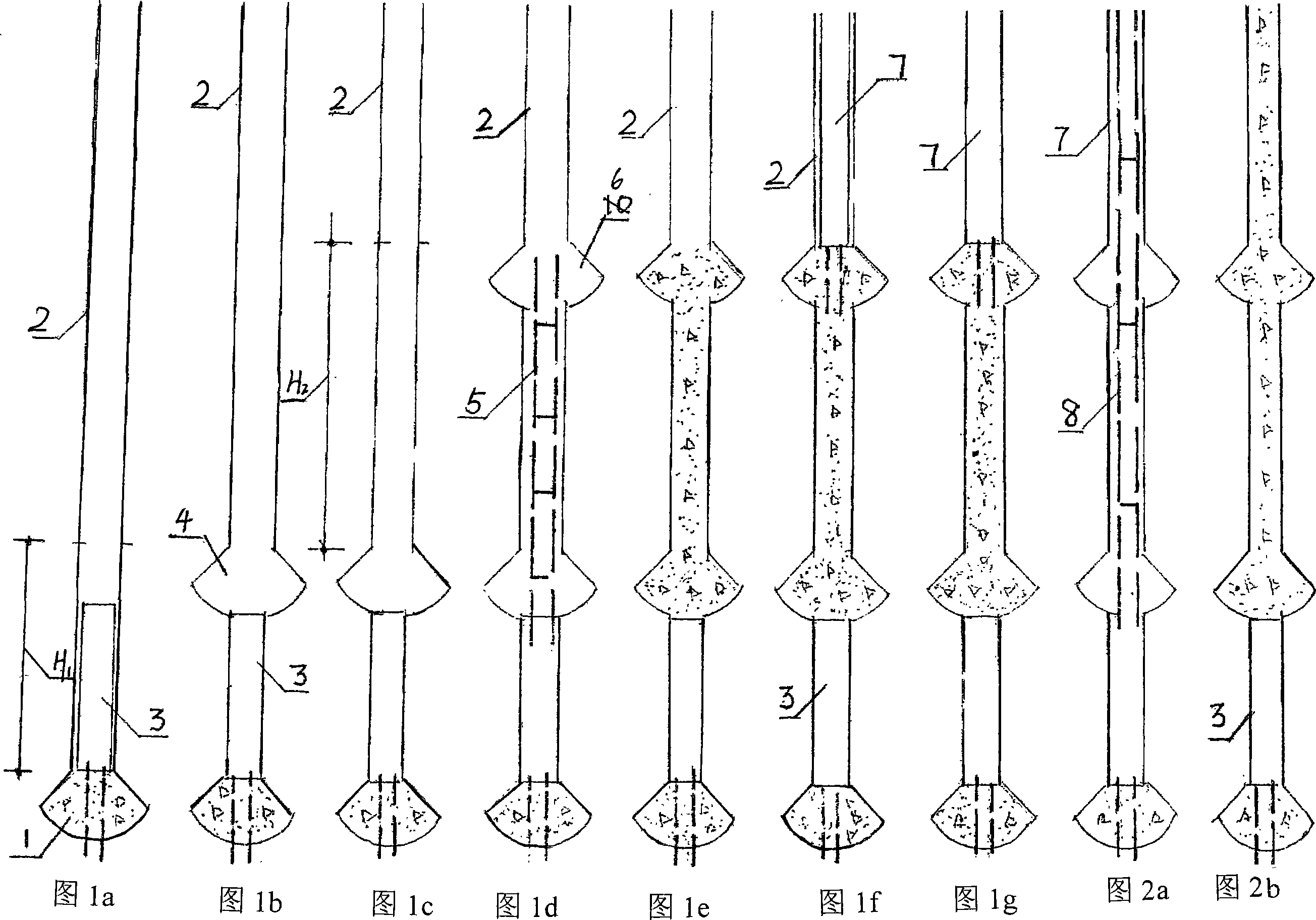

Mechanical piling method for third level bottom-expanded combined pile body

InactiveCN101173513AIncrease profitHigh precision of bottom expansion in constructionBulkheads/pilesEngineeringHardpan

The invention relates to a mechanical pile forming method for there level belled composite pile body, comprising the craft steps that: a, a sinking pipe with a metal pile head is immersed into hardpan to design elevation; b, the metal pile head is taken out; c, a lower base space is processed by a belled device, the sinking pile is drawn upward to setting distance H1, an intermediate base space is processed, the pulverizing soil in the base space is cleaned by drawing out soil device, a prefabricated hollow pile body with an inserted reinforcement arranged at the lower end is run into the sinking pile, the lower base, the intermediate base and the lower pile body are poured by concrete pouring; d, the sinking pile is drawn upward to setting distance H2, an upper base space is processed, the pulverizing soil is fell into the inner of prefabricated hollow pile body, the upper base is poured by concrete pouring; e, an upper prefabricated hollow pile body with an inserted reinforcement arranged at the lower end is run into the sinking pile, the inserted reinforcement is anchored with the upper base; f, the sinking pile is run out, cement slurry is injected into the gaps on the external surface of the pile body. The invention has the advantages of improving the utilization ratio of materials strength and reducing the cost of construction.

Owner:周亚萍

Mechanical pile forming method for high-bearing multi-stage club-footed pile

InactiveCN101135158AImprove carrying capacityImprove strength utilizationBulkheads/pilesHardpanImmersed tube

The present invention relates to construction of building pile foundation engineering, and is especially mechanical piling process of multiple stage under-reamed pile with high bearing capacity. The piling process includes the following steps: immersing immersed tube with metal pile head into hardpan to design elevation; taking out the metal pile head; forming the lower base space and taking out soil; drawing upwards the immersed tube to designed distance; forming the upper base space and taking out soil; pouring concrete to form the lower base and setting steel dowels; setting the prefabricated pile stem; inserting the lower ends of the steel dowels into the upper base space and the upper ends into the prefabricated hollow upper pile stem; connecting the prefabricated lower pile stem, the base and the prefabricated hollow upper pile stem integrally with the steel dowels; withdrawing the immersed tube and injecting cement mortar to the gap. The present invention has the advantages of high material strength utilizing rate, etc.

Owner:王茂华

Pile forming method for high-bearing two-stage bottom expanding prefabricated pile body

InactiveCN101135153AImprove strength utilizationIncreased reduction factorBulkheads/pilesEngineeringHardpan

The present invention relates to construction of building pile foundation engineering, and is especially piling process of two-stage under-reamed prefabricated pile stem with high bearing capacity. The piling process includes the following steps: 1. immersing immersed tube with metal pile head into hardpan to design elevation; 2. taking out the metal pile head; 3. forming the lower base space with blasting and under reaming apparatus and pouring the lower base with concrete; 4. setting the prefabricated hollow pile stem with steel dowels into the immersed tube; 5. drawing upwards the immersed tube to designed distance, forming the upper base space, penetrating the steel dowels through the upper base space and connecting to the lower prefabricated pile stem, setting the upper prefabricated pile stem into the immersed tube, and pouring the upper base; and 6. withdrawing the immersed tube and injecting cement mortar to the gap.

Owner:周亚萍

Agriculture system and method

ActiveUS10542660B2High yieldIncrease capacityDefence devicesSoil loosening devicesSoil scienceEnvironmental engineering

An agricultural enhancement method for removing or overcoming soil fragipan, hardpan, or other natural and / or artificial soil compaction barriers is disclosed. These barriers prevent root and / or water penetration, which inhibits agricultural development. Consequently, removing and overcoming these barriers is beneficial to the soil and to agricultural yields.

Owner:OLIVER TROY

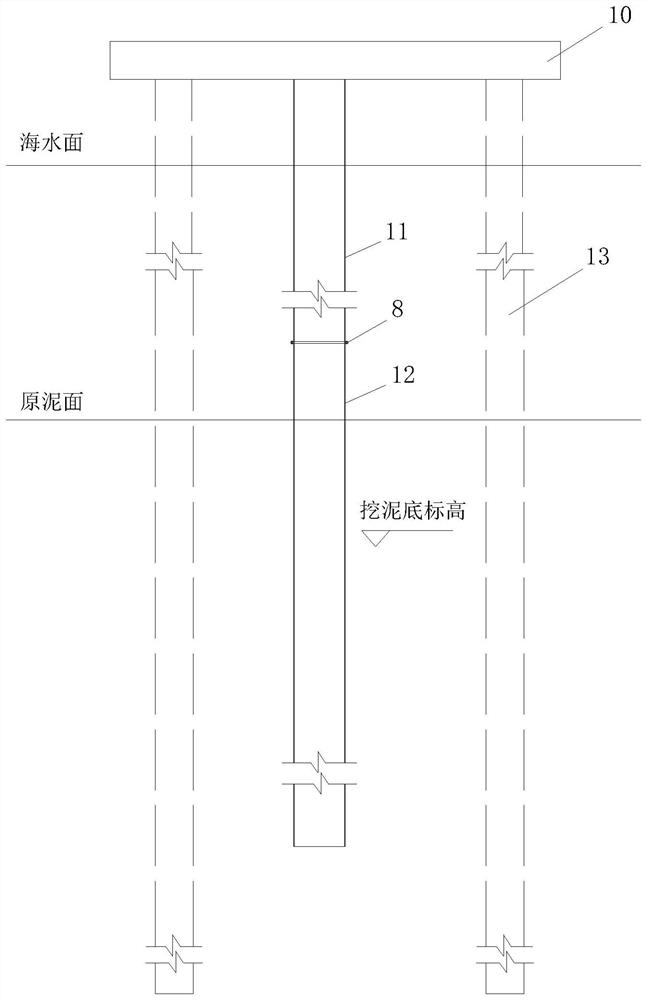

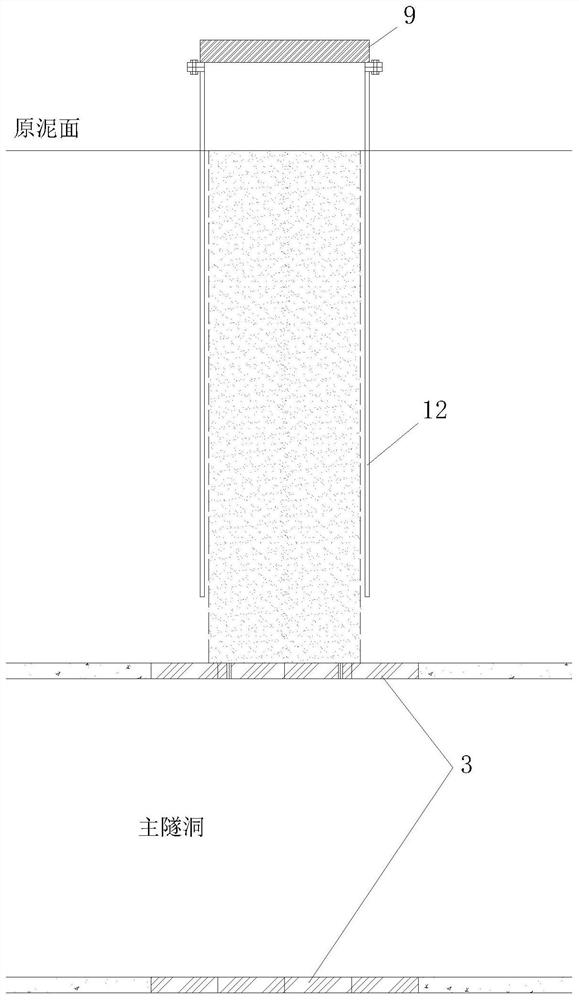

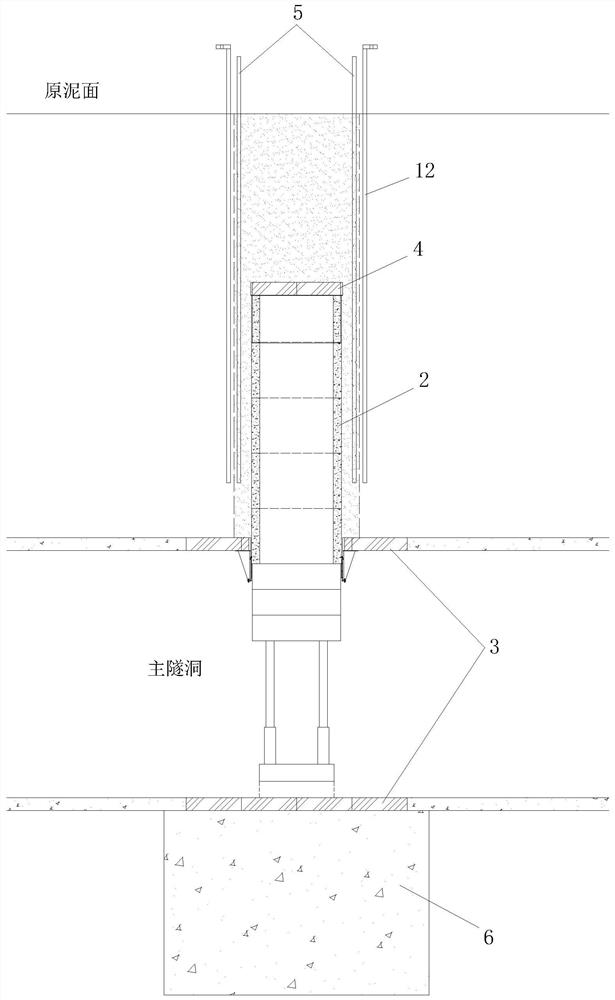

Underwater tunnel vertical jacking solid construction method and structure suitable for hard stratum

PendingCN112878375AHard soilSolve the problem of application in formations with large standard penetration hits such as rocksArtificial islandsUnderwater structuresHardpanPipe

The invention discloses an underwater tunnel vertical jacking solid construction method and structure suitable for a hard stratum. The implementation process comprises the steps that 1, an offshore construction platform is built, and a steel casing is driven into the hard stable stratum in the offshore platform; 2, drilling is conducted under protection of the casing to replace the hard stratum of a vertical pipe jacking area; 3, a shield tunneling method is adopted for tunnel construction, and a seabed main tunnel is built to the position below the jacking area; 4, a vertical pipe is vertically jacked to the sea area section by section through the replaced stratum in the main tunnel; 5, the steel casing is connected with an upper steel structure diffusion structure; and 6, the main tunnel is filled with water, a vertical pipe sealing cover is opened, and the sea area and the main tunnel are connected to achieve the water taking / draining function. The underwater tunnel vertical jacking solid construction method and structure can be well suitable for hard soil, rock stratums and other geological conditions, construction is convenient and safe, the manufacturing cost is economical, the construction period can be shortened, the facility stability is high, and later project running is safer and more reliable.

Owner:华能霞浦核电有限公司 +2

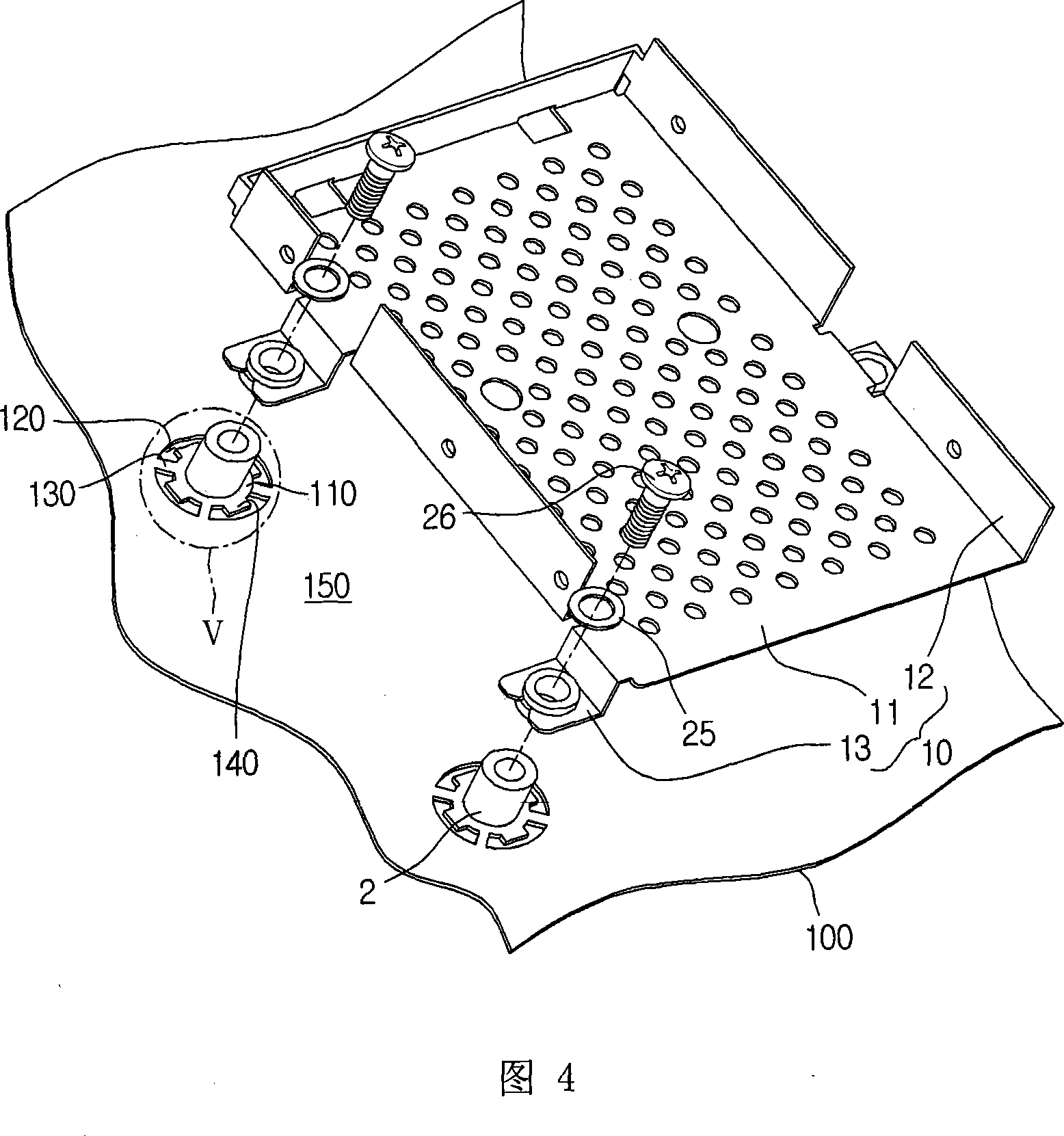

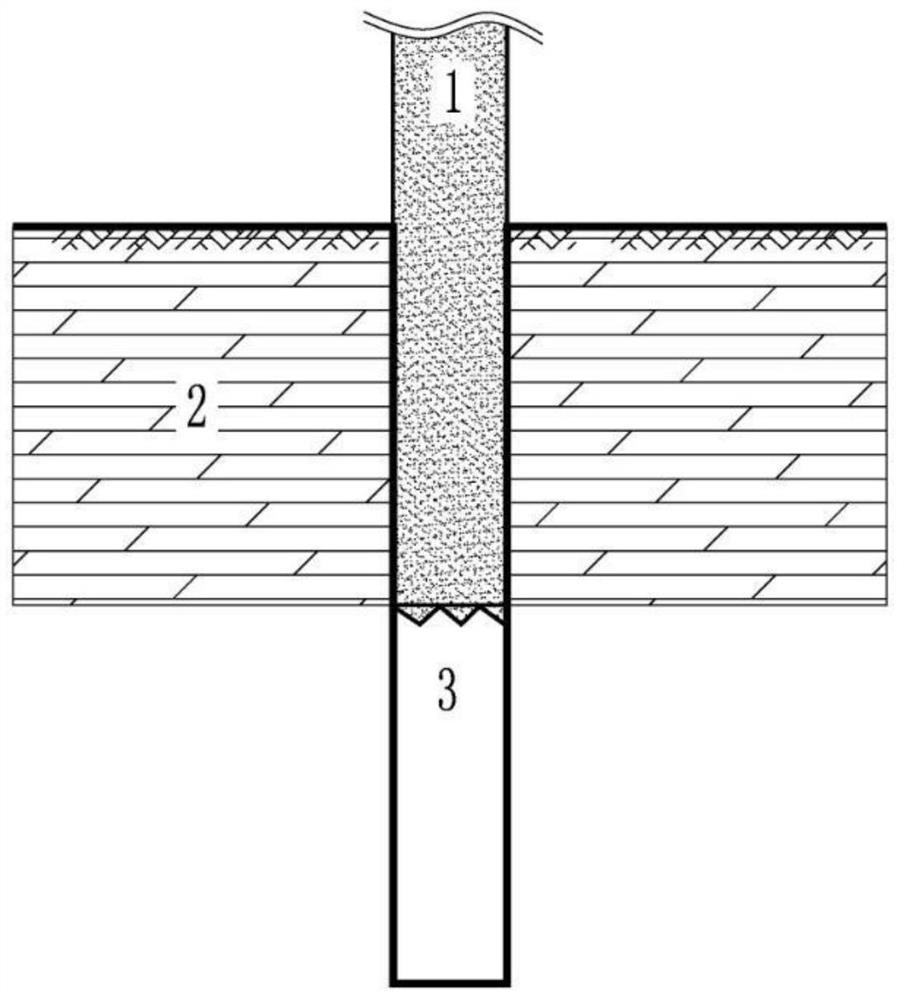

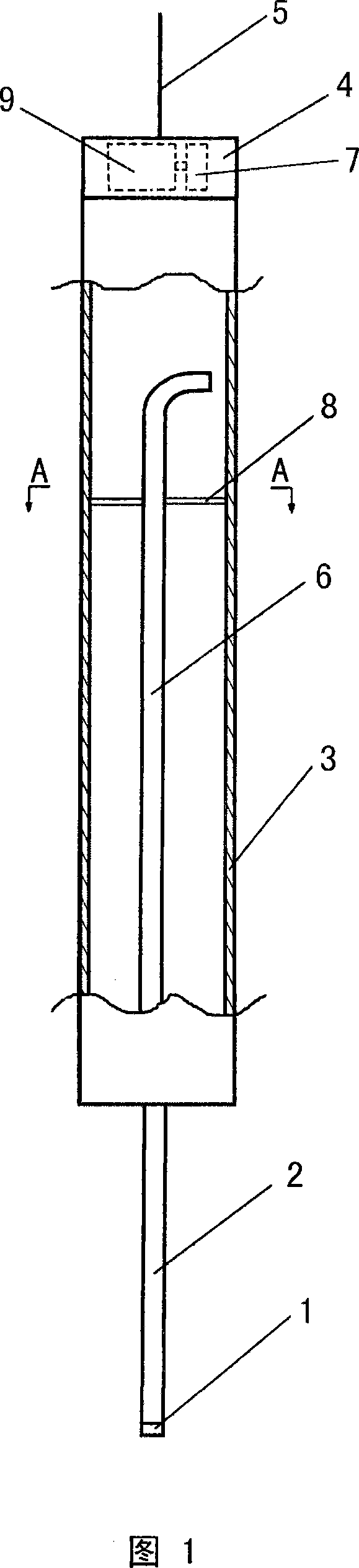

Foundation

InactiveCN101093713AImprove impact absorption performanceFix tightCarrier constructional parts dispositionUndesired vibrations/sounds insulation/absorptionEngineeringHardpan

The invention relates to a base for absorbing the vibration, comprising: the inner part for supporting the hard disk bracket; the outer part which is separated by the middle separation hole and maintains a certain distance from the inner part; a connecting part connecting the inner part and the outer part and an extension part from the inner part to the outer part. The seat can improve the total vibration absorbing effect even the bolt is tightly wrested, which prevents the loose of the bolt and the noise induced by the collision of the gasket and bolt. The bolt can be fixed by machine so as to reduce the cost and time for fixing the bolt manually.

Owner:NANJING LG TONGCHUANG COLOR DISPLAYS SYST CO LTD

Composite hole exploration method combining drilling, Luoyang shovel and drill rod exploration

PendingCN113482523ANo pollution in the processEasy to operateEarth drilling toolsDirectional drillingChiselCrushed stone

The invention discloses a composite hole exploration method combining drilling, a Luoyang shovel and drill rod exploration. The composite hole exploration method is specifically implemented according to the following steps: on a road surface, after a drilling rig is adjusted, a drilling rig tapper is used for tapping, and hard surface layers of the road surface and a roadbed are uncovered; when encountering a clay soil layer or a sand soil layer, the Luoyang shovel is adopted for manual exploration, and the exploration hole diameter of the Luoyang shovel is not smaller than the hole opening diameter of the drilling rig; when encountering miscellaneous fill or gravelly soil hard stratums, a flat-end steel chisel is adopted to drill, explore, crush and break down the fill or gravelly blocks; after the Luoyang shovel and the drill rod detection hole are completed at each frequency, a drilling bit rotation or percussion drilling method is adopted to clean the hole, the hole cleaning depth does not exceed the depth of the Luoyang shovel or the drill rod detection hole, the hole detection depth is measured before each time of hole cleaning, and meanwhile the corresponding depth position of a drill rod is marked before downward drilling; according to the stratum condition encountered during hole exploration, the operation is cyclically implemented until the known underground pipeline (channel) penetrates through the maximum burial depth, and hole exploration is completed; and if encountering an underground pipeline (channel), the drilling rig moves to perform hole exploration again.

Owner:NORTHWEST RES INST OF ENG INVESTIGATIONS & DESIGN

Apparatus and method for monitoring SATA hardpan

Owner:MITAC COMP (SHUN DE) LTD +1

Mixed pile forming method for high-bearing one-stage club-footed pile

InactiveCN101135160AImprove carrying capacityGet the most out of your utilizationBulkheads/pilesReinforced concreteHardpan

The present invention relates to construction of building pile foundation engineering, and is especially mixed piling process of one-stage under-reamed pile with great bearing capacity. The extrusion piling process includes the following steps: erecting prefabricated reinforced concrete immersed pile head on ground, pressing immersed tube onto the reinforced concrete pile head, immersing the immersed tube into hardpan to design elevation, drawing upwards the immersed tube to designed distance, forming base space and taking out soil, pouring the base with concrete, setting the prefabricated pile stem with steel dowels in the lower end, withdrawing the immersed tube and injecting cement mortar to around the pile stem. The pile has the ratio between the base diameter and the pile stem diameter as great as 5-6, deduction coefficient up to 0.9-1.0, high material strength utilizing rate, great bearing capacity and other advantages.

Owner:陈宁华

Bottom expanding and pile-forming method for pipe sinking prefabricated steel concrete pedestal pile

InactiveCN101158156AImprove bearing capacityImprove strength utilizationBulkheads/pilesEngineeringHardpan

The invention discloses a building pile foundation project and a construction method, in particular to a bottom-expanding and pile forming method for a sinking pipe precast steel concrete pedestal pile, comprising penetrating the sinking pipe through a soft soil layer and pressing the sinking pipe to a design height hardpan; taking out a metal pile head, descending the sinking pipe, starting the device to expand the bottom; taking soil with an air soil absorption device; putting a radiation shaped steel bar into a pedestal cavity and nailing the steel bar into the hardpan, enclosing the concrete produced on the ground into a long barrel from a sinking pipe mouth to a sinking pipe bottom. When an iron bar at the barrel bottom contacts the hardpan, the barrel bottom door is pushed open, and the concrete inside the barrel falls into the pedestal cavity to form an on-the-spot pedestal. The precast steel concrete pile body is descended and is integrated with an on-the-spot poured concrete pedestal docking anchor through the steal bar at the bottom as a whole; the grout is poured along an interior side of the sinking pipe and is pulled out to form a pile. The invention has simple and advanced technique, and the pedestal cavity has a regular geometrical shape, selects clear soil without grain virtual soil, has high efficiency, enhances effectively single pile bearing capacity, and enhances construction security.

Owner:王国奋

Agriculture system and method

ActiveUS10609856B2High yieldIncrease capacityExplosive chargesSpadesSoil scienceEnvironmental engineering

An agricultural enhancement method for removing or overcoming soil fragipan, hardpan, or other natural and / or artificial soil compaction barriers is disclosed. These barriers prevent root and / or water penetration, which inhibits agricultural development. Consequently, removing and overcoming these barriers is beneficial to the soil and to agricultural yields.

Owner:OLIVER TROY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com