Mixed pile forming method for high-bearing one-stage club-footed pile

A technology of high bearing capacity and expanding bottom piles, applied in sheet pile wall, building, foundation structure engineering, etc. Reasonable and easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

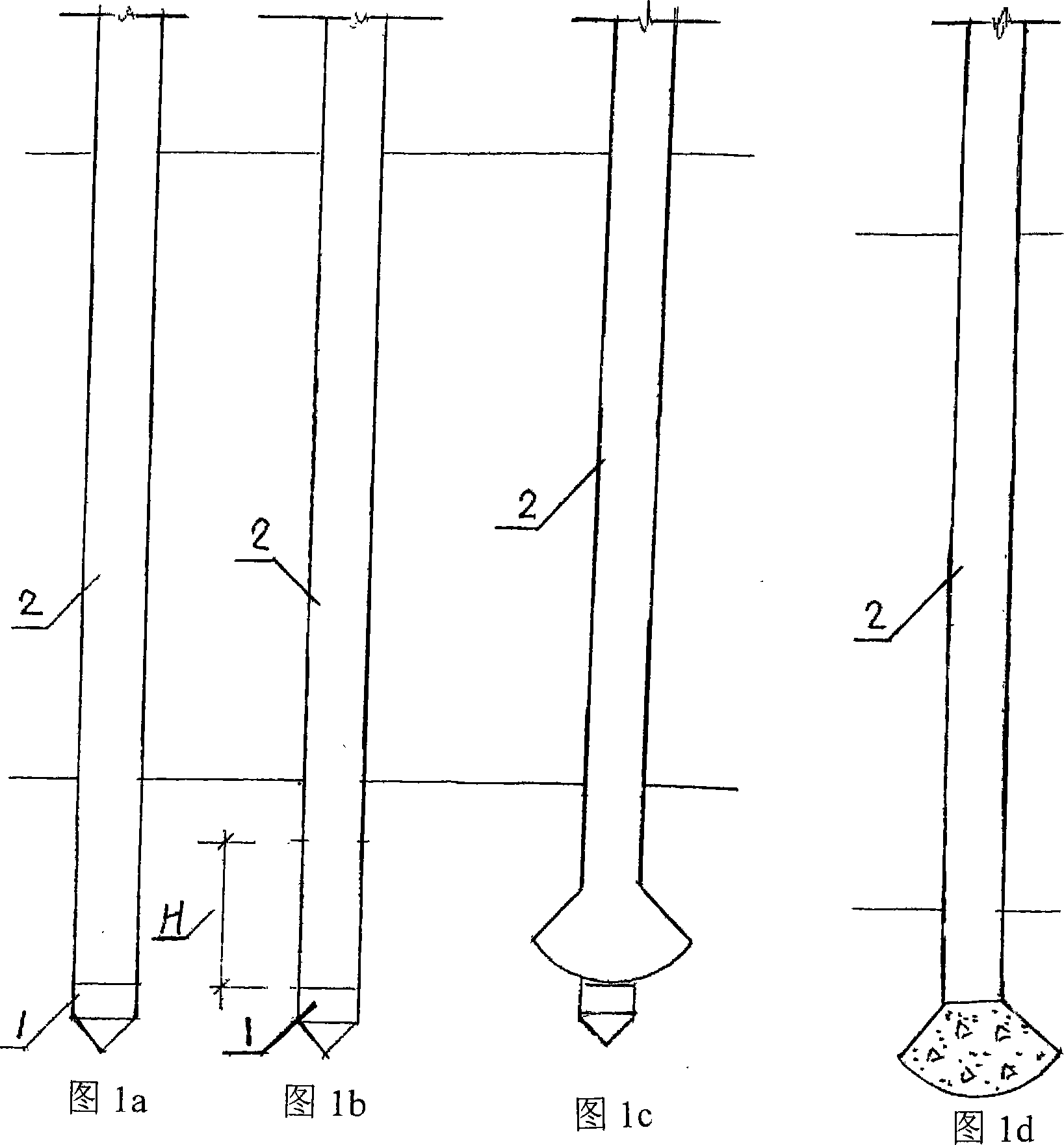

Embodiment 1

[0016] As shown in Figures 1a-1f, the mixed pile-forming method of the first-stage expanded bottom pile with high load-carrying capacity of the present invention comprises the following process steps: a, standing the prefabricated steel concrete pile head vertically on the ground for subsequent use; b 1. Press the immersed tube 2 sets on the steel concrete pile head 1; c. sink the immersed tube 2 into the hard soil layer to the design elevation; d. pull up the immersed tube to the set distance H, where H is 0.6-1.0 of the diameter of the base; e. Take out the metal pile head; c. Put emulsified oil or ammonium antimony explosive from the sinking tube mouth, every 0.5m 3 The dosage is 1-5 kg. After the explosive is detonated, the mouth of the immersed tube is sealed. After the explosion of the explosive is completed, the article that seals the mouth of the immersed tube is opened, and the broken soil is taken, and the space of the lower base is formed by expanding the bottom with...

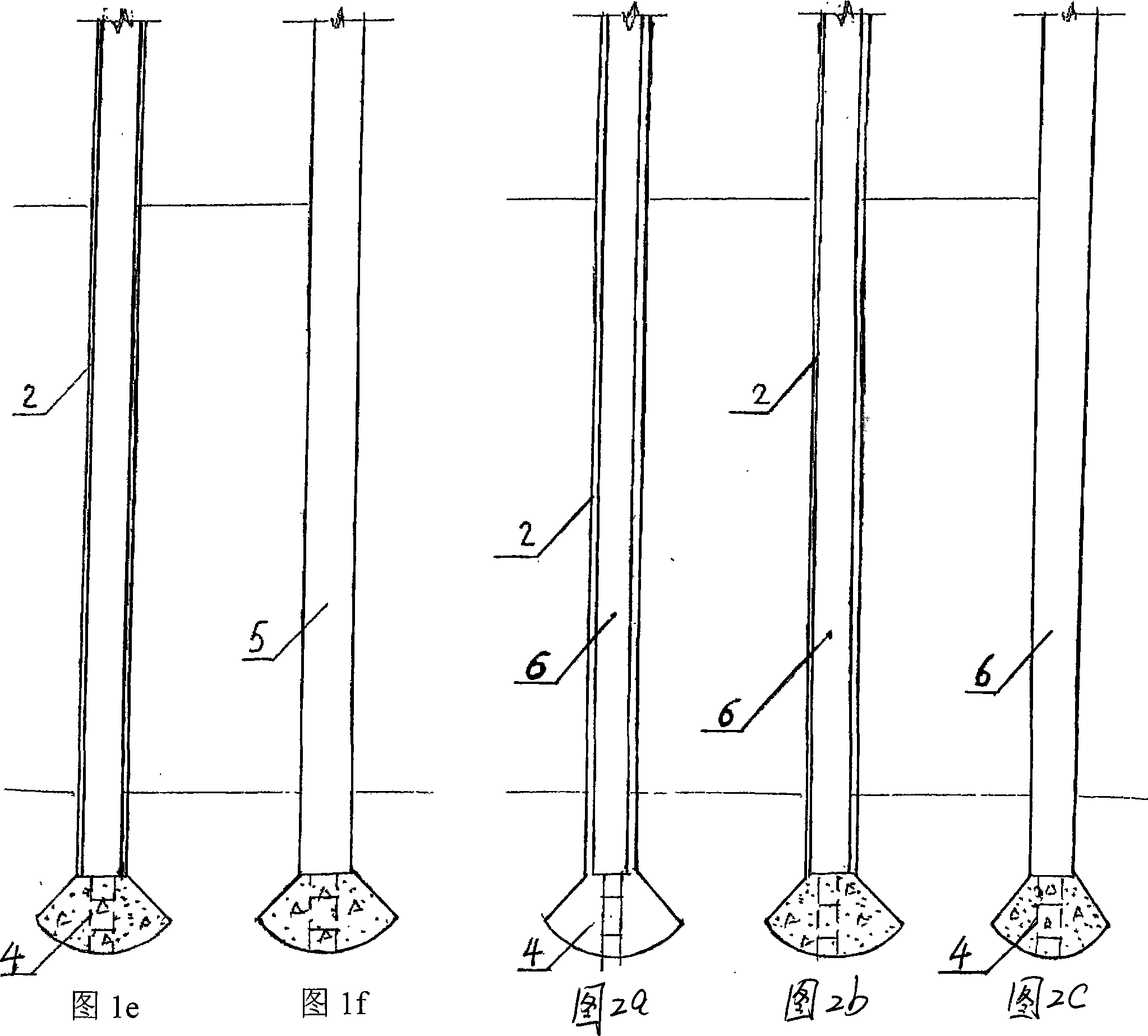

Embodiment 2

[0020] As shown in Figures 2a-2c, the process a-e is the same as that of embodiment 1, and the process f puts the prefabricated hollow pile body 6 with the rib 4 at the lower end into the immersed tube 2; g, pouring concrete into the immersed tube 2 and pouring the base; h 1. Pull out the immersed tube 2, and inject cement slurry into the gap outside the pile body.

Embodiment 3

[0022] Procedures a-e are the same as in Example 1, f, put a section of the pile body of the prefabricated hollow super-hard soil layer into the immersed tube 2 and then drop the rib 4 when it is in place; g, pour the concrete pouring base and cast-in-situ concrete from the immersed tube mouth Steel pipe composite pile body formed by pile body and steel pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com